Page 1

Operating Manual

PrimaX

Gas Transmitter

Order No.: 10115083/04

MSAsafety.com

Page 2

For the Declaration of Conformity, please visit the product page on MSAsafety.com.

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

©

MSA 2017. All rights reserved

Page 3

Contents

1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Liability Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Safety and Precautionary Measures to be Adopted . . . . . . . . . . . . . . 5

1.4 MSA Permanent Instrument Warranty . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Identifying the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Connection - PrimaX P . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Connection - PrimaX I . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Menu Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Maintenance and Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Changeable Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Optional HART Module and Relay . . . . . . . . . . . . . . . . . . . . . . . . . . 24

HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.8 Relay Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Menu Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

GB

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.1 Changing the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Cable Lengths and Cross-sections . . . . . . . . . . . . . . . . . . . . . . . . . . 33

PrimaX

3

Page 4

6.3 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 List of Detectable Gases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5 Sensor Response to Interferants . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6 PrimaX P List of Combustible Gases and Vapours detectable with

Catalytic Sensor Part No. 10112716. . . . . . . . . . . . . . . . . . . . . . . . . 37

7 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.1 Marking, Certificates and Approvals according to the Directive

2014/34/EU (ATEX) and National Standards . . . . . . . . . . . . . . . . . . 40

7.2 Marking and Certificates according to IECEx . . . . . . . . . . . . . . . . . . 43

7.3 Special conditions for the safe use according to ATEX and SIL

applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.4 Safety Relevant Parameters (40°C) . . . . . . . . . . . . . . . . . . . . . . . . . 49

Application with 4-20 mA Current Output . . . . . . . . . . . . . . . . . . . . . 50

8 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1 Calibration Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Sensor Gard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3 Remote Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.4 Flow Through Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.5 Duct Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.6 Pipe Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.7 Sensor Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.8 Sunshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.9 Universal HART Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

GB

9 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.1 Output States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.2 Calibration Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.3 Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.4 Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.5 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.6 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

PrimaX

4

Page 5

1 Safety Regulations

1.1 Correct use

The PrimaX Gas Transmitters are fixed gas transmitters for measuring toxic or combustible gases and

for monitoring oxygen deficiency, excess or inerting. They are suitable for outdoor and indoor applications without limitations, e.g. offshore industry, chemical and petrochemical industry, water and sewage

industry. The signal of the transmitter can be used in combination with MSA control units for further

actions in safety or non safety applications, e. g. MSA SUPREMA, Gasgard XL, 9010/9020.

The two versions of the gas transmitter are delivered either in a flameproof or in a intrinsically safe

enclosure. The electrical parts and interfaces have the same basic functionality.

It is imperative that this operating manual be read and observed when using the device. In particular,

the safety instructions, as well as the information for the use and operation of the device, must be carefully read and observed. Furthermore, the national regulations applicable in the user's country must be

taken into account for a safe use.

WARNING!

This product is supporting life and health. Inappropriate use, maintenance or servicing may affect the

function of the device and thereby seriously compromise the user's life.

Before use the product operability must be verified. The product must not be used if the function test

is unsuccessful, it is damaged, a competent servicing/maintenance has not been made, genuine MSA

spare parts have not been used.

Alternative use, or use outside this specification will be considered as non-compliance. This also

applies especially to unauthorised alterations to the product and to commissioning work that has not

been carried out by MSA or authorised persons.

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately or not as intended.

The selection and use of the product are the exclusive responsibility of the individual operator.

Product liability claims, warranties also as guarantees made by MSA with respect to the product are

voided, if it is not used, serviced or maintained in accordance with the instructions in this manual.

1.3 Safety and Precautionary Measures to be Adopted

Safety Regulations

WARNING!

The following safety instructions must be observed implicitly. Only in this way can the safety and health

of the individual operators, and the correct functioning of the device, be guaranteed.

• The device described in this manual must be installed, operated and maintained in strict accordance with their labels, cautions, instructions, and within the limitations stated.

• The device is designed to detect gases or vapours in air.

• If a device with a combustible sensor is exposed to vibrations, calibration shall be done in sufficient

short intervals until it is verified that the device is not affected by the vibration stress.

• Do not mount the sensing head in direct sunlight as this could cause overheating of the sensor.

• The device must be installed with the sensor inlet pointing downwards to avoid clogging of the gas

inlet by particles or liquids.

• Electrochemical sensors are sealed units which contain a corrosive electrolyte. Should a sensor

develop leakage, it must be immediately removed from service and disposed of properly. Caution

PrimaX

GB

5

Page 6

Safety Regulations

must be exercised so that the electrolyte does not contact skin, clothing or circuitry otherwise

personal injury (burns) and/or equipment damage may result.

• The only absolute method to ensure proper overall operation of the device is to check it with a

known concentration of the gas for which it has been calibrated. Consequently, calibration checks

must be included as part of the routine inspection of the system.

• As with all devices of these types, high levels of, or long exposure to, certain compounds in the

tested atmosphere could contaminate the sensor. In atmospheres where the device may be

exposed to such materials, calibration must be performed frequently to ensure that the operation

is dependable and display indications are accurate.

• The device must not be painted. If painting is done in an area where a device is located, care must

be exercised to ensure that paint is not deposited on the sintered metal flashback arrestor in the

gas sensor inlet, if so equipped. Such paint deposits would interfere with the gas diffusion process.

• Use only genuine MSA replacement parts when performing any maintenance procedures

provided in this manual. Failure to do so may seriously impair instrument performance. Repair or

alteration of the device, beyond the scope of these maintenance instructions or by anyone other

than an authorised MSA service personnel, could cause the product to fail to perform as designed.

• The device is designed for applications in hazardous areas under atmospheric conditions.

• For correct measurements, the combustible gas sensors require an oxygen concentration greater

than 10 Vol%. Oxygen enriched atmospheres, greater then 21 Vol%, can affect the measurement

and the electrical safety of the device.

• The response time of the device will be increased by significant dust deposits on the Sensor.

Checks for dust deposits must be done at regular intervals.

• Catalytic combustible gas sensors may produce low or zero response to combustible gas after

exposure to substances as Silicon, Silane, Silicate, Halide and compounds containing Fluorine,

Chlorine, Iodine or Bromine.

• Catalytic sensor: After exposure of gas above the measuring range, the sensor has to be immediately calibrated / adjusted, independent of the calibration interval. In the case of an adjustment

the sensitivity of the sensor has to be rechecked again after 24 hours.

• In case of very high flammable concentrations >100%LEL the device is able to lock all outputs

(LOC). This function shall be used for standalone applications according to ATEX requirements.

• Catalytic sensor: If the PrimaX is operated in combination with a control unit and (LOC) is deactivated on the PrimaX, the control unit has to ensure the latching after the measuring range was

exceeded.

• Catalytic sensor: Before a reset of an over range (LOC) indication is done it shall be verified that

the gas concentration is below full scale.

• Toxic gases: If the measuring range is exceeded, sensor life time can be reduced or the sensor

might need a recovery phase.

• Used sensors have to be disposed of in an environmentally compatible way.

• At signal underrange between -1.25 % and -10 % of the measuring range the 4 - 20 mA output is

set to 3,8 mA. At signal underrange of more than -10 % of the measuring range the 4 - 20 mA

output is set to the error state (2 mA). To avoid a delayed alarm activation, a calibration should be

done when the output current is set to 3,8 mA and "LO" is shown on the display persistently.

• The lowest range which is suitable for the alarm thresholds should be selected for toxic gases.

• To compensate for possible deviations during measurement of flammable gases a calibration

factor of 1.05 has to be applied when using the CalGard for remote calibration (see chapter 8.3

"Remote Calibration")

GB

PrimaX

6

Page 7

1.4 MSA Permanent Instrument Warranty

Warra nty

Seller warrants that this product will be free from mechanical defect or faulty workmanship for

• Gas Transmitter: eighteen (18) months from date of shipment or one (1) year from installation,

whichever occurs first;

• Oxygen, Toxic or Catalytic Combustible Sensor: eighteen (18) months from date of shipping or one

(1) year from installation, whichever occurs first.

This warranty is applicable provided the product is maintained and used in accordance with Seller's

instructions and/or recommendations. This warranty does not apply to expendable or consumable

parts, whose normal life expectancy is less than one (1) year.

The Seller shall be released from all obligations under this warranty in the event repairs or modifications are made by persons other than its own or authorized service personnel or if the warranty claim

results from physical abuse or misuse of the product. No agent, employee or representative of the

Seller has any authority to bind the Seller to any affirmation, representation or warranty concerning the

goods sold under this contract. Seller makes no warranty concerning components or accessories not

manufactured by the Seller, but will pass onto the Purchaser all warranties of manufacturers of such

components.

Safety Regulations

PrimaX

GB

7

Page 8

2 Description

2.1 Identifying the Unit

Description

PrimaX P PrimaX I

flameproof version

Fig. 1 PrimaX Gas Transmitter

PrimaX P

The PrimaX P is a gas transmitter with an aluminum enclosure. This is a flameproof version for the

detection of combustible or toxic gases or oxygen.

PrimaX I

The PrimaX I is a gas transmitter with a plastic enclosure. It is available as a general purpose version

(not intended for hazardous area) or intrisically safe version. Both versions are designed for a detection

of toxic gases or oxygen.

general purpose version, or

intrinsically safe version

2.2 Overview

The device is factory-calibrated and delivered ready for installation. Each device is configured and calibrated for only one specific gas or vapor.

The enclosures vary depending on the particular version. The electrical parts and interfaces have the

same basic functionality.

The device has:

• a quick and easy pluggable sensor,

• a four digit liquid crystal display (LCD),

• a key pad with a cover

• a detachable backplate for installation on a wall or on a pipe

The device operates with a 4 – 20 mA output signal.

GB

PrimaX

8

Page 9

Description

1

2

3

7

8

9

4

6

5

10

Fig. 2 Exploded View (PrimaX P)

1 Terminal for power connection 6 Sensor

2 Keypad with cover 7 Red LED (PrimaX P only)

3 Connector for factory use 8 Yellow LED (PrimaX P only)

4 Display 9 Green LED (PrimaX P only)

5 Bayonet joint with interlock 10 Identification plate

PrimaX

GB

9

Page 10

Description

Sensors

Description PrimaX P PrimaX I

Detection of toxic gases X X

Detection of oxygen X X

Detection of combustible gases X

The device operates with a 4 – 20 mA output signal.

As an optional feature additional modules are available for these configurations of PrimaX transmitter:

Modules PrimaX P PrimaX I

HART module X X

HART + Relays module X -

HART+ Relays module with galvanically isolated analogue

output

For more information on the HART module → chapter 4.7 "Optional HART Module and Relay".

