Page 1

Hydrogen Sulfide Gas Detection

Ultima® MOS-5

Intelligent Sensor for

The information and technical data disclosed in

this document may be used and disseminated

only for the purposes and to the extent

specifically authorized in writing by MSA.

Instruction Manual 04-14

MSA reserves the right to change published

specifications and designs without prior notice.

Part No. MANMOS5

Revision 1

MANMOS5

Page 2

Ultima MOS-5 Detector

This page intentionally left blank

i

Page 3

Ultima MOS-5 Detector

Table of Contents

TABLE OF FIGURES .................................................................................................................. VI

TABLE OF TABLES ................................................................................................................... VII

QUICK START GUIDE ................................................................................................................. 1

Mounting and Wiring ............................................................................................................................... 1

Tools Required ……..…………………………………………………………………………………………...1

Terminal Connections ............................................................................................................................. 1

1.0 INTRODUCTION .................................................................................................................... 4

1.1 Protection for Life ....................................................................................................................... 4

1.2 Special Warnings ....................................................................................................................... 4

1.3 System Integrity Verification ...................................................................................................... 5

2.0 PRODUCT DESCRIPTION ..................................................................................................... 7

2.1 General Description ................................................................................................................... 7

3.0 INSTALLATION ...................................................................................................................... 8

3.1 Receipt of Equipment ................................................................................................................. 8

3.2 Tools Required ........................................................................................................................... 8

3.3 Choosing Product Locations ...................................................................................................... 8

3.3.1 Remote Mounting of the Sensor from the Electronics .................................................. 9

3.4 Mounting and Wiring ................................................................................................................ 10

3.5 Terminal Connections .............................................................................................................. 11

3.5.1 Terminal Block TB1 – Sensor Connections ................................................................ 11

3.5.2 Terminal Block TB2 – Power and Signal Connections ............................................... 12

3.5.3 DC Power and Ground Connections ........................................................................... 13

3.5.4 Analog Signal Connections ......................................................................................... 13

3.5.5 Terminal Block TB3 – Relay Connections .................................................................. 14

3.5.6 European Union (EU) Approved Applications ............................................................. 15

3.5.7 Cable Termination in the Non-hazardous Area .......................................................... 15

3.6 Maintaining the X/P Integrity .................................................................................................... 15

4.0 OPERATION ......................................................................................................................... 17

4.1 Start-Up Checklist .................................................................................................................... 17

4.2 Start-Up .................................................................................................................................... 17

4.3 Relay Reset .............................................................................................................................. 17

4.4 User Selectable Options .......................................................................................................... 18

4.4.1 Ultima MOS-5 Intelligent Sensor User Menu Structure .............................................. 19

4.4.2 Sensor Range ............................................................................................................. 19

4.4.3 Calibration Output ....................................................................................................... 20

4.4.4 Warning Relay Settings .............................................................................................. 20

4.4.5 Alarm Relay Settings................................................................................................... 21

4.4.6 Modbus Channel 1 Settings ........................................................................................ 21

4.4.7 Modbus Channel 2 Settings ........................................................................................ 22

ii

Page 4

Ultima MOS-5 Detector

4.5

HART........................................................................................................................................ 22

4.6 Gas Check Mode ..................................................................................................................... 23

4.6.1 Procedure for Checking the Calibration ...................................................................... 23

4.7 Calibration ................................................................................................................................ 24

4.7.1 Calibration Procedure ................................................................................................. 24

4.7.2 Aborting Calibration..................................................................................................... 25

4.7.3 Remaining Sensor Life ................................................................................................ 25

4.7.4 Initializing the Remaining Sensor Life ......................................................................... 26

4.8 Calibration Equipment .............................................................................................................. 26

4.8.1 Calibrating with a Breaker Bottle and Ampoules ........................................................ 26

4.8.2 Calibrating with an H2S Portable Purge Calibrator ..................................................... 26

5.0 MAINTENANCE ................................................................................................................... 28

5.1 General Maintenance ............................................................................................................... 28

5.2 Storage ..................................................................................................................................... 28

6.0 TROUBLESHOOTING ......................................................................................................... 29

6.1 Fault Codes and Their Remedies ............................................................................................ 29

6.1.1 F2 - Failed to Complete the Calibration ...................................................................... 29

6.1.2 F3 Flash Checksum Error ........................................................................................... 29

6.1.3 F4 - Sensor Heater Open Error or Sensor Amplifier Error .......................................... 29

6.1.4 F5 - Sensor Heater Shorted Error ............................................................................... 30

6.1.5 F6 - Low Supply Voltage ............................................................................................. 30

6.1.6 F7 - EEPROM Verification Failure .............................................................................. 30

6.1.7 F8 - Failure to Complete Setup ................................................................................... 30

6.1.8 F9 - Gas Check Period Exceeded .............................................................................. 31

6.1.9 F10 – Switch Error ...................................................................................................... 31

6.1.10 F11 Internal Error ........................................................................................................ 31

7.0 CUSTOMER SUPPORT ....................................................................................................... 32

7.1 MSA Office ............................................................................................................................... 32

8.0 MODBUS INTERFACE ........................................................................................................ 33

8.1 Baud Rate ................................................................................................................................ 33

8.2 Data Format ............................................................................................................................. 33

8.3 Modbus Read Status Protocol (Query/Response) ................................................................... 33

8.3.1 Modbus Read Query Message ................................................................................... 33

8.3.2 Modbus Read Response Message ................................................................................. 35

8.4 Modbus Write Command Protocol (Query/Response) ............................................................ 35

8.4.1 Modbus Write Query Message ................................................................................... 35

8.4.2 Modbus Write Response Message ............................................................................. 35

8.5 Function Codes Supported ...................................................................................................... 36

8.6 Exception Responses and Exception Codes ........................................................................... 36

8.6.1 Exception Response ................................................................................................... 36

8.6.2 Exception Code ........................................................................................................... 37

8.7 Ultima MOS-5 Intelligent Sensor Command Register Locations ............................................. 38

8.8 Ultima MOS-5 Intelligent Sensor Command Register Details ................................................. 41

8.8.1 Analog (00H) ............................................................................................................... 41

8.8.2 Mode (01H) ................................................................................................................. 41

8.8.3 Status/Error (02H) ....................................................................................................... 41

iii

Page 5

Ultima MOS-5 Detector

8.8.4

Not Used (03H) ........................................................................................................... 42

8.8.5 Unit Type (04H) ........................................................................................................... 42

8.8.6 Software Revision (05H) ............................................................................................. 42

8.8.7 Status Block (06H) ...................................................................................................... 42

8.8.8 Analog Value (06H) ..................................................................................................... 42

8.8.9 Mode & Error (07H) ..................................................................................................... 42

8.8.10 Error Sensor & Sensor Life (08H) ............................................................................... 42

8.8.11 Display (0x09H & 0x0AH) ........................................................................................... 43

8.8.12 Serial Number (0BH/0CH) .......................................................................................... 43

8.8.13 Alarm Settings (0DH) .................................................................................................. 43

8.8.14 Warn Settings (0EH) ................................................................................................... 44

8.8.15 Com1 Address (0FH) .................................................................................................. 44

8.8.16 Com1 Baud Rate (10H) .............................................................................................. 44

8.8.17 Com1 Data Format (11H) ........................................................................................... 45

8.8.18 Com2 Address (12H) .................................................................................................. 45

8.8.19 Com2 Baud Rate (13H) .............................................................................................. 45

8.8.20 Com2 Data Format (14H) ........................................................................................... 45

8.8.21 Not Used (15H) ........................................................................................................... 46

8.8.22 Reset Alarms (16H) ..................................................................................................... 46

8.8.23 Sensor Life (17H) ........................................................................................................ 46

8.8.24 Sensor Scale (18H) ..................................................................................................... 46

8.8.25 MODEL 10K Controller (Co – Calibration Output) (19H) .......................................... 46

8.8.26 Not Used (1A, AB, 1C H) ............................................................................................ 46

8.9 HART Enable (1D H) ................................................................................................................ 46

8.9.1 HART Test (1Eh) ......................................................................................................... 46

8.9.2 Abort Calibration (1Fh) ................................................................................................ 47

8.9.3 Total Receive Errors (20H) ......................................................................................... 47

8.9.4 Bus Activity Rate % (21H) ........................................................................................... 47

8.9.5 Function Code Errors (22H) ........................................................................................ 47

8.9.6 Starting Address Errors (24H) ..................................................................................... 47

8.9.7 RXD CRC Errors Hi (25H) .......................................................................................... 47

8.9.8 RXD CRC Errors Lo (Same as Hi) (26H) .................................................................... 47

8.9.9 Parity Errors (27H) ...................................................................................................... 47

8.9.10 Overrun Errors (28H) .................................................................................................. 48

8.9.11 Framing Errors (29H) .................................................................................................. 48

8.9.12 Total Software CH1 Errors (2AH) ............................................................................... 48

8.9.13 Not Used (2BH) ........................................................................................................... 48

8.9.14 Clear Hardware Errors (2CH) ..................................................................................... 48

