Page 1

Instruction Manual

ModCon®75 Touch

Controller

THIS MANUAL MUST BE CAREFULLY READ BY ALL INDIVIDUALS WHO HAVE OR WILL

HAVE THE RESPONSIBILITY FOR USING OR SERVICING THE PRODUCT. Like any piece

of complex equipment, this instrument will perform as designed only if it is used and

serviced in accordance with the manufacturer’s instructions. OTHERWISE, IT COULD FAIL

TO PERFORM AS DESIGNED AND PERSONS WHO RELY ON THIS PRODUCT FOR THEIR

SAFETY COULD SUSTAIN SERIOUS PERSONAL INJURY OR LOSS OF LIFE.

The warranties made by Mine Safety Appliances Company with respect to the product are

voided if the product is not used and serviced in accordance wit h the instructi ons in this

manual. Please protect yourself and others by follow ing them. We encourage our customers to write or call regarding this equipment prior to use or for any additional information relative to use or repairs.

For your local MSA contacts please go to our website www.MSAsafety.com

©MSA 2018 - All Rights Reserved

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

USA

Phone 1-800-MSA-2222

Fax 1-800-967-0398

(L )-Y Rev 0

Page 2

MSA Permanent Instrument Warranty

1. Warranty- Seller warrants that this product will be free from

mechanical defect or faulty workmanship f or a period of eighteen

(18) Months from date of shipment or one (1) yea r f rom installation,

whichever occurs first, provided it is maintained and used in

accordance with Seller's instructions and/ or re commendations.

This warranty does not apply to expendable or consumable parts

whose normal life expectancy is less than one (1) y ear such as, but

not limited to, non-rechargeable batteries, sen sor elements, filter,

lamps, fuses etc. The Seller shall be released from all obligations

under this warranty in the event repairs or modifications are made

by persons other than its own or authorized service personnel or if

the warranty claim results from physical abuse or mi suse of the

product. No agent, employee or representative of the Seller has

any authority to bind the Seller to any affirmation, representation or

warranty concerning the goods sold under this cont ract. Seller

makes no warranty concerning components or accessories not

manufactured by the Seller, but will pass onto the Purchaser all

warranties of manufacturers of such compone nt s. THIS

WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED, IMPLIED OR STATUTORY, AND IS STRICTLY

LIMITED TO THE TERMS HEREOF. SELLER SPECIFICALLY

DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE.

2. Exclusive Remedy- It is expressly agreed that Purchaser's sole

and exclusive remedy for breach of the above warranty, for any

tortious conduct of Seller, or for any other cause of act i on, shall be

the repair and/ or replacement at Seller's option, of any equipment

or parts thereof, which after examination by S el l er is proven to be

defective. Replacement equipment and/ or parts will be provided at

no cost to Purchaser, F.O.B. Seller's Plant. Failure of Seller to

successfully repair any nonconforming produ ct shall not cause the

remedy established hereby to fail of its essential purpose.

3. Exclusion of Consequential Damage- Purchaser specifically

understands and agrees that under no circumstanc es will seller be

liable to purchaser for economic, special, incidental or

consequential damages or losses of any kind whatsoever, including

but not limited to, loss of anticipated profits and any other loss

caused by reason of non-operation of the goods. Thi s exclusion is

applicable to claims for breach of warranty, tortious conduct or any

other cause of action against seller.

ModCon®75 Touch

1

Page 3

General Warnings

1. The Controller described in this manual must be installed,

operated and maintained in strict accordance with it s labels,

cautions, warnings, instructions, and within the l im i tations stated.

2. This is a general-purpose (GP) monitor and can be a source of ignition.

Install, locate, and operate only in an area where hazardous

atmosphere is not presented in accordance with all applicable codes.

Locating the Controller in an area where a hazardou s at m osphere is

present can result in ignition of the hazardous atmos phere.

3. Use only genuine MSA replacement parts when performing any

maintenance procedures provided in this manual. Failure to do so

may seriously impair instrument performance. Repair or alteration

of the ModCon75 Touch Controller beyond the scope of these

maintenance instructions or by anyone other than authorized MSA

service personnel, could cause the product to f ail to perform as

designed and persons who rely on this product for their safety

could sustain serious personal injury or loss of life.

4. If a portion of the system in which the Controller is installed fails,

remaining system functions may not operate properly. In this case,

do not use the system until proper repairs are made.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN SERIOUS PERSONAL INJURY OR LOSS OF LIFE.

2

ModCon®75 Touch

Page 4

Table of Contents

Chapter 1,

Overview ............................................................. 8

Introducing the ModCon75 Touch Controller ..................... 8

The ModCon75 Touch System ........................................... 8

Technical Description ......................................................... 9

Operating Panel .................................................................. 9

I/Os ................................................................................... 10

Communications ............................................................... 10

HMI Application ................................................................ 10

Chapter 2,

Operating Instructions ..................................... 11

Before Installation ............................................................. 11

Safety and Environmental Guideline ................................ 12

......................... 12

Mounting ........................................................................... 12

ModCon75 Touch Controller Panel Cutout ...................... 13

Earth Assembly ................................................................ 13

HMI Panel Mounting ......................................................... 14

Chapter 3,

ModCon75 Touch HMI Panel ........................... 15

Overview ........................................................................... 15

Installation Space Considerations .................................... 16

HMI Panel Mechanical Dimensions .................................. 16

......................... 17

Specifications ................................................................... 17

ModCon®75 Touch

3

Page 5

Chapter 4,

ModCon75 Touch CPU Module ....................... 20

Overview ........................................................................... 20

CPU Diagram ................................................................... 20

CPU Installation ................................................................ 20

......................... 20

Removing the CPU ........................................................... 22

RS485 ............................................................................... 22

......................... 22

RS485 Wiring ................................................................... 23

RS485 Termination ........................................................... 23

Battery Backup, Installation, and Replacement................ 23

......................... 24

Specifications ................................................................... 25

Chapter 5,

ModCon75 Touch I/O Module .......................... 26

Overview ........................................................................... 26

I/O Module Diagram ......................................................... 26

I/O Bus Connectors .......................................................... 27

......................... 27

I/O Installation ................................................................... 27

Removing the I/O .............................................................. 28

I/O Module Connection Points .......................................... 29

Specifications ................................................................... 29

Chapter 6,

Power Supply Requirements & Wiring ........... 32

Overview ........................................................................... 32

Safety Considerations ...................................................... 32

ModCon®75 Touch

4

Page 6

......................... 32

Connecting the Power Supply .......................................... 32

Chapter 7,

ModCon75 Touch Wiring ................................. 34

......................... 34

Wiring Procedure .............................................................. 34

Wiring Guidelines ............................................................. 34

I/O Relay Wiring ............................................................... 35

I/O Output’s Power Supply ............................................... 35

......................... 35

Increasing Contact Life Span ........................................... 36

Chapter 8,

Operating Instructions ..................................... 37

Power Up/Main Menu Screen........................................... 37

Touch Screen Buttons ...................................................... 37

Touch Screen Hierarchy ................................................... 38

Add Units Button ............................................................... 38

Password Lock/Unlock ..................................................... 39

......................... 40

View/Edit all X3 Transmitters or Sensors on Network ...... 41

Add/Display Setpoints Button ........................................... 42

......................... 42

Alarm Setup ...................................................................... 43

Latching, Zone Setup ....................................................... 44

Write SP’s ......................................................................... 46

Main Data Screen Button ................................................. 47

Modbus Alarms ................................................................. 48

ModCon®75 Touch

5

Page 7

Fault Status....................................................................... 49

Remote I/O Editor Button (Optional) ................................ 50

Setting Remote Relay ID and Relay State ....................... 51

Remote I/O Editor Setup .................................................. 51

Remote Relay Power Supply Wiring ................................ 52

......................... 52

Remote Relay Wiring ........................................................ 52

Zone Setpoints Editor Button ............................................ 53

......................... 54

Network Settings Button ................................................... 54

Date & Time Settings ................................................. 54

Active Alarm/Fault Button ................................................. 55

Active/Fault Screen Selection........................................... 55

Password Editor ............................................................... 56

Chapter 9,

Technical Specifications ................................. 58

Specifications ................................................................... 58

Dimensions ....................................................................... 59

Appendix A,

Register Maps ................................................... 61

Critical Memory Bits .......................................................... 61

Memory Integers, MI273 through MI297 .......................... 61

Memory Integers, MI300 through MI449 .......................... 62

Memory Integers, MI450 through MI474 .......................... 66

Memory Integers, MI525 through MI599 .......................... 67

Memory Integers, MI600 through MI624 .......................... 69

Memory Integers, MI650 through MI674 .......................... 70

Table 1 .............................................................................. 71

ModCon®75 Touch

6

Page 8

Table 2 .............................................................................. 71

Table 3 .............................................................................. 72

Table 4 .............................................................................. 73

Table 5 .............................................................................. 73

Appendix B,

Optional Remote Relay Module ...................... 74

Dimensions ....................................................................... 74

Specifications ................................................................... 75

Jumper Settings ................................................................ 76

I/O Input Jumper Settings ................................................. 77

Communication Port Jumper Settings .............................. 78

RS485 Pin Layout ............................................................. 78

Opening the Remote Relay Module ................................. 79

Closing the Remote Relay Module ................................... 81

Remote Relay Module Mounting ...................................... 81

DIN-rail Mounting .............................................................. 83

ModCon®75 Touch

7

Page 9

Chapter 1,

Overview

Introducing the ModCon75 Touch Controller

The ModCon75 Touch Controller:

• is a pre-programmed logic controller with an integral operating panel

• self-configuring to Ultima X Gas Monitors with X3 Technology

• offers Modbus communications

• event logging

• operating panels contain a High-Resolution Tou ch S creen:

• The Touch screen displays:

o operator instructions

o alarms, faults, gas values, and transmitter/sensor tags

o real-time system information.

