Page 1

FlameGard® 5

Test Lam

p

The information and technical data disclosed in

this document may be used and disseminated

only for the purposes and to the extent

specifically authorized in writing by MSA.

Instruction Manual

MSA reserves the right to change published

specifications and designs without prior notice.

Part No. MAN5TL-EU

Revision 0

Page 2

ii

FlameGard 5 Test Lamp

EC Declaration of Conformity

MANUFACTURED BY: Mine Safety Appliances Company

1000 Cranberry Woods Drive

Cranberry Township, PA 16066 USA

The manufacturer or the European Authorized Representative

MSA AUER GmbH , Thiemannstraße 1 , D-12059 Berlin

declares that the product : FlameGard 5 Test Lamp

based on the EC-Type Examination Certificate :

Sira 10 ATEX1364

complies with the ATEX directive 94/9/EC, Annex III. Quality Assurance

Notification complying with Annex IV of the ATEX Directive 94/9/EC has been

issued by SIRA Certification Service, Notified Body number: 0518.

The product is in conformance with the directive 2004 / 108/ EC ,(EMC) :

EN 50130-4 : 2002 EN 61000 - 6 - 4 :2007

MSA AUER GmbH

Dr. Axel Schubert

R & D Instruments Berlin , March 2011

Page 3

iii

FlameGard 5 Test Lamp

Warning: Do not leave battery uncharged. It will result in permanent battery damage

Table of Contents

Format Conventions.................................................................................................................. iv

Notes, Cautions, and Warnings ................................................................................................ iv

Contacting Customer Support...................................................................................................iv

1.0 INTRODUCTION ...................................................................................................................... 5

1.1 Notice .........................................................................................................................................5

1.2 Special Warnings .......................................................................................................................5

1.3 Description .................................................................................................................................5

1.4 Upon Receiving..........................................................................................................................5

1.5 Test Lamp Operating Principle ..................................................................................................7

2.0 QUICK START GUIDE ............................................................................................................. 8

3.0 TEST LAMP COMPONENTS .................................................................................................. 9

3.1 Lamp Housing Assembly ...........................................................................................................9

3.2 Microcontroller............................................................................................................................9

3.3 Rotary Switch Setting.................................................................................................................9

3.4 Rechargeable Battery ................................................................................................................9

3.5 Power Jack.................................................................................................................................9

3.6 Push Button..............................................................................................................................10

3.7 Aluminum Case and Cap .........................................................................................................10

3.8 Battery Charge State Indicator.................................................................................................10

4.0 USE AND OPERATION ......................................................................................................... 11

5.0 TEST LAMP MAINTENANCE AND WARRANTY ................................................................ 14

5.1 Maintenance.............................................................................................................................14

5.2 Cleaning the Sapphire Window................................................................................................14

5.3 Recharging the Battery ............................................................................................................15

5.4 Obtaining Service.....................................................................................................................15

5.5 Warranty..................................................................................................................................15

6.0 TROUBLESHOOTING GUIDE............................................................................................... 17

7.0 CUSTOMER SUPPORT......................................................................................................... 18

7.1 MSA Office ......................................................................... Fehler! Textmarke nicht definiert.

7.2 Other Sources for Help ............................................................................................................18

8.0 APPENDIX.............................................................................................................................. 19

8.1 Specifications ...........................................................................................................................19

8.1.2 Regulatory Agencies ...................................................................................................19

8.1.3 Classification Area and Protection Methods ...............................................................20

Page 4

iv

FlameGard 5 Test Lamp

About This Manual

This manual provides instructions for operating, and maintaining the MSA FlameGard 5 Test

Lamp. The intended audience includes installation personnel, field service technicians, and

other technical staff involved in using the Test Lamp.

Format Conventions

Several format conventions are used throughout this manual for Notes, Cautions, and

Warnings. These conventions are described below.

Notes, Cautions, and Warnings

NOTE: Notes provide supplementary details such as exception conditions, alternate methods

for a task, time saving tips, and references to related information.

CAUTION: These notices describe precautions to prevent hazardous conditions that may

damage the equipment.

WARNING: These notices describe precautions to prevent hazardous conditions that may

cause injury to people working with the equipment.

Contacting Customer Support

For additional product information not contained in this manual, please contact MSA Customer

Support. Refer to Section 7.0 for contact information.