8.9.15 Clear Communication Errors (2DH) ............................................................................ 48

8.9.16 User Information (60H to 6FH) .................................................................................... 51

8.9.17 CH2 Total Receive Errors (70H) ................................................................................. 52

8.9.18 CH2 Bus Activity Rate % (71H) .................................................................................. 52

8.9.19 CH2 Function Code Errors (72H) ................................................................................ 52

8.9.20 CH2 Starting Address Errors (73H) ............................................................................ 52

8.9.21 CH2 Number of Register Errors (74H) ........................................................................ 52

8.9.22 CH2 RXD CRC Errors Hi (75H) .................................................................................. 52

8.9.23 CH2 RXD CRC Errors Lo (Same as Hi) (76H) ........................................................... 52

8.9.24 CH2 Parity Errors (77H) ............................................................................................. 52

8.9.25 CH2 Overrun Errors (78H) .......................................................................................... 52

8.9.26 CH2 Framing Errors (79H) .......................................................................................... 53

8.9.27 CH2 Total Software CH1 Errors (7AH) ....................................................................... 53

8.9.28 Not Used (7BH) ........................................................................................................... 53

iv

Page 6

Ultima MOS-5 Detector

8.9.29

CH2 Clear UART Errors (7CH) ................................................................................... 53

8.9.30 CH2 Clear Stats (7DH) ............................................................................................... 53

9.0 APPENDIX ............................................................................................................................ 54

9.1 Warranty ................................................................................................................................... 54

9.2 Principle of Operation ............................................................................................................... 54

9.3 Specifications ........................................................................................................................... 55

9.3.1 System Specifications ................................................................................................. 55

9.3.2 Mechanical Specifications ........................................................................................... 55

9.3.3 Electrical Specifications .............................................................................................. 55

9.3.4 Environmental Specifications ...................................................................................... 57

9.4 Approvals ................................................................................................................................. 57

9.5 Spare Parts and Accessories ................................................................................................... 57

9.5.1 Sensors ....................................................................................................................... 57

9.5.2 Sensor Housing ........................................................................................................... 58

9.5.3 Sensor Accessories .................................................................................................... 58

9.5.4 Calibration Equipment ................................................................................................. 58

9.5.5 Intelligent Sensor (Ultima MOS-5 Intelligent Sensor) Replacement Parts ................. 59

9.5.6 Recommended Spare Parts for One Year .................................................................. 59

9.6 FM Approval ............................................................................................................................. 60

v

Page 7

Ultima MOS-5 Detector

Table of Figures

Figure 1: Ultima MOS-5 Intelligent Sensor Outline and Mounting Dimensions, in inches ..................................... 1

Figure 2: Spring Type Terminal Block Operation ................................................................................................... 2

Figure 3: Screw Type Terminal Block Operation .................................................................................................... 2

Figure 4: Ultima MOS-5 Intelligent Sensor ............................................................................................................. 7

Figure 5: Ultima MOS-5 Intelligent Sensor Outline and Mounting Dimensions, in inches ................................... 10

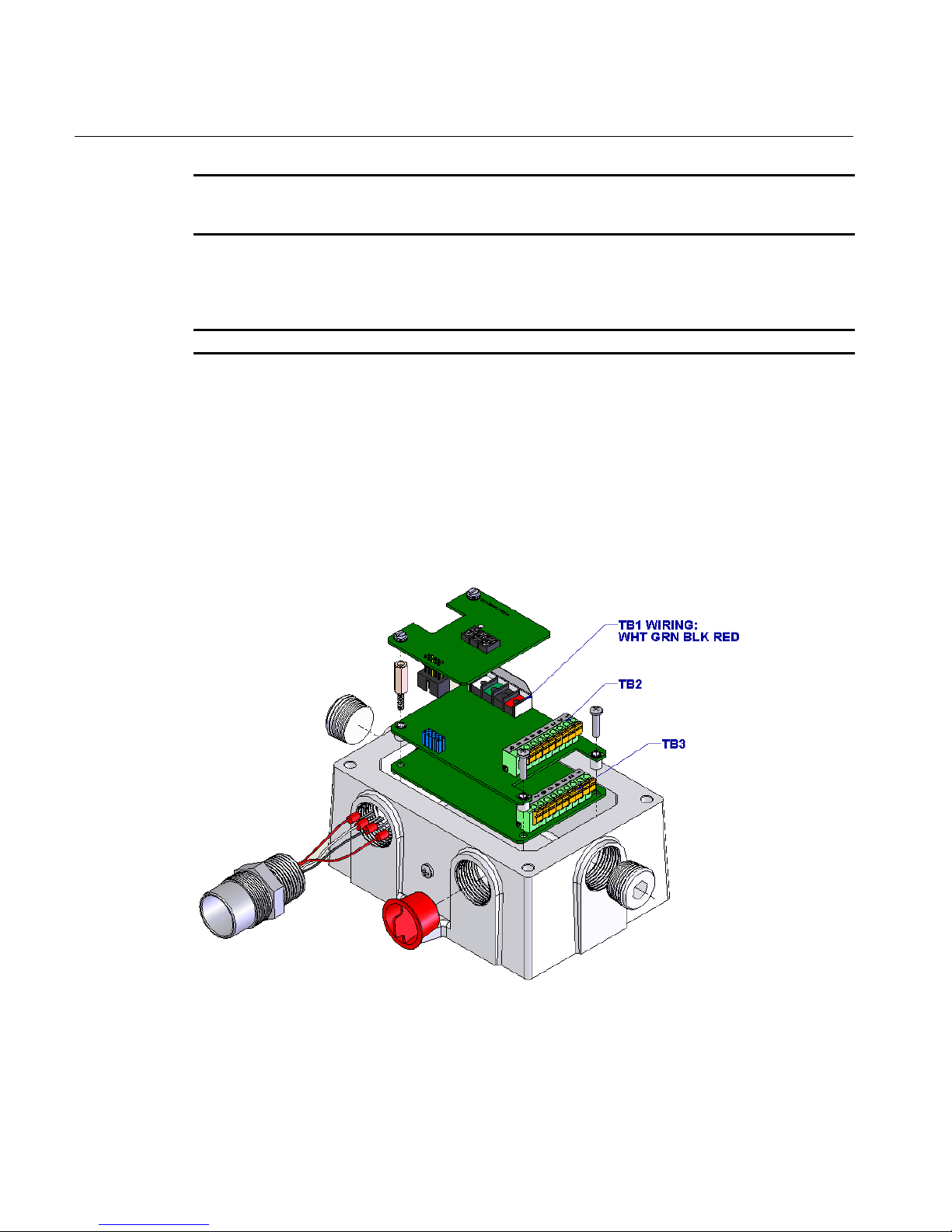

Figure 6: Ultima MOS-5 Intelligent Sensor Terminal Block Locations ................................................................. 11

