Page 1

Operating Manual

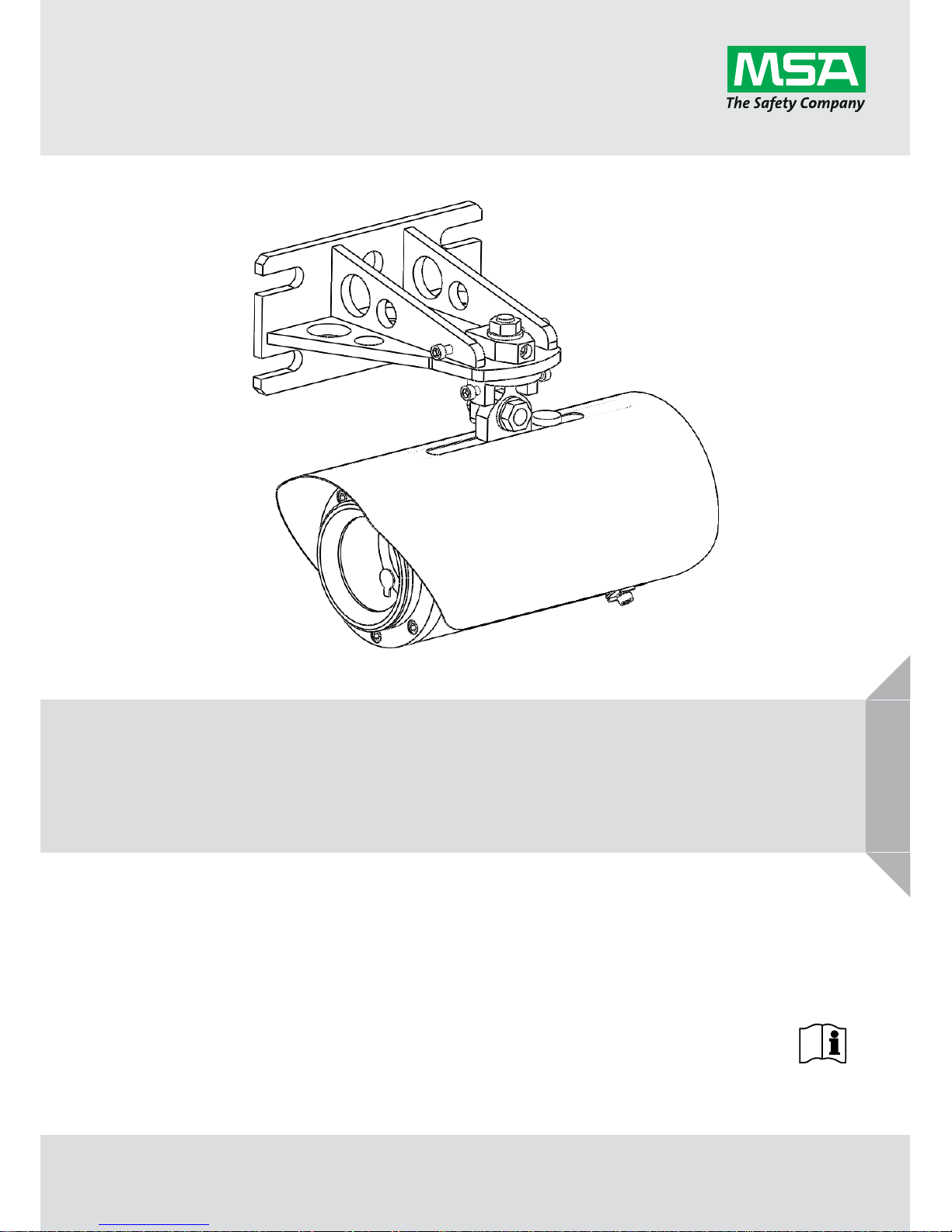

Senscient ELDS™ 1000 / 2000 Series

Open Path & Cross Duct Gas Detectors

A-5170-0 / Rev 15

Page 2

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

Manufacturer:

Senscient Ltd.

Units F1-F4 Arena Business Centre

Holyrood Close

Poole

Dorset

BH17 7FP

United Kingdom

© MSA 2017. All rights reserved

Read and understand this Instruction Manual before installing, operating or servicing

ELDS 1000 / 2000 Series OPGD systems.

Page 3

Safety

Senscient ELDS™

Rev 15

3

GB

Safety

Ensure that you read and understand these instructions BEFORE operating the equipment.

Please pay particular attention to the safety Warnings / Special Conditions of Safe Use.

Warnings / Special Conditions of Safe Use

WARNING

1. The Senscient ELDS™ 1000 / 2000 Series gas detectors are Baseefa ATEX certified for use

in Hazardous (Explosive) Atmospheres; and CSA(UL) certified for use in Hazardous

(Classified) Locations/Zones.

2. For installations in Europe (ATEX Certified) install in accordance with IEC/EN60079-14.

3. For installations in North America and Canada install in accordance with ANSI/NFPA 70, the

Canadian Electrical Code C22.1 and the manufacturer’s instructions.

4. Elsewhere, the appropriate local or national regulations should be used.

5. ELDS™ 1000 / 2000 Series gas detectors must be properly earthed / grounded to protect

against electrical shock and minimise electrical interference. Internal and external

equipotential bonding facilities are provided for this purpose. For electrical installation design

considerations refer to section 3.3.

6. Operators must be fully aware of the action to be taken if the gas concentration exceeds an

alarm level.

7. ELDS 1000 / 2000 Series gas detectors do not contain any parts that can be replaced or

repaired by customers. If units require repair they must be safely removed from any

hazardous location / area in which they are installed, and returned to Senscient. Other than

the rear cover providing access to the terminals for connection purposes, the units are not

intended to be opened during operational service.

8. Test gases may be toxic and/or combustible. Refer to Material Safety Data Sheets for

appropriate warnings and handling procedures / precautions.

9. Do not drill holes in any housing as this will invalidate the explosion-proof protection.

10. In order to maintain electrical safety, units must not be operated in atmospheres with more

than 21% v/v oxygen.

11. Ensure that the bolts which secure the front flameproof enclosure are fully tightened. The

securing bolts are stainless steel M5 X 16mm socket head cap screws grade A4-70. To

ensure replacement suitability contact Senscient or their approved agent/distributor.

12. Do not open the enclosure in the presence of an explosive atmosphere. Keep cover tight

when energised

13. The apparatus is certified for use in Hazardous Areas at atmospheric pressures not

exceeding 1.1 bar (16 psi).

14. Install only in environments with ambient temperature ranges of -40°C to +60°C.

15. For Europe (ATEX), apparatus incorporates an integral threaded cable entry (M25 x 1.5).

Terminate cable only with a suitable equipment certified ATEX cable gland (not a

component). To maintain water and dust ingress protection seal threads with suitable nonhardening sealant as described in IEC/EN 60079-14.

Note: See control drawing for product specification allowing selection of cable glands.

Page 4

Safety

4

Senscient ELDS™

Rev 15

GB

WARNING

16. For US/Canada the apparatus incorporates an integral threaded conduit entry (3/4”-14TPI).

Install a conduit seal within 18 inches. In order to maintain ingress protection seal threads

with a suitable material e.g. a non-hardening thread sealant or PTFE tape etc. See control

drawing at the end of this manual.

17. For all installations use cable / conductors rated for service at temperatures ≥ 85°C

18. At all times during transit, installation and commissioning protect lens from accidental direct

mechanical impact. Use Senscient OEM supplied packaging during transit.

19. The Transmitter and Receiver units must be mounted horizontally and protected from impact

i.e. do not mount at floor level or in areas where moving vehicles, personnel or loads may be

of concern regarding impact.

CAUTION

1. Use only approved parts and accessories with the Senscient ELDS™ 1000 / 2000 Series

gas detectors.

2. To maintain safety standards, commissioning and regular maintenance of

ELDS™ 1000 / 2000 Series gas detectors should be performed by qualified personnel.

3. Transit cases for the alignment telescope and gassing cell are manufactured from nonantistatic materials, and may, under certain circumstances become an electrostatic risk. It is

the user’s responsibility to take adequate precautions during transportation and use if taken

into hazardous areas.

Important Notices

1. Senscient Inc. can take no responsibility for installation and/or use of its equipment if this is

not done in accordance with the appropriate issue and/or amendment of the manual. The

purchaser should make Senscient aware of any External effects or Aggressive substances

that the equipment may be exposed to.

2. The user of this manual should ensure that it is appropriate in all details to the exact

equipment to be installed and/or operated. If in doubt, the user should contact Senscient Inc.

for advice.

3. Effect of explosive atmosphere on materials.

The Senscient ELDS™ 1000 / 2000 Series is manufactured from materials which exhibit good

resistance to corrosive substances and solvents. The Ex d enclosures are made from 316L

stainless steel and the explosion protected windows are made from robust and chemically

inert glass. Senscient are not aware of any significant effects of explosive atmospheres upon

these materials. The purchaser should make Senscient aware of any External effects or

Aggressive substances that the equipment may be exposed to.

4. The final and long term effectiveness of any Gas Detector depends heavily upon the user, who

must be responsible for its proper application, installation and regular maintenance.

Senscient Inc. reserves the right to change or revise the information supplied in this document

without notice and without obligation to notify any person or organisation of such revision or

change.

If further details are required that do not appear in this manual, contact Senscient or one of their

agents. Senscient will supply this manual in other languages of the European Union (countries

covered by the ATEX directive) upon request.

Page 5

Safety

Senscient ELDS™

Rev 15

5

GB

Help Us to Help You

Every effort has been made to ensure the accuracy in the contents of our documents. However,

Senscient can assume no responsibility for any errors or omissions in our documents or their

consequences.

Senscient would greatly appreciate being informed of any errors or omissions that may be found in

our documents. To this end we request that if you believe there are any errors or omissions,

please send us an e-mail at info@senscient.com describing the error or omission, so that we may

take the appropriate action.

Page 6

Contents

6

Senscient ELDS™

Rev 15

GB

Contents

1. Introduction.................................................................................................................................. 8

1.1. Information Notices ........................................................................................................... 10

2. System Description ................................................................................................................... 11

2.1. Introduction ....................................................................................................................... 11

2.2. Transmitter ........................................................................................................................ 12

2.3. Receiver ............................................................................................................................ 13

2.4. Adjustable Mounting Bracket ............................................................................................ 14

2.5. Sunshades ........................................................................................................................ 15

2.6. Cross Duct Mounting Plates ............................................................................................. 17

2.7. SITE Installation & Maintenance Software........................................................................ 19

3. Installation Design & Engineering ........................................................................................... 31

3.1. Introduction ....................................................................................................................... 31

3.2. Siting and Mounting .......................................................................................................... 32

3.3. Electrical Connections....................................................................................................... 44

4. Installation & Commissioning .................................................................................................. 56

4.1. Unpacking an ELDS 1000 / 2000 Series System ............................................................. 56

4.2. Installation Procedure ....................................................................................................... 59

4.3. Alignment .......................................................................................................................... 64

4.4. Cross Duct – Alignment Requirements ............................................................................. 79

4.5. Commissioning Using SITE .............................................................................................. 83

4.6. ELDS Bluetooth™ Wireless Connection ......................................................................... 103

4.7. Installation Checklist ....................................................................................................... 105

5. Functional Testing .................................................................................................................. 108

5.1. Introduction ..................................................................................................................... 108

5.2. SimuGas™ Auto ............................................................................................................. 111

5.3. SimuGas™ Live .............................................................................................................. 113

5.4. SimuGas™ Levels .......................................................................................................... 114

6. Maintenance ............................................................................................................................. 115

6.1. Scheduled Inspection, Cleaning & Testing ..................................................................... 115

6.2. Cleaning Lens-Windows ................................................................................................. 116

Page 7

Contents

Senscient ELDS™

Rev 15

7

GB

7. Problem Solving ...................................................................................................................... 118

7.1. The Commonest Problems, Issues or Misconceptions Affecting Successful Use of

ELDS OPGDs ................................................................................................................. 118

7.2. SITE Diagnostics Screen ................................................................................................ 120

7.3. Troubleshooting Tables................................................................................................... 125

7.4. Event Logs ...................................................................................................................... 129

8. Specifications .......................................................................................................................... 132

8.1. System ............................................................................................................................ 132

9. Certification.............................................................................................................................. 138

9.1. General............................................................................................................................ 138

10. Appendix A – Glossary ........................................................................................................... 143

10.1. Terminology .................................................................................................................... 143

10.2. Measurement Units ......................................................................................................... 143

10.3. Abbreviations .................................................................................................................. 144

11. Appendix B – Accessories & Spare Parts ............................................................................ 145

11.1. ELDS™ Accessories & Spare Parts ............................................................................... 145

12. Appendix C – Functional Testing Using Gas ....................................................................... 147

12.1. Introduction ..................................................................................................................... 147

12.2. Testing with the Gassing Cell ......................................................................................... 147

12.3. Testing Cross Duct ELDS Systems with the Refillable Gas Test Cell ............................ 153

13. Appendix D – Manufacturer’s EC Declarations .................................................................... 158

14. Appendix E – HART Communications .................................................................................. 161

14.1. Overview ......................................................................................................................... 161

14.2. Electrical Connections / Configuration ............................................................................ 161

14.3. Details of ELDS Data Available via HART ...................................................................... 164

15. Appendix F – MODBUS Communications ............................................................................ 168

16. Appendix G – Measurement Range Guidelines ................................................................... 172

17. Appendix H – 4-20mA Current Output Ranges .................................................................... 179

Page 8

Introduction

8

Senscient ELDS™

Rev 15

GB

1. Introduction

The Senscient ELDS™ 1000 / 2000 Series is a range of open path, flammable and / or toxic gas

detectors that is currently available in the following versions.

Senscient ELDS™ Series 1000 CH

4

- Methane Detector

Senscient ELDS™ Series 1000 Ethylene, HF, HCl, NH

3

or CO2 Detectors

Senscient ELDS™ Series 1000 XD – Cross Duct Methane Detector

Senscient ELDS™ Series 2000 H

2

S - Hydrogen Sulfide Detector

Senscient ELDS™ Series 2000 CH

4

+ H2S - Simultaneous Methane &

Hydrogen Sulfide Detector

The Senscient ELDS™ Series 1000 detector consists of a Transmitter unit that sends an infrared

laser beam to a separate Receiver unit that can be installed on a line-of-sight at a distance of up to

200m. The ELDS 1000 Series CH

4

detector can be located where there is a risk that a leak of

flammable methane gas may occur, to provide a rapid, early warning of such a hazard. The

ELDS™ 2000 variants are similar, except that there are two coinciding infrared laser beams, which

can either be used to detect two or more gases, or to detect a single, difficult gas with high

sensitivity (e.g. Hydrogen Sulfide).

All ELDS™ gas detectors operate on the principle of absorption of infrared laser light. Gases

absorb light at specific wavelengths depending on their molecular composition. Hydrocarbon

gases such as methane and propane absorb in the infrared region of the spectrum. If a cloud of

target gas is present, the specific wavelengths of the infrared laser light output by the ELDS™

Transmitter are absorbed by the gas, introducing Harmonic Fingerprints onto the signals reaching

the Receiver that are proportional to the amount of gas in the beam.

The Senscient ELDS™ Transmitter unit produces the precisely controlled infrared laser light

required to detect the target gases; whilst the Receiver unit contains an infrared detector and

advanced signal processing electronics which look for the Harmonic Fingerprint produced by the

presence of target gas in the beam-path. Each unit is housed in a robust 316L stainless steel

housing. The Receiver features two 4 - 20mA analogue outputs which are used to signal the

quantity of each target gas measured in the beam-path, for example 0-1LFL.m CH

4

and

0-250ppm.m H

2

S for the Series 2000 detector. These outputs provide a linear relationship with the

measured gas burden.

