MSA Ultima X, Ultima XE, Ultima XIR, Ultima XA Maintance Manual

Installation & Maintenance Instructions

Ultima® X Series Gas Monitors

Registered Address

ABLE Instruments & Controls Ltd

Cutbush Park, Danehill, Lower Earley,

Reading, Berk shire, RG6 4UT. UK.

Reading

Tel: +44 (0)118 9311188 | Email: info@able.co.uk

Aberdeen

Tel: +44 (0)1224 725999 | Email: ab@able.co.uk

Web

able.co.uk

E-commerce

247abl e.com

Ultima®X Series

Gas Monitors

Instruction Manual

In North America, to contact your nearest stocking location, dial toll-free 1-800-MSA-INST.

To contact MSA International, dial (724) 776-8626.

Inquiries can also be e-mailed to customer.service@msaSafety.com.

© MSA 2014 - All Rights Reserved

This manual is available on the internet at www.msaSafety.com

Manufactured by

MSA NORTH AMERICA

1000 Cranberry Woods Drive, Cranberry Township, PA 16066

(L) -Y Rev 9 10036101

THIS MANUAL MUST BE CAREFULLY READ BY ALL INDIVIDUALS WHO HAVE OR WILL

HAVE THE RESPONSIBILITY FOR USING OR SERVICING THE PRODUCT. Like any piece

of complex equipment, this instrument will perform as designed only if it is used and serviced in accordance with the manufacturer’s instructions. OTHERWISE, IT COULD FAIL TO

PERFORM AS DESIGNED AND PERSONS WHO RELY ON THIS PRODUCT FOR THEIR

SAFETY COULD SUSTAIN SEVERE PERSONAL INJURY OR LOSS OF LIFE.

The warranties made by Mine Safety Appliances Company with respect to the product are

voided if the product is not used and serviced in accordance with the instructions in this

manual. Please protect yourself and others by following them. We encourage our customers to write or call regarding this equipment prior to use or for any additional information relative to use or service.

MSA Instrument Warranty

1. Warranty- Seller warrants that this product will be free from

mechanical defect or faulty workmanship for the following periods:

• Gas Monitor: eighteen (18) months from date of shipment or

one (1) year from installation, whichever occurs first

• Oxygen, Toxic or Catalytic Combustible Sensor: eighteen (18)

months from date of shipment or one (1) year from installation,

whichever occurs first

• IR Sensor source: ten (10) years from date of shipment.

All other IR components: two (2) years from date of shipment.

This warranty is applicable provided the product is maintained and

used in accordance with Seller's instructions and/or

recommendations. This warranty does not apply to expendable or

consumable parts whose normal life expectancy is less than one

(1) year. The Seller shall be released from all obligations under this

warranty in the event repairs or modifications are made by persons

other than its own or authorized service personnel or if the

warranty claim results from physical abuse or misuse of the

product. No agent, employee or representative of the Seller has

any authority to bind the Seller to any affirmation, representation or

warranty concerning the goods sold under this contract. Seller

makes no warranty concerning components or accessories not

manufactured by the Seller, but will pass on to the Purchaser all

warranties of manufacturers of such components. THIS

WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED, IMPLIED OR STATUTORY, AND IS STRICTLY

LIMITED TO THE TERMS HEREOF. SELLER SPECIFICALLY

DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE.

"! WARNING

NOTE: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in

which case the user will be required to correct the interference at his own expense.

This is a class A product in accordance with CISPR 22. In a

domestic environment, this product may cause radio interference, in which case the user may be required to take adequate measures.

2. Exclusive Remedy- It is expressly agreed that Purchaser's sole

and exclusive remedy for breach of the above warranty, for any

tortious conduct of Seller, or for any other cause of action, shall be

the repair and/or replacement at Seller's option, of any equipment

or parts thereof, which after examination by Seller is proven to be

defective. Replacement equipment and/or parts will be provided at

no cost to Purchaser, F.O.B. Seller's Plant. Failure of Seller to

successfully repair any nonconforming product shall not cause the

remedy established hereby to fail of its essential purpose.

3. Exclusion of Consequential Damage- Purchaser specifically

understands and agrees that under no circumstances will seller be

liable to purchaser for economic, special, incidental or

consequential damages or losses of any kind whatsoever, including

but not limited to, loss of anticipated profits and any other loss

caused by reason of nonoperation of the goods. This exclusion is

applicable to claims for breach of warranty, tortious conduct or any

other cause of action against seller.

"

WARNING

i

General Warnings and Cautions

1. The Ultima X Series Gas Monitors described in this manual must

be installed, operated and maintained in strict accordance with

their labels, cautions, warnings, instructions, and within limitations

stated. Verify that the class, group, and temperature ratings of the

equipment agree with the actual classification of the location.

2. The Ultima X Series Gas Monitor is designed to detect gases or

vapors in air. It cannot measure the concentration of gases or

vapors in steam or inert or oxygen-deficient atmospheres. The

oxygen sensor can measure oxygen-deficient atmospheres.

3. Electrochemical sensors are sealed units which contain a corrosive

electrolyte. Should a sensor develop leakage, it must be

immediately removed from service; then, remove it from the

sensing head and discard it properly. Caution must be exercised so

that the electrolyte does not contact skin, eyes, clothing or circuitry;

otherwise, serious personal injury (burns) and/or equipment

damage may result.

4. Use only genuine MSA replacement parts when performing any

maintenance procedures provided in this manual. Failure to do so

may seriously impair instrument performance. Repair or alteration

of the Ultima X Series Gas Monitor, beyond the scope of these

maintenance instructions or by anyone other than an authorized

MSA service personnel, could cause the product to fail to perform

as designed and persons who rely on this product for their safety

could sustain serious personal injury or loss of life.

5. Do not locate the general-purpose enclosure models in an area

which may contain a flammable mixture of gas and air; otherwise,

an explosion may occur. The general-purpose Ultima X Series Gas

Monitors can be a source of ignition and must not be mounted in

an area where a flammable mixture of combustible gas and air

may become present; otherwise, an explosion may occur. If such a

location must be monitored, use an explosion-proof Ultima X

Series Gas Monitor model.

6. The Ultima XIR Infrared combustible gas monitor detects the

presence of most combustible gases by identifying the difference in

the amount of infrared light energy absorbed during the presence

of these gases. This monitor, however, does NOT detect the

presence of hydrogen gas and must never be used to monitor for

hydrogen gas.

7. The standard Ultima XIR Infrared Combustible Gas Monitor does

"

WARNING

ii

not detect the presence of acetylene gas and the presence of

acetylene gas will degrade sensor performance. Custom-built

acetylene sensors are available through your MSA representative.

8. Gas detectors depend on an unimpeded gas flow for proper

operation. In environments where contamination is possible,

ensure that the flow remains unobstructed at the sensor. Failure to

follow this may prevent gas detection and generate inaccurate

readings.

9. CSA performance Certification to standard C22.2 No. 152 is valid

only when the instrument is calibrated on methane per the

instruction manual.

10. Install Product in accordance with all markings and the regulations

of the country in use.

11. Product components may have different hazardous location

ratings. Ensure all components are suitable for the area of

installation and protection technique.

Failure to follow the above can result in serious personal injury or loss of life.

1. As with all gas monitors of these types, high levels of, or long

exposure to, certain compounds in the tested atmosphere could

contaminate the sensors. In atmospheres where an Ultima X

Series Gas Monitor may be exposed to such materials, calibration

must be performed frequently to ensure that operation is

dependable and display indications are accurate.

2. The Ultima X Series Gas Monitor must not be painted. If painting is

done in an area where a Monitor is located, care must be

exercised to ensure that paint is not deposited on the sintered,

metal flashback arrestor in the inlet fitting of the Ultima X Series

Gas Monitor, if so equipped. Such paint deposits would interfere

with the diffusion process, whereby a sample of the atmosphere

being monitored diffuses into the Monitor.

3. The only absolute method to ensure proper overall operation of an

Ultima X Series Monitor is to check it with a known concentration

of the gas for which it has been calibrated. Consequently,

calibration checks must be included as part of the routine

inspection of the system.

4. Protect the Ultima X Series Gas Monitor from extreme vibration.

Do not mount the sensing head in direct sunlight as this may cause

overheating of the sensor.

Failure to follow the above can result in injury, product damage and/or an unsafe

condition.