Page 5

5

FlameGard 5 Test Lamp

1.0 Introduction

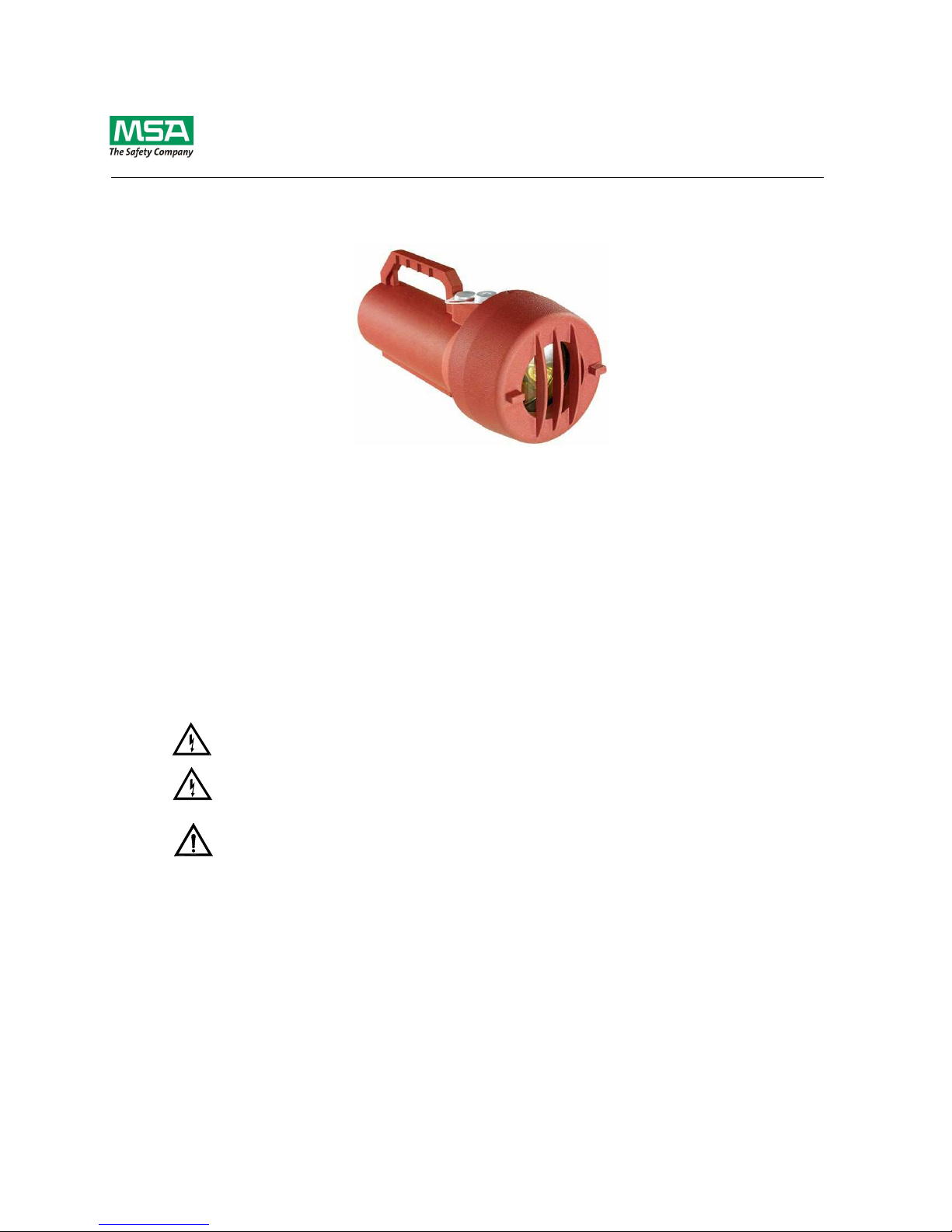

Figure 1: FlameGard 5 Test Lamp

1.1 Notice

All information contained in this instruction manual applies only to the setup and operation of

the FlameGard 5 Test Lamp with flame detectors provided by MSA. The sale of the test lamp

does not license the user to reproduce MSA drawings or to utilize any information contained in

this manual without prior written permission.