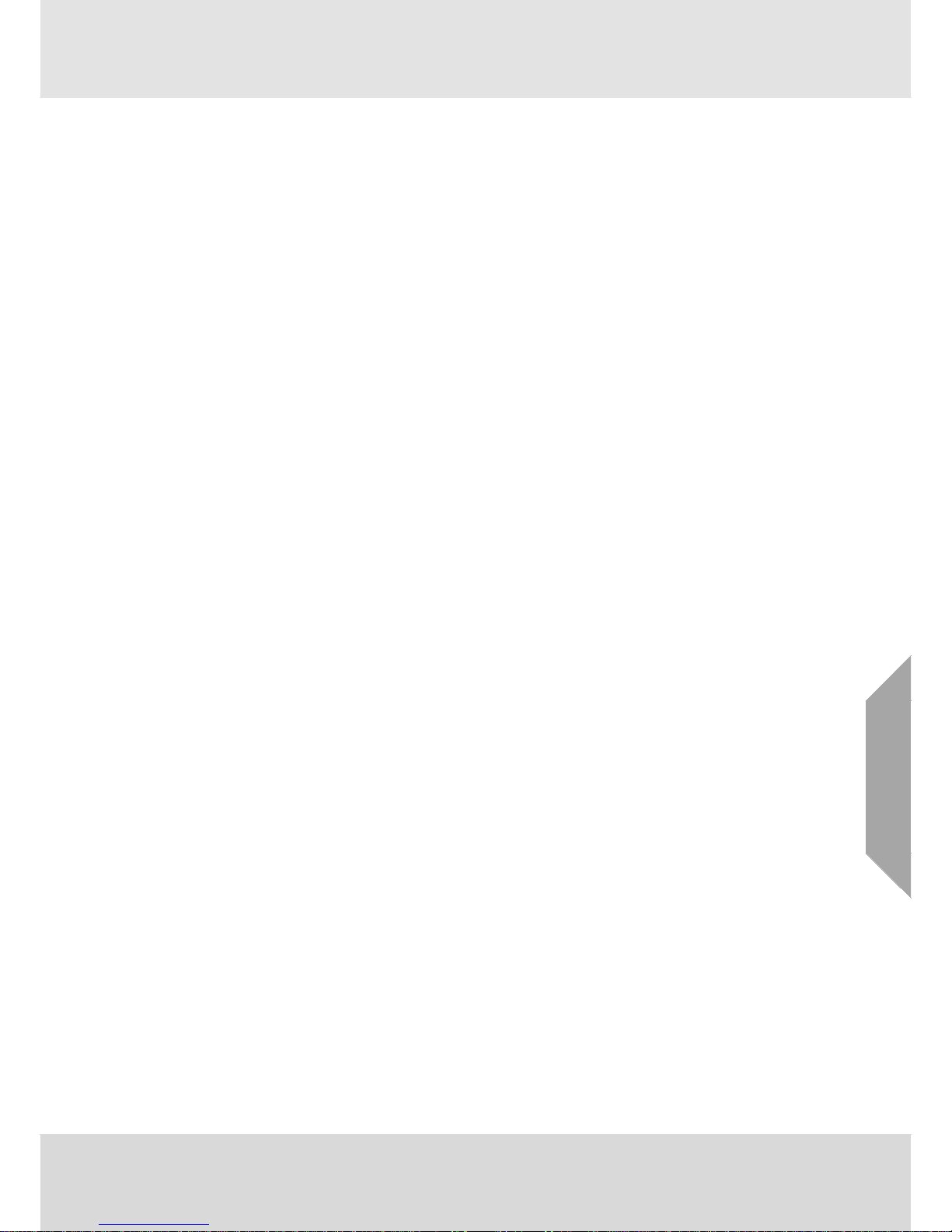

Note that open path detectors do not measure the point concentration of the target gas(es), rather

they measure the integrated concentration over the length of the measurement path between the

Transmitter and Receiver units. This means that the probable size of a gas cloud must be

considered when estimating the concentration of gas that might be present, with alarm levels

being set accordingly. The figures on the following page illustrate this.

Page 9

Introduction

Senscient ELDS™

Rev 15

9

GB

Each of these different gas clouds will produce the same ELDS reading of 1.0 LFL.m, however

only the 1

st

example where the gas cloud is very small actually has a potentially flammable

concentration within it.

THE TRANSMITTED LASER BEAM IS CLASS 1 (EYE-SAFE) PER IEC 60825.

Senscient ELDS™ is designed for use in the most demanding environments/applications and

provides a sensitive, fast and reliable response. The sophisticated ELDS™ open-path technology

provides immunity to sunlight and minimises the effects of environmental factors such as rain, fog,

ice, snow and condensation.

The Transmitter and Receiver units incorporate heated optics designed to minimise the build-up of

humidity, condensation, snow or ice on the glass lens-windows that could otherwise obscure the

optics in extreme conditions.

Both the Transmitter and the Receiver are microprocessor controlled with advanced selfdiagnostics and fault finding facilities.

Local communication between an operator/technician and the gas detector system is provided via

SITE (Senscient Installation & Test Environment) software running on an industrial computer,

using an RS485 or Bluetooth™ wireless communication link to either the Transmitter or Receiver.

SITE provides the user with a menu-style interface to select and invoke commands for

commissioning and configuring the system; and for viewing the system status and readings.

Page 10

Introduction

10

Senscient ELDS™

Rev 15

GB

1.1. Information Notices

The types of information notices used throughout this handbook are as follows:

WARNING

Indicates hazardous or unsafe practice which could result in severe injury or death to personnel.

CAUTION

Indicates hazardous or unsafe practice which could result in minor injury to personnel, or product

or property damage.

Provides useful/helpful/additional information.

If more information beyond the scope of this technical manual is required please contact

Senscient.

Page 11

System Description

Senscient ELDS™

Rev 15

11

GB

2. System Description

2.1. Introduction

Each Senscient ELDS™ 1000 / 2000 Series gas detector consists of two units, a Transmitter and

a Receiver. This separate Transmitter / Receiver configuration provides the most reliable basis for

open path gas detection. There are no transceiver units or retro-panels utilised in the Senscient

ELDS™.

There are several operating ranges of Senscient ELDS™ gas detector, e.g.:

Series 1000 CH

4

, 0 - 1000ppm.m, 0 - 1LFL.m 5 - 40m

40 - 120m

120 - 200m

Series 2000 CH4 0 - 1LFL.m + H2S 5 - 60m

Series 1000 XD CH4 0 - 10%LFL, 0 - 25%LFL, 0 100%LFL 0.5 - 5m

Series 1000 Ethylene 5 - 60m

40 - 120m

120 - 200m

Series 1000 HF 5 - 60m

60 - 120m

Series 1000 HCl 5 - 60m

Series 1000 NH3 5 - 40m

40 - 120m

Series 1000 CO2 5 - 40m

40 - 120m

Refer to Senscient for additional ranges and gases.

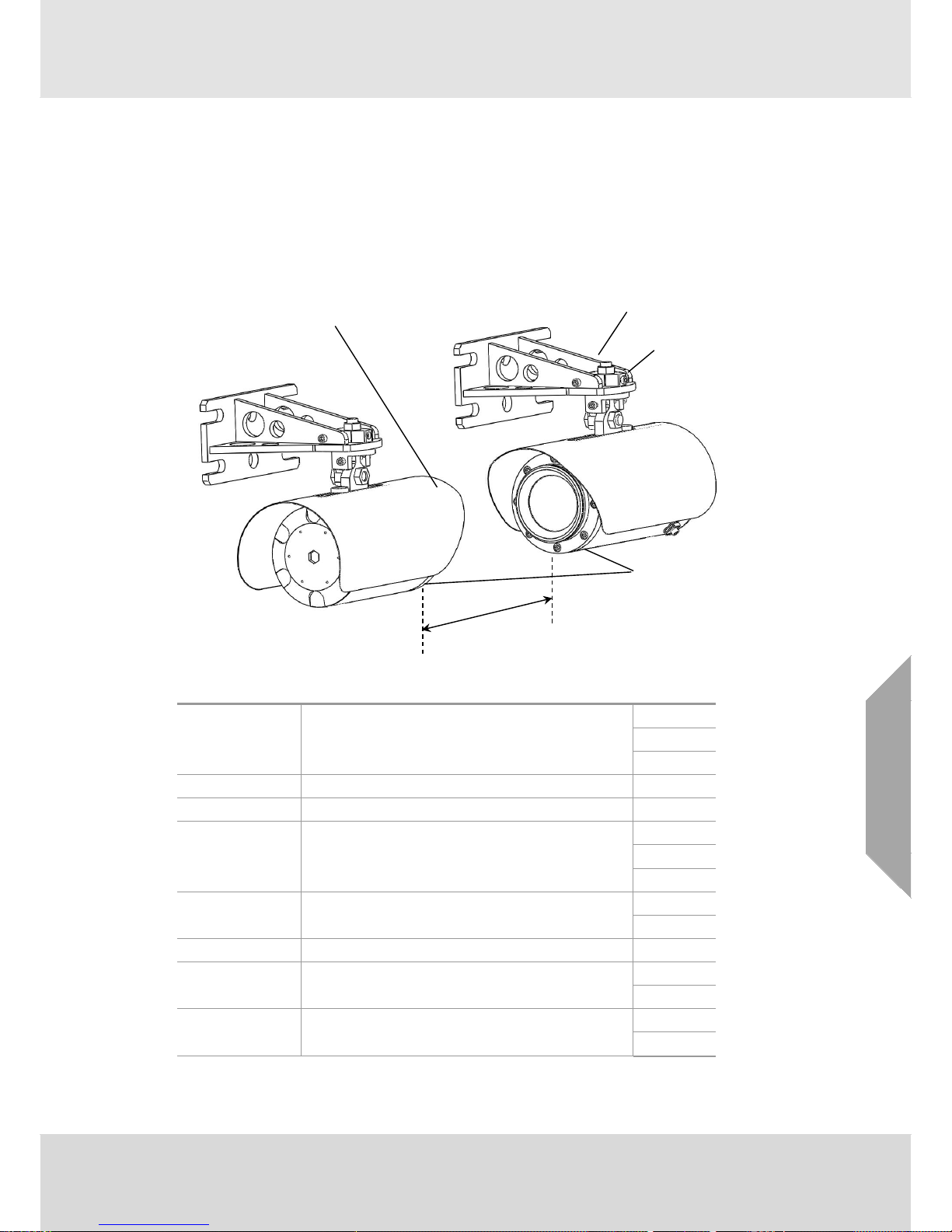

Sun Shade

Monitored Path

Tx and Rx Units

Alignment Adjustment

(horizontal and vertical)

Mounting Bracket

Page 12

System Description

12

Senscient ELDS™

Rev 15

GB

When designing an installation for Senscient ELDS™ 1000 / 2000 Series it is important

that the correct range of the gas detector for each path to be monitored is selected and

specified.

In order to avoid the problems associated with gas detectors being used beyond their

specified ranges or when incorrectly aligned, a procedure within the Senscient

Installation & Test Environment (SITE) checks for correct gas detector type, operating

range and signal levels before allowing an ELDS OPGD to be commissioned.

The Transmitter and Receiver are each mounted upon robust, adjustable mounting brackets. The

design of the mounting and alignment arrangement for the Senscient ELDS™ 1000 / 2000 Series

is highly accommodating, making it simpler to realise a good installation in a variety of locations

and environments. Installation details are given in section 3.

2.2. Transmitter

The Senscient ELDS™ Transmitter produces up to two controlled-divergence beams of infrared

laser light from solid-state laser diodes. The outputs from the laser diodes are partially collimated

using a faceted lens, the facets of which introduce the controlled-divergence that is necessary to

reduce system alignment sensitivity. The Transmitter operates continuously.

THE TRANSMITTED LASER BEAM IS CLASS 1 (EYE-SAFE) PER IEC 60825.

The Transmitter contains a small retained sample of the target gas(es) to be detected by the

system; and uses this retained sample as a reference to maintain its laser diode(s) in Harmonic

Fingerprint lock. By continuously maintaining Harmonic Fingerprint lock it is possible to be certain

that whenever target gas(es) enter the system’s beam-path this will introduce Harmonic

Fingerprints onto the laser signal(s), which will be seen and measured by the Receiver.

Maintaining Harmonic Fingerprint lock maintains detector calibration and ensures that SimuGas™

simulations faithfully simulate the presence of a pre-defined quantity of target gas(es) in the beampath. This is the basis of the SimuGas on-demand functional test technology incorporated in

Senscient’s ELDS OPGDs.