"

CAUTION

iii

Table of Contents

Chapter 1,

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Identifying Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Installing Your Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installing the Ultima XA Gas Monitor . . . . . . . . . . . . . .1-6

Installing the Ultima XE Gas Monitor . . . . . . . . . . . . . .1-6

Installing the Ultima XIR Gas Monitor . . . . . . . . . . . . .1-8

Electrical Connections for Ultima X Gas Monitors . . . . . . . . .1-9

Wiring for all Models . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Use of External Controllers . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Identify PCB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Installing the Ultima X Remote Sensor Module . . . . . . . . . .1-20

Electrical Connections for Remote Sensors . . . . . . . . . . . . .1-21

Chapter 2,

Start-up and Calibration . . . . . . . . . . . . . . . . . . .2-1

Initial Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Calibration Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Ultima Calibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Ultima Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Calibration Output Signal . . . . . . . . . . . . . . . . . . . . . . .2-6

Calibration Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Ultima X Series Gas Monitor Calibration Procedure . . . . . . . .2-7

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Span Gas Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

INITIAL Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Standard Calibration . . . . . . . . . . . . . . . . . . . . . . . . .2-13

OXYGEN Calibration . . . . . . . . . . . . . . . . . . . . . . . . .2-18

XIR Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

iv

Chapter 3,

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Chapter 4, Maintenance . . . . . . . . . . . . . . . . . . . .4-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Ultima XIR Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . .4-4

Replacing an Ultima XE or Ultima XA Sensor . . . . . . . . . . . .4-5

Obtaining Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Appendix A,

Optional Features . . . . . . . . . . . . . . . . . . . . . . . .A-1

1) Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Unpacking, Mounting and Wiring . . . . . . . . . . . . . . . .A-1

Ultima X Series Gas Monitor Internal Relays . . . . . . .A-2

Relay Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Fault Relay or Trouble . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Relay Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

2) Optional RESET Push-button . . . . . . . . . . . . . . . . . . . . . . .A-7

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

RESET Button Selection . . . . . . . . . . . . . . . . . . . . . . .A-7

Optional Push-button Calibration . . . . . . . . . . . . . . . .A-8

3) Optional Horn Relay Software . . . . . . . . . . . . . . . . . . . . . .A-9

To Activate the Horn Relay . . . . . . . . . . . . . . . . . . . . .A-9

To Reset the Horn Relay . . . . . . . . . . . . . . . . . . . . . . .A-9

Appendix B,

Calibration Guide for Additional XIR/XI Gases .B-1

Appendix C,

General Certification Information . . . . . . . . . . .C-1

v

Appendix D,

HART Specific Information . . . . . . . . . . . . . . . . .D-1

HART Field Device Specification . . . . . . . . . . . . . . . . . . . . . .D-1

Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Status Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

Extended Device Status . . . . . . . . . . . . . . . . . . . . . . .D-3

Universal Commands . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Common-Practice Commands . . . . . . . . . . . . . . . . . .D-5

Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Catch Device Variable . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Command #129: Read Sensor Gas Type . . . . . . . . . .D-7

