Page 1

Operating Manual

Ultra Elite-H Mask – Negative Pressure

Mask/Helmet Combination Ultra Elite-H/F1

Order No.: 10110561/03

MSAsafety.com

Page 2

MSA Europe GmbH

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

info.ch@MSAsafety.com

www.MSAsafety.com

©

MSA 2018 All rights reserved

Page 3

Contents

1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Liability Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Mask Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Marking/Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Putting on the Helmet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Donning the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4 Removing the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Cleaning, Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Cleaning/Disinfection of the Helmet . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Cleaning/Disinfection with a Washing Machine . . . . . . . . . . . . . . . . 13

4.3 Cleaning/Disinfection with an Ultrasonic Cleaner . . . . . . . . . . . . . . . 13

4.4 Cleaning by Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Disinfection by Hand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Maintenance of the Exhalation Valve . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Replacing the Speech Diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5 Tightness Test of the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Visual Test and Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Helmet Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Safekeeping and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ultra Elite-H Mask – Negative Pressure

GB

3

Page 4

7 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.3 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.4 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 Applicable Helmets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.1 MSA Gallet F1 Helmets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.2 MSA Gallet F2 X-TREM Helmets . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ultra Elite-H Mask – Negative Pressure

GB

4

Page 5

1 Safety Regulations

1.1 Correct Use

The mask/helmet combination series Ultra Elite-H/F1 with standard thread connection according to

EN 148-1 are not complete respiratory protective devices by themselves, but serve as facepieces in

accordance with DIN 58610 [EN 443 and EN 136 CL3+ with the exception of selection 7.11] for use

with respiratory filters, compressed air breathing apparatus, fresh air hose breathing apparatus and

compressed air line breathing apparatus.

The mask as part of a respiratory protective device ensures an appropriately tight fit of the user’s face

against the ambient atmosphere.

The helmet as part of the whole protective device ensures the protection of the upper half of the head

mainly against the effects of impact, penetration, heat and flames during firefighting.

The masks can only be used in conjunction with following MSA GALLET helmets:

Safety Regulations

• F1SF [EN 443:2008]

• F1E [EN 443:2008]

The instructions for use for the helmets have to be regarded.

The mask/helmet combination series Ultra Elite-H/F2 X-TREM with standard thread connection

according to EN 148-1 are not complete respiratory protective devices by themselves, but serve as

facepieces in accordance with DIN 58610 [EN 136 CL3+ with the exception of selection 7.11].

WARNING!

The helmet type F2 X-TREM is not certificated according to EN 443. Therefore this helmet in combination with the mask must not be used for firefighting in buildings and structures.

The mask/helmet combination provides the function of head protection and respiratory protection in

one system.

WARNING!

According to the European directive 89/656/EWG it has to be verified before first use of the mask that

a correct size has been chosen [proper tight fit], that the mask can be worn in combination with other

protective equipment [for example a protective jacket], that it is a correct choice for the conditions at

the particular place of use and that it fulfils the ergonomic requirements.

It is imperative that this operating manual be read and observed when using the device. In particular,

the safety instructions, as well as the information for the use and operation of the device, must be carefully read and observed. Furthermore, the national regulations applicable in the user's country must be

taken into account for a safe use.

WARNING!

This product is supporting life and health. Inappropriate use, maintenance or servicing may affect the

function of the device and thereby seriously compromise the user's life.

Before use the product operability must be verified. The product must not be used if the function test

is unsuccessful, it is damaged, a competent servicing/maintenance has not been made, genuine MSA

spare parts have not been used.

• Gallet F1 XF [EN 443:2008]

GB

Ultra Elite-H Mask – Negative Pressure

5

Page 6

Alternative use, or use outside this specification will be considered as non-compliance. This also

applies especially to unauthorized alterations to the product and to commissioning work that has not

been carried out by MSA or authorized persons.

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately or not as intended.

The selection and use of the product are the exclusive responsibility of the individual operator.

Product liability claims, warranties also as guarantees made by MSA with respect to the product are

voided if it is not used, serviced, or maintained in accordance with the instructions in this manual.

Changes and modifications not expressly approved by the manufacturer will void the user’s authority

to operate the equipment.