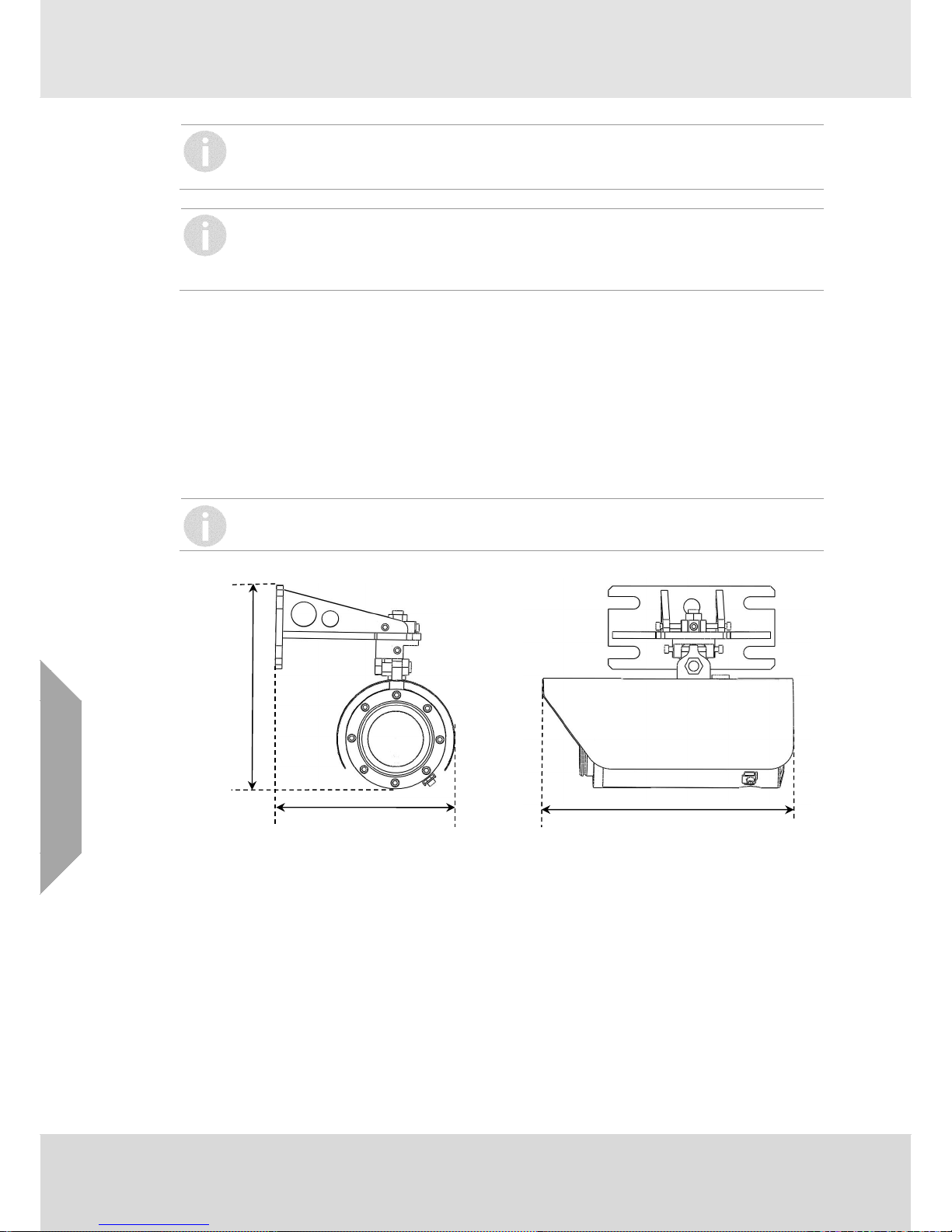

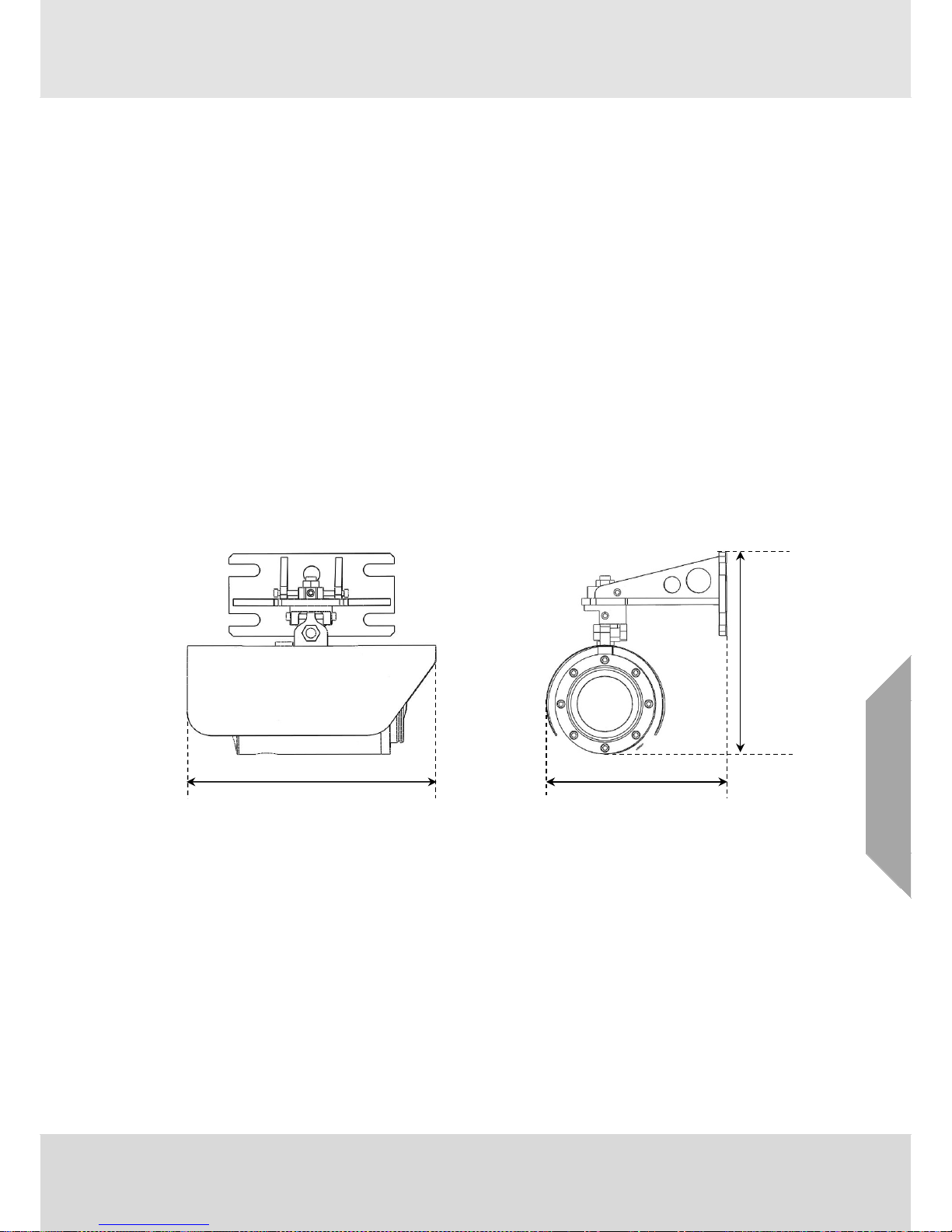

220mm

300mm

245mm

Page 13

System Description

Senscient ELDS™

Rev 15

13

GB

The Transmitter also incorporates links which can be used to communicate with an industrial

computer. Using SITE and these communication links, an industrial computer can be employed to

perform alignment checks, commissioning, configuration, functional testing, diagnostic procedures

and SimuGas™ tests.

The Transmitter window is heated to minimise condensation, frosting and the build-up of snow.

Three connections to the Transmitter are required, +24V, 0V and GND (for electrical safety).

2.3. Receiver

The Senscient ELDS™ Receiver collects infrared laser light from the Transmitter and determines

the size of any Harmonic Fingerprint components that have been introduced onto the beam(s) to

establish the quantity of any target gases present in the beam-path

The Receiver collects and concentrates infrared laser light from the Transmitter onto a single,

infrared detector using an aspheric, condensing lens-window. The detector output is amplified and

processed by a sophisticated electronic signal processing system which effectively removes any

ambient light and extracts Harmonic Fingerprint information related to the quantity of target gas in

the beam-path. The detector amplification chain incorporates an advanced Automatic Gain Control

(AGC) system that enables it to compensate for the wide range of signal levels that can be

received due to effects arising from rain, fog, snow, dirt etc. This enables the ELDS 1000 / 2000

Series to continue operating reliably in the harshest conditions that are likely to be encountered at

Oil & Gas installations around the world.

The solid state, InGaAs photodiode detectors used in the Senscient ELDS™ 1000 / 2000 Series

provide an exceptional dynamic range and superb temperature and long term stability. These

properties contribute significantly to the solar immunity and stability of the Senscient ELDS™

1000 / 2000 Series.

The primary output(s) of the Receiver are two 4-20mA loop outputs which can be configured for

source, sink or two-wire isolated operation. The outputs are factory calibrated to provide the

appropriate full scale range for the measured species and model variant. The output is typically

calibrated in units of LFL.m or ppm.m (see section 10.2 for the explanation of LFL.m and other

terms).

The Receiver also incorporates links which can be used to communicate with an industrial

computer. Using SITE and these communication links, an industrial computer can be employed to

perform alignment checks, commissioning, configuration, functional testing, diagnostic procedures

and SimuGas™ tests.

The Receiver window is heated to minimise condensation, frosting and the build-up of snow.

300mm

220mm

245mm

Page 14

System Description

14

Senscient ELDS™

Rev 15

GB

Between four and eight connections to the Receiver are required, depending upon the number and

configuration of the 4-20mA outputs used. These connections are required to provide +24V, 0V,

4-20mA(1), 4-20mA(2) and GND (for electrical safety).

The ELDS system does not have any gas alarm set functions. The 4-20mA signal outputs from the

Receiver are non-latching. If the ELDS system is intended to indicate a potentially flammable gas

concentration then any auxiliary equipment (e.g. control room plc, control unit or monitoring

apparatus etc.) shall have an alarm set point that is latching, requiring a deliberate action to reset.

If two or more set or alarm functions are provided the lower may be non-latching.

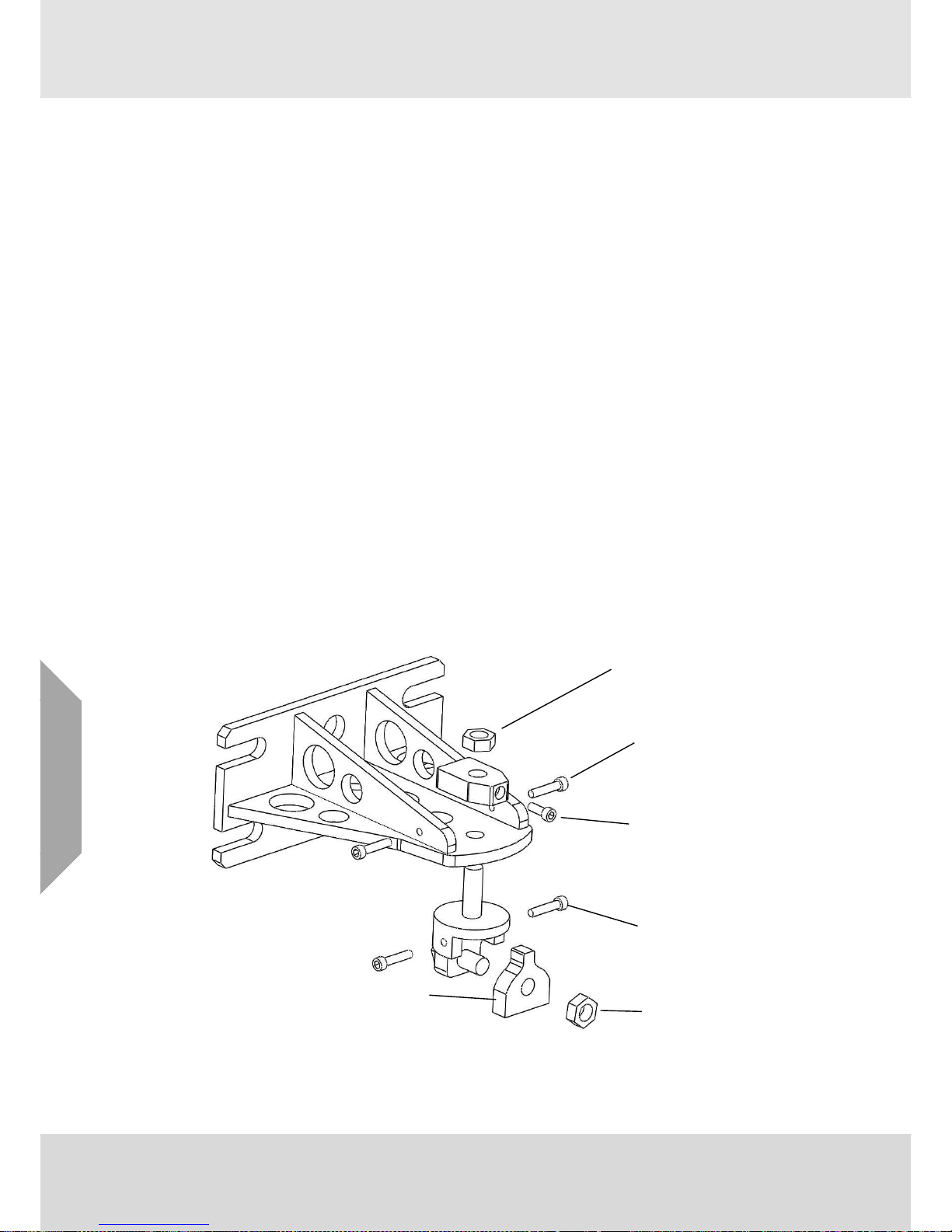

2.4. Adjustable Mounting Bracket

The adjustable mounting brackets for the ELDS 1000 / 2000 Series are:

Purpose-built for the Transmitter and Receiver.

Provide coarse and fine adjustment for quick, simple system alignment.

Rigid, stable and robust.

Made from 316L stainless steel.

The coarse horizontal adjustment facility enables a Transmitter or Receiver to be quickly pointed in

the approximate direction of its counterpart and provides a full 360º of rotation. The fine horizontal

adjustment facility enables a Transmitter or Receiver to be precisely aligned and locked-off with

respect to its counterpart, and has an adjustment range of ±25º.

The fine vertical adjustment facility enables a Transmitter or Receiver to be precisely aligned and

locked-off with respect to its counterpart and has an adjustment range of ±15º.

Alignment details are given in section 4.

Clamp nut

Mounting bracket

adjusting screw (2 off)

Adjustment clamp

lock screw

Pivot block adjusting

screw (2 off)

Clamp nut

Mounting Lug (on unit body)

Page 15

System Description

Senscient ELDS™

Rev 15

15

GB

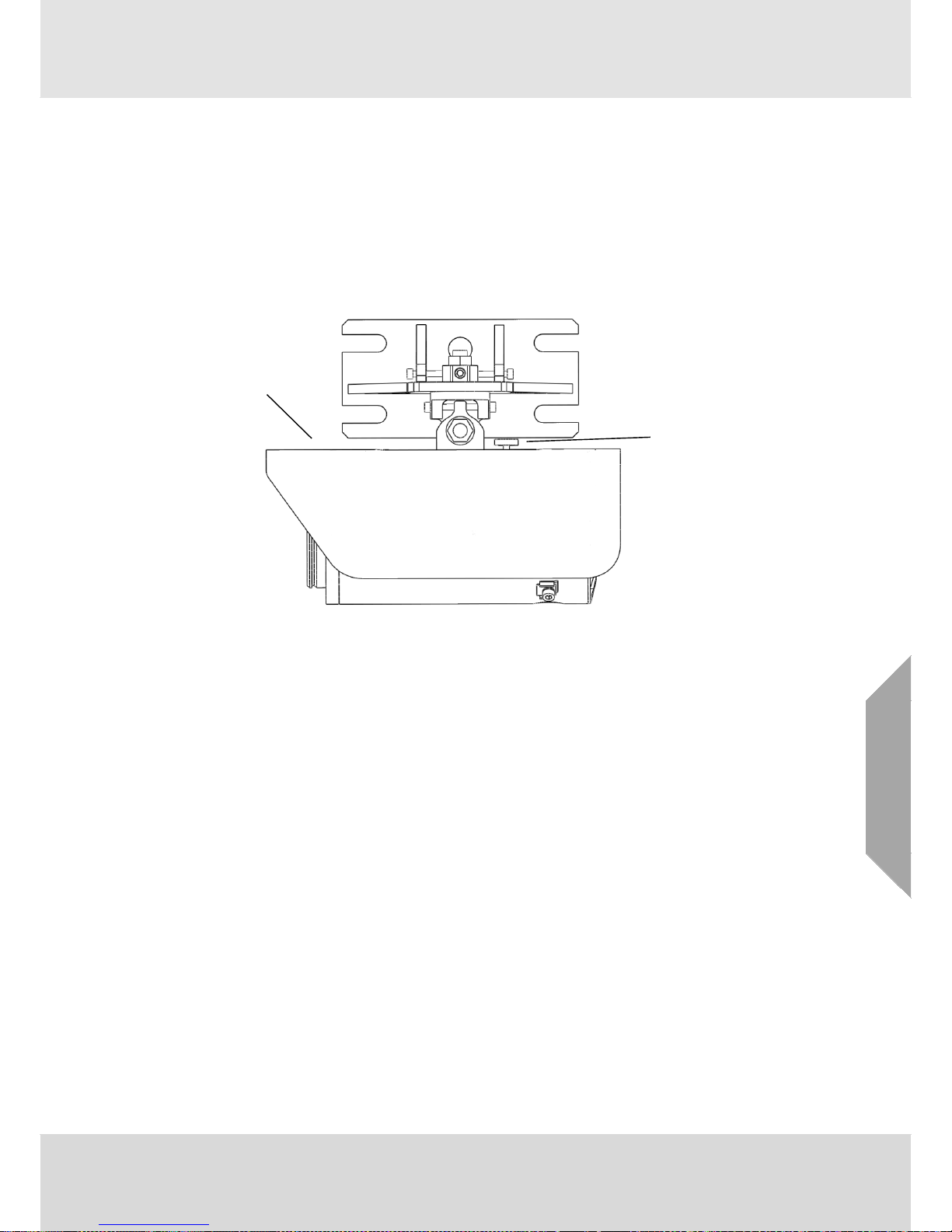

2.5. Sunshades

In order to provide Sun shading which is optimal for a wide range of operating climates, there are

two sunshades available for use with ELDS™ units.

