Page 1

Models FL3100H/FL3101H

UV/IR and UV only

Flame Detectors

The information and technical data disclosed in

this document may be used and disseminated

only for the purposes and to the extent

specifically authorized in writing by General

Monitors.

Instruction Manual DATE 01-16

General Monitors reserves the right to change

published specifications and designs without

prior notice.

MANFL3100H/3101H

Part No. MANFL3100/3101H

Revision H/01-16

Page 2

Models FL3100H/3101H

ii

Page 3

Models FL3100H/3101H

Table of Contents

MODELS FL3100H/FL3101H ........................................................................................................ I

UV/IR AND UV ONLY FLAME DETECTORS ............................................................................... I

TABLE OF FIGURES ................................................................................................................. VII

TABLE OF TABLES .................................................................................................................. VIII

QUICK START GUIDE ................................................................................................................. 1

Mount and Wire the Detector .................................................................................................................. 1

Apply Power to the Detector ................................................................................................................... 4

Testing the Detector Using the TL105 .................................................................................................... 4

1.0INTRODUCTION .................................................................................................................... 5

1.1 Protection for Life ....................................................................................................................... 5

1.2 Special Warnings ....................................................................................................................... 5

1.3 System Integrity Verification ...................................................................................................... 5

2.0PRODUCT DESCRIPTION ..................................................................................................... 7

2.1 General Description ................................................................................................................... 7

3.0INSTALLATION ...................................................................................................................... 8

3.1 Tools Required ........................................................................................................................... 8

3.2 Choosing Product Locations ...................................................................................................... 8

3.2.1 Detector Field of View ................................................................................................... 8

3.2.2 Optical Sensitivity Range .............................................................................................. 8

3.2.3 Environmental Factors .................................................................................................. 8

3.3 Mounting and Wiring ................................................................................................................ 12

3.3.1 Terminal Connections ................................................................................................. 18

3.3.2 Terminal Block TB2 – Alarm Relay Connections ........................................................ 18

3.3.3 Terminal Block TB-2 Warning Relay Connections ...................................................... 19

3.3.4 Fault Relay .................................................................................................................. 19

3.3.5 Alarm Reset Terminal ................................................................................................. 20

3.3.6 Analog Output ............................................................................................................. 20

3.3.7 Cable Requirements ................................................................................................... 21

3.3.8 Power .......................................................................................................................... 21

3.3.9 Modbus Interface ........................................................................................................ 22

3.3.10 Chassis Ground .......................................................................................................... 22

3.3.11 Connection to Fire Cards/Panels ................................................................................ 22

3.3.12 Cable Termination in the Non-Hazardous Area .......................................................... 23

4.0OPERATION ......................................................................................................................... 24

4.1 Checklist ................................................................................................................................... 24

4.2 Start Up .................................................................................................................................... 24

4.3 System Test ............................................................................................................................. 24

4.4 User Selectable Options/Factory Defaults ............................................................................... 24

5.0MODBUS INTERFACE ........................................................................................................ 26

iii

Page 4

Models FL3100H/3101H

Baud Rate ................................................................................................................................ 26

5.1

5.2 Data Format ............................................................................................................................. 26

5.3 Modbus Read Status Protocol (Query/Response) ................................................................... 26

5.3.1 Modbus Read Query Message ................................................................................... 26

5.3.2 Modbus Read Response Message ............................................................................. 27

5.4 Modbus Write Command Protocol (Query/Response) ............................................................ 27

5.4.1 Modbus Write Query Message ................................................................................... 27

5.4.2 Modbus Write Response Message ............................................................................. 28

5.4.3 Function Codes Supported ......................................................................................... 28

5.5 Exception Responses and Exception Codes ........................................................................... 28

5.5.1 Exception Responses ................................................................................................. 29

5.6 Command Register Locations .................................................................................................. 30

5.6.1 Operational Mode Commands .................................................................................... 30

5.7 FL3100H / FL3101H Operational Mode Command Register Details ...................................... 34

5.7.1 Analog (00H) ............................................................................................................... 34

5.7.2 Mode (01H) ................................................................................................................. 34

5.7.3 Status/Error (02H) ....................................................................................................... 34

5.7.4 Faults .......................................................................................................................... 35

5.7.5 UV/IR Only (03H) ........................................................................................................ 35

5.7.6 Model Type (04H) ....................................................................................................... 35

5.7.7 Software Revision (05H) ............................................................................................. 36

5.7.8 COPM Fault (06H) ...................................................................................................... 36

5.7.9 EEPROM Override (07H) ............................................................................................ 36

5.7.10 Options (08H) .............................................................................................................. 36

5.7.11 Comm 1 Address (09H) .............................................................................................. 37

5.7.12 Comm 1 Baud Rate (0BH) .......................................................................................... 37

5.7.13 Comm 1 Data Format (0CH) ....................................................................................... 38

5.7.14 UV Signal Count (0DH) ............................................................................................... 38

5.7.15 IR Signal Count (0EH) ................................................................................................ 38

5.7.16 UV Fault Total (0FH) ................................................................................................... 38

5.7.17 IR Fault Total (10H) ..................................................................................................... 38

5.7.18 Remote Reset (11H) ................................................................................................... 38

5.7.19 Remote Alarm Test (12H) ........................................................................................... 39

5.7.20 Clear COPM Faults (13H) ........................................................................................... 39

5.7.21 Serial Number (15/16H) .............................................................................................. 39

5.7.22 HART Enable (1D) ...................................................................................................... 39

5.7.23 HART Test (1E) ........................................................................................................... 39

5.7.24 Not Used (1F) .............................................................................................................. 40