X-

PrimaX

GB

10

Page 11

3 Installation

The device should be installed where gas leaks are expected. The installation position depends on the

gas density, either in the upper area of the room under the ceiling for gases lighter than air or close to

the ground for gases heavier than air. Also consider how air movement may affect the ability of the

device to detect gas. The display on the front of the instrument must always be clearly visible, the view

must not be obstructed.

Before beginning the installation, check that the delivered components are complete

and correct, referring to the shipping documents and the sticker on the shipment carton.

When preparing the assembly, make sure that the mounting arrangement is correct for

the particular device.

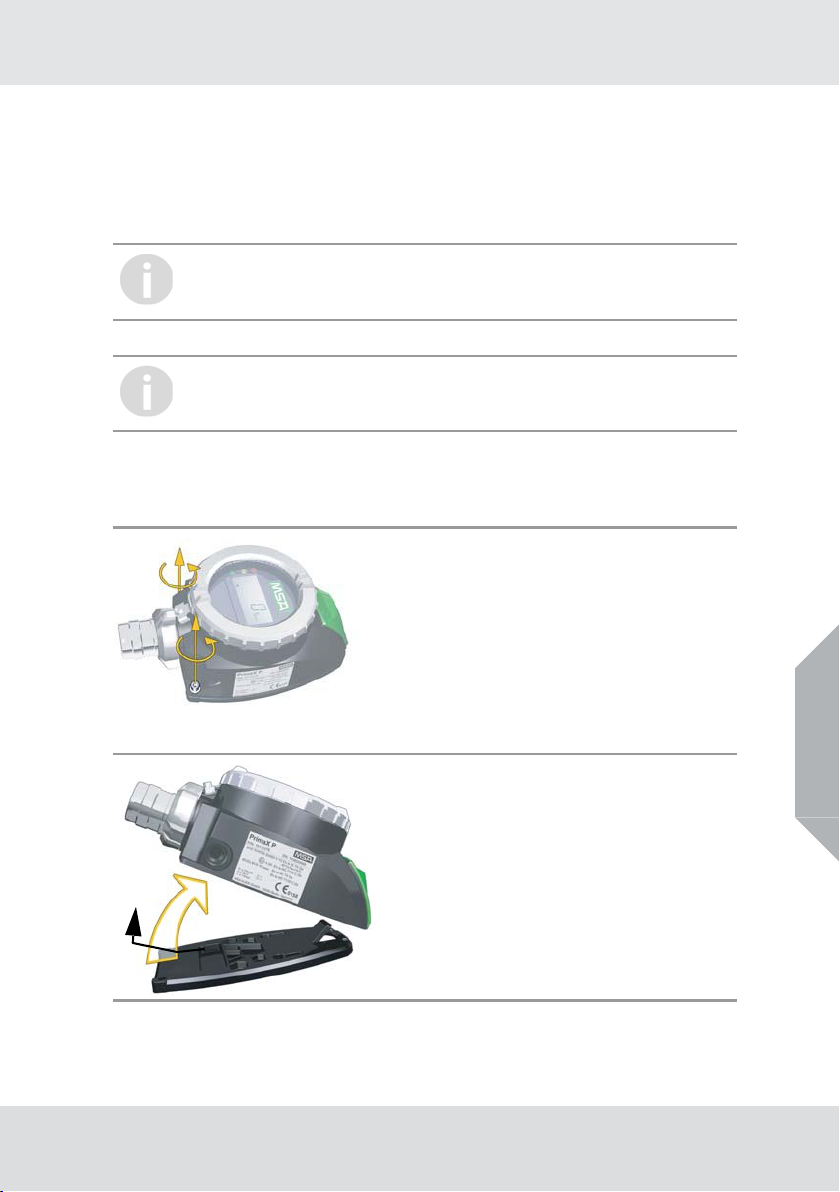

3.1 Mechanical Installation

Preparation

To install the device, first remove the backplate.

Installation

Undo Screws

(1) Unscrew the device.

Remove Device

(2) Remove the device from the backplate by lifting up

the lower edge as shown.

PrimaX

GB

11

Page 12

Wall or Pipe Mounting

For pipe mounting a pipe mounting kit is necessary (→ chapter 8.6 "Pipe Mounting Kit").

Install the Backplate

(1) Use the two keyhole slots for attaching the mounting plate

to the wall. Use 6mm diameter screws and suitable

plugs.

(2) For a wall installation use the backplate as a template for

drilling the holes for the two fixing screws, for a pipe

installation use the pipe clip.

(3) Attach the backplate to the wall or the pipe clip with M6 x

20 screws.

a) The hitch should point away from the wall or pipe.

b) The straight edge of the backplate should be at the

bottom.

Attach the Device to the Backplate

(4) Attach the device to the top of the backplate.

(5) Fold down the device, till it is closed to the backplate.

Installation

Fasten Device

(6) Screw the device to the backplate.

PrimaX

GB

12

Page 13

3.2 Electrical Installation

1 2

3 4

1 2

3 4

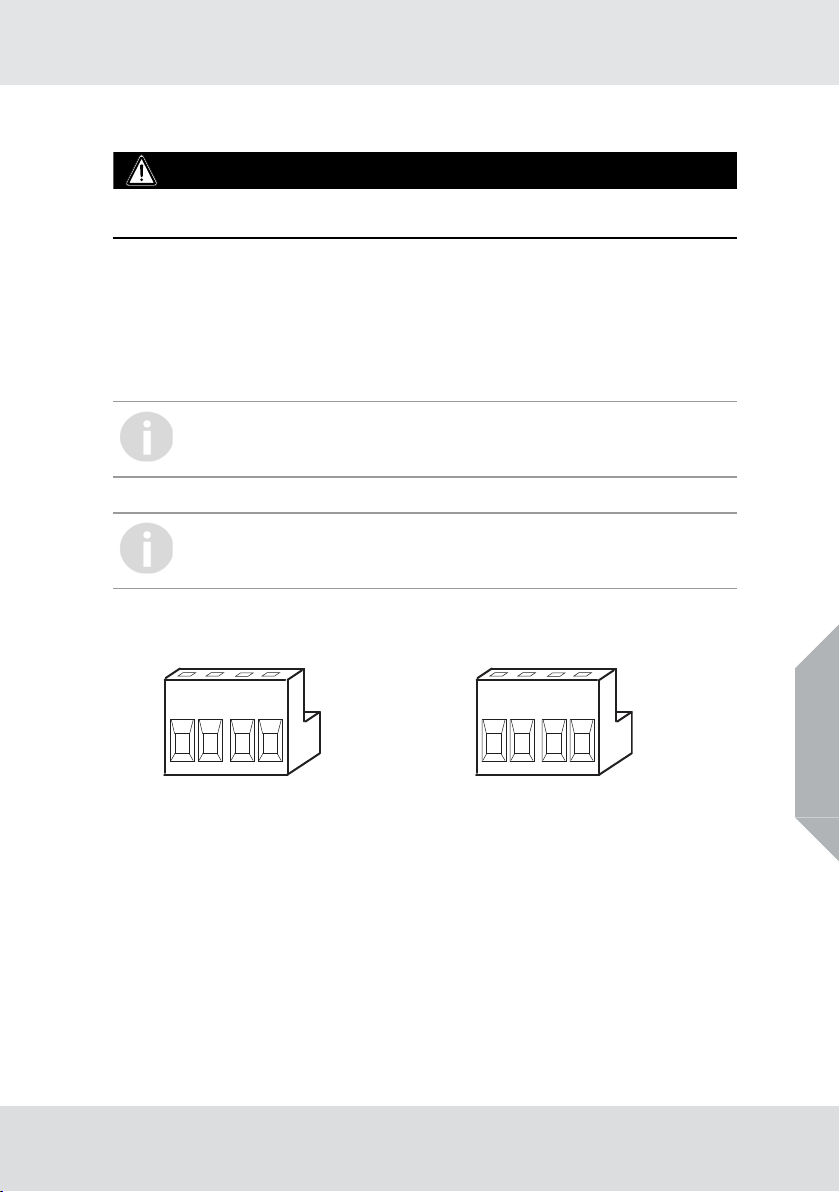

Instructions for Electrical Connection

WARNING!

The device must be installed only in compliance with the applicable regulations, otherwise the safe

operation of the instrument is not guaranteed.

• Shielded cable for measuring devices is recommended.

• Always observe maximum cable lengths and cross-sections (→ chapter 6.2 "Cable Lengths and

Cross-sections").

• Water or impurities can penetrate the instrument through the cable. In hazardous areas, it is

recommended to install the cable in a loop just before entry into the instrument or to slightly bend

it to prevent water from entering.

The power supply is defined as 24 VDC. If the input supply voltage at the terminal of the

transmitter is less than 10 V, the device will shut down. The 24 V power supply shall fulfill

the requirements for a PELV/SELV of EN 60950.

Operating the PrimaX I version in hazardous areas requires an intrinsically safe power

supply.

Electrical Connection - PrimaX P

Terminal PrimaX P

Installation

Fig. 3 Terminal PrimaX P (3-wire sensor) Fig. 4 Terminal PrimaX P (4-wire sensor)

1 Power supply (+), 24 V DC 1 Power supply (+), 24 V DC

2 0 V DC 2 0 V DC

3 4–20mA (Signal) 3 4–20mA (Signal)

4 empty 4 Isolated ground

PrimaX

GB

13

Page 14

PrimaX P

Power supply (+) 24 V DC

0 V DC (-)

4–20mA(Signal)

Isolated ground

Fig. 5 3-wire/4-wire connection - PrimaX P

(1) Unscrew the interlock between cover and bayonet joint of sensor.

(2) Unscrew the aluminum lid of the enclosure.

(3) Unplug the 4-way terminal block.

The block is located behind a plastic cover above the display.

(4) Unscrew clamping nut at the cable gland.

(5) Put clamping nut on the cable.

(6) Insert cable for connection into the device.

(7) Connect cable to terminal.

Use a shielded cable with 3 wires for the 3-wire sensor.

Use a shielded cable with 4 wires for the 4-wire sensor.

(8) Tighten cable gland clamping nut, check that cable cannot move within the cable gland.

(9) Replace enclosure lid and secure the interlock.

Electrical Connection - PrimaX I

Terminal PrimaX I

Installation

GB

1 2

Fig. 6 Terminal PrimaX I

1 Power supply (+), 24 V DC

24–20mA (Signal)

PrimaX

14

Page 15

PrimaX I

Power supply (+)

4 – 20 mA (Signal)

Fig. 7 2-wire connection - PrimaX I

(1) Remove plastic cover.

It is bolted with 4 screws.

(2) Remove the 2-way terminal block.

It is located behind a plastic cover above the display.

(3) Unscrew clamping nut at the cable gland.

(4) Put clamping nut on the cable

(5) Insert cable for connection into the device.

(6) Connect cable to terminal.

a) Use a 2-wire shielded cable.