Safety Regulations

Ultra Elite-H Mask – Negative Pressure

GB

6

Page 7

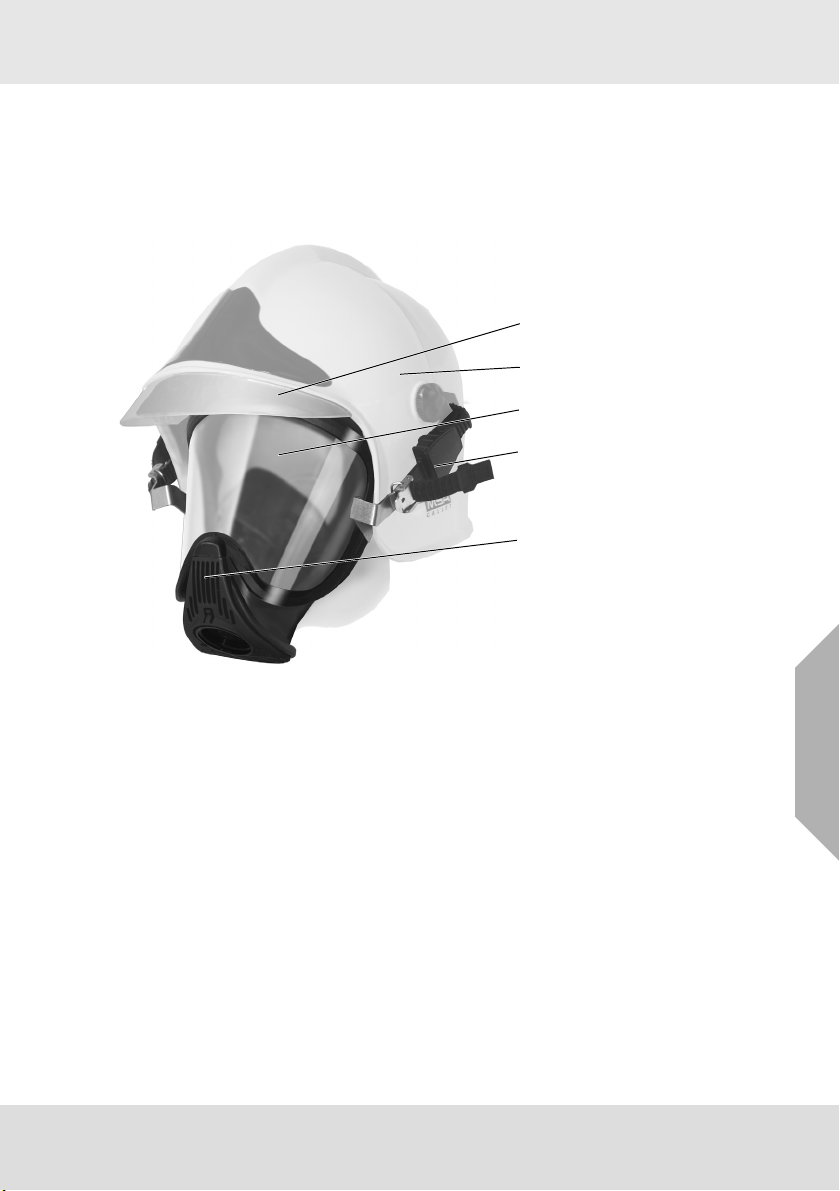

2 Description

1

2

3

4

5

The face blank is made of a special soft rubber compound and assures a snug, comfortable fit and a

tight seal. Some versions of the mask are also available in small size.

The inhalation air flows from the connector of the mask past the inhalation valve to the inside of the

lens [thus keeping the lens largely fog-free] and then through the check valves into the nose cup.

The exhalation air passes through the exhalation valve directly to the ambient air.