5.7.25 Comm 1 Total Illegal number of registers Errors (20H) .............................................. 40

5.7.26 Comm 1 Bus Activity Rate % (21H) ............................................................................ 40

5.7.27 Comm 1 Function Code Errors (22H) ......................................................................... 40

5.7.28 Comm 1 Starting Address Errors (23H) ...................................................................... 40

5.7.29 Comm 1 Total Receive Errors (24H) ........................................................................... 40

5.7.30 RXD CRC Errors Hi (25h) ........................................................................................... 40

5.7.31 RXD CRC Errors Lo (Same as Hi) (26h) .................................................................... 40

5.7.32 Comm 1 Overrun Errors (27H) .................................................................................... 40

5.7.33 Comm 1 Parity Errors (28H) ....................................................................................... 40

5.7.34 Comm 1 Framing Errors (29H) ................................................................................... 41

5.7.35 Comm 1 Total UART Receive Errors (2AH) ............................................................... 41

5.7.36 Comm 1 Total Receive Errors (2BH) .......................................................................... 41

5.7.37 Clear Comm 1 UART Errors (2CH) ............................................................................. 41

5.7.38 Clear Comm 1 Modbus Errors (2DH) .......................................................................... 41

5.7.39 HART Current (2E) ...................................................................................................... 41

iv

Page 5

Models FL3100H/3101H

Comm 2 Address (2FH) .............................................................................................. 41

5.7.40

5.7.41 Comm 2 Baud Rate (30H) .......................................................................................... 42

5.7.42 Comm 2 Data Format (31H) ....................................................................................... 42

5.7.43 Not Used (32H) ........................................................................................................... 42

5.7.44 Input Voltage (33H) ..................................................................................................... 42

5.7.45 Alarm Test Voltage (34H) ........................................................................................... 43

5.7.46 Reset Relays Voltage (35H) ....................................................................................... 43

5.7.47 Dip Switch Settings (36H) ........................................................................................... 43

5.7.48 Not Used (37 – 3FH) ................................................................................................... 43

5.7.49 See Event Logging - Section 6.0 (40H – 67H) ............................................................ 43

5.7.50 User Information (68h to 77h) ..................................................................................... 43

5.7.51 Comm 2 Total Illegal Number of Registers Errors (78H) ............................................ 43

5.7.52 Comm 2 Bus Activity Rate % (79H) ............................................................................ 43

5.7.53 Comm 2 Function Code Errors (7AH) ......................................................................... 43

5.7.54 Comm 2 Starting Address Errors (7BH)...................................................................... 43

5.7.55 Comm 2 Total Receive Errors (7CH) .......................................................................... 43

5.7.56 RXD CRC Errors Hi (7DH) .......................................................................................... 44

5.7.57 RXD CRC Errors Lo (Same as Hi) (7EH) ................................................................... 44

5.7.58 Comm 2 Overrun Errors (7FH) ................................................................................... 44

5.7.59 Comm 2 Parity Errors (80H) ....................................................................................... 44

5.7.60 Comm 2 Framing Errors (81H) ................................................................................... 44

5.7.61 Comm 2 Total UART Receive Errors (82H) ................................................................ 44

5.7.62 Not Used (83H) .......................................................................................................... 44

5.7.63 Clear Comm 2 UART Errors (84H) ............................................................................. 44

5.7.64 Clear Comm 2 Modbus Errors (85H) .......................................................................... 44

6.0EVENT LOGGING ................................................................................................................ 45

6.1.1 Faults .......................................................................................................................... 45

6.1.2 Warning ....................................................................................................................... 45

6.1.3 Alarm ........................................................................................................................... 45

6.1.4 Maintenance ................................................................................................................ 45

6.1.5 Setting Clock ............................................................................................................... 45

7.0MAINTENANCE ................................................................................................................... 48

7.1 General Maintenance ............................................................................................................... 48

7.2 Cleaning the Lenses/Light Rods .............................................................................................. 48

7.3 Sensitivity Check ...................................................................................................................... 49

7.3.1 Alarm Test ................................................................................................................... 49

7.3.2 TL105 Test Lamp ........................................................................................................ 50

7.3.3 TL105 Operating Instructions ...................................................................................... 50

7.3.4 TL105 Recharging Instructions ................................................................................... 50

7.4 Storage ..................................................................................................................................... 51

8.0TROUBLESHOOTING ......................................................................................................... 52

8.1 Troubleshooting ....................................................................................................................... 52

8.1.1 Introduction ................................................................................................................. 52

9.0CUSTOMER SUPPORT ....................................................................................................... 53

9.1 Other Sources of Help .............................................................................................................. 53

10.0 APPENDIX ................................................................................................................ 54

v

Page 6

Models FL3100H/3101H

Warranty ................................................................................................................................... 54

10.1

10.2 Principle of Operation ............................................................................................................... 54

10.2.1 UV Detector - FL3100H and FL3101H........................................................................ 54

10.2.2 UV/IR Flame Detector - FL3100H ............................................................................... 55

10.2.3 COPM Circuitry ........................................................................................................... 55

10.2.4 Alarm Test ................................................................................................................... 56

10.2.5 Two-color Visual Indicators ......................................................................................... 56

10.2.6 Three-color Visual Indicators ...................................................................................... 56

10.3 Specifications ........................................................................................................................... 57

10.3.1 System Specifications ................................................................................................. 57

10.3.2 Mechanical Specifications ........................................................................................... 58

10.3.3 Electrical Specifications .............................................................................................. 58

10.3.4 Environmental Specifications ...................................................................................... 59

10.4 Approvals ................................................................................................................................. 59

10.5 Accessories .............................................................................................................................. 59

10.5.1 Mounting Swivel/Union ............................................................................................... 59

10.5.2 Mounting Bracket ........................................................................................................ 59

10.6 Storage ..................................................................................................................................... 59

