Page 1

Operating Manual

SUPREMATouch

Fire and Gas Warning Unit

Order No.: 10121863/05

MSAsafety.com

Page 2

For the Declaration of Conformity, please visit the product page on MSAsafety.com.

Software Versions

The operation manual refers to the following software versions:

Module

Software version

Flash or EPROM

MCP 20 3.02.01

MDO 20 3.02.01

MGO 20 3.01.02

MAO 20 3.01.02

MAI30/MAR30 1.01.01

MGI30/MGR30 1.01.01

Software status ATEX and TÜV SIL 3

MSA Europe GmbH

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

info.ch@MSAsafety.com

www.MSAsafety.com

©

MSA 2017 All rights reserved

Page 3

Contents

1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1 Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 10

1.2 Liability Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 System Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Operation and Display unit MDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4 Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Bus Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.7 System Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.8 Safety Concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.9 During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 19

3.1 Operation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Access Authorisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Measure Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Entering System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 30

Measuring Points Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Information Subwindow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sensor Data Subwindow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Alarms Subwindow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Relay Output Assignment Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Relay Outputs Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Time Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

TCP/IP window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Sensors Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status Texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Gas Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 52

Measuring Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Linearity Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

SD card Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.2 Maintain Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Calibration Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

IBR (Bridge Current) Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Interface Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

SD Backup Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

49

GB

SUPREMATouch

3

Page 4

4.3 Diagnosis Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Measuring Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Switch Inputs Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Modules Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.4 PC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.1 Sensor Simulation Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.2 Replacing Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.3 Replacing Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.1 Plug-In Modules– Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.2 Replacing Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Plug-In Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.3 Diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.4 System Fail Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.5 ID Rack Assignment in decimal and hexadecimal figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.6 Digital Message Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.7 LED and Sounder Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.8 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.1 Calibration Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.2 Calibrating Passive Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.3 First Calibration with Pre-Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Passive Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.4 Calibrating Active Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Calibration with a Variable Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Calibration Using the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.5 Calibration with Automatic Valve Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.6 Separate Zero Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7.7 Calibration of Groups of Measuring Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.8 Remote Calibration of Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.9 Setting the Bridge Current

8 System Expansions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1 Connecting Additional Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.2 Connection of Additional Relay Driver Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.3 Connection of Additional Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

GB

9 Special conditions to comply with the requirements of DIN EN 61508 for SIL 1-3 according to

TÜV Certificate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.1 Conditions for configuration, installation, operation and maintenance . . . . . . . . . . . . . . . . . . . . . 102

9.2 Additional conditions to fulfill the requirements of IEC 61508 for a certain SIL . . . . . . . . . . . . . . 103

9.3 Possible Configurations and Acquirable SILs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9.4 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.5 Permitted System Expansions over CAN Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.6 Permitted Hardware Modules and Software Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.7 Permitted Software Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.8 TÜV-Certificate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

SUPREMATouch

4

Page 5

10 Special conditions to comply with the requirements of ATEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.1 Measurement Value Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.2 Data Processing/MCP Module (Central Processing Module). . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.3 Display + Operation/MDO Module (Display and Operating Module) . . . . . . . . . . . . . . . . . . . . . . 115

11.4 Digital + Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

11.5 Power Supply, Bus Connections, Connecting Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

MSP Module (System Power Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

MIB Module (Interconnection Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

MST Module (System Terminals). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

MAT Module (analogue Terminal Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

MAT Module TS (analogue Terminal Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

MUT Module (Universal Terminals) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

MRO8 Module (Relay Output Module: Common Alarms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

MRC TS Module (Relay Connection Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

MRO8 TS Module (Relay Output Module: Non-redundant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

MRO8 TS Module: Function of the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

MRO8 TS Module: Relay Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

MRO16 TS Module (Relay Output Module (Redundant)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

MRO16 TS Module: Module Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

MRO16 TS Module: Relay Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

11.6 Minimal Module Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

12 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

12.1 Installation Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

12.2 Installation Instructions for Following the EMC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Instruction on Meeting the EMC Requirements on the SUPREMATouch Control System . . . . . 122

12.3 Installation, Step by Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

12.4 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

12.5 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

12.6 Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Configuration MIB Module

Configuration MAT Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Configuration MAT TS Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Configuration MRO8 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Configuration MRC TS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MRO8 TS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MRO16 TS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MUT Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MAR Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MST Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MAO Module (MAO20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configuration MCP20 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Configuration MDO20 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Configuration MDC20 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Configuration MAI30/MGI30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Configuration MAR30/MGR30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Configuration MHS30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Configuration MBC20 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Configuration MBT20 Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

GB

SUPREMATouch

5

Page 6

Configuration in the SUPREMATouch menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

MRD Dummy Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

12.7 System Configuration (Hardware) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Front: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Rear:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Maximum Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

12.8 Systems Consisting of Several Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Systems with Central Recording of Measuring Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

12.9 Connecting the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

12.10 Connecting the Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

12.11 Connecting the Switching Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

12.12 Connecting the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

12.13 System Ports (MST Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

12.14 Connecting the System Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

12.15 Labelling Concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

13 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.1 Start-up Procedure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.2 Switch On the Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.3 System Configuration/Parameterisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

13.4 Preadjusting Passive Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

13.5 First Calibration with Pre-Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

13.6 Completing Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

14 Connecting Peripheral Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

14.1 Connecting a PC/Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

14.2 Connecting a Protocol Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

14.3 Bus Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

15 Redundant Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

15.1 Application/Function Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

15.2 Function of Redundant Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

15.3 Design of the Redundant System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

15.4 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

16 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

16.1 4-20 mA (2-wire). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

16.2 4-20 mA (3-wire). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

16.3 4-20 mA with ext. power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

16.4 Series 47K-ST, -PRP (3-wire) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

16.5 Series 47K-ST, -PRP (5-wire) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

16.6 Series 47K-HT (3-wire). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

16.7 Series 47K-HT (5-wire). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

16.8 Fire Detector Apollo Series 65 (not explosion-proof) (without safety barrier). . . . . . . . . . . . . . . . 209

16.9 Push-Button Detector (not explosion-proof) (without safety barrier) . . . . . . . . . . . . . . . . . . . . . . 211

16.10 Explosion-proof Push-Button Detector with Barrier Z 787 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

16.11 Ex-Fire Detector Apollo Series 60 with Barrier Z 787 and MTL 710pressure-resistant . . . . . . . . 214

16.12 Explosions-Proof Fire Detector CERBERUS DO1101EX/DT1101EX with Barrier Z 787 . . . . . . 216

16.13 Explosion-Proof Push-Button Detector with Barriers MTL 728 and MTL 710 . . . . . . . . . . . . . . . 218

16.14 Explosion-Proof Fire Detector Apollo Series 60 with Barriers MTL 728. . . . . . . . . . . . . . . . . . . . 220

16.15 Explosion-Proof Fire Detector CERBERUS DO1101EX/DT1101EX with Barriers MTL 728 and

MTL 710 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

GB

SUPREMATouch

6

Page 7

17 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

17.1 MAI30/MGI30 Module: Analog Input Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

17.2 MAR30/MGR30 Module: analogue Redundant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

17.3 MAT Module: Analogue Terminal Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

17.4 MAO20 Module: Analog Output Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

17.5 MBC Module: Bus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

17.6 MCP Module: Central Processing Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

17.7 MDC Module: Display Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

17.8 MDO Module: Display + Operating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

17.9 MGO Module: General Output Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

17.10 MHD TS Module: Modular High Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

17.11 MHS30 Module: Module HART Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

17.12 MIB Module: Interconnection Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

17.13 MRC TS Module: Relay Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

17.14 MRD Module: Dummy Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

17.15 MRO10 8 Module: Relay Output Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

17.16 MRO10 8 TS Module: Relay Output Unit (Rail-Mount Installation) . . . . . . . . . . . . . . . . . . . . . . . 228

17.17 MRO10 16 TS Module: Redundant Relay Output Unit (Rail-Mount Installation) . . . . . . . . . . . . . 229

17.18 MRO20 8 TS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

17.19 MRO20 8 TS SSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

17.20 MRO20 16 TS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

17.21 MRO10 16 TS SSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

17.22 MSP Module: System Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

17.23 MST20 Module: System Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

17.24 Relay Contact Data (MRO10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

18 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

18.1 Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

18.2 Rail-mounted Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

19 Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

19.1 Modules and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

19.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

GB

SUPREMATouch

7

Page 8

User Instruction Manual

SUPREMATouch

Fire and Gas Warning Unit

MSAsafety.com

Page 9

MSA Europe GmbH

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

info.ch@MSAsafety.com

www.MSAsafety.com

©

MSA 2017 All rights reserved

Page 10

Safety Regulations

1 Safety Regulations

1.1 Correct Use

The SUPREMATouch is a stationary gas warning system with multiple measurement sites, which

operates continuously to monitor work sites for the presence of combustible and toxic mixtures of

gas and/or vapor with air and to monitor the ambient air for oxygen content. The system supplies

power to the sensors, displays the measured concentrations, and monitors the limit values, but it

also actuates alarm devices. The various functions of the gas warning system (the acquisition of

the measurement values, the evaluation of the signals, the actuation of the alarm devices etc.) are

performed by the various modules of the SUPREMATouch.

The SUPREMATouch can process the standardized current and voltage outputs of various types

of sensors. This means that the system can display and evaluate not only gas measurements but

other measurement variables as well (e.g., temperature and pressure).

The SUPREMATouch is a modular system, allowing a wide variety of applications.

