Page 1

Operating Manual

G1 Facepiece

Order No.: D2058000/04

MSAsafety.com

Page 2

MSA Europe GmbH

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

info.ch@MSAsafety.com

www.MSAsafety.com

©

MSA 2019 All rights reserved

Page 3

Contents

1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Liability Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Safety and Precautionary Measures. . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Mask Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Harness Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Component Housing Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 G1 Heads-Up Display (HUD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Filter Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Donning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Removing the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Spectacle Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Cleaning, Disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Preparing the Mask for Cleaning or Disinfection. . . . . . . . . . . . . . . . 18

5.2 Suitable Cleaning and Disinfection Procedures . . . . . . . . . . . . . . . . 18

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Maintenance of the Exhalation Valve . . . . . . . . . . . . . . . . . . . . . . . . 20

Removing the Spring Retainer and Exhalation Valve . . . . . . . . . . . . 21

Installing the Spring Retainer and Exhalation Valve . . . . . . . . . . . . . 22

6.4 Replacing the Speech Diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.5 Tightness Test of the Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.6 Visual Test and Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

GB

G1 Facepiece

3

Page 4

7 Safekeeping and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.1 Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.2 Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.3 ATO Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

G1 Facepiece

GB

4

Page 5

1 Safety Regulations

1.1 Correct Use

G1 Facepieces - hereafter called masks -are full face masks with a positive pressure connection.

They are not complete respiratory protective devices by themselves, but serve as facepieces

[EN 136 CL3+] for use with compressed air breathing apparatus of the G1 series and respiratory filters.

The mask as part of a respiratory protective device ensures an appropriately tight fit of the user’s face

against the ambient atmosphere.

When using a compressed air breathing apparatus, the operating manual for the compressed air

breathing apparatus must be read and observed.

If the mask is used as part of a filtering device using the filter adapter, respiratory protective filters

equipped with a standardized thread according to EN 148-1 must be used.The type and concentration

of contaminants and the oxygen concentration in the ambient air must be known to decide if the use of

a filtering device is permissible. The instructions for use of the respiratory filters have to be regarded,

including any information regarding the use in potentially explosive atmospheres. When in doubt use

a supplied air breathing apparatus. The permitted minimum oxygen concentration of ambient air

depends on national regulations.

When used in oxygen or an enriched-oxygen atmosphere, the increased potential hazard of flammability has to be regarded.

WARNING!

According to the European directive 89/656/EC it has to be verified before first use of the mask that a

correct size has been chosen (proper tight fit), that the mask can be worn in combination with other

protective equipment (for example a protective jacket), that it is a correct choice for the conditions at

the particular place of use and that it fulfils the ergonomic requirements.

Safety Regulations

WARNING!

Read this manual carefully before using the device. The device will perform as designed only if it is

used and maintained in accordance with the manufacturer's instructions. Otherwise, it could fail to

perform as designed and persons who rely on this device for their safety could sustain serious personal

injury or death.

Before use the product operability must be verified. The product must not be used if the function test

is unsuccessful, it is damaged, a competent servicing/maintenance has not been made, genuine MSA

spare parts have not been used.

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately or not as intended.

The selection and use of the product are the exclusive responsibility of the individual operator.

Product liability claims, warranties also as guarantees made by MSA with respect to the product are

voided if it is not used, serviced, or maintained in accordance with the instructions in this manual.

Changes and modifications not expressly approved by the manufacturer will void the user’s authority

to operate the equipment.

G1 Facepiece

GB

5

Page 6

1.3 Safety and Precautionary Measures

• The device may be used in explosive atmospheres according to the class stated in the

ATEX certification, see chapter 2.5.

• The ATEX class of any other equipment used together with this device has to be regarded as well.

The lowest class sets the limit.

• If the device is used in an explosive atmosphere, dissipative clothes and footwear must be used

in conjunction with dissipative grounds. When used in explosive atmospheres there must be direct

contact between the head harness and the head. Do not use head coverings (e.g.fire hoods)

under the head harness.

• If the device is used in an explosive atmosphere, the neck strap has to be correctly attached to

the mask with carabiner hooks, see chapter 2.5. (The rubber neck strap has to be attached to the

metal rings of the harness, the textile neck strap has to be attached to the lens ring with carabiner

hooks.)