2.5.1 Standard Sunshade

The standard sunshade is suitable for use in cold, temperate and moderately warm climates; and

is fitted along the mounting bar on the top of each ELDS™ unit. This sunshade’s position is

adjustable in order to facilitate use of the alignment telescope or provide easier access to the

electrical connections inside the terminal compartment.

The standard sunshade is fixed by a single retaining screw as illustrated. Loosen this in order to

allow adjustment of the position of the sunshade. Tighten the retaining screw to ensure that the

sunshade remains in the desired position.

Sunshade

Retaining Screw

Page 16

System Description

16

Senscient ELDS™

Rev 15

GB

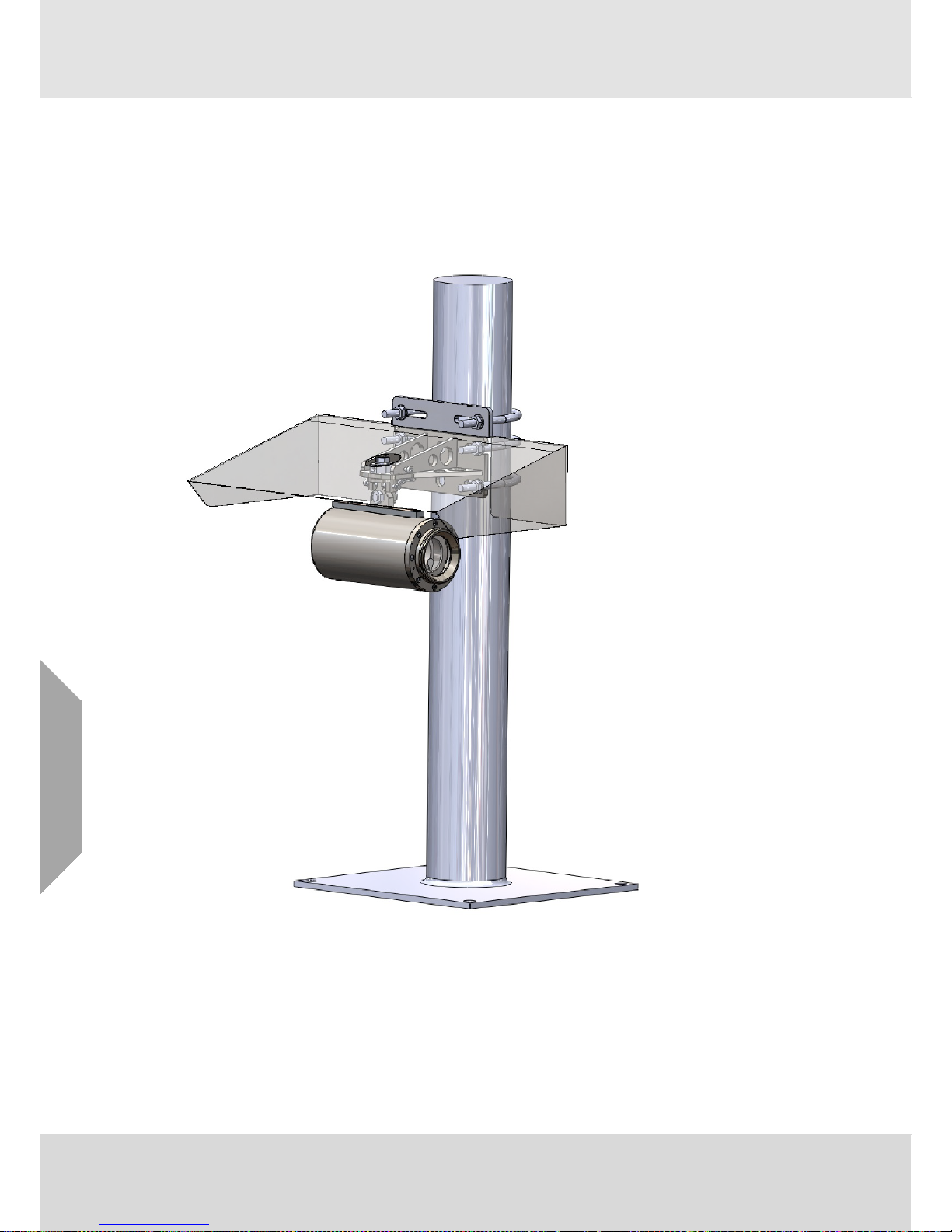

2.5.2 Enhanced Sunshade

The enhanced sunshade is designed for use in hot climates where intense, direct sunlight has the

potential to significantly increase the operating temperature of ELDS™ units unless greater

shading from solar radiation is provided. The enhanced sunshade is fitted above the mounting

bracket, attached to the same pole, wall or mounting structure that the mounting bracket is

attached to (see illustration below).

Depending upon the particular details of the installation, it may be necessary to temporarily

remove the enhanced sunshade in order to gain access to the terminal compartment or use the

alignment telescope. Make sure to re-fit the enhanced sunshade after completing any activities

that temporarily require its removal.

Page 17

System Description

Senscient ELDS™

Rev 15

17

GB

2.6. Cross Duct Mounting Plates

Cross Duct ELDS systems are designed to be mounted on the opposite sides of flat, parallelwalled ducts using one of three (3) available variants of Mounting Plate, or the standard Adjustable

Mounting Bracket (ELDS VZ unit only).

The installation designer’s attention is drawn to the fact that each Transmitter or Receiver

unit of a Cross Duct ELDS system weighs approximately 10kg, which may be sufficient to

cause unwanted bending of duct walls, especially if the duct walls are thin.

2.6.1 Standard Cross Duct Mounting Plate

The standard, 400mm x 400mm mounting plate substantially spreads the weight / load and

provides localised reinforcement of the duct wall; and is therefore recommended for use wherever

possible – and in particular on thin-walled ducts.

2.6.2 Small Cross Duct Mounting Plate

The small, 250mm x 250mm mounting plate is capable of being mounted on smaller ducts; but

consideration needs to be given as to how the weight / load will affect the duct wall when units are

so mounted. Local reinforcement / bracing of the duct wall may be required.

The installation Design Authority is responsible for ensuring that the method chosen for

mounting Cross Duct ELDS units on the intended duct is sufficiently rigid and stable.

Page 18

System Description

18

Senscient ELDS™

Rev 15

GB

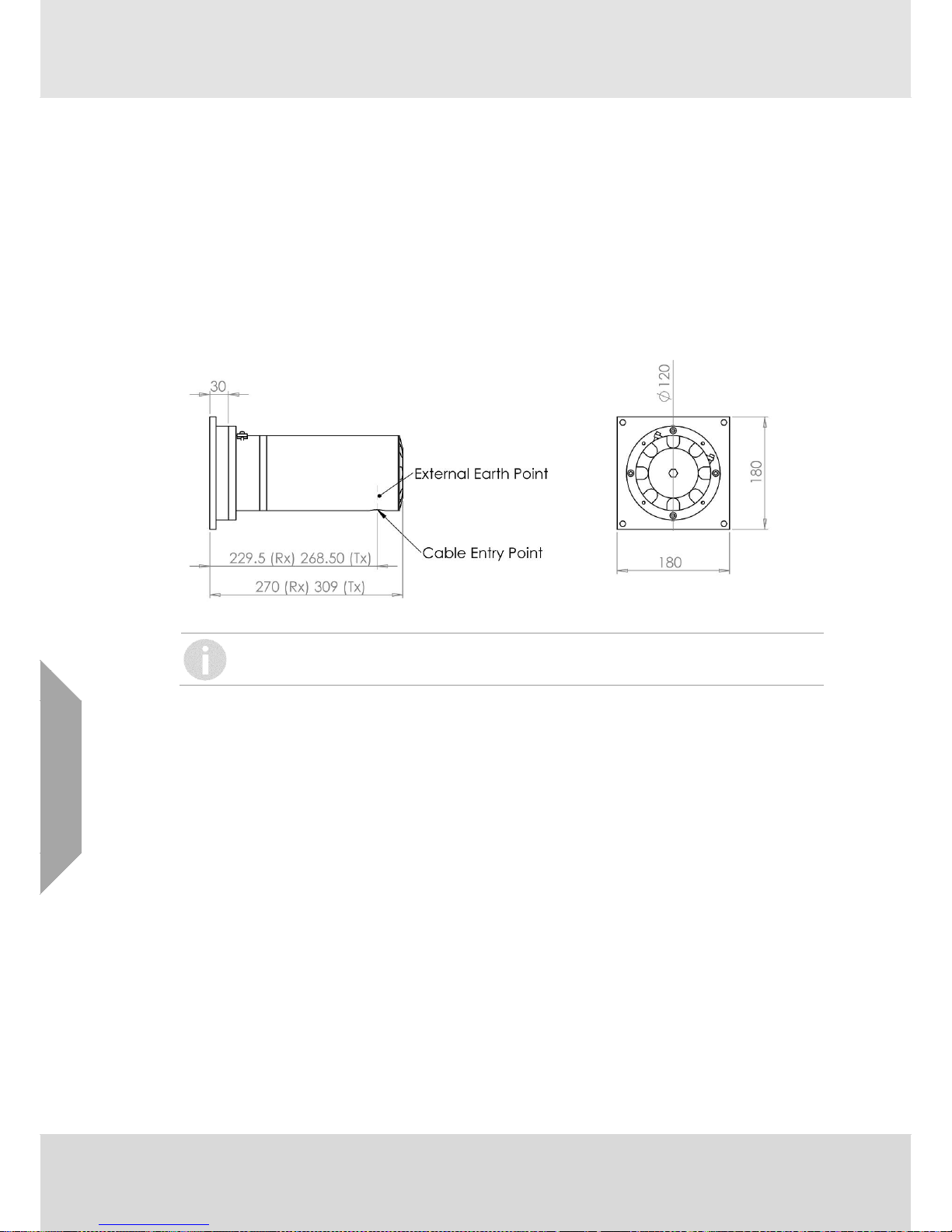

2.6.3 Retrofit Cross Duct Mounting Plate

The 180mm x 180mm retrofit mounting plate is capable of being mounted on the same mounting

holes as an earlier generation of Cross Duct unit supplied by another manufacturer. There is a

reasonable likelihood that mounting Cross Duct ELDS units on ducts using the retrofit mounting

plate will cause bending of the duct wall. Consequently, this method of mounting Cross Duct ELDS

units should only be considered for retrofit applications where it is impossible or impractical to

engineer a superior mounting arrangement. In such circumstances, the installation Design

Authority should also consider local reinforcement / bracing of the duct wall to reduce bending;

and / or the use of alignment adjustment bushings* to provide compensation for such bending.

NB: Customer / user should retain the original installation’s internal plates - to which this retrofit

mounting plate will be attached.

The installation Design Authority is responsible for ensuring that the method chosen for

mounting Cross Duct ELDS units on the intended duct is sufficiently rigid and stable.

* Alignment adjustment bushings are available from Senscient (Part Number A-5126-0) for use

with Cross Duct ELDS systems where the duct walls are highly out-of-parallel, or have bent under

load by an amount greater than the angular tolerance of the Cross Duct ELDS system. Provided

that the angular errors arising from these sources are less than ±5° (per side) and the duct wall

deformation is relatively stable, the alignment adjustment bushings should be capable of returning

the alignment of Cross Duct ELDS systems to within their operational angular tolerance.

(NB: Alignment adjustment of ELDS VZ units is made possible by use of the standard Adjustable

Mounting Bracket.)

Page 19

System Description

Senscient ELDS™

Rev 15

19

GB

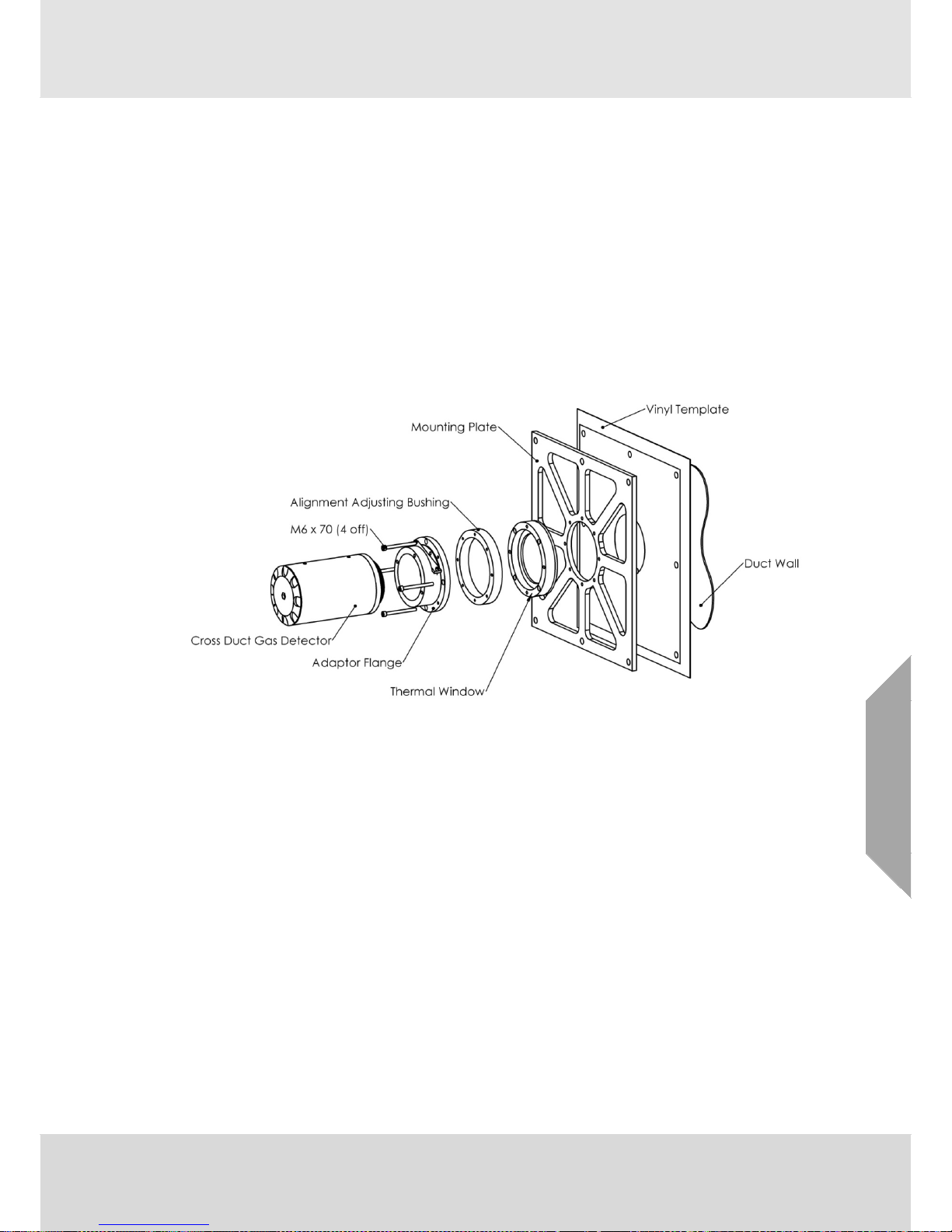

2.6.4 Thermal Window for Cross-Duct Units

In order to allow ELDS Cross Duct units to be mounted upon ducts which may temporarily reach

internal temperatures that are higher than the maximum upper service temperature for which

ELDS systems are certified (+60ºC), a mounting arrangement which includes a thermal window is

available. This arrangement insulates an ELDS unit’s lens-window from hot gases inside the duct,

allowing ELDS XD units to continue being used provided that air temperatures outside of the duct

are within the certified range.