Command #130: Read Device Real Time Clock . . . .D-7

Command #131: Read Alarm Setpoints . . . . . . . . . . .D-8

Command #132: Read Alarm Control Actions . . . . . .D-9

Command #133: Read Min, Max, Avg Values . . . . . .D-9

Command #134: Read Last Cal Date . . . . . . . . . . . .D-10

Command #135: Read Gas Table . . . . . . . . . . . . . . .D-10

Command #136: Read Input Voltage Value . . . . . . .D-10

Command #137: Read Auto Zero Comp Value . . . .D-11

Command #139: Read Sensor Status message . . . .D-11

Command #140: Read Swap Delay Status . . . . . . .D-11

Command #141: Read Cal Signal Status . . . . . . . . .D-12

Command #142: Read Alert Option Status . . . . . . . .D-12

Command #143: Read Sensor Temperature . . . . . .D-13

Command #144: Read Relay Normal State . . . . . . .D-13

Command #173: Write RTC . . . . . . . . . . . . . . . . . . .D-14

Command #174: Write Alarm Setpoints . . . . . . . . . .D-15

Command #175: Write Alarm Setpoint

Control Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-16

Command #176: Write Average Interval . . . . . . . . . .D-17

Command #177: Write Upper Trim Point . . . . . . . . .D-18

Command #178: Write Gas Table . . . . . . . . . . . . . . .D-19

Command #179: Write Sensor Data Sheet

Reset Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-20

Command #180: Write Sensor Swap Delay Enable .D-21

Command #181: Write Cal Signal Enable . . . . . . . .D-22

Command #182: Write Calibration Mode . . . . . . . . .D-23

Command #183: Write Calibration Abort . . . . . . . . .D-24

Command #184: Write Calibration Step . . . . . . . . . .D-25

vi

Command #185: Write Alarm Acknowledge . . . . . . .D-26

Command #186: Write Protect Mode . . . . . . . . . . . .D-27

Command #187: Write Alert Option . . . . . . . . . . . . .D-28

Command #188: Write Relay Normal State . . . . . . .D-29

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-32

Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-32

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-32

Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-32

Busy and Delayed-Response . . . . . . . . . . . . . . . . . .D-33

Long Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-33

Non-Volatile Memory . . . . . . . . . . . . . . . . . . . . . . . . .D-33

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-34

Write Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-34

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-34

Capability Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-34

Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-35

Calibration Using a HART® Communicator . . . . . . . . . . . . .D-35

Sensor Zero Selection Menu . . . . . . . . . . . . . . . . . .D-35

Standard Zero/Span Calibration Selection Menu . . .D-37

Initial Calibration Procedures . . . . . . . . . . . . . . . . . .D-40

User Calibration Selection Menu . . . . . . . . . . . . . . .D-40

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-54

Span Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-54

Zero Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-57

vii

List of Figures

Figure 1-1. General-Purpose Ultima XA Monitor . . . . . . . . . .1-1

Figure 1-2. -Proof Ultima XE Monitor . . . . . . . . . . . . . . . . . . .1-2

Figure 1-3. Explosion-Proof Ultima XIR Monitor . . . . . . . . . . .1-2

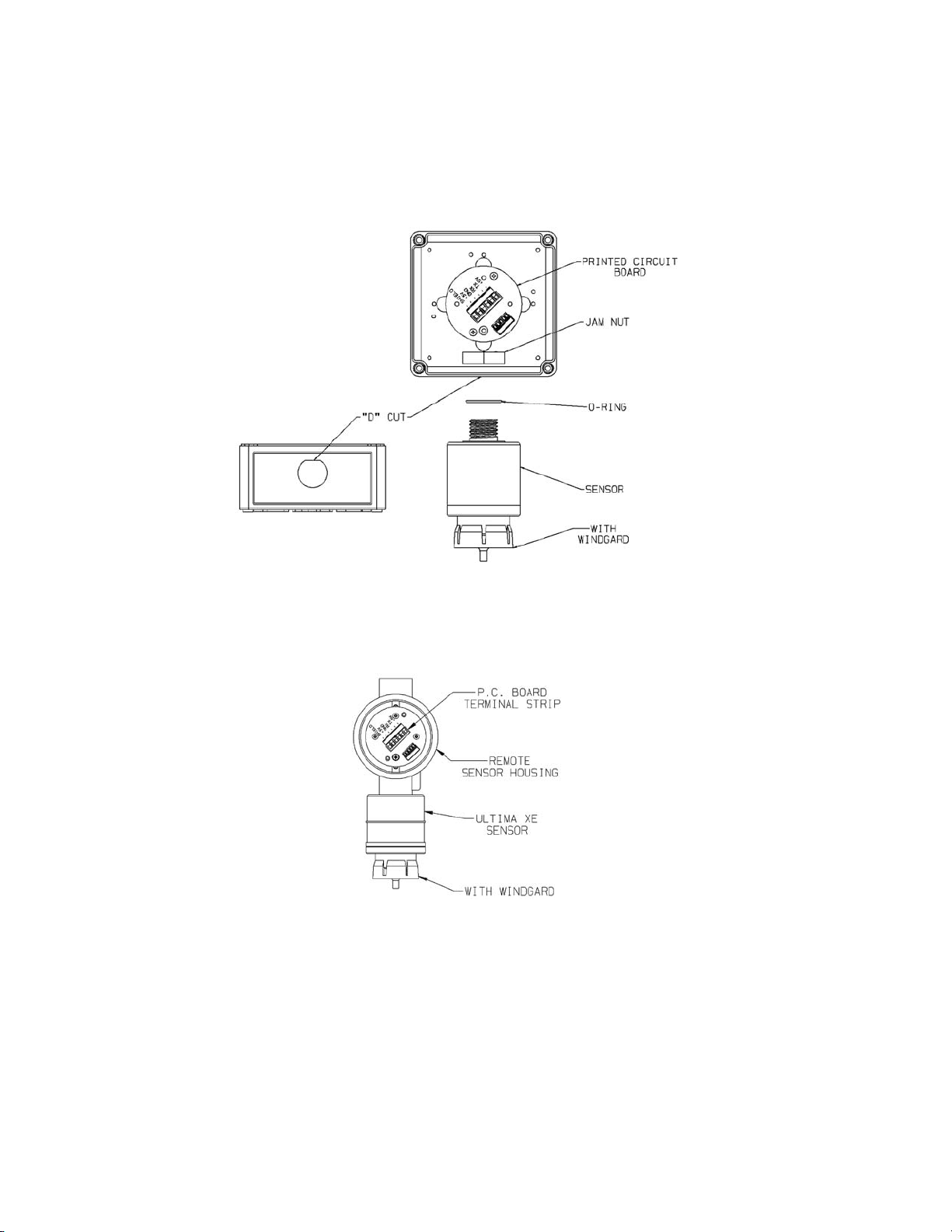

Figure 1-4. General-Purpose XA Remote Sensor Module . . .1-3

Figure 1-5. Explosion-Proof XE Remote Sensor Module . . . .1-3

Figure 1-6. Explosion-Proof XIR Remote Sensor Module . . .1-4

Figure 1-7. Ultima XE and XIR Mounting Bracket . . . . . . . . .1-7

Figure 1-8. Ultima XIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Figure 1-9. Ultima XE Grounding Terminals . . . . . . . . . . . . . .1-9

Figure 1-10. General-Purpose Two-Wire Operation . . . . . . .1-14

Figure 1-11. Explosion-Proof Two-Wire Operation . . . . . . . .1-14

Figure 1-12. General-Purpose Three-Wire Operation . . . . . .1-15

Figure 1-13. Explosion-Proof Three-Wire Operation . . . . . . .1-15

Figure 1-14. Two-Wire Printed Circuit Board

(no HART Protocol) . . . . . . . . . . . . . . . . . . . . . .1-16

Figure 1-15. Two-Wire Printed Circuit Board

(with HART Protocol) . . . . . . . . . . . . . . . . . . . . .1-17

Figure 1-16. Three-Wire Printed Circuit Board

(no HART Protocol) . . . . . . . . . . . . . . . . . . . . . .1-18

Figure 1-17. Three-Wire Printed Circuit Board

(with HART Protocol) . . . . . . . . . . . . . . . . . . . . .1-19

Figure 1-18. Remote Module General-Purpose

Ultima X Series Wiring . . . . . . . . . . . . . . . . . . . .1-20

Figure 1-19. Remote Module Explosion-Proof

Ultima X Series Wiring . . . . . . . . . . . . . . . . . . . .1-20

Figure 2-1. LCD Gas Concentration Display . . . . . . . . . . . . . .2-1

Figure 2-2. Ultima Calibrator . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-3. Ultima Controller . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-4. Ultima X Optional Push-button Calibrator . . . . . . .2-5

Figure 2-5. Apply ZERO Gas Flag . . . . . . . . . . . . . . . . . . . .2-14

Figure 2-6. Apply SPAN Gas Flag . . . . . . . . . . . . . . . . . . . . .2-15

Figure 2-7. Calibration End Display . . . . . . . . . . . . . . . . . . .2-17

Figure 4-1. "Change Sensor" Scrolls Across the Display . . . .4-6

Figure 4-2. Sensor Assembly and Sensor Guard

for General-Purpose Model . . . . . . . . . . . . . . . . .4-7

Figure A-1. Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Figure A-2. Relay Printed Circuit Board . . . . . . . . . . . . . . . . .A-6

Figure D-1. Zero cal step screen . . . . . . . . . . . . . . . . . . . . .D-41

viii

Figure D-2. Span cal step screen . . . . . . . . . . . . . . . . . . . . .D-41

Figure D-3. Select Sensor Calibration

from the Sensor Trim Menu . . . . . . . . . . . . . . . .D-42

Figure D-4. First Warning screen . . . . . . . . . . . . . . . . . . . . .D-43

Figure D-5. Second Warning screen . . . . . . . . . . . . . . . . . .D-44

Figure D-6. Standard Calibration function select screen . . .D-45

Figure D-7. Calibration initiated screen . . . . . . . . . . . . . . . .D-46

Figure D-8. Selection Confirmation screen . . . . . . . . . . . . . .D-47

Figure D-9. Sensor Zero Countdown screen . . . . . . . . . . . .D-48

Figure D-10. Zero Adjustment screen . . . . . . . . . . . . . . . . . .D-49

Figure D-11. Span Countdown screen . . . . . . . . . . . . . . . . .D-50

Figure D-12. Adjusting Span screen . . . . . . . . . . . . . . . . . . .D-51

Figure D-13. Calibration Completion message . . . . . . . . . . .D-52

Figure D-14. Calibration Gas Reminder screen . . . . . . . . . .D-53

Figure D-15. Loop Control Reminder message . . . . . . . . . .D-54

Figure D-16. Calibration Status screen . . . . . . . . . . . . . . . . .D-55

Figure D-17. Sensor Trim Point screen . . . . . . . . . . . . . . . .D-56

Figure D-18. Additional Sensor Status screen . . . . . . . . . . .D-57

Figure D-19. Device Status screen . . . . . . . . . . . . . . . . . . . .D-58

ix

List of Tables

Table 1-1. Installation Outline Drawing List . . . . . . . . . . . . . .1-10

Table 1-2. Cable Length and Wire Size for Units without

Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Table 1-3. Installation Outline Drawings

for Ultima X Power Supplies . . . . . . . . . . . . . . .1-12

Table 1-4. Remote Module Wiring and Placement . . . . . . . .1-22

Table 1-5. Remote Sensor Wiring Cable . . . . . . . . . . . . . . . .1-22

Table 1-6. Low Temperature Wiring Cable . . . . . . . . . . . . . .1-22

Table 2-1. Instrument Operation . . . . . . . . . . . . . . . . . . . . . . .2-2

Table 2-2. Factory-set Span Values . . . . . . . . . . . . . . . . . . . .2-9

Table 2-3. Calibration Guide for Combustible Gas Sensor . .2-11

Table 3-1. Performance Specifications . . . . . . . . . . . . . . . . . .3-1

Table 3-2. Sensor Response to Interferants . . . . . . . . . . . . . .3-4

Table 4-1. Operational Display Messages . . . . . . . . . . . . . . . .4-1

Table 4-2. Configuration Display Messages . . . . . . . . . . . . . .4-2

Table 4-3. Troubleshooting Guidelines . . . . . . . . . . . . . . . . . .4-2

Table 4-4. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Table A-1. Power Cable Distances for the Ultima X

Series Gas Monitor with Internal Relays . . . . . .A-2

Table A-2. Relay Specifications . . . . . . . . . . . . . . . . . . . . . . . .A-2

Table A-3. Push-button Calibration . . . . . . . . . . . . . . . . . . . . .A-8

Table D-1. Device Identification . . . . . . . . . . . . . . . . . . . . . . .D-1

Table D-2. Current Values . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2

Table D-3. Device Variables Exposed by the Ultima Monitor .D-3

Table D-4. Dynamic Variable implemented by Ultima Monitor D-3

Table D-5. Additional Device Status (Command #48) . . . . . .D-4

Table D-6. Supported Commands . . . . . . . . . . . . . . . . . . . . .D-6

Table D-7. Device-Specific Commands . . . . . . . . . . . . . . . . .D-7

Table D-8. Gas Type Descriptions . . . . . . . . . . . . . . . . . . . .D-30

Table D-9. Alarm Control Actions . . . . . . . . . . . . . . . . . . . . .D-30

Table D-10. Gas Table Values . . . . . . . . . . . . . . . . . . . . . . .D-30

Table D-11. Calibration Modes . . . . . . . . . . . . . . . . . . . . . . .D-31

Table D-12. Sensor Status Codes . . . . . . . . . . . . . . . . . . . .D-31

Table D-13. Sampling Rates . . . . . . . . . . . . . . . . . . . . . . . . .D-32

Table D-14. Command Response Times . . . . . . . . . . . . . . .D-33

Table D-15. Capability Checklist . . . . . . . . . . . . . . . . . . . . . .D-34

Table D-16. Default Configuration . . . . . . . . . . . . . . . . . . . .D-35

x

1-1

Chapter 1,

Installation

General Description

The Ultima X Series Gas Monitor is designed to sample the

environment where mounted and alert you to potentially dangerous

levels of your target gas, depending on your particular model. The

Ultima X Series device uses various detection methods, depending on

the gas of interest. Detection methods can be electrochemical, infrared,

pellement or other technologies. The Ultima XE Gas Monitor is an

explosion-proof device suitable for installation in hazardous locations.