Description

Fig. 1 Overview mask/helmet combination

1 Helmet Visor 4 Adapter with tightening strap

2 Helmet 5 Connector with inhalation and exhalation valves

3Lens

Ultra Elite-H Mask – Negative Pressure

GB

7

Page 8

2.1 Mask Versions

1

2

3

4

5

6

Ultra Elite-H • Standard version

Ultra Elite-H small • as standard version, small size

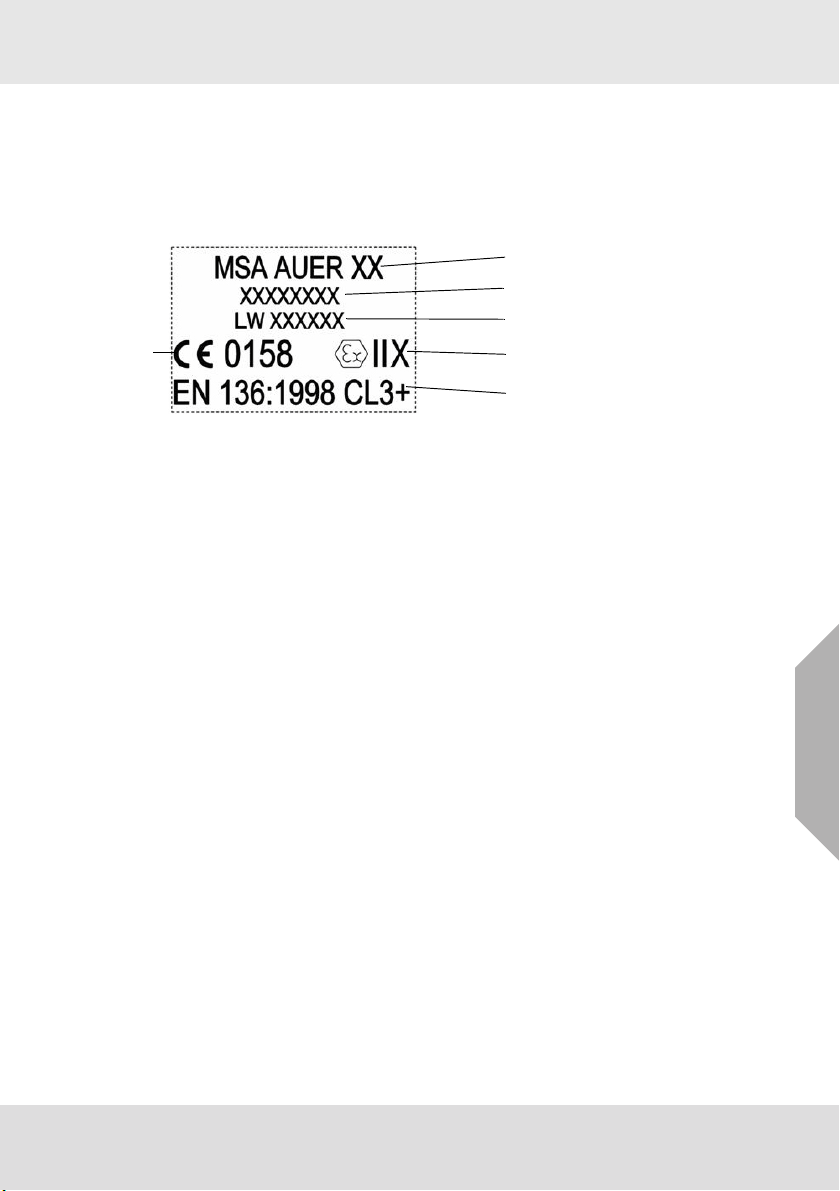

2.2 Marking/Certification Marking

The mask is marked on the outer face blank as shown in Fig. 2:

Fig. 2 Marking of mask body

1 Mask Version

2 Part Number

3 Marking [date code, serial number]

4 CE-marking with notified body number

[DEKRA EXAM, Zertifizierungsstelle Dinnendahlstr. 9, 44809 Bochum]

5 X: ATEX classification A, B or C according to the Lens typ.

6 EN standard, class

Description

GB

Ultra Elite-H Mask – Negative Pressure

8

Page 9

Certification

Mask with Lenses from Polycarbonate with Silicate Coating

The masks according to chapter 2.1

comply with the following directives, standards or standardised documents:

Directive 2014/34/EU [ATEX] : BVS 05 ATEX H 027 X

for masks

I M1

II 1 G IIA T6 -40 °C Ta +60 °C

II 1 D

for helmets F1SF and F1E:

I M1

II 1 G IIA T6 -40 °C Ta +60 °C

II 1 D

in the helmet colours orange or fluorescent, with

front plate fluorescent, orange, white, blue,

yellow, red or black

The mask/helmet combination with F2 X-TREM helmets are not tested for use in explosive atmospheres.

for masks

EN 136 CL3+

Directive 89/686/EC or

Regulation (EU) 2016/425,

respectively

:

with the exception of Section 7.11

for mask/helmet combinations

DIN 58610:2006

for helmets

see operating manual helmet

Description

GB

0158

DEKRA EXAM GmbH, Dinnendahlstr. 9, 44809

Bochum, Germany, Notified body number: 0158

The Declaration of Conformity can be found under the following link: https://MSAsafety.com/DoC

Ultra Elite-H Mask – Negative Pressure

9

Page 10

3Use

The mask is either carried using the harness in front of the chest or in the mask container.

