Page 1

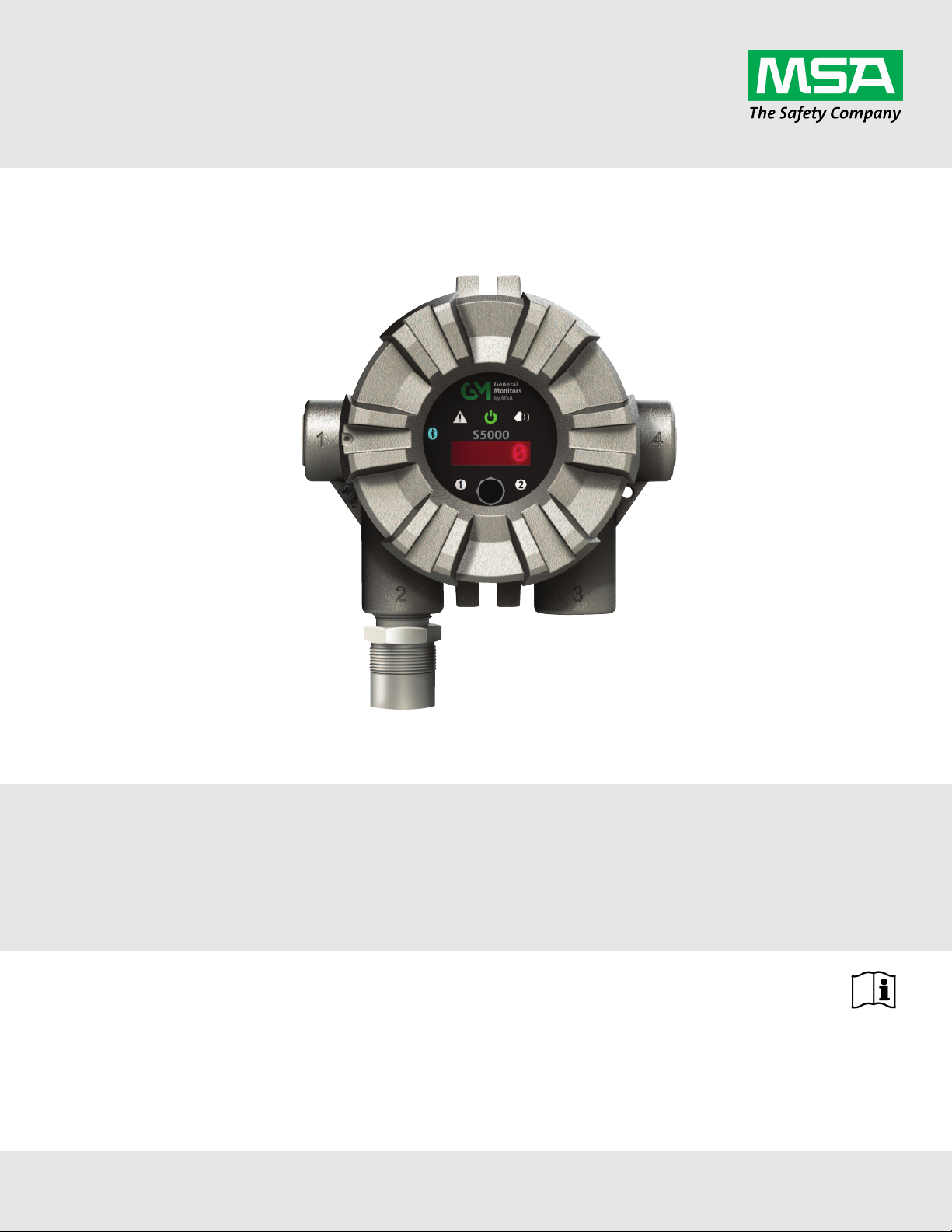

Operating Manual

General Monitors S5000

Gas Monitor

Order No.: MANS5000/06

Print Spec: 10000005389 (EO)

CR:800000042524

MSAsafety.com

Page 2

WARNING!

Read this manual carefully before using or maintaining the device. The device will perform as designed only if it is used and

maintained in accordance with the manufacturer's instructions. Otherwise, it could fail to perform as designed, and persons

who rely on this device could sustain serious injury or death.

The warranties made by MSA with respect to the product are voided if the product is not installed and used in accordance

with the instructions in this manual. Please protect yourself and your employees by following the instructions.

Please read and observe the WARNINGS and CAUTIONS inside. For additional information relative to use or repair, call 1800-MSA-2222 during regular working hours.

For countries of Russian Federation, Republic of Kazakhstan and Republic of Belarus, the gas detector will be delivered

with a passport document that includes valid approval information. On the CD with manual instruction attached to the gas

detector the user will find the documents "Type Description" and "Test Method" - appendixes to Pattern Approval

Certificate of Measuring instrument, valid in the countries of use.

MSA is a registered trademark of MSA Technology, LLC in the US, Europe and other Countries. For all other trademarks

visit https://us.msasafety.com/Trademarks.

This product incorporates Bluetooth® wireless technology. The Bluetooth word mark and logos are registered trademarks

owned by Bluetooth SIG, Inc., and any use of such marks by MSA is under license. Other trademarks and trade names are

those of their respective owners.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

You are cautioned that changes or modifications not expressly approved by the party responsible for compliance could void

the user's authority to operate the equipment.

English:

This device complies with RSS-210 of the Industry Canada Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

French:

Ce dispositif est conforme à la norme CNR-210 d'Industrie Canada applicable aux appareils radio exempts de licence. Son

fonctionnement est sujet aux deux conditions suivantes: (1) le dispositif ne doit pas produire de brouillage préjudiciable, et

(2) ce dispositif doit accepter tout brouillage reçu, y compris un brouillage susceptible de provoquer un fonctionnement

indésirable.