The Ultima XA Gas Monitor is a general-purpose version in a plastic

enclosure for use in nonexplosive atmospheres only. The Ultima X Gas

Monitor can be ordered with the standard 4 to 20 mA analog output or

with an optional HART (Highway Addressable Remote Transducer)

protocol, which is superimposed on the 4 to 20 mA signal. The unit is

factory-calibrated and shipped ready for installation.

The main sensor input is provided via a five-terminal interface that

provides a digital interface for 3 VDC or 5 VDC sensor modules. Many

different sensor modules are available, providing sensing capability for a

large variety of gases. The operating range varies with the type of cell

(e.g., electrochemical, pellistor or infrared combustible, etc.).

Identifying Your Unit

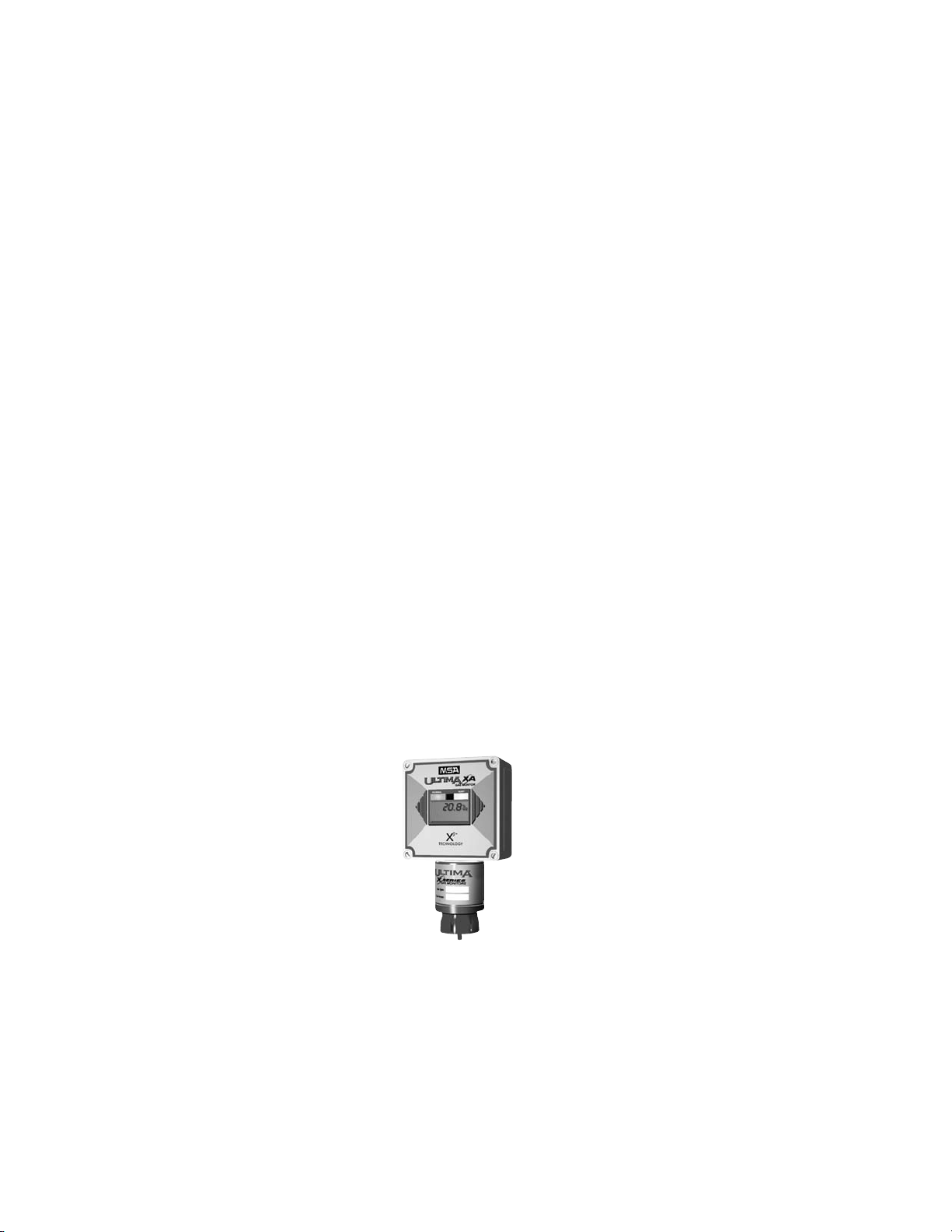

The Ultima XA Gas Monitor is housed in a rugged, plastic generalpurpose enclosure (FIGURE 1-1).

Figure 1-1. General-Purpose Ultima XA Monitor

The Ultima XE Gas Monitor is housed in a 316 stainless steel

explosion-proof enclosure (FIGURE 1-2 shows the Ultima XE

with the optional explosion-proof HART port).

.

The Ultima XIR Gas Monitor is housed in a 316 stainless steel

explosion-proof enclosure (FIGURE 1-3).

If your application requires the sensor head to be located separately

from the control unit, all models are available with Remote Sensor

Modules (shown in FIGURES 1-4, 1-5 and 1-6).

Figure 1-3. Explosion-Proof Ultima XIR Monitor

Figure 1-2. Explosion-Proof Ultima XE Monitor

1-2

Figure 1-5. Explosion-Proof XE Remote Sensor Module

Figure 1-4. General-Purpose XA Remote Sensor Module

1-3

To determine your sensor type and options, check the shipping carton.

Checked items are included in the carton. The carton label identifies:

• Type of unit supplied (Gas Monitor, Gas Monitor Less Sensor, or

Remote Sensor Module)

• Type of gas (combustible gas, toxic gas or oxygen)

• Range [% LEL, PPM (parts per million), or %]

• Output (2- or 3-wire, 4 to 20 mA, or 4 to 20 mA with HART)

• Any options such as internal relays and/or LEDs.

• If your unit contains internal relays, see Appendix A.

Also check the sensor ID label located on the inside of the sensor. This

can be viewed by unscrewing the lower portion of the sensor. If

performing this while the unit is powered, see the following Warning.

The sensor ID label identifies the detectable gas and the gas range.

For Ultima XE sensors marked Class I, Groups A, B, C and D

and not used in Class II areas, unscrew sensor cap at least

three full turns (but no more than four full turns from its

tightly-closed position), wait 10 seconds, and then remove

cap completely. Failure to follow this warning can result in

the ignition of a hazardous atmosphere.

For the Ultima XE Sensor marked Class II Groups F and G,

atmosphere must be free of dust and the power removed

from the unit before the sensor cap can be removed from the

housing. Failure to follow this warning can result in the ignition of a hazardous atmosphere.

"

WARNING

Figure 1-6. Explosion-Proof XIR Remote Sensor Module

1-4

Your Ultima XE Series Gas Monitor may also include a separate HART

Module if you ordered the following optional accessories:

1). Internal Power Supply and explosion-proof HART Port

2). External RESET Push-button and explosion-proof HART Port.

Installing Your Gas Monitor

NOTE: Reference installation outline drawings listed in TABLE 1-1.

Generally, the Ultima X Series Gas Monitors or remote sensing

module should be mounted close to the area where a leak is likely to

occur or where the gas is expected. Install the Ultima X Series Gas

Monitors or the remote sensing module at a high level (ceiling) or low

level (floor), depending on the density of the gas most likely to be

found. Install the unit so that the front display of the unit is not blocked

or hidden from view.

Mount the Ultima XE or XA Gas Monitor or remote sensing

module with the sensor inlet fitting (FIGURE 1-1, 1-2, 1-4 or

1-5) pointed downward; otherwise, the inlet may become

clogged with particulate matter or liquids.

Mount the Ultima XIR Gas Monitor or XIR Remote Sensing

Module with the sensor inlet fitting extended horizontally

from the main enclosure (FIGURE 1-3 and 1-6) to prevent the

build-up of particulate or liquid matter on the monitor's optical surfaces.