10.7 Final Assembly ......................................................................................................................... 60

vi

Page 7

Models FL3100H/3101H

Table of Figures

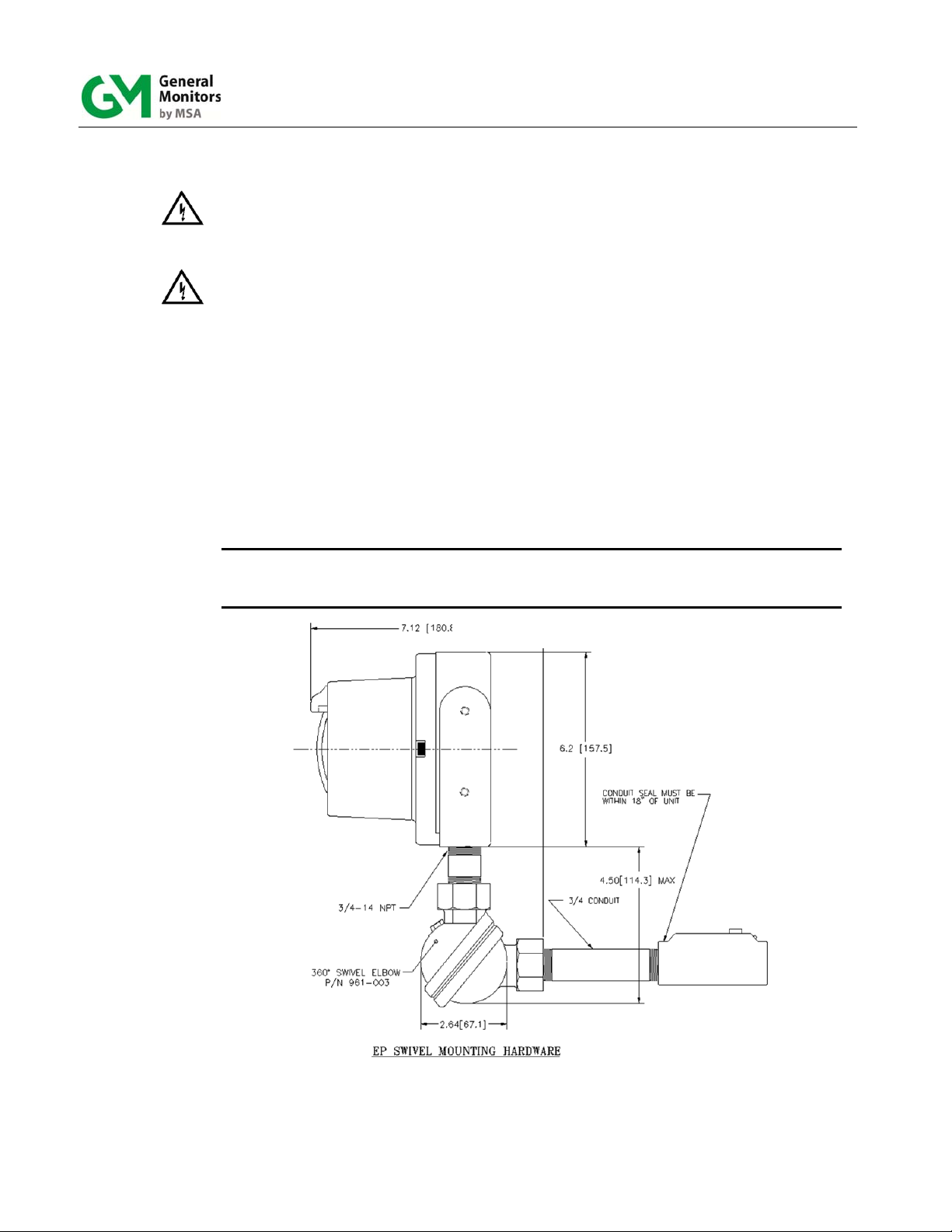

Figure 1: P/N 961-004 Union Swivel Mounting Hardware ................................................................................. 1