It is imperative that this operating manual be read and observed when using the product. In particular, the safety instructions, as well as the information for the use and operation of the product,

must be carefully read and observed. Furthermore, the national regulations applicable in the

user's country must be taken into account for safe use.

DANGER!

This product is supporting life and health. Inappropriate use, maintenance or servicing may affect

the function of the device and thereby seriously compromise the user's life.

Before use the product operability must be verified. The product must not be used if the function

test is unsuccessful, it is damaged, a competent servicing/maintenance has not been made,

genuine MSA spare parts have not been used.

Alternative use, or use outside this specification will be considered as non-compliance. This also

applies especially to unauthorised alterations to the product and to commissioning work that has

not been carried out by MSA or authorised persons.

1.2 Liability Information

MSA accepts no liability in cases where the device has been used inappropriately or not as

intended. The selection and use of the device are the exclusive responsibility of the individual

operator.

Product liability claims, warranties and guarantees made by MSA with respect to the device are

voided, if it is not used, serviced or maintained in accordance with the instructions in this manual.

GB

SUPREMATouch

10

Page 11

System Concept

2 System Concept

2.1 System Features

• Modular system

• 19” rack system for the connection of up to 256 sensors

• Complete system for up to 64 sensors with common relays (Alarms 1–4, signal fail, horn,

inhibit, power) in one 19” rack

• Maximum number of switching outputs in the system: 512

• Minimal installation work (bus system)

• Redundancy possible

• Maximum refresh rate of 3–4 seconds for alarm outputs (1–2 s for data acquisition; 1 s for

computation; 1 s for data output)

• Maximum refresh rate of 3–5 seconds for signal fail outputs (1–2 s for data acquisition; 1–2 s

for computation; 1 s for data output)

• Maximum response time of 15 seconds for system fails

• External voltage operation (85–265 VAC) no switching necessary

• Power supply unit on the rack, 250 W

• For higher power requirements, external power supplies can be connected

• Battery connection for emergency power operation

• Operating voltage range of the system modules: 19.2 VDC–32 VDC.

Recommended voltage: 24 VDC.

• Universal sensor interface with automatic sensor detection

• Operation of passive catalytic/semiconductor sensors, 3- or 5-wire.

• Automatic pre-setting of passive detectors in first calibration

• Operation of active transmitters with 4–20 mA output, 2- or 3-wire

• System operation via a graphical touch screen with a resolution of 320 x 240 pixels and individual function keys

• Self-explanatory error messages

• System configuration and parametrization optionally via laptop (Windows user interface)

• The SUPREMATouch can be connected via a bus connection to the company communications

network (data evaluation, data display, etc.)

• Key switch connection or three password levels to control access

• Key switch connection for relay inhibiting

• Remote key switches for acknowledgment and reset

• Common alarm LEDs for 1st to 4th alarm, signal fail (sensor), system fail, inhibit, power supply

fail

• Protocol printout of status changes + system operations (standard ASCII, 80 CHR)

• 1 x USB + 1 x RS232 or 2 x RS232 interfaces for data transfer to an industrial PC/laptop/printer

• RS232 interfaces are electrically isolated

• RS232/RS485 converters used for longer transmission distances

• 8 MRO Module common alarm relays supplied by the rack power supply unit

• External relays are supplied with power separately

• Recommended operational lifetime according to EN 50271: 20 years

GB

SUPREMATouch

11

Page 12

System Concept

2.2 Design

The modules of the SUPREMATouch are mounted in a rack. For expanded systems, additional

modules can be placed in a second rack or installed on top hat rails in a switch box.

Data is exchanged between the modules over a CAN bus, so it is possible to connect satellites

over long distances.

For measurement tasks that require redundant signal input and processing, additional modules

can be added at any time to expand the gas warning system.

The sensors must have the type of protection against ignition prescribed for the installation site.

The connection between the input module of the SUPREMATouch and the sensors is established

by a screened remote-measurement cable of the 2, 3, 4 or 5 wire type.

For servicing, the sensors can be electrically isolated from the SUPREMATouch by mechanically

disconnecting the plug-in connection (MAT, MAT TS modules).

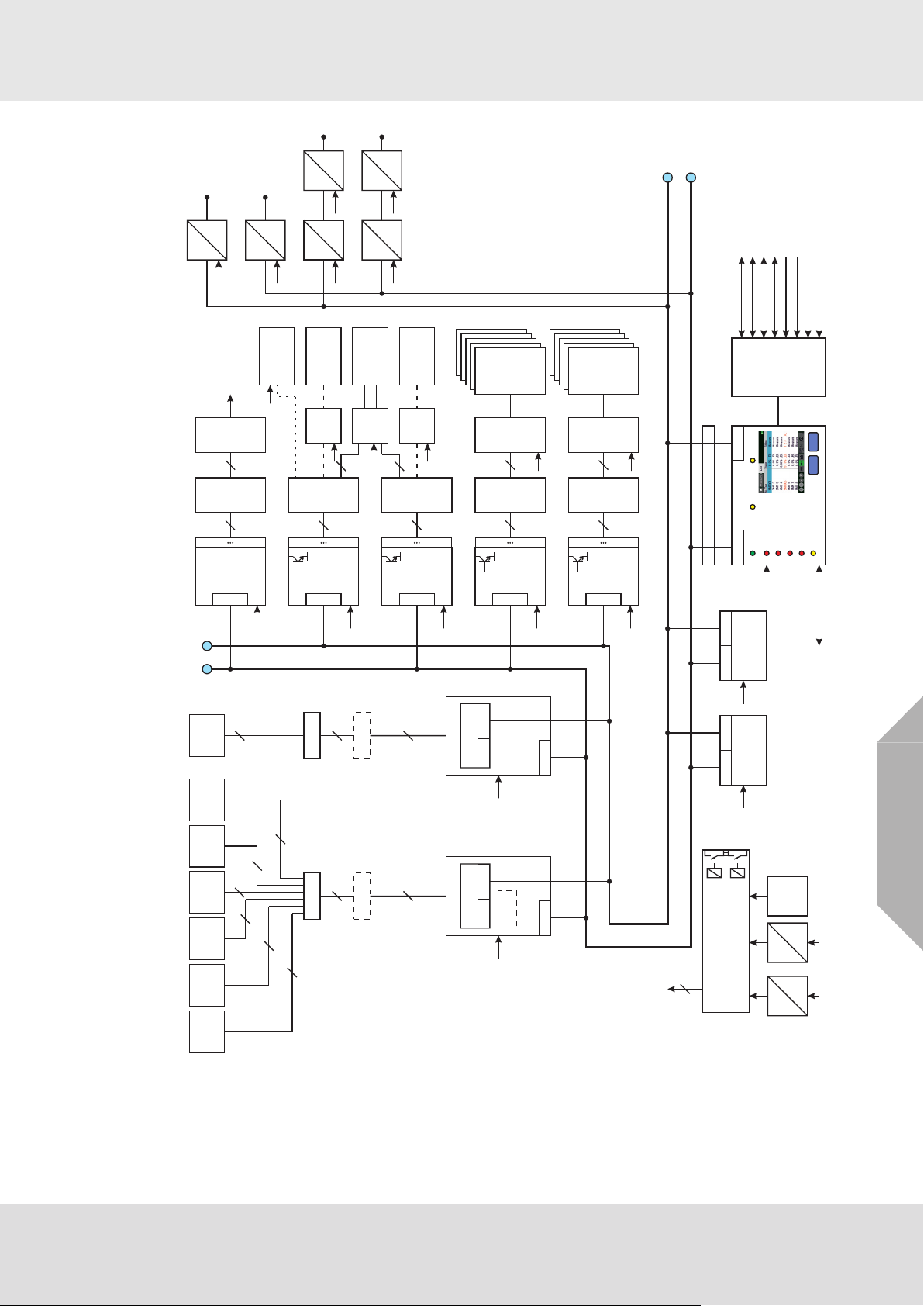

The following block circuit diagram shows the possible layout of a non-redundant system.

Sensors

The system distinguishes between passive detectors and active transmitters.

As a general rule, passive detectors simply consist of a highly sensitive (half) measuring bridge

while active transmitters possess their own electronics and have a standardised signal output

(4–20 mA).