Do not paint the Ultima X Series Gas Monitors. If painting is

done in an area where a sensor is located, exercise CAUTION to ensure paint is not deposited on the sensor inlet fitting. Such paint deposits would interfere with the diffusion

process, whereby a sample of the monitored atmosphere

diffuses into the sensor. In addition, solvents in the paint

may cause an alarm condition to occur.

Protect the Ultima X Series Gas Monitors from extreme

vibration. Do not mount sensing head in direct sunlight as

this may cause overheating of the sensor.

"

CAUTION

1-5

Do not locate the general-purpose enclosure models in an

area which may contain a flammable mixture of gas and air;

otherwise, an explosion may occur. The general-purpose

Ultima X Series Gas Monitors can be a source of ignition and

must not be mounted in an area where a flammable mixture

of combustible gas and air may become present; otherwise,

an explosion may occur. If such a location must be monitored, use an explosion-proof gas monitor.

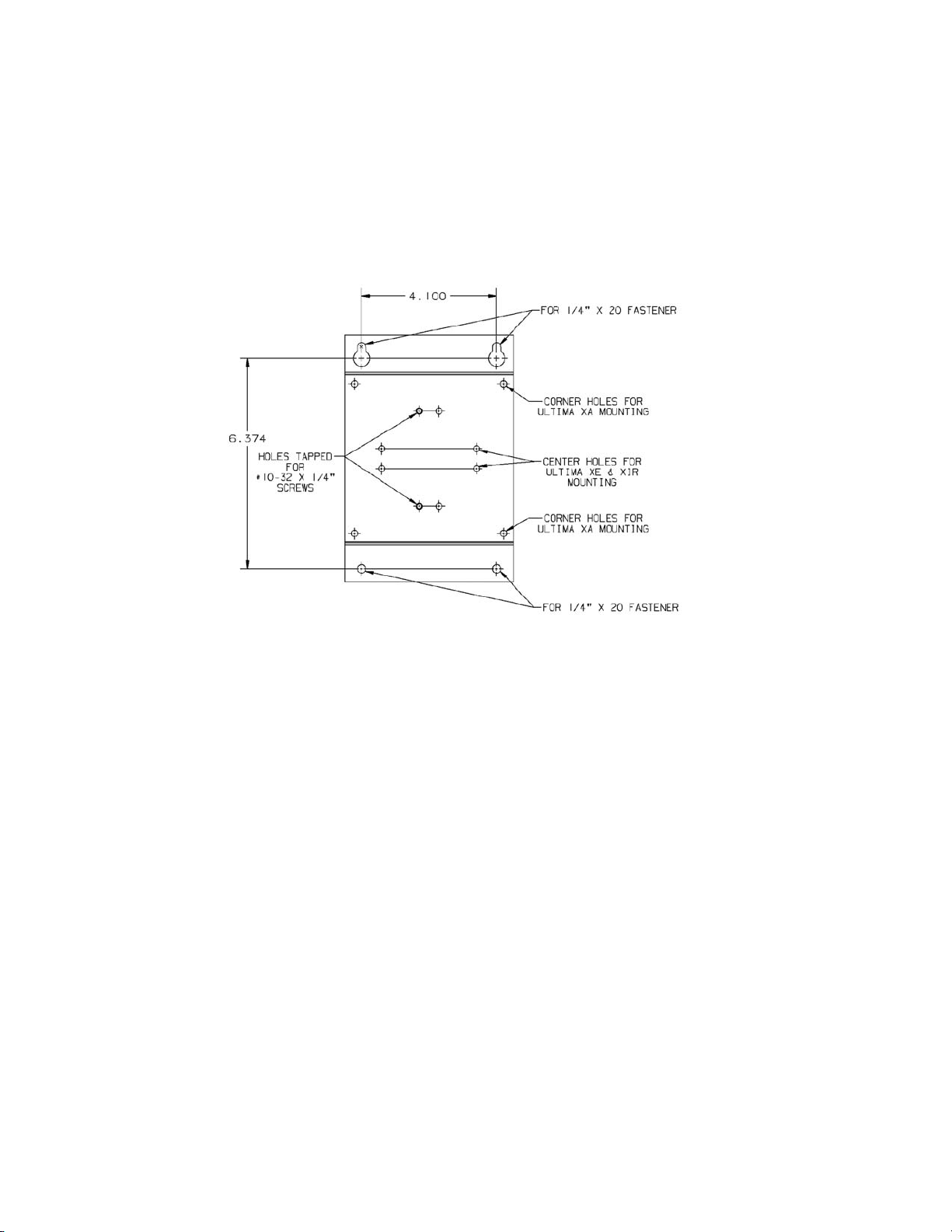

Installing the Ultima XA Gas Monitor

Remove lid and drill enclosure for power, signal and optional relay cable

entry. Use one of the following methods to mount the general-purpose

Ultima XA Gas Monitor/Less Sensor or the Ultima XA Gas Monitor.

• Using customer-installed wiring holes, install the Ultima XA Gas

Monitor to the end of rigid conduit.

• Use mounting holes in the corners of the Ultima XA enclosure to

mount directly to a wall.

• Use mounting holes in the corners of the Ultima XA enclosure to

mount to the optional Mounting Kit (P/N 10047561);

see FIGURE 1-7.

• The Ultima XA gas sensor is not shipped attached to the main

enclosure. Ensure the sensor wiring harness is through the entry

and the sensor is pointed downward.

Installing the Ultima XE Gas Monitor

• The optional Mounting Bracket Kit (P/N 10047561) can be attached

to the rear holes of the Ultima XE Gas Monitor (FIGURE 1-7).

• The Ultima XE Gas Monitor main enclosure can be rotated 360°

and mounted to ensure easy access to any of the four entryways.

The electronics assembly inside the metal enclosure can be

repositioned in any of the four self-aligning interior holes to ensure

the display is properly oriented.

• The Ultima XE Gas Monitor sensor is not shipped attached to the

main enclosure. Ensure the sensor wiring harness is through the

entry and the sensor is pointing downward. Tighten with a strap

wrench.

"

WARNING

1-6

.

Figure 1-7. Ultima XE and XIR Mounting Bracket

1-7

Installing the Ultima XIR Gas Monitor

The Ultima XIR Gas Monitor contains no user- or field-serviceable parts and must be returned to the factory for repair.

Any attempt to open the monitor will damage the unit and

void the warranty.

Under no circumstances should a wrench or pry-bar be

applied to the two legs that support the unit's reflectors during installation or removal of the sensor (FIGURE 1-8).

Applying force to the legs can permanently damage the

monitor.

It is recommended that the monitor's environmental guard

be installed on the unit at all times. If the monitor is to be

operated without the guard, frequent checks should be

made to ensure particulate or liquid matter has not collected

on the windows.

• The optional Mounting Bracket (P/N 10047561) can be attached to

the rear holes of the Ultima XE Gas Monitor (FIGURE 1-7).

• The Ultima XIR Gas Sensor is factory-installed on the stainless

steel gas monitor. The Ultima XIR Monitor must be installed with

the XIR sensor in a horizontal position (see FIGURE 1-3) to

prevent the build-up of particulate or liquid matter on the monitor

optical surface.

• The Ultima XIR Gas Sensor is intended for use only on

metal enclosures.

.

Figure 1-8. Ultima XIR

"

CAUTION

"