Figure 1. The ModCon75 Touch Controller

8

ModCon®75 Touch

Page 10

• Two types of modules are compatible with M odCon75 Touch

Controllers:

o DIN rail I/O Module plugs directly into the back of a ModCon75 Touch Controller for

a self-contained PLC unit with a local I/O config urat ion (integral to ModCon75

Touch Controller).

o Remote Relay Modules can also be easily integrated to greatly extend the

system’s external notification capacity.

• These features combine to offer a cost-effective solution for gas

detection controller applications requiring:

o operator interface

o the ability to control small to medium processes.

Technical Description

ModCon75 Touch Controller

Dimensions :

• 211.1 x 150.1 x 114.1 mm (8.31 x 5.91 x 4.49")

Mounting:

• Panel-mounted via brackets

Power Requirement:

• 24 VDC controller unit

Real-time Clock (RTC)

Battery Back-up:

• Protects real-time clock (RTC) and all data, including variable data.

Operating Panel

• Contains a High-Resolution touch screen:

o Touch Screen Displays

o 1 Audio-out 3.5mm jack-Not Supported, No Customer Connection

o 1 Micro SD slot

o 2 type A, USB host ports-Not Supported, No Customer Connection

o 1 Mini-B USB device port-Factory use only

o 2 Ethernet ports, RJ45, 10/100 Mbps

o 1 Power input connector, 24 VDC

Note:

• The HMI panel is designed to comply with NEMA 4X, IP66 and IP65 when installed into

a NEMA 4X, IP66 and IP65 enclosure. Note however that the Audio Protection Seal

must remain plugged in for NEMA 4X, IP66 and IP65, in which case the audio sound

level from the internal speaker is significantly reduced.

ModCon®75 Touch

9

Page 11

I/Os

• 16 Sink or Source, 24VDC inputs available-Not S upported, No Customer

Connection.

• 9 Zone Relays, Horn, and Fault relay, 24VDC outputs available.

NOTE:

o Inputs are not used in the standard ModCon75 Tou ch Controller.

Communications

RJ45

• The controller has two Ethernet ports, which may be used to.

o establish communications with devices to run a remote display

o establish Modbus TCP communications

PLC Application

• enables the user to perform automation tasks

HMI Application

• The HMI application customizes the operato r interface to.

o enable the operator to enter data via the controller touch screen

o variables allow the user to display system data on the ModCon75 Touch LCD

screen

o sensor status, tag name and sensor values

o I/O status and values

ModCon®75 Touch

10

Page 12

Chapter 2, Mounting

Before Installation

• Check the contents of the Controller Kit.

• Kit contains:

o the HMI panel, Figure 6

o the CPU module, Figure 8

o the I/O module, Figure 15

o a three-pin power supply connector

o four mounting brackets, each with an inserted sc rew

o a rubber seal to be seated in back of the HMI panel

Figure 2. HMI Panel and Mounting Brackets

11

ModCon®75 Touch

Page 13

Safety and Environmental Guideline

• This is a general-purpose (GP) monitor and can be a source of ignition.

Install, locate, and operate only in an area where hazardous atmosphere

is not present and in accordance with all applicable codes.

• Do not install in areas with.

o excessive or conductive dust

o corrosive or flammable gas

o moisture or rain

o excessive heat

o regular impact shocks or excessive vibration.

• Do not place in water or allow water to leak onto the controll er.

• Do not allow debris to fall inside the unit during instal lation.

• Do not touch live wires.

• Double-check all the wiring before turning ON the power supply.

• Stay as far as possible from high-voltage cables and power equipment.

• Allow a minimum of 0.4” of space for ventilati on between the top and bottom edges of

the controller and the enclosure walls

Read and follow all instructions, warnings, and cauti ons pertaining to this controller.

•

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT INSERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

.

Mounting

NOTE:

o The mounting panel cannot be more than 0.2” thick.

• To max i m ize system performance, avoid electromagnetic

interference by.

o mounting the controller on a metal panel

o earthing the ModCon75 Touch Controller according to Figure 4.

• Make a panel cutout for your ModCon75 Touch Controller.

o See Figure 3 for cutout dimensions.

• If you are mounting the controller on a metal panel, earth the power supply.

o Bore a hole (Figure 4).

o Scrape the panel paint away from the contact area to ensure a conductive

connection.

o Ensure proper ingress protection per applicable codes and standards.

o Drive the screw into the hole.

ModCon®75 Touch

12

Page 14

Figure 3. ModCon75 Touch Controller Panel Cut-out—Front View

o On the screw’s shank, place the following hardware in t hi s order:

washer, ring terminal, second washer, spring, and nut as shown

in Figure 4.

Figure 4. Earth Assembly

• Slide the HMI panel into the cutout, ensuring that the rubber seal is in place as shown

in Figure 5.

• Push the four mounting brackets into their slots on the sides of the HMI panel as

shown in Figure 5.

• Tighten the bracket screws against the HMI panel. Hold t he brackets securely against

the unit while tightening the screws.

ModCon®75 Touch

13

Page 15

Figure 5. HMI Panel Mounting

ModCon®75 Touch

14

Page 16

Chapter 3,

Panel.

serves the HMI panel’s embedded speaker.

must be kept in place for IP65, IP66 and NEMA 4X complian ce.

end of the power cable.

ports

10/100Mbps.

ModCon75 Touch HMI Panel

The platform comprises the CPU controller, HMI panel and I/O module that snap together to form the ModCon75 Touch Controller.

HMI Panel

• High-resolution touch screen provides the operator interf ace for the system.

• The DIN-rail structure on the panel’s back is design ed to physically support the CPU

controller and the I/O module.

HMI Panel Diagram

Figure 6. HMI Panel Front and Rear View

Screen Protection

2 Audio Outlet Seal Prevents dust accumulation in the small outlet that

A plastic sheet attached to the HMI Panel screen for

protection. Remove it during installation on the HMI

Caution: Keep the seal in place when the embedded speaker is not used. The seal

3 DIN-rail structure Physical support for the CPU and I/O m odules.

4 24VDC power input Connection point for the HMI Panel’s power source.

Connect the Terminal Block supplied with the kit t o the

5 2 Ethernet (RJ45)

6 USB Device Not Supported, No Customer Connection.

7 2 USB Host ports Not Supported, No Customer Connection.

Support high-speed Ethernet communications,

ModCon®75 Touch

15

Page 17

8 Micro SD slot Supports standard micro SD cards.

(AUX)

9 Audio-out jack Not Supported, No Customer Connection.

10 Auxiliary connector

Provides the electrical connection for the CPU.

Installation Space Considerations

• Allocate space for:

o The HMI Panel including the CPU and I/O modules that will be installed on it.

o Opening the doors of the CPU and I/O modules.

HMI Panel Mechanical Dimensions

Figure 7. HMI Panel Mechanical Dimensions

16

ModCon®75 Touch

Page 18

Power Supply

consumption

Display

(brightness)

50% of its original level.

Height x Width (mm)

HMI Panel Interface Connections

Ethernet CAT-5e shielded cable with RJ45 connector

Micro SD Standard micro SD

• Disconnect system power before connecting or disconnecting any modules or device s.

• Components in this system are electrostat i c discharge sensitive (ESDS). Use proper

personal grounding procedures when removing, handling or adjusting the electronic

modules.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

Specifications

Table 1. Specifications for ModCon75 HMI Panel

Input voltage 24VDC

Permissible range 20.4VDC to 28.8VDC

Maximum current

LCD type TFT

Backlight type White LED

Luminous intensity

Backlight longevity 50k hours

Note: Panel’s longevity is the typical operating t i m e after which the brightness drops to

Resolution (pixels) 800 x 480 (WVGA)

Size 7”

Viewing area

0.75A @ 24VDC

Typically, 400 nits (cd/m2), at 25°C

152.4 x 91.44

Color support 65,536 (16bit)

17

ModCon®75 Touch

Page 19

Surface treatment Anti-glare

System

1GB user memory

Data speed: up to 200Mbps

Audio

IP66 or NEMA 4X.

Communication

Ethernet port

USB device – Not Supported, No Customer Connection

USB host - Not Supported, No Customer Connection

Environmental

Rear side: IP20, NEMA 1

IP66 or NEMA 4X.

Touch screen Resistive Analog

Actuation force (min) >80 g (0.176 lb.)

Processor 32bit, 800Mhz RISC Processor, with Graphic A cc el erator

Internal memory RAM: 512MB

ROM: 3GB system memory

External memory Micro SD or Micro SDHC card

Size: up to 32GB

Note: The audio outlet seal must be inserted in the outl et in order to comply with IP65,

Number of ports 2

Port type 10/100 Base-T (RJ45)

Auto crossover Yes

Auto negotiation Yes

Isolation voltage 500VAC for 1 minute

Cable Shielded CAT5e cable, up to 100m (328 ft.)