SUPREMATouch

GB

12

Page 13

MRO10 16 TS

MRO20 16 TS

MRO10 16 TS SSR

5 x

5 x

5 x

5 x

5 x

MIB 20

Output

4-20mA

Ext

Int = GWS250-24

Bat

40

5

2

system

failure

relay

Modbus RTU,

Modbus TCP,

Profibus DP

2

CAN BCAN A

Terminator

CANBCANA

Terminator

CANB

CANA

CAN A CAN B

MCP 20

24 V

CAN A CAN B

MCP 20

24 V

24 V

MGI30

MGR30

MAT 10 (TS)

passive

detector

passive

detector

fire/smoke

detector

manual call

point

MUT10

40

3

24V=

ป

24V=

ป

BAT

24V=

MGO 20

24 V, 500 mA

40 Drivers

1

40

CAN

24 V

MGO 20

24 V, 500 mA

40 Drivers

1

40

CAN

MGO 20

24 V, 500 mA

40 Drivers

1

40

CAN

MGO 20

24 V, 500 mA

40 Drivers

1

40

CAN

24 V

24 V

24 V

MUT10

40

MUT10

40

MUT10

40

MRC10

-TS

40

5 x

MRO10 8 TS

MRO20 8 TS

MRO20 8 TS SSR

MRC10

-TS

MRC10

-TS

MRC10

-TS

40

40

MRO10 8 TS

MRO20 8 TS

MRO20 8 TS SSR

5 x

MRO10 8 TS

MRO20 8 TS

MRO20 8 TS SSR

5 x

MHD 10

MAO 20

1

8

CAN

24 V

MUT10

40

MGT40

-TS

40

CAN

24 V

Gateway

CAN

24 V

Modbus RTU,

Modbus TCP,

Profibus DP

CAN bridge

24 V

24 V

CAN

CAN

CAN

CAN

CAN bridge

CAN/fibre optic

24 V

CAN

CAN/fibre optic

24 V

CAN

24 V

24 V

24 V

24 V

24 V

5 x

5 x

5 x

5 x

MUT10

40

MRC10

-TS

40

5 x

MRO10 8 TS

MRO20 8 TS

MRO20 8 TS SSR

24 V

ACK

MDO 20

2. ALARM

1. ALARM

SIGNAL FAILURE

3. ALARM

4. ALARM

CAN A

CAN B

RES

POWER

INHIBIT

SYSTEM

24 V

MDC 20

RS 232 / USB

Lock A/B

Reset

Acknowledge

Password switch

MST 20

2 x CANA, 2 x CANB

RS 232 / USB to PC

Ethernet

RS 232 to Printer

CAN

CAN

40

3

2

3

2

24 V

MAI30

MAR30

MAT 10 (TS)

transmitter

(4..20mA)

transmitter

(4..20mA)

MUT10

40

MHS30

CAN

CAN

Switch

8 x

Gateway

System Concept

GB

Fig. 1 Block circuit diagram of a system layout (redundant)

SUPREMATouch

85VAC...264VAC

24V power supply

13

Page 14

System Concept

Fail Conditions

Signals that are above full-scale range or signal fails that were caused by an interruption of the

digital communication are always latched.

Signal fails caused by signals below the measuring range are non-latching. Measurement values

that are over the full-scale range will trigger all 4 alarms.

Horn

If an audible alarm device is connected to the horn relay, it will sound as soon as a new alarm is

triggered. It continues to sound even when the alarm condition no longer exists. Pressing the

ACKNL key silences the horn, regardless of whether or not the alarm condition still exists.

When a redundant system is used, the ACKNL or RESET key has to be pressed for at

least 1 second.

2.3 Operation and Display unit MDO

The operation and display unit includes the following components:

• Colour TFT touch screen with 320 x 240 resolution

• 2 keys

• 8 LED indicators

• 1 beeper

The TFT screen is a full graphic display with a resistive touch panel. The character height is

approximately 4 mm.

Fig. 2 Display and Operation Module (MDO)

NOTICE

To prevent damage to the touch screen, avoid touching it with sharp objects. Only use fingers or

the touch screen pen provided.

GB

SUPREMATouch

14

Page 15

System Concept

4

3

2

1

6

Fig. 3 Display with keys

1 ACKNL (acknowledge) key 4 SYSTEM LEDs

2 RESET key

3 SIGNAL LEDs 6 Display

2.4 Keys

WARNING!

All alarms, failures and overrange indications are reset with the keys (if the conditions no

longer apply).

It is possible to selectively reset alarms in two steps using the graphical user interface.

ACKNL key

RESET key

2.5 LED Indicators

The 8 LED indicators provide system and signal status information.

To acknowledge all alarms, press the ACKNL key to make the LED change to

‘steady state’.

Pressing the ACKNL key silences the horn, regardless of whether or not the

alarm condition still exists.

If a signal no longer exceeds the alarm threshold and the alarm has been

acknowledged, the LED is turned off by pressing the RESET key.

For non-latching alarms or if the signal still exceeds the alarm threshold, the

RESET key has no effect.

GB

SYSTEM:

POWER (green) power supply on/off

FAIL (yellow) system specific error (e.g. defective CPU)

INHIBIT (yellow)

on: inputs are inhibited or a calibration is pending

flashing: outputs connected to one or more inputs are locked

SUPREMATouch

15

Page 16

System Concept

SIGNAL:

AL 1–AL 4 (red)

FAIL (yellow)

2.6 Bus Protocol

The SUPREMATouch uses the CAN bus protocol. On the Interconnection Board (MIB module),

the DIL switch can be used to set the transfer speed to 10, 20, 50, 125, 250, 500 or 1,000 kBits/s

for all of the connected modules. All modules on one bus must operate at the same bit rate; if one

of the modules uses a different rate, an error state occurs on the bus. This is detected, and appropriate messages are displayed.

Each module receives a code (Node ID) in the range of 1–127 by the use of the DIL switch of the

MIB module board on the basis of its slot in the rack. Each of the modules on one bus must have

its own code. If duplicate codes are detected, an error message is generated.

2.7 System Power Supply

The system is supplied with an operating voltage of 24 VDC (19.2–32 VDC). 3 pairs of terminals

for the connection of three 24 VDC power supply sources (EXT, INT, BAT) are provided on the

Interconnection Board (MIB module). Therefore the power can be taken from 3 different sources

(redundancy). If all three supply voltages (EXT, INT and BAT) are present, the system selects

only one of these to supply the module, in the following order of prioritisation:

1st = EXT, 2nd = INT, 3rd = BAT.

The system module hardware manages the power supply changeover.

When an external power pack or battery supply is used, MSA recommends that the power is

filtered through an appropriate EMC (electromagnetic compatibility) filter. See chapter 12.2

"Installation Instructions for Following the EMC Directives"for low voltage installation information.

In order to protect the battery and the SUPREMATouch against damage, an additional deep

discharge contactor component is required in the corresponding 24 V feeder (e.g. deep discharge

contactor C1900-TLS, Mentzer or similar).

• The customer is responsible for providing a safety cut-out (maximum rack power, 480 W/20 A).

• 85–264 VAC is supplied via screw terminals directly on the power supply unit.

• The EXT, INT and BAT voltages are supplied to each system module.

• Voltages required for the individual modules are obtained in the modules themselves from the

24 V.

• The power requirement that must be met is derived from the type and number of sensors

connected and from the components installed in the system.

• Maximum power provided for one rack is 480 W (maximum current of 20 A).

• The transmitter/detector input modules measure all input voltages and can generate error

messages, which can be shown on the display unit. In addition, a POWER FAIL relay

(optional: redundant) is de-energized when the status of the system power supply changes.

EXT Terminals (External Power Supply, 24 VDC)

• Connection for voltage supply from an external power supply unit; power is sent to all units in

the rack.

• Required when a redundant power supply is provided or when the internal rack power supply

is not sufficient to operate all of the sensors.

• Maximum supply current of 20 A for one rack.

input signal alarms

(each input can have up to four alarms)

specific input signal statuses

(measurement values that are over full-scale, below the measurement

range and signal failures)

GB

SUPREMATouch

16

Page 17

System Concept

INT Terminals (Internal Power Supply, 24 VDC 250 W)

• Connection for voltage supply from an internal rack power supply or an external power supply

unit.

• Power supplied to all rack units and the sensors.

• Internal power supply unit (MSP module) has a supply voltage input of 85–265 VAC

(47–63 Hz) or 120–330 VDC.

• If the rack power supply unit cannot supply enough power, the sensors, modules or relays must

be supplied by external power supply units.

• The internal rack power supply can be omitted if, because of a high power requirement or a

redundant design, the power is being supplied by an external power supply via the INT terminals.

• Maximum supply current of 20 A.

BAT Terminals (Backup Battery Power Supply)

• Backup battery power supply for all units of a rack (21 –28 VDC).

• In the case of failure of internal and/or external power supply, the backup battery power supply

will supply power to the system.

• Maximum supply current of 20 A.

Power Supply Plans

All of the system cards and the sensors can be supplied from each of the 3 pairs of terminals

connections. A voltage changeover switch is provided on each system card, which ensures that

only one of the voltages being applied is accepted. Various power supply plans are available to

suit the number and type of sensors and/or the required degree of redundancy in the power

supply.

If the internal rack power supply unit is not sufficient to power all the sensors, an external unit must

be provided. The internal unit must then be disconnected. A redundant power supply is then

provided by external units via the BAT or INT terminals.

Supply Plan A: Internal Power Supply Unit

All of the units of the system and the sensors are supplied by the rack power supply unit (INT

terminals). This variant is used when power supply redundancy is not required and the power

which can be supplied by the unit installed in the rack (250 W) is sufficient to supply all of the rack

modules and the connected sensors.

Supply Plan B: External Power Supply Unit

All system modules housed in the rack and the sensors are supplied by the external power supply

unit (EXT terminals). This variant is used when power supply redundancy is not required and the

power of the unit installed in the rack (250 W) is not sufficient to supply all of the system modules

and the connected sensors. A maximum of 20 A can be supplied across the terminals (480 W

system power).

Supply Plan C: Internal Power Supply Unit + Battery

All units of the system and the sensors are supplied by the rack power supply unit (INT terminals)

or by the backup power supply (BAT terminals). This variant is used when there must be redundancy in the power supply and the power of the unit installed in the rack (250 W) is sufficient for

all rack modules and the connected sensors.