• Use and storage of the mask with Kevlar (textile) harness in a vincinity that generates strong electrostatic charges in explosive atmospheres is not allowed.

Safety Regulations

G1 Facepiece

GB

6

Page 7

2 Description

1

2

4

5

3

7

6

8

9b

9a

10

11a

11b

The inhalation air flows from the component housing of the mask past the inhalation valve to the inside

of the lens (thus keeping the lens fog-free) and then through the inlet valves into the nosecup.

The exhalation air passes through the exhalation valve directly to the ambient air.

Fixed Push-to-Connect component housing only: If in a safe atmosphere no demand valve is attached,

ambient air can be inhaled directly through an open port to facilitate breathing and speaking with no

resistance.

The faceblank is made of a special soft rubber compound and assures a snug, comfortable fit and a

tight seal. The mask and the nosecup are available in 3 sizes (small, medium, large).

The mask is available with different head harnesses and different component housings.

Description

Fig. 1 Overview (not true to size)

1 Forehead strap 8 Nosecup

2 Buckle 9a Head harness rubber

3 Faceblank 9b Head harness Kevlar

4 Light pipes, left (fixed Push-to-

Connect only)

5 Component housing 11a Nomex (textile) neck strap

6 Light pipes, right (fixed Push-to-

Connect only)

7Lens

10 Filter adapter

11b Rubber neck strap

G1 Facepiece

GB

7

Page 8

2.1 Mask Versions Harness Versions

The mask is available with different head harnesses; Kevlar (textile) 4-point or rubber (5-point).

The rubber head straps are numbered to indicate the correct tightening sequence.

Fig. 2 Kevlar (textile) harness

Description

Fig. 3 Rubber harness

G1 Facepiece

GB

8

Page 9

Component Housing Versions

The mask is available with different component housings:

Fig. 4 Fixed Push-To-Connect Fig. 5 Push-To-Connect

Description

Fig. 6 M45x3 Fig. 7 ESA

2.2 G1 Heads-Up Display (HUD)

When the mask version with the G1 fixed Push-to-Connect component housing is used in connection

with a G1 SCBA, the light pipes on the mask are part of the HUD. The HUD is integrated into the

demand valve and projects light into the mask.

The HUD provides the pressure and alarm status to the user through light pipes into the mask. The

pressure status is on the right side of the user, while the alarm status is on the left side of the user.

For details about the HUD, see G1 SCBA operating manual.

2.3 Filter Adapter

Using the filter adapter with the G1 fixed Push-to-Connect component housing, protective filters

equipped with a standardized thread according to EN 148-1 can be attached to the mask. The instructions for use of the respiratory filters have to be regarded, including any information regarding the use

in potentially explosive atmospheres.

G1 Facepiece

GB

9

Page 10

2.4 Marking

2

5

4

3

1

6

The mask is marked on the outer faceblank as shown in Fig. 8:

Description

XXXXXXXXX

MY XXXXXX

0158

EN 136:1998 CL3+

Fig. 8 Marking of mask body

1 Manufacturing location code

2 Serial number

3 For applicable ATEX classification, see operating manual.

4 EN standard, class

5 CE-marking with notified body number (DEKRA EXAM, Zertifizierungsstelle Dinnendahlstr. 9, 44809 Bochum)

6 Part number/ATO code

2.5 Certification

The masks comply with the following directives, standards or standardized documents:

Approvals

Regulation (EU) 2016/425

0158

(X)

GB

EN 136: 1998, class 3+

DEKRA

The Declaration of Conformity can be found under the following link: https://MSAsafety.com/DoC

DEKRA EXAM GmbH, Dinnendahlstr. 9, 44809

Bochum,Germany, Notified Body number: 0158

G1 Facepiece

10

Page 11

Atex Categories

The lowest ATEX class of a part sets the limit for the complete device.