© MSA 2020. All rights reserved

Page 3

US

26776 Simpatica Circle

Lake Forest, CA 92630

USA

For your local MSA contacts please go to our website www.MSAsafety.com

General Monitors S5000 3

Page 4

US

Contents

1 Safety Regulations 7

1.1 Correct Use 7

1.2 Product Warranty 9

2 Description 10

2.1 Display 10

2.2 No Tool Interface 10

2.3 Bluetooth® Wireless Technology 11

2.4 Dual Sensing 11

2.5 Retrofit Installations 12

2.6 XCell Sensors Optimized for Fixed Gas Applications 12

2.7 TruCal Sensing Technology for CO and H2S Electrochemical Sensors 12

2.8 SafeSwap 13

2.9 Housing 13

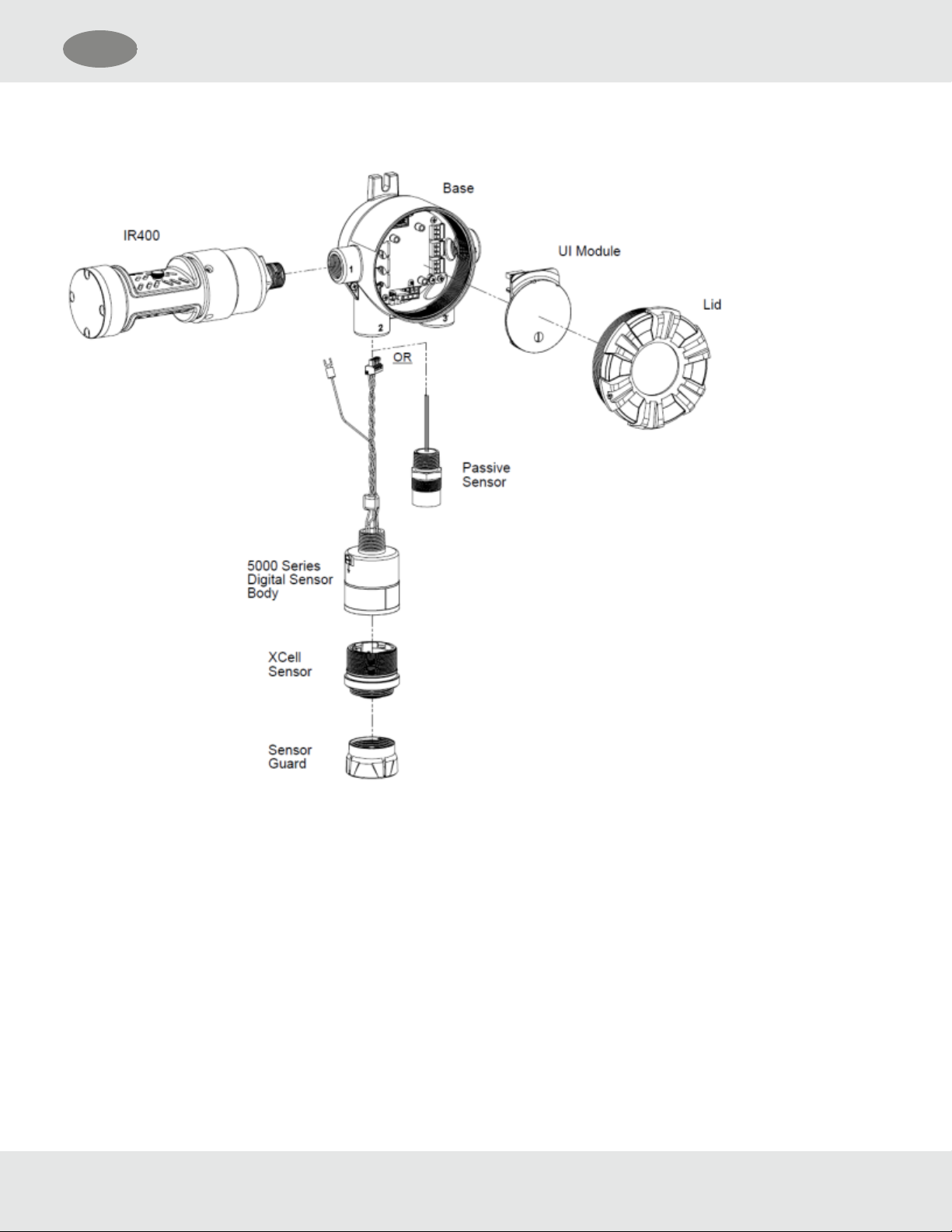

2.10 Component Overview 14

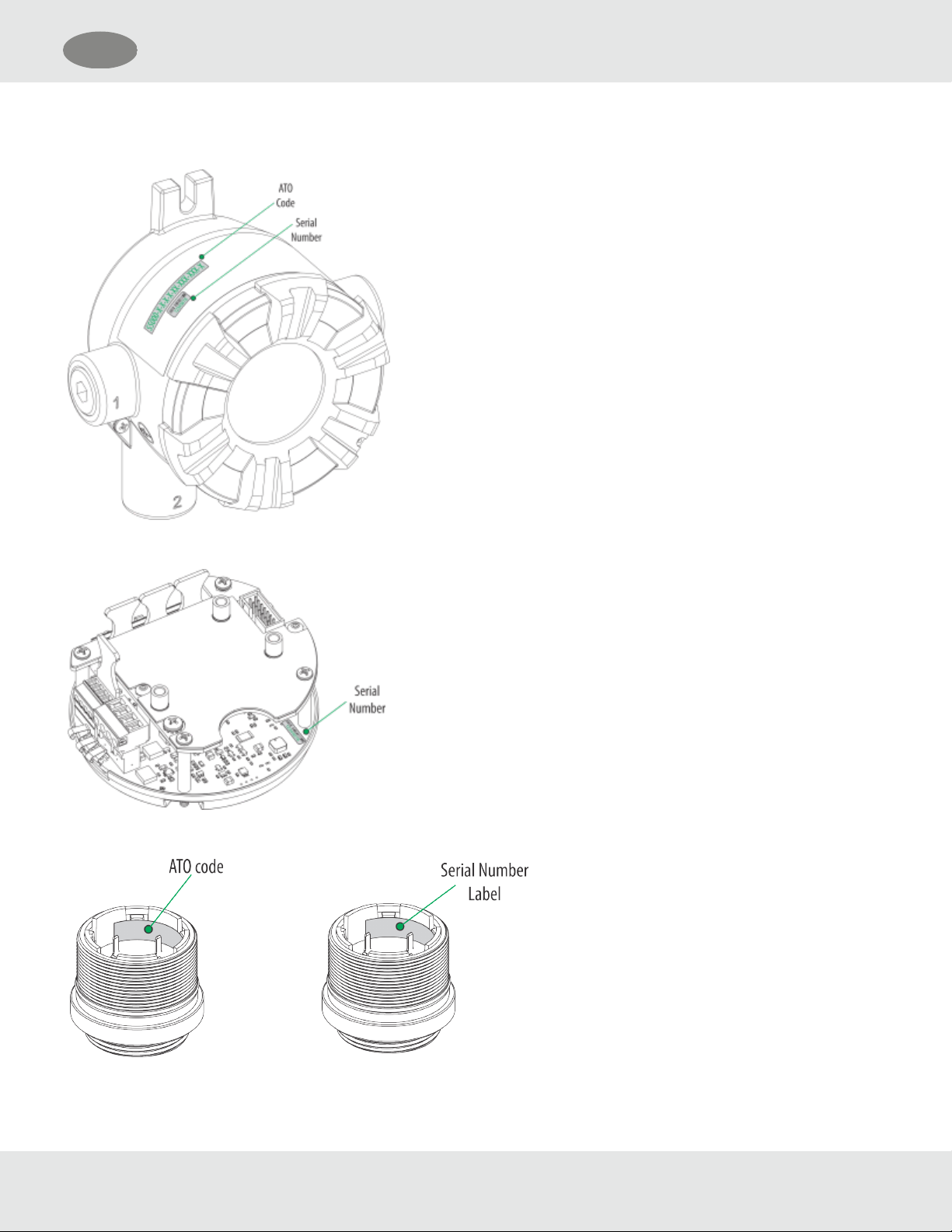

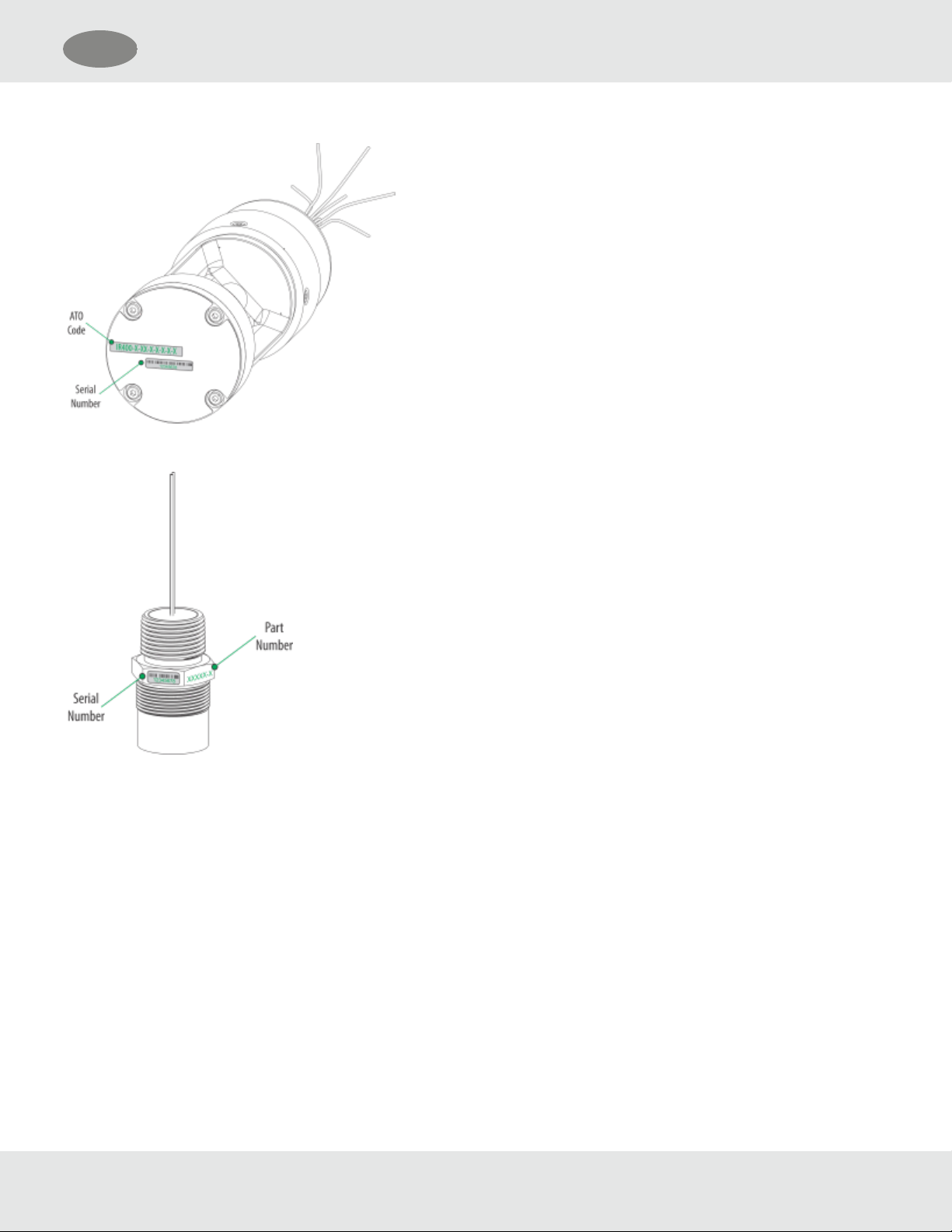

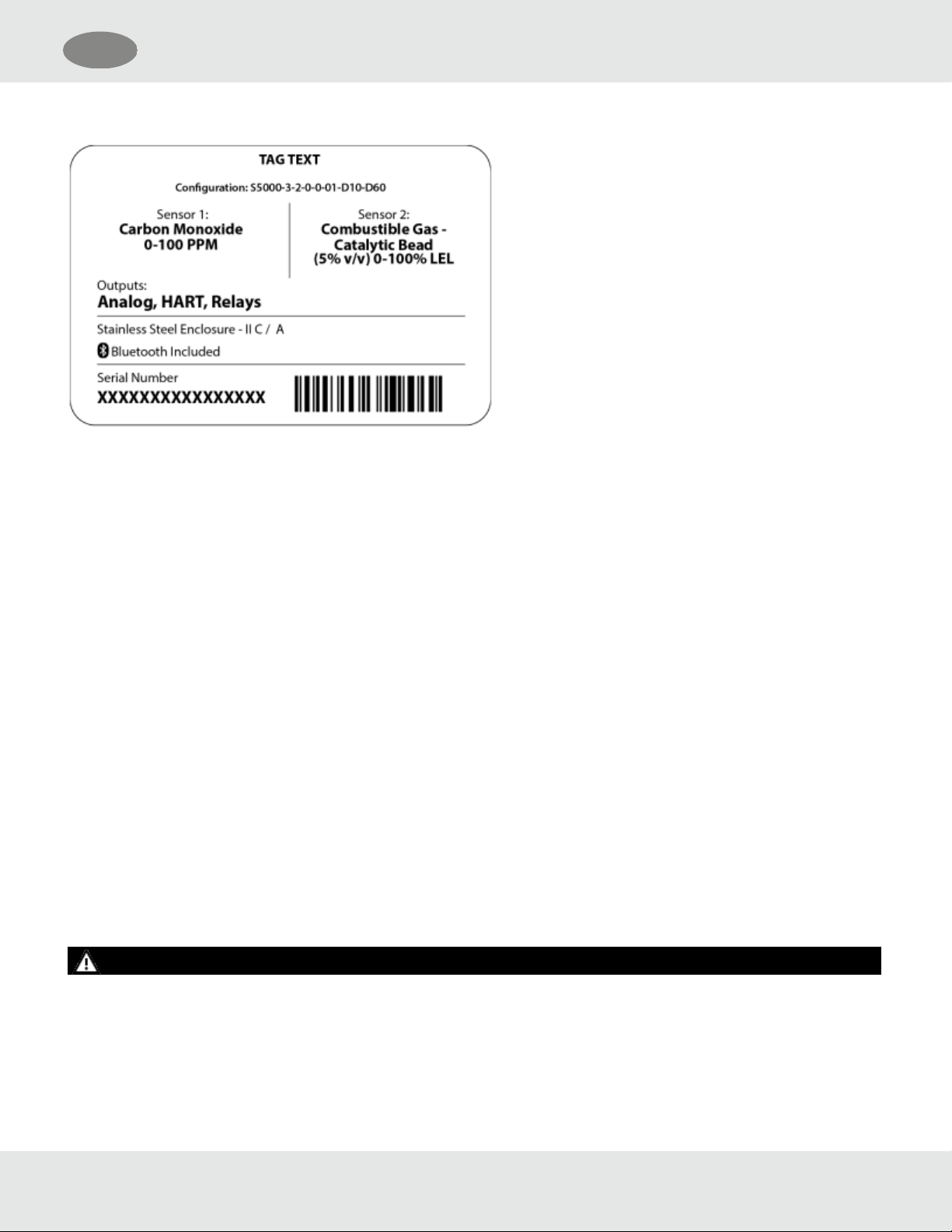

2.11 Label Overview 15

3 Installation 17

3.1 Installation Warnings - Read Before Installation 17

3.2 Reviewing Shipment and Identifying Product Model 17

3.3 Product Installation Check List 18

3.4 Mounting 18

3.4.1 Sensor Mounting Location 19

3.4.2 Transmitter Mounting Location 19

3.4.3 Sensor Orientation 19

3.4.4 Connecting Sensor to Transmitter Housing or Remote Junction Box 20

3.4.5 Integrated Mounting Points 22

3.4.6 Adjustable Pipe Mount 23

3.4.7 Duct Mount 24

3.4.8 Mounting with a Sunshield 24

3.4.9 Mounting with an SM5000 Sampling Module 25

3.5 Installing a Remote Sensor Junction Box 26

3.6 Electrical Power Connections 27

3.6.1 Electrical Warnings - Read before Connecting Power 27

3.6.2 Retrofit Applications with S4000CH, S4000TH, or TS4000H 28

3.6.3 Electrical Hardware Requirements 28

3.6.4 Power Load Requirements and Maximum Mounting Distances 29

3.6.5 Instructions for Power and Analog Output 35

3.6.6 Relay Electrical and Power Connections 37

4 Operation 39

4.1 Startup 39

4.1.1 Initial Startup 39

4.1.2 Sensor Warm Up Times 39

4.1.3 Startup after Power Failure 40

4.2 Settings 40

4.2.1 Instrument Settings 41

4.2.2 Sensor Setup 53

General Monitors S5000 4

Page 5

US

4.2.3 Relay Settings 56

4.2.4 HART Settings 58

4.2.5 HART AO 58

4.2.6 Calibration Alert 59

4.2.7 Bluetooth 59

4.2.8 Modbus Settings 60

4.2.9 EZ Touch Button 61

4.2.10 Swap Delay 61

4.2.11 UI Password 62

4.2.12 Transmitter Setting Reset 63

4.3 Info Menu - Viewing Device Status 63

4.3.1 AO Type 63

4.3.2 View or Change System Time 64

4.3.3 Last Calibration 64

4.3.4 Non-Critical Fault Log 64

4.3.5 Device Tag 64

4.3.6 Bluetooth FCC/IC ID 65

4.3.7 Sensor Life and Health Status (only displayed if XCell Sensor is connected) 65

4.4 Setting only configurable via Bluetooth®, Modbus, or HART 65

4.4.1 AO Custom Levels 66

4.4.2 Relay Zone - Horn Mode 66

4.4.3 Unit Device ID/Tag 66

4.4.4 Alarm Direction 67

4.4.5 Alarm Enable/Disable 67

5 Calibration 68

5.1 Calibration Equipment 68

5.2 Calibration Frequency 70

5.3 Calibration Frequency for XCell Sensors with TruCal (H2S & CO only) 71

5.3.1 XCell Sensor with TruCal and Diffusion Supervision (CO&H2S Only) 71

5.3.2 XCell Sensor with TruCal without Diffusion Supervision (CO&H2S Only) 71

5.4 Calibration Types: Zero vs. Span 71

5.5 How to Zero Calibrate XCell and IR Sensors 72

5.6 How to Calibrate XCell Sensors 73

5.7 How to Calibrate an Oxygen XCell Sensor 75

5.8 How to Calibrate an IR Sensor 75

5.9 How to Calibrate a Passive Sensor (Catalytic Bead or MOS) 75

5.10 XCell Catalytic Bead Failsafe 76

5.11 Calibration Confirmation 76

6 Maintenance 77

6.1 IR Sensor Cleaning Procedure 77

6.2 Replacing an XCell Sensor 78

6.3 Clearing a Blockage 80

6.4 Replacing a Passive Sensor (Cat Bead or MOS) 81

6.5 Troubleshooting 81

7 Ordering Information 87

7.1 Replacement Parts 87

General Monitors S5000 5

Page 6

US

8 Appendix: Specifications 90

9 Appendix: General Certification Information 94

10 Appendix: HART Specific Information 101

General Monitors S5000 6

Page 7

US

1 Safety Regulations

1 Safety Regulations

1.1 Correct Use

The S5000 Gas Monitor, hereafter also called device, is a gas monitor for measuring toxic and combustible gases as well

as oxygen. Using sensors, the device tests the ambient air and triggers the alarm as soon as the gas exceeds a specific

concentration level.

WARNING!

Do not use silicone-type lubricants in assembling the device and do not allow silicone vapors to be drawn into the flow

system while in operation. Silicone can desensitize the combustible gas sensor, thereby giving erroneously low readings.

Use only genuine MSA replacement parts when performing any maintenance procedures provided in this manual. Failure to

do so may seriously impair sensor and gas monitoring performance, alter flameproof/explosionproof characteristics or void

agency approvals.

Failure to follow these warnings can result in serious personal injury or death.

WARNING!

As with all gas monitors of this type, high levels of, or long exposure to, certain compounds in the tested atmosphere could

contaminate the sensors. In atmospheres where an S5000 Gas Monitor may be exposed to such materials, calibration

must be performed frequently for dependable operation and to confirm that display indications are accurate.

These effects include, but are not limited to:

• Passive MOS sensors may be adversely affected by prolonged exposure to certain substances. Loss of sensitivity or

corrosion may be gradual if such agents are present in low concentrations or it may be rapid at high concentrations.

Examples of these substances are as follows:

– Halides: compounds containing fluorine, chlorine, bromine and iodine

– Heavy metals, e.g. tetraethyl lead

– Caustic and Acidic liquids and vapors

– Glycol

• The H2S Digital Sensor may be adversely affected by the following substances:

– Alcohols (methanol, ethanol, isopropanol)

– Nitrogen dioxide (NO2)

– Chlorine (Cl2)

– Paint solvents (acetone, turpentine, toluene, mineral spirits, etc.)

• The CO Digital Sensor may be adversely affected by the following substances:

– Alcohols (methanol, ethanol, isopropanol)

– Paint solvents (acetone, turpentine, toluene, mineral spirits, etc.)

•

The O2 Digital Sensor may be adversely affected by the following substances:

– Long term exposure to low levels of Acetylene

– Paint solvents (acetone, turpentine, toluene, mineral spirits, etc.) in high concentrations larger than 1000 ppm or

prolonged exposure to lower concentrations

General Monitors S5000 7

Page 8

US

1 Safety Regulations

• Prolonged exposure of the H2S Digital Sensor to humidity levels of 5% RH or lower will result in gas measurement

readings of H2S that are greater than the actual gas concentration present.

• It is not recommended to expose the O2, H2S and CO Digital Sensors to environments containing oxygen levels above

30% (v/v) or below 5% (v/v). The O2sensor will operate at concentrations below 5% (v/v) but not for prolonged periods

of time.

Failure to follow these warnings can result in serious personal injury or death.

This device complies with Part 15 of the FCC Rules. Operation is subject to the -following two conditions:

• this device may not cause harmful interference, and

• this device must accept any interference received, including interference that may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the interference at

his own expense.

WARNING!

The Digital Sensor Xcell sensor module utilizes thread locker suitable to an ambient temperature of -55°C to +74°C. If the

Digital Sensor is exposed to temperatures outside of its listed ratings, reapplication of thread locker when changing out the

Xcell sensor module may be required.

Failure to follow this warning can result in serious personal injury or death.

NOTICE

This is a Class A product in accordance with CISPR 22. In a domestic environment, this product may cause radio

interference, in which case the user may be required to take adequate -measures.

NOTICE

The XCell sensor refers to the sensor portion of the Digital Sensor throughout this manual.

FCC Warning Statements

Changes or modifications not expressly approved by the manufacturer could void the user's -authority to operate the

equipment.

Industry Canada (IC) Warning Statements

The installer of this radio equipment must ensure that the antenna is located or pointed such that it does not emit RF field in

excess of Health Canada limits for the general population; consult -Safety Code 6, obtainable from Health Canada's

website www.hc-sc.gc.ca.

General Monitors S5000 8

Page 9

US

1.2 Product Warranty

The warranties made by GM with respect to the product are voided if the product is not installed, used and serviced in

accordance with the instructions in this manual. Please protect yourself and your employees by following the instructions.

ITEM WARRANTY PERIOD

S5000 Gas Monitor MSA warrants that this product will be free from mechanical defects and faulty workmanship for

the period specified in this table for each component, provided it is maintained and used in

accordance with MSA’s instructions and/or recommendations. Warranty shall not exceed.

1 Safety Regulations

Main Transmitter

Housing and PCBA

XCell Sensors 3 years from date of shipment.

IR Sensor 2 years from date of shipment.

Passive Catalytic

Bead

Passive MOS 2 years from date of shipment.

This warranty does not cover filters, fuses, etc. Certain other accessories not specifically listed here may have different

warranty periods. This warranty is valid only if the product is maintained and used in accordance with Seller's instructions

and/or recommendations. The Seller shall be released from all obligations under this warranty in the event repairs or

modifications are made by persons other than its own or authorized service personnel or if the warranty claim results from

physical abuse or misuse of the product. No agent, employee or representative of the Seller has any authority to bind the

Seller to any affirmation, representation or warranty concerning this -product. Seller makes no warranty concerning

components or accessories not manufactured by the Seller, but will pass on to the Purchaser all warranties of

manufacturers of such components.

2 years from date of shipment.

Shall not exceed 2 years and 6 months from date of manufacture.

Shall not exceed 3 years and 6 months from date of manufacture.

Shall not exceed 2 years and 6 months from date of manufacture.

2 years from date of shipment.

Shall not exceed 2 years and 6 months from date of manufacture.

Shall not exceed 2 years and 6 months from date of manufacture.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED OR STATUTORY, AND

IS STRICTLY LIMITED TO THE TERMS HEREOF. SELLER SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedy

It is expressly agreed that Purchaser's sole and exclusive remedy for breach of the above warranty, for any tortious

conduct of Seller, or for any other cause of action, shall be the replacement at Seller's option, of any equipment or parts

thereof, which after examination by Seller is proven to be defective. Replacement equipment and/or parts will be provided

at no cost to Purchaser, F.O.B. Seller's Plant. Failure of Seller to successfully replace any nonconforming equipment or

parts shall not cause the remedy established hereby to fail of its essential purpose.

Exclusion of Consequential Damage

Purchaser specifically understands and agrees that under no circumstances will seller be liable to purchaser for economic,

special, incidental or consequential damages or losses of any kind whatsoever, including but not limited to, loss of

anticipated profits and any other loss caused by reason of non-operation of the goods. This exclusion is applicable to

claims for breach of warranty, tortious conduct or any other cause of action against seller.