Supply Plan D: External Power Supply Unit + Battery

All modules of the system and the sensors are supplied by the external power supply unit

(EXT terminals) or by the backup power supply (BAT terminals). This variant is used when the

power supply must be redundant and the power that can be supplied by the unit installed in the

rack is not sufficient to supply the system modules and the connected sensors. A maximum of

20 A can be supplied across the terminals (480 W system power).

2.8 Safety Concept

The individual functional modules are connected to each other by a CAN bus. The CAN bus is

designed to be virtually error-proof. Every module can detect errors on the bus and handle them

appropriately. The probability of an undiscovered communications error on the bus is 4.7 * 10

Error statuses on the CAN bus are indicated on the DISPLAY + OPERATION unit (MDO module).

-14

GB

.

SUPREMATouch

17

Page 18

System Concept

Each module with a microcontroller has a watchdog timer, which can trigger the system fail signal

line of its rack. As a result, the SYSTEM FAIL common relays on the interconnection board (MIB

module) are de-energized. This common failure signal is also indicated by the DISPLAY + OPERATION unit.

All modules are checked for signs of activity at fixed periodic time intervals by the CENTRAL

PROCESSING unit (MCP module) via the CAN bus. The failure of a module can thus be recognized, and the appropriate messages will be generated. These messages are logged in the MDO's

log books and, parallel to it, the System Fail is activated by the relevant modules.

The operating voltages of the connected voltage supply units (EXT, INT and BAT) are monitored

by the transmitter/detector input modules. If a malfunction occurs here, the POWER-FAIL

common relay is released.

Gas Warning Systems

In simpler expansion stages of safety requirements according to EN 61508, the gas warning

system can be operated via one of the two possible CAN bus connections. Starting with SIL 3,

both CAN bus connections are required. In this case, two CENTRAL PROCESSING units (MCP

modules) are present and all of the input and output signals important for system operations are

available over additional modules on both CAN buses in parallel. If one of these CAN bus connections fails, a SYSTEM FAIL message is generated. The system still remains functional by

using the remaining CAN bus connection.

In the case of a SYSTEM FAIL message, the SYSTEM FAIL LED will light up and the system fail

relays change to failure condition. A System Fail message indicates a malfunction of the

SUPREMATouch and therefore an service is required immediately. The connection of the

switching outputs of the system fail relays has to enable an immediate triggering message.

Gas Warning Systems with Higher Safety Requirements

For gas warning systems with higher safety requirements according to EN 61508 SIL 3 the system

can be provided with redundancy using additional modules. Redundant signal processing has the

same structure and functions the same way as standard non-redundant processing. Communications between the modules proceed over an internal connection, which is designed as a redundant

CAN bus.

If one of the two signal processing routes malfunctions, an error message appears on the

DISPLAY + OPERATION unit (MDO module) (SYSTEM FAIL). The remaining signal processing

channel takes over all of the necessary functions until the defective module can be replaced. The

failure of individual modules does not lead automatically to the failure of the entire system. Only

the functions assigned to the specific module in question are unavailable. The system fail relay

has to be connected and monitored (see chapter 9 "Special conditions to comply with the requirements of DIN EN 61508 for SIL 1-3 according to TÜV Certificate"and 10 "Special conditions to

comply with the requirements of ATEX").

2.9 During Operation

GB

WARNING!

In case of operation with catalytic combustion detectors: To guarantee the unambiguity of catalytic

combustion sensor operation it must be ensured at all times (e.g. by checking with hand-held test

instruments) that the environmental atmosphere to be monitored by the sensors is free of combustible gases prior to the sensors and the system being switched on or overrange indications are

reset.

SUPREMATouch

18

Page 19

System Operation

3 System Operation

The modular control system’s user interface is the integrated operation and display unit. This unit

displays alarms and warnings as well as system parameters.

Selection and input are touch-controlled, which means that the integrated Display and Operation

module is very easy to use..

Connecting the operating unit to a PC provides a more user-friendly interface with additional

features.

The software SUPREMA Manager can be used to create and manage the configuration and

parametrization of multiple SUPREMA systems. See separate operating manual for SUPREMA

Manager for details.

Both the PC program and the SUPREMATouch system use graphical user interfaces (GUIs). The

input fields are set up as selection fields as much as possible, with all known inputs displayed.

3.1 Operation Menu

The operation menu is divided into four submenus:

•Measure

• Setup

• Maintain

• Diagnosis

These submenus can be selected by tapping the corresponding menu item. The Measure

submenu is automatically activated at system start-up.

If another menu is active and there is no operator activity for 3 minutes, the system returns to the

Measure submenu. If an alarm occurs the Measure submenu is automatically activated.

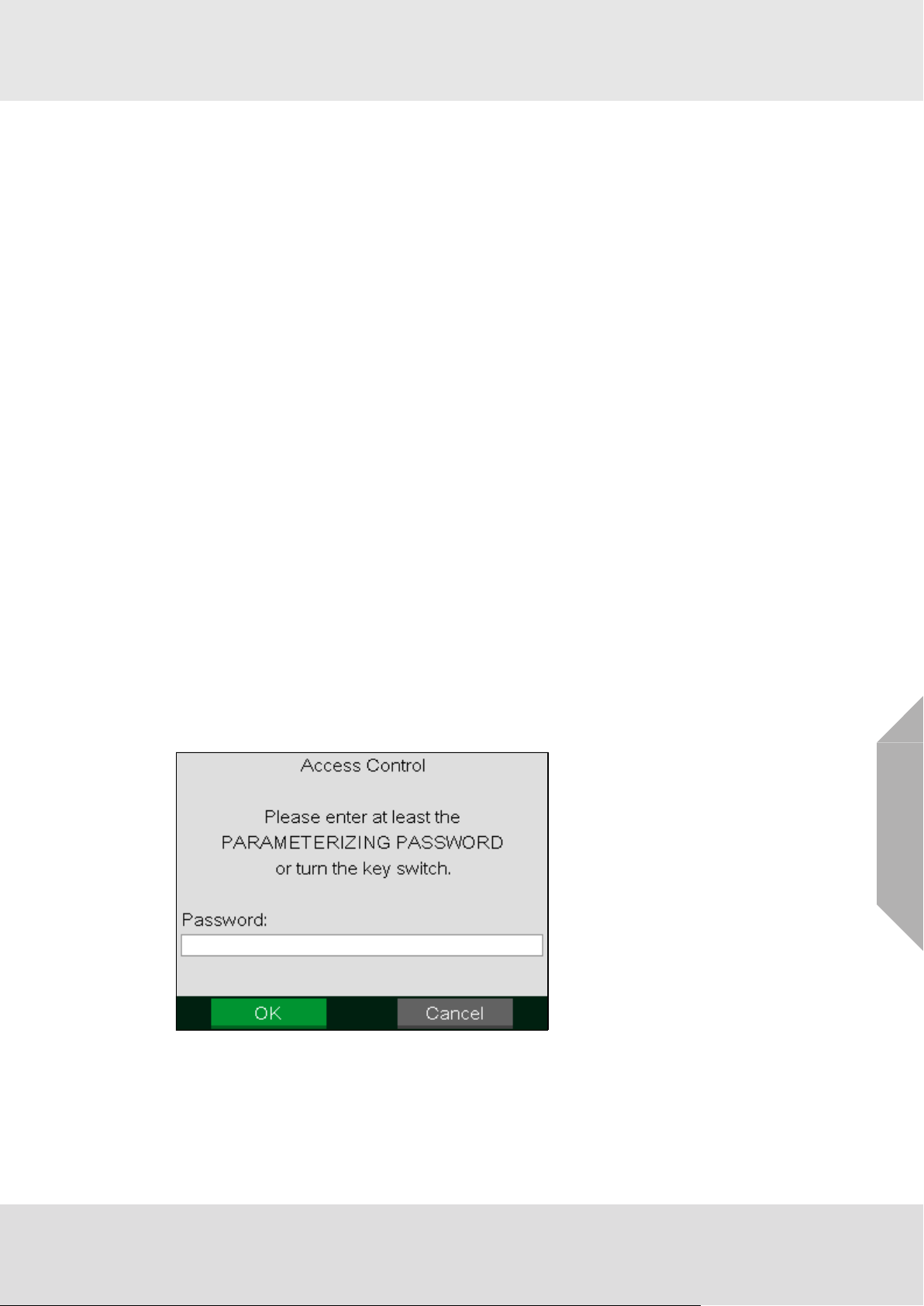

3.2 Access Authorisation

In the various windows, data can be displayed and entered and certain actions can be initiated by

using the touch screen (e.g., starting a calibration procedure). However, editing items or initiating

actions requires access authorisation by entering the password required for the control level or

operating a keyswitch, if fitted.

Three user groups with different password control levels are defined:

• Maintenance

• Parametrisation

• Configuration

Fig. 4 Access control

If the user wants to change a value or press a button when the required authorisation is not yet

issued, the appropriate password must be entered in the pop up window or the key switch must

be activated. Password authorisation remains in effect until measurement mode is activated either

through user input or automatically due to inactivity of 3 minutes or alarms.

SUPREMATouch

GB

19

Page 20

System Operation

If a user with modification authorisation is logged in at the PC and there has not been any communication between the PC and the SUPREMATouch system for more than 5 minutes, password

authorisation will automatically expire.

While SUPREMA Manager is connected to the SUPREMATouch, it is not possible to

simultaneosly change settings via the MDO.

Whether password authorisation is still in effect is indicated by a small lock symbol in lower right

corner of each password controlled window.