G1 Facepiece

Harness

Faceblank

Neck strap

Filter Adapter for Fixed Push-to-Connect

Connector pieces

Lens

Rubber I M1

Kevlar (Textile)

Rubber

Textile

Push-To-Connect

M45x3

ESA

Standard Lens

Anti-fog lens

Anti-scratch lens

II 1G IIC

II 1D

I M1

II 1G IIC

II 1D

I M1

II 1G IIC

II 1D

I M1

II 1G IIB

II 2G IIC

II 1D

I M1

II 1G IIC

II 1D

I M1

II 1G IIC

II 1D

I M1

II 1G IIC

II 1D

I M1

II 1G IIA

II 2G IIB

II 1D

I M1

II 1G IIB

II 2G IIC

II 1D

Description

GB

G1 Facepiece

11

Page 12

Example:

ATO: A-M/I-M-E-R-P

A= Anti-fog lens

M/I= Faceblank: Medium

M= Nosecup: Medium

E= Head Harness: Rubber

R= Neck strap: Rubber

P= Regulator: Push to Connect

Atex Category:

I M1

II 1G IIA

II 2G IIB

II 1D

Description

G1 Facepiece

GB

12

Page 13

3Use

The mask is carried using the neck strap in front of the chest. To ensure protection from dirt and debris,

ensure the mask opening is towards the user's body.

WARNING!

When used in explosive atmospheres there must be direct contact between the head harness and the

head. Do not use head coverings (e.g.fire hoods) under the head harness.

WARNING!

Ensure that the top of the mask seal only lies on the user's forehead. Hair or spectacle side arms

should not be between the mask's seal and the user’s skin.

The mask could otherwise leak. This danger also exists for instance for mask wearers with beards or

deep scars in the sealing area.

WARNING!

In order to guarantee a proper fit for those wearing glasses, the G1 Facepiece spectacle kit must be

worn since ordinary glasses cannot be worn under the mask.