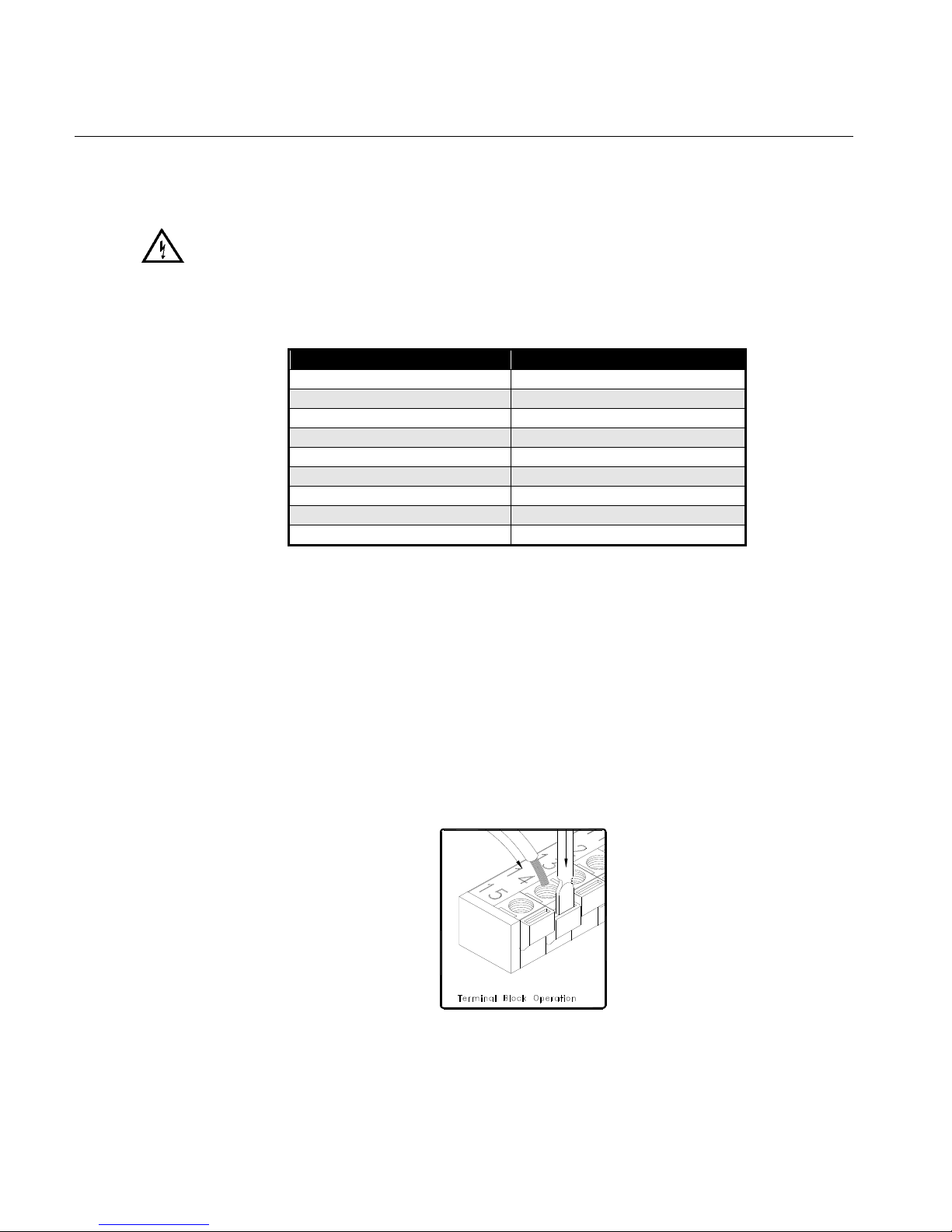

Figure 7: Spring Type Terminal Block Operation ................................................................................................. 12

Figure 8: Screw Type Terminal Block Operation .................................................................................................. 13

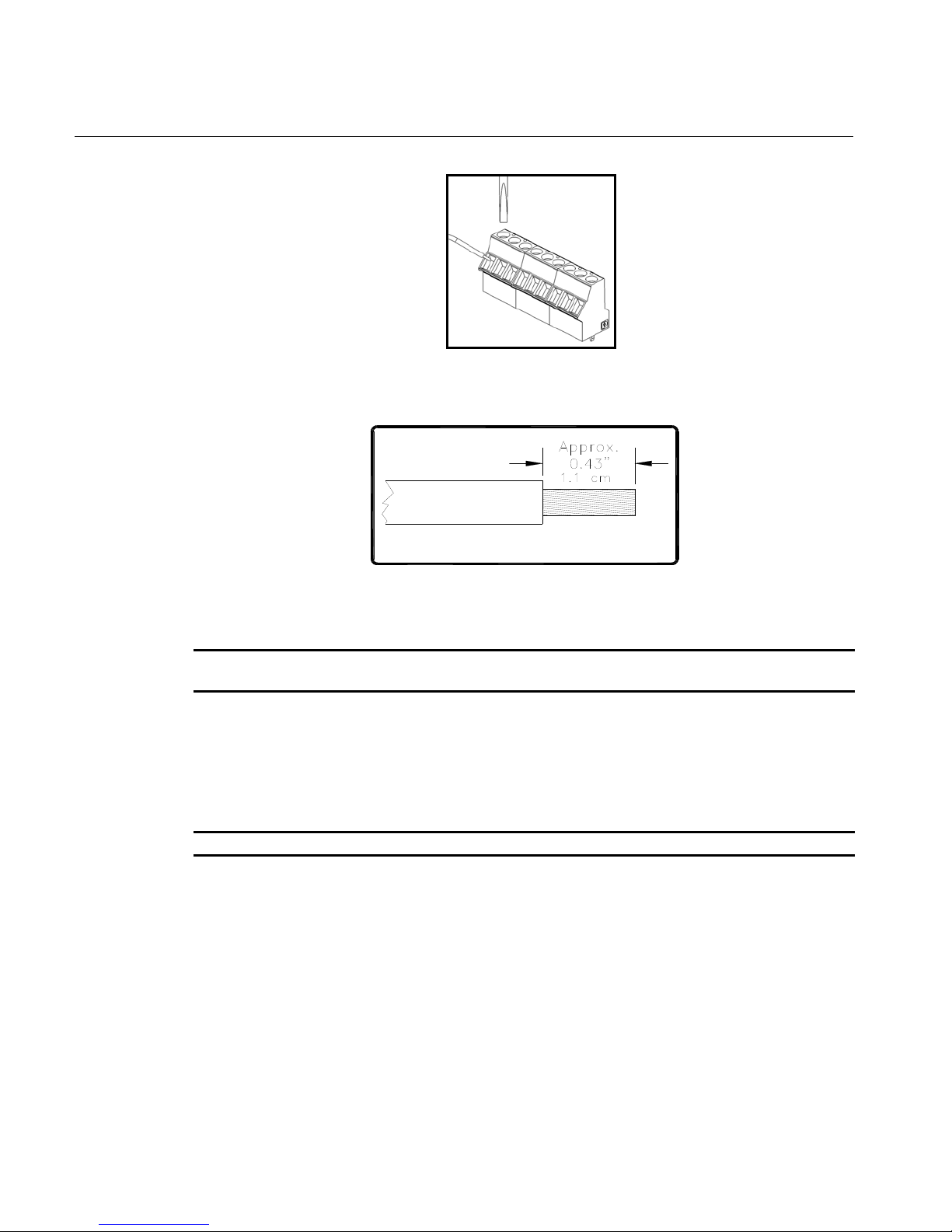

Figure 9: Wire Strip Length ................................................................................................................................... 13

Figure 10: Relay Protection for DC and AC Loads ............................................................................................... 14

Figure 11: Relay Reset ......................................................................................................................................... 18

Figure 12: User Menu Structure ........................................................................................................................... 19

Figure 13: Gas Check ........................................................................................................................................... 23

Figure 14: Automatic Calibration Mode ................................................................................................................ 24

Figure 15: Calibration in Progress Mode .............................................................................................................. 24

Figure 16: Calibration Complete Mode ................................................................................................................. 25

Figure 17: Ampoules............................................................................................................................................. 26

Figure 18: Portable Purge Calibrator .................................................................................................................... 27

vi

Page 8

Ultima MOS-5 Detector

Table of Tables

Table 1: TB2 Power and Signal Connections ....................................................................................................... 12

Table 2: Alarm Relay Connections ....................................................................................................................... 14

Table 3: Warn Relay Connections ........................................................................................................................ 14

Table 4: Fault Relay Connections ........................................................................................................................ 14

Table 5: MSA Contact Information ....................................................................................................................... 32

Table 6: Data Format ............................................................................................................................................ 33

Table 7: Exception Codes .................................................................................................................................... 37

Table 8: Command Register Locations ................................................................................................................ 40

Table 9: Com1 Baud Rate .................................................................................................................................... 45

Table 10: Com1 Data Format ............................................................................................................................... 45

Table 11: Com2 Baud Rate .................................................................................................................................. 45

Table 12: Com2 Data Format ............................................................................................................................... 46

Table 13: Sensor Scale ........................................................................................................ ................................ 46

Table 14: 24 VDC Cable Lengths ......................................................................................................................... 56

Table 15: Analog Output Cable Lengths .............................................................................................................. 56

Table 16: Sensor Cable Lengths .......................................................................................................................... 56

vii

Page 9

Ultima MOS-5 Detector

Quick Start Guide

Mounting and Wiring

Tools Required

• “5mm” Allen head wrench to remove enclosure lid (included with gas detector).

• Flat-head screwdriver maximum 3/16 in (5 mm) width for terminal block (not inclu ded).

• Adjustable wrench for conduit or cable gland connections (not inclu ded).