WARNING

1-8

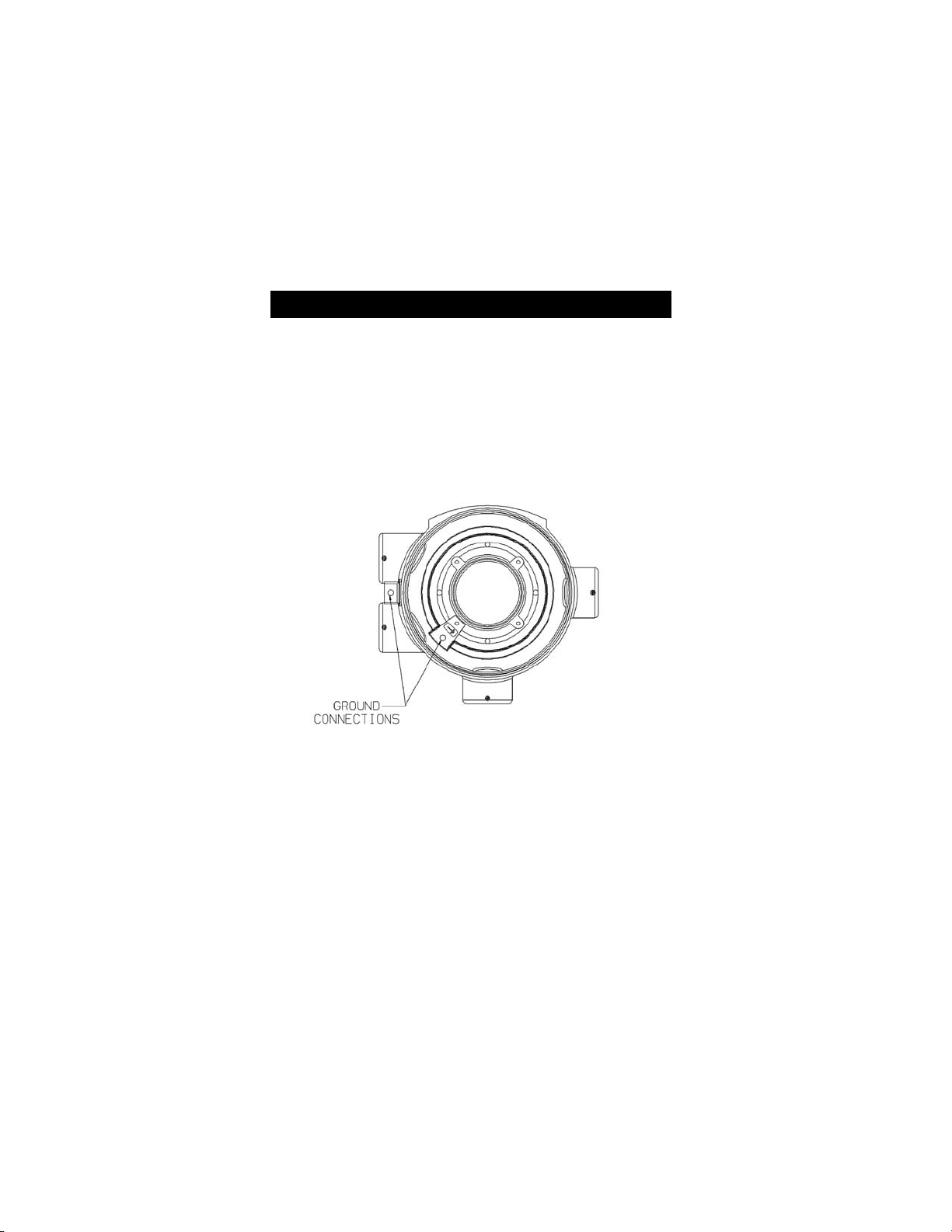

Electrical Connections

for Ultima X Gas Monitors

Before wiring the Ultima X Series Gas Monitors, disconnect

power source supplying the monitor; otherwise, electrical

shock or ignition of hazardous atmospheres could occur.

For Ultima XE and XIR installations, the internal grounding

terminal (located on the interior bottom of the Ultima XE

main enclosure) must be used for equipment grounding. The

external grounding terminal is only to be used as a supplemental bonding connection where local authorities permit or

require such a connection. See FIGURE 1-9 for location of

grounding terminals.

.

NOTE: For Ultima X Series units with internal relays, see Appendix A.

This assembly is marked to identify power, ground and signal

connections.

• A two-wire connection is possible for certain:

• Toxic Gas models

• Oxygen models

• A three-wire connection is required for all:

• Combustible Gas models

• Toxic and Oxygen models with internal relays.

Figure 1-9. Ultima XE Grounding Terminals

"

WARNING

1-9

Wiring for all Models

Install wiring in accordance with the electrical code of the country in use

and UL 61010-A1 or CSA C22.2 No. 1010.1, as applicable. In these

installations, twisted-pair, instrument quality cable is recommended.

Shielded cable is recommended for cable runs where interferences from

radio frequency interference (RFI), electromagnetic interference (EMI)

or other noise sources exist (such as motors, welding equipment,

heaters, etc.).

NOTE: See Installation Outline Drawings for wiring details as specified

in TABLE 1-1.

Table 1-1. Installation Outline Drawing List

MODEL TYPE DOCUMENT NO.

Ultima XA Gas Monitor SK3015-1027

Ultima XE Gas Monitor SK3015-1025

Ultima XIR Gas Monitor SK3015-1026

Conduit may also be needed in areas where large amounts of electrical

noise is expected.

Use caution when selecting a cable size. TABLE 1-2 expresses the

maximum cable length when only using the Ultima X Series Gas

Monitors. Ultima X Series options may take additional power which

requires a heavier cable or a short cable run. Cable distances for units

with internal relays are specified in Appendix A, TABLE A-1.

When selecting cable size, consider future needs (i.e., addition of

sensors and/or options available with the Ultima X Series Gas

Monitors). See Chapter 3, TABLE 3-1, "Performance Specifications"

for proper input voltage.

Ensure that water and dirt are not able to enter the unit via the wire or

conduit. If the unit is installed in a location known to be wet or damp, it

is good practice to loop or bend the entry into the unit that prevents

water incursion.

All cable shields should be terminated to earth ground at one end only.

1-10

Table 1-2. Cable Length and Wire Size

for Units Without Internal Relays

GAS SENSOR DC WIRE MAXIMUM MAXIMUM

TYPE OUTPUT VOLTAGE SIZE CABLE LENGTH LOAD

SUPPLY (AWG) WITHOUT HART RESISTANCE

(FEET) (METERS) (OHMS)

Oxygen

or Toxic 2 Wire 12 VDC 22 4000 1219 100

900(w/HART) 274 (w/HART) 50 (w/HART)

24 VDC 22 7,000 2134 500

Oxygen

or Toxic 3 Wire 24 VDC 22 10,000 3048 500

Combustible 3 Wire 12 VDC 18 900 274 250

16 1,400 427 250

12 3,600 1097 250

Combustible 3 Wire 24 VDC 18 2,500 762 500

16 4,200 1280 500

12 10,000 3048 500

XIR 3 wire 12 VDC 18 300 91 250

16 500 152 250

12 900 274 250

XIR 3 wire 24 VDC 18 2,000 610 500

16 3,500 1067 500

12 5,000 1524 500

An external power supply is required to supply 8-30 VDC to the Ultima X

Series Gas Monitor (For power requirements, see Chapter 3,

"Specifications"). All connections should be made by following appropriate

wire code procedures.

For proper installation of an AC power supply used with an Ultima X Series

transmitter, refer to the following drawings for detailed information. Optional

12 VDC or 24 VDC internal and external power supplies can be ordered

with the Ultima X Series Gas Monitors.

1-11

Table 1-3. Installation Outline Drawings

for Ultima X Power Supplies

MODEL POWER POWER SUPPLY POWER INSTALLATION OUTLINE

SUPPLY OUTPUT VOLTAGE SPECIFICATION DRAWING NUMBER

XA External 12 VDC 1.25 Amps, 15 W 10000020129

External 24 VDC 0.46 Amps, 11 W 10000020127

Internal 12 or 24 VDC see above SK3015-1027

XE External 12 VDC 1.25 Amps, 15 W 10000020130

External 24 VDC 0.46 Amps, 11 W 10000020128

Internal 12 or 24 VDC see above SK3015-1025 (XE) or

SK3015-1026 (XIR)

Use of External Controllers

The Ultima X Series Gas Monitors may be connected to any device

capable of accepting 4-20 mA analog signals, such as:

• Suprema Controller

• Model 9010/9020 Controller

• GasGard family controllers

• Quad Gas Controller

• Programmable Controllers

• DCS’s, etc.

When using any of the the Ultima X Series accessories (such

as relays) with the 4 to 20 mA output Ultima X Series Gas

Monitor, a three-wire connection must be used. Failure to

use a three-wire connection could damage the electronics

within the Ultima X Series Gas Monitor which can result in

serious personal injury or loss of life.

Be sure to install your Ultima X Series Gas Monitor according to National Electrical and local procedural codes. Failure

to do so can result in an unsafe condition.

"

WARNING

1-12

Identify PCB Configuration

• Identify the main pc board as a two-wire or a three-wire unit:

• For XA Gas Monitors:

while looking at the main pc board, locate the identifying label

on the underside of the lid:

• A-ULTX-PCB-A-1 is a two-wire unit, 4-20 mA output

• A-ULTX-PCB-A-2 is a two-wire unit with HART protocol on

the 4-20 mA output

• A-ULTX-PCB-A-3 is a three-wire unit, 4-20 mA output

• A-ULTX-PCB-A-4 is a three-wire unit with HART protocol

on the 4-20 mA output

• For XE and XIR Gas Monitors:

locate the identifying label on the side of the plastic shroud for

the main pc board:

• A-ULTX-PCB-E-1 is a two-wire unit, 4-20 mA output

• A-ULTX-PCB-E-2 is a two-wire unit with HART protocol on

the 4-20 mA output

• A-ULTX-PCB-E-3 is a three-wire unit, 4-20 mA output

• A-ULTX-PCB-E-4 is a three-wire unit with HART protocol

on the 4-20 mA output.