WARNING!

Ensure that the top of the mask seal only lies on the user's forehead. Hair should not be between the

mask's seal and the user’s skin.

The mask could otherwise leak. This danger also exists for instance for mask wearers with beards or

deep scars in the sealing area.

WARNING!

The tightness of the mask/helmet combination depends on the correct size of the helmet, the adjustment of the adapter with tightening strap [if possible] and the helmet´s inner shell.

It is necessary to adjust the helmet’s inner shell accurately to your head size.

If the helmet or the inner shell do not fit your head properly, or if the wrong mask size is chosen, there

is a risk of leakage.

3.1 Putting on the Helmet

(1) Select a helmet suitable for the user’s head size.

(2) Adjust the helmet according to the helmet’s operating

manual.

(3) Grip the helmet with both hands with the chinstrap open.

(4) Pull the helmet from the forehead over the head.

(5) Close and slightly tighten the chin strap.

Use

Ultra Elite-H Mask – Negative Pressure

GB

10

Page 11

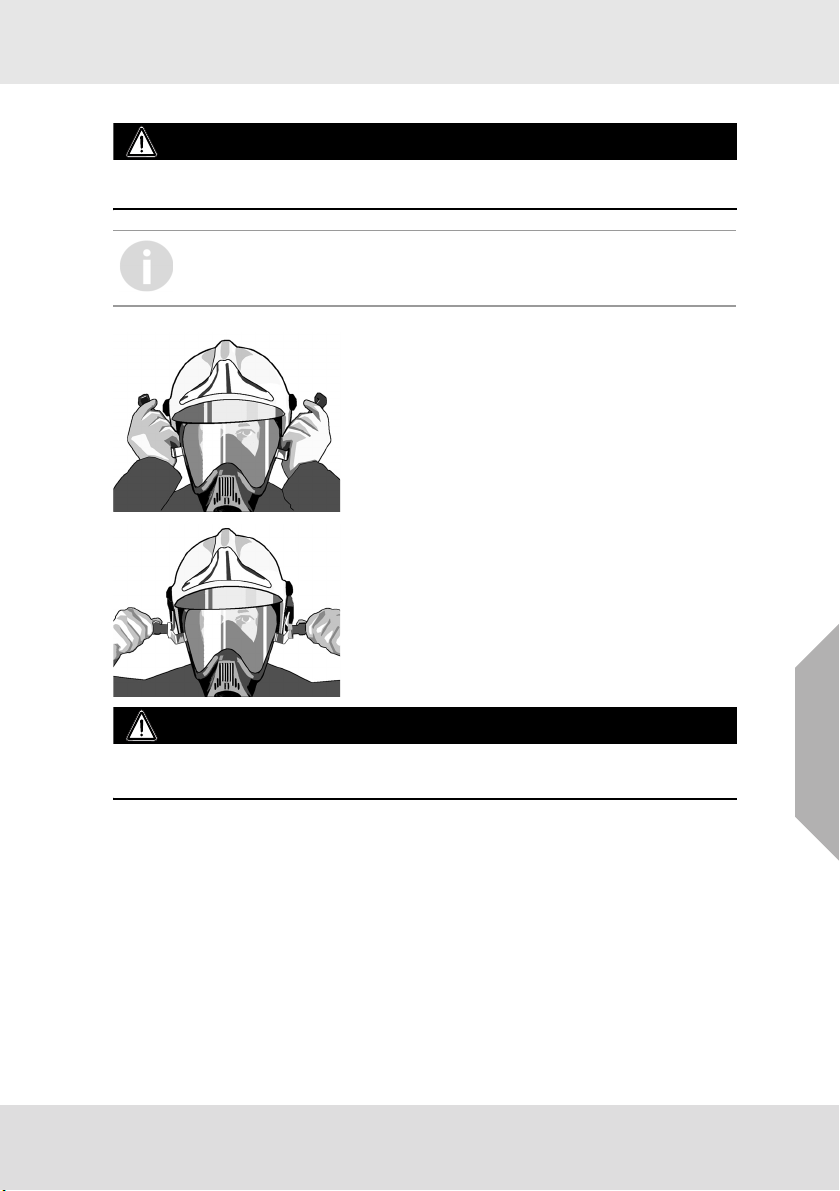

3.2 Donning the Mask

WARNING!