Lock symbol

The system is delivered with the default password AUER for all three password levels. MSA

recommends to change the passwords when accessing the SUPREMATouch for the first time.

In the Measure and Diagnosis submenus, data is only displayed, password access control is not

required.

Changing the Password

The password must have a minimum of four characters and may not have more than eight. Any

symbol from the ASCI character set can be used. The password is case-sensitive.

If no password at all is wanted, the password can be deleted by entering nothing instead of a new

password. Authorisation can then be granted only by using the key switch. In this case, an additional security dialog is initiated with the warning that the approval of the system is revoked in the

event of unauthorized changes.

To change a current password/create a new password, carry out the following:

(1) Select the corresponding password field in the Setup/System menu.

Enter the current password or actuate the key switch.

(2) After entering the password or actuating the key switch, leave the window with the OK button.

When the key switch was actuated, it can be released again after leaving the password

window.

(3) Enter the new password in the Password and Confirmation fields of the Setup/System menu.

(4) Confirm the new password with OK.

To replace a forgotten password, a higher-level password can be entered. If the current

parameterisation password is also lost, a new password can be entered by actuating the

key switch. If there is no key switch to close, connect terminal contacts 1 (GND) and 2

(PSW) on the MST module with a wire jumper, provided that these terminals can be

accessed safely.

3.3 Measure Menu

When the system configuration is successfully completed, the Measure menu will appear automatically after the system is started. For display of measured values, it is possible to choose from

different display types:

• List (default after start-up)

•Bars

•LEDs

•Groups

Displayed measurement and status values are updated once per second.

Unlike the common alarm LEDs on the MDO front panel, the touch screen display of alarms and

failures does not flash.

GB

SUPREMATouch

20

Page 21

System Operation

If the user is in the List, Bars or LEDs window and does not tap any key for 60 seconds, the window

automatically starts scrolling (one page per 5 seconds).

(1) To scroll through the list manually use the arrow buttons in the lower left corner of the window

or move the list while touching it.

For all display types, it is possible to manually switch between different modes of displaying the

measured information. In one mode all inputs are shown, in the other modes only the inputs in

alarm or fail status are shown.

(2) To switch between modes touch the bell or the sign symbol in the lower right corner of the

measure window.

If one of these selection modes is chosen, the corresponding symbol has a blue background.

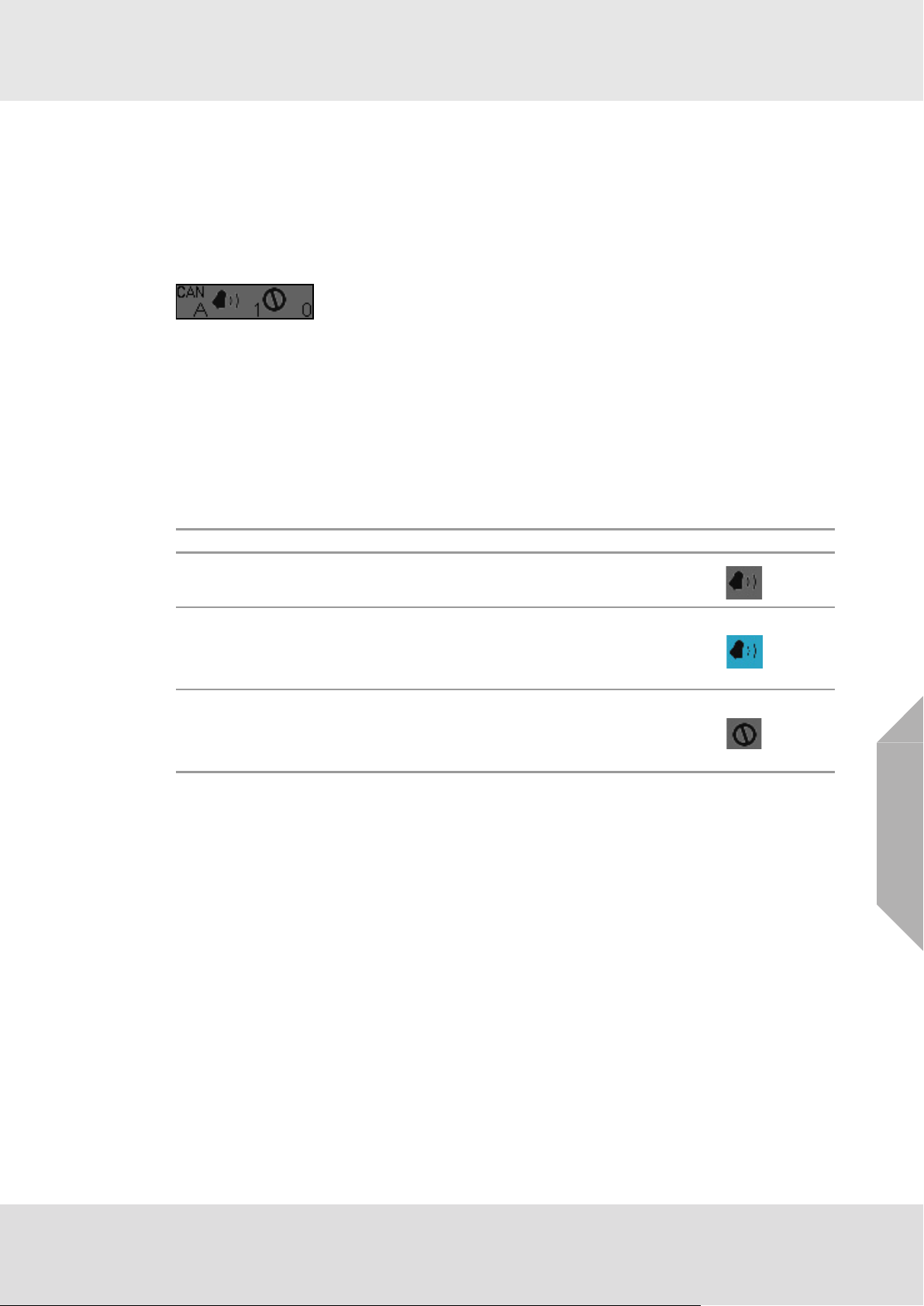

The number of measuring points in alarm and in fail and the CAN bus, A or B, currently

selected as the information source is also shown in this area.

It is possible to switch to the CAN bus by touching the CAN symbol. If the CAN bus is manually

selected, the CAN symbol has a blue background. If the CAN bus is automatically selected, the

CAN symbol has a grey background.

Modes

Mode Display Indicated by

All Inputs

Alarm Inputs

Fail Inputs

In this mode, all the measured inputs in the system are

displayed. The inputs are arranged by their input number.

When no alarm is triggered, this mode behaves like the All

Inputs Mode.

As soon as alarms are triggered, only the inputs in alarm are

displayed, sorted by the time of alarm triggering.

When no measuring point is in fail status, this mode behaves

like the All Inputs Mode.

As soon as at least one input is in fail status, only the inputs in

fail status are displayed, arranged by their input number.