Protection Front face: IP65/66, NEMA 4X

Note: The audio outlet seal must be inserted in the out l et in order to comply with IP65,

ModCon®75 Touch

18

Page 20

Operating temperature -20°C to 55°C (-4°F to 131°F)

8.4Hz to 150Hz, 1G acceleration

Storage temperature -30°C to 70°C (-22°F to 158°F)

Relative Humidity (RH) 5% to 95% (non-condensing)

Operating Altitude 2,000m (6,562 ft.)

Shock IEC 60068-2-27, 15G, 11ms duration

Vibration IEC 60068-2-6, 5Hz to 8.4Hz, 3.5mm constant ampl itude,

19

ModCon®75 Touch

Page 21

Chapter 4,

ModCon75 Touch CPU Module

• The CPU cannot operate independently. It m ust be pl ugged into the

back of an HMI panel. The HMI panel provides the CPU’s power

source.

Features:

• IO/COM Bus connector for interfacing I/O module s

• Isolated RS485.

• Backup battery.

CPU Diagram

Figure 8. CPU Front and Rear View

1. DIN-rail clips

2. Battery pull-tab (remove during installation)

3. Battery compartment cover

4. IO/COM Bus connector, Shipped covered. Leave c overed when not in use.

5. RS485 connector

6. RS485 termination selection DIP switch

7. CANbus connector-Not Supported, No Customer Connection

8. CPU door

9. CPU connector to HMI panel

Installation

• Disconnect system power before connecting or disconnecting any modules.

• Components in this system are electrostat i c discharge sensitive (ESDS). Use proper

personal grounding procedures when removing, handling or adjusting the electronic

modules.

FAILURE TO FOLLOW THE THESE WARNINGS CAN RESULT IN SERIOUS

PERSONAL INJURY OR LOSS OF LIFE.

ModCon®75 Touch

20

Page 22

The AUX connector on the back of the HMI panel prov ides t he connection point for the

CPU, including power.

The DIN-rail type structure on the back of the panel provides the physical support.

1. Remove the AUX connector cover from the panel.

2. Remove the IO/COM bus connector cover.

3. Plug the CPU into the HMI panel AUX connector as sh own in Figure 9. The guide

tunnel on the CPU will be used to install the I/O module as shown in Figure 12.

4. Verify that the DIN-rail clips located on the top and bottom of the CPU have been

locked onto the DIN-rail structure on the back of t he HMI panel as shown in Figure 10.

Figure 9. CPU Assembly

Figure 10. Locked Figure 11. Unlocked

ModCon®75 Touch

21

Page 23

Figure 12. Guide Tunnel

Removing the CPU

1. Power off the HMI panel before removing the CPU.

2. Disconnect the RS485 connector.

3. Disconnect the I/O module connected to the CPU (by pushing the Bus Connector lock

to the right).

4. On the CPU, pull the top DIN-rail clip up and the bott om clip down to the unlocked

position as shown in Figure 11.

5. Pull the CPU out of its place.

About the CPU I/O Bus Connector

• The IO/COM Bus connector on the right side of the CPU provides the electrical

connection point for the I/O module. The connect or is shipped covered by a protective

cover, protecting the connector from debris, damage and ESD.

RS485

• Disconnect power before making any communications connections.

FAILURE TO FOLLOW THIS WA RNING CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

22

ModCon®75 Touch

Page 24

The CPU is shipped with a 4-pin RS485 terminal block. This connector is marked with a pin

assignment that is identical to the corresponding marking on the CPU as shown in Figure

13.

Figure 13. RS485 Terminal Block

D+ Tx/Rx+ (Ultima X3 A)

D- Tx/Rx- (Ultima X3 B)

SG Signal Ground

Functional Ground

Note:

RS485 Wiring

• Use shielded twisted-pair cable, incompliance with EIA RS 485 specifications.

• When wiring each node, connect the cable shield to the functional ground point of the

RS485 terminal block.

• In order to avoid ground loops, do not connect the R S 485 f unct i onal ground terminal to

the earth of the system, as it is internally connected t o the HMI panel’s functional

ground point.

RS485 Termination

• Use the DIPswitches shown in figure 9 to set the RS485 termination accordi ng to the

table as shown in Table 2.

• The device is shipped with both its DIP switches set to ON; change the settings if the

device is not at one of the ends of the RS485 network.

Table 2. DIP Switch Settings

Battery: Back-up, Installation and Replacement

Backup

• In order to preserve back-up values for the Real Time Clock (RTC) and system data in

the event of power off, the battery must be conne cted.

23

ModCon®75 Touch

Page 25

Battery Installation

• The CPU is shipped with the battery installed, but wit h a pl ast ic battery pull-tab inserted

in the battery compartment. Pull out the Battery pull-tab during installation in order to

connect the battery.

Battery Replacement

• Components in this system are electrostat i c discharge sensitive (ESDS). Use proper

personal grounding procedures while servicing the battery.

FAILURE TO FOLLOW THIS WARNING CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

Caution

• To preserve back-up values for RTC and system dat a during battery replacement, the

CPU must be powered from the HMI panel.

1. Open the CPU door and remove the battery cover.

2. Remove the used battery and insert the new one, ensuring that the polarity is aligned

with polarity as shown in Figure 14.

3. Replace the battery cover.

4. Dispose of the used battery according to local and nat i onal st andards and regulations.

Figure 14. Battery Polarity

ModCon®75 Touch

24

Page 26

Specifications

General

Horn and Fault relay

the HMI panel and via System Tag).

Customer Connection

Communication

RS485

RS485

Environmental

8.4Hz to 150Hz, 1G acceleration

Table 3. Specifications for ModCon75 Touch CPU

I/O Support Zone relay module includes 9 Zone Alarm,

Ladder Memory 1MB

Bit Operation

Battery Model: CR2032 Lithium battery

Connectors IO/COM Bus connector

Voltage limits -7 to +12 VDC maximum, Common+Differential

Baud rate range 1,200 – 115,200 bps

Nodes Up to 32

Isolation voltage 500VA C f or 1 minute

Cable type Shielded twisted pair in compliance with EIA

0.13 μs

Battery Lifetime: 4 years typical at 25°C

Battery Low detection and indication (via

CANbus connector – Not Supported, No

.

Cable Length Maximum 1,200 m (3,937 ft.)

Termination Set using DIP Switches

Protection IP20, NEMA1

Operating temperature

Storage temperature

Relative Humidity (RH) 5% to 95% (non-condensing)

Operating Altitude 2,000m (6,562 ft.)

Shock IEC 60068-2-27, 15G, 11ms duration

Vibration IEC 60068-2-6, 5Hz to 8.4Hz, 3.5mm constant ampl itude,

-20°C to 55°C (-4°F to 131°F)

-30°C to 70°C (-22°F to 140°F)

25

ModCon®75 Touch

Page 27

Chapter 5,

(not shown).

Lock

connect the I/O module to the CPU.

Cover)

ModCon75 Touch I/O Module

• The ModCon75 Touch HMI panel is delivered with o ne I/O Module. An

optional Remote Relay Module is also available and is described in

detail in Appendix B.

I/O Modules

• I/O Modules provide a ModCon75 Touch Controlle r wit h an on-board

I/O configuration.

• The I/O Module plugs directly into the back of the ModCon75 Touch

HMI panel, creating a self-contained control unit wit h a local I/O

configuration.

I/O Module Diagram

1 Din-rail clips

2 Input I/Os Input I/O connection points – Not Supported, No

3

4 I/O Bus-left Left-side Connector

5 Bus Connector

6 I/O Bus-Right

Figure 15. I/O Module

(Bus Connector

Provide physical support for CPU and I/O Module. There

are two clips: one at the top (shown), one at the bott om

Customer Connection

Slide the Bus Connector Lock to the left to electrically

Right-Side Connector shipped covered. Leave covered

when not in use.

26

ModCon®75 Touch

Page 28

7 Output I/Os Output I/O connection points

from being scratched. Remove tape during installation.

8

9 I/O LEDs Green LEDs

10

11 Status LED Tricolor LED, Green/Red/Orange

Note Refer to page 29 for LED indications

12 Module door Shipped covered with protective tape to prevent the door

13 Screw holes Enable panel-mounting; hole diameter: 4mm (0.15”)

About the I/O Bus Connectors

• The I/O Bus connectors provide the physical and electrical connection points between

modules. The connector is shipped covered by a protective cover, protecting the

connector from debris, damage and ESD.

• The I/O Bus – Left (# 4 in Figure 15) will be connected to the ModCon75 Touch CPU

module.

• The I/O Bus – Right (# 6 in Figure 15) do not remove its Bus Connector Cover.

• Disconnect system power before connecting or disconnecting any modules.

• Components in this system are electrostat i c discharge sensitive (ESDS). Use proper

personal grounding procedures when removing, handling or adjusting the electronic

modules.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

Installation

The Din-rail type structure on the back of the HMI pan el prov i des the physical support for

the I/O module.

1. Check the CPU to which you will connect the I/O module to verify its Bus Connector is

not covered.

2. Verify the I/O module Bus Connector (Left) is not covered and the Bus Connector

(Right) is covered.

3. Use the upper and lower guide-tunnels (tongue a nd groove) to slide the I/O module

into place as shown in Figure 16.