General Monitors S5000 9

Page 10

US

2 Description

2 Description

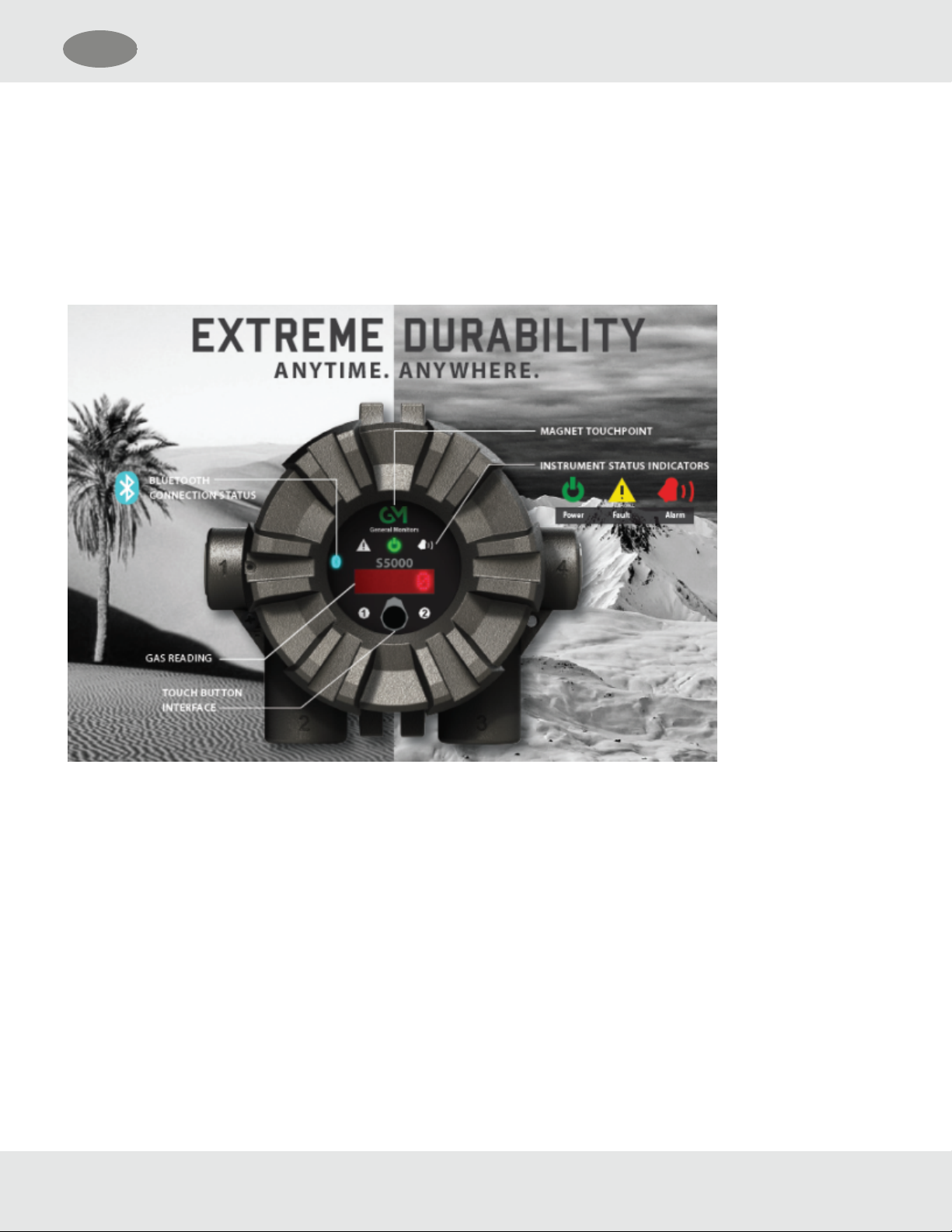

2.1 Display

The S5000 utilizes a dot matrix LED display, capable of displaying four alphanumeric characters at a time. The display will

scroll words that exceed four letters. Most of the messages scroll twice across the screen before moving onto next

selection.

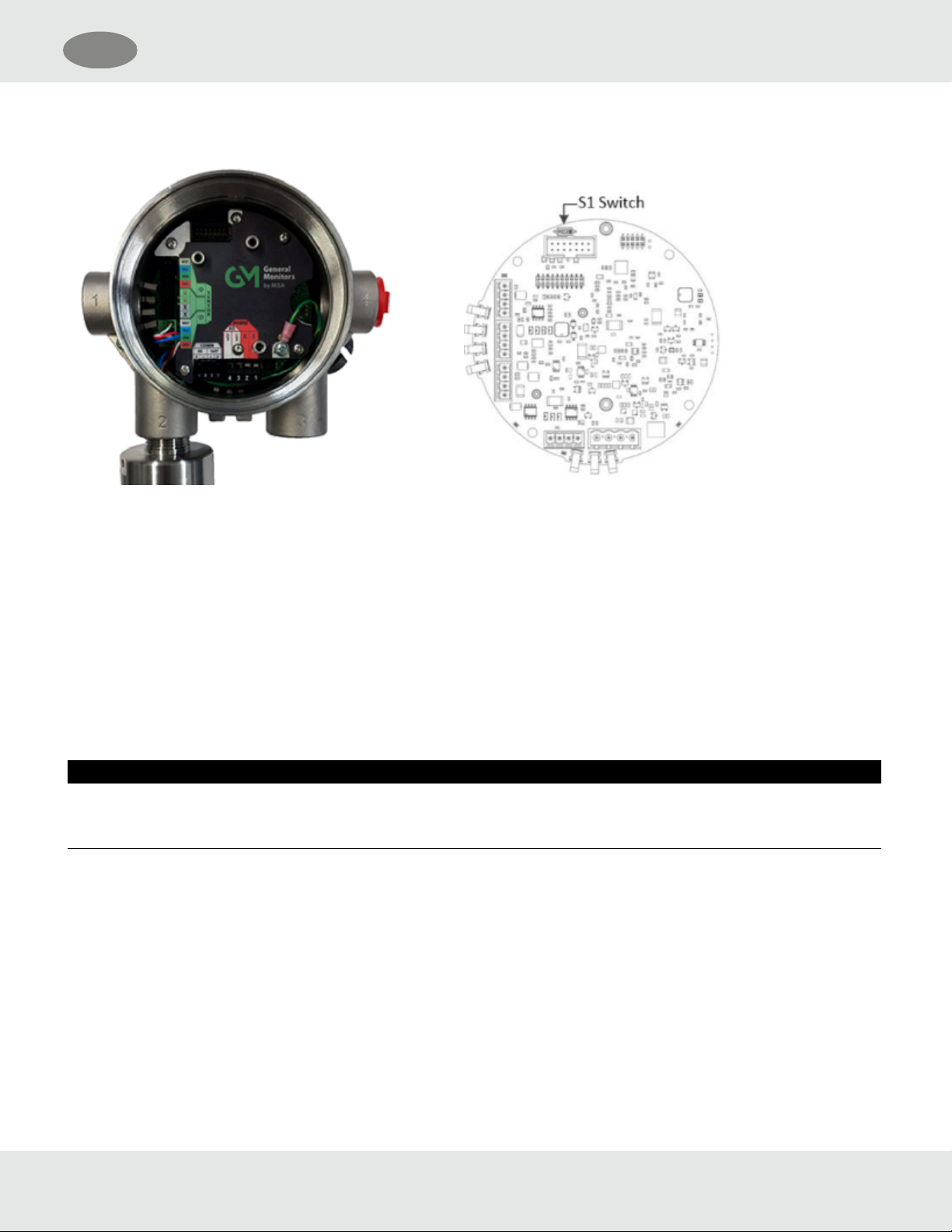

Figure 1 S5000 Main Display

In addition to the red LED display, the S5000 uses six icons to indicate status. Green LED indicates power supply status.

A yellow triangle and red bell indicate fault and warning or alarm conditions respectively. The Bluetooth®icon indicates that

the Bluetooth®wireless technology is enabled on the device. Yellow "1" and "2" icon indicate which sensor gas reading is

being displayed, or during configuration which sensor's options are being accessed.

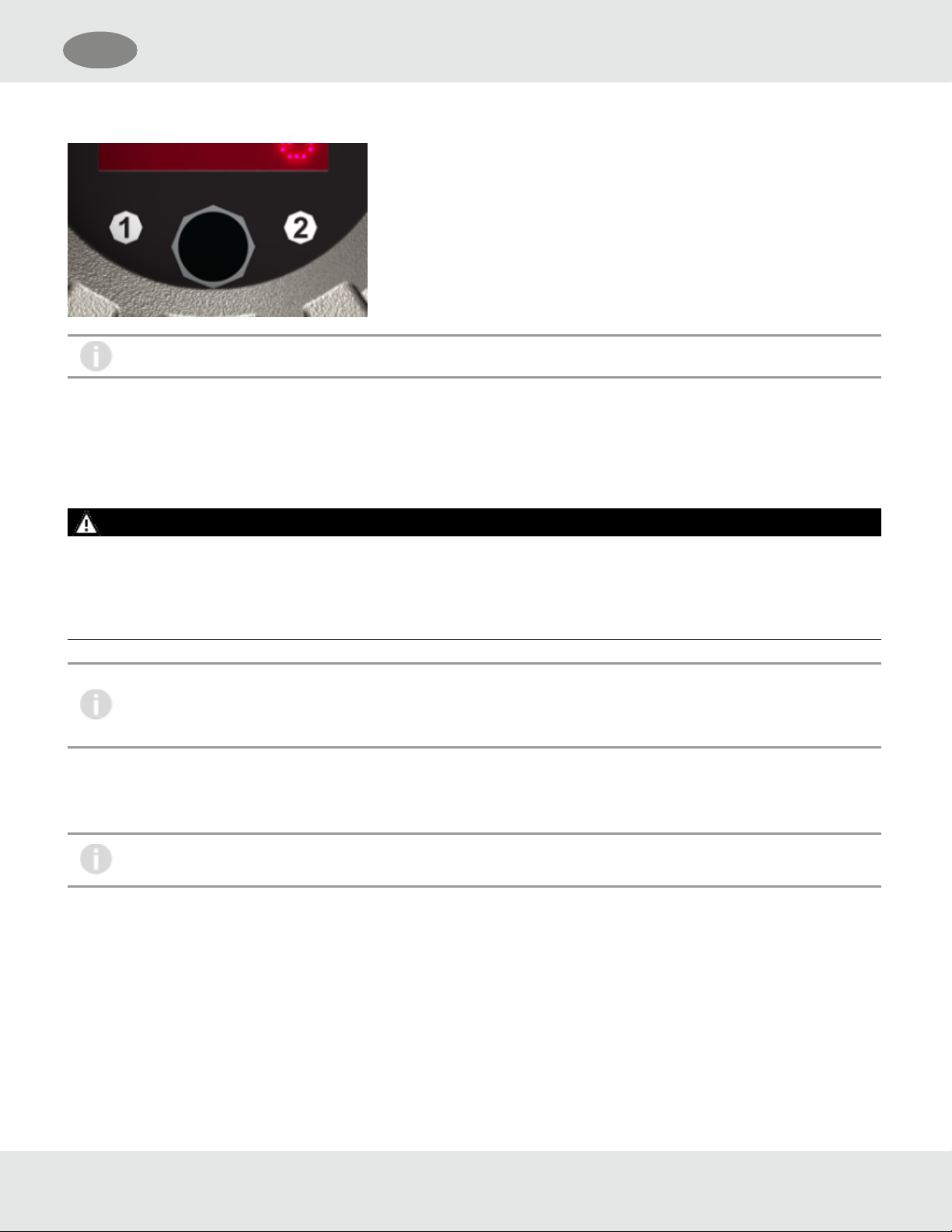

2.2 No Tool Interface

The S5000 does not require any tools or third party devices to change settings, reset alarms or perform any maintenance

operation. The EZtouchbutton works through the glass and does not require opening the explosion proof enclosure. The

EZtouchbutton works with bare fingers or with gloved hands, so long as the gloves are not black. See 4 Operation for more

information on navigating the menu with the EZtouchbutton.

General Monitors S5000 10

Page 11

US

2 Description

Figure 2 Interface

The user menu can also be accessed using the round GM magnet on the General Monitors logo.

2.3 Bluetooth®Wireless Technology

The S5000 comes by default with Bluetooth communication. Using the X/SConnectApp on an appropriate smart phone or

tablet, users are able to interface with the S5000 menu options in a larger and more user friendly setting. The Bluetooth

communication can interact with the device within a maximum transmission distance of 70feet (21m).

WARNING!

Bluetooth operation is dependent upon signal availability of the wireless service(s) necessary to maintain the

communication link. Loss of wireless signal will prevent communication of alarms and other information to linked devices.

Take appropriate precautions in the event a loss of wireless signal occurs.

Failure to follow this warning can result in serious personal injury or death.

If ordered with Bluetooth, the device will be shipped with Bluetooth enabled. See 4 Operation for instructions on

disabling Bluetooth.

If the device was not ordered with Bluetooth it cannot be upgraded.

The S5000 and user provided communication device will need to be paired. This requires both devices to be in range and for

a pairing sequence inputting a 6digitpairing code. The instructions will be displayed on both the S5000 and communication

device.

There are communication devices capable of being used in classified areas. Please contact your MSA

representative for additional information.

2.4 Dual Sensing

The S5000 supports two Digital Sensors, or one IRSensor point IR detector and one Digital Sensor simultaneously with

four wire connections. However, the device will only support one passive sensor, either combustible catalytic bead or

metal oxide semiconductor (MOS) sensors, based on the ATO configuration. Passive catalytic bead uses three wires,

passive MOS uses four wires.

The S5000 Gas Monitor generates two independent analog outputs; one for each sensor connected to the transmitter. The

analog output associated with Sensor1 also has the digital HART (Highway Addressable Remote Transducer)

General Monitors S5000 11

Page 12

US

2 Description

communication superimposed on the analog signal. If two sensors are connected, the digital HART communication carries

information for both sensors.

2.5 Retrofit Installations

The S5000 has the conduit entries located in the exact same orientation and distance from the wall and the mounting holes

for attaching to a wall are identical to the S4000Series detectors. Users will be able to re-use the existing wiring for the

remotely mounted sensors.

2.6 XCell Sensors Optimized for Fixed Gas Applications

XCell toxic and combustible catalytic bead sensors are developed and manufactured by MSA. Now optimized for fixed gas

applications, the XCell sensor platform is available in the S5000 and provides multiple benefits, including a standard 3-year

warranty on all XCellsensors.

One important optimization for fixed gas was incorporating the GM catalytic bead into the XCell sensor.

The XCell Oxygen sensor does not use lead, but rather a non-consuming reaction chemistry. The XCell Oxygen sensor is

expected to last well over 3years and can be safely stored on the shelf for at least 1 year without sensor performance

degradation. Changes in barometric pressure across the range of 86 kPA - 108 kPA have a negligible effect on the

operation of the sensor.

2.7 TruCal Sensing Technology for CO and H2S Electrochemical Sensors

Using patented pulse check technology and proprietary Adaptive Environmental Compensation (AEC) algorithms, all XCell

sensors with TruCal verify operation by actively adjusting the sensor output for changes in sensitivity. Some XCell sensors

with TruCal also include Diffusion Supervision, which monitors the sensor inlet for obstructions that could prevent gas from

reaching the sensor.

Every six hours, an electrical pulse stimulates the XCell sensor similar to having actual calibration gas applied, providing a

snapshot of the sensor's sensitivity at the time of the pulse. Using this sensitivity snapshot, the sensor can diagnose

sensor failures like electrode poisoning, electrolyte leaking, or electrical connectivity issues.