Provided that there is adequate ventilation; and any in-duct temperature excursion is not of too

long a duration (≤ 15 minutes), it should be possible to mount and operate XD ELDS units on

ducts where air / gas temperatures inside the duct of up to 120ºC are temporarily present. Longer

term operation at high duct temperatures, or operation in conditions of restricted ventilation would

require measurement of the temperatures that the XD ELDS units become exposed to - in order to

ensure that the maximum certified operating temperature of +60ºC is not exceeded.

2.7. SITE Installation & Maintenance Software

SITE (Senscient Installation and Test Environment) is a software application provided by

Senscient to enable the installation, commissioning and testing of all types of ELDS OPGD

products; and is supplied pre-installed on ATEX or CSA (UL) certified industrial computers. Due to

the complexity of the computing and communications technologies employed by SITE, Senscient

can only provide support to users that are running SITE on factory tested and approved platforms.

SITE is capable of communicating with ELDS units either over RS485 or Bluetooth™ * wireless

communications links. The RS485 connection is made via a USB:RS485 adaptor included as part

of the installation kit. The Bluetooth™ connection is built into the industrial computer and is factory

activated and configured for use with SITE and ELDS units. More detailed information and

guidance with respect to the type of communication link to use when working with ELDS units is

provided in sections 4.5 to 4.7.

*All ELDS units can be commissioned using the RS485 communications link, regardless of their

type or age. From November 2011 onwards, Bluetooth™ communications were added alongside

RS485 with the introduction of Mod State 1, open-path, ELDS units. (The Mod State of ELDS units

can be found on the certification / serial number label on the terminal compartment cover.)

The necessary steps to commission a system using SITE are outlined in section 4.5 and some key

maintenance and problem solving guidance is provided in section 7.2. The following sections here

provide an overview of SITE itself.

Page 20

System Description

20

Senscient ELDS™

Rev 15

GB

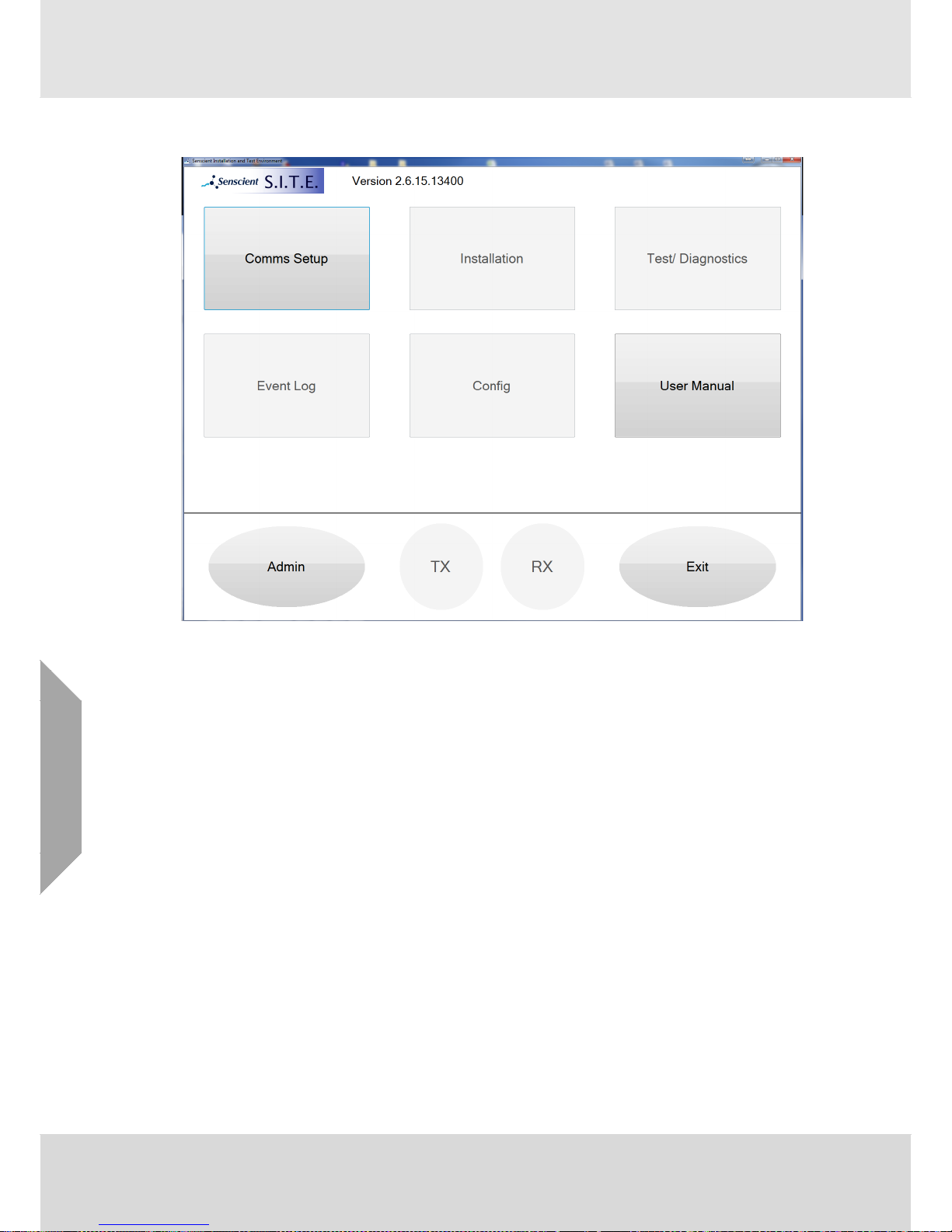

2.7.1 SITE Main Screen

The SITE screen is divided into two areas. At the top are a sequence of ‘buttons’ that are used to

access installation and maintenance facilities, to connect SITE to ELDS units and also to provide

access to this Technical Manual.

The area at the bottom provides access to various administration functions via the Admin button,

and also allows individual access to the Tx or Rx to be selected for operations initiated by the

Config, Event Log and Installation buttons.

An outline description of these functions is provided in the following sections, however more

detailed information is also provided in later sections of this document as individually detailed

below.

Note that the SITE version is presented at the top of the screen, 2.6.15.13400 in this example.

When SITE first starts this number is truncated to just the first 3 number groups (which is sufficient

to uniquely identify the SITE version), however clicking on the number will reveal the additional

group which defines the precise software build version as illustrated here.

Page 21

System Description

Senscient ELDS™

Rev 15

21

GB

2.7.2 Comms Setup

Selecting the Comms Setup button will open a separate dialogue as illustrated below which

facilitates connecting SITE to an ELDS Tx, Rx or both. Further details of this are provided in

section 4.5 as part of the commissioning instructions.

The majority of the functions available in SITE only become active once a connection to an ELDS

unit is made in this way. As illustrated above most of the buttons except Comms Setup,

User Manual and Admin are ‘greyed’ and unavailable until a connection is made.

The connection to an ELDS unit can be either via a wired (RS485) connector or via a Wireless RF

(Bluetooth) link, the appropriate option is initiated by selecting the required “radio button” selector.

The additional Modbus option is provided to allow units that are configured for Modbus operation

to be reverted back to ELDS communication over the RS485, this is necessary in order to utilise

any other facilities within SITE to maintain or inspect a unit via the RS485 link. Once connected via

the “MODBUS” option in this connection dialogue box it is possible ‘un-select’ Modbus operation in

the unit by navigating to the Config/Modbus page and clicking the option to disable Modbus.

Details of configuring Modbus are described in detail in section 2.7.6.

Once a connection is made then one of the indicators TX or RX at the bottom of the main SITE

screen will turn green and become slightly larger as illustrated here:

Page 22

System Description

22

Senscient ELDS™

Rev 15

GB

In this case both an ELDS Transmitter and Receiver has been connected, the ‘active’ connection

is to the Transmitter (the TX button is green and larger). To select the Receiver simply use the

mouse or touchpad to select (click on) the RX button which will then change to green and become

larger.

2.7.3 Installation

The installation button allows an ELDS Transmitter (see section 4.5.1 for more detail) or Receiver

(see section 4.5.2 for more detail) to be installed.

It is essential to install an ELDS Transmitter first when installing an ELDS system. This is

because essential calibration information must be copied from the Transmitter to the

Receiver, so SITE must access the appropriate Transmitter before any attempt is made to

install a particular Receiver. Once a Transmitter has been installed by SITE it will

remember the details of that unit and so it is not necessary to re-install the Transmitter if

the Receiver needs to be re-installed at a later date.

Select the appropriate unit to be installed (TX or RX) before selecting the Installation option.

2.7.4 Test/Diagnostics

The Test/Diagnostics button provides access to key information and test functions regarding the

connected ELDS unit(s). These functions are described in detail in section 7.2 with specific

information regarding the Receiver and Transmitter being in sections 7.2.1 and 7.2.2 respectively.

This option will provide information on either the Transmitter or Receiver or both depending

on which ELDS units are connected. If only one unit is connected then the whole of the

screen is filled with information regarding just that unit. If both a Transmitter and Receiver

then the screen will split vertically with the Receiver information on the left side and the

Transmitter on the right side.

2.7.5 Event Log

This button provides access to the internal ‘event’ log of the selected ELDS unit.

The ELDS unit selected for interrogation is determined by the TX or RX buttons at the

bottom of the SITE main screen. The larger (green) button identifies the unit that will be

examined.

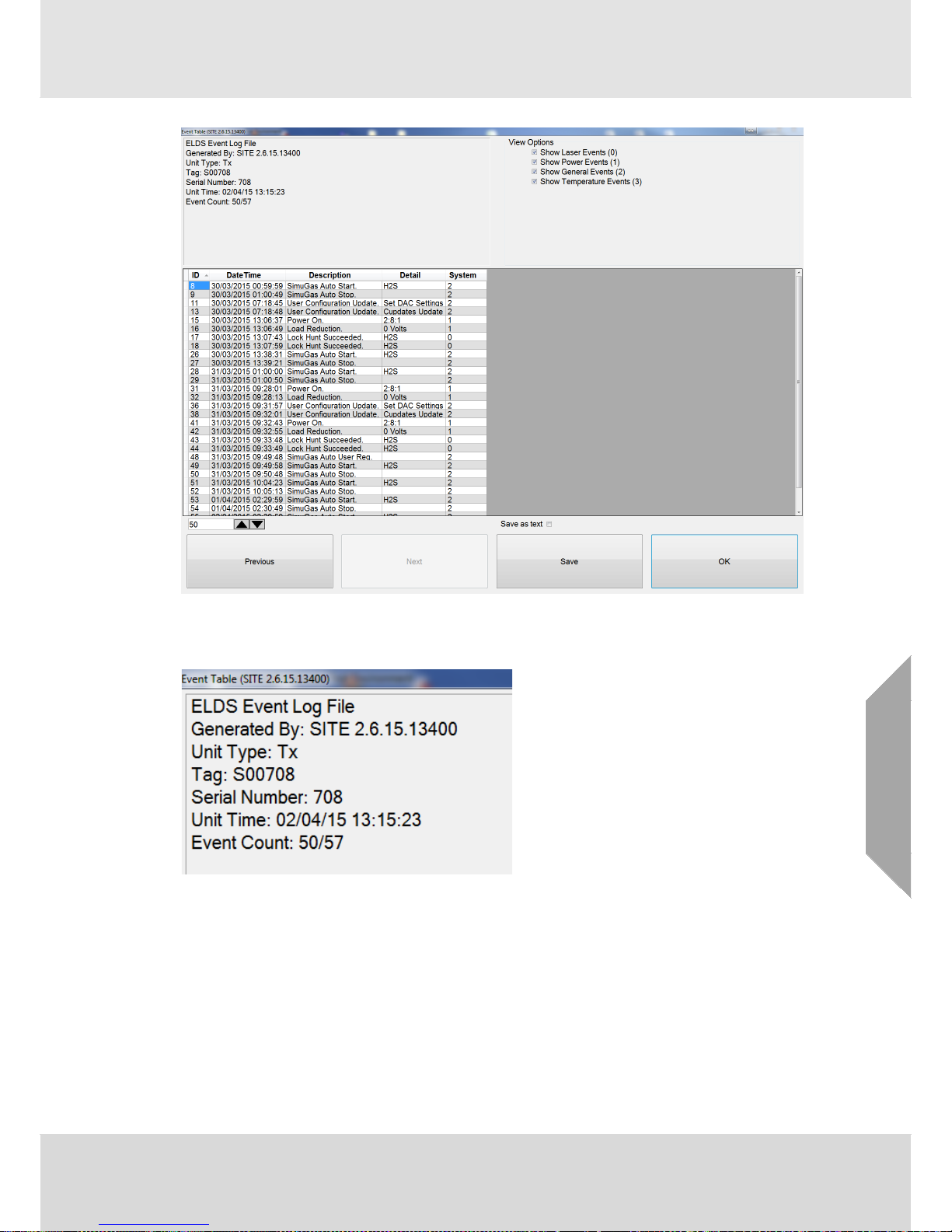

The following screen is presented and will normally be populated by the most recent 50 events

recorded in the ELDS unit selected.

Page 23

System Description

Senscient ELDS™

Rev 15

23

GB

The format and options of this event viewer screen are described in the following sections.

Header

The header information is presented in the top-left corner of the Events screen. Some key

information about the unit and SITE version is presented along with the time of the download

(based on the internal time in the ELDS unit) as well as an indication of the events selected. In this

example the display has selected (read) 50 events from the unit, however the total number of

events available is 57. Note that ELDS units can hold up to 186000 events, this is a rolling buffer

so once it becomes full the oldest events are discarded as new events are stored.