(7) Tighten cable gland clamping nut, check that cable cannot move within the cable gland.

(8) Replace plastic cover, tighten the screws and secure the interlock.

Installation

PrimaX

GB

15

Page 16

4Operation

1

2

65

3

7

4

The device is factory-calibrated and delivered ready for installation. Each device is

configured and calibrated for only one specific gas or vapor.

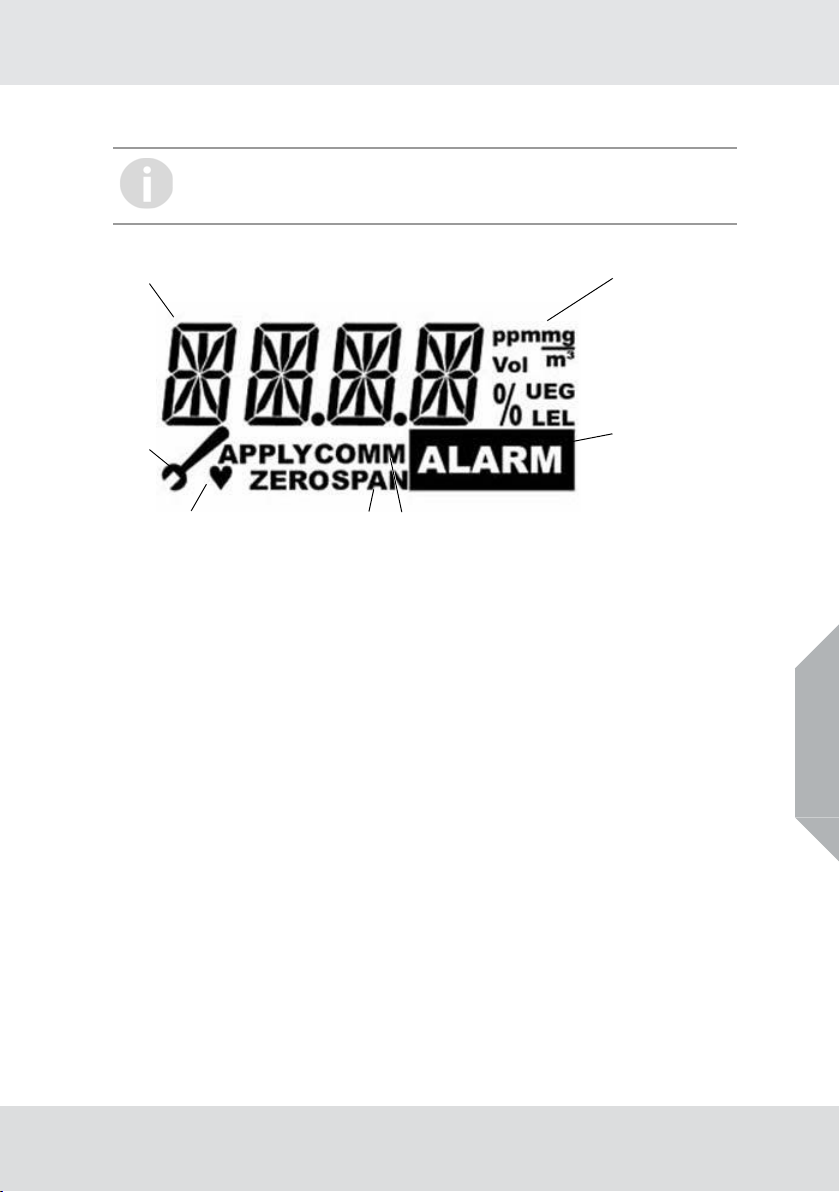

Fig. 8 Display overview

1 Measuring value/Menu//Text dimensions 5 Calibration

2 Units 6 Alive signal (flashing)

3 LOC, alarm indication (optional) 7 Maintenance

4 Signal for an active communication

Operation

PrimaX

GB

16

Page 17

4.1 Startup

1

4

2

3

During startup a self-test is performed and the output signal is set to the service current (default

3.0 mA). The following information is displayed:

Display Test

The display shows all segments.

Note: The PrimaX P also shows all LEDs and afterwards the yellow LED is flashing during the startup

procedure.

Software Version

The display shows the firmware version.

Sensor

The display shows the configured type of sensor operating with each individual detector, e.g.:

COMB (combustible), CO, H

Range

The display shows the measuring range predefined for the gas detector, e.g.: 100% LEL.

Countdown

The countdown for sensor stability is displayed.

Normal Operation

After countdown, the gas concentration (ppm, Vol%, % LEL, % UEG, mg/m

symbol flashes to indicate alive status.

S.

2

3

4.2 Menu Sequence

Operation

) is displayed. The heart

GB

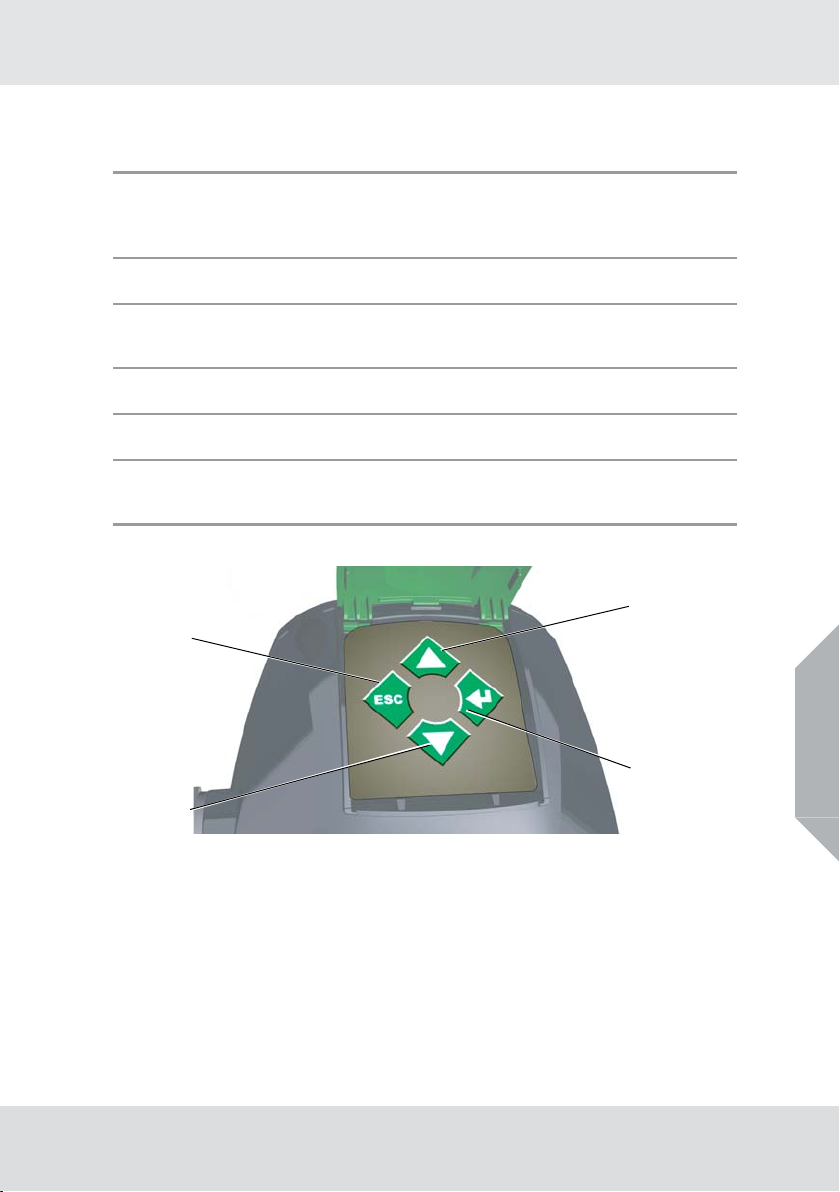

Fig. 9 Keypad - operating buttons

1 ESC button 3 ENTER button

2 UP button 4 DOWN button

To navigate in the menu sequence, 4 buttons are available.

In general:

(1) Press ENTER to get access to a menu sequence.

(2) Press UP or DOWN until the desired menu is displayed.

(3) Press ENTER to get access to a menu.

(4) Press ESC to cancel the process.

PrimaX

17

Page 18

The following table lists the menu items. Detailed descriptions can be found in the chapters 4.3 "Calibration", 4.4 "Maintenance and Info" and 4.5 "Password".

Menu item Text Password?

M-01 Calibration Yes

M-02 ZERO Calibration Yes

M-03 Show Test Gas Concentration No

M-04 Setup Calibration Yes

M-05 Sensor Exchange Yes

M-06 LCD and LED Test No

M-07 Loop Test Yes

M-08 Device Info No

M-09 Sensor Info No

M-10 Changing the Range Yes

M-00 Reset Alarm Ye s

4.3 Calibration

WARNING!

The test gases used for calibration are possibly posing a health risk. Proper ventilation or extraction

has to be ensured.

General

The calibration must be done at regular intervals in accordance with applicable national and regional

regulations.

The device is calibrated at the factory. Nevertheless, it is recommended to recalibrate the device after

installation. The frequency of calibration depends on the duration of use and the chemical exposure of

the sensor. New sensors must be calibrated frequently until it is clear from the calibration data that they

have stabilised. Suitable regulators and pipes for calibration must be used.

Operation

GB

A calibration cap is recommended for sensor calibration,

flow rate 1l/ min (± 20%).

Connect power to the device at least one hour before attempting a calibration.

Carry out the calibration during commissioning as well as at regular intervals. This

ensures optimum operation of the sensor.

It is recommended that all calibration components are connected before starting a calibration as it is necessary to apply test gas to the device during a countdown.

PrimaX

18

Page 19

Operation

When monitoring flammable gas in safety related applications the PrimaX must be calibrated with a known concentration of the gas being monitored.

The lower explosive limits (LEL) of the gases and vapors in the following example were taken from EN

60079-20-1. Local regulations may specify different LEL values; always ensure the correct values are

used.

It is recommended that the PrimaX zero is calibrated using clean air, free of measuring gas, and calibration gas of approximately 50 % of measuring range (comb. and TOX) in air of the gas being monitored. The recommended calibration gas for oxygen is 50% of measuring range, but for a measuring

range 0-25 vol% O

Calibration example for Methanol

Methanol calibration gas concentration being used = 3,5 Vol%

Methanol volume concentration for 100%LEL = 6,0 Vol%

Methanol calibration gas concentration in %LEL

, the device can be calibrated using 20.9 vol% O2.

2

For oxygen a zero calibration with gas is not required, it is performed internally.

3,5 Vol% CH

Calibration Procedure

The calibration can be performed as a manual or an automatic calibration (→ M-04).