GB

SUPREMATouch

21

Page 22

System Operation

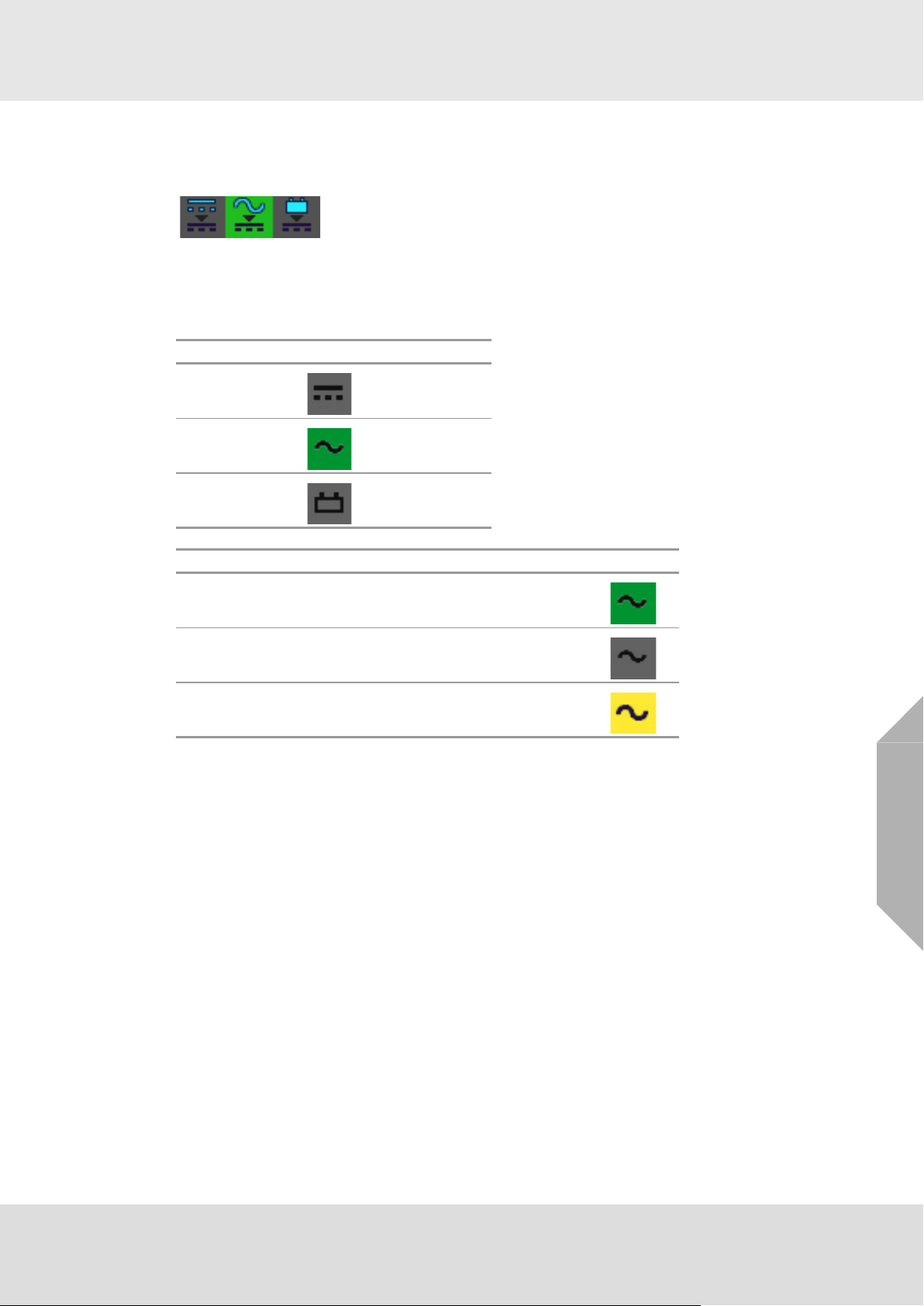

Power Supply Indicator

The power supply indicator gives a quick overview of the current status of the power supply of the

system.

Fig. 5 Power Supply Indicator

By tapping on the Power Supply Indicator, a window with information on the measuring values of

all transmitter/detector input nodes appears.

The 3 different power supplies are indicated with 3 different symbols.

Power Supply Symbol

External

Internal

Battery supply

Status (indicated by background colour)

good:

not configured =

failure =

connected, the voltage is below 30 V and

above 21V (for battery above 22 V)

=

GB

SUPREMATouch

22

Page 23

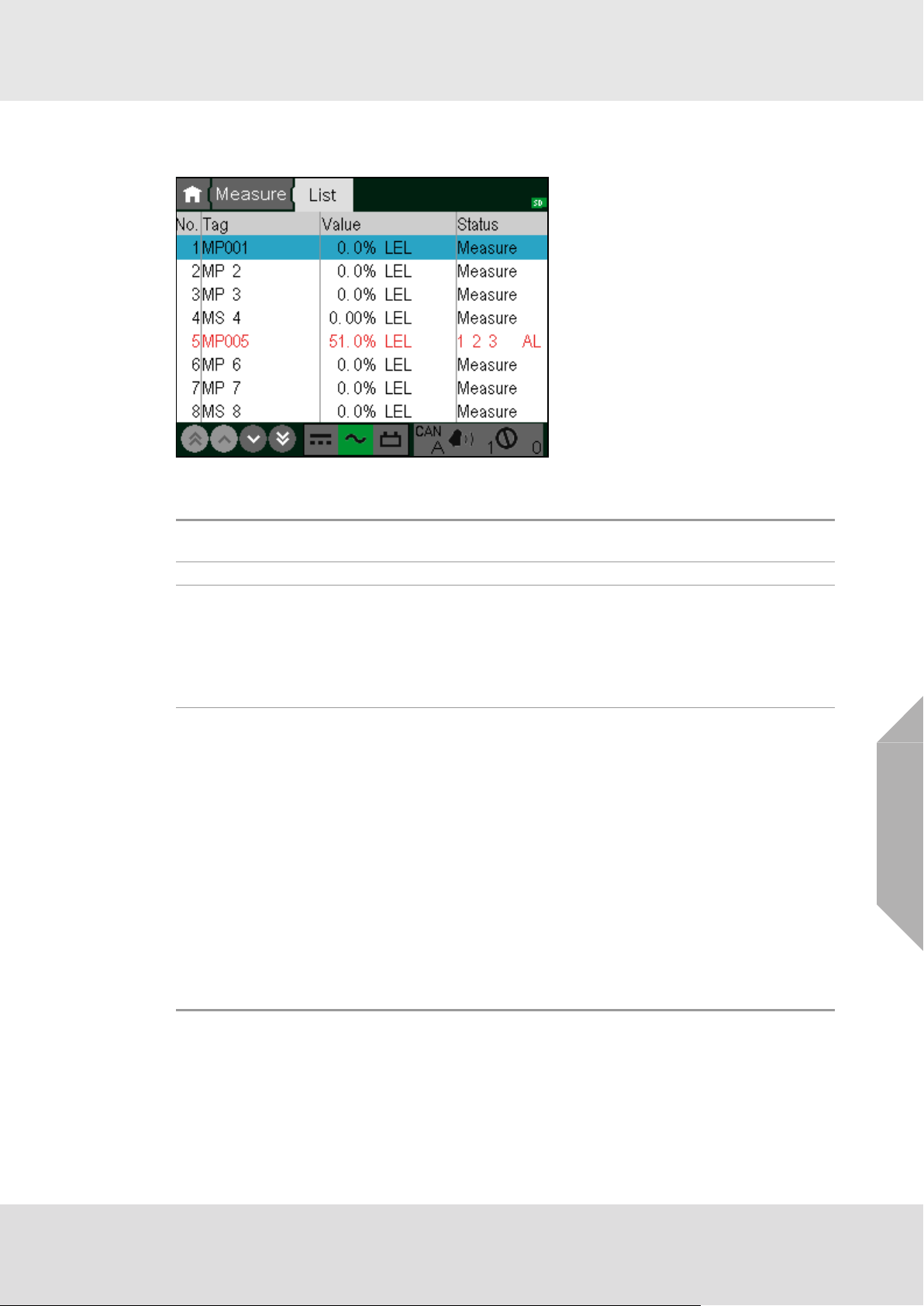

List Window

In this window, the current input data is displayed as a text list.

Fig. 6 List display (with a measuring point in Alarm)

The following input data is shown in this display:

System Operation

No.

Tag The customer defined input description.

Value

Status

The number of measured input in the system. This number is defined by the system

configuration.

Numerical value and dimension of measurement.

The measured values are displayed in intervals of 1 second, as long as they are

within measuring range. If measuring range is exceeded, the highest value reached

is retained.

In case of signal fail or an alarm suppression (during the warm-up period of specific

sensor types), dashes are displayed instead of the measured value.

Current status of the input. The status is updated at intervals of 1 second.

The following values can be displayed:

•Measure

• Calib. (Measurement point in calibration mode)

• Inhibit (Measurement point inhibited)

• Overflow (Measured value above full scale)

• SignalErr. (Measured value below measurement range, or value missing)

• SystemErr. (It was not possible for the MDO to get the measured value)

• PA-failed (Preadjustment error)

• For specific sensor types, text can be defined for special statuses. These are

labelled with F: (e.g. F:OpticErr).

• suppressed (Alarm suppressed during warm-up period of specific sensor types)

• alarms 1, 2, 3 and 4

• Free (measuring point has not been parameterized)