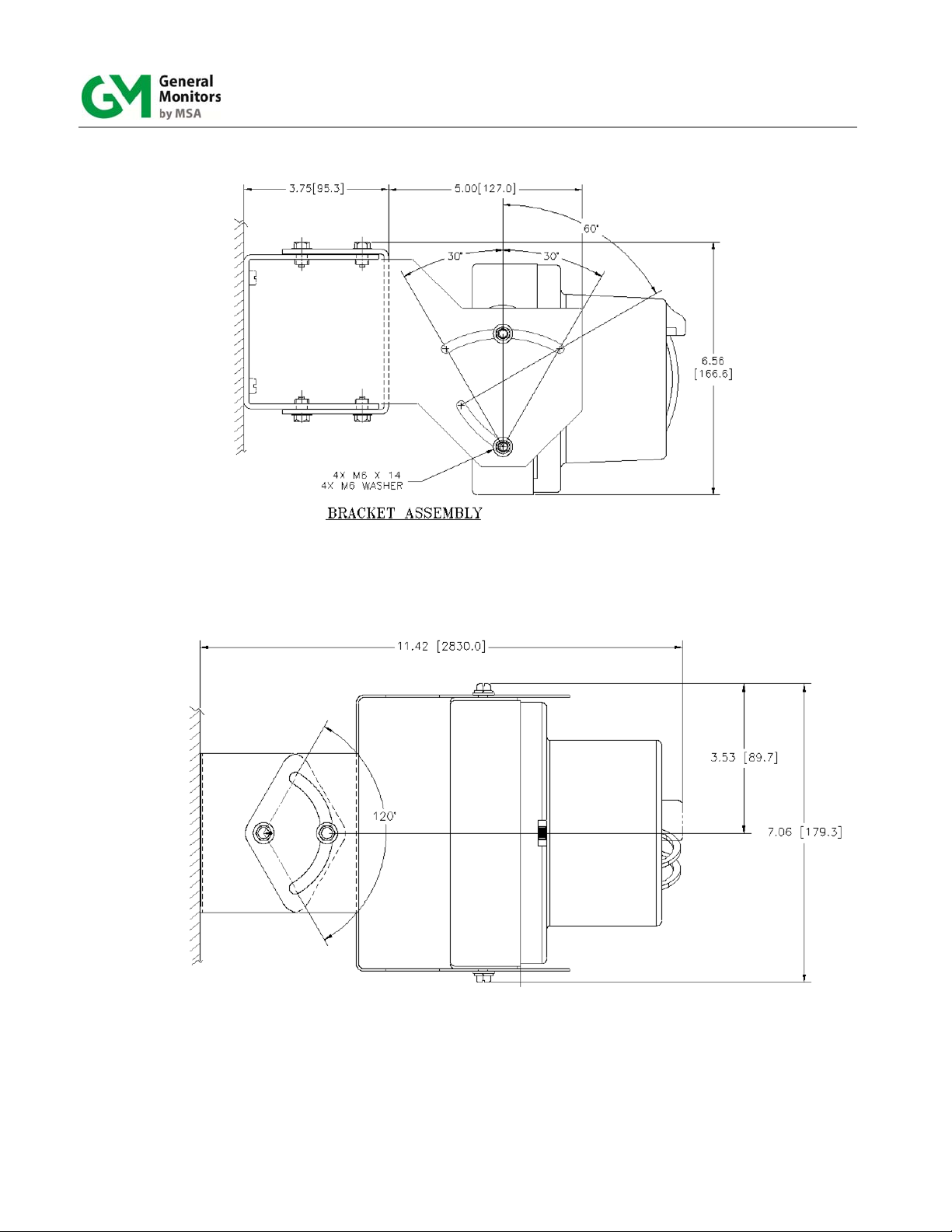

Figure 2: P/N 71172 Side View Bracket Assembly ............................................................................................ 2

Figure 3: P/N 71172 Top View Bracket Assembly ............................................................................................ 2

Figure 4: P/N 71172 Rear View Bracket Assembly ............................................................................................ 3

Figure 5: Field Terminations ............................................................................................................................... 3

Figure 6: Model FL3100H ..................................................................................................................................... 7

Figure 7: Model FL3101H ..................................................................................................................................... 7

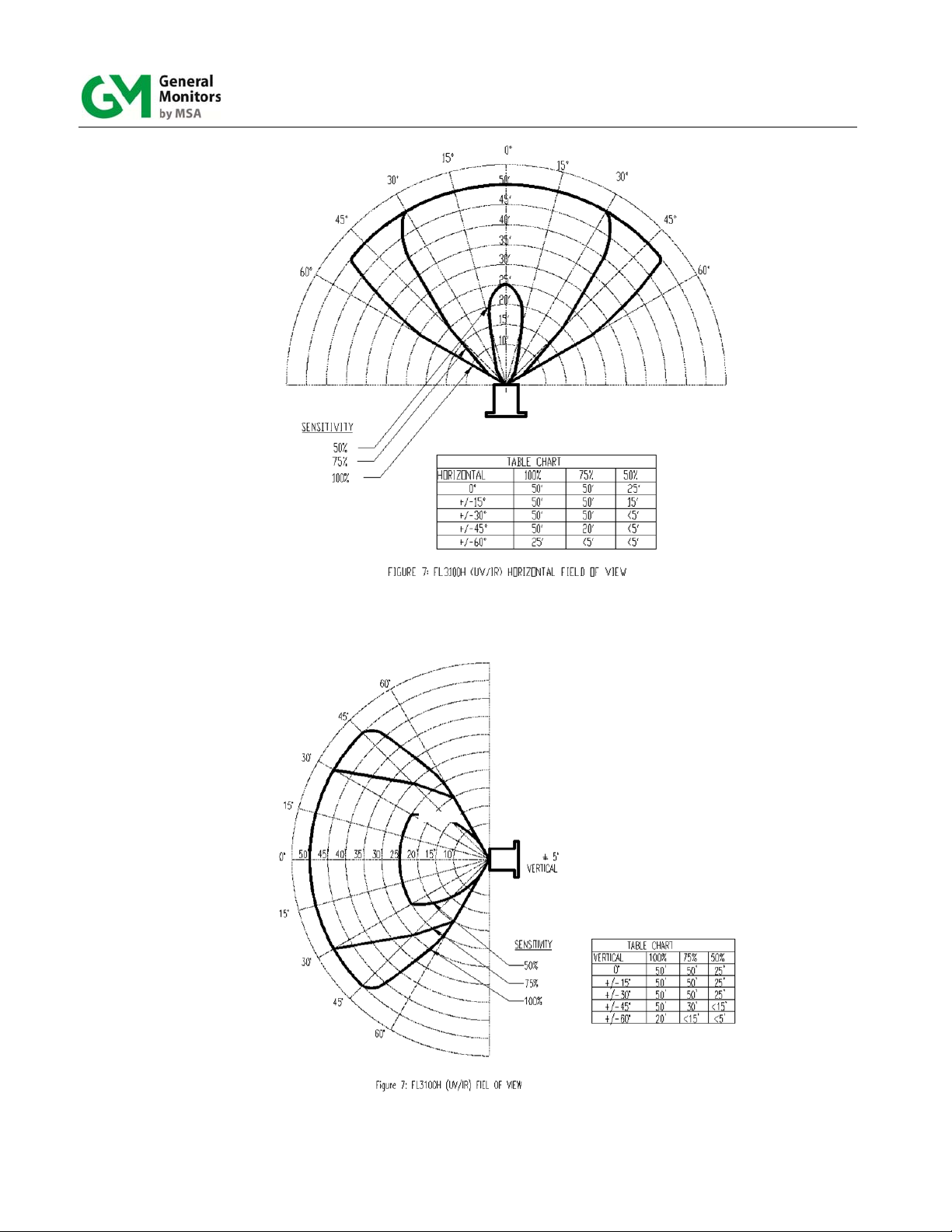

Figure 8: FL3100H (UV/IR) Field of View ............................................................................................................ 9