Automatic Calibration (automatic): a countdown is displayed. After the countdown the value is

measured and displayed. When the value is stable the current value is selected automatically.

Manual Calibration (manual): the measuring value is displayed. When the value is stable press

ENTER to select the current value.

Waiting for calibration gas

After starting any calibration step, calibration gas (zero or test gas) must be applied until calibration

step is finished.

4

O x

100% LEL

6,0 Vol% CH

PrimaX

O

4

= 58,3 % LEL

GB

19

Page 20

Calibration Steps

The calibration procedure can be canceled at any time by pressing ESC. The previous

transmitter calibration will be used.

(M-01) - ZERO and SPAN Gas Calibration

(1) Press ENTER and select menu 1.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

(4) Apply zero gas (synthetic air).

(5) Wait until countdown is finished (automatic) or press ENTER (manual).

OK is displayed.

(6) Apply test gas.

(7) Wait until calibration is finished (automatic) or press ENTER (manual).

OK is displayed.

Idle time countdown starts, during this time the test gas can be removed and the output

signal remains on service current level.

(8) Remove test gas during the countdown.

(M-01) - Oxygen Calibration

(1) Press ENTER and select menu 1.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

(4) Apply synthetic air.

(5) Wait until countdown is finished (automatic) or press ENTER (manual).

OK is displayed.

(6) The device goes to measuring mode.

(M-02) - ZERO Gas Calibration

(1) Press ENTER and select menu 2.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

(4) Apply zero gas (synthetic air).

(5) Wait until calibration is finished (automatic) or press ENTER (manual).

OK is displayed.

(6) The device goes to measuring mode.

4.4 Maintenance and Info

(M-03) - Show Test Gas Value

(1) Press ENTER and select menu 3.

(2) Press ENTER button.

Test gas concentration is displayed.

(3) Press ENTER button to go back to Menu or ESC to go back to measuring mode.

(M-04) - Setup Calibration

This menu is used to set the test gas concentration for span calibration and all calibration countdown

times.

(1) Press ENTER and select menu 4.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

Operation

GB

PrimaX

20

Page 21

Operation

(4) Set the test gas concentration with the UP or DOWN button.

(5) Press ENTER button.

(6) Set the zero calibration countdown time in seconds with the UP or DOWN button.

a) Note: time = 0 → (manual) zero calibration, otherwise an (automatic) calibration is

performed by the device.

(7) Press ENTER button.

(8) Set the span calibration countdown in seconds with the UP or DOWN button.

a) Note: time = 0 → (manual) span calibration, otherwise an (automatic) calibration is carried

(9) Press ENTER button.

(10) Set the idle time countdown in seconds with the UP or DOWN button.

(11) Press ENTER button.

(M-05) - Sensor Exchange

This menu initiates the initial calibration and resets the sensor lifetime counter.OX/TOX sensors can

be exchanged under power (hot swapped) with this function.

Hot swaps must not be carried out for COMB sensors.

Only OX/TOX sensors can be exchanged with this menu.

For COMB sensors with this menu only the initial calibration is initiated and the sensor life time is reset.

out by the device.

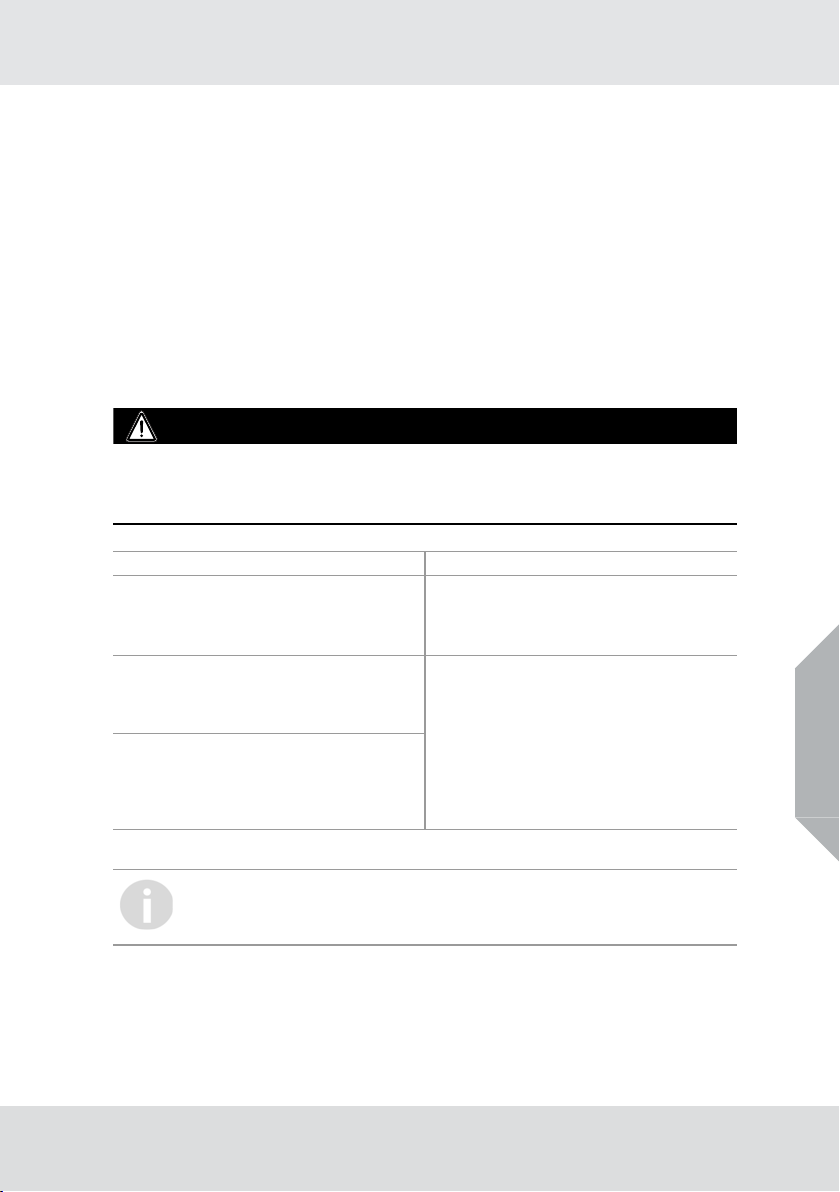

WARNING!

If an (OX/TOX) sensor is connected: If a COMB sensor is connected:

(1) Press ENTER and select menu 5.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Pass-

word").

• An hourglass symbol is shown to signify the

time span (max. 15 min) during which it is

possible to hot-swap a sensor without triggering an error code

(5) Change the sensor during this time span.

(6) Press ENTER or ESC to start the running-

in time countdown.

(7) (Perform a ZERO and SPAN or Oxygen

calibration (M-01).

(1) Press ENTER and select menu 5.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Pass-

word").

(4) (Perform a ZERO and SPAN calibration (M-

01).

GB

Sensors that are no longer required have to be disposed of in an environmentally

compatible way.

(M-06) - LCD/LED Test

LCD and LED test (LED only available in PrimaX P). All segments will be displayed and the LEDs will

flash sequentially.

(1) Press ENTER and select menu 6.

(2) Press ENTER button.

PrimaX

21

Page 22

Operation

(M-07) - Loop Test

In this menu a 4 - 20 mA loop test will be performed.

(1) Press ENTER and select menu 7.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

The loop test mA value is displayed (default value = 12 mA).

(4) Press UP or DOWN to change the value.

(5) Press ENTER button to start the test.

(6) Press ENTER button to go back to menu or ESC to go back to measuring mode.

(M-08) - Device Information

In this menu device information is shown, i.e. gas type, measuring range, firmware version.

(1) Go through the information with the ENTER button.

(M-09) - Sensor Information

This menu shows the minimum and maximum measured gas concentrations, which can be reset by

holding the UP or DOWN button.

It shows the sensor life time in months since sensor exchange (→ M-05).

If a COMB or a TOX sensor is connected this menu shows the response time (as calculated during

zero span calibration).

If an OX/TOX sensor is connected this menu shows the measured mV value.

If a COMB sensor is connected this menu shows the detector (U

voltage (U

(1) Go through the information with the ENTER button.

) in mV.

X

), compensator (UK) and differential

D

PrimaX

GB

22

Page 23

(M-10) - Range Selection

WARNING!

Test gas concentration has to be checked and device has to be calibrated if the range is changed.

This menu allows to set up the optional measuring ranges for connected OX/TOX sensors.

(1) Press ENTER and select menu 10.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

(4) Press UP or DOWN button to select the range and/or the measuring unit (TOX: ppm, mg/m

COMB: LEL, UEG).

(5) Press ENTER button.

(M-00) - Reset Alarm

menu to reset a LOC of combustible sensor or an alarm. It appears only in the menu if there is a latched

LOC or alarm.

(1) Press ENTER and select menu 0.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

OK is displayed.

The calibration is set to invalid and service current is supplied until recalibrated.

Success message confirms that latched alarm is reset.

4.5 Password

Menus which should only be changed by qualified and authorized persons are locked by a four digit

password.

Operation

3

;

The default password is 0000.

After entering the password menu, the values of the digits will be set from left to right:

(1) Press UP or DOWN to change the value.

The value will be increased or decreased.

(2) Press ENTER to get to the next digit.

With ESC, one digit can be backspaced.

If all four digits are entered, the password will be validated.

PrimaX

GB

23

Page 24

4.6 Changeable Parameters

Values default minimum maximum

regarding sensor (e.g.: CO

Span/Test Gas Value

Zero Calibration Time 30 s 0 s 2000 s

Span Calibration

Time

Idle Time after calibration

Range See 6.4 "List of Detectable Gases" List of detectable gases

Loop Test 12 mA

= 60ppm, H

O

= 20.8 vol%, combus-

2

tible = 50% LEL)

30 s 0 s 2000 s

30 s 10 s 2000 s

S 10ppm,

2

10% of Range 100% of Range

2 mA with

2-wire version

0 mA with

3/4-wire version

4.7 Optional HART Module and Relay HART

Introduction

"HART" is an acronym for Highway Addressable Remote Transducer. The HART Protocol makes use

of the Bell 202 Frequency Shift Keying (FSK) standard to superimpose digital communication signals

at a low level on top of the 4 - 20 mA.

The HART Protocol provides two simultaneous communication channels:

the 4 - 20 mA analog signal and a digital signal. The 4 - 20 mA signal communicates the primary

measured value (in the case of a field instrument) using the 4 - 20 mA current loop. Additional device

information is communicated using a digital signal that is superimposed on the analog signal.

PrimaX is registered with the HART foundation and can be accessed at

http://www.hartcomm.org/

The device is available with an optional HART module or a module with HART and Relays for alarm

and failure. It uses the HART Protocol Revision 7 and can only communicate with HART Masters who

support revision 7 or higher.