AEC uses the sensitivity snapshots provided by the pulse check to adjust sensor output, compensating for environmental

impacts on sensor accuracy. If the AEC adjustment is greater than expected based on typical environmental impact

variations, the transmitter LED’s will slowly flash GREEN, alerting users that the sensor should be calibrated to reset the

AEC cycle. Users can also enable a Calibration Alert function that will send a milli-amp signal on the analog output to the

control room. The result is a sensor that actively self-monitors for operation and accuracy, with far fewer manual

calibrations.

Diffusion supervision actively monitors the sensor inlet for obstructions. If an obstruction is detected, the sensor will go

into a fault mode to alert users and the control room that it is not seeing gas due to an obstruction. Objects residing directly

on or in the sensor inlet that result in a significant impact to the gas path are very likely to be detected by Diffusion

Supervision. Examples include paint, tape, water, and dirt. Small amounts of these materials can be visible on the inlet

while not impacting the gas path enough to trigger a Diffusion Supervision Fault. A fault signal will only be sent out when

the system determines that the amount of material that has accumulated on or inside the sensor inlet is negatively affecting

the gas path.

Actual TruCal sensor performance will depend on the application, background gas exposure, and environment. To validate

XCell sensors with TruCal, it is recommended that users follow their regular calibration cycle and record the "as found" and

"as left" values. This data can be used to extend the time between calibrations depending on the required specification of

the application.

General Monitors S5000 12

Page 13

US

2 Description

2.8 SafeSwap

The S5000 comes with patented SafeSwap technology, which allows users to change or replace XCellsensors without

needing to power down the instrument. Swap delay is enabled on the S5000 by default; a feature that gives users a

2minute window to change sensors without triggering a fault condition. SafeSwap and Swap Delay are only applicable for

XCellsensors. For more information on SafeSwap and Swap Delay, see 6 Maintenance.

WARNING!

• As part of the product certification, it was verified that optional communication functions of this gas detection

instrument while operating at the maximum transaction rate do not adversely affect the gas detection operation and

functions of the instrument. The product certification, however, does not include or imply approval of the SafeSwap

feature, communications protocol or functions provided by the software of this instrument or of the communications

apparatus and software connected to this instrument.

• Follow the warnings below when removing or replacing sensors. Reference Figure 3 for component overview.

– Never remove or replace a Sensor Body Assembly or an IRSensor while under power or when explosive hazards

are present.

– Confirm that the area is free of explosive hazards before removing or replacing an XCell Sensor under power.

– To remove an XCell Sensor, unscrew XCell Sensor three full turns, wait 10 seconds, and then remove the XCell

Sensor completely.

Failure to follow these warnings can result in serious personal injury or death.

2.9 Housing

The S5000 comes in 316StainlessSteel for the highest corrosion resistance. All housings have ¾”NPT conduit entries.

Custom tags are available and easily attach to an integral ring. The JB5000 junction box comes in 316 Stainless Steel for

the highest corrosion resistance. The housing is offered in ¾" NPTof M25 conduit entries.

General Monitors S5000 13

Page 14

US

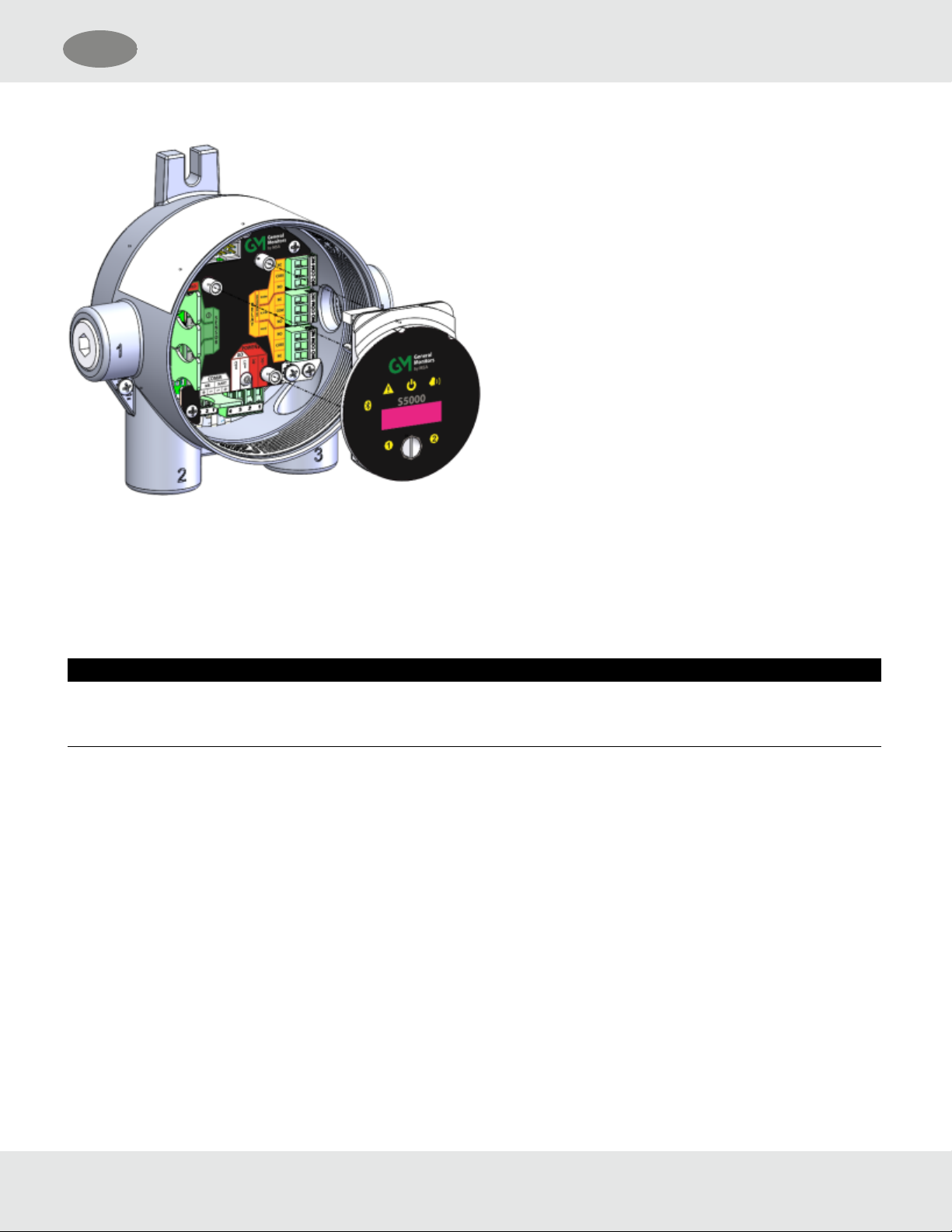

2.10 Component Overview

Figure 3 Exploded View

2 Description

General Monitors S5000 14

Page 15

US

2.11 Label Overview

Figure 4 Transmitter - Position of Labels

2 Description

Figure 5 Board stack - Position of Labels

Figure 6 Digital Sensor - Position of Labels

General Monitors S5000 15

Page 16

US

Figure 7 IRSensor - Position of Labels

Figure 8 Passive Sensor - Position of Labels

2 Description

General Monitors S5000 16

Page 17

US

3 Installation

3 Installation

3.1 Installation Warnings - Read Before Installation

WARNING!

• Refer to 9 Appendix: General Certification Information before installation and operation.

• Some Digital Sensors are provided in a fritless sensor housing. The fritless sensor housing is labeled as Div 2 or Zone 2

and is approved for Div 2 or Zone 2 installations only. The protection method is Nonincendive or Type n respectively.

Ensure all components are approved for the wiring method being used and in accordance with the National Electric

Code of the country of use, any applicable local regulations, and this manual.

• As part of the product certification, it was verified that optional communication functions of this gas detection

instrument while operating at the maximum transaction rate do not adversely affect the gas detection operation and

functions of the instrument. The product certification, however, does not include or imply approval of the SafeSwap

feature, communications protocol or functions provided by the software of this instrument or of the communications

apparatus and software connected to this instrument.

• Follow the warnings below when removing or replacing sensors. Reference Figure 3 for component overview.

– Never remove or replace a sensor body assembly or an IRSensor while under power or when explosive hazards

are present.

– Confirm that the area is free of explosive hazards before removing or replacing an XCell Sensor under power.

– To remove an XCell Sensor, unscrew XCell Sensor three full turns, wait 10 seconds, and then remove the XCell

Sensor completely.

• Plug all unused conduit entries with a suitably certified blanking/stopping plug.

• Do not paint the device. Avoid painting in areas where the S5000 and remote sensor junction box are located. If painting

is required in an area where an S5000 or remote sensor has been installed, exercise caution to ensure paint is not

deposited on the sensor inlet fitting. Paint solvents can also cause an alarm condition to occur or potentially poison

electrochemical sensors.

• Protect the device from extreme vibration.

• Do not mount the sensing head in direct sunlight without a sunshield (P/N 10180254).

• IR Sensors contain no user- or field-serviceable parts and must be returned to the factory for repair. Any attempt to open

the monitor will damage the unit and void the warranty.

Failure to follow these warnings can result in serious personal injury or death.

NOTICE

When installing the IRSensor, under no circumstances should a pry-bar be applied to the two legs that support the unit's

reflectors during installation or removal of the sensor. Applying force to the legs can permanently damage the IRSensor.

3.2 Reviewing Shipment and Identifying Product Model

To determine the sensor type and options, check the shipping carton.

General Monitors S5000 17

Page 18

US

3 Installation

Figure 9 Shipping Label

Passive, Digital, and IR sensors are shipped attached to the S5000. Passive and IR Sensors are one-piece sensors.

Digital sensors comprise two parts: the Sensor Body Assembly and the XCell Sensor. Sensor Body Assemblies must be

installed and tightened using a strap wrench.

Check the sensor details before attaching to the S5000 housing. The sensor details are listed on the inside of the XCell

Sensor. Unscrew the XCell Sensor from the sensor body assembly and check the label on the inside for gas type, range,

configuration ordered, serial number, and firmware revision number.

3.3 Product Installation Check List

Before Installation

• Review national electrical codes

• Review local procedural and building codes

• Determine optimum transmitter placement

• Determine wire requirements

• Determine mounting hardware requirements

• Review approvals and ensure suitability for installation

Mounting

• Attach appropriate sensor to housing or junction box (see 3.4.3 Sensor Orientation for proper sensor orientation)

• Mount transmitter or junction box using appropriate mounting hardware

• Confirm free air flow around the sensor

3.4 Mounting

WARNING!

Refer to 9 Appendix: General Certification Information before installation.

Some toxic gases are provided in a fritless sensor housing. The fritless sensor housing is labeled as Div 2 or Zone 2 and is

approved for Div 2 or Zone 2 installations only. The protection method is Nonincendive or Type n respectively. Ensure all

General Monitors S5000 18

Page 19

US

3 Installation

components are approved for the wiring method being used and in accordance with the National Electrical Code of the

country of use, any applicable local regulations, and this manual.

Failure to follow this warning can result in serious personal injury or death.

3.4.1 Sensor Mounting Location

The best location for the transmitter and the sensor may not be the same location. Sensors should be placed in a location

where a gas leak is most likely to be detected. When the best sensor placement would not allow the transmitter display to

be easily viewed or accessed, a remote junction box can be used to mount the sensor remotely from the transmitter,

allowing both to be installed in the optimum location.

Two main factors should be considered when choosing a sensor location. The first is the density of the target gas relative

to the air. Gases, such as propane, that are heavier than air should be placed near ground level while gases that are lighter

than air should be placed above potential leak sources.

Optimum sensor placement will depend on the surrounding processing equipment, such as pipes, valves, or turbines. MSA

offers a gas and flame mapping service that systematically evaluates potential sources of leaks and recommends detector

quantity and placement to create the most effective detection system.

3.4.2 Transmitter Mounting Location

The transmitter display should be mounted so that the screen is visible and easily accessed after installation. The

electronics assembly inside the enclosure have one orientation inside the cylindrical housing. Take care to position the

conduit entries and display so that the display is read in the correct orientation.