Page 24

System Description

24

Senscient ELDS™

Rev 15

GB

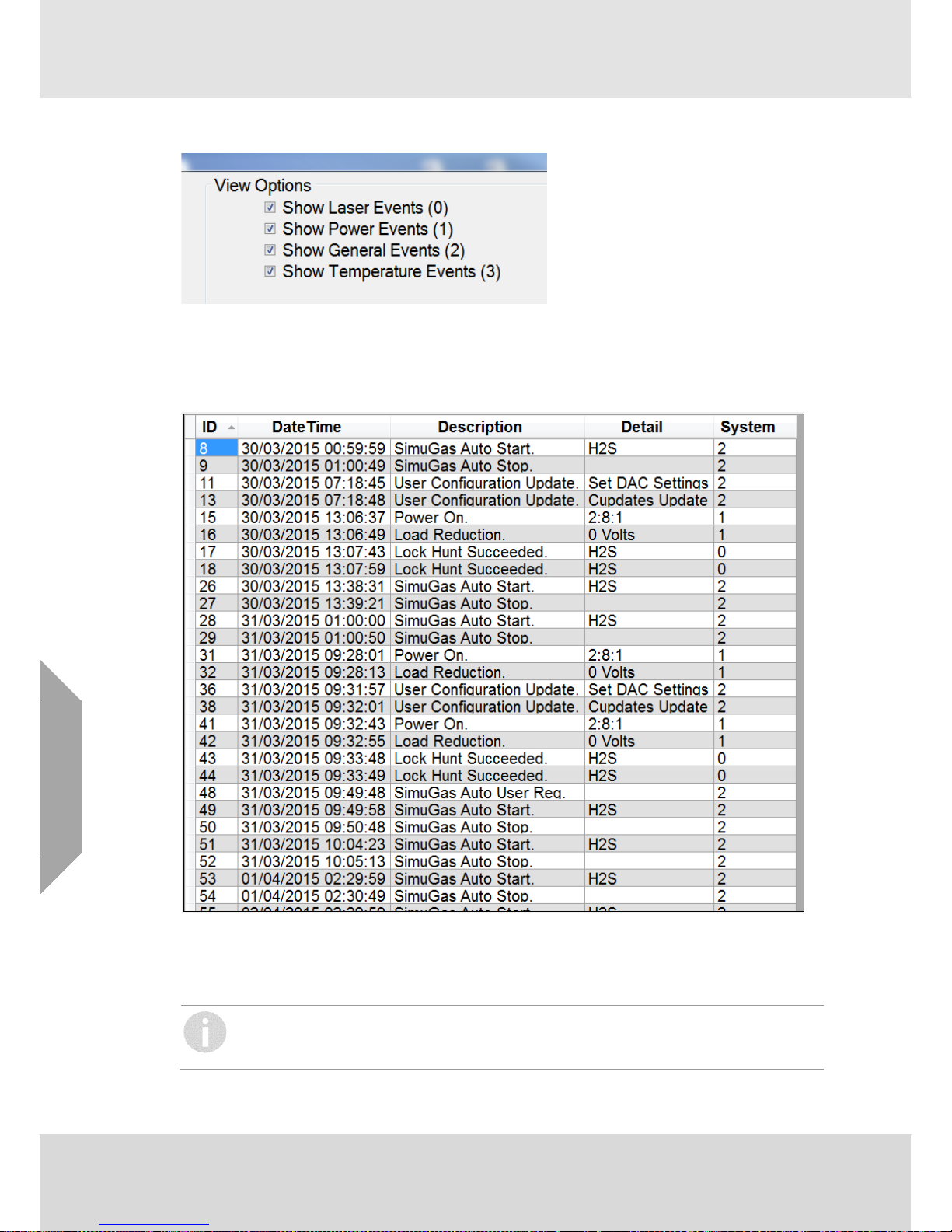

View Options

It is possible to filter the ‘class’ of events that are presented in the view by selecting/deselecting

the options in this area (top-right of the Events screen). By default all event classes are presented,

deselect the desired options to remove the associated events from the presentation.

Event List

The events are presented in the table area as illustrated here. Each event has an ID number which

is effectively an ‘index’ to the event number within the ELDS unit, a Date/Time field which indicates

the time that the event was created, a general Description field and for some events also a Detail

field. The System column refers to the event class (as is identified by the View Options above).

Some events within an ELDS unit relate to system processes and are not normally

displayed for users. These ‘housekeeping’ events have ID numbers associated

and explain

why the ID numbers may have ‘gaps’ as is the case in this example above.

Page 25

System Description

Senscient ELDS™

Rev 15

25

GB

It is possible to re-order the displayed events by clicking on the header of any of the columns. In

this example the events are ordered by ascending ID number (the default when the events are first

read). Pressing the ID column header will reverse this order, or pressing any of the other column

headers will order the events by the data in the appropriate column.

A detailed description of the events that may be displayed is presented in section 7.4 below.

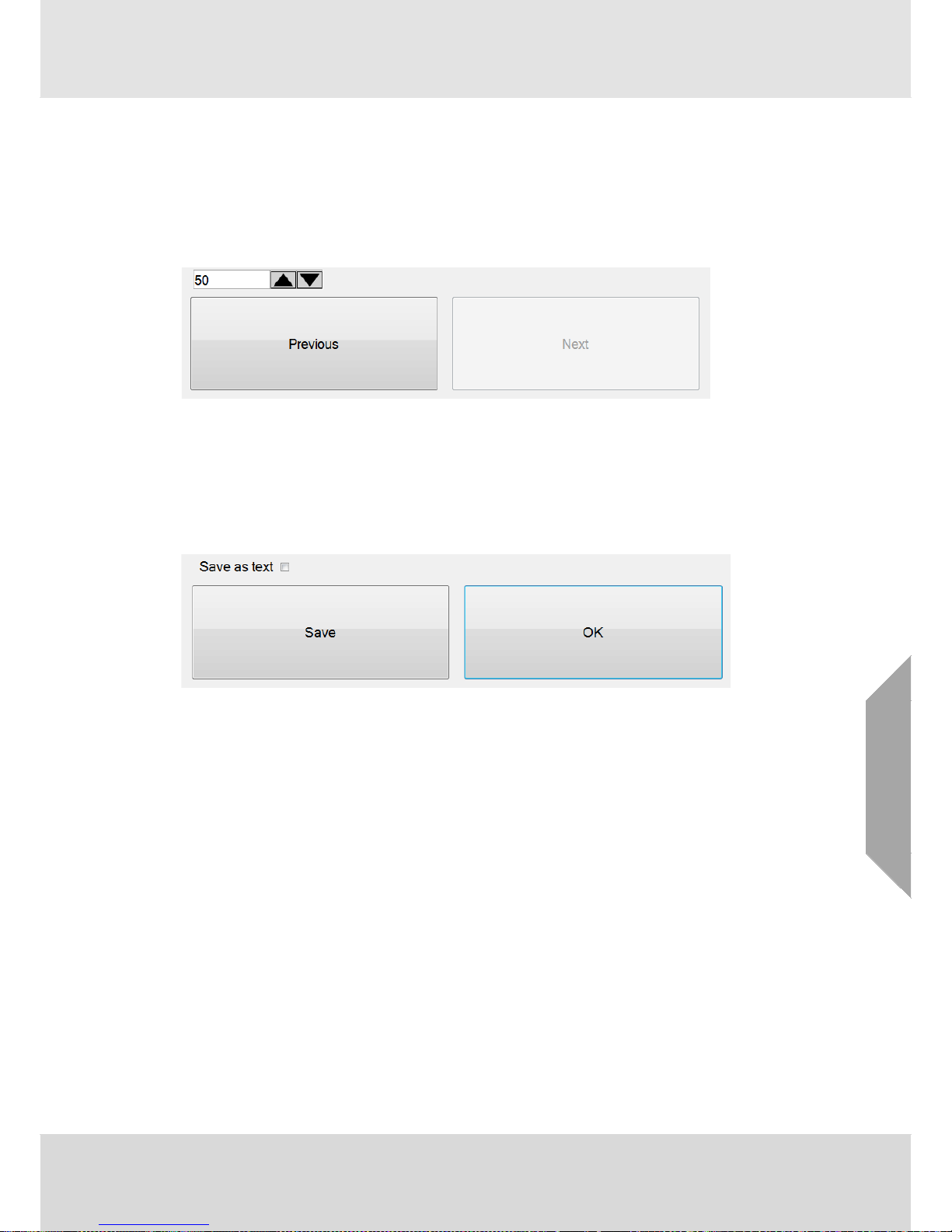

Read Options

SITE will initially read the last 50 events from the connected unit, however it is possible to

select/read further events if required by using the Previous or Next buttons at the bottom left of the

Events screen. Each press of these buttons will read the selected number of additional events

from the unit (determined by the numeric selection box).

If further events are not available then the appropriate button will be greyed and unavailable.

Output Options

The contents of the Event display can be output / saved to allow them to be incorporated into other

PC applications or to be supplied back to Senscient.

Pressing the Save button (bottom right of the Events screen) will output the data in an ‘internal’

format that can be used by Senscient to examine the event data in full detail. This is the preferred

format for supply of individual event information to Senscient (but note that Senscient generally

recommends supplying full ‘snapshots’ rather than just the events, see section 2.7.8).

Alternatively, if the “Save as text” checkbox is selected then the data is output as text format in a

“comma separate variable” (*.csv) file. Selecting this format is most useful if users wish to import

the event data into a spreadsheet for presentation or analysis.

Once the Save button is pressed a standard Windows File dialogue box is presented that allows

the user to select the location and name of the file that will be written.

Page 26

System Description

26

Senscient ELDS™

Rev 15

GB

2.7.6 Config

This button provides access to configuration information and to processes that allow the

configuration to be changed once a unit has been installed.

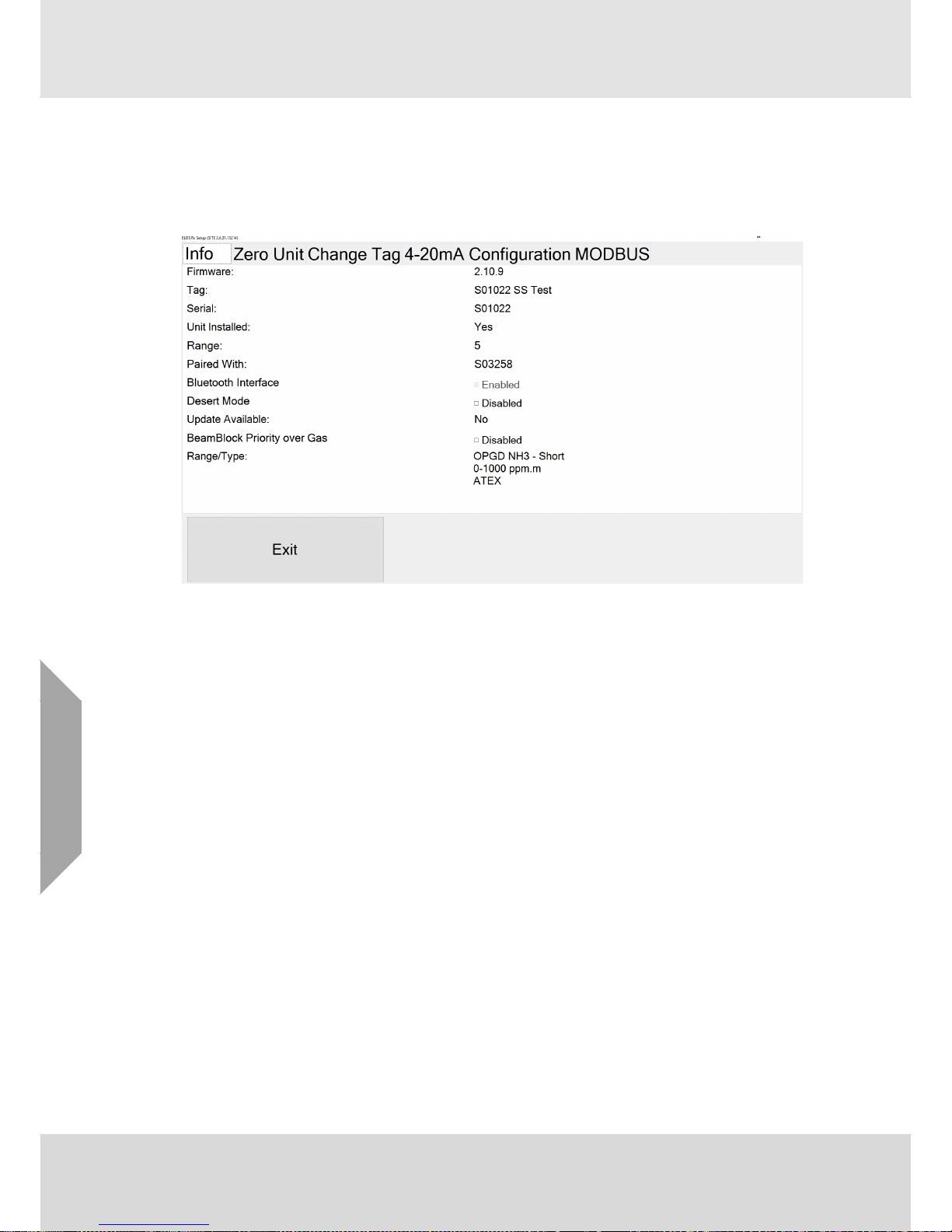

A new screen is presented with a range of options as illustrated below:

The screen is arranged with several ‘tabs’ or pages of information and in addition up to 3 context

sensitive buttons at the bottom. The ‘tabs’ displayed will depend on the unit (Tx or Rx) and also on

the connection type. The example here is for a Receiver. A Transmitter will not include the

“Zero Unit”, or “4-20mA Configuration” options but will include a “SimuGas” option.

Info

This tab contains key information regarding the unit including the unit identity, firmware release

and configuration. In addition it provides access to three configurable items relating to Bluetooth

access, the control of the window heaters on the unit and the behaviour of Beam-Block in the

presence of gas.

Bluetooth Enabled/Disabled indicates if Bluetooth communication is currently facilitated on the

unit. By default all ELDS units are shipped with Bluetooth communication active, however some

customers may choose to inhibit this communication protocol for security reasons. The Bluetooth

support can be disabled or enabled as appropriate by checking the associated checkbox. In the

example above the Bluetooth is currently active so unchecking this checkbox will immediately

disable the Bluetooth connectivity in the unit. Note that access to this feature is restricted by

password access (see section 2.7.8 below). More details of how to disable Bluetooth are provided

in section 4.5.3 below.

Desert Mode is a feature to allow the control of the window-heaters on the ELDS unit to be

changed such that they are likely to be ‘off’ for a majority of the time in hot environments. This will

ensure that the power consumption and internal temperature of the ELDS unit will be minimised

and ensure the longest possible life of the internal components. It is recommended that the

“Desert” feature be enabled on units deployed in hot environments where daytime temperature is

likely to routinely exceed 25°C.

Page 27

System Description

Senscient ELDS™

Rev 15

27

GB

Beamblock Priority over Gas controls how the unit responds when the beam is blocked in the

presence of gas. Normally, ELDS units signal an error current (2.5mA by default) to indicate that

the beam is blocked. In the presence of gas, however, this behaviour is changed such that the last

gas value detected is maintained on the 4-20mA outputs whenever a beam-block occurs.

Optionally users can change this behaviour (for firmware versions 002.010.009 or later) such that

the ELDS does not ‘latch’ the last gas level but rather will signal the Beam-Block current even if

gas was being reported when the obstruction occurs.

Zero Unit

Units are normally ‘zeroed’ during installation; however it is also possible to repeat the zero

process at any time. This is recommended if a unit is physically disturbed (for example if the

alignment is inadvertently changed) or if units exhibit fingerprint or bad zero errors.

Change Tag

The unit ‘tag’ is normally assigned during installation but may be amended at any subsequent time

as required.

4-20mA Configuration

This tab provides information on the range of ‘fault’ conditions that apply to the unit and which will

be signalled over the 4-20mA current loop. A description of the configuration of this is provided in

section 4.5.2, item 8 therein. This tab provides repeat access to this facility should the original

arrangement require adjustment at a later time.