In order to guarantee a proper fit for those wearing glasses, the Ultra Elite-H Mask spectacle kit must

be worn since ordinary glasses cannot be worn under the mask.

When fitting the mask in position the chin strap of the helmet must be loose. Remove

chin piece if necessary.

(1) Push helmet backwards onto neck so that the forehead

area is not covered.

(2) Open buckles and pull tightening straps on the belt

tongues until the grip tabs of the tightening straps reach

the stop [longest setting].

(3) Attach the helmet adapter to the slots on both sides of

the helmet.

(4) Draw pulling tabs of tightening straps on both sides of

the helmet until the mask fits onto the face.

(5) Push the helmet forward again until fitting comfortably.

(6) Tighten chin straps and fix their end with Velcro fastener.

(7) Ensure that the fit of the respiratory mask is checked by

a second person.

Use

WARNING!

The chin strap must fit tightly under the chin.

If necessary, remove chin protector.

Ultra Elite-H Mask – Negative Pressure

GB

11

Page 12

3.3 Leak Check

In order to check the mask-to-face tightness a leak test must be performed before each use.

(1) Seal the mask connector or the inlet opening side of an

attached filter with the ball of your hand.

(2) Test tightness by inhaling and exhaling. Whilst doing so:

(3) If necessary retighten the straps, or

when inhaling there must be negative pressure, no

inflowing air should be noticeable.

try a mask of a different size.

If the leak test fails the mask must not be used.

3.4 Removing the Mask

(1) Open buckles on the adapters.

(2) Pull mask until stopped by the straps.

(3) Lift both hooks of the helmet adapter to the side and pull

them back out of the helmet slots.

(4) Remove the mask to the front.

Use

Do not grip the mask by the exhalation valve!

(5) Remove the helmet.

Ultra Elite-H Mask – Negative Pressure

GB

12

Page 13

Cleaning, Disinfection

4 Cleaning, Disinfection

The cleaning and disinfection of the masks is performed in accordance with the cleaning intervals

chapter 5.2.

There are three possible kinds of cleaning:

• Using a washing machine

• disk washing type (Meiko)

• tumbling type (Miele)

• Using an ultrasonic cleaner

• Cleaning by hand.

WARNING!

Do not use cleaning products containing hydrocarbons or solvents [e.g. nitro-thinner].

Cleaned parts must not be dried in radiant heat [sun, radiators]. When using a drying cabinet, the

temperature must not exceed +60°C.

Perform a tightness test after every cleaning, disinfection and maintenance or after every exchange of

parts.

4.1 Cleaning/Disinfection of the Helmet

(1) Clean and disinfect the helmet according the helmet operating manual.

4.2 Cleaning/Disinfection with a Washing Machine

Follow the washing agent’s user instructions on this CD/DVD.

(1) After cleaning check the two screws for the lens ring. Retighten the screws hand-tight if neces-

sary.

4.3 Cleaning/Disinfection with an Ultrasonic Cleaner

When cleaning/disinfecting with an ultrasonic cleaner please follow the cleaning agent’s

user instructions on this CD/DVD.

Ultra Elite-H Mask – Negative Pressure

GB

13

Page 14

Cleaning, Disinfection

4.4 Cleaning by Hand

(1) Remove inhalation and exhalation valve discs.

(2) Unbutton the nose cup.

(3) Unscrew the speaking diaphragm with the special tool.

(4) Clean mask using lukewarm water and mild cleaning agent EW 80 and thoroughly rinse in

running water.

(5) Disinfect the mask after cleaning. Removed components must be separately cleaned and disin-

fected.

(6) Dry mask and components and reassemble mask in reverse order.

(7) Perform a tightness test [ chapter 5.5].

4.5 Disinfection by Hand

Clean the mask before disinfecting.