4. Verify that the DIN-rail clips located at the top and bottom of the I/O module have

snapped onto the DIN-rail.

5. Slide the Bus Connector Lock all the way to the l ef t as sh own in Figure 17.

27

ModCon®75 Touch

Page 29

Figure 16. Guide Tunnels

Guide Tunnels

Bus Connector

Unlocked

Bus Connector

Locked

Figure 17. Bus Connector

Removing the I/O Module

• Disconnect the system power

• Disconnect the I/O terminals (#7, 8 shown in Figure 15).

• On the I/O module, pull the top DIN-rail clip up and the bot tom clip down.

• Open the door of the I/O module and hold it with two f i ngers; then pull it carefully from

its place.

28

ModCon®75 Touch

Page 30

Output I/O

Input I/O – Not

I/O Module Connection Points

Outputs

not used

group

bus

output

Alarm Relay Function

Output

Function

0

Zone 1

1

Zone 2

2

Zone 3

3

Zone 4

4

Zone 5

5

Zone 6

6

Zone 7

7

Zone 8

8

Zone 9

9

Horn

10

Fault

Not

Isolated

• The I/O connection points are arranged in two gro ups of eleven points each as shown

in Figure 18.

Supported,

No Customer

Connection

Figure 18. Connection Points

• I/O Outputs O0 – O7 share common CM2

• I/O Outputs O8 – O10 share common CM3

• I/O Outputs O11 – O15 not used

Specifications

Table 4. Specifications for ModCon75 Touch I/O Module

Number of outputs Only I/O outputs O0 – O10 used, I/O outputs O11 – O15

Output type Relay, SPST-NO (Form A)

Isolation groups Two groups of 8 outputs each

Isolation voltage

Group to bus 1,500VAC for 1 minute

Group to group 1,500VAC for 1 minute

Output to output within

Output power supply to

Output power supply to

None

None

1,500VAC for 1 minute

ModCon®75 Touch

29

Page 31

Current 2A maximum per output

(Resistive load)

used in.

Output Power Supply

voltage

consumption

LED Indications

Color

LED State

Status

mismatch

8A maximum per group

Voltage 250VAC / 30VDC maximum

Minimum load 1mA, 5VDC

Switching times 10ms maximum

Short-circuit protection None

Life expectancy 100k operations at maximum load

Note: Life expectancy of the relay contacts depends on the application that they are

– The Relay outputs require an external power supply

Nominal operating

Operating voltage 20.4 – 28.8VDC

Maximum current

Input LEDs Green Input state

Output LEDs Green Output state

Status LED A triple color LED. Indications are as follows:

24VDC

80mA@24VDC

Green

Green/Red Slow blink Configuration

ON Operating normally

Slow blink Boot

Rapid blink OS initialization

Red Slow blink No IO exchange

Rapid blink Communication error

Orange Rapid blink OS Upgrade

30

ModCon®75 Touch

Page 32

Environmental

Protection IP20, NEMA1

8.4Hz to 150Hz, 1G acceleration.

Operating temperature -20°C to 55°C (-4°F to 131°F)

Storage temperature -30°C to 70°C (-22°F to 158°F)

Relative Humidity (RH) 5% to 95% (non-condensing)

Operating Altitude 2,000 m (6,562 ft.)

Shock IEC 60068-2-27, 15G, 11ms duration

Vibration IEC 60068-2-6, 5Hz to 8.4Hz, 3.5 mm constant amplitude,

31

ModCon®75 Touch

Page 33

Chapter 6,

Power Supply Requirement and Wiring

• The ModCon75 Touch Controller and I/O module require an external 24VDC powe r

supply.

• The permissible input voltage range is 20.4 - 28.8 VDC, with less than 10% ripple.

• A non-isolated power supply can be used, provided that a 0 V signal is connected to

the chassis.

Safety Considerations

• This equipment is designed to operate at SELV/PELV/Class 2/Limited Power

environments.

• All power supplies in the system must include double insulation. Power supply outputs

must be rated as SELV/PELV/Class 2/Limited Power.

• Ensure power supply is disconnected during installat ion.

• Do not touch live wires.

• Standard safety considerations require that metal cabinet panels be earthed to avoid

electrocution.

• Do not connect either the 'Neutral' or 'Line' signal of the 110/220 VAC to the device’s

0V pin.

• In the event of voltage fluctuations or non-conformity to voltage power supply

specifications, connect the device to a regulated p ower supply.

• A technician or engineer trained in the local and nat ional electrical standards must

perform all tasks associated with the electrical wiring of the device.

• Double-check all wiring before turning ON the power supply.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

Connecting the Power Supply

• Do not use tin, solder, or any other substance on the stripp ed wire that might cause the

wire strand to break.

• Install unit at maximum distance from high-voltage cables and power equipment.

• To avoid damaging the wire, do not exceed a maximum torque of 0.5 Nm (5 kgf-m).

• Use crimp terminals for wiring.

• Use 26-12 AWG wire (0.13 mm²-3.31 mm²) for all wiring purp oses.

1. Strip the wire to a length of 7 ±0.5 mm (0.250–0.300 inches).

2. Unscrew the terminal to its widest position before inserting a wire.

3. Connect the +V and 0V terminals as shown in Figure 19 & 20.

4. Tighten enough to keep the wire from pulling free.

32

ModCon®75 Touch

Page 34

Figure 19. HMI Power Supply Connection

0V +V 24VDC

Figure 20. I/O Power Supply Connection

33

ModCon®75 Touch

Page 35

Chapter 7,

ModCon75 Wiring

General Wiring

• Do not connect either the “Neutral” or “Line” signal of t he 110/220VAC to device’s 0V

point.

• Do not touch live wires.

• All wiring activities are to be performed while power is OFF.

• Use over-current protection, such as a fuse or cir cuit breaker, to avoid excessive

currents into the I/O module supply port.

• Unused points should not be connected (unless oth erwise specified). Ignoring this

directive may damage the device.

• Double-check all wiring before turning on the power supply.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

Note:

• To avoid damaging the wire, use a maximum torque of 0.5 Nm (5kgf-cm).

• Do not use tin, solder or any substance on stripped wire that might cause the wire

strand to break.

Wiring Procedure

Use crimp terminals for wiring; use 26-12 AWG wire (0.13 mm2 – 3.31 mm2).

1. Strip the wire to a length of 7+/-0.5mm (0.250-0.300 inches).

2. Unscrew the terminal to its widest position before inserting a wire.

3. Insert the wire completely into the terminal to ensu re a proper connection.

4. Tighten enough to keep the wire from pulling free.

Wiring Guidelines

In order to ensure that the device will operate prop erly and to avoid electromagnetic

interference:

• Use a metal cabinet. Make sure the cabinet and its doors a re properly earthed.

• Use wires that are properly sized for the load.

• Route each I/O signal with its own dedicated common wire. Connect common wires at

their respective common (CM) points at the I/O module.

• Individually connect each 0V point in the system to the power supply 0V terminal.

• Individually connect each functional earth point ( ) to the earth of the system

(preferably to the metal cabinet chassis). Use the shortest and thickest wires possible:

less than 1m (3.3’) in length, minimum wire size 14 A WG (2 mm

• Connect the power supply 0V to the earth of the system .

ModCon®75 Touch

2

).

34

Page 36

Figure 21. ModCon75 Touch Wiring

I/O Relay Wiring

I/O Output’s Power Supply

• The I/O relay outputs require an external 24VDC power sup pl y. Connect the 24V and

0V terminals as shown in Figure 21 & 22.

• To avoid risk of fire or property damage, always use a li m i t ed current source or connect

a current limiting device in series with the relay contacts.

• The 0V of the module must be connected to the HMI panel’s 0V. Ignoring this directive

may damage the device.

• In event of voltage fluctuations or non-conformity to voltage power supply

specifications, connect the module to a regulated power supply.

FAILURE TO FOLLOW THE THESE WARNINGS CAN RESULT IN SERIOUS

PERSONAL INJURY OR LOSS OF LIFE.

ModCon®75 Touch

35

Page 37

The outputs are arranged in two isolated groups:

• O0-O7 share common CM2

• O8-O15 share common CM3

Figure 22. VDC Connection points

Increasing contact life span

To increase the life span of the relay contacts when driving inductive loads protect the

module from potential damage by reverse EMF, connect:

• A clamping diode in parallel with each inductive DC load as shown in Figure 23.

• An RC snubber circuit in parallel with each inductive AC load as shown in Figure 24.

Figure 23. DC Load

Figure 24. AC Load

ModCon®75 Touch

36

Page 38

Chapter 8,

Operating Instructions

Power up/Main Menu Screen

• This screen appears when power is applied to the ModCon75 Touch Controller.

Figure 25. Power-up/Main Menu Screen

Touch Screen Buttons

8.1 Add Units:

• Add, and view/edit Ultima X3 ID’s and sensor tags.

8.2 Add/Display Set points:

• View/Edit Sensor Alarm Features including Enable/Disable, A l arm Direction, Latch

Status, Alarm Level, Alarm Zone.

8.3 Main Data Screen:

• Displays sensor tag, sensor type/range, and active/last sensor val ue with engineering

units for all transmitters on the network in a sequencing manner or the ability to choose

a specific transmitter to view. Also gives the user the abil i ty to silence alarms, unlatch

local zones and unlatch remote X3.