The FlameGard 5 Test Lamp is easy to set up and operate. However, this manual should be

read in full, and the information contained herein understood, before attempting to operate the

test lamp in service.

1.2 Special Warnings

Warning: Do not leave battery uncharged. It will result in permanent battery damage.

WARNING: UV light is injurious to one’s vision. Do not stare into functioning lamp. Wear eye

protection of UV blocking glasses to prevent eye injury.

CAUTION: Do not attempt to recharge the FlameGard 5 Test Lamp in areas where

combustible gases or potential explosive gases are located.

1.3 Description

The FlameGard 5 Test Lamp is a battery operated rechargeable test lamp specifically designed

to test MSA’s UV/IR and Multi-Spectral IR Flame Detectors. The test lamp provides a highenergy, broadband radiation source that emits sufficient energy in both the ultraviolet and

infrared spectra to activate UV and/or IR detectors. To simulate the flickering of a fire, the test

lamp automatically flashes at various selectable rates.

1.4 Upon Receiving

FlameGard 5 Test Lamp leaves the factory with the battery disconnected. The customer must

connect and fully charge the battery before use. If you connect the battery and activate the

Page 6

6

FlameGard 5 Test Lamp

push button, the RED LED will stay on for 60 seconds. It will continue to do so until the battery

has been fully charged.

Since the FlameGard 5 Test Lamp goes to fault mode when a charger is plugging in and no

battery is present, you must plug in the battery before the charger.

Make sure to keep the lens and the reflector is kept clean from debris and fingerprints. Grease

on the window will absorb the required energy from reaching the flame detector.

Please follow the steps outlined below to connect the battery:

• Loosen the Set Screw on the Cap.

• Unscrew the Cap counterclockwise and remove it from the Body.

• Remove the two screws holding Reflector on the Body.

• Pull the Reflector off to reveal a 4-Pin Connector on the PC Board.

• Plug the 4 wire Connector coming from the Body into the 4 -Pin Connector on the PC

board. The pins on the connector align one way only.

• Reposition the Reflector on the Body and tighten 2 screws to hold the Reflector on the

Body.

• Reinstall the Cap to the FlameGard 5 Test Lamp Body by screwing it on clockwise.

• Tighten the Set Screw on the Cap.

• Follow Section 5.3 in this Instruction Manual to recharge the battery.

Page 7

7

FlameGard 5 Test Lamp

1 FlameGard 5 Test Lamp body 6 Cap

2 Piezo ON/OFF switch 7 Set screw

3 Charging plug cover 8 Refllector

4 PC board 9 4-pin battery connector

5 Reflector mounting screw

Figure 2: FlameGard 5 Test Lamp Battery Connection

1.5 Test Lamp Operating Principle

A variety of flashing test patterns, selectable through a rotary switch, allows the FlameGard 5

Test Lamp to check the operation of MSA flame detectors. When the specific flashing pattern

for a given type of flame detector is appropriately selected, the test lamp triggers the alarm or

test mode. Please refer to Table 2 for rotary switch settings.

Page 8

8

FlameGard 5 Test Lamp

2.0 Quick Start Guide

Figure 3: Approximate Distance between a FlameGard 5 Test Lamp and a Flame Detector

It is important to begin a series of flame detector checks with a fully charged Test Lamp.

• Stand between 3 and 12 m from a Flame Detector that is to be tested and aim the Test

Lamp directly into the detector window

• Press the ON button and be sure the high intensity pulsing beam strikes the detector

face squarely.

• On some Flame Detectors shaking the lamp from side to side or up and down may

increase the simulation of flame flicker and improve the response of the flame detector

to the lamp.

• When the Flame Detector senses the Test Lamp, the red LED will blink slowly. The

green light may also blink. After a time delay the red LED will start to blink quickly.

This signifies the completion of the test.

NOTE: Please refer to Table 2 for maximum distance to each detector.

NOTE: The FlameGard 5 Test Lamp triggers a Flame Detector into alarm. The system must

be disabled during test if you do not want false trips.

To conserve charge, do not operate the test lamp longer than is necessary to test a Flame

Detector.

When the battery level drops below the level required to maintain the proper intensity of the

lamp, an internal low voltage circuit will shut the lamp off until the battery has been recharged.