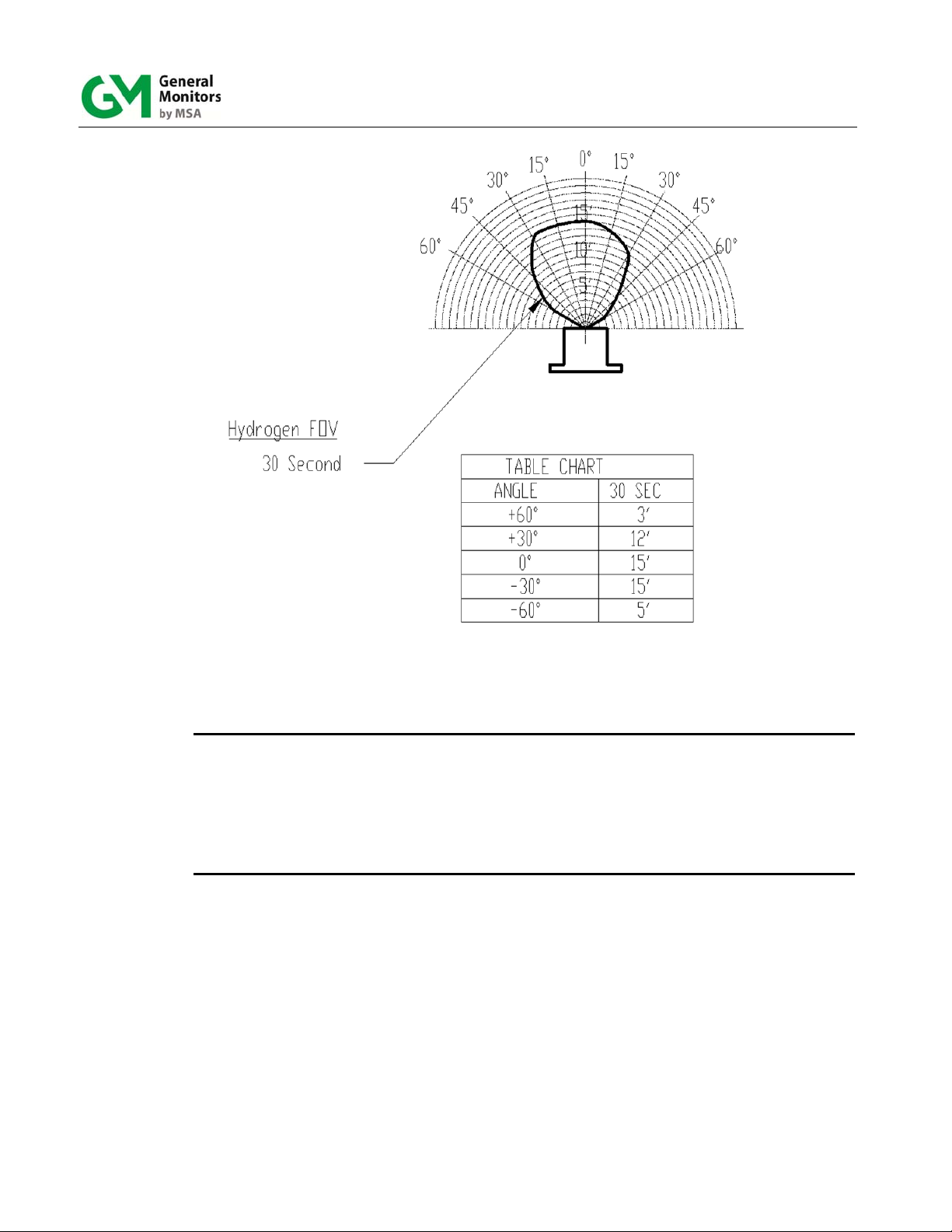

Figure 9: FL3100H (UV/IR) Hydrogen Flame Detector Field of View ............................................................. 10