8.4 Remote IO Editor (Optional):

• Setup remote relay modules on the network.

8.5 Zone Set points Editor:

• View/Edit Zone Relay Features including: normally open/normally closed (NO/NC)

relays, Latch/No Latch relays, On/Off Rel ay Delay, Relay Delay Time. Also gives the

user the ability to view relay status (Open/Closed) at a glance for all zones.

8.6 Network Settings:

• View/Edit network address and DNS.

8.7 Active Alarms/Faults:

• View active alarms/faults and alarm/faults histo ry.

8.8 Password Editor:

• User programmable.

ModCon®75 Touch

37

Page 39

Figure 26. ModCon75 Touch Screen Hierarchy

8.1 Add Units Button:

• Password protected; see Figure 27.

• A password is required to be entered on the Main Menu Screen to be able to edit

the settings within any of the touch screen buttons. The controller will

automatically lock 5 minutes after the touch screen was last touched.

o Press anywhere within the Enter Password box an d enter the controller password.

o Password is user-configurable (Def aul t = 0). Type password using displayed

keyboard and press OK. The password lock/unlock graphic should change to

appear unlocked when correct password is entered as shown in Figure 28.

ModCon®75 Touch

38

Page 40

Locked

Unlocked

Figure 27. Password Locked

Figure 28. Password Unlocked

Figure 29. Add Units Screen

Use the screen shown in Figure 29 to:

• Add new X3 transmitters/sensors to the network registry.

o Add new transmitters/sensors to the network registry by pressing and holding the

Start Scan button until the scanning begins, and the button is greyed out.

o Briefly press and release Stop Scan to interrupt/st op a scan process.

• View all X3 transmitters/sensors on the network regi stry.

o Press X3 ID’s button to view/scroll thru all X 3 transmitters in the network registry.

ModCon®75 Touch

39

Page 41

• Touch the white box the left of ‘Store Previous Tag Information’ to add check mark.

Checking this box will store all previous tag inform at i on when attempting to make

changes in case the user wishes to revert to a previous stat e.

• X3 ID’s: to view network registry list.

• Sensor Tag’s: to view sensors connected to an individual Ultima X3.

• Edit ON: to edit X3 tag (X3 ID’s button) and edit sensor tag’s (Sensor Tags button).

• Press Home - to go back to Main Menu Screen.

• If new X3 transmitters/sensors are added/removed from the Modbus network, user

must run Start Scan to repopulate the network registry. If Start Scan is not run, the

output from added/removed X3 transmitters/sensors, including alarm/fault conditions,

will not be displayed on the MdoCon75 Touch Controller.

FAILURE TO FOLLOW THIS WA RNING CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE

Figure 30. Add Units to the Network

To add X3 transmitters/sensors to the network: press Start Scan once the following three

steps are completed:

1. First, verify all X3 transmitters/sensors (up to 25 X3 transmitters each with up to 3

sensors for a maximum of 75 sensors) are wired properly t o t he network.

2. Next, confirm each X3 transmitter connected to the network has a unique ID set by

using the Ultima/Ultima X Series Controller and Calibrator (Valid network ID’s are 2-

26).

NOTE:

o ID 0 is the broadcast Modbus address; ID 1 is the ModCon75 Touch address.

o Baud rate = 19200 and Parity = even.

3. Press and hold the Start Scan button until the scanning begins, and button is greyed

out.

NOTE:

o Verify that the ModCon75 Touch Controller found all Ult i m a X3

transmitters on the network. If the total number is less than the actual

number on the network, check your wiring and make sure that each

X3 transmitter on the network has its own unique addr ess in the

range of 2 through 26.

This process may take several minutes.

40

ModCon®75 Touch

Page 42

View/Edit all X3 Transmitters or Sensors on the Network

• Press X3 ID’s button. See Figure 31.

o Displays Slave ID (X3 transmitter ID), X3 tag, Fails, and Success f ound on the

network.

• To edit X3 Tag first verify that the password lock/unlock graphic is in the unlock

position (review instructions on page 41to unlock p assword lock/unlock graphic). Next

press the Edit On button so it reads Edit Off. Next press on an existing X3 Tag or in the

field to the right of the slave ID and within the X3 Tag column. Edit the X3 Tag using

the displayed keyboard and press OK when finished. The updated/new X3 Tag should

now be displayed. To finish editing press the E di t Off button so that it reads Edit On.

• Swipe up to view X3 ID’s information for X3 transmitters in addition to the six shown

initially.

• Press Sensor Tags button. See Figure 31.

o Displays X3 ID, Sensors 1 Tag, Sensor 2 Tag, and Sensor 3 Tag found on the

network.

• To edit Sensor Tags first verify that the passwor d l ock/unlock graphic is in the unlock

position (review instructions on page 41to unlock p assword lock/unlock graphic). Next

press the Edit On button so it reads Edit Off. Next press on an existing Sensor Tag or

in the field to the right of the X3 ID and within the approp riate Sensor Tag column. Edit

the Sensor Tag using the displayed keyboard and press OK when finished. The

updated/new Sensor Tag should now be displaye d. To finish editing press the Edit Off

button so that it reads Edit On.

• Swipe up to view Sensor Tags information for X3 transmit ters in addition to the six

shown initially.

Figure 31. Node IDs Found

41

ModCon®75 Touch

Page 43

8.2 Add/Display Setpoints Button:

Press

• Failure to follow the instructions in this section can result in the ModCon75

Touch Controller not properly indicating a sensor alarm/fault condition.

FAILURE TO FOLLOW THIS WA RNING CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE

• Press Add/Display Setpoints button (see Figure 24) to acc ess the

screen shown in Figure 29. Within this screen the use r wil l be able to

view/edit alarm Enable/Disable status, Alarm Di rection, Latch Status,

Alarm Levels, and Alarm Zone and write changes to a specific Sl ave

ID (X3 transmitter).

Figure 32. Add/Display Set

points screen

Here

Figure 33. To Select a Slave ID

(X3 Transmitter)

• Press Select Slave ID button, see Figure 32.

• Swipe up to view Slave ID’s for X3 transmitters in addition to the

six shown initially. Press in the gray area to the left of a Slave ID

as shown in Figure 30. Slave ID and X3 Tag will highlight y el l ow

42

ModCon®75 Touch

Page 44

when selected. Press Confirm Selection button to return to the

screen in Figure 33.

• Verify the Slave ID number changes to the Slave I D Number you

selected.

o The current alarm settings for all sensors on the selected Slave ID are displayed. If

less than three sensors are connected to a sin gle Slave ID, the sensor alarm settings

for sensors that are not connected will be greyed out.

o To modify any settings, verify the password lock/unlock graphic is unlocked

(Review instructions on page 38 to unlock password lock/unlock graphic).

Edit the Enable/Disable status for each alarm level on each sensor as

appropriate. Valid options are On and Off.

Edit the Alarm Direction status for each alarm level on each sensor as

appropriate. Valid options are Increase and Decrease.

Edit the Latch Status for each alarm level on each sensor as appropriate. Valid

options are Latch and No Latch.

Edit the Alarm Level setpoints for each alarm level on each sensor as

appropriate. Valid options are determined by sensor range. For combustible

sensors, the maximum LEL value is 60%. All invalid alarm levels entries will be

detected when attempting to write to the slaves. An Error Writing! prompt will be

displayed if an invalid alarm level is attempting to write to slave.

Edit the Alarm Zone status for each alarm level on each sensor as appropriate.

Valid options are whole numbers 0-9. Any value entered out side of this range or

not a whole number within the range will prompt ‘Value not in range’. Press OK

to confirm Alarm Zone selection.

o When all desired changes are made, press the Write SP’s button to

write changes to the selected Slave ID.

o Repeat this procedure for all desired Slave ID editing.

Note:

o If Write SP’s button is not pressed prior to exit i ng the Add/Display Setpoints screen

any modifications to alarm settings will not be saved to the X3 transmitter(s). Upon

re-entering, the Add/Display Setpoints screen the alarm settings will revert t o their

previous state.

Figure 34. Allows users to Set

Latching / Non-latching Alarms

43

ModCon®75 Touch

Page 45

• This Latching Function only changes the relay operation of the Ultima

X3 transmitters. For latching an alarm on the ModCon75 Touch

Controller, use a Zone relay and program it for lat ching, Zone Setpoints

Editor on the Home screen.

• A latched relay at the Ultima X3 unit may be cleared at the ModCon75

Touch Controller by pressing the Unlatch Remote X3 button on the

Main Data Screen.

Figure 35. Allows Users to Assign Zone Control Relays to

Caution, Warning and Alarm Set points for Sensors 1, 2, and 3.

• Relay outputs and corresponding zones. Relay outputs shown correspond with I/O

module terminal blocks per DSK3204-344.

Output O0=Zone 1 Output O5=Zone 6

Output O1=Zone 2 Output O6=Zone 7

Output O2=Zone 3 Output O7=Zone 8

Output O3=Zone 4 Output O8=Zone 9

Output O4=Zone 5 Output O9=Horn Relay

• The Horn relay Output (O9):

o Is used for remote alarms.

o Activates a horn on any caution, warning, or alarm condition.

o Silence of Horn is accomplished by pressing the Sil ence button on the Main Data

Screen

.