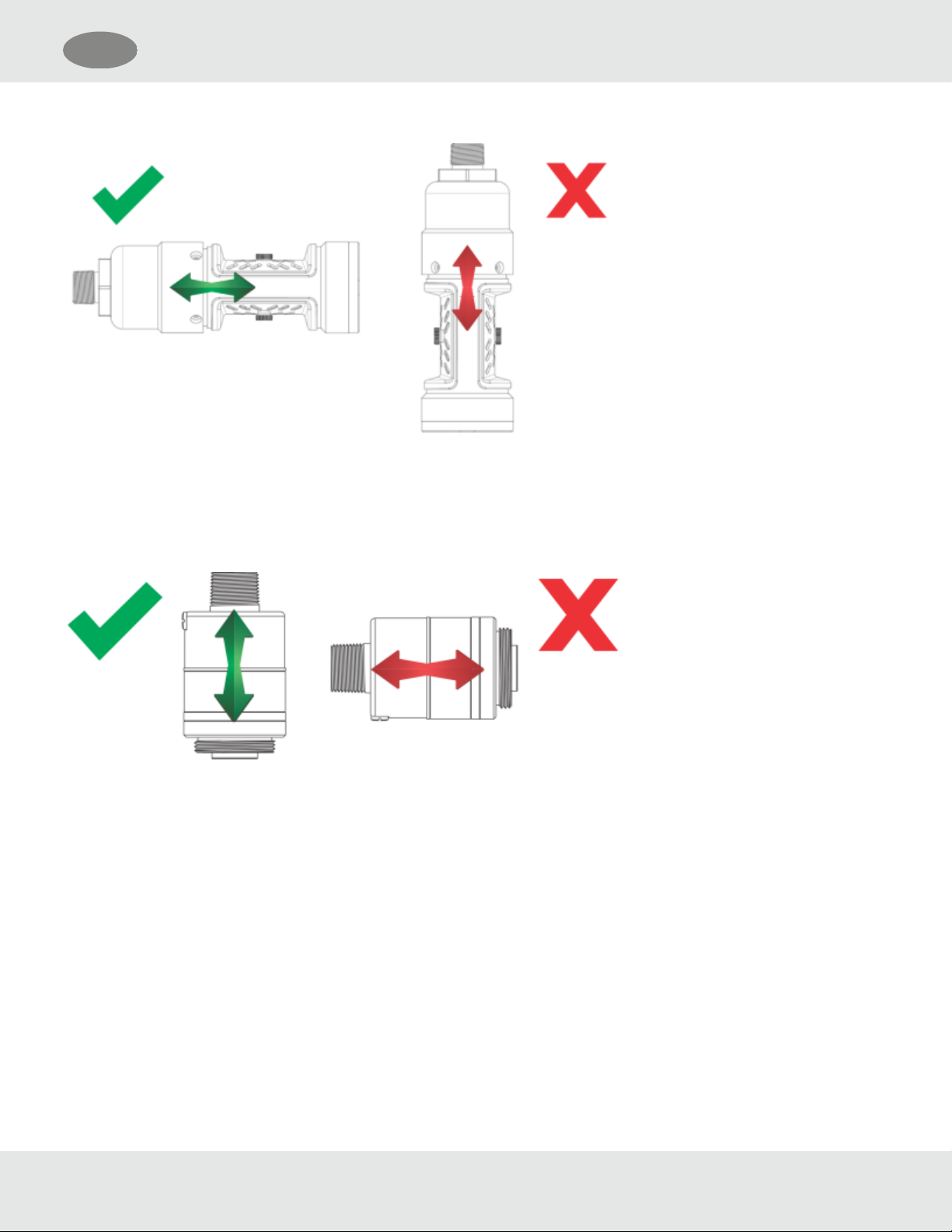

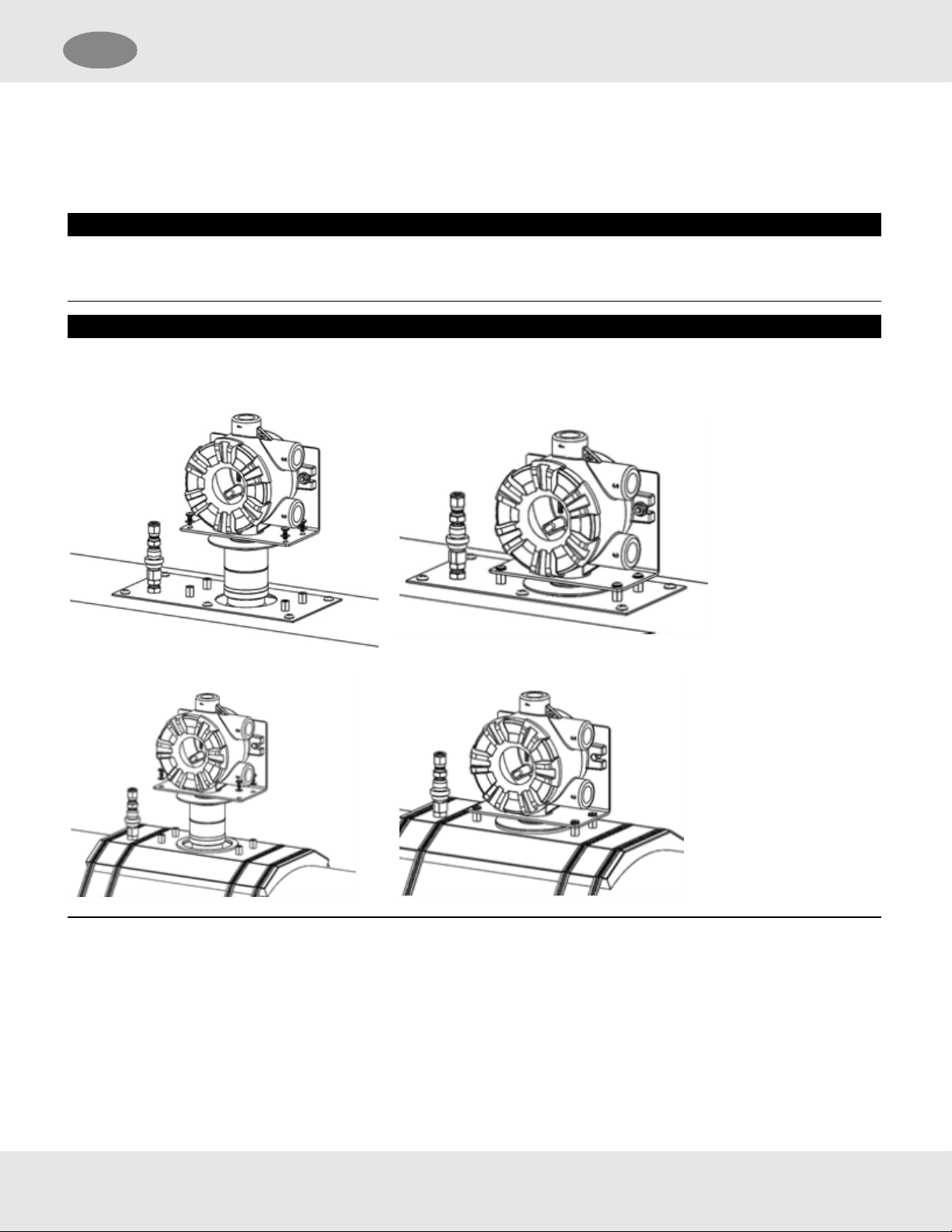

3.4.3 Sensor Orientation

WARNING!

Mount the IR Sensor with the sensor inlet fitting extended horizontally from the main enclosure (see Figure 10 ) to prevent

the build-up of particulate or liquid matter on the monitor's optical surfaces.

Mount the digital sensor with the sensor inlet fitting (see Figure 11 ) pointed downward; otherwise, the inlet may become

clogged with particulate matter or liquids.

Failure to follow this warning can result in serious personal injury or death.

Sensor orientation will depend on the sensor type. If mounting an IRSensor, whether locally on the transmitter or via

remote junction box, the sensor should be mounted horizontally. If the IRSensor is not mounted horizontally, the sensor

will be prone to more frequent beam blocking issues due to accumulated dust and condensation on the surface of the

IRSensor. Figure 10 shows the correct and incorrect mounting orientations for the IRSensor.

General Monitors S5000 19

Page 20

US

3 Installation

Figure 10 Correct and Incorrect Mounting Orientations for IR Sensor

All other sensors, including electrochemical, catalytic bead, oxygen, passive catalytic bead, and passive MOS should be

mounted vertically with the gas inlet pointed downward. If the sensor is not mounted with the gas inlet facing down, it is

more likely to become clogged with particulate matter or liquids. Figure 11 shows the correct and incorrect mounting

orientation for digital sensors. Passive catalytic bead and MOS sensors come already installed on the transmitter housing.

Figure 11 Correct and Incorrect Mounting Orientation for Digital Sensors

3.4.4 Connecting Sensor to Transmitter Housing or Remote Junction Box

Digital and IRSensors are shipped attached to the main enclosure. The main sensor input is provided via a four-terminal

connection that provides a digital interface for all sensor modules. Up to two sensors (excluding passive sensors) can be

connected to a single transmitter with two analog outputs capable of representing the readings of the individual sensors.

Passive sensors are shipped already attached and electrically wired to the device. Only one passive sensor can be used

on a single S5000, and they are not interchangeable with other passive sensors or digital sensors.

Consider the sensor dimensions when choosing a mounting location for the transmitter or junction box.

To connect the sensor:

(1) Loosen the set screw located on the lid using a 1.5mm Allen wrench.

(2) Turn the lid counter-clockwise to remove.

(3) Pull out display module to expose terminal connections.

General Monitors S5000 20

Page 21

US

Figure 12 Terminal Connections

3 Installation

(4) Route the cable from the sensor through a conduit entry hole in the enclosure so that the sensor is oriented in the

correct position (see 3.6 Electrical Power Connections for details).

(Repeat to attach a second sensor to the S5000 transmitter).

(5) Connect the sensor to the "Sensor 1" position on the electronics assembly.

a) If using a second sensor, connect it to the second sensor position.

NOTICE

If only using one sensor and it is connected to “Sensor2”position, the S5000 will enter Sensor Missing fault. See Disable

Sensor in 4.2.2 Sensor Setup for details on how to clear this fault.

General Monitors S5000 21

Page 22

US

3 Installation

Figure 13 Connecting Sensor to the

Stack and Grounding Terminal

Figure 14 SOURCE/SINK Switch

Location

(6) Verify the sensor connector is firmly seated on the terminal board.

(7) Attach the sensor's ground to either of the grounding screws inside the S5000 housing.

(8) Set the analog output to SOURCE or SINK using tweezers, flat head screwdriver or similar tool.

a) With the display board removed, locate “S1” switch on the main board (see Figure 14 ).

b) Set “S1” switch in the required position:

For SINK, set switch to the right side.

For SOURCE, set switch to the left side.

(9) Replace the display module. Push firmly on the board stack.

NOTICE

Ensure that the electronics assembly is fully engaged in the mounting holes. If not fully seated, the touch interface

performance can be negatively affected.

(10) Replace the cover by turning clockwise.

(11) Tighten the set screw located on the lid using a 1.5mm Allen wrench.

NOTE: The JB5000 junction box is not compatible with IR400 and passive sensors.

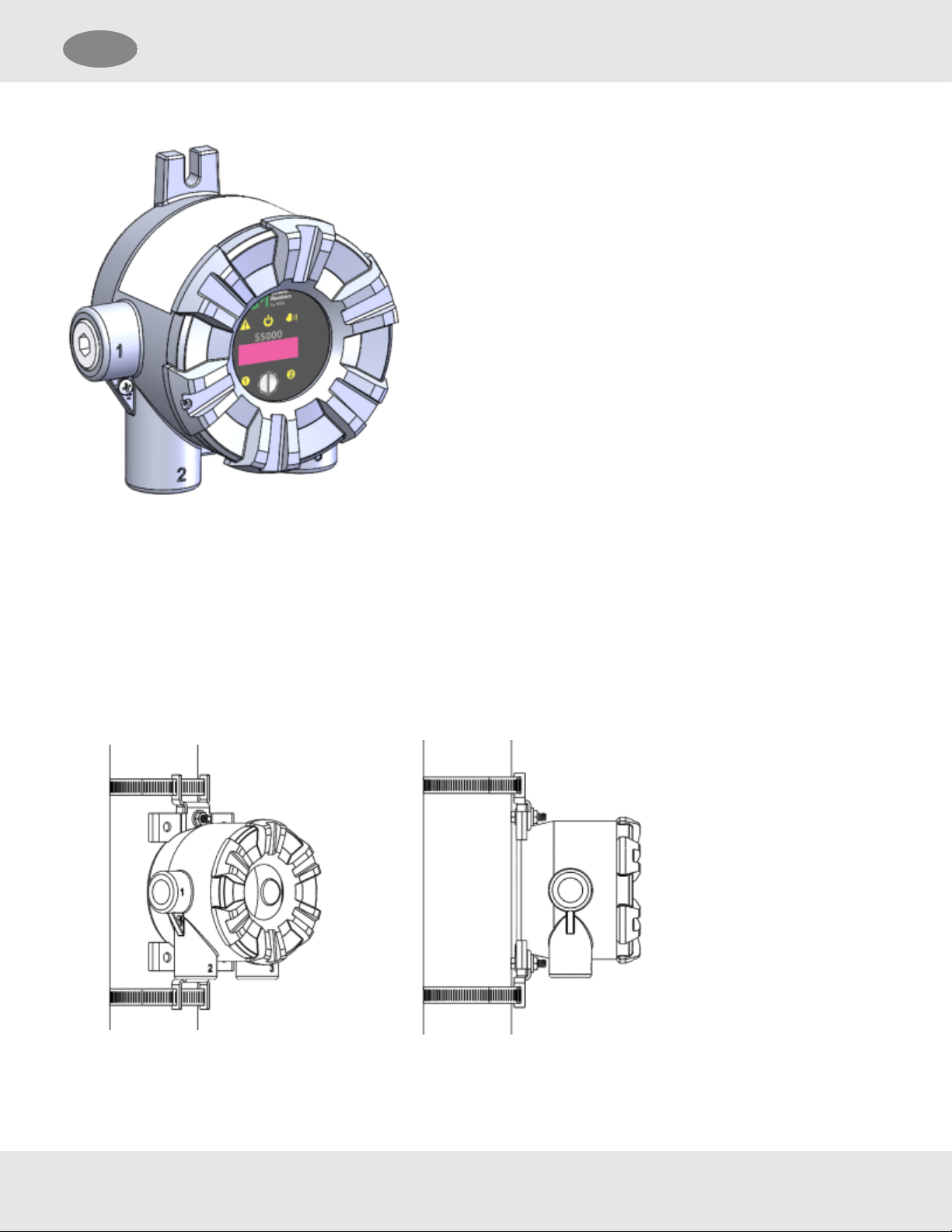

3.4.5 Integrated Mounting Points

The S5000 transmitter can be surface mounted without any additional brackets using the integrated mounting tabs.

General Monitors S5000 22

Page 23

US

Figure 15 Integral Mounting Tabs

3 Installation

Mounting Points JB5000 Junction Box

The JB5000 junction box can be mounted directly using the 4 integrated 10-32 threaded holes on the back of the enclosure

or with the use of a mounting bracket (P/N 10206570).

3.4.6 Adjustable Pipe Mount

A Universal Pipe Mount Kit (P/N 10176946) can be used to mount the S5000 on pipes ranging from 20-150mm in diameter.

Two brackets are mounted over the top of the integrated mounting tabs and fitted with an adjustable pipe band (not

included).

Figure 16 Adjustable Pipe Mount

General Monitors S5000 23

Page 24

US

3.4.7 Duct Mount

Duct mount kits are available for monitoring atmosphere inside flat or round ducts. Round duct mount kits are available for

small ducts 12-20" in diameter (P/N10179323) and large ducts 20-40" in diameter (P/N 10179324). The flat duct mount

(P/N10179322) is universal for flat ducts.

NOTICE

Consider the sensor type before choosing a duct mount location. IRSensors should be mounted horizontally and all other

sensors should be mounted vertically.

NOTICE

Air flow in the duct must be zero to ensure proper calibration.

Figure 17 Flat Duct Mount

3 Installation

Figure 18 Round Duct Mount

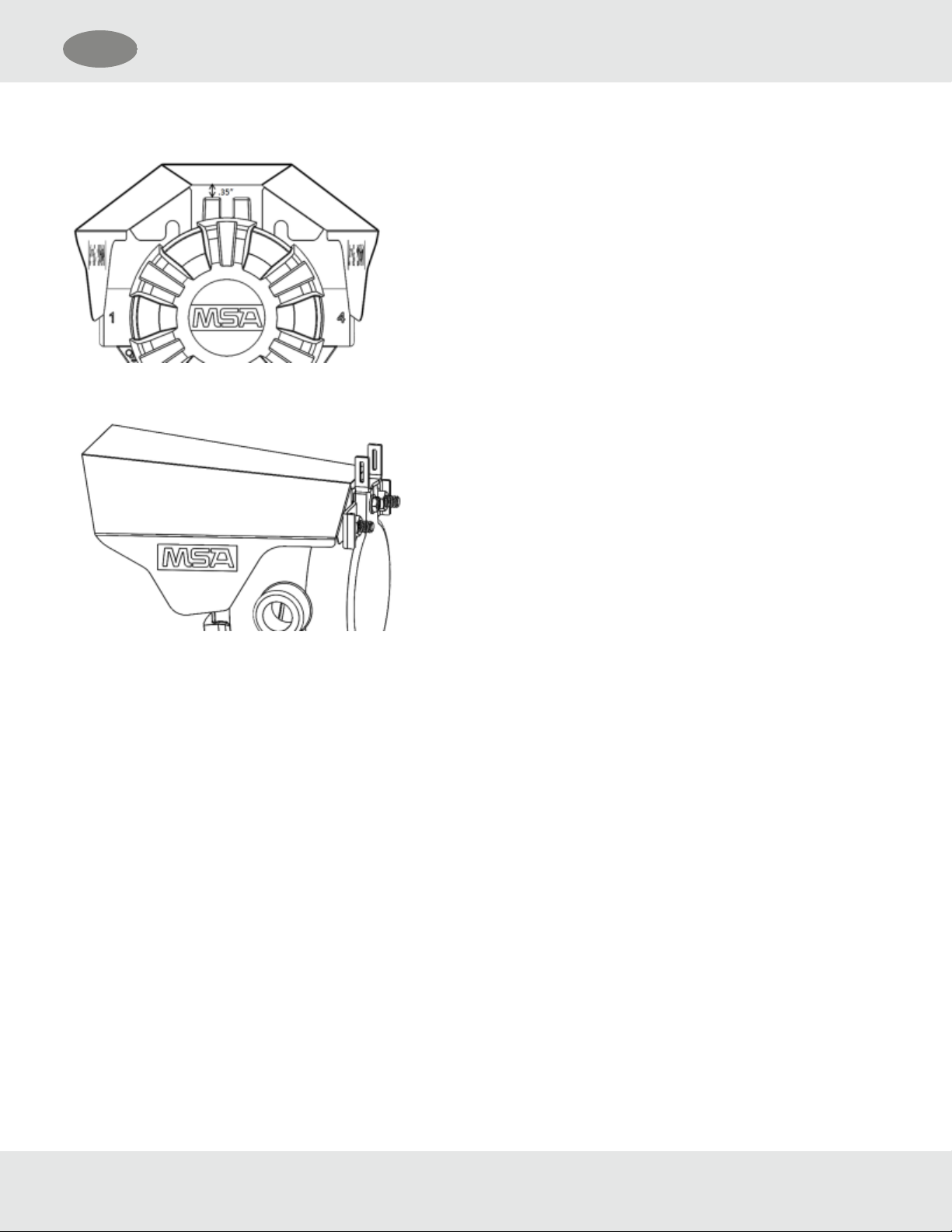

3.4.8 Mounting with a Sunshield

A sunshield is required to protect the S5000 from direct sun light (P/N 10180254). The sunshield can be used in any of the

mounting configurations.