Use a disinfectant according to the user instructions on this CD/DVD.

(1) Disassemble and clean the mask (see chapter 4.4).

(2) Disinfect the mask using recommended disinfectant. Please observe the user instruction for the

disinfectant.

(3) Thoroughly rinse mask in running water.

(4) Dry mask and components and reassemble mask in reverse order.

(5) Perform a tightness test (see chapter 5.5).

Ultra Elite-H Mask – Negative Pressure

GB

14

Page 15

5 Maintenance

5.1 Maintenance Instructions

This device should be regularly checked and serviced by trained specialists. Inspection and service

records must be maintained. Always use original parts from MSA.

Repairs and maintenance must be carried out only by authorised service centres or by MSA. Changes

to devices or components are not permitted and will result in loss of approval.

MSA is liable only for maintenance and repairs carried out by MSA.

MSA recommends the following maintenance intervals. If necessary considering the

usage, tasks may be at even shorter intervals than indicated.

Observe national laws and regulations!

If in any doubt, ask your local MSA contact person.

5.2 Maintenance Intervals

Maximal Intervals

Devices Work to be Performed

helmet See helmet operating manual.

masks

mask/

helmet

combination

*)

For a 2-year interval cleaned and disinfected masks have to be stored airtight. Otherwise masks

should be cleaned and disinfected at least semi-annually. After each cleaning and disinfection the

facepiece must be checked.

**)

For airtightly packed facepieces, which are not exposed to increased climatic and mechanical stress

[for example transport on vehicles], this interval can be extended to 2 years.

Cleaning and Disinfec-

*)

tion

Visual, Functional and

Tightness Check

Replacement of the exhalation valve disc

Replacement of the

Speech Diaphragm

User check X

**)

Before

use

After

6-monthly

Use

XX

XX

Two

years

*)

**)

Four

years

X

Maintenance

Six

years

X

GB

Ultra Elite-H Mask – Negative Pressure

15

Page 16

5.3 Maintenance of the Exhalation Valve

The year of manufacture is located on the valve disc.

In case of a leak remove the exhalation valve disc and replace it with a new one as follows:

(6) Open the pivot cap of the connector.

(7) Pull the old exhalation valve disc off the connector.

(8) Replace the defective components.

(9) Close the pivot cap of the connector.

(10) Perform a tightness test [ chapter 5.5].

5.4 Replacing the Speech Diaphragm

The year of manufacture is located on the speech diaphragm.

(1) Unbutton the nose cup.

(2) Unscrew the threaded socket from the mask inside with the special tool.

(3) Remove the speech diaphragm.

(4) Assemble the new speech diaphragm with the gasket towards the connector.

(5) Perform a tightness test [ chapter 5.5].

5.5 Tightness Test of the Mask

The testing of the masks for tightness is performed using an applicable MSA test device

in accordance with the relevant operating manual.

Maintenance

(1) Fit mask tight onto the test device.

Use the test plate or test band to fix the mask.

(2) Generate a negative pressure of 10 mbar.

(3) Measure the pressure change after 1 min.

The mask including the exhalation valve meets the requirements if for a moistened exhalation valve and a negative pressure generated inside the mask the pressure change does not

exceed 1 mbar in a minute.

Leaking masks must not be used.

Ultra Elite-H Mask – Negative Pressure

GB

16

Page 17

Safekeeping and Storage

5.6 Visual Test and Function Test

Visual Test

(1) Inspect the mask for possible damages like for example deformations, stickings or cracks. Valve

discs, especially exhalation valve discs, are crucial functional elements of the mask.

(2) Defective or damaged parts have to be replaced immediately.

(3) For helmets: refer to the helmet operating manual.

Functional Test

After assembling the mask the mobile parts, especially the valve discs, have to be tested for unrestricted mobility.

5.7 Helmet Maintenance

For detailed information about helmet maintenance refer to the helmet operating

manual.

6 Safekeeping and Storage

WARNING!

In order to avoid damage to or the deformation of the masks keep no additional loose objects in the

mask container.

For the safekeeping of the mask the mask container should be used. This also applies to masks with

installed filters, except CO and NO filters.

MSA rubber products are protected by an anti-aging agent that can become visible as a light coating.

This coating is harmless and can be removed during cleaning.