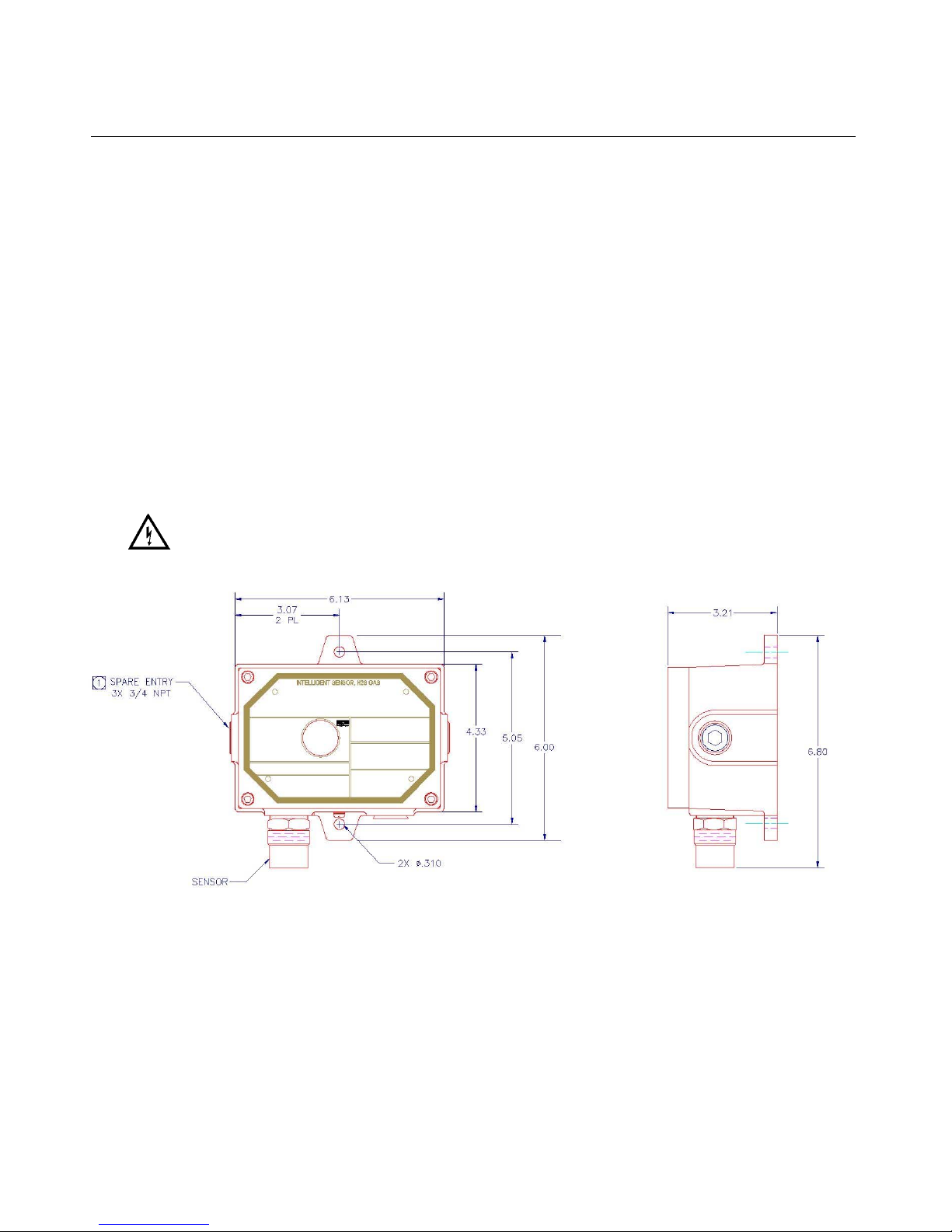

The outline and mounting dimensions for the Ultima MOS-5 Intelligent Sensor (Figure 1) should

be used when making installation determinations.

Information on Class I Division 1 and Zone 1 wiring methods can be found in the NEC and

CEC.

WARNING: Acetic acid will cause damage to metal components, metal hardware, ceramic

IC’s, etc. If damage results from the use of a sealant that outgases acetic acid

(RTV silicone), the warranty will be void.

Figure 1: Ultima MOS-5 Intelligent Sensor Outline and Mounting Dimensions, in inches

Terminal Connections

The terminal blocks (TB) are located inside the housing and can be accessed by removing the

cover. A label inside of the housing cover provides a diagram of all the terminal connections.

It is recommended that a minimum three-wire shielded cable be used for making the power and

0-20mA Output connection on TB2 of the Ultima MOS-5 Intelligent Sensor. It is also

recommended that separate two-wire shielded twisted pair cables be used for making the

Modbus connections. The spring type terminal block accepts 14 AWG to 20 AWG and the

1

Page 10

Ultima MOS-5 Detector

screw type terminal block accepts 12 AWG to 18 AWG stranded or solid wire. Each wire should

be stripped before wiring the Ultima MOS-5 Intelligent Sensor. To connect wiring to the spring

type terminal block, insert a screwdriver into the orange tab and press down (Figure 2), opening

the terminal. Insert the wire into the terminal and release the orange tab, clamping the wire in

the terminal. Check the hold of the wire by gently tugging it to ensure it is locked in.

Figure 2: Spring Type Terminal Block Operation

To connect wiring to the screw type terminal block, loosen the top screw counter clock wise

(Figure 3). Insert the wire into the terminal and tighten the top screw clockwise.

Figure 3: Screw Type Terminal Block Operation

NOTE: Power must remain disconnecte d until all other wiring connections have been made.

The maximum distance between the Ultima MOS-5 Intelligent Sensor and the power supply is

2,000 feet or 610 meters (each cable run should be as short as possible). See Section 9.3.3 for

cable length specifications.

Connect +24 VDC to TB2, position 9. Connect the ground or common wire to TB2, position 8.

For making power and ground connections to display devices, see Figures 2 and 3.

To connect the analog signal, please refer to Section 3.5.4.

2

Page 11

Ultima MOS-5 Detector

MSA recommends that the Ultima MOS-5 Intelligent Sensor be calibrated 1 hour after start-up

and that the calibration be checked at least every 90 days to ensure system integrity.

The instrument is now ready to operate. Please consult the manual for more information on the

instrument’s many features.

NOTE: If in case of device failure during set-up or testing, please consult Troubleshooting

(Sec. 6.0) or call the factory.

3

Page 12

Ultima MOS-5 Detector

1.0 Introduction

1.1 Protection for Life

MSA’s mission is to benefit society by providing solutions through industry leading safety

products, services, and systems that save lives and protect capital resources from the dangers

of hazardous flames, gases, and vapors.

This manual provides instruction for installing and operating the Ultima MOS-5 Intelligent

Sensor for hydrogen sulfide gas detection. Although the Ultima MOS-5 Intelligent Sensor is

easy to install and operate, this manual should be read in full and the information contained

herein understood before attempting to place the system in service.

The safety products you have purchased should be handled carefully and installed, calibrated,

and maintained in accordance with the respective product instruction manual. Remember these

products are for your safety.

1.2 Special Warnings

The Ultima MOS-5 Intelligent Sensor contains components, which can be damaged by static

electricity. Special care must be taken when wiring the system to ensure that only the

connection points are touched.

WARNING: Hydrogen sulfide (H

loss of consciousness or death.

S) is an extremely toxic gas, and exposure may result in a

2

DO NOT OPEN WHEN AN EXPLOSIVE ATMOSHPERE IS PRESENT.

READ AND UNDERSTAND INSTRUCTION MANUAL BEFORE

OPERATING OR SERVICING. OPEN CIRCUIT BEFORE REMOVING

COVER.

NE PAS OUVRIR UN PRÉSENCE D’ATMOSPHÉRE EXPLOSIVE. LIRE

ET COMPRENDRE MANUEL D’INSTRUCTIONS AVANT D’UTILISER OU

SERVICE. OUVRIR LE CIRCUIT AVANT D'ENLEVER LE COUVERCLE.

SPECIAL CONDITIONS OF SAFE USE PERTAINING TO ATEX/IECEx INSTALLATIONS:

The Ultima MOS-5 shall not be used as a Safety Related Device as defined by ATEX Directive

94/9/EC,

When alternative detector elements are utilized, they shall only be mounted remotely in a

suitable certified enclosure in accordance with requirements of their respective certificates and

relevant local requirements. The associated cable shall be connected to the Intelligent Gas

Sensors using a suitably certified cable entry device with a ¾” thread form.

The Universal Gas Sensor (P/N 51457-XX) is suitable for use with the following enclosure

types and service temperature ranges that are dependent on the type of cement used in their

construction; therefore, they shall only be used with the enclosure type and where the surface

temperature, at the point of mounting, is as detailed below:

4

Page 13

Ultima MOS-5 Detector

Cement Ambient Range Enclosure Type

2850FT Cat 11

or 2762 Cat 17

2850FT Cat 11 -40°C to +120°C Enclosures that are certified by a notified body and

2762 Cat 17 -40°C to +180°C Enclosures that are certified by a notified body and

-40°C to +70°C Enclosures that are certified by a notified body and

satisfy the requirements of the current edition of EN

60079-1 or EN 60079-7 and European Directive

94/9/EC.

satisfy the requirements of the current edition of EN

60079-7 and European Directive 94/9/EC.

satisfy the requirements of the current edition of EN

60079-7 and European Directive 94/9/EC.

1.3 System Integrity Verification

To ensure operation at optimum performance, MSA recommends that certain maintenance

items be performed.

Commissioning Safety Systems

Before power-up, verify wiring, terminal connections and stability of mounting for all integral

safety equipment including the following items:

• Power supplies

• Control modules

• Field detection devices

• Signaling and output devices

• Accessories connected to field and signaling devices

After the initial application of power (and any factory specified warm-up period) to the safety

system, verify that all signal outputs, to and from devices and modules, are within the

manufacturers’ specifications. Initial calibration, calibration checking, or testing should be

performed per the manufacturer’s recommendations and instructio ns.

Proper system operation should be verified by performing a full, functional test of all component

devices of the safety system, ensuring that the proper levels of alarming occur.

Fault and malfunction circuit operation should be verified.

Periodic Testing/Calibration of Field Devices

Periodic testing/calibrating should be performed per the manufacturer’s recommendations and

instructions. Testing/Calibrating procedures should include, verify integrity of all optical surfaces

and devices

5

Page 14

Ultima MOS-5 Detector

When testing produces results outside of the manufacturer’s specifications, re-calibration or

repair and replacement of the suspect device(s) should be performed as necessary. Calibration

intervals should be independently established through a documented procedure, including a

calibration log, maintained by plant personnel or third party testing services.