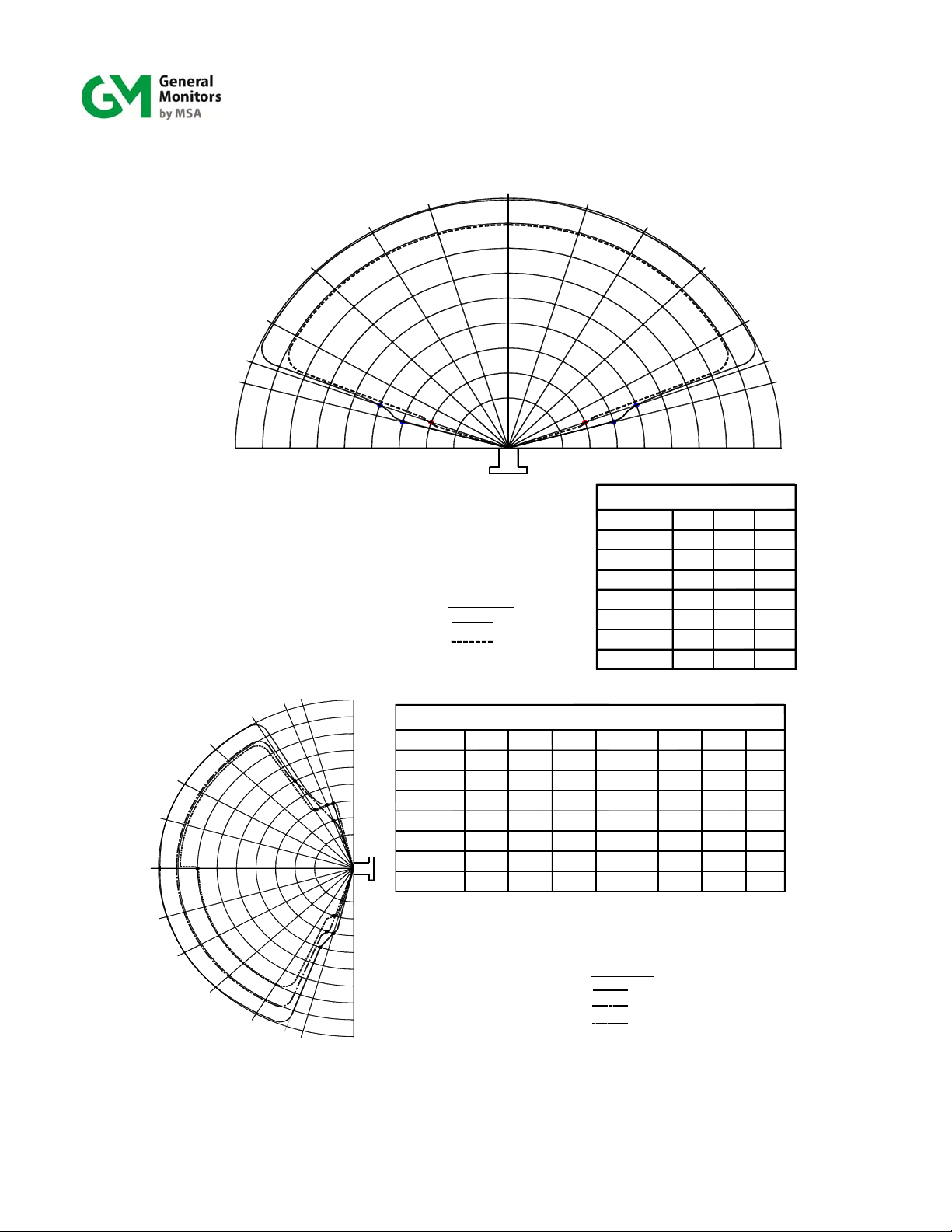

Figure 10: FL3101H (UV) Field of View ............................................................................................................. 11

Figure 11: P/N 961-004 Swivel Elbow Drawing ................................................................................................ 12

Figure 12: P/N 71072 Side View Mounting Bracket Drawing .......................................................................... 13

Figure 13: P/N 71072 Top View Mounting Bracket Drawing ........................................................................... 13

Figure 14: P/N 71072 Rear View Mounting Bracket Drawing ......................................................................... 14

Figure 15: FL3100H and FL3101H Outline Drawing ........................................................................................ 15

Figure 16: FL3100H and FL3101H Outline Drawing ........................................................................................ 15

Figure 17: FL3100H and FL3101H Field Terminations .................................................................................... 16

Figure 18: Detector Housing and Base ............................................................................................................ 17

Figure 19: Terminal Block Operation ................................................................................................................ 17

Figure 20: Protection Circuits for Relay Contacts .......................................................................................... 18

Figure 21: DIP switch Location ......................................................................................................................... 25

Figure 22: UV and IR Windows .......................................................................................................................... 49

Figure 23: Spectral Response of UV and IR Detectors ................................................................................... 55

Figure 24: P/N 71450 FL3100H (UV/IR), Final Assembly ................................................................................ 60

Figure 25: P/N 71451 FL3101H (UV), Final Assembly .................................................................................... 61

vii

Page 8

Models FL3100H/3101H

Table of Tables

Table 1: TB2 Alarm Relay Connections ........................................................................................................... 18

Table 2: TB2 Warning Relay Connections ....................................................................................................... 19

Table 3: Fault Relay Connections ..................................................................................................................... 19

Table 4: Alarm Reset Terminal Connections ................................................................................................... 20

Table 5: Maximum Cable Requirements .......................................................................................................... 21

Table 6: Power Connections ............................................................................................................................. 21

Table 7: Maximum Cable Lengths for +24 VDC Supply .................................................................................. 21

Table 8: Connections for the Modbus Interface .............................................................................................. 22

Table 9: Connections for the Second Modbus Interface ................................................................................ 22

Table 10: Chassis Ground Connection ............................................................................................................ 22

Table 11: DIP Switch Options ............................................................................................................................ 25

Table 12: Data Format ........................................................................................................................................ 26

Table 13: Modbus Query Messages .................................................................................................................. 26

Table 14: Modbus Read Response Messages ................................................................................................. 27

Table 15: Modbus Write Query Message.......................................................................................................... 27

Table 16: Modbus Write Response Message ................................................................................................... 28

Table 17: Exception responses ......................................................................................................................... 29

Table 18: Exception Code Field ........................................................................................................................ 29

Table 19: Operational Mode Commands .......................................................................................................... 33

Table 20: Fire Status Mode ................................................................................................................................ 34

Table 21: Status/Error ........................................................................................................................................ 34

Table 22: Model Type ......................................................................................................................................... 35

Table 23: EEPROM Override .............................................................................................................................. 36

Table 24: Setting Options .................................................................................................................................. 37

Table 25: Comm 1 Baud Rate ............................................................................................................................ 37

Table 26: Comm 1 Data Format ......................................................................................................................... 38

Table 27: Remote Reset ..................................................................................................................................... 38

Table 28: Remote Alarm Test ............................................................................................................................ 39

Table 29: Clear COPM Faults Function ............................................................................................................ 39

Table 30: Comm 2 Baud Rate ............................................................................................................................ 42

Table 31: Comm 2 Data Format ......................................................................................................................... 42

Table 32: Event Logging Registry Table ......................................................................................................... 47

Table 33: Troubleshooting Table ...................................................................................................................... 52

Table 34: Locations ............................................................................................................................................ 53

viii

Page 9

Models FL3100H/3101H

Quick Start Guide

Mount and Wire the Detector

Pay special attention to the conduit seal entry (Canadian Electrical Code Handbook Part 1,

Section 18-154). Also, lithium based grease is applied to the O-ring seal between the backplate and housing, as additional protection to avoid water ingression into the housing. Mount

detector using swivel mount or mounting bracket hardware.