1-13

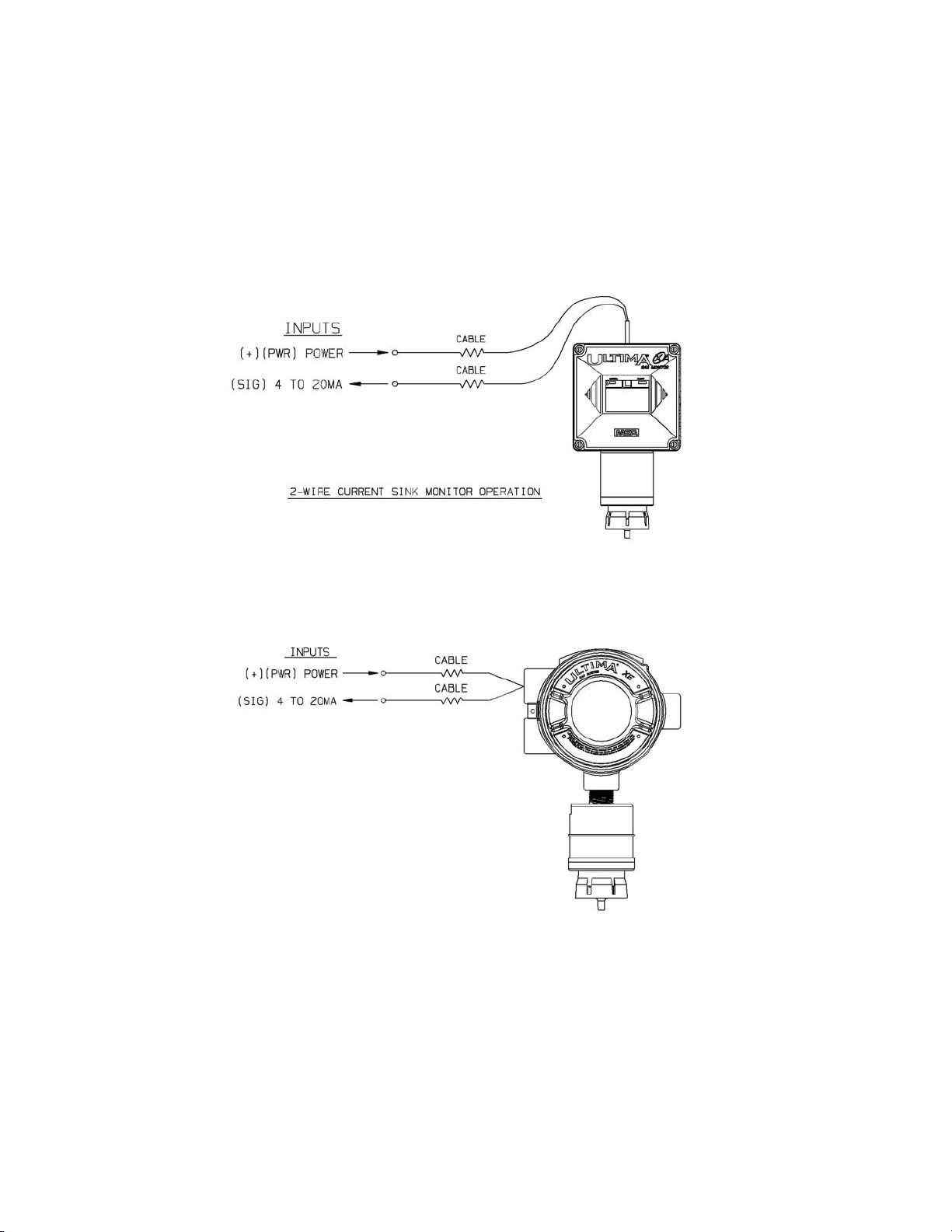

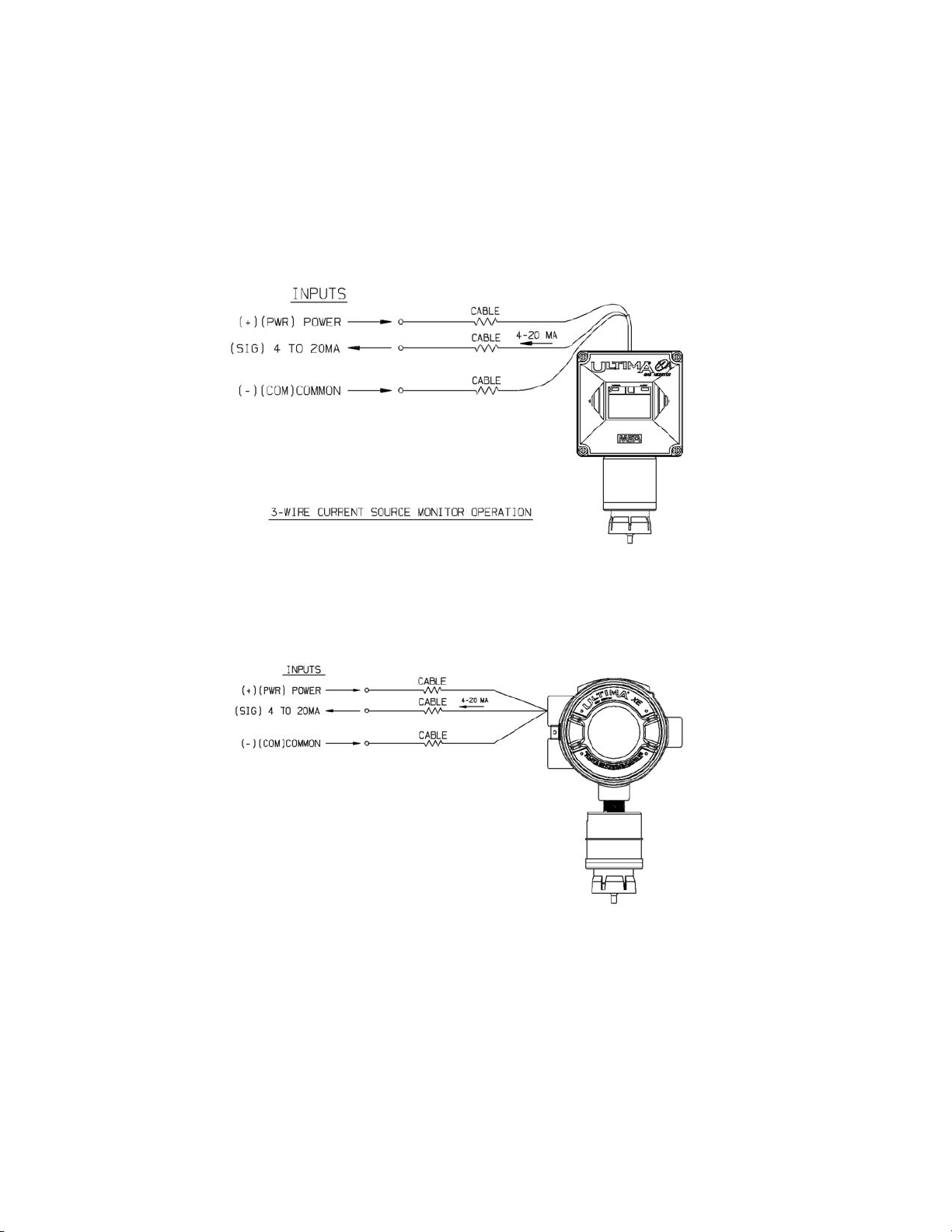

• Two-wire 4 to 20 mA Ultima X Series Monitors operate in the

current loop mode (FIGURE 1-10 for general-purpose)

(FIGURE1-11 for explosion-proof).

.

.

Figure 1-11. Explosion-Proof Two-Wire Operation

Figure 1-10. General-Purpose Two-Wire Operation

1-14

• Three-wire Ultima X Series Monitors operate in the current source

mode (see FIGURE 1-12 for general-purpose) (FIGURE 1-13 for

explosion-proof).

.

.