Periodic System Verification

The following system verifications should be performed at least annually:

Verify wiring, terminal connections and stability of mounting for all integral safety equipment

including, the following items:

• Power supplies

• Control modules

• Field detection devices

• Signaling and output devices

• Accessories connected to field and signaling devices

Calibration intervals should be independently established through a documented procedure,

including a calibration log maintained by plant personnel or third party testing services.

6

Page 15

Ultima MOS-5 Detector

2.0 Product Description

2.1 General Description

The Ultima MOS-5 Intelligent Sensor is for the detection of hydrogen sulfide (H2S) gas. The

microprocessor-based electronics process information at the sensor site within an explosionproof housing.

A digital display provides indications and display codes that can be viewed through a window in

the cover. A red LED above the digital display signifies an “alarm” condition, while a red LED

below the digital display signifies a “warning” condition. Analog signal (4-20 mA) and relays

provide remote and/or discrete indications of the sensor’s operation. Optional dual redundant

Modbus, HART, or HART and single Modbus provide digital communication.

The Ultima MOS-5 Intelligent Sensor is rated explosion-proof for use in the following hazardous

areas:

• CSA/FM: Class I, Division 1, Groups B, C, D and Class I, Zone 1, IIB+H

• ATEX/IECEx: Zone 1, Group IIB + H

2

2

7

Figure 4: Ultima MOS-5 Intelligent Sensor

Page 16

Ultima MOS-5 Detector

3.0 Installation

3.1 Receipt of Equipment

All equipment shipped by MSA is pre-packed in shock absorbing containers, which provide

protection against physical damage (original containers should be kept for future shipping or

storage needs).

Shipping container contents should be carefully removed and checked against the packing list.

If any damage has occurred or there is any discrepancy in the order, please notify MSA as

soon as possible.

All correspondence with MSA must specify the equipment part number and serial number.

Although the factory tests each unit, a complete system checkout is suggested upon initial

installation to ensure system integrity.

WARNING: Only suitably skilled and competent personnel should carry out installation and

maintenance.

WARNING: The Ultima MOS-5 Intelligent Sensor contains components, which can be

damaged by static electricity. Special care must be taken when wiring the system to ensure that

only the connection points are touched.

3.2 Tools Required

• “5mm” Allen head wrench to remove enclosure lid (included with gas detector).

• Flat-head screwdriver maximum 3/16 in (5 mm) width for terminal block connections

(not included).

• Adjustable wrench for conduit or cable gland connections (not inclu ded).

3.3 Choosing Product Locations

There are no standard rules for sensor placement, since the optimum sensor location is

different for each application. The customer must evaluate conditions at the facility to make this

determination. In generally, experience suggests the device is more effective at detecting gas if

the following recommendations are followed:

• Mount sensor pointing down to prevent water build-up on the sensor head.

• Do not place sensor where contaminating substances may coat it.

• Although the Ultima MOS-5 Intelligent Sensor is RFI resistant, do not install sensor in

close proximity to radio transmitters or similar equipment.

• Locate the Ultima MOS-5 Intelligent Sensor where prevailing air currents contain the

maximum concentration of gas.

• Locate the Ultima MOS-5 Intelligent Sensor near possible sources of gas leaks.

8

Page 17

Ultima MOS-5 Detector

• Observe the Ultima MOS-5 Intelligent Sensor temperature specification and locate the

unit away from concentrated sources of heat.

• Install sensor in an area that is as free from wind, dust, water, shock, and vibration as

possible. See Section 0 for the environmental specifications of the unit. If dust and rain

cannot be avoided, we recommend the use of our splash guard (P/N 10395-1).

Sensors may be adversely affected by prolonged exposure to certain substances. Loss of

sensitivity or corrosion may be gradual if such agents are present in low concentrations or it

may be rapid at high concentrations. Examples of these substances are as follows:

• Silicones (often contained in greases and aerosols)

• Halides: compounds containing fluorine, chlorine, bromine and iodine

• Heavy metals, e.g. tetraethyl lead

• Caustic and Acidic liquids and vapors

• Glycol

The presence of contaminants in an area does not necessarily preclude the use of an Ultima

MOS-5 Intelligent Sensor. The feasibility of using a sensor in such areas must be determined

by an analysis of the specific factors in each application, and MSA should be consulted before

attempting any such installation.

Sensors used in these areas usually require more frequent calibration checks than normal, and

typically have a shorter life. In many such applications the standard 2-year warranty would not

apply.

IMPORTANT: Each H

Inside the cap is a desiccant. Do not remove this cap until the system is ready

to be powered. Save the cap and re-cap the sensor anytime the system power

is off for more than 1 hour.

WARNING: MSA discourages the painting of sensor assemblies. If the sensor head is

painted over, the gas will not be able to diffuse into the sensor. If the assembly

cover is painted over, the digital display cannot be read.

S sensor is shipped with a red plastic cap fitted over the sensor head.

2

3.3.1 Remote Mounting of the Sensor from the Electronics

If it is necessary to remotely mount the sensor from the electronics and the housing, the

maximum distance can be no greater than 3,700 feet (1,125) meters, using 14 AWG wire.

Sensors that are remotely mounted must be placed in an explosion-proof rated sensor

housing (P/N 10252-1), and the cable run must be contained in a conduit running from the

sensor housing to the electronics.

For remote mounting in Canada where the location is classified using the Zone classification

system, the sensors must be mounted in sensor housing B14-020. Only sensors 51457 can

be used in this configuration.

9

Page 18

Ultima MOS-5 Detector

3.4 Mounting and Wiring

WARNING: Unused cable entry holes must be sealed with an approved explosion-proof plug.

Red caps supplied by MSA are for dust protection only and must not be left on the

unit when installed.

WARNING: Conduits must be sealed within 18 inches of the enclosure.

The outline and mounting dimensions for the Ultima MOS-5 Intelligent Sensor (Figure 5) should

be used when making installation determinations. A complete list of the mechanical

specifications can be found in Section 9.3.2.

To prevent possible corrosion due to moisture or condensation, the conduit connected to the

Ultima MOS-5 Intelligent Sensor housing should be sealed or contain a drain loop.

NOTE: For ATEX and IECEx applications, conduit connections must only be made via suitably

certified ATEX (or IECEx as appropriate) conduit stopping boxes.

Information on Class I Division 1 and Zone 1 wiring methods can be found in the NEC or CEC.

Figure 5: Ultima MOS-5 Intelligent Sensor Outline and Mounting Dimensions, in inches

WARNING: Acetic acid will cause damage to metal components, metal hardware, ceramic

IC’s and other parts. If damage results from the use of a sealant that outgases

acetic acid (RTV silicone), the warranty will be void.

Once correctly installed, the Ultima MOS-5 Intelligent Sensor requires little or no maintenance,

other than periodic calibration checks to ensure system integrity. MSA recommends that a

schedule be established and followed.

10

Page 19

Ultima MOS-5 Detector

NOTE: The Ultima MOS-5 Intelligent Sensor full 2-year warranty will be voided if customer

personnel or third parties damage the Ultima MOS-5 Intelligent Sensor during repair

attempts.

Sensor heads exposed to the elements may require the accessory mounting threads to be

lubricated. Grease must not be used. As an alternate, PTFE (Teflon) tape may be used on

sensor accessory threads.

NOTE: Do not use any material or substance on threads that contact the sensor housing.

The removal of particulate matter from sensor accessories may be done through the use of an

appropriate halogen-free solvent. Water or ethanol is an example of a suitable solvent. The

accessories should be thoroughly dried, with compressed air if necessary, before refitting to the

sensor body.

3.5 Terminal Connections

The terminal blocks (TB) are located inside the housing and can be accessed by removing the

cover. A label on the inside of the housing cover provides details of all the terminal

connections.

Figure 6: Ultima MOS-5 Intelligent Sensor Terminal Block Locations

3.5.1 Terminal Block TB1 – Sensor Connections

TB1 contains the four sensor connections, white (W), black (B), red (R) and green (G). Remove

the display board by loosening the 2 captive screws on the board and lifting it straight up.

Connect the color-coded wires from the sensor to the matching colored terminals on TB1. The

11

Page 20

Ultima MOS-5 Detector

label on the inside of the cover can serve as a guide. Replace the display board by pressing it

into place and tightening the two captive screws.

WARNING: Do not connect +24 VDC to TB1. Damage to electronics or sensor may result.

3.5.2 Terminal Block TB2 – Power and Signal Connections

TB2 contains the connections for Power, Relay Reset, Remote Calibration, Modbus, and 0-20

mA Output Signal. The terminal connections are as follows:

TB2 position Function

1 0-20 mA Output

2 CH1 Modbus 3 CH1 Modbus +

4 CH2 Modbus 5 CH2 Modbus +

6 Remote Calibration

7 Relay Reset

8 Ground

9 +24 VDC Power

Table 1: TB2 Power and Signal Connections

It is recommended that a minimum three-wire shielded cable be used for making the power and

0-20mA Output connection on the Ultima MOS-5 Intelligent Sensor. It is also recommended

that separate two-wire shielded twisted pair cables be used for making the Modbus

connections. The spring type terminal block accepts 14 AWG to 20 AWG and the screw type

terminal block accepts 12 AWG to 18 AWG stranded or solid wire. Each wire should be

stripped before wiring the Ultima MOS-5 Intelligent Sensor. To connect wiring to the spring type

terminal block, insert a screwdriver into the orange tab and press down (Figure 7). Insert the

wire into the terminal and release the orange tab, clamping the wire in the terminal. Check the

hold of the wire by gently tugging it to ensure it is locked in. To connect wiring to the screw type

terminal block, loosen the top screw counterclockwise (Figure 8). Insert the wire into the

terminal and tighten the top screw clockwise. Check the hold of the wire by gently tugging it to

ensure it is locked in.