ModCon®75 Touch

44

Page 46

Figure 36. Current Setpoint values Read from the Selected Ultima X3 Unit

• If less than three sensors are connected to a single Sl ave ID (X3

transmitter) the sensor alarm settings for sensors that are not connected

will be greyed out. In addition, the word DISABLED will be displayed to

the right of each Sensor # that is not connected, see Figure 37.

Figure 37. Shows Disabled Sensor

Figure 38. Alarm Level Decimal

ModCon®75 Touch

45

Page 47

• Press the desired Alarm Level to change.

o To modify any settings, verify the password lock/u nl ock graphic is unlocked

(Review instructions on page 38 to unlock pass wor d lock/unlock graphic).

NOTE:

o The decimal point must be entered when typing the Alarm Level; the Decimal is not

fixed; therefore, enter 19.5 as shown in Figur e 38.

• Pressing the Alarm Level to change, a new widow will come up.

o Type 19.5 and press the OK button

Verify the Alarm Level changes to the new number.

• Repeat the above for each desired Alarm Level change.

NOTE:

o The ModCon75 Touch Controller displays t o one decimal point.

o With certain sensors (ClO2, CO2, etc.), alarm set points in the Ultima X3 unit may

be represented to two decimal points. In this insta nce, the ModCon75 Touch

Controller will round to the nearest single decimal.

Figure 39. Displays all changed alarm

settings prior to uploading to X3 transmitter(s).

• Write SP’s button:

o Saves all changes to the ModCon75 Touch Controller and Ultima X3.

o Sets Controller relays (connections located on ba ck of unit) to activate according to

caution, warning or alarm settings set on the Choo se Zone event screen.

o Provides status messages during the save proces s.

o Verifies that all values were saved by displaying Done! When complete.

o Indicates a problem during settings upload by display i ng Error Writing! This could

indicate that a value outside an alarm level range w as ent ered such as a %LEL

greater than 60 for a combustible sensor. The setting value in error will

automatically revert to its previous setting .

NOTE:

o If user does not press Write SP’s, the changes will not be made. A Combustible

sensor alarm level cannot be set Greater than 60%LE L.

46

ModCon®75 Touch

Page 48

Figure 40. Verification Screen

• Press the Home button to return to the Main Menu Scre en. No changes made will take

effect and be saved unless the Write SP’s button was pressed before the Home button.

8.3 Main Data Screen Button:

Figure 41. Main Data Screen

• Running/Paused Button - By default this button indicates Running and the controller

will cycle through all Slave ID’s/sensors on the netw ork. Press this button to change to

Paused and user will be able to remain on the Slave ID and associated sensors

present when button was pressed. Press Paused b utton to change to Running.

• Choose Specific ID Button - Press this button to more quickly select and pause on

desired Slave ID and associated sensors.

• Unlatch Remote X3 Button - Unlatches all Ultima X3’s.

• Unlatch Local Zones Button - Unlatches all Zone relays (Will turn Green when a Zone

Relay latches).

• Silence Button - Silences all Horns (Will turn Green when a Horn needs silenced).

• Main Data Screen displays one Ultima X3 with up t o three sensors on the ModCon75

Controller.

o Sensor tag, gas type, detection range, actual ga s value, and engineering units are

47

ModCon®75 Touch

Page 49

displayed for each connected sensor.

• Home Button – Takes user back to Main Menu Screen.

Figure 42. All Clear Status Screen

Modbus Alarms

• ModCon75 Touch will switch to the Main Menu Screen whenever a Modbus

communications failure is detected. A flashing error banner at the bottom of the screen

will indicate which Slave ID(s) is/are affected, see Figure 43.

• If Modbus communications are lost with all Slav e ID’s on the network the error banner

will also indicate! NO UNITS RESPONDING!

• The fault relay will be activated during Modbus communications failure.

• The flashing Modbus communications failure b anner with affected Slave ID will also be

displayed at the top of the Main Data Screen see Fi gure 44.

Figure 43. Modbus Alarm Indication on Main Menu Screen

ModCon®75 Touch

48

Page 50

Figure 44. Modbus Alarm Indication on Main Data Screen

Fault Status

• ModCon75 Touch will switch to the Main Data Sc reen to display an active sensor fault

and indicate which slave ID(s) and which sensor(s) is/are affected, see Figure 45.

• The Main Data Screen will also indicate an active s ensor fault, see Figure 46.

Figure 45. Sensor Fault

Figure 46. Main Menu Screen

ModCon®75 Touch

49

Page 51

• The ModCon75 will display the following sensor faults:

o + LOC

o Over-range

o Quick under-range

o Under-range

o Sensor missing

o Sensor End of Life

o Calibration fault

o Power Fail fault

o Configuration reset

o Span Calibration Fault

o Zero Calibration Fault

o Parameter Fault

o Incompatible Sensor

o Sensor Warning

• All other faults are shown as General Fault

8.4 Remote I/O Editor Button: (Optional: Requires Remote Relay Modules)

Figure 47. Remote Relay Editor Screen

Optional: Remote Relay units

• A total of five remote relay units may be added to the Modbus network (see Appendix

C for additional details). Modbus ID numbers of the remot e relay modules must be set

for ID#30, 31, 32, 33 or 34.

o To modify any settings, verify the password lock/unlock graphic is unlocked.

Review instructions on page 37 to unlock pass word lock/unlock graphic .

• Each Remote Relay has five additional relays (Relay O0 thru Relay O4).

• Relay O0 – Local Horn relay

• Relay O1 thru Relay O4 can be setup for any combination of Zone relay output (Zone 1

thru Zone 9).

NOTE:

o If Zone Alarms are programmed as Latch, one can silence the alarm at the

ModCon75 Touch (Silence Button), but the Zone alarm will not be cleared until the

unlatch input is initiated at the ModCon75 Touch Controller.

50

ModCon®75 Touch

Page 52

Figure 48. Remote Relay Module

Setting the Remote Relay ID number and the Relay state:

• Set the Slave ID number by pressing the left or right arr ows on the Remote relay

module keypad to select the slave ID, press the ente r key and enter the desired ID

number (ID#30, 31, 32, 33 or 34), press the enter key to set the ID number

selected, see Figure 48.

• Set the relays to Normally Open (NO) or Normally Closed (NC) by pressing the left or

right on the Remote relay keypad to select the NO or NC r el ays press the enter key

and enter the desired relay state, 0 for NC or 1 for NO relays, press enter key again

to set relay state, see Figure 48.

NOTE:

o Changing the Relay state to NC or NO will only change Relays O1 thru O4, Relay

O0 (Local Horn Relay) will always be a NC relay.

Remote I/O Editor set up:

• Press the Remote I/O Editor Button to view or edit configuration of up to five remote

relay modules connected to the ModCon75 Touch network.

NOTE:

o To modify any settings, verify the password lock/unlock graphic is unlocked.

Review instructions on page 38 to unlock password lock/unlock graphic.

• Press the white square next to the Remote relay m odule ID number (a check mark will

appear) to select the module being used. Repeat check marking each Remote relay

modules to be connected to the network.

• Offline will appear to the right of the Remote relay module that was just check marked

until the Remote relay module has been set to the ID numbe r selected as shown in

Figures 47 and 48.

• The four white squares in a row on each Remote rel ay module ID number can be set to

the desired zone relays (1 thru 9) as shown in Figure 47.

NOTE:

o The zone relays can be set to X3 transmitters in the Add/Display Set points section

and can be edited in the Zone Set points Editor Section.

51

ModCon®75 Touch

Page 53

Remote Relay Power Supply Wiring

• The Remote relay module requires an external 24V DC power supply.

• Disconnect power while wiring the Remote relay m odule.

• Use separate wires to connect the functional earth line (pin 3) and the 0V line (pin 2) to

the system earth ground.

• Install an external circuit breaker. Guard against short-circuiting in external wiring.

• Double-check all wiring before turning on the power supply.

• Do not connect either the “Neutral” or “Line” signal of t he 110-220VAC to device’s 0V

pin.

• In the event of voltage fluctuations or non-conformity to voltage power supply

specifications, connect the device to a regulated p ower supply.

FAILURE TO FOLLOW THESE WARNINGS CAN RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

Remote Relay Wiring

Figure 49. Power Supply Wiring

Figure 50. Remote Relay Wiring

ModCon®75 Touch

52

Page 54

• Increasing Contact Life Span as shown in Figure 50.

o To increase the life span of the relay output conta cts and protect the device from

potential damage by reverse EMF, connect:

A clamping diode in parallel with each inductive DC load.

An RC snubber circuit in parallel with each inductive AC load.

Figure 51. Remote Relay, Increasing Contact Life S p an

• Detailed specifications, dimensions and jumpe r set t i ngs for the Optional Remote Relay

Module can be found in Appendix B.