Figure 1-13. Explosion-Proof Three-Wire Operation

Figure 1-12. General-Purpose Three-Wire Operation

1-15

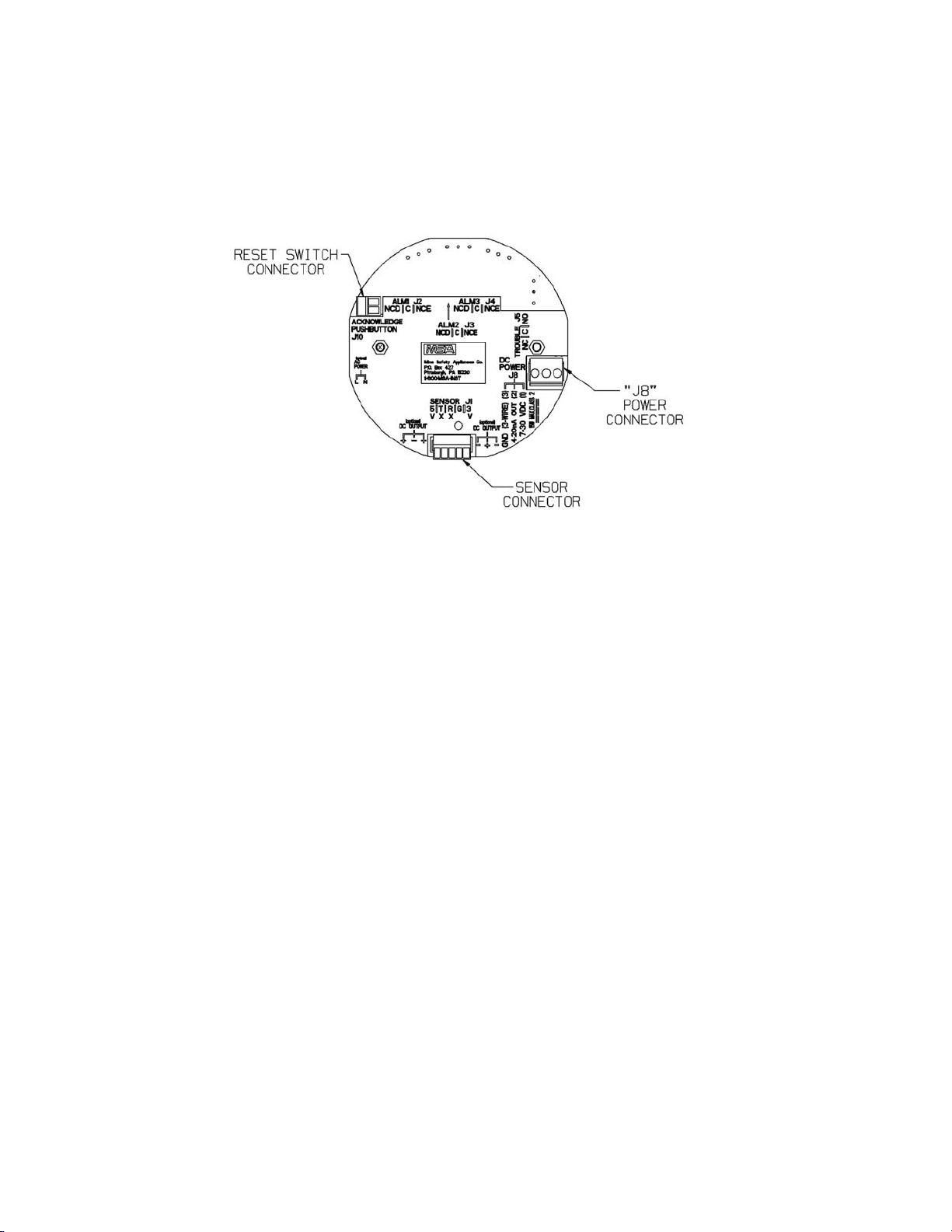

Installation of Two-Wire, 4-20 mA Output (no HART Protocol)

1. Connect 8-30 VDC power lead to J8-1 (see FIGURE 1-14)

2. Connect J8-2 to the 4-20 mA output on the remote system.

3. Connect the sensor module to main pc board connector J-1.

4. Assemble lid on the enclosure.

Figure 1-14. Two-Wire Printed Circuit Board

(no HART Protocol)

1-16

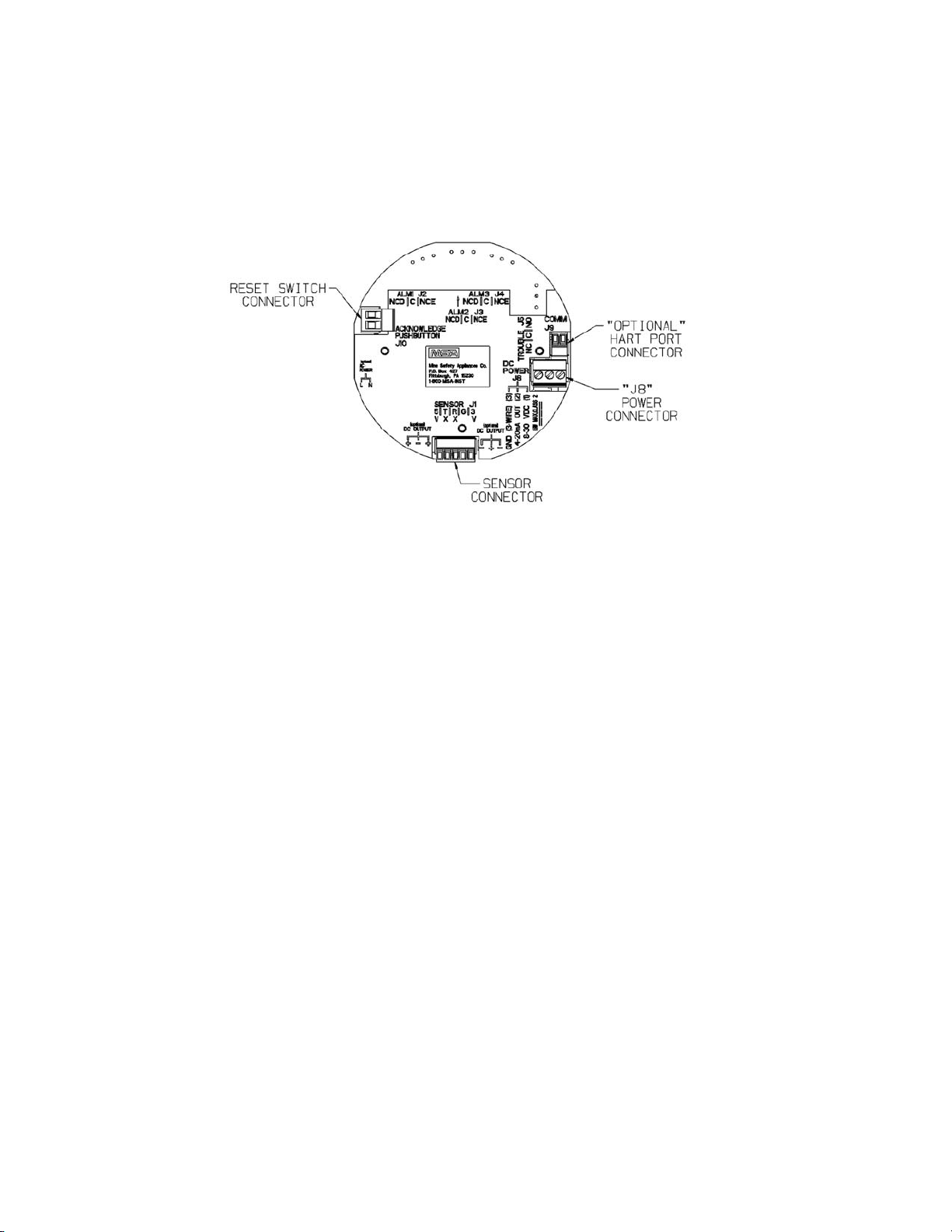

Installation of Two-Wire, 4-20 mA Output with HART Protocol

1. Connect 12-30 VDC power lead to J8-1 (see FIGURE 1-15).

NOTE: The HART signal is not available below 12 VDC

on the two-wire pc board.

2. Connect J8-2 to the 4-20 mA input on the remote system.

3. Terminate the 4-20 mA line with 230-500 Ohms of resistance.

4. Connect sensor module to main pc board connector J-1.

5. Assemble lid on the enclosure.

Figure 1-15. Two-Wire Printed Circuit Board

(with HART Protocol)

1-17

Loading...

Loading...