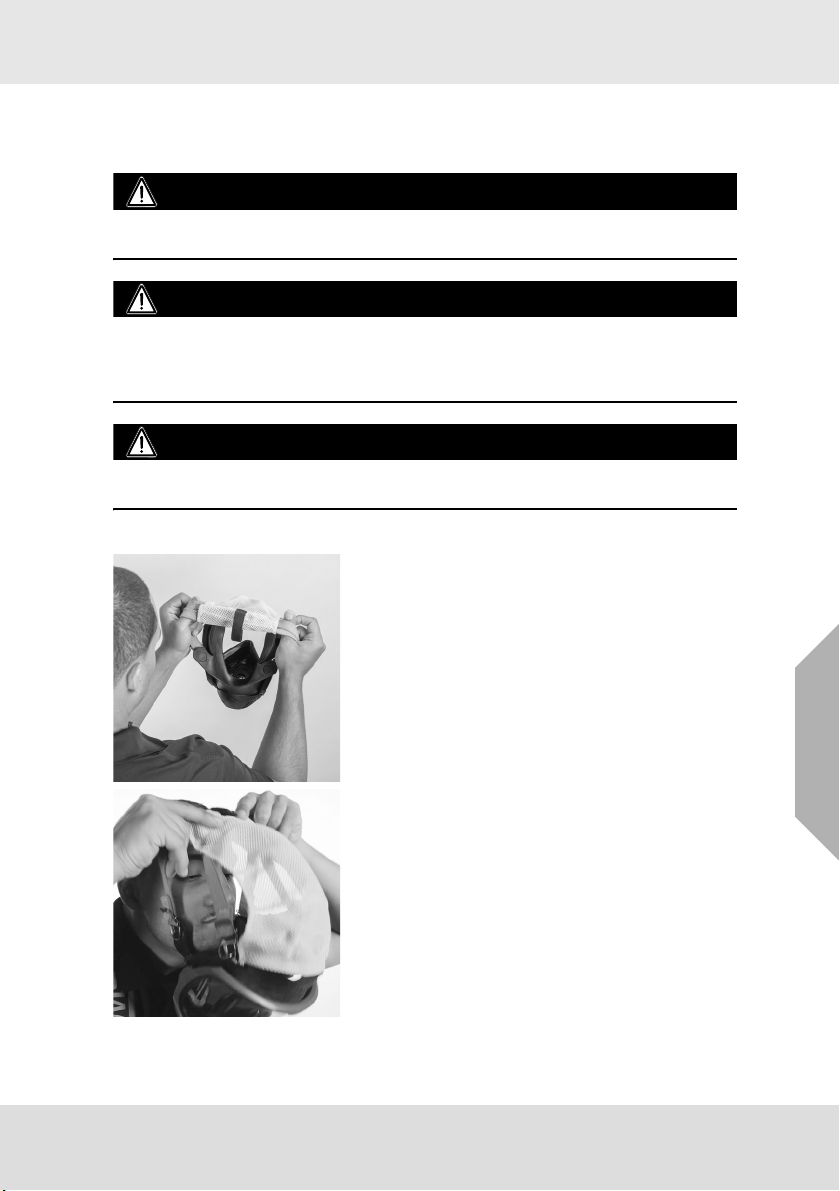

3.1 Donning

Use

(1) Spread the harness with both hands.

(2) Position the chin into the chin cup.

G1 Facepiece

GB

13

Page 14

(3) Pull the head straps over your head.

a) Ensure that the harness is sitting correctly and is not

twisted.

(4) Adjust mask and tighten the straps firmly and evenly.

a) Tighten the lower straps first by pulling them straight

back, not out.

b) Tighten the temple straps in the same manner.

c) If present, tighten the top strap for best visibility and fit.

3.2 Leak Check

In order to check the mask-to-face tightness a leak test must be performed before each use.

Use

(1) Seal the inlet (component housing) with the palm of your

hand or by attaching the non-pressurized regulator.

(2) Check tightness.

(3) Inhale and hold breath for a few seconds.

(4) Exhale.

(5) If necessary retighten the straps.

The mask must stay collapsed on face.

The exhalation valve should open and release the

pressure inside the mask.

a) If the leak check fails, re-don the mask.

If the leak check still fails, the mask must not be used.

G1 Facepiece

GB

14

Page 15

3.3 Removing the Mask

(1) Loosen the head harness by pulling the buckles

forward using your fingers.

(2) Grip the chin straps and pull the head harness forward

over the head.

Use

(3) Grip the front of the mask (as shown) and pull the

mask away and down from the user.

G1 Facepiece

GB

15

Page 16

4 Spectacle Kit

WARNING!

Before using a spectacle kit, an optometrist must examine the spectacle kit and prescribe the correct

lenses to fit into the lens frame on the spectacle kit.

Failure to obey this warning can result in serious injury or death.

(1) Flip the head harness over the front of the mask so the

harness is covering the lens of the mask.

This will open up the faceblank to make it easier to

install the spectacle kit.

(2) Squeeze in on the wire frame of the spectacle kit at the

large bends about 5 cm from the ends.

Do not overbend the wire.

Spectacle Kit

(3) Push the top part of the frame into the lens. The face-

blank has three rubber tabs to grab the frame.

a) Place the frame in the middle of the lens with the

smaller tabs grabbing the wire frame.

G1 Facepiece

GB

16

Page 17

Spectacle Kit

(4) Take one end of the wire frame and push it up into the

mask so it follows the edge where the lens and the

faceblank meet.

a) The end of the wire frame must be positioned into

small pockets in the faceblank on the edge of the

lens.

(5) Repeat step (4) on the opposite side.

(6) The frame for the spectacles can be adjusted up/down

and in/out depending on the facial features. Don the

mask and adjust to optimize visibility.

G1 Facepiece

GB

17

Page 18

Cleaning, Disinfection

5 Cleaning, Disinfection

The cleaning and disinfection of the masks is performed in accordance with the cleaning intervals

chapter 6.2.

Follow the washing agent’s user instructions on this CD/DVD.

The power supply for the HUD (if applicable) is not part of the G1 Facepiece and is therefore not damaged during cleaning.

WARNING!

Do not use cleaning products containing hydrocarbons or solvents [e.g. nitro-thinner].

Cleaned parts must not be dried in radiant heat [sun, radiators].

When using a drying cabinet, the temperature must not exceed +60°C.

Perform a tightness test (chapter 6.5) after every cleaning, disinfection and maintenance or after every

exchange of parts.