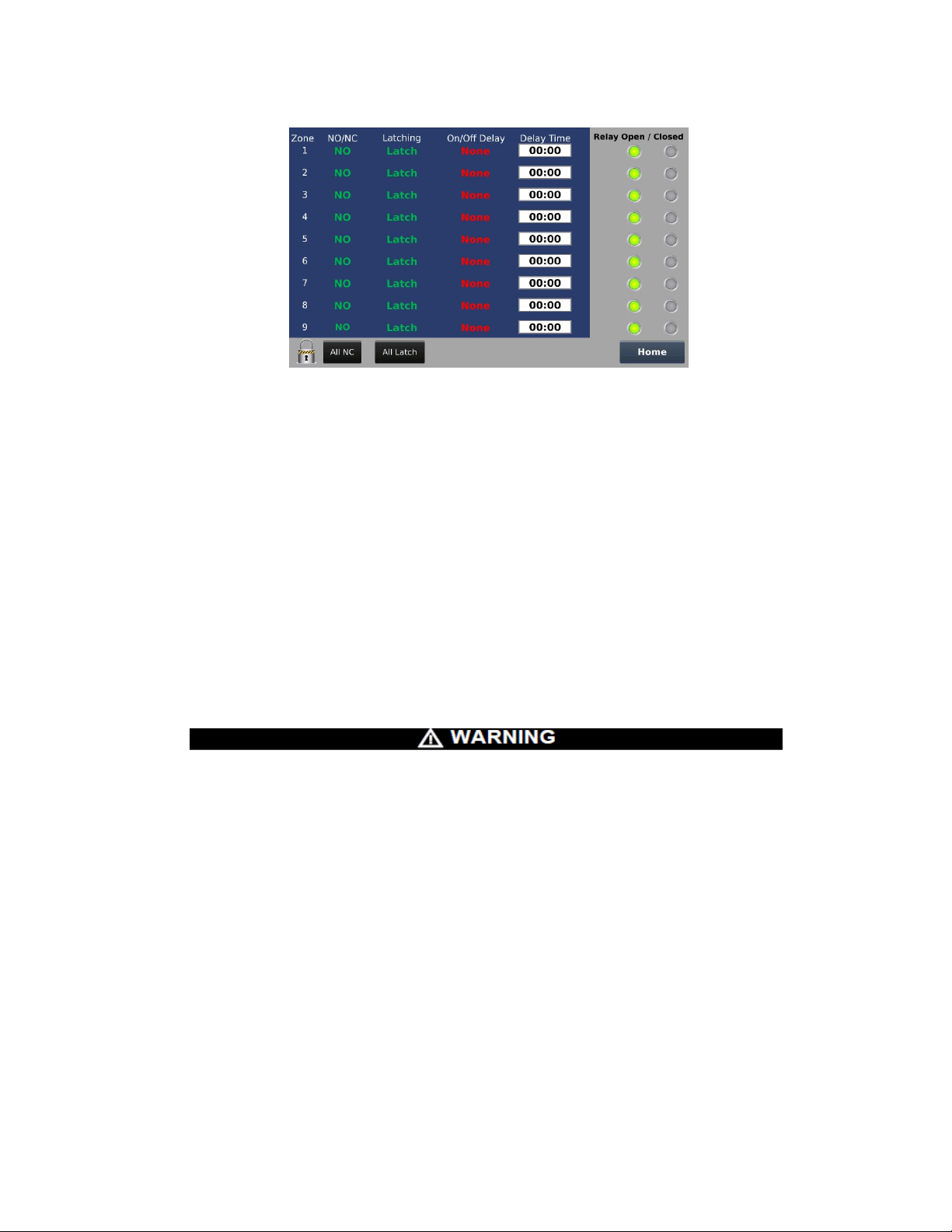

8.5 Zone Setpoints Editor Button:

• The Zone Setpoints Editor Screen enables the user to modi fy the following zone relay

settings:

o Relay State – Normally open (NO - Closed while Alarming) or Normally Closed (NC

- Open While Alarming)

o Relay Latch State – Latch or No Latch

o Relay Delay Type – None, On Delay, or Off Delay

o Delay Time – 00:00 to 59:59

• To Modify any settings, verify the password lock/unlock graphic is unlocked. Review

instructions on page 37 to unlock password lock/unlock graphic.

• When NO/NC is set to NO the zone relay contact wil l close when activated/energized. If

set to NC, the zone relay contact will open when activated/de-energized

.

ModCon®75 Touch

53

Page 55

Figure 52. Zone Set points Editor Screen

• If Latch is selected the zone relay contact will remain in the alarmin g state even after

the alarm condition that it is associated with it has cea sed. To change the zone relay

contact back to the non-alarming state the use must press the Unlatch Local Zones

button on the Main Data Screen, see Figure 41. If No Latch is sel ected the zone relay

contact will return to the non-alarming state automaticall y after the alarm condition that

it is associated with has ceased.

• Zone relays can be set to either On Delay or Off Delay onl y if the Latching setting is set

to No Latch.

o On Delay – Zone relay contact will change to the alarm state only when an

associated alarm level is activated, and the set Delay Time has elapsed.

o Off Delay (Typically used for fan control) – Zone relay contact will remain in the

alarming state for the set Delay Time after the associated alarm level has cleared.

NOTE:

o When the Latching setting is set to Latch the On Delay, Off Delay, and Delay Time

are disabled.

• Do not use On Delay for any safety critical function. Us e onl y for Process control.

FAILURE TO FOLLOW THIS WARNI N G CA N RESULT IN SERIOUS PERSONAL

INJURY OR LOSS OF LIFE.

8.6 Network Settings Button:

• Press Network Settings button on the Main Menu screen.

• To modify any settings, verify the password lock/unlock graphic is unlocked.

Review instructions on page 37 to unlock pass word lock/unlock graphic.

• For Ethernet capability, enter IP Address, Subnet M ask and Default Gateway

information.

• Press Date or Time to change settings.

ModCon®75 Touch

54

Page 56

Figure 53. Network & Date/Time Settings

8.7 Active Alarms/Faults Button:

• Press the Active Alarms/Faults button on the Main M enu screen.

• To modify any settings, verify the password lock/unlock graphic is unlocked.

Review instructions on page 38 to unlock password lock/unlock graphic.

• The Active Alarms/Faults screen allows the user to view the following:

o Active Alarms

o Active Faults

o Alarm History

o Fault History

• The Active Alarms/Faults History screen allows the user the save the following to a

Micro SD card.

o Alarm History

o Fault History

• Press the Active Alarms button to change the screen. A nother window will appear

allowing the user to select the Active Alarms, Activ e Faults, Alarm History, and Fault

History as shown in Figure 54.

Figure 54. Active/Fault Screen Selection

55

ModCon®75 Touch

Page 57

• Use the up and down arrows to scroll through and sel ect the desired screen to view.

Press the OK button to change the current screen to the one selected.

• In the Alarm/Fault History screen, the data table can be sav ed to a Micro SD card or

cleared by press the appropriate button as shown in Figure 55

Figure 55. Save/Clear History

• The Active Alarm/Fault History screen will display the following messages when using

a Micro SD card.

o Failed to Write

o No SD Card

o Current Table Written

.

8.8 Password Editor:

• To create a new password press and hold the area indicated in Figure 56 for

approximately 5 seconds until a new window appears, see Figure 57.

• In the new window that appears, touch the Previous Password box. Enter the previous

password (default password is 0 (zero)) from dis played keyboard and press OK. Next,

enter the new password from keyboard and press OK. Finally, press Save to set new

password, see Figure 57.

56

ModCon®75 Touch

Page 58

o

Press

(5Sec)

User can change this password to protect against unauthorized changes.

Here

Figure 56. Password Editor

Figure 57. Enter Password

57

ModCon®75 Touch

Page 59

Chapter 9,

Technical Specifications

Table 5. ModCon75 Touch Specifications

Input Voltage 24VDC

Permissible Voltage Range 22 to 28.8VDC with less than 10% Ripple

Maximum Current Consumption 0.75A @ 24 VDC

LCD Type TFT

Backlight White LED

Resolution 800 x 480 (WVGA)

Back-Up Battery 4 years at 25°C (77°F)

Dimensions Figure 58 thru 60

Environment IP65/66 / Nema 4X (Front Panel)

Operational Temperature -20°C to 55°C (-4°F to 131°F)

Storage Temperature -30°C to 70°C (-22°F to 158°F)

Relative Humidity 5% to 95% (non-condensing)

NOTE:

• See detailed ModCon75 Touch HMI Panel specifications on page 15.

• See detailed ModCon75 Touch CPU Module specif ications on page 20.

• See detailed ModCon75 Touch I/O Module sp ecif ications on page 26.