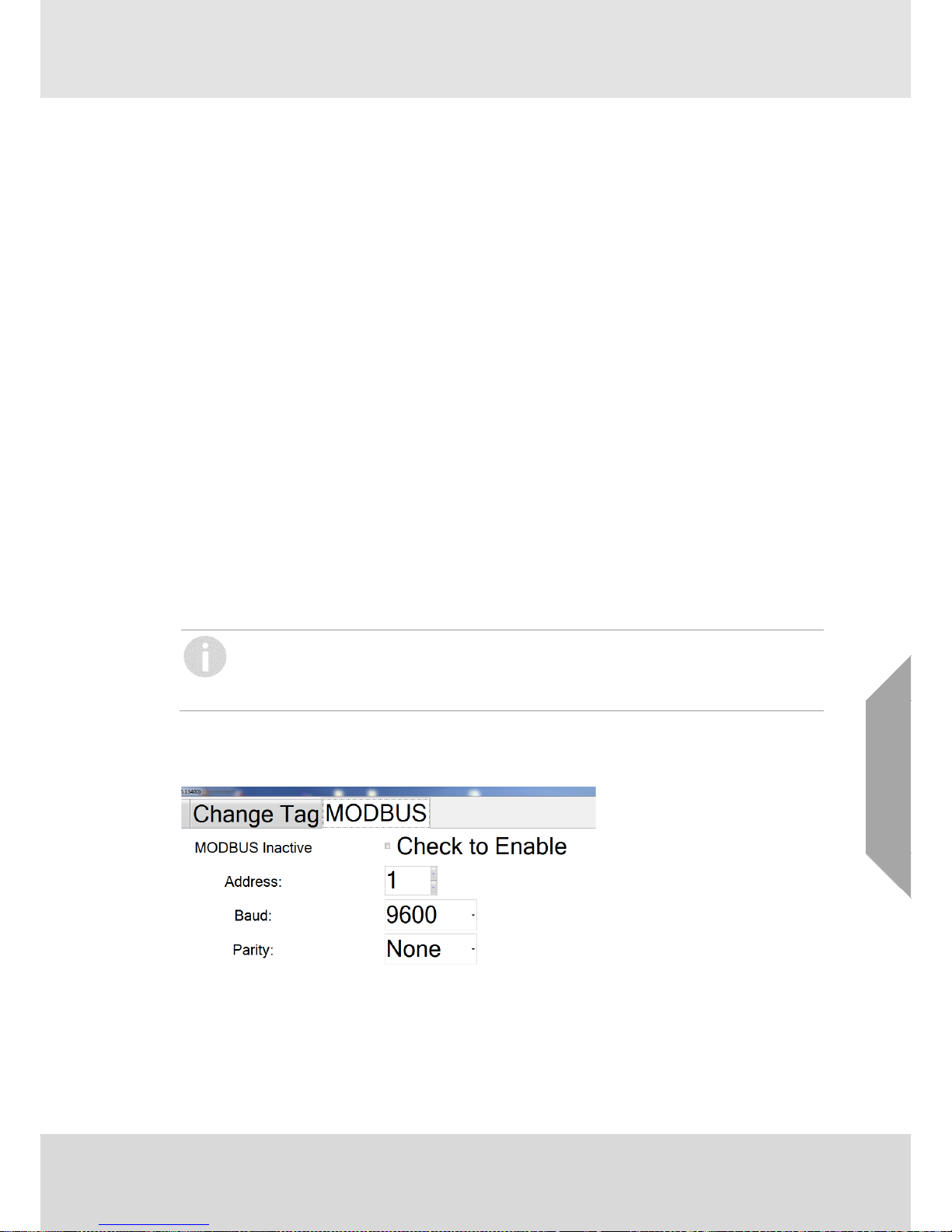

MODBUS

MODBUS support is available from all current ELDS units and is also historically supported for

most units. Units are not shipped with MODBUS support active and this tab provides a mechanism

to allow MODBUS to be configured and activated as required.

MODBUS shares the RS485 communication link, once MODBUS is activated then normal

interaction with the unit using SITE can only be undertaken using the Bluetooth link.

Ensure that Bluetooth communication is available with a unit prior to activating MODBUS

as without it further modifications or inspection of the unit with SITE will not be possible.

MODBUS can be activated through either a Bluetooth connection or via an RS485 link, however

Senscient recommend the use of a Bluetooth link when activating MODBUS. The following options

are presented on the MODBUS screen.

The Address must be assigned as required and must be in the range 1 to 247. This is a unique

value that identifies the unit on the MODBUS link.

Baud defines the communication speed that will apply, the default setting is normally 9600

however other rates are supported and can be selected as required.

Page 28

System Description

28

Senscient ELDS™

Rev 15

GB

Parity defines the parity checking that will be applied to the link. The default is ‘none’ but other

options are available as required from the drop-down list.

Once the required settings are selected check the “Check to Enable” option and then press the OK

button at the bottom right of the dialogue. This will write the changes to the ELDS unit and enable

the interface.

If this change is made via the RS485 link then SITE will not be able to communicate further

with the unit and will disconnect. This process may take a short while to complete in this

case.

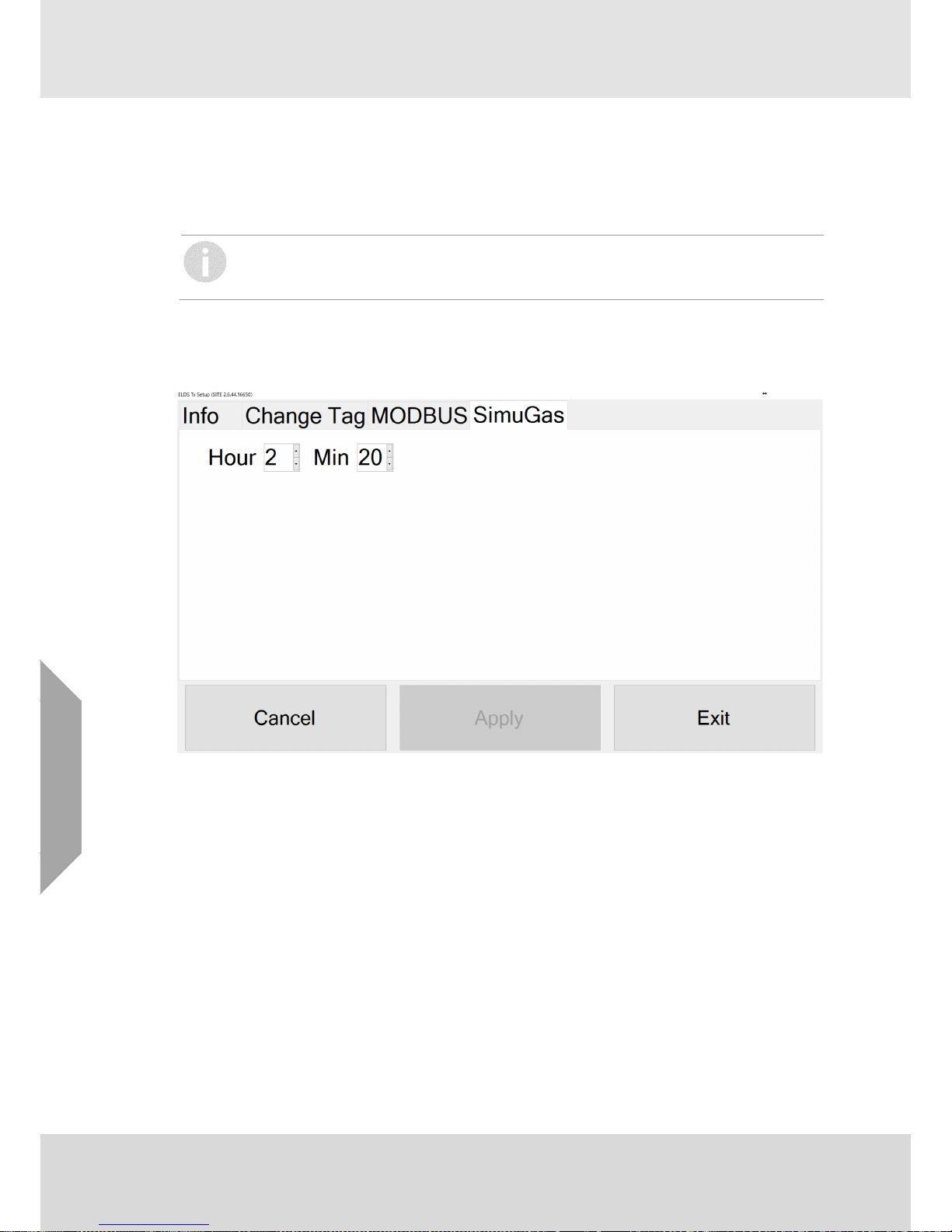

SimuGas

This tab is provided on Tx units and allows the user to examine and change the time of day that

the automatic SimuGas process will occur.

For older ELDS units the SimuGas time can be selected over the range Midnight (0 hours, 0

minutes) to 03:00 am (3 hours, 0 minutes). Units with firmware versions 002.010.018 or later will

support SimuGas at any time of the day. The time can be specified in 10 minute increments. When

any change is made the “Apply“ button will become enabled and will write the required changes to

the unit if clicked.

For older firmware version it is also the case that the revised SimuGas time will not apply until the

pending SimuGas occurs, for such versions SITE will provide a warning following “Applying“ the

change and offer the user the opportunity to re-start the Tx (which will then correctly establish the

revised SimuGas time). For later firmware versions this step is not necessary and will not be

presented.

2.7.7 User Manual

This provides a convenient link to this manual.

2.7.8 Admin

This provides a range of ‘administration’ items as illustrated below:

Page 29

System Description

Senscient ELDS™

Rev 15

29

GB

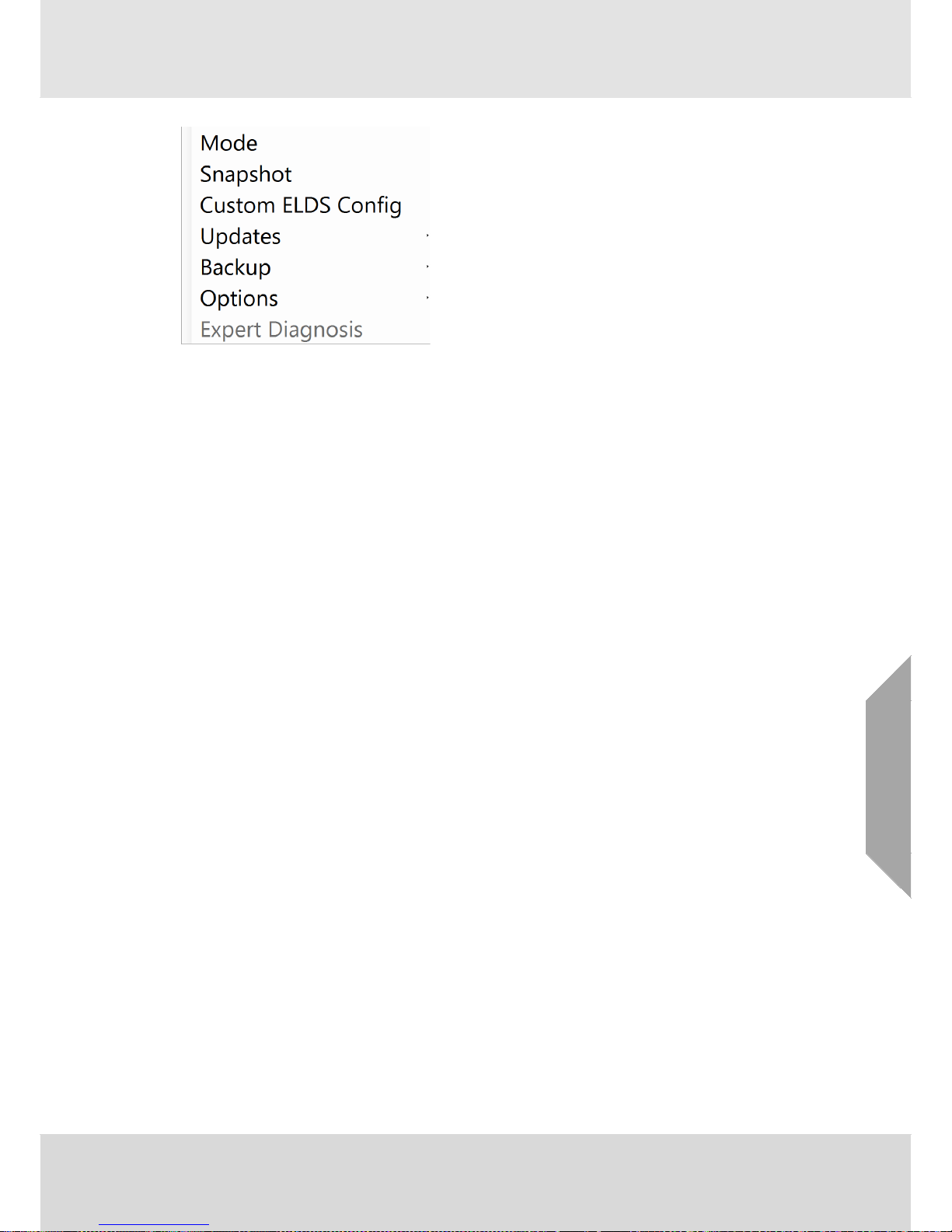

Mode

This provides access to a ‘log in’ screen and allows Senscient personnel or approved users to

access more advanced features of SITE. Appropriate passwords to access these features are

provided by Senscient; Senscient will normally require that users have additional training regarding

the additional features provided.

Snapshot

This will instruct SITE to download a complete ‘picture’ of the connected unit. This ‘snapshot’ may

take up to 2 minutes to acquire and will be automatically uploaded to the Senscient ‘service’ server

if an internet connection is available. In addition the snapshot is stored on the PC running SITE

and may be copied from there. The snapshot will be located in the following location within

“My Documents”

\Senscient\SITE\Log\nnnn

Here nnnn represents the unit serial number of the ELDS unit, for example S01234. Note that the

physical location of “My Documents” varies depending on the version of Windows being used on

the PC. Generally users should find a link to the appropriate place located in the “Start” button or

on their desktop.

Page 30

System Description

30

Senscient ELDS™

Rev 15

GB

Custom ELDS Config

This provides a direct access to the facility to adjust or configure the 4-20mA loop fault currents

and behaviours (see section 2.7.6 above and also section 4.5.2 item 8 below).

Updates

This provides access to SITE updates. It also can provide access to firmware updates but this

facility is limited to authorized users and is not described in further detail here.

If a “SITE update” is available then this sub-item will be accessible and selecting it will

automatically update the copy of SITE on the PC. Note that this process does take a few minutes

to complete. All these options are dependent on internet access.

Senscient recommends that users keep their SITE version updated by periodically checking this

option and updating when new versions of SITE become available. New versions generally

provide enhanced/improved features and in addition may correct issues that might arise.

Backup

This provides the option to create a ‘zip’ backup of the current SITE installation information. This is

located in the following location within “My Documents”

\Senscient\SITE\SBU

and takes the form of a ‘zipped’ folder which contains a record of the units that have been installed

by SITE on the PC.

There is also an option to ‘Purge’ the current configuration. These options are provided to facilitate

some advanced trouble-shooting options for Senscient engineers and are not intended for

customer use.

Options

Contact Us, provides a convenient link to Senscient support through the email client on the PC

running SITE.

Auto Install, provides a means to enable an advanced feature of ELDS which is not currently

activated. This is a ‘place holder’ for future enhancements involving more flexible installation

options.

Remote Assistance is an advanced feature that may be utilised by authorized users or Senscient

engineers.

Expert Diagnosis

This is an advanced feature provided for use by Senscient Engineers. This option is not available

to normal users of SITE.

Page 31

Installation Design & Engineering

Senscient ELDS™

Rev 15

31

GB

3. Installation Design & Engineering

3.1. Introduction

WARNING

The applicable National Code of Practice regarding selection, installation and maintenance of

electrical apparatus for use in Hazardous Areas / Hazardous (Classified) Locations / Zones must

be complied with at all times.

The Senscient ELDS™ 1000 / 2000 Series has been designed, engineered and field-tested to be

the most robust, reliable Open-Path Gas Detector (OPGD) available. The design and ELDS™

technology employed in the Senscient ELDS™ 1000 / 2000 Series make it far more resistant to

the adverse effects of the operating environment and non-ideal installations than previous

generations of OPGDs.

With careful consideration of the intended operating environment and the installation design, the

installer/operator can maximise the reliability, availability and performance achieved with ELDS™

OPGDs.

Before designing or specifying an installation for Senscient ELDS™, it is strongly recommended

that the installation design authority reads and understands this chapter, and considers how the

information and recommendations provided can be applied to their installation(s).

If a design authority has any queries concerning their installation design, they should contact

Senscient or their local agents.