Please refer to Section 5.3 for complete recharging instructions.

It is mandatory that the FlameGard 5 Test Lamp be kept on charge when not in use to prevent

excessive battery discharge. The batteries may be charged an average of 500 times before the

battery pack is replaced.

NOTE: Please refer to Section 3.8 for Battery Charge State Indicator details.

NOTE: Please refer to Section 5.3 for detailed information on Recharging the Battery. The

normal recharge time for the rechargeable battery is 3.5 hours.

Page 9

9

FlameGard 5 Test Lamp

3.0 Test Lamp Components

3.1 Lamp Housing Assembly

NOTE: Do not put fingerprints on the reflector or the light bulb, as this will reduce the available

radiation required by the individual detector.

The lamp housing assembly consists of a gold-plated parabolic reflector with the lamp affixed to

its center. A light emitting diode (LED) that serves as a battery charge indicator is also housed

near the edge of the reflector.

3.2 Microcontroller

The FlameGard 5 Test Lamp’s flashing patterns are controlled by a microcontroller. This device

also monitors battery voltage and shuts down the flash lamp output when the battery charge is

low. The microcontroller resides on the functional board.

3.3 Rotary Switch Setting

A rotary switch is used to configure the test lamp to function with FlameGard 5 UV/IR and MSIR

Detectors. Positions of the rotary switch for each of these detectors are noted in Table 2 and

are labeled next to the rotary switch inside the lamp. The rotary switch resides on the functional

board

. (Do not operate the Test Lamp in factory mode. Damage may result to the Test Lamp)

3.4 Rechargeable Battery

The FlameGard 5 Test Lamp is powered by a 12V rechargeable battery. It is mandatory to

keep the test lamp docked with its battery charger when the test lamp is not being used. This

will increase the expected life of the battery and will always keep the test lamp available for

immediate use.

Warning: Do not leave battery uncharged. It will result in permanent battery damage.

NOTE: The normal recharge time for the rechargeable battery is 3.5 hours.

3.5 Power Jack

The power jack is located directly under the aluminum cap and can be accessed when the cap

is removed. The cap must always be in place when operated in a hazardous location. An Allen

wrench is included with the test lamp to unscrew or affix the plug. With the plug removed, the

battery can be recharged by connecting the jack to the FlameGard 5 Test Lamp battery

charger. The battery charger operates from a 110 – 240 VAC power line.

Page 10

10

FlameGard 5 Test Lamp

3.6 Push Button

The push button toggles the lamp ON or OFF. Press the button once to turn the lamp on, and

press it again to turn the instrument off. After flashing for a maximum of 5 minutes, the test

lamp will turn itself off. This is to prevent the battery becoming completely discharged if the

ON / OFF button is accidentally bumped on.

3.7 Aluminum Case and Cap

The FlameGard 5 Test Lamp red aluminum housing is explosion proof for use in hazardous

locations (8.1.3). It can also be used for general-purpose, non-hazardous applications.

3.8 Battery Charge State Indicator

The tri-color LED affixed to the gold parabolic reflector displays the charge state of the battery.

The flashing patterns and colors of the signals are shown in Table 1.

Battery Charge LED Color and Flashing Pattern

Fully charged

Solid green

Charging

Solid yellow

Charging paused

Blinking yellow. This occurs if the battery is too hot (> 60°C)

Fault

Blink red once per second

Discharged

Solid red for one minute after the push button is pressed, then off

Never charged &

switch pushed

Solid red for one minute after the push button is pressed, then off

Battery not connected

Solid red for one minute after the push button is pressed, then off

Wrong charger

connected

Solid red for one minute after the push button is pressed, then off

Table 1: Charge State Indicator

NOTE: The FlameGard 5 Test Lamp attempts to detect improper chargers. However it can not

detect all improper chargers, care must be used to ensure the proper charger is used.

If the improper charger is used, disconnect the charger and wait 1 minute until the red LED goes

out before connecting the proper charger.

Page 11

11

FlameGard 5 Test Lamp

4.0 Use and Operation

Figure 4: Reflector Mounting in Body

1 Set screw (lock) 4 Corresponding holes on FlameGard 5 Test lamp

body

2 Cap assy 5 Charging plug

3 Mounting screws on reflector 6 Piezo ON/OFF switch

Page 12

12

FlameGard 5 Test Lamp

Prior to opening of the test lamp make sure that the set screw located on the cap is loosened

sufficiently to remove the cap.