Operation

22 mA

GB

The following HART functions are also available:

ZERO SPAN Calibration / Oxygen Calibration; ZERO Calibration; Sensor Exchange;

LCD/LED Test; Loop Test; Range setup; Reset alarm; Readout all measured data and

information.

PrimaX

24

Page 25

Electrical installation

1

1

Fig. 10 HART ports

1 Optional HART port

For wiring diagrams → chapter 10.6 "Wiring Diagrams".

Relays

Relay nominal switching capacity (resistive load):

Alarm Relay 2A / 30V DC

Failure Relay 2A / 30V DC

Operation

Fig. 11 Location of Relay

1 Relay Terminals

PrimaX

GB

25

Page 26

Operation

132

132

ALARM FAILURE

Fig. 12 Relay Terminals

Alarm Relay Failure Relay

1 Normally closed energised(NC) 1 Normally closed energised(NC)

2 Common (COM) 2 Common (COM)

3 Normally open energised(NO) 3 Normally open energised(NO)

4.8 Relay Operation Startup

If relays are used the alarm threshold will be displayed at startup

Menu Sequence

Menu item Text Password?

M-11 Relay Info No

M-12 Relay Setup Yes

M-13 Relay Test Yes

(M-11) - Relay Info

(1) Press ENTER and select menu 11.

(2) Press ENTER button.

(3) Go through the information with the ENTER button.

• The alarm threshold and if the alarm is activated with a rising or falling gas concentration.

• if an alarm would be latched.

• the alarm relay delay time in seconds.

• if the alarm relay is normally energised.

• the failure relay delay time in seconds.

• if the failure relay is normally energised.

It shows:

GB

PrimaX

26

Page 27

(M-12) - Relay Setup

(1) Press ENTER and select menu 12.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

(4) Set the alarm threshold with the UP or DOWN button.

(5) Press ENTER button.

(6) Set rising or falling alarm option with the UP or DOWN button.

(7) Press ENTER button.

(8) Set if latched with the UP or DOWN button.

(9) Press ENTER button.

(10) Set the alarm relay delay with the UP or DOWN button.

(11) Press ENTER button.

(12) Set alarm relay normally energized option with the UP or DOWN button.

(13) Press ENTER button.

(14) Set the failure relay delay with the UP or DOWN button.

(15) Press ENTER button.

(16) Set the failure relay normally energized option with the UP or DOWN button.

(17) Press ENTER button.

(M-13) - Relay Test

(1) Press ENTER and select menu 13.

(2) Press ENTER button.

(3) Enter password (→ chapter 4.5 "Password").

(4) The relays are now Switched and can be tested.

(5) Press ENTER button to go back to menu or ESC to go back to measuring mode.

Operation

PrimaX

GB

27

Page 28

Changeable Parameters for Relays

Values default minimum maximum

Alarm threshold

Alarm relay normally energized yes yes no

Latch alarm yes yes no

Alarming direction

Alarm delay time 0 s 0 s 600 s

Failure relay normally energized

Failure relay delay time 0 s 0 s 600 s

Setting required for ATEX conditions:

Latch alarm = yes: Alarm output self-retaining

Alarm delay time = 0s, no delay of output

Failure relay normally energized = yes

Changeable Parameters with HART

For all parameters which can be changed over keypad see chapter 4.6 "Changeable

Parameters"

30% of Range

= 20 vol%)

(O

2

decrease;

O

2

other increase

yes yes no

5 % of Range 100% of Range

Increasing Decreasing

Operation

Values default minimum maximum

Password 0000 0000 9999

Ta g M SA - -

Description PrimaX - -

Long tag - -

Message - -

Enable LOC if combustible enable enable disable

In case of very high flammable concentrations >100%LEL the device is able to lock all

outputs (LOC). This function shall be used for standalone applications according to

ATEX requirements.

PrimaX

GB

28

Page 29

Operation

Output States

State Failure Relay Alarm Relay

Normal

Star tup

Calibration

Latched voltage overrange Switched

Loop not connected Switched

Underrange Switched

Error Switched

Safety critical error Switched

LOC (combustible) Switched

Latched LOC (combustible) Switched

Alarm threshold exceed Switched

Switched: the relay state has switched from the normal state. The normal state can be set to energised

if alarm/failure or de-energised if alarm/failure. Normally de-energised if alarm/failure meets the ATEX

and SIL requirements. In case of switched relays the device will go to the normal state when the related

condition (non-latched alarm and/or fail) has been removed. For additional information about output

states, see chapter 10 "Appendix"

LOC: The PrimaX Gas Monitor has been exposed to a high gas concentration (above the LEL), and

the over-range condition still exists.

Latched LOC: The PrimaX Gas Monitor has been exposed to a high gas concentration (above the

LEL), and there is a possibility that the over-range condition may still exist.

Startup state

(default: switched)

PrimaX

GB

29

Page 30

5 Maintenance

5.1 Changing the Sensors

DANGER!

Remove and reinstall sensors carefully, ensuring that the components are not damaged; otherwise the

approval may be adversely affected, wrong readings could occur, and persons relying on this product

for their safety could sustain serious personal injury or death.

Before changing the sensor, the Sensor Exchange mode must be activated. This

ensures the sensor must be calibrated after exchange and the sensor lifetime counter is

reset. See chapter 4.2 "Menu Sequence".

Remove Interlock

(1) Unscrew the socket head screw.

(2) Remove the interlock.

Maintenance

Remove Bayonet Joint

(3) Turn the bayonet ring counter-clockwise.

(4) Remove the bayonet ring by pulling it down.

PrimaX

GB

30

Page 31

Replace Sensor

(5) Unplug the sensor carefully.

(6) Plug in the new sensor carefully.

(7) Replace the bayonet ring.

(8) Replace the interlock.

Maintenance

PrimaX

GB

31

Page 32

6 Technical Data

6.1 Specifications

Enclosure

Dimensions in mm

(Height X Width X Depth)

Weight 1.6 kg 1.2 kg

Humidity 15 % to 90 % rel. humidity 15 % to 90 % rel. humidity

Power supply 19.2 V - 28.0 V 19.2 V - 28.0 V

Power consumption 3W 0.7W

Temperature range

(instrument)

Temperature range

(sensor)

Signal output

HART (option)

Relay (option)

Signal output tolerance 1 % 1 %

Pressure 80 – 120 kPa 80 – 120 kPa

Max. load resistance 300 Ohm 300 Ohm

Air velocity 0 – 6 m/s 0 – 6 m/s

PrimaX P PrimaX I

aluminum enclosure

flameproof

IP 67 ingress protection

220 X 162 X 100 220 X 162 X 81

-40 to +70 °C

see sensor

4 – 20 mA

yes

yes

plastic enclosure

intrinsically safe

IP 66 ingress protection

-40 to +70 °C

see sensor

4 – 20 mA

yes

no

Technical Data

Measuring Methods

Oxygen Electrochemical sensor

Toxic gases Electrochemical sensor

Combustible gases Thermo-catalytic sensor

Relay nominal switching capacity (resistive load):

Alarm Relay 2A / 30V DC

Failure Relay 2A / 30V DC

PrimaX

GB

32

Page 33

Refresh Rate of Output Signals

4 - 20 mA output signal (analog) 100 ms

Alarm (LED and relay) 100 ms

Failure (LED and relay) 100 ms

Display (measuring value) 1 s

Display (alarm) 2100 ms

6.2 Cable Lengths and Cross-sections

The maximum load resistance for all combinations is 300 Ohm.

Technical Data

Sensor type

Toxic Gases and Oxygen Sensors with

4 – 20 mA Signal Output (2- wire Sensor)

Catalytic Combustible Gas Sensor with

4 – 20 mA Signal Output (3- wire Sensor)

Toxic Gases and Oxygen Sensors with

4 – 20 mA Signal Output (3- wire Sensor)

Catalytic Combustible Gas Sensor with

4 – 20 mA Signal Output (4- wire Sensor)

Toxic Gases and Oxygen Sensors with

4 – 20 mA Signal Output (4- wire Sensor)

6.3 Performance Specifications

Warm u p time

Storage temperature

Crosssection

1.0 mm

1.5 mm

1.0 mm

1.5 mm

1.0 mm

1.5 mm

1.0 mm

1.5 mm

1.0 mm

1.5 mm

Combustible 95 s

OX/TOX 36 s

-40°C to +70°C

or temperature range of the sensor

Max. length at 24 V DC

2

2

without

relay

2

980 m 700 m

2

1470 m 1050 m

without

relay

2

3920 m 2000 m

2

5880 m 3000 m

2

2

2

2

1960 m

2940 m

with relay

with relay

with relay

420 m

630 m

1848 m

2772 m

GB

PrimaX

33

Page 34

6.4 List of Detectable Gases

Gas Default range Selectable range(s) Temperature Range

Ammonia (NH

Ammonia (NH

Carbon Monoxide (CO) 200 ppm

Chlorine (Cl

Hydrogen (H

Hydrogen Chloride (HCl) 30 ppm

Hydrogen Cyanide (HCN) 30 ppm

Hydrogen Sulphide (H2S) 50 ppm

Methane (CH

Nitric Oxide (NO) 100 ppm - -15 – 40 °C

Nitrogen Dioxide (NO

Oxygen (O

part no. 10112718

(recommended)

Oxygen (O

part no. 10148289

Propane (C

Sulphur Dioxide (SO

) 100 ppm 50 ppm -20 – 40 °C

3

) 500 ppm 1000 ppm -20 – 40 °C

3

) 10 ppm 5 ppm -20 – 40 °C

2

) 1000 ppm - -20 – 50 °C

2

) 100 % LEL - -40 –70 °C

4

)10ppm

2

)

2

)

2

) 100 % LEL - -40 – 70 °C

3H8

)50ppm

2

100 ppm

500 ppm

-20 – 50 °C

1000 ppm

10 ppm

20 ppm

-20 – 40 °C

10 ppm

20 ppm

-40 – 40 °C

50 ppm

10 ppm

20 ppm

-40 – 50 °C

100 ppm

20 ppm

100 ppm

-20 – 50 °C

25 vol. % 10 vol. % -30 – 55 °C

25 vol. % 10 vol. % -20 – 50 °C

10 ppm

20 ppm

-20 – 50 °C

100 ppm

Technical Data

GB

Gases Zero drift Full scale drift Zero deviation

Lower limit of the

measuring range

CO ≤ 2 ppm/month ≤ 5 %/month ≤ 4 % of full scale 3 % of full scale

H

S ≤ 2 ppm/month ≤ 5 %/month

2

≤ 2 % full scale, at

least 1 ppm

1 % full scale, at least 1

ppm

PrimaX

34

Page 35

Technical Data

Resolution of display

Measuring range Resolution

1 to 10 0.1

25 Vol % oxygen 0.1

10 to 2000 1

Response time (diffusion mode)

Oxygen Response time Recovery time

t20 t90 t10

≤8s ≤ 25 s ≤ 25 s

Toxic Response time Recovery time

t90 t10

CO ≤20 s ≤ 44 s

H

S ≤12 s ≤ 32 s

2

Combustible Response time Recovery time

t50 t90 t50 t10

Methane ≤ 10 s ≤ 18 s ≤ 10 s ≤ 18 s

Propane ≤ 12 s ≤ 20 s ≤ 12 s ≤ 20 s

Combustible Response time Recovery time

t50

*)

t90

*)

t50

*)

t10

1-Ethoxy-2-Propanol ≤ 20 ≤ 48 ≤ 20 ≤ 48

Hydrogen ≤ 10 ≤ 18 ≤ 10 ≤ 18

Methane ≤ 10 s ≤ 18 s ≤ 10 s ≤ 18 s

Propane ≤ 12 s ≤ 20 s ≤ 12 s ≤ 20 s

*)

Response times with calibration cap and a flow rate of 1l / min

The response time will be increased up to 60 seconds by using the Sensor gard.