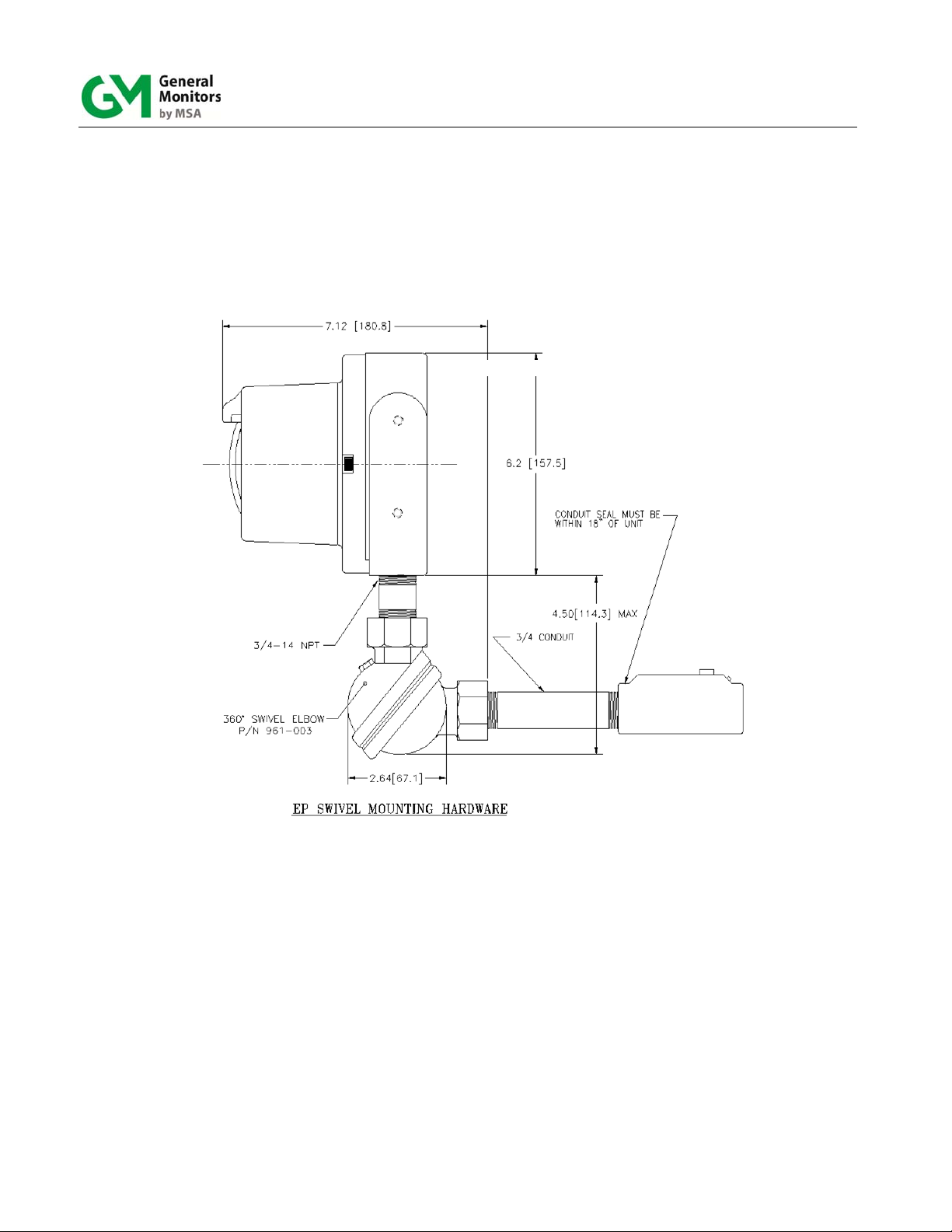

Figure 1: P/N 961-004 Union Swivel Mounting Hardware

1

Page 10

Models FL3100H/3101H

Figure 2: P/N 71172 Side View Bracket Assembly

Figure 3: P/N 71172 Top View Bracket Assembly

2

Page 11

Models FL3100H/3101H

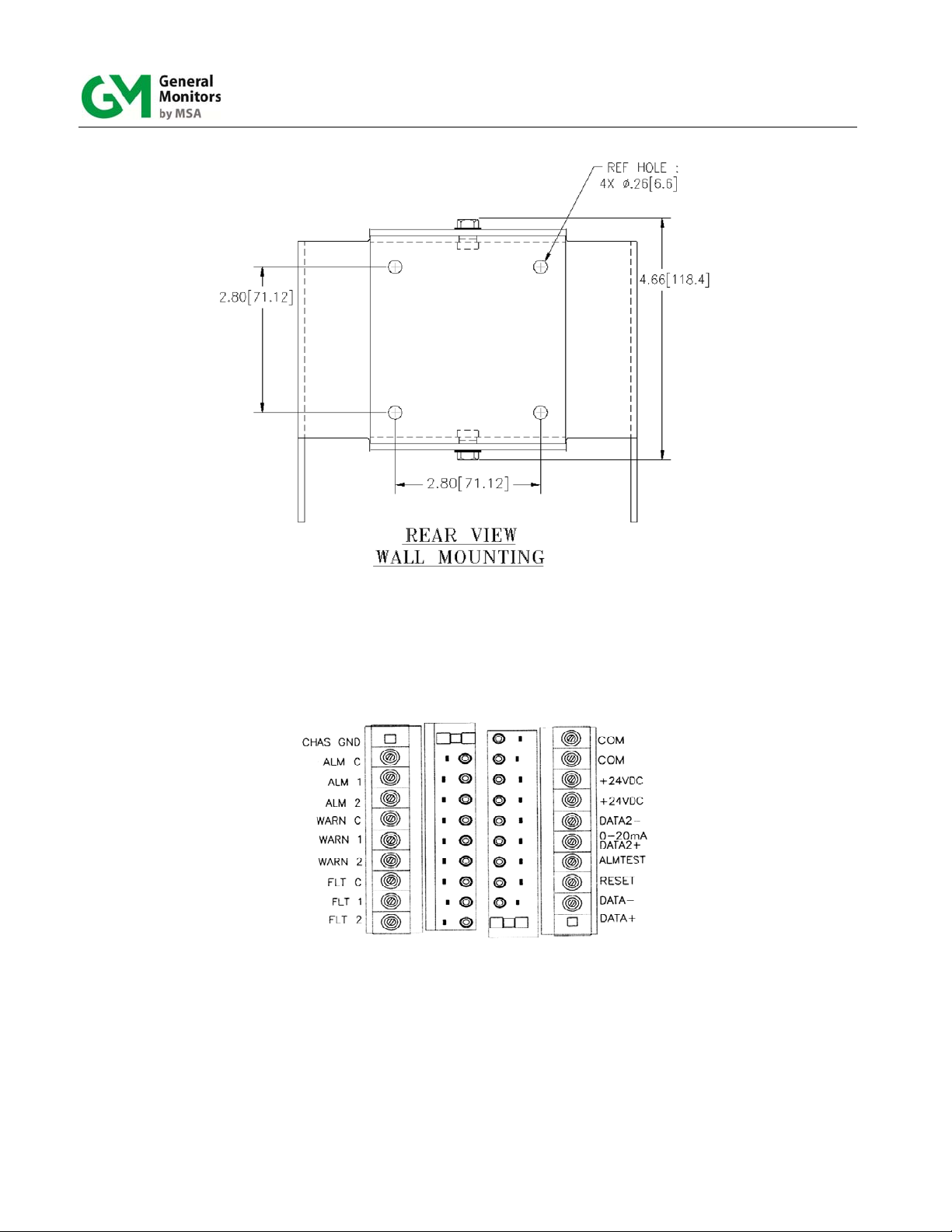

Figure 4: P/N 71172 Rear View Bracket Assembly

Term #

Terminal Block 2 Terminal Block 1

Term #

10

1

2

3

4

5

6

7

8

9

10

9

8

7

6

5

4

3

2

1

Figure 5: Field Terminations

3

Page 12

Models FL3100H/3101H

Apply Power to the Detector

Two light emitting diodes (LEDs) are visible through the UV window (the larger window on

UV/IR units). Immediately upon powering up the detector, the LEDs will start blinking alternately

- green and red in the two-color configuration and green, yellow, and red in the three-color

configuration. The flashing pattern lasts 10 seconds. Upon the detector entering the “Ready”

mode, the green LED will flash off 1 second, every 10 seconds. Section 10.2.6 (Three-color

Visual Indicators) describes the flashing scheme of the product configuration with three LEDs.

Testing the Detector Using the TL105

Test the integrity of your system by using the TL105 test lamp. The original configuration (i.e.

sensitivity and relay options) can be changed by using the “Switch Selectable Options” (Table

11) and then changing the dipswitch settings located on the bottom of the power board (SW1).

The instrument is now ready to operate. Please consult the manual for more information on the

instrument’s many features.

NOTE: If you have any problems in the set-up or testing of the detector, please refer to the

“Troubleshooting Section”, or call the factory direct.

Worldwide service is available by calling:

Lake Forest, California

(24 hr. service)

Houston, Texas