5.1 Preparing the Mask for Cleaning or Disinfection

(1) Remove inhalation and exhalation valve discs.

(2) Unbutton the nosecup.

(3) Removed components must be separately cleaned and disinfected.

(4) Dry mask and components and reassemble mask in reverse order.

(5) Perform a tightness test [ chapter 6.5].

5.2 Suitable Cleaning and Disinfection Procedures

WARNING!

Depending on lens type, only certain cleaning and disinfection procedures are permitted.

Only use the procedures permitted for the lens type, other procedures will damage the lens.

Procedure

Cleaning/Disinfec-

tion by hand

Cleaning/Disinfec-

tion washing

machine (tumbling

type)

Part number

washing instruc-

tion

10127480 XXX

10127346 X---X

Mask with

Standard Lens

(Marking P)

G1 Facepiece

Mask with

Anti-Fog Lens

(Marking A)

Mask with

Anti-Scratch-

Lens (Marking H)

GB

18

Page 19

Lens Identification

2

3

1

Fig. 9 Marking

1 Marking placement

2 Mask with Standard Lens (Marking P)

3 Mask with Anti-Fog Lens (Marking A)

4 Mask with Anti-Scratch Lens (Marking H)

Cleaning, Disinfection

GB

G1 Facepiece

19

Page 20

6 Maintenance

6.1 Maintenance Instructions

This product should be regularly checked and serviced by trained specialists. Inspection and service

records must be maintained. Always use original parts from MSA.

Repairs and maintenance must be carried out only by authorized service centres or by MSA. Changes

to devices or components are not permitted and will result in loss of approval.

MSA is liable only for maintenance and repairs carried out by MSA.

MSA recommends the following maintenance intervals. If necessary considering the

usage, tasks may be at even shorter intervals than indicated.

Observe national laws and regulations!

If in any doubt, ask your local MSA contact person.

6.2 Maintenance Intervals

Work to be

Performed

Cleaning and

Disinfection

Visual, Functional

and Tightness

**)

Check

Replacement of

the exhalation

valve disc

Replacement of

the Speech

Diaphragm

Replacement of

the O-ring for

component

housing

User check X

*)

For a 2-year interval cleaned and disinfected masks have to be stored airtight. Otherwise masks

should be cleaned and disinfected at least semi-annually. After each cleaning and disinfection the

mask must be checked.

**)

For airtightly packed face pieces, which are not exposed to increased climatic and mechanical stress

[for example transport on vehicles], this interval can be extended to 2 years.

6.3 Maintenance of the Exhalation Valve

Maximal Intervals

Before use After Use 6-monthly

*)

Two

years

XX*)X

XX

**)

*)

X

Four

years

X

Maintenance

Six

years

X

GB

The year of manufacture is located on the valve disc.

In case of a leak remove the exhalation valve disc and replace it with a new one as follows:

G1 Facepiece

20

Page 21

Removing the Spring Retainer and Exhalation Valve

(1) Pull one side of the spring retainer fork off of the locking

lug and out of the slot until the spring retainer releases.

(2) Inspect the spring retainer and spring.

Discard if the spring is deformed, the retainer forks

are broken, or if the retainer is otherwise damaged.

(3) Remove the exhalation valve.

Discard if the valve is torn, tacky, or otherwise

damaged.

NOTE: Be careful not to damage the valve seat. If it is

damaged, replace the component housing.

Maintenance

(4) Inspect the valve seat in the component housing.

If any blemishes or damage is present, replace the

component housing.

G1 Facepiece

GB

21

Page 22

Installing the Spring Retainer and Exhalation Valve

(1) Insert the exhalation valve stem into the housing

assembly.

NOTE: Ensure the valve stem is inserted into the center slot.

(2) Fit the retainer spring over the ring of the exhalation

valve.

(3) Align the forks on the flat surface of the component

housing and slide forward until each fork snaps into

place.

Maintenance

6.4 Replacing the Speech Diaphragm

(1) Unbutton the nose cup.

(2) Unscrew the threaded socket from the mask inside with the special tool.

(3) Remove the O-ring and the speech diaphragm.