PrimaX

*)

GB

35

Page 36

6.5 Sensor Response to Interferants

Interference factors may differ from sensor to sensor and with life time.

It is not advisable to calibrate with interference gases.

This table does not claim to be complete. The sensor might also be sensitive to other

gases.

Gas Sensor Interferant

Combustible wide variety of combustible gases and vapours

Ammonia (NH

Ammonia (NH

) 100 ppm

3

) 1000 ppm

3

Carbon Monoxide (CO)

Chlorine (Cl

Hydrogen (H

)

2

)

2

Hydrogen Chloride (HCl)

Hydrogen Cyanide (HCN)

Hydrogen Sulphide (H

2

Nitric oxide (NO)

S)

20 ppm H

2 ppm

30 ppm Cl

5 ppm

200 ppm SO

-20 ppm

100 ppm NO

69 ppm

100 ppm NO

-5 ppm

1 ppm Br

1 ppm

10 ppm NO

4.5 ppm

300 ppm CO

<60 ppm

10 ppm HCN

3 ppm

0.2 ppm AsH

0.7 ppm

20 ppm H

60 ppm

0.1 ppm PH

0.3 ppm

100 ppm NO

-5 ppm

100 ppm Cl

-9 ppm

100 ppm HCN

1 ppm

20 ppm HCN

5 ppm

S

2

2

200 ppm H

S

2

120 ppm

2

100 ppm H

2

40 ppm

2

2

2.4 ppm ClO

2

0.55 ppm

2

0.25 ppm O

3

0.11 ppm

15 ppm H

S

2

<3 ppm

100 ppm C

2H4

80 ppm

3

5 ppm Cl

2

< +/- 0.1 ppm

S

2

100 ppm NO

45 ppm

3

20 ppm SO

2

8 ppm

10 ppm NO

2

-7 ppm

2

100 ppm NO

2

-21 ppm

100 ppm SO

2

1 ppm

10 ppm NO

2

3.5 ppm

Technical Data

10 ppm NO

6.5 ppm

100 ppm ethanol

4 ppm

20 ppm H

0.1 ppm

35 ppm NO

10 ppm

20 ppm HCN

7 ppm

10 ppm NO

< +/- 0.5 ppm

100 ppm NO

1 ppm

20 ppm SO

6 ppm

2

S

2

2

2

GB

PrimaX

36

Page 37

Technical Data

Gas Sensor Interferant

50 ppm NO

<-5 ppm

Nitrogen Dioxide (NO2)

400 ppm H

<0.1 ppm

20 ppm NH

2

3

< 0.1 ppm

200 ppb O

3

<120 ppm

Oxygen (O

Sulphur Dioxide (SO

6.6 PrimaX P List of Combustible Gases and Vapours detectable with Catalytic Sensor

) no data

2

)

2

Part No. 10112716

300 ppm CO

<3 ppm

Relative response factors of tested gases with reference to Propane

For the gases or vapours shown in the tables of this chapter the response curves have been tested

according to EN 60079-29-1:2007. If the LEL of a substance was not listed in EN 60079-20-1:2010,

the LEL has been taken from the Chemsafe data base (Dechema, Frankfurt). Due to legal requirements other locally used LEL values might be mandatory. It is highly recommended that the gas

detector is exposed to clean air when calibrating the zero and a mixture of the target gas in air with a

concentration of approximately 50% LEL. If calibration with the target gas is not possible a reference

calibration can be performed with 0.85 % (v/v) Propane C

data given in the table of this chapter. These values are only valid for new sensors and, unless otherwise stated, they refer to an ambient temperature of 20°C. If using a reference gas to calibrate the gas

detector the displayed values may vary by up to +/- 20% from the target gas concentration.

Reference calibration example for 50% Methanol:

20 ppm SO

<-15 ppm

20 ppm H

<-35 ppm

50 ppm C

< 0.1 ppm

5 ppm NO

-5 ppm

2

10 ppm Cl

2

<80 ppm

S

2

400 ppm CO

<0.1 ppm

2H4

5 vol% CO

2

< 0.1 ppm

2

in air and using the relative response

3H8

(1) Relative response factor for Methanol from table = 0.62

Propane calibration gas concentration being used

(2)

C

3H8

= 0.89 Vol %

(3) Propane volume concentration for 100 % LEL = 1.7 Vol %

(4) Propane calibration gas concentration in % LEL

= 0.89 Vol % C

3H8

x

100 % LEL

1.7 Vol % C

3H8

= 52.4 % LEL

(5) Gas detector span setting = 52.4 % LEL x 0.62 = 32.5 % LEL

PrimaX

GB

37

Page 38

Technical Data

Gas CAS-No.

Acetaldehyde (C

O) 75-07-0 4.0 fluid 0.64

2H4

LEL

(vol%)

Response

time (s) (t50)

Response time

*)

(s) (t90)

Gas/

Fluid

Response

factor

*)

Acetic acid (C2H4O2) 64-19-7 4.0 fluid 1.51

Acetic anhydride

((CH

CO)2O)

3

108-24-7 2.0 fluid 1.56

Acetone (C3H6O) 67-64-1 2.5 ≤ 9 ≤ 24 fluid 0.94

Acetylene (C2H2) 74-86-2 2.3 gas 0.76

Acrylonnitrile (C3H3N) 107-13-1 2.8 fluid 0.75

Allyl alcohol (C3H6O) 107-18-6 2.5 fluid 0.90

Ammonia (NH3) 7664-41-7 15.0 gas 0.38

Benzene (C6H6) 71-43-2 1.2 fluid 1.21

1.3-Butadiene (C4H6) 106-99-0 1.4 gas 1.01

i-Butane ((CH3)3CH) 75-28-5 1.3 gas 1.20

n-Butane (C4H10) 106-97-8 1.4 gas 1.09

n-Butanol (Butylalcohol) (C

4H10

O)

71-36-3 1.4 fluid 1.40

2-Butanone (C4H8O) 78-93-3 1.5 ≤ 12 ≤ 31 fluid 1.13

i-Butylacetate

(C

O)

6H12

n-Butylacetate

(C

O)

6H12

110-19-0 1.3 fluid 1.48

123-86-4 1.2 fluid 1.56

Butylbenzene (C10H14) 104-51-8 0.8 fluid 3.85

1-Butylene (C4H8) 106-98-9 1.6 gas 0.94

i-Butylene (C4H8) 115-11-7 1.6 gas 0.93

Cyclohexane (C6H12) 110-82-7 1.0 fluid 1.49

Cyclopentane (C5H10) 287-92-3 1.4 fluid 1.05

Diethylether (C4H10O) 60-29-7 1.7 fluid 1.16

1.4-Dioxane (C4H8O2) 123-91-1 1.4 fluid 2.22

Ethane (C2H6) 74-84-0 2.4 gas 0.87

Ethanol (C2H6O) 64-17-5 3.1 ≤ 11 ≤ 31 fluid 0.89

Ethene (C2H4) 74-85-1 2.3 gas 0.77

1-Ethoxy-2 propa-nol

(C

5H12O2

)

1569-02-4 1.3 ≤ 14 ≤ 46 fluid 1.71

Ethyl acetate (C4H8O2) 141-78-6 2.0 ≤ 13 ≤ 46 fluid 1.12

Ethyl acrylate (C5H8O2) 140-88-5 1.4 fluid 1.45

Ethyl benzene (C8H10) 100-41-4 0.8 fluid 1.49

Ethylen oxide (C2H4O) 75-21-8 2.6 gas 0.99

Gasoline 65/95 64742-49-0 0.9 ≤ 10 ≤ 21 fluid 1.40

n-Heptane (C7H16) 142-82-5 0.85 fluid 1.75

n-Hexane (C6H14) 110-54-3 1.0 fluid 1.48

M

M

M

D

M

M

M

M

M

M

M

M

M

D

M

M

M

M

M

M

M

M

M

M

D

M

D

D

M

M

M

D

M

M

GB

PrimaX

38

Page 39

Technical Data

Gas CAS-No.

Hydrogen (H

) 1333-74-0 4.0 ≤ 6 ≤ 16 gas 0.53

2

LEL

(vol%)

Response

time (s) (t50)

Response time

*)

(s) (t90)

Gas/

Fluid

Response

factor

*)

Methane (CH4) 74-82-8 4.4 gas 0.55

Methanol (CH4O) 67-56-1 6.0 fluid 0.62

Methyl tert-butylether

(C

O)

5H12

1634-04-4 1.5 fluid 1.12

n-Nonane (C9H20) 111-84-2 0.7 fluid 1.85

n-Pentane (C5H12) 109-66-0 1.1 gas 1,38

Propane (C3H8) 74-98-6 1.7 ≤ 14 ≤ 24 gas 1.00

1-Propanol (C3H8O) 71-23-8 2.1 ≤ 10 ≤ 50 fluid 0.98

2-Propanol (C3H8O) 67-63-0 2.0 ≤ 11 ≤ 25 fluid 1.04

Propene (C3H6) 115-07-1 2.0 ≤ 8 ≤ 19 gas 0.85

Propylene oxide

(C

O)

3H6

75-56-9 1.9 fluid 1.15

Toluene (C7H8) 108-88-3 1.0 ≤ 15 ≤ 46 fluid 1.22

Vinyl chloride (C2H3Cl) 75-01-4 3.6 gas 1.08

Xylenes (C8H10) 1330-20-7 0.9 fluid 1.47

All response factors relate to propane (measured at 50 % LEL; 0.85 % (v/v))

*

Response times are with a flow through adapter and a gas flow of 1 l/min

D

Response factor defined by DEKRA EXAM

Response factor defined by MSA (not included in the EC-Type Examination Certificate BVS