12

Figure 7: Spring Type Terminal Block Operation

Page 21

Ultima MOS-5 Detector

Figure 8: Screw Type Terminal Block Operation

Figure 9: Wire Strip Length

NOTE: Up to 12 AWG wire can be used if it is carefully striped. This applies only to a screw

type terminal connection (Figure 8).

3.5.3 DC Power and Ground Connections

• The customer must provide primary DC power.

Since the Ultima MOS-5 Intelligent Sensor is designed to operate continuously, a power switch

is not included, in order to prevent accidental system shutdown.

NOTE: Power must remain disconnected until all other wiring connections have been made.

See Section 9.3.3 for cable length specifications.

To connect +24 VDC to the Ultima MOS-5 Intelligent Sensor, connect the red wire (+24 VDC)

to TB2, position 9. Connect the ground or common wire to TB2, position 8.

3.5.4 Analog Signal Connections

The Ultima MOS-5 Intelligent Sensor Intelligent Transmitter provides a 4 to 20 mA output

signal. This signal can be sent to an industrial analog to digital converter, or logic solver.

The 4 to 20 mA signal provides for control room or other locations remote to the Ultima MOS-5

Intelligent Sensor to display indications of operation and alarm conditions.

To connect the 4 to 20 mA output signal with another unit, connect the wire into TB2, position 1,

labeled 4-20 mA OUT.

13

Page 22

Ultima MOS-5 Detector

If a readout device is being used, the DC ground, COM of both systems must be connected

together. The analog output can also be configured as a HART communication link.

3.5.5 Terminal Block TB3 – Relay Connections

TB3 contains the connections for the relay contacts (optional). The function for the warn and

alarm relay connections vary according to the normal state of the relay. Use the following as a

guide for determining the Normally Open (NO) and the Normally Closed (NC) contact:

TB3 position Relay Contact (De-Energized) Relay Contact (Energized)

1 Normally Closed Normally Open

2 Common Common

3 Normally Open Normally Closed

Table 2: Alarm Relay Connections

TB3 position Relay Contact (De-Energized) Relay Contact (Energized)

4 Normally Closed Normally Open

5 Common Common

6 Normally Open Normally Closed

Table 3: Warn Relay Connections

TB3 position Relay Contact (Energized)

7 Normally Open

8 Common

9 Normally Closed

Table 4: Fault Relay Connections

NOTE: Fault relay is normally energized. Relay will change state after power up.

WARNING: Contact with PCB components should be avoided to prevent damage by static

electricity. All wire connections are made to the Terminal Blocks.

WARNING: Relay contacts must be protected against transient and over voltage conditions

(Figure 10).

14

Figure 10: Relay Protection for DC and AC Loads

Page 23

Ultima MOS-5 Detector

North American Approved Applications - The alarm relay contact ratings are 8 A @ 250 VAC

and 8 A @ 30 VDC resistive max.

European Union (EU) Approved Applications - The alarm relay contact ratings are 8 A, 30 V

RMS/42.4 V peak or 8 A @ 30 VDC resistive max.

3.5.6 European Union (EU) Approved Applications

Interconnecting cables must have an overall screen, or screen and armor. Cables BS5308 Part

2, Type 2, or equivalent, are suitable. Note that the terms ‘screen’ and ‘shield’ are equivalent for

the purpose of this manual. The cable armor must be terminated in a suitable cable gland, at

the detector, to ensure a positive electrical connection.

3.5.7 Cable Termination in the Non-hazardous Area

• The cable armor must be connected to safety earth in the safe area.

• The cable screen (drain wire) must be connected to an instrument earth in the safe

area.

• The power supply OV return must be connected to an instrument earth in the safe

area.

• The interconnecting cables should be segregated from power and other noisy cables.

Avoid proximity to cables associated with radio transmitters, welders, switch mode

power supplies, inverters, battery chargers, ignition systems, generators, switch gear,

arc lights, and other high frequency or high power switching process equipment. In

general, a minimum separation of at least 1 meter between instrument and other

cables should be maintained. Greater separations are required where long parallel

cable runs are unavoidable. Avoid running instrument cable trenches close to lightning

conductor earth pits.

• Complete all cable insulation testing before connecting the cable at either end.

WARNING: Under NO circumstances should equipment be connected or disconnected when

under power. This is contrary to hazardous area regulations and may lead to

serious damage to the equipment. Equipment damaged in this manner is not

covered under warranty.

3.6 Maintaining the X/P Integrity

Some of the factors that influence the explosion-proof integrity of the Ultima MOS-5 Intelligent

Sensor housing are:

• Strength of the enclosure material

• Thickness of the enclosure walls

• Flame path between the housing and cover

• Flame path of threaded joints

The acceptable limits for explosion-proof housings that are used in Class I hazardous locations

are defined in CSA Standard C22.2 No.30-M1986, FM 3615, and EN50014.

15

Page 24

Ultima MOS-5 Detector

Anytime the cover of the Ultima MOS-5 Intelligent Sensor housing is removed or the cover bolts

are loosened, the flame path between the lid and the housing is affected. If power is to be left

on while removing the cover or loosening the cover bolts on the Ultima MOS-5 Intelligent

Sensor, the area must be declassified.

When replacing the cover, the gap between the lid and the housing should be less than 0.0015

inch (0.038 mm). Make sure that the flame path is clear of dirt and debris before replacing the

cover. This can be verified by tightening the cover bolts to a torque setting of 50 inch-pounds or

by using a feeler gauge to ensure the gap between the cover and the housing is less than

0.0015 inch (0.038 mm).

There are four entry holes, one each on the left and right sides, and two on the bottom of the

Ultima MOS-5 Intelligent Sensor housing. These holes are dedicated for the sensor, the reset

switch, and conduit. Each hole is tapped for ¾” NPT threads. If a particular entry hole is not

used, it must be plugged during operation in the field. The factory installs plugs in the unused

entry holes, except one. A red plastic cap is placed into the remaining hole and must be

removed before conduit can be attached to the housing.

The Ultima MOS-5 Intelligent Sensor will have the following items placed in the three remaining

entry holes, at the factory:

• A sensor, if present (otherwise a red plastic cap)

• A reset switch, if present (otherwise an aluminum housing plug – optional)

• An aluminum housing plug

The sensor, reset switch, and aluminum - housing plug have 7 threads. Each of these

components is screwed into the housing using 5 to 7 turns. If any of these parts must be

replaced, apply 5 to 7 turns upon replacing the component to ensure the explosion proof

integrity of the device is maintained.

16

Page 25

Ultima MOS-5 Detector

4.0 Operation

4.1 Start-Up Checklist

Prior to starting the system, verify the following:

• Inhibit any external devices, such as trip amplifiers, PLC, or DCS systems.

• Verify that the optional settings are set for the desired configuration.

• Verify that the unit is properly mounted. Ensure the conduit/cable gland entries are

pointed downward.

• Verify that the signal wiring is correct.

• Verify that the power supply is connected properly. The Ultima MOS-5 Intelligent

Sensor is powered by +24 VDC (20 to 36 VDC voltage range). The detector will output

a low voltage fault (F6) at 18.5 VDC or below.

• Make sure the lid is securely installed or the area has been declassified.

• Make sure the HART option is selected if desired.

• Make sure Modbus is properly configured if desired.

4.2 Start-Up

Before applying power to the system for the first time, all wiring connections should be checked

for correctness and the housing cover replaced. Upon first power-up, the sensor may take up to

fifteen minutes to stabilize.

At the initial application of power, the unit test all LED segments by displaying “88.8”. The

software revision letter is then displayed for a few seconds. When the software revision level

appeared, the unit enters Operational Mode and the current ga s concentration at the sensor will

be displayed. For details on Calibrating and Gas Checking the unit, see Sections 4.56 and 4.7.

4.3 Relay Reset

If the warn and alarm relays are configured as latching, they must be manually reset after an

alarm occurs. This can be accomplished by three different methods:

• The relays can be reset by using a magnet. To do this, place the magnet over the MSA

logo on the cover of the unit. After 3 seconds, the display shows “rSt”. After the LED

displayed this code, remove the magnet. The relays are now reset (Figure 11).

17

Page 26

Ultima MOS-5 Detector

Figure 11: Relay Reset

• The relays can be reset via the remote reset input terminals on TB2. Connect a

normally open switch between terminal TB2-7 and TB2-8. Closing the switch

momentarily will reset the relays. MSA explosion-proof switch, P/N 30051-1 can be

used for this purpose. See Section 9.5 for ordering instructions.

• The relays can be reset via the Modbus Interface (Section 8.8.22).