58

ModCon®75 Touch

Page 60

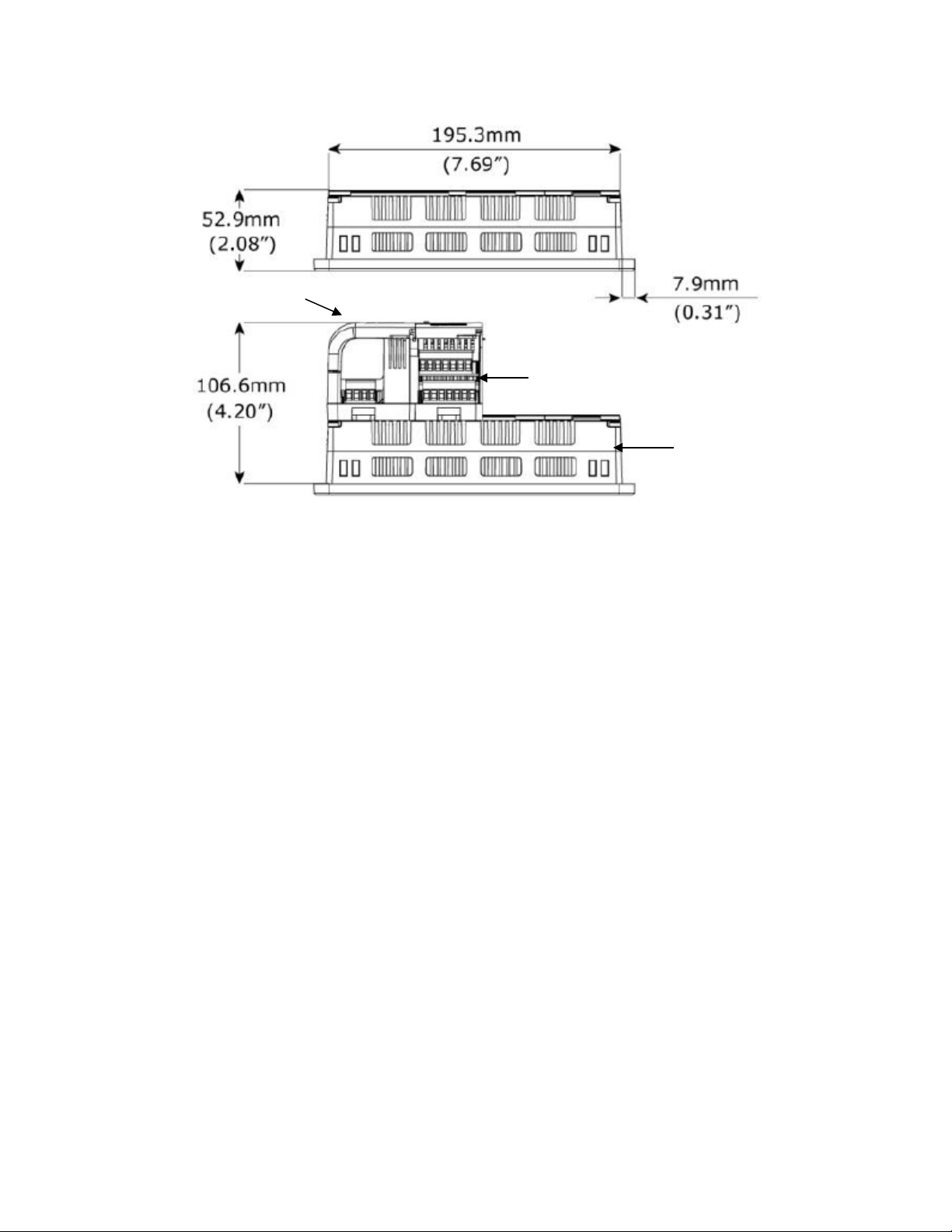

Dimensions

Figure 58. Dimensions, Front

Figure 59. Dimensions, Side

ModCon®75 Touch

59

Page 61

HMI

I/O Module

CPU Module

Figure 60, Dimensions, Top

60

ModCon®75 Touch

Page 62

Appendix A,

Critical Memory Bits

Read Coil function 01 Supported

10

Modbus Comm Failure

261

Sensor 1 Calibration Active

262

Sensor 2 Calibration Active

263

Sensor 3 Calibration Active

670

Zone 1 Alarm

671

Zone 2 Alarm

672

Zone 3 Alarm

673

Zone 4 Alarm

674

Zone 5 Alarm

675

Zone 6 Alarm

676

Zone 7 Alarm

677

Zone 8 Alarm

678

Zone 9 Alarm

Write Coil Function 05 Supported

194

Acknowledge Alarm

Memory Integers

Read Input Register Function 04 Supported

Refer to Table 1 for descriptions

273

Ultima X3 #2 Fault status message

274

Ultima X3 #3 Fault status message

275

Ultima X3 #4 Fault status message

276

Ultima X3 #5 Fault status message

277

Ultima X3 #6 Fault status message

278

Ultima X3 #7 Fault status message

279

Ultima X3 #8 Fault status message

280

Ultima X3 #9 Fault status message

281

Ultima X3 #10 Fault status message

282

Ultima X3 #11 Fault status message

283

Ultima X3 #12 Fault status message

284

Ultima X3 #13 Fault status message

285

Ultima X3 #14 Fault status message

Register Maps

The following register maps are provided for read-only use.

61

ModCon®75 Touch

Page 63

286

Ultima X3 #15 Fault status message

287

Ultima X3 #16 Fault status message

288

Ultima X3 #17 Fault status message

289

Ultima X3 #18 Fault status message

290

Ultima X3 #19 Fault status message

291

Ultima X3 #20 Fault status message

292

Ultima X3 #21 Fault status message

293

Ultima X3 #22 Fault status message

294

Ultima X3 #23 Fault status message

295

Ultima X3 #24 Fault status message

296

Ultima X3 #25 Fault status message

297

Ultima X3 #26 Fault status message

Memory Integers

Read Input Register Function 04 Supported

300

Ultima X3 #2 Gas Value Sensor 1, Left of the Decimal Point

301

Ultima X3 #3 Gas Value Sensor 1, Left of the Decimal Point

302

Ultima X3 #4 Gas Value Sensor 1, Left of the Decimal Point

303

Ultima X3 #5 Gas Value Sensor 1, Left of the Decimal Point

304

Ultima X3 #6 Gas Value Sensor 1, Left of the Decimal Point

305

Ultima X3 #7 Gas Value Sensor 1, Left of the Decimal Point

306

Ultima X3 #8 Gas Value Sensor 1, Left of the Decimal Point

307

Ultima X3 #9 Gas Value Sensor 1, Left of the Decimal Point

308

Ultima X3 #10 Gas Value Sensor 1, Left of the Decimal Point

309

Ultima X3 #11 Gas Value Sensor 1, Left of the Decimal Point

310

Ultima X3 #12 Gas Value Sensor 1, Left of the Decimal Point

311

Ultima X3 #13 Gas Value Sensor 1, Left of the Decimal Point

312

Ultima X3 #14 Gas Value Sensor 1, Left of the Decimal Point

313

Ultima X3 #15 Gas Value Sensor 1, Left of the Decimal Point

314

Ultima X3 #16 Gas Value Sensor 1, Left of the Decimal Point

315

Ultima X3 #17 Gas Value Sensor 1, Left of the Decimal Point

316

Ultima X3 #18 Gas Value Sensor 1, Left of the Decimal Point

317

Ultima X3 #19 Gas Value Sensor 1, Left of the Decimal Point

318

Ultima X3 #20 Gas Value Sensor 1, Left of the Decimal Point

319

Ultima X3 #21 Gas Value Sensor 1, Left of the Decimal Point

320

Ultima X3 #22 Gas Value Sensor 1, Left of the Decimal Point

321

Ultima X3 #23 Gas Value Sensor 1, Left of the Decimal Point

ModCon®75 Touch

62

Page 64

ModCon®75 Touch

322

Ultima X3 #24 Gas Value Sensor 1, Left of the Decimal Point

323

Ultima X3 #25 Gas Value Sensor 1, Left of the Decimal Point

324

Ultima X3 #26 Gas Value Sensor 1, Left of the Decimal Point

325

Ultima X3 #2 Gas Value Sensor 1, Right of the Deci m al P oi nt

326

Ultima X3 #3 Gas Value Sensor 1, Right of the Deci m al P oi nt

327

Ultima X3 #4 Gas Value Sensor 1, Right of the Deci m al P oi nt

328

Ultima X3 #5 Gas Value Sensor 1, Right of the Deci m al P oi nt

329

Ultima X3 #6 Gas Value Sensor 1, Right of the Deci m al P oi nt

330

Ultima X3 #7 Gas Value Sensor 1, Right of the Deci m al Point

331

Ultima X3 #8 Gas Value Sensor 1, Right of the Deci m al P oi nt

332

Ultima X3 #9 Gas Value Sensor 1, Right of the Deci m al P oi nt

333

Ultima X3 #10 Gas Value Sensor 1, Right of the Decimal P oi nt

334

Ultima X3 #11 Gas Value Sensor 1, Right of the Decimal Point

335

Ultima X3 #12 Gas Value Sensor 1, Right of the Decimal P oi nt

336

Ultima X3 #13 Gas Value Sensor 1, Right of the Decimal P oi nt

337

Ultima X3 #14 Gas Value Sensor 1, Right of the Decimal P oi nt

338

Ultima X3 #15 Gas Value Sensor 1, Right of the Decimal Point

339

Ultima X3 #16 Gas Value Sensor 1, Right of the Decimal P oi nt

340

Ultima X3 #17 Gas Value Sensor 1, Right of the Decimal P oi nt

341

Ultima X3 #18 Gas Value Sensor 1, Right of the Decimal P oi nt

342

Ultima X3 #19 Gas Value Sensor 1, Right of the Decimal Point

343

Ultima X3 #20 Gas Value Sensor 1, Right of the Decimal P oi nt

344

Ultima X3 #21 Gas Value Sensor 1, Right of the Decimal P oi nt

345

Ultima X3 #22 Gas Value Sensor 1, Right of the Decimal P oi nt

346

Ultima X3 #23 Gas Value Sensor 1, Right of the Decimal Point

347

Ultima X3 #24 Gas Value Sensor 1, Right of the Decimal P oi nt

348

Ultima X3 #25 Gas Value Sensor 1, Right of the Decimal P oi nt

349

Ultima X3 #26 Gas Value Sensor 1, Right of the Decimal Point

350