M

10 ATEX E 009 X)

D

M

M

M

M

M

D

D

D

D

M

D

M

M

PrimaX

GB

39

Page 40

Approvals

7 Approvals

7.1 Marking, Certificates and Approvals according to the Directive 2014/34/EU (ATEX) and National Standards

PrimaX P

MSA Europe GmbH

Manufacturer:

Product: PrimaX P

Schlüsselstr.12

CH - 8645 Rapperswil-Jona

EC-Type Examination Certificate:

Standards:

Performance: EN 60079-29-1:2007, EN 50104:2010, EN 50271:2010

Gas:

Other gases:

Marking: Prima X P U

BVS 10 ATEX E009 X

EN 60079-0:2012 + A11:2013, EN 60079-1:2014,

EN 60079-11:2012, EN 60079-31:2014

Measure range: 0-100 % LEL

Methane, Propane, 2-Butanone, Acetone, Ethanol,

Ethyl acetate, (FAM-) Standard mineral spirit 65/95,

2-Propanol, Propene, Toluene, Hydrogen,

1-Ethoxy-2-Propanole (40 °C)

Oxygen: 0-10 % (V/V), 0-25 % (V/V)

PFG 11 G 001: EN 45544 -1:1999; EN 45544 -2:1999

Tox: H

S: 0-20 ppm; 0-100 ppm;

2

CO: 0-100 ppm; 0-1000 ppm

= 60 VDC

m

Main housing

Prima X

Combustible sensor

Prima X

Ox/Tox sensor

I 2G Ex db ia (ia) IIC T4/T6 Gb

II 2D Ex tb ia (ia) IIIC T130°C / T85°C Db IP 67

T4 -40°C ≤ Ta ≤ +70°C, T6 -40°C ≤ Ta ≤ +40°C

T130°C -40°C ≤ Ta ≤ +70°C,

T85°C -40°C ≤ Ta ≤ +40°C

Ex db IIC T4/T6 Gb

Ex tb IIIC T130°C / T85°C Db IP 67

T4 -40°C ≤ Ta ≤ +70°C ,T6 -40°C ≤ Ta ≤ +40°T130°C -40°C ≤ Ta ≤

+70°C ,

T85°C -40°C ≤ Ta ≤ +40°C

Ex ia IIC T4 Gb

Ex ia IIIC T135°C Db IP 67

-40°C ≤ Ta ≤ +70°C

GB

PrimaX

40

Page 41

Approvals

Option:

Special Conditions for Safe Use

• Do not open the instrument when energized.

• For dust applications the installation conditions according to EN 60079-31 has to be considered.

• Intensive electrostatic charging processes have to be prevented on the instrument label.

• The joint widths of the flameproof joint of this apparatus are in parts longer, and its gaps are in

In case of using the PrimaX Ex-Sensor, the complete device type PrimaX P is in accordance to

temperature class T6/T85°C, ambient temperature range -40°C ≤ Ta ≤ +40°C or to temperature class

T4/T130°C, ambient temperature range -40°C ≤ Ta ≤ +70°C

In case of using the PrimaX Ox-Tox-Sensor, the complete device type PrimaX P is in accordance to

temperature class T4/T130°C, ambient temperature range -40°C ≤ Ta ≤ +70°C

Avoid electrostatic charge on the temporary used calibration cap when used for calibration.

Cable gland

• M25 x 1,5;Torque 8 -12 Nm; only ATEX certified versions for gas and dust shall be used.

• NPT ¾"- 14; fixture with 2 layer PTFE sealing tape or according to the instructions of the NPT

The HART-interface is subject of this type examination certificate only for the purpose of maintenance

and parametrization.

When the HART-/ relay module is used the alarm shall be configured latching.

If a device with a combustible sensor is exposed to vibrations , calibration shall be done in sufficient

short intervals until it is verified that the device is not affected by the vibration stress.

After exposure of gas above the measuring range, the sensor has to be immediately calibrated/

adjusted, independent of the calibration interval. In the case of an adjustment the sensitivity of the

sensor has to be rechecked again after 24 hours.

HART Module Connector, only for temporary connection of an intrinsic safe HART Field

Communicator

P

≤ 200 mW, Uo ≤ 2,7 V, I0 ≤ 137 mA, Lo ≤ 10 µH, Co ≤ 1nF

o

≤ 5mW, Ui ≤ 5V, Ii ≤ 1mA, Li = 0, Ci = 0

P

i

Relay: switching voltage = 30 VDC; switching current = 2 ADC

parts shorter than the values of Table 2 of EN 60079-1:2014. For maintenance or repair contact

the manufacturer.

supplier; when removed, new PTFE sealing has to be used after reinstalling; only ATEX certified

versions for gas and dust shall be used.

GB

Quality Assurance Notification: 0158

Year of Manufacture: see Label

Serial Nr.: see Label

PrimaX

41

Page 42

PrimaX I

MSA Europe GmbH

Manufacturer:

Product: PrimaX I

EC-Type Examination Certificate: BVS 10 ATEX E009 X

Standards: EN 60079-0:2012 + A11:2013, EN 60079-11:2012

Performance EN 50104 :2010, EN 50271 :2010

Schlüsselstrasse 12

CH-8645 Rapperswil-Jona

Approvals

Gas: Oxygen: 0-10 % (V/V), 0-25 % (V/V)

Other gases:

Marking: Prima X I

Option:

Special conditions for safe use:

It is not allowed to open the key pad cover during usage in areas where EPL Ga, Group IIC is required.

Avoid electrostatic charge on the temporary used calibration cap when used for calibration.

Quality Assurance Notification: 0158

Year of Manufacture: see Label

Serial Nr.: see Label

PFG 11 G 001: EN 45544 -1:1999; EN 45544 -2:1999

Tox: H

S: 0-20 ppm; 0-100 ppm;

2

CO: 0-100 ppm; 0-1000 ppm

II 1G Ex ia IIC T4 Ga

-40°C ≤ Ta ≤ +70°C

II 2D Ex ia IIIB T135°C Db

-40°C ≤ Ta ≤ +40°C

Pi ≤ 700 mW, Ui ≤ 28 V, Ii ≤ 100 mA, Li = 0, Ci = 0

HART Module Connector, only for temporary connection of an intrinsic safe HART

Field Communicator

P

≤ 700 mW, Uo ≤ 28 V, I0 ≤ 100 mA, Lo ≤ 10 µH, Co≤ 1nF

o

≤ 5mW, Ui ≤ 5V, Ii ≤ 1mA, Li = 0, Ci = 0

P

i

GB

PrimaX

42

Page 43

7.2 Marking and Certificates according to IECEx

PrimaX P

MSA Europe GmbH

Manufacturer:

Product: PrimaX P

Schlüsselstrasse 12

CH-8645 Rapperswil-Jona

Approvals

IEC-Type Examination Certificate: IECEx BVS 10.0043 X

Standards:

Perfomance: none

Gas: see manual

Marking: Prima X P

Option:

IEC 60079-0:2011, IEC 60079-1:2014,

IEC 60079-11:2011 IEC 60079-31:2013

Main housing U

Ex db ia (ia) IIC T4/T6 Gb

Ex tb ia (ia) IIIC T130°C / T85°C Db IP 67

T4 -40°C ≤ Ta ≤ +70°C,T6 -40°C ≤ Ta ≤ +40°C

T130°C -40°C ≤ Ta ≤ +70°C,T85°C -40°C ≤ Ta ≤ +40°C

Prima X

Combustible sensor

Ex db IIC T4/T6 Gb

Ex tb IIIC T130°C / T85°C Db IP 67

T4 -40°C ≤ Ta ≤ +70°C ,T6 -40°C ≤ Ta ≤ +40°C

T130°C -40°C ≤ Ta ≤ +70°C, T85°C -40°C ≤ Ta ≤ +40°C

Prima X

Ox/Tox sensor

Ex d ia IIC T4 Gb

Ex ia IIIC T130°C Db IP 67

-40°C ≤ Ta ≤ +70°C

HART Module Connector, only for temporary connection of an intrinsic safe HART

Field Communicator

≤ 185 mW, Uo ≤ 2,7 V, I0 ≤ 137 mA, Lo ≤ 10 µH, Co≤ 1nF, Pi ≤ 5mW, Ui ≤

P

o

5V, I

≤ 1 mA, Li = 0, Ci = 0

i

Relays: switching voltage: 30 VDC;

switching current: 2 ADC

= 60 VDC

m

GB

PrimaX

43

Page 44

Approvals

Special conditions for safe use:

• Do not open the instrument when energized.

• For dust applications the installation conditions according to EN 60079-31 have to be considered.

• Intensive electrostatic charging processes on the instrument label have to be prevented on the

instrument label.

• The joint widths of the flameproof joint of this apparatus are in parts longer, and its gaps are in

parts shorter than the values of Table 2 of EN 60079-1:2014. For maintenance or repair contact

the manufacturer.

In case of using the PrimaX Ex-Sensor, the complete device type PrimaX P is in accordance to

temperature class T6/T85°C, ambient temperature range -40°C ≤ Ta ≤ +40°C or to temperature class

T4/T130°C, ambient temperature range -40°C ?≤ Ta ≤ +70°C

In case of using the PrimaX Ox-Tox-Sensor, the complete device type PrimaX P is in accordance to

temperature class T4/T130°C, ambient temperature range -40°C ≤ Ta ≤ +70°C

Avoid electrostatic charge on the temporary used calibration cap when used for calibration.

Cable gland: M25 x 1,5 ;Torque 8 -12 Nm; only ATEX certified versions for gas and dust shall be used.

NPT ¾”- 14; fixture with 2 layer PTFE sealing tape or according to the instructions of the NPT supplier;

when removed, new PTFE sealing has to be used after reinstalling; only ATEX certified versions for

gas and dust shall be used.

Quality Assurance Notification: 0158

Year of Manufacture: see Label

Serial Nr.: see Label

PrimaX

GB

44

Page 45

PrimaX I

MSA Europe GmbH

Manufacturer:

Product: PrimaX I

IEC-Type Examination Certificate: IECEx BVS 10. 0043 X

Standards: IEC 60079-0:2011, IEC 60079-11:2011

Performance: non

Gas: see manual

Schlüsselstrasse 12

CH-8645 Rapperswil-Jona

Approvals

Marking: Prima X I

P

≤ 700 mW, Ui ≤ 28 V, Ii ≤ 100 mA, Li = 0, Ci = 0

i

Option:

Special conditions for safe use:

• It is not allowed to open the key pad cover by use in areas where Category 1G, Group IIC is

required.

• Avoid electrostatic charge on the temporary used calibration cap when used for calibration.