When closing, make sure that the captive screws (located on the reflector) are matched with

the holes located on the body of the test lamp.

Before beginning a flame detector check, adjust the rotary switch setting in the FlameGard 5

Test Lamp according to the type of MSA flame detector used. Table 2 shows the rotary switch

configurations for MSA flame detectors FlameGard 5 MSIR and FlameGard 5 UV/IR. Using a

fully charged FlameGard 5 Test Lamp, stand up to the distance specified in Table 2 from the

flame detector to be tested and aim the FlameGard 5 Test Lamp 5 directly into the detector

window. Press the ON button and ensure the high intensity intermittent beam strikes the

detector face. If the system is operating normally, the instrument will go into a warning condition

after a few flashes of the test lamp. If the lamp remains on for the period set by the time delay

adjustment, the Flame Detector will go into alarm

1

.

NOTE: Before testing any MSA flame detector, see Table 2 and Figure 5 to ensure the rotary

switch setting is correct for the particular detector.

CAUTION: When operating in conditions involving fog, rain or frost, UV and IR radiation are

(diminished) with increasing levels of moisture. The moisture level will affect the

potential range of the detector. When using the test lamp in conditions of frost,

make sure that the lens is free of frost and ice. A plastic card can be used without

scratching the lens cap to remove frost build-up.

NOTE: Recharging the battery and normal docking of the test lamp when not in use is

mandatory. This will extend the useful life of the battery and also make the test lamp

available for immediate use. Normal recharge time is approximately 3 hours; the

maximum recharge time is 3.5 hours.

1

For test initiation with the FlameGard 5 MSIR Flame Detector, please refer to the FlameGard 5 MSIR Flame

Detector Instruction Manual.

Page 13

13

FlameGard 5 Test Lamp

Figure 5: Location of Functional Board under Lamp Assembly

NOTE: Location of the rotary switch in the FlameGard 5 MSIR Flame Detector control board,

shown in Figure 5.

Detector Test Mode Initiation or Detector Alarm Trigger with FlameGard 5 Test Lamp

Flame Detector

to Test

Rotary Switch

Setting

Maximum Distance

to Detector (ft)

Results

FlameGard 5

UV/IR

20 [6 m]

FlameGard 5 UV/IR triggers into

alarm mode

FlameGard 5

UV/IR-E

20 [6 m]

FlameGard 5 UV/IR-E triggers into

alarm mode

FlameGard 5

MSIR

35 (High Sensitivity)

[11 m]

FlameGard 5 MSIR enters test

mode

FlameGard 5

MSIR

18 (Medium

Sensitivity)

[5.5 m]

FlameGard 5 MSIR enters test

mode

FlameGard 5

MSIR

8 (Low Sensitivity)

[2.5 m]

FlameGard 5 MSIR enters test

mode

Table 2: Detector Test Mode Initiation or/Detector Alarm Trigger with FlameGard 5 Test Lamp

Rotary Switch

shown in position 1

(for testing

FlameGard UV/IR

Flame Detectors)

FlameGard

Rotary Switch Configurations

SWI

FLAMEGARD DETECTOR

0 FACTORY

1 UV/IR

2

3

4 MSIR

Page 14

14

FlameGard 5 Test Lamp

5.0 Test Lamp Maintenance and Warranty

5.1 Maintenance

Routine maintenance for the test lamp is minimal:

• When the test lamp is not being used, it is mandatory

to ensure that the test lamp

is docked on the charger and the charger is connected to a live 110 – 240VAC

power supply adapter. Permanent battery damage will occur if not charged for 60

days.

• Make sure that the test lamp lens is free of frost or large accumulations of moisture

during frosty conditions or inclement weather.

• The battery life will be affected by extreme temperatures. Store and charge the

battery between +5°C and +30°C (+41°F and 86°F) if possible.

There are no user serviceable parts inside the test lamp. After a number of years, the battery

may fail. This will be indicated by a flashing red indicator at the front of the lamp. The unit

should be returned to MSA for a replacement battery. If the test lamp is to be discarded, the

battery must be recycled at this point.