Senscient is committed to ensuring that customers achieve reliable operation of their Senscient

ELDS™ OPGDs. For this reason, Senscient ELDS™ OPGDs should only be installed by fully

trained personnel (trained by Senscient or a Senscient authorised trainer). This training will

provide the installer with a clear understanding of the Senscient ELDS™ OPGD product and the

associated accessories and tools. It will also provide familiarity with the installation, alignment and

commissioning procedures, plus installation assessment skills to identify any potential problem

areas.

For each installation, it is recommended that the installer should check the installation and

operating environment against the Check List presented in section 4.7.

The transmitted laser beam is Class 1 (eye-safe) per IEC 60825.

Page 32

Installation Design & Engineering

32

Senscient ELDS™

Rev 15

GB

3.2. Siting and Mounting

3.2.1 General

When designing an installation for a Senscient ELDS™ OPGD it is important to give consideration

to where it is to be located with respect to gas leak hazards, what potential sources of problems

may be encountered in this location; and how the unit is to be mounted and supported.

3.2.2 Location for Best Coverage

Guidance on the positioning of gas detectors to provide the best detection coverage is contained

in national Codes of Practice. It is recommended that the installation designer consults these

Codes of Practice. Senscient would advise that the best current methodology for siting all types of

fixed gas detectors is based upon the expert use of gas dispersion modelling, performed for the

particular area(s) of plant or facility where potential gas leak hazards exist. There are a number of

organisations with the gas dispersion modelling tools and expertise necessary to perform this

work. In general, for OPGDs the following positions usually provide the best results:

Running parallel to the physical perimeter of an area of plant or facility containing potential gas

leak hazards.

Forming a continuous ‘ring-fence’ surrounding an area of plant or facility containing potential

gas leak hazards.

At sufficient distance from any potential leak sources for dispersion to produce a gas cloud of a

size that will reliably be intercepted by the beam-paths of the OPGDs employed.

Between potential leak sources and any known or likely sources of ignition.

For natural gas: beam-path parallel to the ground / floor and above the height of most of the

valves and flanges in the vicinity.

For toxic gases: beam-path parallel to the ground / floor at ‘breathing height’ (~ 1.4m - 1.7m).

For gas mixtures significantly denser than air: beam-path parallel to the ground / floor and

below all potential leak sources*.

For gas mixtures significantly lighter than air: beam-path parallel to the ground / floor and

above all potential leak sources*.

* In most instances the hazardous gases leaking from a plant or facility are mixtures of a

number of gases with different chemical and physical properties. In a gas mixture the

constituent gases will retain most of their chemical properties, but the physical properties of

the gas mixture will approximate the sum of the physical properties of the constituent

gases.

For sour natural gas, the above principle means that this gas mixture will be both toxic and

flammable; whilst the density of this mixture will tend to be dictated by its methane content.

Only accurate gas dispersion modelling will determine the precise physical properties of a

leak of sour natural gas, but typically this mixture’s density will be similar to, or even slightly

lower than that of air. Only leaks of very cold natural gas or of neat hydrogen sulfide are

likely to be slightly denser than air.

CAUTION

Dispersion modelling provides little support for the practice of placing hydrogen sulfide detectors

close to the ground. In the majority of instances leaks of sour natural gas or hydrogen sulfide will

not sink; whilst the toxicity hazard is greatest at the height where such gas can be breathed in.

Page 33

Installation Design & Engineering

Senscient ELDS™

Rev 15

33

GB

3.2.3 Location to Maximise Reliability and Availability

Care in choosing the location of ELDS™ OPGDs can contribute significantly to the overall

reliability and availability.

When locating units, attempt to avoid areas where they may be adversely affected by the

following:

Vibration - Angular vibration of the structure to which ELDS™ OPGD units are attached should be

kept to less than ± 0.5°. Where possible, avoid locations where high levels of vibration will be

directly induced into the mounting structure. If close proximity to significant sources of vibration is

unavoidable, take steps to reduce coupling of this vibration and maximise the rigidity of the

mounting structure.

Intense Heat - ELDS™ OPGDs are certified and specified for operation in environments up to

+60°C. If sources of intense heat (flarestacks, intense sunlight, etc.) are present, the effect of

these will be reduced by the fitted sunshade. If the sunshade proves insufficient in an extremely

hot installation (greater than 35°C) then further shielding should be provided or the detector should

be relocated.

Sources of Heavy Contamination - Avoid locations where high levels of contaminants will

persistently be blown onto the unit’s lens-windows. Potential sources of heavy contamination

include generator/turbine exhausts, flare-stacks, drilling equipment, process vents/chimneys etc. If

sources of heavy contamination cannot be avoided, consider fitting extra shielding and/or

providing good access for more routine cleaning.

Snow and Ice in Ambients Below -20°C - The heated optics on ELDS™ OPGD units will melt

snow or ice on the lens-windows in ambient temperatures down to approximately 20°C. Below this

temperature, snow or ice blown onto the lens-window will not be melted until the ambient

temperature rises. If long-term, outdoor operation in very cold climates is intended, it is

recommended that extra shielding/covers are employed to prevent snow/ice from being blown onto

the windows and building up.

Deluge and Flooding - Senscient ELDS™ OPGDs are rated IP66/67 and as such will not be

damaged by occasional deluge or flooding. However, during such instances the unit will

completely lose its IR signal and will enter the BEAM-BLOCK/FAULT state. Also, when the

deluge/flooding subsides, there is the possibility that contaminants will be left on the windows.

Therefore, it is recommended that ELDS™ OPGD units be located away from areas particularly

prone to deluge or flooding.

Areas Prone to Subsidence and Settling - Where possible, it is recommended that ELDS™

OPGD units are not mounted on structures located where problems with subsidence, settling or

thawing of permafrost are known to cause significant movement. If such locations cannot be

avoided, the foundations of the mounting structure should be engineered to minimise any angular

movements.

Areas Prone to Earthquakes - In locations prone to earthquakes, there is a chance that during or

after an earthquake, the units of an ELDS™ OPGD will become misaligned with respect to each

other. Provided that the ELDS™ OPGD units do not suffer from direct mechanical impact damage

during an earthquake, they should remain undamaged by such events. Anti-vibration mounts are

unlikely to be of any benefit and are not recommended. After an earthquake it is recommended

that ELDS™ OPGDs are visited and their alignment be checked.

Accidental Impact - Mount Transmitter and Receiver horizontally to protect from impact.

Locations where there is a likelihood of equipment, personnel or moving objects accidentally

knocking ELDS™ OPGD units out of alignment should be avoided. If such locations cannot be

avoided, measures including improved mechanical protection and warning notices should be

considered.

Page 34

Installation Design & Engineering

34

Senscient ELDS™

Rev 15

GB

Intense Electromagnetic Fields - Senscient ELDS™ OPGDs comply with FM6325 and

EN50270, and as such are well protected from interference by electromagnetic fields. However,

locations in close proximity to radio/radar Transmitters, heavy electrical plant and high voltage

power cables may experience field strengths in excess of those specified in EN50270. Where

possible, such locations should be avoided or units should be installed as far as possible from the

source of the electromagnetic field. Measures including additional screening, filtering and transient

suppression may also be of benefit in such locations.

3.2.4 Beam-path

The Transmitter and Receiver unit lens-windows should face each other directly across the area to

be protected and, depending on the range of the system deployed, should be the following

distance apart:

Senscient ELDS™ Detector Series Type Path length between units

1000 CH4 5 – 40m, 40 –120m, 120 – 200m

1000 Ethylene 5 – 60m

1000 HCl 5 – 60m

1000 NH3 5 – 40m, 40 – 120m

1000 CO2 5 – 40m, 40 – 120m

1000 HF 5 – 60m, 60 – 120m

1000 XD, Cross Duct,

0-10%LFL, 0-25%LFL, 0-50%LFL, 0-100%LFL CH

4

0.5 – 5.0m

2000 CH4 + H2S 5 – 60m

2000 H2S 0 - 100ppm.m 5 – 60m

2000 H2S 0 - 250ppm.m 5 – 60m

2000 H2S 0 - 500ppm.m 5 – 60m

The beam-path and immediate surrounds should be kept free of obstructions that might hinder the

free movement of air in the protected area or block the infrared beam. A clear beam-path of 20cm

diameter or greater is recommended. In particular, for optimum availability, avoid areas affected by

the following:

Steam vents and plumes

Smoke stacks and chimneys

Walkways and personnel areas

Splash and spray, e.g. from moving equipment, cooling towers, etc.

Parking, loading, cranes, vehicle temporary stops, e.g. bus stops, road junctions, etc.

Vegetation, e.g. shrubs, bushes, branches, etc. - if currently clear, movement due to

weather and future growth or planting must be considered

Where c. and d. cannot be avoided, consider indicating the beam by marking the walkway

or road with paint.

Page 35

Installation Design & Engineering

Senscient ELDS™

Rev 15

35

GB

In order to fit the alignment telescope used during the alignment process, a clear

accessible arc of at least 30cm radius is required close to the unit as shown above.

CAUTION

For reliable operation, a clear beam-path of at least 10cm radius or greater is recommended.

When selecting locations for ELDS units, ensure that only one ELDS Transmitter unit is within

the field-of-view and pointing towards any ELDS Receiver unit. Do NOT run ELDS beam-paths

such that there are multiple Transmitters running along the same axis, because the Receiver at

the end of the run will see laser signals from all of the Transmitters on this axis and this may

cause problems. Detailed guidance is provided in section 3.2.10.

Telescope clearance arc

radius - more than 30cm

Beam clearance arc -

radius more than 10cm

Page 36

Installation Design & Engineering

36

Senscient ELDS™

Rev 15

GB

3.2.5 Supporting Structure

The Transmitter and Receiver units should be fixed to rigid, stable supporting structures using the

mounting brackets supplied.

The maximum movement of the supporting structure under all anticipated operating

conditions must be ±0.5º.

If no suitable mounting structure already exists then structures similar to that shown below are

recommended:

The pipe can be filled with concrete to provide extra stability if necessary.

100mm to 150mm (4” to 6”) dia. steel pipe,

nominal 6mm wall thickness

up to

3m

500mm

minimum

500mm

minimum

Concrete foundation

500mm

minimum

Page 37

Installation Design & Engineering

Senscient ELDS™

Rev 15

37

GB

3.2.6 Wall Mounting

The mounting bracket can be directly attached to a suitable wall or similar structure as is illustrated

below:

3.2.7 Orientation

Senscient ELDS™ OPGDs are solar immune and therefore there is no need to take account of the

sun’s movement when considering orientation.

When positioning the units do not install them with the optical axis at an angle greater than 45º to

the horizontal - to avoid dirt / water build-up on the lens-windows.

Page 38

Installation Design & Engineering

38

Senscient ELDS™

Rev 15

GB

3.2.8 Mounting Cross Duct ELDS Systems

Cross Duct ELDS systems are specifically designed and engineered for installation with their

beam-path running across the duct, perpendicular to the direction of flow through the duct. In order

to facilitate installation in this manner, the walls of the duct at the location where the Cross Duct

ELDS system is to be installed must be flat and parallel to each other to within ±2.5° (per side).

Provided that this requirement is met it is then a simple matter of mounting each half of the Cross

Duct ELDS system directly opposite its counterpart. Self-adhesive templates (01-1389-D) are

provided to assist with the location and drilling of suitable holes in the duct wall.

The most important requirement for successful installation of a Cross Duct ELDS system is

that the optical centre lines, as indicated by the cross-hairs on the self-adhesive templates

are directly opposite each other on the duct wall.

Page 39

Installation Design & Engineering

Senscient ELDS™

Rev 15

39

GB

3.2.9 Positioning Cross Duct ELDS Systems

Guidance on the positioning of gas detectors to provide the best detection coverage is contained

in national Codes of Practice. It is recommended that the installation designer consults these

Codes of Practice. Senscient would advise that the best current methodology for siting all types of

fixed gas detectors is based upon the expert use of gas dispersion modelling, performed for the

particular area(s) of plant or facility where potential gas leak hazards exist. Organisations with gas

dispersion modelling tools and relevant expertise are available to perform this work on a contract

or consulting basis.

There are a number of factors that Senscient would suggest be taken into consideration by

designers of installations for Cross Duct gas detectors. These factors may not be relevant to all

duct applications and installations but are provided to assist the installation designer in those

instances where they are.

1. In general, the flow in ducts is not turbulent and approaches laminar flow throughout the

majority of a duct’s length.

2. In general, louvers and grills at duct inlets do not create significant flow turbulence and do not

produce significant mixing of air or other gases entering a duct.

3. As a consequence of factors 1 & 2, for most ducts there is no location at which air and other

gases entering the duct can be considered to have become uniformly mixed.

4. In most instances, any flammable gas entering a duct will proceed to flow along the duct in an

approximately laminar fashion, remaining on the same side and at the same height as that at

which it entered the duct. Any dispersion or mixing of this flammable gas with the air flowing in

the duct will tend to be very gradual.

5. Where the design of an installation for Cross Duct gas detectors is intended to make use of

dispersion or mixing effects, these effects must be modelled for the appropriate duct geometry,

detector location(s) and flow conditions - to determine that the required dispersion or mixing

will actually occur.

Page 40

Installation Design & Engineering

40

Senscient ELDS™

Rev 15

GB

When the installation designer takes the above factors into account, in general they will establish

that the best locations for Cross Duct gas detectors are as follows:

1. As close to the duct inlet as reasonably practicable - to minimize the distance that any

flammable gas has to cover before it passes through the Cross Duct detector’s beam-path,

minimizing any time delay before this hazardous condition is detected.

2. For tall ducts – at multiple heights running across the width of the duct, with as a minimum one

Cross Duct beam-path running reasonably close to the bottom of the duct and another Cross

Duct beam-path running reasonably close to the top of the duct.

3. For tall / large ducts where practicable – at multiple heights running across the width of the

duct with Cross Duct beam-paths separated vertically by a 0.4m pitch.

CAUTION

Do NOT install Cross Duct ELDS units with their beam-paths running vertically in the duct. This

will tend to lead to the build-up of water and contamination upon the lens-window of the unit

mounted on the bottom of the duct, leading to low signal and beam-blockage problems.

The installation Design Authority must ensure that the duct hazardous (classified) location

and / or hazardous area is in compliance with the ELDS unit’s certification (see section 9

for ELDS certification details).

In addition, the duct environment shall not exceed the following:

Pressure: 80kPa (0.8Bar) to 110kPa (1.1Bar)

Temperature: -55ºC to +60ºC

Oxygen Content: less than 21%v/v.

3.2.10 Siting Multiple ELDS™ Systems

For reliable operation it is important that each ELDS™ Receiver unit only detects light from a

single ELDS™ Transmitter, i.e. that ELDS™ systems are installed as a Transmitter and Receiver

pair that are optically isolated from other ELDS™ systems.

In situations where multiple ELDS™ are to be installed in proximity to each other along a common

border or fence line, the following mounting and orientation recommendations should be adopted.

Arrangement for 2 ELDS™ Systems

Where two ELDS™ systems are to be installed along a common border or fence line, it is

recommended that the units be orientated as illustrated below.

Mounting the transmitters and receivers such that the beams of the two ELDS™ systems are

running in opposite directions ensures complete optical isolation. In this arrangement for two

ELDS™ systems it is not necessary to make use of the heights or pole sides upon which the units

are mounted to provide optical isolation.

Tx 1

Tx 2

Rx 1

Rx 2

Page 41

Installation Design & Engineering

Senscient ELDS™

Rev 15

41

GB

Arrangement for Multiple ELDS™ Systems

For applications where three (3) or more ELDS™ systems are to be installed running along a

common border or fence line, the arrangement illustrated above is recommended. (The ELDS™