GB

SUPREMATouch

23

Page 24

System Operation

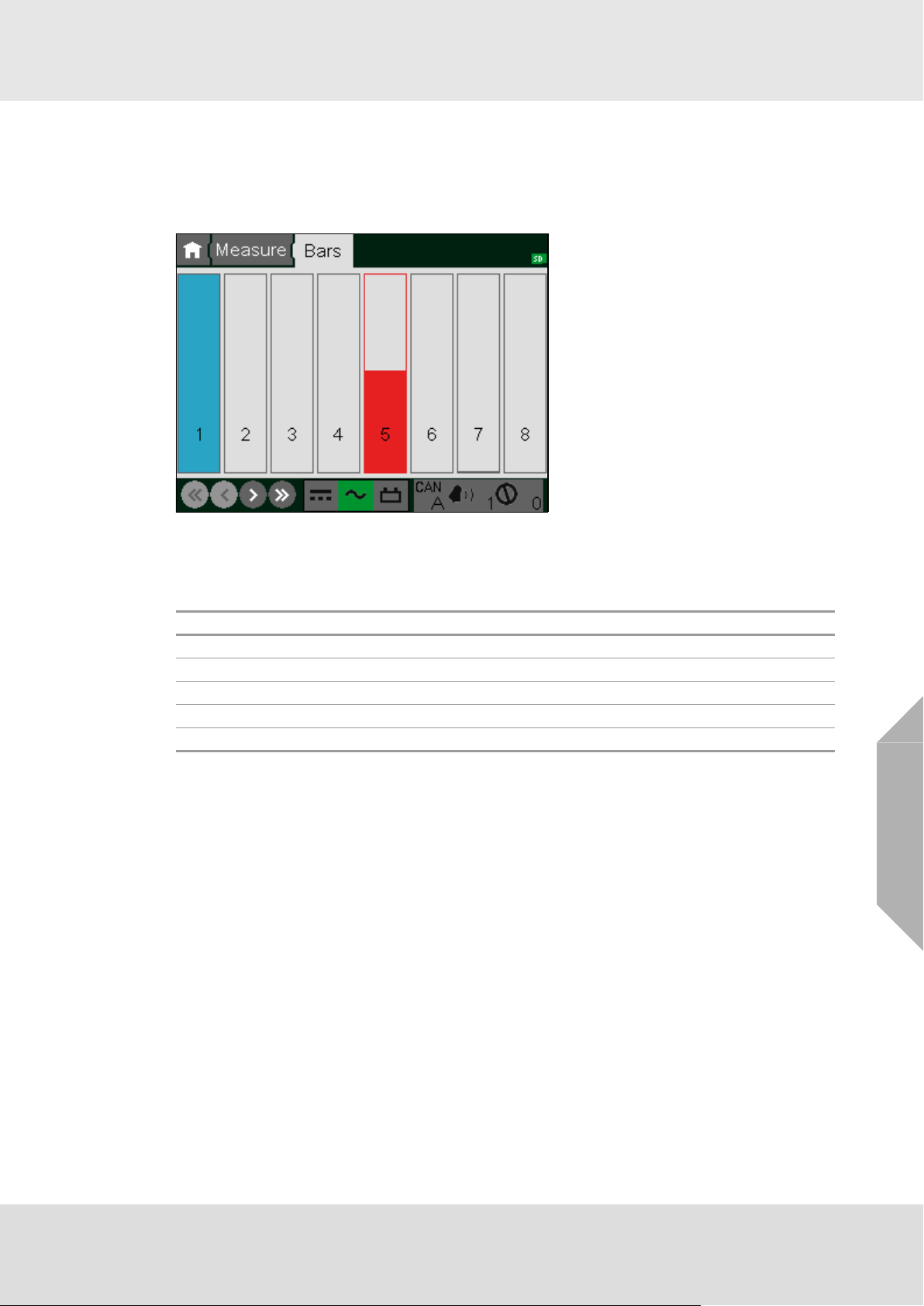

Bar Display

This display shows the measured values as vertical bars, where each bar represents the relative

measurement value of an input with respect to full scale. The value range that can be displayed

is 0–100% of full scale.

The corresponding input number is shown in each bar.

Fig. 7 Bar display

Measured values are displayed as solid bars. In error-free operation with no alarms, the bars are

grey. Any alarm will cause the corresponding bar to change to red. When a status message occurs

for an input, the bar is shown only as an outline with a status identification letter.

Letter Meaning

I Inhibit

C Calibrating

F Fault (measuring value below range, measuring value missing)

O Measurement range exceeded (overflow)

S Alarm suppressed (during the warm-up period of special sensor types)

If an input is not configured no bar is displayed in that column.

GB

SUPREMATouch

24

Page 25

System Operation

LED Display

This window shows the status values of the inputs as LEDs. Under each LED column the corresponding input number is shown. In redundant systems, the information is shown separately for

each CAN bus.

• LED off (grey): not inhibited, no alarm, no failure

• LED on: inhibited, alarm, failure

If an input is not configured no LEDs are displayed in that column.

Fig. 8 LED Display

Measuring Information

Any item in the measuring list can be selected with a double-tap. A selected item is highlighted in

blue. By double-tapping an item in the List/Bar/LED window, a window pops up that shows additional information on the selected item and gives the option to inhibit, acknowledge or reset this

input. Tapping on the shown chart enlarges the chart to full screen. Tapping again reduces the

size again.

Fig. 9 Measuring information

GB

SUPREMATouch

25

Page 26

System Operation

Group Information

Any item in the group list can be selected by tapping it. A selected item is highlighted in blue. By

double-tapping an item, a window pops up that shows additional information on the selected item

and gives the option to de-inhibit, acknowledge or reset all measuring points of this group.

Group View

In this window, the status of each group of measuring points is displayed as a text list.

The following status information is shown in this display:

No.

Tag The customer defined group description.

n. Al. Number of measuring points in this group which have the n-th alarm pending.

Fail

Inh. Number of measuring points in this group which are inhibited or in calibration mode.

The number of the group in the system. This number is set by the system and cannot

be changed by the user.

Number of measuring points in this group which have a signal fail pending or are

suppressed.

GB

SUPREMATouch

26

Page 27

Entering System Parameters

4 Entering System Parameters

The TFT display touch screen is used to select data for editing or to enter data. At the top of the

screen is a breadcrumb menu where an item can be selected by simply tapping it. Tapping an item

more left the current item, returns to the related menu level. Tapping on the house symbol returns

to the root menu. Each menu level is represented by a mask with different icons for each menu

entry which can be selected by tapping it.

Fig. 10 Menu list and input

All types of controls are used by just touching them. The following types of interactive controls are

available:

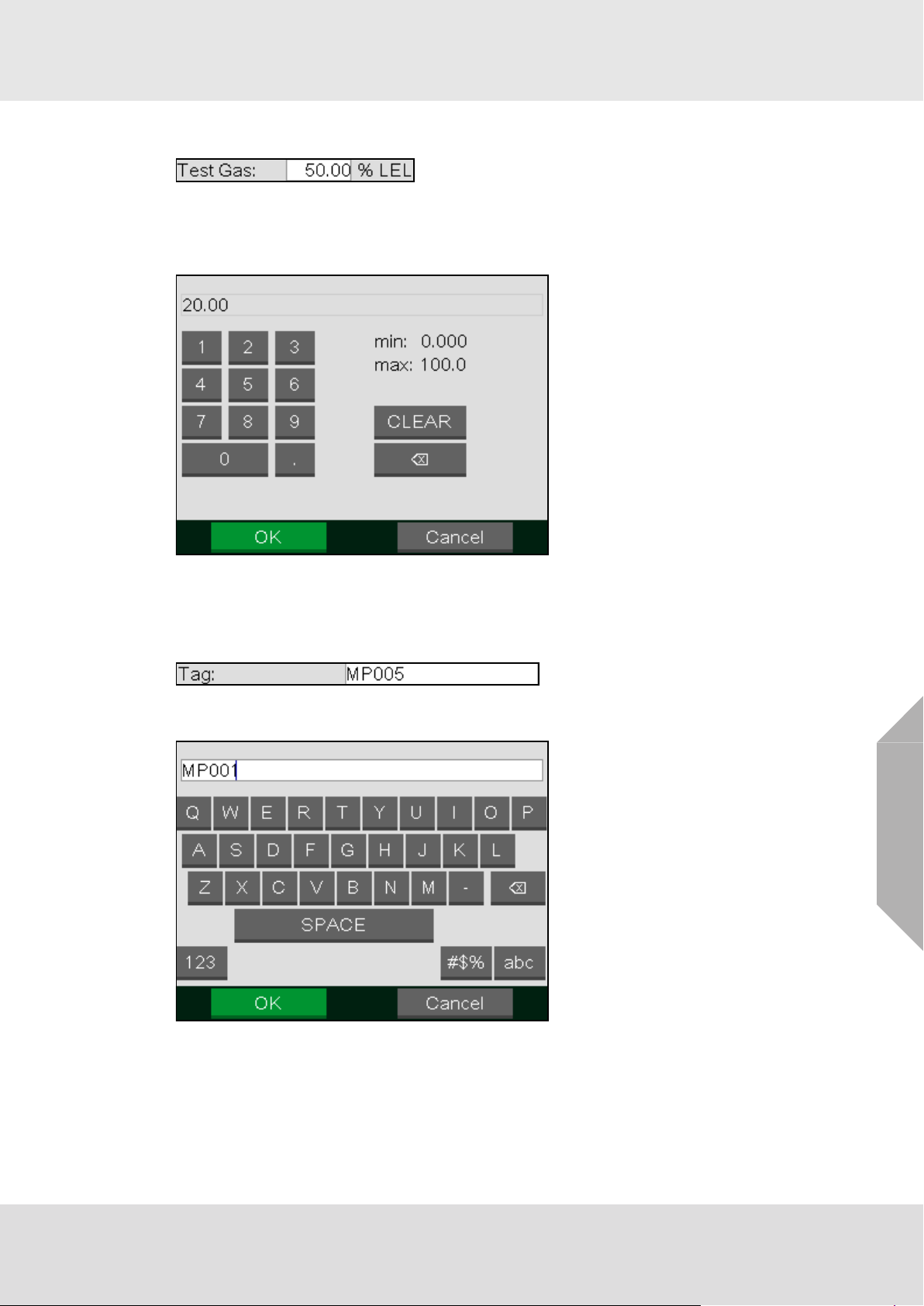

Buttons

Buttons trigger actions. They are activated by tapping them.

Selection Fields

Selection fields contain a list of possible values that can be selected. By tapping an item, a new

window pops up and shows all available values. To select a new value, tap it and press the OK

button.

GB

Fig. 11 Selection window

SUPREMATouch

27

Page 28

Entering System Parameters

Number Fields

Number fields can contain integers or decimal numbers that can be changed. When tapping the

field, a new window pops up that allows a new value to be entered. To store a new value, press

the OK button. It is not possible to store a value if it is not in the range indicated by the min and

max values.

Fig. 12 Number input

Pressing the CLEAR button deletes the entered number. Pressing the button deletes the last

digit.

Text Fields

Text fields can contain numbers, letters and special characters that can be changed by the operator. By tapping the field, a new text editor window pops up. To save the text, press the OK button.

GB

Fig. 13 Text editor window

The new character is always inserted at the position indicated by the cursor. To change the cursor

position, tap the required new position. Pressing the button deletes the character in front of the

cursor.

SUPREMATouch

28

Page 29

Entering System Parameters

Display Fields

Display fields display information that cannot be changed. They are not affected by tapping it.