In most countries it is illegal to dispose of the battery with other garbage. MSA has a Recycle

Program in place to recycle the used batteries.

NOTE: The removal of particulate matter and any film buildup on the Sapphire Window is

necessary to ensure proper sensitivity of the system. It is recommended that the

window be cleaned at least every 30 days if the detector is located in a particularly dirty

environment.

5.2 Cleaning the Sapphire Window

A clean, soft, lint-free cloth, tissue or cotton swab should be used to apply the cleaning solution.

The window is not glass; it is made from sapphire. The cleaning solution should be Industrial

Strength Windex

®

with Ammonia D.

Do not touch the window with fingers.

1. Wet the window with the solution.

2. Rub with a dry, unsoiled cloth until the window is clean.

3. Completely dry the window.

CAUTION: Do not use a commercial glass cleaner other than Industrial Strength Windex

®

with

Ammonia D.

Page 15

15

FlameGard 5 Test Lamp

5.3 Recharging the Battery

Before the lamp is used for the first time, or after it has been used to the point where the red

LED at the front has come on solidly, the battery must be recharged. To recharge the battery,

take the test lamp to a non-hazardous area where there is no possibility of an explosive gas or

dust atmosphere being present. The temperature in this area must be between 32°F (0°C) and

104°F (40°C). No damage will occur if the unit is outside the temperature range, but the battery

will not charge.

Use an Allen wrench to remove the charging plug stopper and connect the MSA Switching

Power Supply to the charging socket exposed by removing the charging stopper.

Plug the Switching Power Supply into an electrical outlet between 100 and 240 VAC 50 to

60 Hz rated to provide at least 1.5 A. The charge indicator LED at the front of the test lamp will

change to the color yellow to show that the battery lamp is charging. When the charge is

complete (less than 3.5 hours), the charge indicator will change to green. If the lamp is to be

stored, leave it connected to the Switching Power Supply to keep the battery charged.

Before using the test lamp, unplug the charging connector from the test lamp, carefully insert

the charging plug stopper using an Allen wrench and screw it all the way into the hole. Do not

over-tighten the stopping plug. The lamp can now be safely used in hazardous locations as

specified on the test lamp nameplate and in Section 8.1.3 of this manual.

5.4 Obtaining Service

The FlameGard 5 Test Lamp contains no user serviceable parts. To obtain information

regarding factory service, contact MSA or your MSA representative. Please have the following

information available:

• Instrument model number (on the nameplate)

• Instrument serial number (on the nameplate)

• Description of the problem

5.5 Warranty

Caution: There are no user serviceable parts inside the FlameGard 5 Test Lamp. Work

performed by persons not authorized by MSA will void the warranty.

MSA warrants the FlameGard 5 Test Lamp and the accessory battery charger to be free from

defects in workmanship or material under normal use and service within two (2) years from the

date of shipment.

MSA will repair or replace without charge any equipment found to be defective during the

warranty period. Full determination of the nature of, and responsibility for, defective or

damaged equipment will be made by MSA personnel.

Defective or damaged equipment must be shipped prepaid to MSA or the representative from

which shipment was made. In all cases, this warranty is limited to the cost of the equipment

Page 16

16

FlameGard 5 Test Lamp

supplied by MSA. The customer will assume all liability for the misuse of this equipment by its

employees or other personnel.

All warranties are contingent upon proper use in the application for which the product was

intended and do not cover products which have been modified or repaired without MSA

approval or which have been subjected to neglect, accident, improper installation or application,

or on which the original identification marks have been removed or altered.

EXCEPT FOR THE EXPRESS WARRANTY STATED ABOVE, MSA DISCLAIMS ALL

WARRANTIES WITH REGARD TO THE PRODUCTS SOLD, INCLUDING ALL IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS AND THE EXPRESS WARRANTIES

STATED HEREIN ARE IN LIEU OF ALL OBLIGATIONS OR LIABILITIES ON THE PART OF

MSA FOR DAMAGES INCLUDING, BUT NOT LIMITED TO, CONSEQUENTIAL DAMAGES

ARISING OUT OF / OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE

PRODUCT.

Page 17

17

FlameGard 5 Test Lamp

6.0 Troubleshooting Guide

The following table lists potential problems that can affect the test lamp circuit. Follow the

individual steps to pinpoint and define circuit ailments.