(4) Insert the new speech diaphragm:

a) Place the speech diaphragm into the component housing with the yellow side visible.

b) Reinsert the O-ring.

(5) Screw in the threaded socket with the special tool (Torque: 5 Nm).

(6) Perform a tightness test ( chapter 6.5).

G1 Facepiece

GB

22

Page 23

Safekeeping and Storage

6.5 Tightness Test of the Mask

The testing of the masks for tightness is performed using an applicable MSA test device

(i. e. SmartCHECK) in accordance with the relevant operating manual.

(1) Fit mask tight onto the test device.

(2) Test mask according to test device operating manual.

The mask including the exhalation valve meets the requirements if for a moistened exhalation valve

and a vacuum of 10 mbar generated inside the mask the pressure change does not exceed 1 mbar in

a minute.

Leaking masks must not be used.

Opening Pressure Test of the exhalation valve

The opening pressure of the exhalation valve has to be at least 4.2 mbar, otherwise the mask must not

be used.

6.6 Visual Test and Function Test

Visual Test

(1) Inspect the mask for possible damages like for example deformations, stickings or cracks. Valve

discs, especially exhalation valve discs, are crucial functional elements of the mask.

(2) Defective or damaged parts have to be replaced immediately.

Functional Test

After assembling the mask the mobile parts, especially the valve discs, have to be tested for unrestricted mobility.

(1) Inspect the lens for cracks, scratches, and a tight seal with the mask rubber.

(2) Ensure the exhalation valve is clean and operates easily. The valve must move off the seat and

return when released.

(3) Inspect the inlet valve for damage. Ensure the valve disc is in place.

7 Safekeeping and Storage

WARNING!

In order to avoid damage to or the deformation of the masks keep no additional loose objects in the

mask container.

For the safekeeping of the mask the mask container should be used.

MSA rubber products are protected by an anti-aging agent that can become visible as a light coating.

This coating is harmless and can be removed during cleaning.

To ensure a long life for rubber components, keep them in a cool, dry place that is protected from ultraviolet radiation, according to ISO 2230:2002, Rubber Products – Guidelines for Storage.

G1 Facepiece

GB

23

Page 24

8 Ordering Information

2B

4

13

9

27

22

17

1

18

7C

7C

6

5

16

12

31b

32

30

31a

10

19

24

28

25

13

2A

8

7B

11B 14 16

20

21

23

22

15 26

7A

11A

11C

3

29

3

32

8.1 Exploded View

Ordering Information

Fig. 10 G1 Facepiece exploded view

G1 Facepiece

GB

24

Page 25

Ordering Information

1 Nosecup 14 Lightpipe assembly, left

2A Harness, kevlar 15 Lightpipe assembly, right

2B Harness, rubber 16 Screw 30x8

3 Buckle D-ring 17 Inlet valve

4 Buckle 18 Inlet valve seat

5 Neck strap, cloth 19 Button, head harness

6 Neck strap, rubber 20 Speech diaphragm

7A Component housing Fixed Push-To-Connect 21 O-ring

7B Component housing Push-To-Connect 22 Inlet valve assembly

7C Component housing M45x3 23 Screw ring

8 Lens 24 Retainer, exhalation valve

9 Lens ring, upper 25 Exhalation valve assembly

10 Lens ring, lower 26 Retainer, inhalation valve

11A Cover, component housing

Fixed Push-To-Connect

11B Cover, component housing Push-To-Connect 28 Spring, exhalation valve

11C Cover, component housing M45x3 29 Pullstrap, head harness

12 Clamp, component housing 30 Adapter ESA

13 Screw, lens ring 31a/b Gasket

27 Inhalation valve

32 Sealing ring

G1 Facepiece

GB

25

Page 26

8.2 Spare Parts and Accessories

Description Article No.