Check Boxes

Check boxes represent options that can be enabled or disabled. Tapping the box switches

between enabled and disabled status.

An enabled check box shows a cross. A disabled check box is empty.

Lists

Fig. 14 List

Lists display information. No parameters can be entered. To scroll through the list, use the

scrollbar or press down and drag the list in the desired direction (up/down or left/right).

In some lists (e.g. SystemEventList), additional information about the selected item can be

displayed by double-tapping the item.

GB

SUPREMATouch

29

Page 30

Entering System Parameters

4.1 Setup Menu

Using the Setup menu, the operator can set parameters for sensor inputs and relay outputs, as

well as other system parameters. Although data can be retrieved and displayed, changing and

activating of actions is possible only after entering the parameterisation password or operating the

key switch. The menu is structured as follows:

Inputs &

Outputs

Sensors

Measuring Points

Relay Outputs Display

System

Groups Time

Switch Inputs TCP/IP

Head Params

Logging

Dimensions Printer

Status Texts

Lin Tables

Gas Names

Passwords

SD card

Assignment

Ranges

Allocation

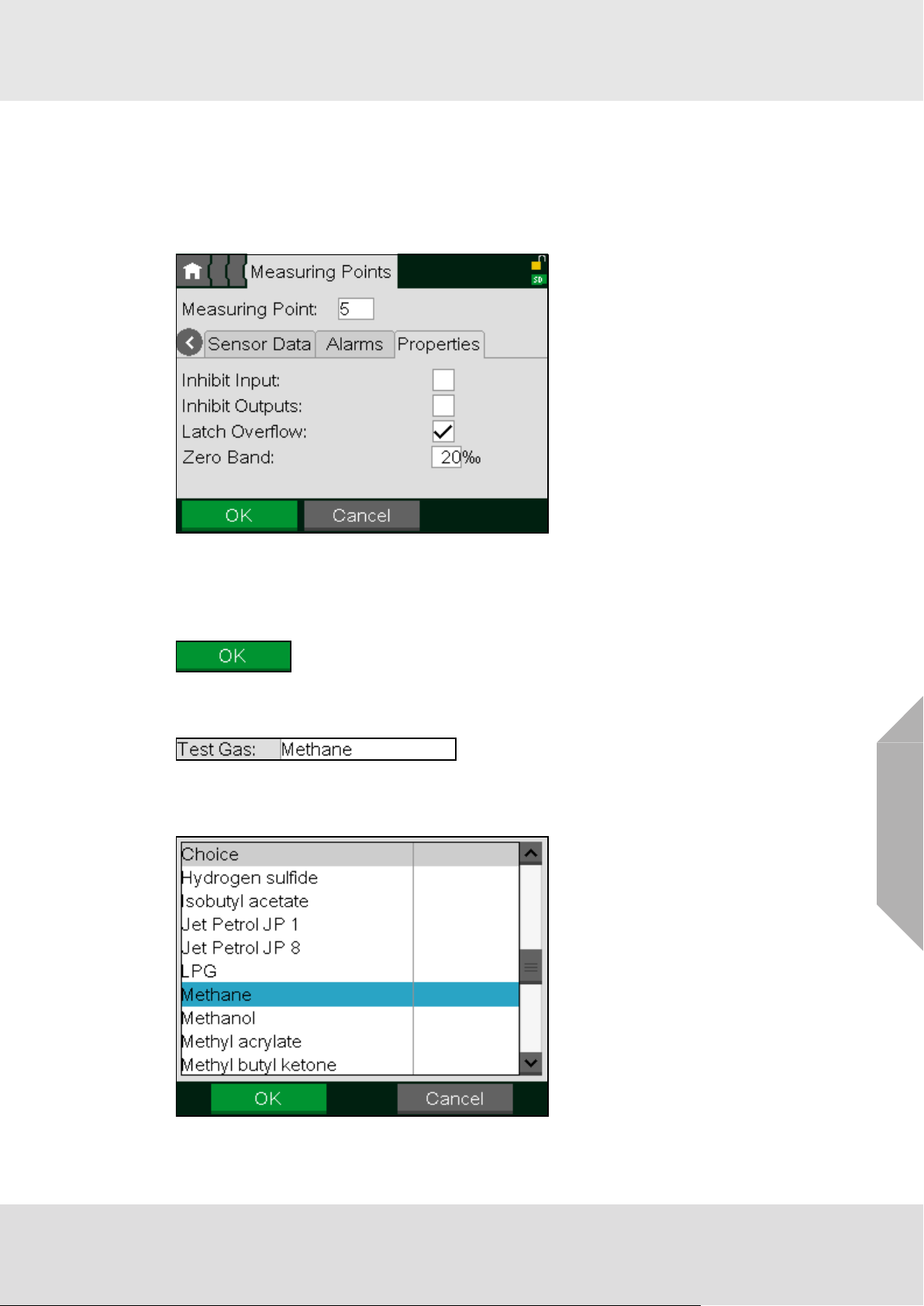

Measuring Points Submenu

This window shows all parameters that describe a sensor input. Input parameters can be viewed

and changed here.

The Measuring Point window is divided into four subwindows:

• Information

• Sensor data

•Alarms

• Properties

GB

SUPREMATouch

30

Page 31

Entering System Parameters

Fig. 15 Measuring Point Setup

The following paragraphs describe the functions of the individual window fields and buttons. The

first fields described are identical in all subwindows.

All parameter changes using the window fields described below apply to the inputs

selected in that field.

Field Field Type Function

List of all configured sensor inputs.

If an input is displayed that has not yet been set up, the settings

from the last input setting remain or default values are used as

Measuring

Point

Information,

Sensor Data,

Alarms and

Properties

OK Button

Cancel Button

Clear Button

Selection field

Button Press this button to display the corresponding subwindow.

the preliminary settings for the input of certain fields. This field

can be accessed without a key switch or password if an input is

entered for which input parameters have already been set. If a

number is entered that has not been used before, authorization

with a password or key switch is required.

Tap this button to accept the settings entered in all subwindows

for the selected input. After tapping the button, the parameters

are immediately checked to see if they are valid. If the parameters are valid, they become part of the system’s parameter set.

If they are not valid, a warning appears.

Press this button to discard the settings entered in all subwindows for the selected input.

Press this button to delete the parametrization of the selected

input. Default values are used as the preliminary settings. The

delete function will not work if the input is being calibrated or

linked with a relay output.

GB

SUPREMATouch

31

Page 32

Entering System Parameters

Information Subwindow

The Information subwindow contains general data on the selected input.

Field Field Type Function

Tag

Marking

Sensor

Serial No.

Installation

Area

Sensor Data Subwindow

The Sensor data subwindow contains settings for the sensor at the selected input.

text, 10 characters;

empty by default

text, 20 characters;

empty by default

text, 10 characters;

empty by default

text, 20 characters;

empty by default

Enter a customer specific designation for the selected input

Enter a customer specific description for the selected input.

Enter serial number of the input device for the selected input.

Enter a customer specific description of the installed location

of the input device for the selected input.

Fig. 16 “Sensor data” subwindow

Field Field Type Function

Sensor Type

Range

Dimensions

Meas. Gas

Zero Gas

(Zero Gas)

Valve No.

Selection,

empty by

default

Selection,

default: 100

Selection,

default: %LEL

Selection,

empty by

default

Selection,

empty by

default

Selection,

empty by

default

Contains a list of supported input device types.

Set the type of device used for the selected input.

Contains a list of supported measurement ranges.

Set the measurement range that applies for the selected input.

Contains a list of supported measurement dimensions.

Set the measurement dimension for the selected input.

Contains a list of supported gases.

Set the gas to be measured with the sensor for the selected

input.

Contains a list of ‘Zero’ gases used to calibrate the zero-point of

the gas sensors.

Set the zero gas that will be used to calibrate the gas sensor for

the selected input.

Contains a list of available outputs that can be used as zero gas

valve output.

This valve will be used during the calibration of the input. If no

valve should be used, select free.

GB

SUPREMATouch

32

Page 33

Entering System Parameters

Field Field Type Function

Selection,

Test Gas

(Test Gas)

Valve No.

Auto Button

Alarms Subwindow

Alarms

Alarms can be latching or non-latching (also see Measuring Points submenu).

Non-latching alarms:

When a signal exceeds the alarm threshold, a new alarm is triggered and the corresponding LED

flashes at a frequency of 0.5 Hz. Pressing the ACKNL (acknowledge) key makes the LED change

to ‘steady state’. When the signal is below the alarm threshold, the LED will turn off, regardless of

whether the alarm has been acknowledged or not. For non-latching alarms, the RESET key has

no effect.

Latching alarms:

When a signal exceeds the alarm threshold, a new alarm is triggered and the corresponding LED

flashes at a frequency of 0.5 Hz. Pressing the ACKNL (acknowledge) key makes the LED change

to ‘steady state’. When the signal no longer exceeds the alarm threshold, the LED remains in

‘steady state’ if the alarm has been acknowledged, or in the ‘flashing state’ if the alarm has not

been acknowledged. If the signal no longer exceeds the alarm threshold and the alarm has been

acknowledged, the LED is extinguished by pressing the RESET key. If the signal still exceeds the

alarm threshold, pressing RESET has no effect.

In the Alarms subwindow, parameters can be set for up to four alarm levels for the selected input.