General Monitors S5000 24

Page 25

US

Figure 19 Sunshield with Surface Mount

Figure 20 Sunshield with Universal Pipe Mount

3 Installation

3.4.9 Mounting with an SM5000 Sampling Module

An aspirated (P/N10158101) and a DC pump (P/N10043264) model are available for use with the S5000 with the Digital

Sensor. For more information on mounting requirements and use with the SM5000 sampling modules, see the SM5000

operating manual(s).

General Monitors S5000 25

Page 26

US

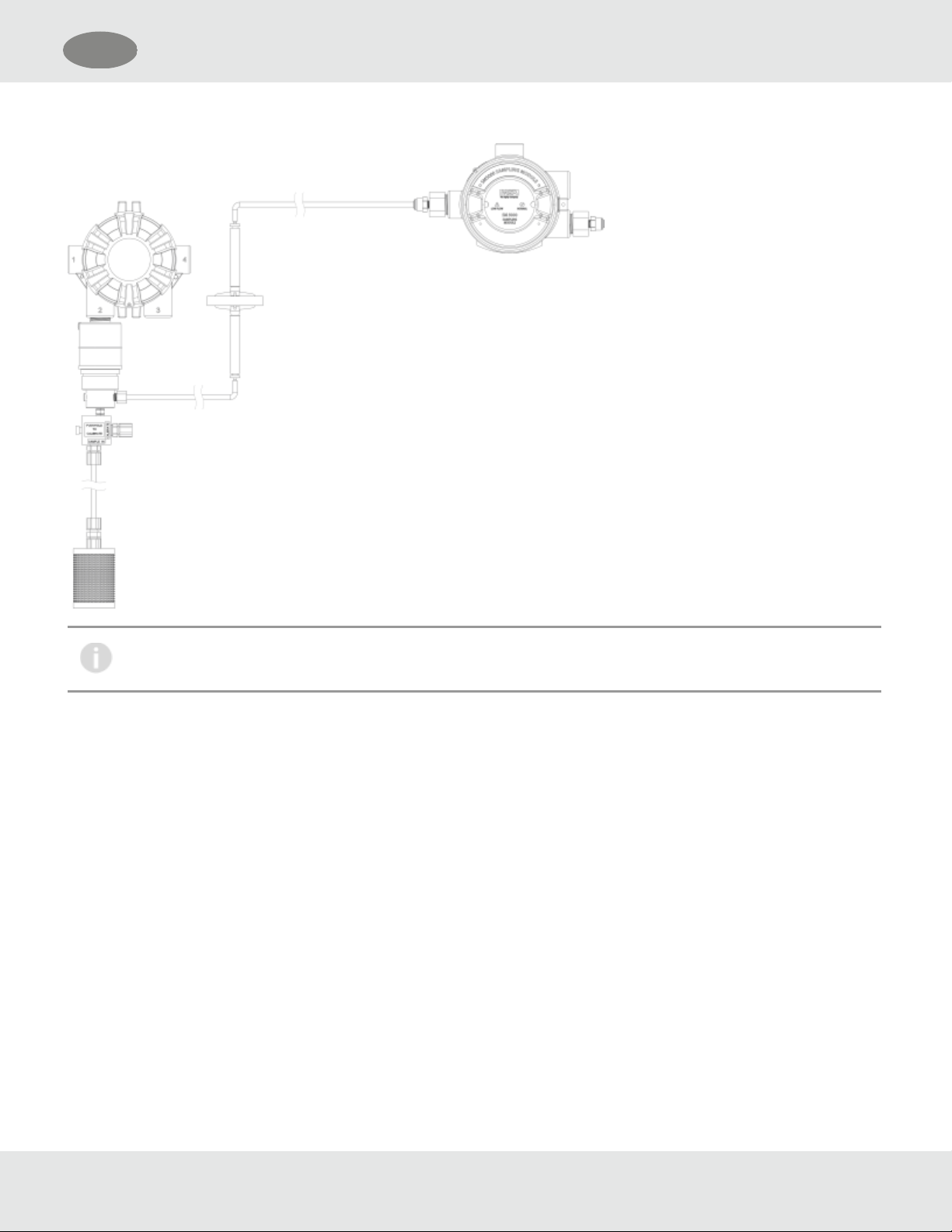

Figure 21 Mounting the SM5000 with a Digital Sensor

3 Installation

SM5000 is not for sale in EU.

Diffusion Supervision must be disabled when using the SM5000.

3.5 Installing a Remote Sensor Junction Box

Sensors mounted remotely must use the S5000 junctionbox. The junction box housing is the same construction as the

transmitter. The mounting options and instructions for connecting the sensor are the same for sensors connected directly

to the S5000 transmitter housing. The junction box is available in 316StainlessSteel.

Sensors can be remote mounted up to 100m from the transmitter housing, as long as the S5000 transmitter is mounted

within maximum distance from the power supply, as indicated in Table 1 .

The junction box does not have an illuminated display and has two connectors for attaching a single sensor input and an

output connects to the transmitter. A 16AWG 4element cable with a braided shield should be used for the electrical

connection between the junction box and the S5000 transmitter. Specific cable recommendations are available upon

request.

General Monitors S5000 26

Page 27

US

Figure 22 Junction Box

3 Installation

Figure 23 Junction Box Electrical Connections

3.6 Electrical Power Connections

3.6.1 Electrical Warnings - Read before Connecting Power

WARNING!

• Before wiring the S5000 transmitter, disconnect the power source supplying the transmitter and ensure no hazardous

atmosphere present; otherwise, electrical shock or ignition of hazardous gases could occur.

• Install wiring in accordance with the electrical code of the country in use, the local authority having jurisdiction and

these installation instructions, as applicable.

General Monitors S5000 27

Page 28

US

3 Installation

• Do not make any connections to the S5000 main board or junction box input, output, and relay connections while under

power. Making connections under power could lead to electrical shock or ignition of a hazardous atmosphere.

• Ensure that water and dirt are not able to enter the unit via the wire or conduit. If the unit is installed in a location known

to be wet or damp, it is good practice to loop or bend the entry into the unit that prevents water incursion.

• The internal grounding terminal (located on the interior metal board stack plate) must be used for equipment grounding.

The external grounding terminal is only to be used as a supplemental bonding connection where local authorities permit

or require such a connection.

• As part of the product certification, it was verified that optional communication functions of this gas detection

instrument while operating at the maximum transaction rate do not adversely affect the gas detection operation and

functions of the instrument. The product certification, however, does not include or imply approval of the SafeSwap

feature, communications protocol or functions provided by the software of this instrument or of the communications

apparatus and software connected to this instrument.

• Follow the warnings below when removing or replacing sensors. Reference Figure 3 for component overview.

– Never remove or replace a sensor body assembly or an IRSensor while under power or when explosive hazards

are present.

– Confirm that the area is free of explosive hazards before removing or replacing an XCell Sensor under power.

– To remove an XCell Sensor, unscrew XCell Sensor three full turns, wait 10 seconds, and then remove the XCell

Sensor completely.

Failure to follow these warnings can result in serious personal injury or death.

3.6.2 Retrofit Applications with S4000CH, S4000TH, or TS4000H

The S5000 was designed to be easily retrofitted with existing S4000CH, S4000TH, and TS4000H wiring. When replacing

an existing S4000CH, S4000TH, or TS4000H with the equivalent S5000 sensor technology, the following items need to be

checked in order for the S5000 to operate:

(1) Wire gauge needs to be 18-14 AWG

(2) Sufficient power must be supplied to the S5000 in accordance with the maximum wire lengths. (See the tables in

3.6.4 Power Load Requirements and Maximum Mounting Distances)

If these requirements are met, performance of the S5000 should meet the noise immunity standard equivalent of the

S4000CH, S4000TH, and TS4000H using the existing wiring; However, the installation may not meet the latest EMC

EN50270 noise immunity standard that the S5000 meets with the grounding and wiring scheme as indicated in this manual

and corresponding I/O drawing.

3.6.3 Electrical Hardware Requirements

Braided shielded, twisted pair, instrument quality wire or cable should be used to minimize the possibility of noise

interference and contact with other voltages. Selection of shielded cable must comply with local requirements.

Conduit, in addition to braided shielded wire, may also be needed in areas where a large amount of electrical noise is

expected. All cable shields should be terminated to earth ground at one end only.

The S5000 has a four-wire power terminal, one four-wire communication terminal, and three four-wire sensor terminals.

Relays can be added as an option. Terminals for power and relays can take wires up to 12AWG while all other terminals

take wires up to 14AWG. Four conductors are also required for the S5000 remote junction boxes.

General Monitors S5000 28

Page 29

US

Incoming power and signal cables should be a braided shield cable such as AlphaWire3248 or equivalent. The braided

shield must be terminated to the board stack as shown in Figure 27 , or alternatively, the earth ground at the user’s power

source location.

An external Class2 power supply is required to supply 12-30VDC to the S5000. Incoming power and signal cables should

be a braided shield cable such as AlphaWire3248 or equivalent.

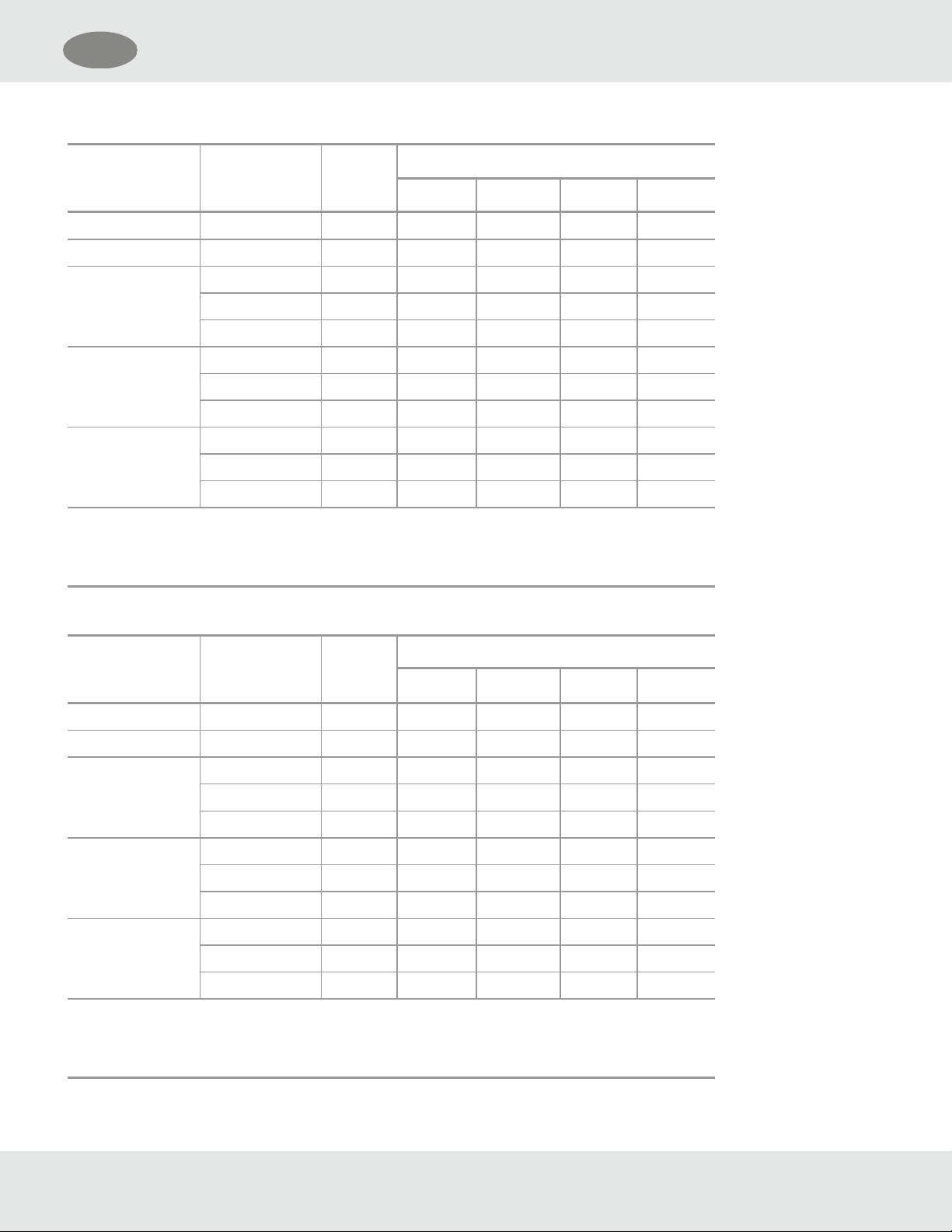

3.6.4 Power Load Requirements and Maximum Mounting Distances

Consider future needs when selecting cable size and power supply. The maximum distance between the S5000 transmitter

and the power supply depends on the sensor configuration (sensing technology and one or two sensors), wire gauge, and

the power supply voltage. The table below outlines the maximum transmitter mounting distances. First determine if the

sensor(s) will be locally or remotely mounted. Then choose sensor type(s). The corresponding maximum power and

mounting distances by wire gauge are shown.

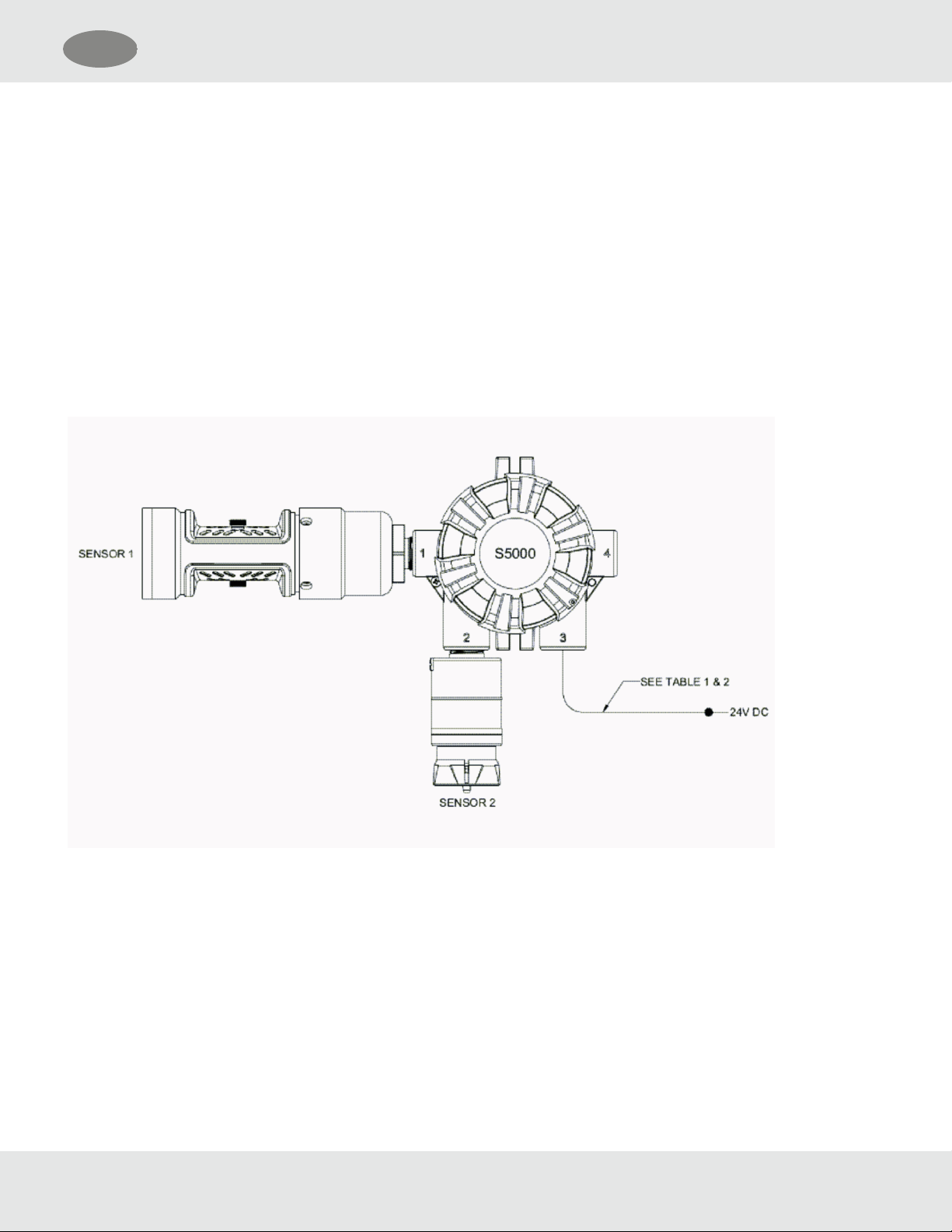

Figure 24 Local Sensors

3 Installation

General Monitors S5000 29

Page 30

US

Table 1 Maximum Mounting Distance for Local Sensors, Imperial Units

3 Installation

Local Sensor 1 Local Sensor 2

Max.