This section is intended to be a guide in correcting problems, which may arise in the field. MSA

should be contacted for assistance if the corrective action listed does not eliminate the problem.

Condition Possible Solution

Test lamp does not flash Battery may require a recharge

Check Table 2

Test lamp flashes but is unable to trigger

detector

Verify that rotary switch settings are

set as specified in Table 2

Test lamp does not flash, and battery has

been recharged for 4 hours

Lamp filament may be broken. Check

power and lamp connectors

During charging the charge indicator lamp

at the front of the unit flashed red

The test lamp must be returned to

MSA for a replacement battery pack

During charging the charge indicator lamp

flashes yellow. Charging is not complete

after 4 hours.

The unit is too hot. If the battery

temperature is above 60°C (140°F) the

charging pauses until the battery pack

cools. Put the lamp into a cooler

location or wait until the indicator turns

green (this could take more than

10 hours)

Lamp stops flashing after 5 minutes of use

This is an intentional part of the design

to prevent the lamp draining the battery

if the on/off button is knocked. Press

the on/off button again and the lamp

will resume flashing

During operation the lamp stops flashing

and the charge indicator is solid red

The battery has been discharged.

Recharge the battery, in a non-

hazardous location, using the MSA

battery charger

When activating the push button, the RED

LED is on for one minute.

1-The battery needs charging

2-The battery was just plugged in and

has not been fully charged

3- The battery is not connected

4- The wrong charger maybe in used

instead of the test lamp charger

Table 3: Troubleshooting Table

Page 18

18

FlameGard 5 Test Lamp

7.0 Customer Support

7.1 MSA Contact Information

Address Phone/Web/Email

Please, contact your local MSA representative (see last page).

7.2 Other Sources for Help

MSA provides extensive documentation, white papers, and product literature for the company’s

complete line of safety products. Many of these documents are available online at the MSA

website at

http://www.msanet.com.

Page 19

19

FlameGard 5 Test Lamp

8.0 Appendix

8.1 Specifications

Electrical specification

12 VDC 130 W Max

Operating temperature:

5°F to +122°F (-15°C to +50°C)

Storage temperature:

5°F to +122°F (-15°C to +50°C)

Charging temperature

32°F to +104°F (0°C to +40°C)

Humidity range:

0 to 90% ± 3% RH, non-condensing

Weight:

7.9 lb (about 3.5 kg)

Dimensions:

13” L x 5” D (330 mm L x 127 mm D)

Approvals:

CSA, ATEX, and CE Mark

Charging time:

3.5 hours

Output spectra:

Broadband emissions in UV, visible and IR

Charger input:

110 – 240 VAC, 50/60Hz @1.5 A

Output:

24 VDC @ 2.1 A

Detection range:

See Table 2 for maximum distance per flame

detector model

8.1.1.1 Regulatory Agency Approvals

8.1.2 Regulatory Agencies

The FlameGard 5 Test Lamp is certified by the following regulatory agencies:

• ATEX – Hazardous Locations

• Canadian Standards Association (CSA) – Hazardous Locations

Page 20

20

FlameGard 5 Test Lamp

8.1.3 Classification Area and Protection Methods

The FlameGard 5 Test Lamp is certified as follows:

• Protection Method Ex d IIB+H2 T4

• Area Classifications Class I, Division 1 and 2, Groups C and D

• Conforms With Electromagnetic Compatibility Directive (2004/108/EC)

PLEASE NOTE:

The following instructions apply to equipment covered by certificate # Sira 10 ATEX1364

• The equipment may be used with flammable gases and vapors with apparatus

groups IIB+ H

2

and with temperature class T4.

• The equipment is only certified for use in ambient temperatures in the range

-15

o

C to +50oC (5°F to +122°F) and should not be used outside this range.

• Installation shall be carried out by suitably-trained personnel in accordance

with the applicable code of practice e.g. EN 60079-14:1997.

• Inspection and maintenance of this equipment shall be carried out by suitably

trained personnel in accordance with the applicable code of practice e.g.

EN€60079-17.

• Repair of this equipment shall be carried out by suitably trained personnel in

accordance with the applicable code of practice e.g. EN 60079-19.

Loading...

Loading...