• The relays can be reset via the HART communication.

NOTE: Red LEDs above and below the digital display indicate that the alarm and warn relays

are active. Latching relays can only be reset if the gas concentration has fallen below

the respective relay set point.

4.4 User Selectable Options

The Ultima MOS-5 Intelligent Sensor includes many selectable options to provide the user with

the most flexible H

warn and alarm relay set points and configuration, HART communications and Modbus

communications settings. These allow the unit to operate with a wide variety of PLC and DCS

systems. The following sections explain the available options and how they can be customized.

A flow diagram is included to help the user in understanding the process of reviewing and

changing the available options (Figure 12).

NOTE: If the unit was ordered without relays, HART, or Modbus communications, changing the

relay, HART, or Modbus settings will have no effect on the operation of the unit.

Modbus

• Dual Redundant Modbus

• Single Modbus and HART

HART

• HART is a Master to Slave -One to One communication channel.

S gas detector possible. These options include selectable sensor range,

2

18

Page 27

Ultima MOS-5 Detector

4.4.1 Ultima MOS-5 Intelligent Sensor User Menu Structure

Operate

Rm

“rSt”

Reset

Relays

Hm HmHm

Rm

Enter Gas Check Mode

“- -”

Rm

“AC”

Rm

Enter Calibration

Mode

Hm

“SE” Time Out

Rm

Am

“Sr”

Set Sensor Range

20,50,100 ppm

“SE”

Hm

N

“Fi”

Y

Fault

N

Hm – Hold magnet

Am – Apply magnet

Rm – Remove magnet

N – No

Y - Yes

Gas

Detected?

Y

Gas

Removed?

Reset Sensor

Life?

Am

Reset Sensor Life

to 100%

Apply Gas and

Remove When

Complete

If Hart Enabled

N

N

N

Am

“Co”

Y

If Hart installed

Y

“Hrt” Enable Disable

“Lo”

Warm Relay

“Hi”

Alarm Relay

“CH1”

Modbus Ch. 1

If Hart Enabled

N

“CH2”

Modbus Ch. 2

Y

“Fi”

Finished

Enable Disable

Am

Am

Energized or

De-Energized

Am

Energized or

De-Energized

Am

Baud

Rate

Am

Baud

Rate

Am

Latching or

Non-Latching

Latching or

Non-Latching

Data

Format

Data

Format

“Fi”

“Fi”

Address

Address

Setpoint

Setpoint

“Fi”

“Fi”

“Fi”

“Fi”

NOTE: “Co” stands for Calibration Output. When “Co” is enabled and calibration is

successful, the analog output goes from 1.5 mA to 3.2 mA for five seconds, settling

at the desired value of 4 mA. This option is commonly used with the MSA Model

10000 Controller system.

4.4.2 Sensor Range

The sensor range is selectable between 0-20 ppm, 0-50 ppm, or 0-100 ppm depending on the

installed sensor. To adjust the sensor range of the Ultima MOS-5 Intelligent Sensor, apply the

magnet to the MSA logo on the cover of the unit until “SE” is displayed, then remove the

magnet. This puts the unit into setup mode. After a few seconds “Sr” will be displayed. Apply

and remove the magnet to adjust the sensor range. The current sensor range will be displayed.

To change the sensor range, apply and remove the magnet repeatedly until the desired range

is displayed. Once the desired range is displayed, wait three seconds and “Fi” will be displayed.

19

Figure 12: User Menu Structure

Page 28

Ultima MOS-5 Detector

Apply and remove the magnet, to return to the next level of the setup menu. When “Fi” is

displayed again, apply and remove the magnet, the unit will go to calibration mode. The display

will flash the remaining sensor life for a few seconds. Ensure that the sensor is seeing clean air

during this time. Apply the calibration gas concentration to the sensor (50% FS of the desired

range of H

Calibration) to “CP” (Calibration in Progress) indicating that the sensor is responding to the

calibration gas.

After 3 to 5 minutes, the display will change from “CP” to “CC”, indicating that the

calibration is complete. Remove the gas and wait for the unit to return to normal operation. The

unit is now calibrated and the new span value has been stored in the non-volatile memory

(EEPROM). If a fault occurs during this process, please refer to the notes section below.

NOTE: When the sensor range is changed, the warning and alarm set points are automatically

It is recommended to go back through the SE mode to confirm range and sensor set-

2S. *See notes section below.). The display will change from “AC” (Automatic

scaled to the new range. The unit must now be calibrated to the new range (Section

4.7.1). The Sensor Range and the Alarm/Warning set points will remain at the previous

setting if the calibration is aborted, faulted, or the power is cycled before the calibration

is completed.

points have been changed correctly. Changing the sensor range will require that the

operator change the H2S concentration previously used for calibrating the unit. It is

necessary to use 50% of the "new" full scale reading when changing the scale, as well

as after the scale is changed during normal calibration maintenance periods (i.e.

10ppm for a 0-20ppm, 25ppm for a 0-50ppm and 50ppm for a 0-100ppm). It is

important to note that changing a unit’s range may require changing the sensor

to match the new sensor range. (-1 sensor for 0-100 ppm, -5 sensor for 0-50 ppm,

and -9 for 0-20 ppm).

Once the operator reaches the calibration mode, the operator will have 12 minutes to complete

a calibration. If the 12 minute timeframe elapses and the calibration is not complete (unit must

return to "0" reading for calibration to be considered complete), the unit's display will show an

"F2" fault. If this occurs while changing the Sensor Range, the operator must start the Sensor

Range process over until the process is completed properly without any faults being shown

throughout the process. If faults continue during this process, please consult the factory

directly.

4.4.3 Calibration Output

To enable the calibration output feature of the Ultima MOS-5 Intelligent Sensor, apply the

magnet to the MSA logo on the cover of the unit until “SE” is displayed, then remove the

magnet. This puts the unit into setup mode. After a few seconds “Co” will be displayed. Apply

and remove the magnet to enter the calibration output setting. The current setting (Enable or

Disable) will then be displayed. To change this setting, apply and remove the magnet

repeatedly until the desired setting is displayed. Once it is displayed, wait three seconds and

“Fi” will be displayed. Apply and remove the magnet to return to the next level of the setup

menu. When “Fi” is displayed again, apply and remove the magnet to return to normal

operation.

4.4.4 Warning Relay Settings

To adjust the warning relay settings of the Ultima MOS-5 Intelligent Sensor, apply the magnet

to the MSA logo on the cover of the unit until “SE” is displayed, then remove the magnet. This

20

Page 29

Ultima MOS-5 Detector

puts the unit into setup mode. After a few seconds “Lo” will be displayed. Apply and remove the

magnet to change the warning or “low” alarm settings.

First, the energized/de-energized state of the relay is shown by either “En” or “dE” being

displayed, respectively. Apply and remove the magnet until the desired state is displayed.

After a few seconds the latching/non-latching state of the relay is shown by either “La” or “nL”.

Apply and remove the magnet, until the desired state is displayed.

After a few seconds, the current warning relay set point is displayed. Apply and remove the

magnet, until the desired set point is displayed. Once the desired set point value is displayed,

wait 3 seconds and “Fi” will be displayed. Apply and remove the magnet to return to the next

level of the Setup menu. When “Fi” is displayed again, apply and remove the magnet to return

to normal operation.

The default warning relay settings are non-latching, de-energized, 30% FS set point. The

maximum allowable set point is 50 ppm.

NOTE: The warn relay set point cannot be set higher than the alarm relay set point.

4.4.5 Alarm Relay Settings

To adjust the alarm relay settings of the Ultima MOS-5 Intelligent Sensor, apply the magnet to

the MSA logo on the cover of the unit until “SE” is displayed, then remove the magnet. This

puts the unit into setup mode. After a few seconds “Hi” will be displayed. Apply and remove the

magnet, to change the alarm or “high” alarm settings.

First, the energized/de-energized state of the relay is displayed by either “En” or “dE” being

displayed respectively. Apply and remove the magnet, until the desired state is displayed.

After a few seconds the latching/non-latching state of the relay is displayed by either “La” or

“nL”. Apply and remove the magnet until the desired state is displayed.

After a few seconds the current Alarm relay set point is displayed. Apply and remove the

magnet until the desired set point is displayed. Once the desired set point value is shown, wait

3 seconds and “Fi” will be displayed. Apply and remove the magnet to return to the next level of

the setup menu. When “Fi” is displayed again, apply and remove the magnet, to return to

normal operation.

The default Alarm relay settings are: latching, de-energized, 60% FS set point.

NOTE: The alarm relay set point cannot be set lower than the Warning relay set point.

4.4.6 Modbus Channel 1 Settings

To change the Modbus Channel 1 settings of the Ultima MOS-5 Intelligent Sensor, apply the

magnet to the MSA logo on the cover of the unit until “SE” is displayed, then remove the

magnet. This puts the unit into setup mode. After a few seconds “CH1” will be displayed. Apply

and remove the magnet to change the Modbus Channel 1 settings.