Power

(W)

Max. Distance (ft)

1

18 AWG 16 AWG 14 AWG 12 AWG

Passive CB None 6.0 1280 2030 3230 5130

Passive MOS None 10.8 710 1130 1790 2850

Digital CB None 6.0 1280 2030 3220 5130

Digital CB 8.4 910 1450 2300 3660

Digital Toxic 6.7 1140 1810 2880 4580

Digital Toxic None 3.6 2130 3380 5370 8550

Digital Toxic 4.3 1770 2820 4480 7120

Digital CB 6.7 1140 1810 2880 4580

IR Sensor None 8.9 860 1370 2180 3470

Digital CB 11.8 650 1040 1650 2620

Digital Toxic 9.6 800 1270 2020 3210

1

- When sizing a system's 24V supply, a 1A inrush current with a 1ms duration should be

considered for each device on the power supply

Assumes transmitter was ordered with relays

Table 2 Maximum Mounting Distance for Local Sensors, Metric Units

Local Sensor 1 Local Sensor 2

Max.

Power

(W)

Max. Distance (m)

1

1 mm

2

1.5 mm22.5 mm24 mm

Passive CB None 6.0 470 710 1180 1890

Passive MOS None 10.8 260 390 660 1050

Digital CB None 6.0 470 710 1180 1890

Digital CB 8.4 340 510 840 1350

Digital Toxic 6.7 420 630 1050 1690

Digital Toxic None 3.6 790 1180 1970 3150

Digital Toxic 4.3 650 980 1640 2620

Digital CB 6.7 420 630 1050 1690

IR Sensor None 8.9 320 480 800 1280

Digital CB 11.8 240 360 600 960

Digital Toxic 9.6 290 440 740 1180

1

- When sizing a system's 24V supply, a 1A inrush current with a 1ms duration should be

considered for each device on the power supply

2

Assumes transmitter was ordered with relays

General Monitors S5000 30

Page 31

US

Figure 25 Local and Remote Sensors

3 Installation

General Monitors S5000 31

Page 32

US

Table 3 Maximum Mounting Distance for Local and Remote Sensors, Imperial Units

3 Installation

Remote Sensor Local Sensor

Max.

Power

(W)

Max. Distance (ft)

1

18 AWG 16 AWG 14 AWG 12 AWG

Passive CB None 6.2 1240 1970 3140 4990

Passive MOS None 11.2 690 1090 1730 2760

Digital CB None 6.2 1240 1970 3130 4980

Digital CB 8.6 890 1420 2260 3590

Digital Toxic 6.9 1110 1770 2810 4460

IR Sensor 11.9 640 1020 1620 2580

Digital Toxic None 3.6 2130 3380 5370 8550

Digital Toxic 4.3 1770 2820 4480 7120

Digital CB 6.7 1140 1810 2880 4580

IR Sensor 9.6 800 1270 2020 3210

IR Sensor None 9.0 850 1350 2140 3410

Digital CB 11.9 640 1020 1620 2580

Digital Toxic 9.7 790 1250 1980 3160

1

- When sizing a system's 24V supply, a 1A inrush current with a 1ms duration should be

considered for each device on the power supply

Assumes transmitter was ordered with relays

General Monitors S5000 32

Page 33

US

Table 4 Maximum Mounting Distance for Local and Remote Sensors, Metric Units

3 Installation

Remote Sensor Local Sensor

Max.

Power

(W)

Max. Distance (m)

1

1 mm

2

1.5 mm22.5 mm24 mm

Passive CB None 6.2 460 690 1150 1840

Passive MOS None 11.2 250 380 630 1010

Digital CB None 6.2 460 690 1150 1840

Digital CB 8.6 330 490 830 1320

Digital Toxic 6.9 410 620 1030 1640

IR Sensor 11.9 240 360 590 950

Digital Toxic None 3.6 790 1180 1970 3150

Digital Toxic 4.3 650 980 1640 2620

Digital CB 6.7 420 630 1050 1690

IR Sensor 9.6 290 440 740 1180

IR Sensor None 9.0 310 470 780 1260

Digital CB 11.9 240 360 590 950

Digital Toxic 9.7 290 440 730 1160

1

- When sizing a system's 24V supply, a 1A inrush current with a 1ms duration should be

considered for each device on the power supply

2

Assumes transmitter was ordered with relay

General Monitors S5000 33

Page 34

US

Figure 26 Remote Sensors

3 Installation

Table 5 Maximum Mounting Distance for Remote Sensors, Imperial Units

Remote Sensor1Remote Sensor

2

Max.

Power

(W)

Max. Distance (ft)

1

18 AWG 16 AWG 14 AWG 12 AWG

IRSensor Digital CB 12.4 620 980 1560 2480

IRSensor Digital Toxic 9.8 780 1240 1980 3150

Digital CB Digital CB 9.1 840 1340 2130 3380

Digital CB Digital Toxic 6.9 1100 1760 2790 4440

Digital Toxic Digital Toxic 4.3 1770 2810 4470 7110

1

- When sizing a system's 24V supply, a 1A inrush current with a 1ms duration should be

considered for each device on the power supply

Assumes transmitter was ordered with relays

General Monitors S5000 34

Page 35

US

Table 6 Maximum Mounting Distance for Remote Sensors, Metric Units

3 Installation

Remote Sensor1Remote Sensor

2

Max.

Power

(W)

Max. Distance (m)

1

1 mm

2

1.5 mm22.5 mm24 mm

IRSensor Digital CB 12.4 230 340 570 910

IRSensor Digital Toxic 9.8 290 430 720 1160

Digital CB Digital CB 9.1 310 470 780 1250

Digital CB Digital Toxic 6.9 410 610 1020 1640

Digital Toxic Digital Toxic 4.3 650 980 1640 2620

1

- When sizing a system's 24V supply, a 1A inrush current with a 1ms duration should be

considered for each device on the power supply

Assumes transmitter was ordered with relays

3.6.5 Instructions for Power and Analog Output

WARNING!

Read all electrical warnings and wiring requirements before connecting power to the S5000.

Failure to follow this warning can result in serious personal injury or death.

2

Connector for HART analog output and power are provided to increase ease of connecting power.

Connect power and remote sensor cable shields to shield terminals on the main PC board. Provide shield terminations

inside he sensor housing as indicated on the installation outline drawing.

(1) Remove the cover by turning counter-clockwise.

(2) Remove the display module to expose the wiring terminations and sensor connections.

(3) Remove the 5.08mm pitch connector for power supply. The power connector is larger than other 3.81mm pitch

connectors.

(4) Use a small flat head screw driver to open wire entries on connector.

(5) Insert wires to connector so that when installed each wire is in the correct location.

1. +DC

2. -DC

3. mA1 - analog output of sensor1

4. mA2 - analog output of sensor2

(6) Tighten screws on connector and tug gently on wires to ensure they are secure.

(7) Attach the connector to the board stack.

General Monitors S5000 35

Page 36

US

3 Installation

(8) Make sure the appropriate wires are in the correct terminals.

(9) Remove enough of the wire housing to expose the 3-4inches of the cable shielding, but do not expose so much that it

goes beyond the cable entry.

(10) Attach the cable, shielding exposed, to the grounding point.

(11) Replace the display module. Push firmly on the board stack where indicated.

(12) Replace the S5000 cover by turning clockwise. Be sure to align threads to avoid cross-threading.

Figure 27 Connecting Power and Grounding Cable

NOTICE

Ensure that the electronics assembly is fully engaged in the mounting holes. If not fully seated, the touch interface

performance can be negatively affected.

Care must be taken to ensure the S5000 inside glass surface glass is free of smudges/dirt and grease. Dirt and grease can

interfere with the touch interface of the display.

S5000 Installation Outline Drawings

Table 7 Installation Outline Drawings

Model Document No.

S5000 324102

General Monitors S5000 36

Page 37

US

3 Installation

3.6.6 Relay Electrical and Power Connections

Relay Board Stack Overview

The S5000 can be purchased with three relays. Two of the relays can be configured for either de-energized (default) or

energized and latching or non-latching. The third relay is a dedicated fault relay.

All electrical connections to internal relays can be made directly on the PC board. The board is labeled for Normally Open

(NO) and Normally Closed(NC) de-energized state.

Figure 28 PC Board with Relays

Relay Specifications

Table 8 Relay Specifications

Temperature Range -40 to +85°C (-40 to 185°F)

Relays SPDT (Single Pole Double

Throw)

Fault Normally Energized

Warning Configurable

Alarm Configurable

Relay Rating

125 or 250 VAC (Resistive) 5A, 100K Cycles

1.6 HP @ 250VAC

30 VDC (Resistive) 5A, 100K cycles

General Monitors S5000 37

Page 38

US

3 Installation

If using ACpower, the relay wires should not be run within the same conduit or cable tray as the DCpower supplied to the

S5000 or the S5000 junction box. A separate wire entry on the device should be used for ACpower connected to the relays.

The S5000 is built with an additional wire entry to allow this.

Exceeding the volt-amp rating of the relay can cause damage to the switching contacts.

Relay Connections to Inductive Loads

If connecting the relays to motors, fluorescent lighting, or other inductive loads, it is necessary to suppress any sparks or

inductive feedback that may occur at the relay contact. These effects may render the unit inoperative.

One way to reduce these effects is to install a Quencharc®(P/N630413) across the load being switched.

Fault Relay Wiring and Configurations

The Fault relay state in non-fault operating condition is Energized and terminal connections are supplied for Normally

Closed and Normally Open.

The energized fault relay setting provides an electrical path for fail-safe relay operation. In the event of any failure, including

loss of power, the relay will change to the de-energized state to indicate a fault condition.

The Fault relay state cannot be reconfigured.

Relay Energy State and Terminal Connections

The S5000 relay states are labeled for the default de-energized state. The alarm/warning relay energy state can be changed

on the device, which will exchange the normally open and normally closed terminals. The preferred relay energy state

should be determined before making connections. Table 9 shows the terminal connections by energy state and is

applicable to both relay1 and relay2.

Table 9 Relay Terminal Connections by Energy State

Energy State NC (Normally Closed) NO (Normally Open)

De-Energized (default) Closed Open

Energized Open Closed

General Monitors S5000 38

Page 39

US

4 Operation

4 Operation

WARNING!

Refer to 9 Appendix: General Certification Information before installation and operation.

Failure to follow this warning can result in serious personal injury or death.

The S5000 Series gas monitor is factory calibrated and shipped with the most common default options to minimize set up

effort. Using sensors, the device tests the ambient air and triggers an alarm as soon as the gas exceeds a specific

concentration level.

4.1 Startup

4.1.1 Initial Startup

The first time the S5000 is powered on, the following will appear on the display:

• S5000

• Software Version No.

• Sensor Warm-up

• Wait

The S5000 will remain in Start-up mode in which the fault relay is de-energized and the analog output is 3.5mA by default.

The time the S5000 stays in Start-up mode depends on the sensor.

Oxygen and Carbon Monoxide sensors require a 30 minute warm-up time before being fully functional. The device will be in

fault during the 30 minute start-up time. All other sensor start-up times vary, the unit will be in fault for the first 2 minutes of

the start-up time and the analog output signal will be at the maintenance level (3.5mA default).

A full calibration is recommended after onehour of a sensor being installed and acclimated to the environmental conditions.

See 5 Calibration for calibration details.

4.1.2 Sensor Warm Up Times

WARNING!

For optimal sensor performance, allow sensors 24 hours to acclimate to application conditions before performing an initial

calibration

Failure to follow this warning can result in serious personal injury or death.

IR Sensor: ≤ 10 min

H2S: ≤ 5 min

SO2: ≤ 5 min

Cl2: ≤ 10 min

NH3: ≤ 5 min

Cat Bead: ≤ 5 min

General Monitors S5000 39

Page 40

US

4 Operation

Passive MOS: ≤ 5 min

Passive Cat Bead: ≤5 min

CO: 30 min (see note)

O2: 30 min

Carbon Monoxide sensor gas codes D10, D11, D12, and D14 may require initial warm-up periods longer than 30 minutes. If

the 30-minute warm up is over, the sensor may show a positive reading that exceeds alarm levels. In the event of a shortterm power outage, the warm-up time for carbon monoxide gas codes D10, D11, D12, and D14 will be significantly less.

See the table below to estimate required warm-up time.

Table 10 Warm Up Times CO

Reading Level

<10ppm

1

<1ppm

Time left unpowered Time to warm up

1 min ≤ 5 min ≤ 5min

8 hours ≤ 30 min ≤ 30min

5 days ≤ 30min 2-4 hrs

1 month ≤ 2hrs 6-10 hrs

1

- The minimum alarm level of all three CO sensors is 10ppm. Below

this level would not cause an alarm on the device.

4.1.3 Startup after Power Failure

If the S5000 loses power, all of the settings are saved to the internal memory. When power is restored to the device, it will

go back to the same settings as before the loss of power. To check the settings, go through the menu or view on the X/S

Connect App.

4.2 Settings

The S5000 is a tool free transmitter. The infrared EZtouch button on the face of the display can be used to navigate through

the menu structure. The button is designed for use with fingers with a “press” and “release” action, and works best without

gloves.

The button works the same as the magnet does with the S4000 menu.

Changing a value

(1) Press and hold EZ Touch button.

(2) Wait for relevant menu to scroll (each menu scrolls twice).

(3) Release to enter menu while it is scrolling.

(4) Use Press and Release function to change values.

The EZ touch interface can be disabled, but will require a password. Menu settings can also be activated using a magnet

on the General Monitors logo.

Values that are changed in the menu are saved after main setup loop “Finished”, except for sensor range selection under

sensor setup. Each menu ends with "Finished?" scrolling twice on the display. If the button is not touched during

General Monitors S5000 40

Page 41

US

"Finished?", the menu will begin at the start again and scroll through the options and values again. The new values that

were entered will be displayed on the first pass.

When user exits a menu by touching "Finished?" and there isn't a second sub menu, the previous menu will be displayed

starting at the menu that had just been used.