Nosecup small 10149572-SP

Nosecup medium 10149573-SP

Nosecup large 10149574-SP

3S, ULTRA ELITE head harness, spare D2055014-SP

Harness, 4 pt adjustable 10144215-SP

Buckle D-ring 10149551-SP

Buckle 10144217-SP

Neck strap, assembly, textile, G1 Facepiece 10144220-SP

Neck strap, assembly, rubber G1 Facepiece 10159699-SP

Lens, PC 3 mm, G1 facepiece 10168597-SP

Lens, APEC 4 mm, G1 facepiece 10144194-SP

Lens, PC-HC 3 mm, G1 facepiece 10176797-SP

Lens ring, upper 10144195-SP

Lens ring, lower 10144196-SP

Cover, component housing 10144187-SP

Screw, lens ring 10144221-SP

Lightpipe assembly, left 10144180-SP

Lightpipe assembly, right 10144204-SP

Screw, coated SS, 30x8, threadforming 10144233-SP

Inlet valve seat 10144192-SP

Inlet valve 10144193-SP

Button, head harness, black (medium) 10144219-SP

Button, head harness, gray (large) 10144235-SP

Button, head harness, green (small) 10144234-SP

Speaking diaphragm 10144209-SP

O-ring 10144232-SP

Inlet valve assembly 10144191-SP

Screw ring 10144213-SP

Retainer, exhalation valve 10144177-SP

Exhalation valve assembly 10144174-SP

Retainer, inhalation valve 10144208-SP

Inhalation valve 10144207-SP

Spring, exhalation valve

Speaking diaphragm retaining tool 10169560

Kit, filter adapter assembly, G1 facepiece 10144231-SP

Ordering Information

GB

10193368-SP

G1 Facepiece

26

Page 27

Ordering Information

8.3 ATO Code

For this product, order numbers have been replaced by an ATO (Assemble To Order) code.

To order a mask according to EN136 PC with a medium sized faceblank, a medium nosecup, rubber

head harness, rubber neck strap and Push-To-Connect connector piece, the ATO code would be

E-M/I-M-E-R-P:

Application

E - Europe

EN 136 PC

C - Europe

EN 136 PC

A - Europe

EN 136

APEC

Faceblank

Size Faceblank

S/I - Small Hycar

M/I - Medium Hycar

L/I - Large Hycar

Faceblank

Material

Nosecup

S - Small

M - Medium C - Cloth

L - Large

S - Small

M - Medium C - Cloth

L - Large

S - Small

M - Medium C - Cloth

L - Large

Head

Harness

4 - 4-point

Adjustable

E - Rubber

EU with

buckles

4 - 4-point

Adjustable

E - Rubber

EU with

buckles

4 - 4-point

Adjustable

E - Rubber

EU with

buckles

Neck

Strap

0 - None

R - Rubber M - M45 x 3

0 - None

R - Rubber M - M45 x 3

0 - None

R - Rubber M - M45 x 3

Regulator

I - Fixed PushTo-Connect

P - Push to

Connect

E - ESA ("M"+

ESA-Adapter)

I - Fixed PushTo-Connect

P - Push to

Connect

E - ESA ("M"+

ESA-Adapter)

I - Fixed PushTo-Connect

P - Push to

Connect

E - ESA ("M"+

ESA-Adapter)

GB

G1 Facepiece

27

Page 28

Ordering Information

B - Siz e

C - Material

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

S - Small 4 - 4 PT Adjustable 0 - None 1 - Fixed Push-To-Connect

M - Medium E - Rubber EU with buckles C - Cloth P - Push to Connect

L - Large R - Rubber M - M45 x 3

E - ESA ("M"+ ESA-A dapter)

A - Applicaon

D - Nos ecup

E - Hea d Harness

F - Neck Strap

G - Re gulat or

Faceblank

A - Europ e EN 136 A PEC

(An-fog l ens "A")

S/I - Small Hycar

M/I -Med iu m Hyca r

L/I - Large Hycar

E - Eu rope EN136 PC

(Standard lens "P")

S/I -Small Hycar

M/I - Med iu m Hyca r

L/I - Large Hycar

C - E urope EN136 PC

(An -scrat ch lens "H")

S/I - Small Hycar

M/I - Med iu m Hyca r

L/I - Large Hycar

The following table shows all possible configurations that can be ordered for the G1 Facepiece

GB

G1 Facepiece

28

Page 29

For local MSA contacts, please visit us at MSAsafety.com

Because every life has a purpose...

Loading...

Loading...