21

Page 30

Ultima MOS-5 Detector

First, the current Baud Rate Modbus Channel 1 is displayed. If another baud rate is to be

selected, apply and remove the magnet until the desired baud rate is displayed. The choices

are 19.2k baud “19.2”, 9600 baud “96”, 4800 baud “48”, or 2400 baud “24”.

After a few seconds, the current Data Format for Modbus Channel 1 is displayed. If another

data format is to be selected, apply and remove the magnet until the desired data format is

displayed. The choices are: 8-N-1 “8n1”, 8-N-2 “8n2”, 8-E-1 “8E1”, or 8-O-1 “8O1”.

After a few seconds, the current address for Modbus Channel 1 is displayed. Apply and

remove the magnet until the desired address is displayed. Once the desired address is

displayed, wait for 3 seconds and “Fi” will be displayed. Apply and remove the magnet to

return to the next level of the Setup menu. When “Fi” is displayed again, apply and remove the

magnet to return to normal operation.

Default settings for Channel 1 are: address 1, 19.2k baud, 8-N-1.

NOTE: The address can be adjusted from 1 to 247. Channel 1 and Channel 2 addresses may

be the same.

4.4.7 Modbus Channel 2 Settings

NOTE: If HART is enabled the Modbus 2 settings do not appear on the display. To use Modbus

2 make sure HART is disabled.

To change the Modbus channel 2 settings, apply the magnet to the MSA logo and set the unit

in set up mode. Once “CH2” is displayed, follow the same steps as in section 4.4.5 above.

Default settings for Channel 2 are: address 2, 19.2k baud, 8-N-1.

NOTE: The address can be adjusted from 1 to 247. Channel 1 and Channel 2 addresses may

be the same.

4.5 HART

This option is not shown if HART was not purchased for the Ultima MOS-5 Intelligent Sensor.

When HART is selected via setup, the Channel 2 setup is not displayed or available. When

Channel 2 is changed from HART to Modbus, the previous settings are used.

To change the HART setting of the Ultima MOS-5 Intelligent Sensor, apply the magnet to the

MSA logo on the cover of the unit until “SE” is displayed, then remove the magnet. This puts

the unit into setup mode. After a few seconds “Hrt” will be displayed. Apply and remove the

magnet to enter the HART setting. The current setting (Enable or Disable) will then be

displayed. To change this setting, apply and remove the magnet repeatedly until the desired

setting is displayed. Once it is displayed, wait three seconds and “Fi” will be displayed. Apply

and remove the magnet to return to the next level of the setup menu. When “Fi” is displayed

again, apply and remove the magnet to return to normal operation.

The Ultima MOS-5 Intelligent Sensor has a HART option. The HART option allows the user to

get management information and to remotely calibrate the unit. Because HART preserves the

4-20 mA signal, it enables two-way digital communication to occur without disturbing the

22

Page 31

Ultima MOS-5 Detector

integrity of the analog connection. The DDL is available at the HART foundation’s website

(http://www.hartcomm2.org/index.html). If the Ultima MOS-5 Intelligent Sensor is ordered with

the HART option it is in the enabled state. The HART function can also be disabled and then

Channel 2 can be used for Modbus.

The Ultima MOS-5 Intelligent Sensor HART configuration is compatible with the Emerson 375

Field Communicator and AMS Aware. http://www.emersonprocess.com/

http://www.emersonprocess.com/ams/

4.6 Gas Check Mode

The sensor’s response can be checked without activating external alarms by placing the Ultima

MOS-5 Intelligent Sensor in Gas Check Mode. In this mode, the alarm relays are inhibited and

the analog output is fixed at 1.5 mA. Please see section 9.3.3 for more information on the

analog output values.

NOTE: If HART is enabled, the current may be different. See HART analog output selection

chart.

4.6.1 Procedure for Checking the Calibration

Place the magnet over the MSA logo on the cover of the Ultima MOS-5 Intelligent Sensor.

Remove the magnet when a flashing pair of bars, “- -” appears on the display (about 10

seconds) (Figure 13). Apply the test gas to the sensor. The value of the gas concentration will

be indicated by the flashing display and should stabilize in 1 to 2 minutes.

Figure 13: Gas Check

When the reading has stabilized and the test is complete, remove the gas and the unit will

return to normal operation, when the concentration drops below 5% full-scale.

If, after the reading has stabilized, the sensor is to be calibrated, simply apply the magnet to the

MSA logo on the housing cover and the unit will enter Calibration Mode.

Gas Check Mode can be aborted if gas has not been applied to the sensor. Simply reapply the

magnet to the MSA logo on the cover and the unit will return to normal operation.

NOTE: The test gas concentration must be at least 10% full-scale before the unit will complete

the gas check sequence. If the Ultima MOS-5 Intelligent Sensor is placed in the gas

check mode and no gas is applied for twelve minutes, the unit will revert to a Fault

condition. Re-applying the magnet over the MSA logo will return the unit to normal

operation.

23

Page 32

Ultima MOS-5 Detector

4.7 Calibration

MSA recommends that the Ultima MOS-5 Intelligent Sensor be calibrated 1 hour after start-up,

and again 24 hours after initial start-up, and that the calibration be checked at least every 90

days to ensure system integrity of this life protecting equipment.

The above statement is not intended to discourage the customer from checking calibration

more frequently. Frequent calibration checks are recommended for environments that have

problems, such as mud collecting on the sensor head, sensors accidentally being painted over,

etc.

MSA recommends that a calibration schedule be established and followed. A logbook should

also be kept, showing calibration dates and dates of sensor replacement.

4.7.1 Calibration Procedure

If hydrogen sulfide (H2S) gas is suspected to be present, it will be necessary to purge the

sensor environment with clean air.

Entering Calibration Mode automatically disables the alarm circuits by sending a 1.5 mA output

signal and disabling the warn and alarm relays, if present. This will also prevent activation of

the remote relay contacts when using an MSA readout/relay display module with the Ultima

MOS-5 Intelligent Sensor. Please see section 9.3.3 for more information on the analog output

values.

To enter Calibration Mode, place the magnet over the MSA logo on the cover of the unit (Figure

4) and hold it there until “AC” (Figure 14) appears on the display (about 10 seconds). The

display will flash the remaining sensor life (Section 4.7.3) for a few seconds. Ensure that the

sensor is seeing clean air during this time.

Figure 14: Automatic Calibration Mode

Apply the calibration gas concentration to the sensor (50% FS of the desired range of H

The display will change from “AC” (Automatic Calibration) to “CP” (Calibration in Progress)

indicating that the sensor is responding to the calibration gas (Figure 15).

S).

2

24

Figure 15: Calibration in Progress Mode

Page 33

Ultima MOS-5 Detector

After 3 to 5 minutes, the display will change from “CP” to “CC” indicating that the calibration is

complete. (Figure 16).

Figure 16: Calibration Complete Mode

Remove the gas and wait for the unit to return to normal operation. Once the gas concentration

decreases, the display will read a few percent LEL and then will reach “0.”

The unit is now calibrated and the new span value has been stored in the non-volatile memory

(EEPROM).

NOTE: The sensor life figure displayed is that calculated on completion of the last calibration.

To determine the current sensor life, calibrate unit and then repeat steps 1 and 2.

4.7.2 Aborting Calibration

If calibration is to be aborted and gas has not been applied, wait ninety seconds and reapply

the magnet. The unit will then returns to normal operation with the previous calibration values

unchanged.

NOTE: Once gas has been applied, it is not possible to abort a calibration.

If the Ultima MOS-5 Intelligent Sensor is placed in the Calibration Mode and no gas is applied

for 12 minutes, the unit reverts to a Fault (F2) condition. Re-applying the magnet over the MSA

logo returns the unit to operational mode with the previous calibration values unchanged.

4.7.3 Remaining Sensor Life

The Ultima MOS-5 Intelligent Sensor provides an estimate of remaining sensor life, in percent

remaining, to provide the user with an early warning of the need for sensor replacement. The

remaining sensor life is updated each time the unit is calibrated. The current remaining sensor

life estimate is displayed during the zeroing portion of a calibration sequence. It can also be

read via the Modbus or HART interface (Section 8.0).

NOTE: Remaining sensor life is an estimate of sensor degradation derived from sensor

sensitivity. Because sensor sensitivity is affected by factors other than the natural

sensor degradation, users must establish their own reference by resetting sensor life

whenever these factors are at play. Some examples of these factors are new sensor

installations, sensor replacement, change of the target gas, and changes in the access

of gas to the sensor. If sensor life is not reset, the remaining sensor life indicator will

no longer reflect the true state of the sensor.

25

Page 34

Ultima MOS-5 Detector

4.7.4 Initializing the Remaining Sensor Life

The remaining sensor life estimate must be initialized each time a new hydrogen sulfide sensor

is installed. The initialization should be done during the first calibration of a newly installed

sensor. After the sensor has been on power for a minimum of 1 hour, enter calibration mode as

described in Section 4.7. While the display is flashing the remaining sensor life estimate during

zeroing, apply the magnet to the MSA logo on the cover. The flashing number will change to

“100”, indicating the sensor has 100% of remaining sensor life. Complete the calibration per

Section 4.7.1.

4.8 Calibration Equipment

4.8.1 Calibrating with a Breaker Bottle and Ampoules