Quality Assurance Notification: 0158

Year of Manufacture: see Label

Serial Nr.: see Label

HART Module Connector, only for temporary connection of an intrinsic safe HART

Field Communicator

P

≤ 700 mW, Uo ≤ 28 V, I0 ≤ 100 mA, Lo ≤ 10 µH, Co≤ 1nF

o

≤ 5mW, Ui ≤ 5V, Ii ≤ 1mA, Li = 0, Ci = 0

P

i

Ex ia IIC T4 Ga

-40°C≤ Ta ≤ +70°C

Ex ia IIIB T130°C Db

-40 °C ≤ Ta ≤ +40 °C

GB

PrimaX

45

Page 46

7.3 Special conditions for the safe use according to ATEX and SIL applications

Safety relevant parameters for the Gas Transmitters

Typ e B

Structure 1oo1 or 1oo2

HFT 0 or 1

PFD, PFH, SFF see table

λ

, λD, λDU, λ

tot

MTTR 72 h

T1 16 weeks (Proof-Test-Interval)

Possible structures and acquirable SILs

The following table shows, which structure has to be selected, to fulfil the requirements of a special SIL.

LDM = Low Demand Mode

HDM = High Demand or Continuous Mode

Structure 1oo1 XXX

Structure 1oo2 XXXXXX

Depending on the selected configuration and the sensor version, the following safety-relevant parameters have to be considered while implementing the safety loop:

DD

SIL1 SIL2 SIL3

LDM HDM LDM HDM LDM HDM

see table

Approvals

PrimaX

GB

46

Page 47

Approvals

General conditions for the safe use

• The application advice and the limitations of the manual have to be considered. For calibration

and maintenance, the regional and national regulations have to be considered.

• A defect transmitter has to be repaired within 72 hours.

• The HART

• The alarm conditions of the transmitter must be periodically checked together with the typical gas

calibration checks.

• The relays must be energised under normal conditions.

• The relay contacts must be protected with a fuse rated 0.6 of the nominal specified relay contact

current.

• The failure relay contacts must be safety related processed for warning purposes when the 4 to

20 mA link is not use for the alarm condition.

• The tests of the 4-20 mA - output signal and alarm conditions and the test of the alarm and fault

relays, LEDs and display have to be done during every calibration phase.

• The connected controller has to monitor the 4-20 mA signal current for values below 4 mA and

above 20 mA.

• For the correct use of the combustible sensor a minimum oxygen concentration of 10 Vol% is

necessary.

• The presence of catalytic poisons has to be avoided for the combustible sensor.

• A functional check/calibration check has to be done for the complete system.

• A visual check has to be done monthly.

• A system check has to be done every year.

• For the test gas, the gas has to be used which is defined for the measurement. The concentration

of the test gas has to be in the middle of the measure range.

• For zero gas, synthetic air has to be used.

• An adjustment has to be done under the following conditions:

difference at zero > +/- 5 % UEG

difference at sensitivity > +/- 20 % of the rated value

• If the calibration is inside of the valid tolerance, the calibration interval can be doubled.

• The maximum of the calibration interval is 16 weeks.

• The sensor has to be replaced if the sensor sensitivity during the operation is reduced to less than

50 % of the initial sensitivity.

• After exposure of gas above the measuring range, the sensor has to be immediately calibrated/

adjusted, independent of the calibration interval. In the case of an adjustment the sensitivity of the

sensor has to be rechecked again after 24 hours.

• If the appearance of catalytic poisons for the combustible sensor can not be avoided, the calibra-

tion interval has to be considerably reduced.

®

interface is not allowed to be used for the transmission of safety related data.

GB

PrimaX

47

Page 48

Approvals

Special conditions for SIL 2

• The use of the sensors in a High Demand or Continuous Mode is allowed only in a 1002 - struc-

ture.

• The outputs of the sensors (4-20 mA - loops and relay contacts) must to be monitored regarding

deviations.

Special conditions for SIL 3

• The use of the sensors is allowed only in a 1oo2 - structure.

• The outputs of the sensors (4-20 mA - loops and relay contacts) must to be monitored regarding

deviations.

PrimaX

GB

48

Page 49

Safety Relevant ParametersMSA

7.4 Safety Relevant Parameters [40°C]t

Application with Relay

Ammonia (NH

) 3737 2469 1269 415 854 88.9 67.3 7.9E-04 5.6 1.2E-05 1.2 4.2E-07 4.2 8.7E-09 8.7

3

Carbon Monoxide

λ

total

λ

S

fitfitfitfitfit%%

3187 2194 994 255 739 92.0 74.4 3.4E-04 3.4 7.0E-06 0.7 2.5E-07 2.5 5.3E-09 5.3

λ

D

λ

DU

λ

DD

SFF DC PFD

1oo1

PFD

% of

2

1oo1

SIL

PFD

1oo2

PFD

1oo2

% of SIL 3

PFD

1oo2

PFD

1oo2

PFD

1oo2

PFD

1/h % of SIL 1 1/h % of SIL 3

(CO)

Chlorine (Cl

) 4332 2766 1566 589 978 86.4 62.4 7.8E-04 7.9 1.7E-05 1.7 5.9E-07 5.9 1.3E-08 12.7

2

Combustible 6666 3933 2733 1066 1667 84.0 61.0 1.4E-03 14.3 3.1E-05 3.1 1.1E-06 10.7 2.4E-08 24.2

Hydrogen (H

Hydrogen Chloride

) 3737 2469 1269 415 854 88.9 67.3 7.8E-04 5.6 1.2E- 05 1.2 4.2E-07 4.2 8.7E-09 8.7

2

4297 2749 1549 578 970 86.5 62.7 1.0E-04 7.8 1.6E- 05 1.6 5.8E-07 5.8 1.2E-08 12.4

(HCl)

Hydrogen Cyanide

3995 2598 1398 490 907 87.7 64.9 7.5E-04 6.6 1.4E- 05 1.6 5.6E-07 5.6 1.2E-08 12.0

(HCN)

Hydrogen Sul-

phide (H

S)

2

Nitrogen Dioxide

)

(NO

2

Nitrogen Oxide

3187 2194 994 255 739 92.0 74.4 5.6E-04 3.4 7.0E-06 0.7 2.5E-07 2.5 5.3E-09 5.3

4237 2718 1518 561 958 86.8 63.1 7.5E-04 7.5 1.6E- 05 1.6 5.6E-07 5.6 1.2E-08 12.0

4877 3039 1839 748 1091 84.7 59.3 1.0E-03 10.0 2.1E- 05 2.1 7.5E-07 7.5 1.6E-08 16.4

(NO)

Oxygen (O

Sulphur Dioxide

)

(SO

2

) 6044 3622 2422 655 1767 89.2 73.0 8.8E-04 8.8 1.9E-05 1.9 6.5E-07 6.5 1.4E-08 14.2

2

4297 2749 1549 578 970 86.5 62.7 5.6E-04 7.8 1.6E- 05 1.6 5.8E-07 5.8 1.2E-08 12.4

1oo2

PrimaX

49

Page 50

Safety Relevant ParametersMSA

Application with 4-20 mA Current Output

λ

total

λ

S

λ

D

λ

DU

λ

DD

SFF DC PFD

1k

PFD

1oo1

PFD

1oo2

PFD

1oo2

PFD

1oo2

PFD

1oo2

PFD

1oo2

PFD

fit fit fit fit fit % % % of SIL 2 % of SIL 3 1/h % of SIL 1 1/h % of SIL 3

Ammonia

)

(NH

3

Carbon Mon-

1734 867 867 363 504 79.1 58.1 4.9E-04 4.9 1.0E-05 1.0 3.6E-07 3.6 7.6E-09 7.6

1183 592 592 202 389 82.9 65.8 2.7E-04 2.7 5.5E-06 0.6 2.0E-07 2.0 4.2E-09 4.2

oxide (CO)

Chlorine (Cl

) 2328 1164 1164 536 628 77.0 53.9 7.2E-04 7.2 1.5E-05 1.5 5.4E-07 5.4 1.1E-08 11.5

2

Combustible 4662 2331 2331 1013 1318 78.3 56.5 1.4E-03 13.6 3.0E-05 3.0 1.0E-06 10.1 2.3E-08 22.9

Hydrogen (H

Hydrogen

) 1734 1437 1 43 7 363 504 79 .1 5 8 .1 4 .9 E-0 4 4.9 1.0E- 05 1.0 3.6E- 07 3.6 7.6E-09 7.6

2

2294 1117 1117 526 621 77.1 54.1 7.1E-04 7.1 1.5E- 05 1.5 5.3E-07 5.3 1.1E-08 11.2

Chloride (HCl)

Hydrogen Cy-

1992 867 867 438 558 78.0 56.0 5.9E-04 5.9 1.2E- 05 1.2 4.4E-07 4.4 9.3E-09 9.3

anide (HCN)

Hydrogen Sul-

phide (H

2

Nitrogen Dioxide (NO

)

2

Nitrogen Oxide

1183 592 592 202 389 82.9 65.8 2.7E-04 2.7 5.5E-06 0.6 2.0E-07 2.0 4.2E-09 4.2

S)

2233 1147 1147 509 608 77.2 54.5 6.8E-04 6.8 1.4E- 05 1.4 5.1E-07 5.1 1.1E-08 10.8

2874 1437 1437 695 741 75.8 51.6 9.3E-03 9.3 2.0E- 05 2.0 7.0E-07 7.0 1.5E-08 15.2

(NO)

Oxygen (O

Sulphur Diox-

ide (SO

) 4040 2020 2020 602 1418 85.1 70.2 8.1E-04 8.1 1.7E-05 1.7 6.0E-07 6.0 1.3E-08 13.0

2

2294 1147 1147 526 621 77.1 54.1 7.1E-04 7.1 1.5E- 05 1.5 5.3E-07 5.3 1.1E-08 11.2

)

2

1oo2

PrimaX

50

Page 51

8 Accessories

For part numbers → chapter 9 "Spare Parts".

8.1 Calibration Cap

Using calibration cap allows span gas calibration procedure to be accurate in windy environmental

conditions.

The calibration cap is pushed on to the front of the sensor and is sealed by an O- ring. The surface

area S < 20 cm

Fig. 13 Calibration cap

The calibrating cap must be removed after completing the calibration!

The gas is supplied via either of the gas inlets by means of suitable flexible tube.

8.2 Sensor Gard

2

.

WARNING!

Accessories

Fig. 14 Sensor gard

The sensor gard should be fitted at all times except when using the flow through adapter or duct mount

kit.

Ambient weather condition can affect the gas mixture inside of the sensor gard. Use sensor gard for

functional test only. Calibration cap is recommended for sensor calibration.

Using the sensor gard will extend the response time, depending on the gas flow rate.

Gas flow rate: 1,0 l/min

PrimaX

GB

51

Page 52

8.3 Remote Calibration

Fig. 15 PrimaX with CalGard

The CalGard stainless steel remote calibration adaptor provides reliable operation of remotely installed