Some instrument settings are only configurable through Bluetooth®X/SConnect App, Modbus, or HART. See

4.4 Setting only configurable via Bluetooth®, Modbus, or HART.

4.2.1 Instrument Settings

The following settings are saved to the device memory and will not change if the sensor type is changed.

(1) Scroll to Settings.

(2) Select Instrument.

(3) Select to enter the menu.

4 Operation

General Monitors S5000 41

Page 42

US

Table 11 Default Device Settings

Setting Menu 1 Default Range of options

Sensor Setup Sensor1/Sensor2

Disable Enabled Enable/Disable

Gas Label and Unit see Table 12 see Table 12

Range see Table 12 see Table 12

Cal Level see Table 12 see Table 12

Warning Level see Table 12 see Table 12

Alarm Level see Table 12 see Table 12

Alarm Action see Table 12 see Table 12

Sensor Reset No Yes/No

Relay Settings Relay Zone/Mapping Common Common/Discrete

4 Operation

Relay1/Relay 2

Energized/De-energized

De-energized Relay1/Relay2

Energized/De-energized

HART Enabled/Disabled Enabled Enable/Disable

HART AO Analog Output Enabled 1.25 or 3.5

Cal Alert Enable/Disable Enabled Enable/Disable

Bluetooth

®

Enable/Disable Enabled Enable/Disable

Modbus Baud Rate 19200 2400-115200BPS

Format 8-n-1

Address 1 1-247

EZ Touch Enable/Disable Enabled

Swap Delay Enabled Enabled Enable/Disable

UI Password Enabled/Disabled

New Password

Disabled

No

Enable/Disable

Yes/No

Transmitter Reset No No Yes/No

General Monitors S5000 42

Page 43

US

Table 12 Digital Sensor Default Settings

4 Operation

Gas (Code)

Ammonia

(D40)

Ammonia

(D41)

Carbon

Monoxide

(D10)

Carbon

Monoxide

(D11)

Carbon

Monoxide

(D12)

Carbon

Monoxide

H2Resistant

(D14)

Carbon

Monoxide

(D36)

Carbon

Monoxide

(D37)

Thread

3

Type

TruCal

Range

Default

2

Display

Resolution

5

Unit

Default

Warn

Default

Warn

Default

AO4

(mA)

Alarm

Default

Alarm

Default

4

AO

(mA)

Alarm

Action

Default

Coarse 0-100 1 PPM 10 5.6 20 7.2 Increasing

Non-Latch

Coarse 0-1000 10 PPM 100 5.6 200 7.2 Increasing

Non-Latch

Fine 0-100 1 PPM 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-500 1 PPM 50 5.6 150 8.8 Increasing

Non-Latch

Fine 0-1000 1 PPM 100 5.6 300 8.8 Increasing

Non-Latch

Fine 0-100 1 PPM 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 PPM 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-500 1 PPM 50 5.6 150 8.8 Increasing

Non-Latch

Cal

Level

Default

Alarm

Min

Alarm

Max

Range

Min

Range

max

Cal

Level

Min

Cal

Level

Max

25 2 100 0-10 0-100 1 FS

300 100 1000 190 1000 290 FS

60 10 1000 0-10 0-

5 FS

1000

300 10 1000 0-10 0-

5 FS

1000

400 10 1000 0-10 0-

5 FS

1000

60 10 1000 0-10 0-

5 FS

1000

60 10 1000 0-10 0-

5 FS

1000

300 10 1000 0-10 0-

5 FS

1000

1

1

1

1

1

1

1

1

General Monitors S5000 43

Page 44

US

4 Operation

Gas (Code)

Carbon

Monoxide

(D38)

Carbon

Monoxide

(D39)

Catalytic

Bead

5% Methane

(D60)

Catalytic

Bead

4.4%

Methane

(D65)

Catalytic

Bead

2.1%

Propane

(D61)

Thread

3

Type

TruCal

Range

Default

2

Display

Resolution

5

Unit

Default

Warn

Default

Warn

Default

AO4

(mA)

Alarm

Default

Alarm

Default

4

AO

(mA)

Alarm

Action

Default

Fine 0-1000 1 PPM 100 5.6 300 8.8 Increasing

Non-Latch

Fine 0-100 1 PPM 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Cal

Level

Default

Alarm

Min

Alarm

Max

Range

Min

400 10 1000 0-10 0-

Range

max

Cal

Level

Min

Cal

Level

Max

5 FS

1000

60 10 1000 0-10 0-

5 FS

1000

50 5 60 0-2020-100 10 100

57 5 60 0-2020-100 10 100

29 5 60 0-2020-100 10 100

1

1

Catalytic

Bead

1.7%

Propane

(D66)

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

General Monitors S5000 44

36 5 60 0-2020-100 10 100

Page 45

US

4 Operation

Gas (Code)

Catalytic

Bead 1.05%

Heptane

(D62)

Catalytic

Bead 0.85%

Heptane

(D67)

Catalytic

Bead 0.8%

Nonane

(D63)

Catalytic

Bead 0.7%

Nonane

(D68)

Catalytic

Bead 4%

Hydrogen

(D64)

Thread

3

Type

TruCal

Range

Default

2

Display

Resolution

5

Unit

Default

Warn

Default

Warn

Default

AO4

(mA)

Alarm

Default

Alarm

Default

4

AO

(mA)

Alarm

Action

Default

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Fine 0-100 1 % LEL 10 5.6 30 8.8 Increasing

Non-Latch

Cal

Level

Default

Alarm

Min

Alarm

Max

Range

Min

Range

max

Cal

Level

Min

Cal

Level

Max

45 5 60 0-2020-100 10 100

56 5 60 0-2020-100 10 100

61 5 60 0-2020-100 10 100

70 5 60 0-2020-100 10 100

20 5 60 0-2020-100 10 100

Chlorine

(D30)

Chlorine

(D31)

Chlorine

(D32)

Coarse 0-5 0.1 PPM 0.5 5.6 1.0 7.2 Increasing

2.0 0.3 5.0 0-1.0 0-5.0 0.1 FS

Non-Latch

Coarse 0-10 0.1 PPM 0.5 4.8 1.0 5.6 Increasing

2.0 0.3 10.0 0-1.0 0-10.0 0.1 FS

Non-Latch

Coarse 0-20 0.1 PPM 2.0 5.6 4.0 7.2 Increasing 10.0 0.6 20.0 0-1.0 0-20.0 0.1 FS

General Monitors S5000 45

1

1

Page 46

US

4 Operation

Gas (Code)

Thread

3

Type

TruCal

Range

Default

2

Display

Resolution

5

Unit

Default

Warn

Default

Warn

Default

AO4

(mA)

Alarm

Default

Alarm

Default

4

AO

(mA)

Alarm

Action

Default

Cal

Level

Default

Alarm

Min

Alarm

Max

Range

Min

Range

max

Cal

Level

Min

Cal

Level

Max

Non-Latch

Hydrogen

Sulfide (D20,

D83)

Hydrogen

Sulfide (D21,

D84)

Hydrogen

Sulfide (D22,

D85)

Hydrogen

Sulfide (D24,

D77)

Hydrogen

Sulfide (D25,

D78)

Hydrogen

Sulfide (D26,

D79)

Hydrogen

Sulfide (D27,

D86)

Hydrogen

Sulfide (D28,

D87)

Fine 0-10.0 0.1 PPM 1.0 5.6 3.0 8.8 Increasing

Non-Latch

Fine 0-50.0 0.1 PPM 5.0 5.6 15.0 8.8 Increasing

Non-Latch

Fine 0-

100.0

0.1 PPM 10.0 5.6 30.0 8.8 Increasing

Non-Latch

Fine 0-20.0 0.1 PPM 6.0 8.8 12.0 13.6 Increasing

Non-Latch

Fine 0-50.0 0.1 PPM 15.0 8.8 30.0 13.6 Increasing

Non-Latch

Fine 0-

100.0

0.1 PPM 30.0 8.8 60.0 13.6 Increasing

Non-Latch

Fine 0-10.0 0.1 PPM 1.0 5.6 3.0 8.8 Increasing

Non-Latch

Fine 0-50.0 0.1 PPM 5.0 5.6 15.0 8.8 Increasing

Non-Latch

5.0 1.0 100 0-10 0-100 5 FS

40.0 1.0 100 0-10 0-100 5 FS

40.0 1.0 100 0-10 0-100 5 FS

10.0 1.0 19 0-10 0-20 5 FS

25.0 3.0 48 0-10 0-50 5 FS

50.0 5.0 95 0-10 0-100 5 FS

5.0 1.0 100 0-10 0-100 5 FS

40.0 1.0 100 0-10 0-100 5 FS

Hydrogen Fine 0- 0.1 PPM 10.0 5.6 30.0 8.8 Increasing 40.0 1.0 100 0-10 0-100 5 FS

1

1

1

1

1

1

1

1

1

General Monitors S5000 46

Page 47

US

4 Operation

Gas (Code)

Thread

Type

Sulfide (D29,

D88)

Hydrogen

Fine 0-20.0 0.1 PPM 6.0 8.8 12.0 13.6 Increasing

Sulfide (D42,

D80)

Hydrogen

Fine 0-50.0 0.1 PPM 15.0 8.8 30.0 13.6 Increasing

Sulfide (D43,

D81)

Hydrogen

Fine 0Sulfide (D44,

D82)

Oxygen FM

Fine 0-25.0 0.1 % 19.5 16.48 18.0 5.15 Increasing

(D15)

Oxygen

Fine 0-25.0 0.1 %VOL 19.5 5.248 18.0 5.152 Decreasing

(D16)

Low Oxygen

Fine 0-25.0 0.1 % 1 4.64 5.28 Increasing

(D17)

Sulfur

Coarse 0-25.0 0.1 PPM 2.0 5.28 5.0 7.2 Increasing

Dioxide

(D50)

Sulfur

Coarse No 0-100 1 PPM 10 5.6 20 7.2 Increasing

Dioxide

(D51)

1

- FS = Full Scale range

3

TruCal

Range

Default

2

Display

Resolution

5

Unit

Default

Warn

Default

Warn

Default

AO4

(mA)

Alarm

Default

Alarm

Default

4

AO

(mA)

Alarm

Action

Default

100.0 Non-Latch

Non-Latch

Non-Latch

0.1 PPM 30.0 8.8 60.0 13.6 Increasing

100.0

Non-Latch

Non-Latch

Non-Latch

Non-Latch

Non-Latch

Non-Latch

Cal

Level

Default

Alarm

Min

Alarm

Max

Range

Min

Range

max

Cal

Level

Min

Cal

Level

Max

10.0 1.0 19 0-10 0-20 5 FS

25.0 3.0 48 0-10 0-50 5 FS

50.0 5.0 95 0-10 0-100 5 FS

20.8 17.0 24 5-25 5-25 15 25

20.8 15.0 25 15-25 15-25 15 25

20.8 0.2 25 0-2 0-25 20.8

FS

(Room

Air)

10.0 0.4 25 0-5 0-25 2.5 25

10 1 100 0-25 0-100 7 FS

1

1

1

1

1

General Monitors S5000 47

Page 48

US

4 Operation

Warn

Default

AO4

Alarm

Default

Gas (Code)

Thread

3

Type

TruCal

Range

Default

2

Display

Resolution

5

Unit

Default

Warn

Default

(mA)

2

- The maximum range value on catalytic bead cannot be set below 20%.

3

- Class1 Division2 only sensors do not have a flame arrestor (aka Frit). Course threads on the sensor assembly and sensor body are used to prevent a customer from

Alarm

Default

4

AO

(mA)

Alarm

Action

Default

Cal

Level

Default

Alarm

Min

Alarm

Max

Range

Min

Range

max

Cal

Level

Min

installing into a Class1 Division1 sensor body.

4

- Analog Output for default range and alarms

5

- Display resolution is not a configurable option

- TruCal not available

- Adaptive Environmental Compensation (AEC) Equipped

- AEC and Diffusion Supervision Equipped

Cal

Level

Max

General Monitors S5000 48

Page 49

US

Table 13 IR Sensor Default Settings

4 Operation

Gas (Code) Range

IR400

0-100 0-100 %LEL 30 8.8 60 13.6 Increasing

5% Methane

(R31)

IR400

0-100 0-100 %LEL 30 8.8 60 13.6 Increasing

4.4%

Methane

(R43)

IR400

0-100 0-100 %LEL 30 8.8 60 13.6 Increasing

2.1%

Propane

(R32)

IR400

0-100 0-100 %LEL 30 8.8 60 13.6 Increasing

1.7%

Propane

(R44)

IR400

0-100 0-100 % LEL 30 8.8 60 13.6 Increasing

Range

Default

Unit

Default

Warn

Default

Warn Default

AO1(mA)

Alarm

Default

Alarm

DefaultAO

(mA)

1

Alarm

Action

Default

Non-Latch

Non-Latch

Non-Latch

Non-Latch

Cal Level

Default

Alarm

Min

Alarm

Max

Cal

Level

Min

Cal

Level

Max

50 5 60 Fixed at 50% 1

50 5 60 Fixed at 50% 1

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

Display

Resolution

2

Hexane

(R34)

IR400

Pentane

(R35)

IR400

Ethylene

Non-Latch

0-100 0-100 % LEL 30 8.8 60 13.6 Increasing

Non-Latch

0-100 0-100 % LEL 30 8.8 60 13.6 Increasing

Non-Latch

General Monitors S5000 49

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

Page 50

US

4 Operation

Gas (Code) Range

(R36)

IR400

0-100 0-100 % LEL 30 8.8 60 13.6 Increasing

Butane

(R37)

IR400

0-100 0-10.0 PPM 30 8.8 60 13.6 Increasing

Ethane

(R38)

IR400

0-100 0-50.0 PPM 30 8.8 60 13.6 Increasing

Hexane IEC

(R45)

IR400

0-100 0-100.0 PPM 30 8.8 60 13.6 Increasing

Pentane

IEC (R46)

IR400

0-100 0-25.0 %VOL 30 8.8 60 13.6 Increasing

Butane IEC

(R47)

Range

Default

Unit

Default

Warn

Default

Warn Default

AO1(mA)

Alarm

Default

Alarm

DefaultAO

(mA)

1

Alarm

Action

Default

Non-Latch

Non-Latch

Non-Latch

Non-Latch

Non-Latch

Cal Level

Default

Alarm

Min

Alarm

Max

Cal

Level

Min

Cal

Level

Max

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

50 5 60 Fixed at 50% LEL 1

Display

Resolution

2

IR400

Ethane IEC

0-100 0-100 %LEL 30 8.8 60 13.6 Increasing

Non-Latch

50 5 60 Fixed at 50% LEL 1

(R48)

IR400

Ethylene

0-100 0-100 %LEL 30 8.8 60 13.6 Increasing

Non-Latch

50 5 60 Fixed at 50% LEL 1

IEC (R50)

IR700 0-2000 0-2000 PPM 600 8.8 1200 13.6 Increasing 1000 100 1900 1000 20

General Monitors S5000 50

Page 51

US

4 Operation

Gas (Code) Range

Range

Default

Unit

Default

Carbon

Dioxide

(R51)

IR700

0-5000 0-5000 PPM 1500 8.8 3000 13.6 Increasing

Carbon

Dioxide

(R52)

IR700

Carbon

010000

0-10000 PPM 3000 8.8 6000 13.6 Increasing

Dioxide

(R53)

IR700

Carbon

030000

0-30000 PPM 9000 8.8 18000 13.6 Increasing

Dioxide

(R54)

IR700

Carbon

050000

0-50000 PPM 15000 8.8 30000 13.6 Increasing

Dioxide

(R55)

1

- Analog Output for default range and alarms

Warn

Default

Warn Default

AO1(mA)

Alarm

Default

Alarm

DefaultAO

(mA)

1

Alarm

Action