To ensure a long life for rubber components, keep them in a cool, dry place that is protected from ultraviolet radiation, according to ISO 2230:2002, Rubber Products – Guidelines for Storage.

Ultra Elite-H Mask – Negative Pressure

GB

17

Page 18

7 Ordering Information

1

2

3

16151413

12

4

7

8

9

11

10

5

6

7.1 Exploded View

Ordering Information

Fig. 3 Mask exploded view

1 Nose cup valve seat 9 Cover Elite, assembly

2 Nose cup valve disc 10 Inhalation valve seat Elite

3 Nose cup [without valves] 11 Inhalation valve disc

4 Carrying strap 12 Lens ring

5 Speech diaphragm ring 13 Adapter with tightening strap

6 Speech diaphragm 14 Screw for lens ring

7 Exhalation valve disc Elite 15 Lens

8 Clamp Elite 16 Face blank

Ultra Elite-H Mask – Negative Pressure

GB

18

Page 19

7.2 Mask

Description Article No.

Ultra Elite-H 10045891

Ultra Elite-H – small 10045892

7.3 Accessories

Description Article No.

Elite spectacles [plastic frame] D2056730

Elite spectacles [metal frame] D2056733

Special tool [for replacing exhalation valve and speech diaphragm] D2055038

Exhalation valve closure D2056703

Mask hanger [package of 4] D2055753

Mask tightness test kit [for more MSA testing instruments refer to

www.MSAsafety.com]

Advantage container 10026179

Test plate D6125721

Test band D6125715

7.4 Replacement Parts

Description Article No.

Service kit Ultra Elite [exhalation valve disc, inhalation valve disc, 2 nose cup

valve discs, inhalation valve seat]

Nose cup Elite, assembly D2056915

Lens [with silicate coating] D2056802

Lens ring, assembly D2056705

Clamp D2056717

Speech diaphragm [package of 2] D2055708

Nose cup valve seat [package of 2 D2056708

Nose cup valve disc [package of 20] D2055731

Threaded ring [speech diaphragm] D2056709

Inhalation valve disc [package of 20] D2056714

Inhalation valve seat [package of 5] D2056715

Exhalation valve disc [package of 10] D2056716

Carrying strap, assembly D2055707-SP

Connector, assembly D2056710

Connector Elite D2056713

Ordering Information

D6063705

D2056704

GB

Ultra Elite-H Mask – Negative Pressure

19

Page 20

8 Applicable Helmets

8.1 MSA Gallet F1 Helmets

Helmets

F1 SF* [EN 443:2008]

F1 E* [EN 443:2008]

F1 E [EN 443:2008]

F1 SF [EN 443:2008]

* The mask/helmet combination with neck curtain for which all helmet components are marked with * comply with directive: vfdb-Richtlinie 0802:04

Helmets

Gallet F1 XF [EN 443:2008]

size M, L

Neck curtain:

aluminium

wool (integral)

nomex

Lamp:

Lamp holder (mounted, spare)

Integrated light module

Retro-reflective stickers:

Applicable Helmets

Colour of the shell

red*

yellow*

blue*

black*

white*

orange*

green luminescing*

nickel

Colour of the shell

all colours

GB

Grey

Ultra Elite-H Mask – Negative Pressure

20

Page 21

8.2 MSA Gallet F2 X-TREM Helmets

Helmets

INDUSTRY [EN397]

-unvented shell

-no chinstrap

GA3200-BA00

Optional:

2-point chinstrap

WILDLAND RESCUE [EN12492]

-Vented shell

-3-point chinstrap

GA33xx

Optional:

Retro-reflective stickers (GA3230):

TRAFFIC RESCUE [directive 89/686/EC]

-unvented shell

-3 point chinstrap

GA35xx

Optional:

Wool neck curtain (GA3240)

Applicable Helmets

Colour of the shell

White

White

Blue

Yellow

Black

Grey

Orange

Red

Green

Photoluminescent

silver, yellow, red, blue or green

GB

White

Blue

Yellow

Black

Orange

Red

Photoluminescent

Retro-reflective stickers (GA3230):

Ultra Elite-H Mask – Negative Pressure

silver, yellow, red, blue or green

21

Page 22

For local MSA contacts, please visit us at MSAsafety.com

Because every life has a purpose...

Loading...

Loading...