Ireland

Singapore

United Arab Emirates

United Kingdom

Toll Free: +1-800-446-4872

Phone: +1-949-581-4464

Fax: +1-949-581-1151

Phone: +1-281-855-6000

Fax: +1-281-855-3290

Phone: +353-91-751175

Fax: +353-91-751317

Phone: +65-6748-3488

Fax: +65-6748-1911

Phone: +971-4-294-3640

Phone: +44-1625-619583

Fax: +44-1625-619098

4

Page 13

Models FL3100H/3101H

1.0 Introduction

1.1 Protection for Life

General Monitors’ mission is to benefit society by providing solutions through industry leading

safety products, services, and systems that save lives and protect capital resources from the

dangers of hazardous flames, gases, and vapors.

This manual provides instruction for installing and operating General Monitors’ Models

FL3100H and FL3101H for UV/IR and UV Only Flame Detection. While the FL3100H/3101H is

easy to install and operate, this manual should be read in full and the information contained

herein understood before attempting to place the system in service.

The safety products you have purchased should be handled carefully and installed, and

maintained in accordance with the respective product instruction manual. Remember these

products are for your safety.

1.2 Special Warnings

Through engineering design, testing, manufacturing techniques, and rigid quality control,

General Monitors supplies the finest flame detection systems available. The user must

recognize his responsibility for maintaining the flame detection system in operational condition.

Installation and maintenance must be carried out by suitably skilled and competent personnel

only.

The FL3100H UV/IR and FL3101H UV only flame detectors contain components, which can be

damaged by static electricity. Special care must be taken when wiring the system, to ensure

that only the connection points are touched.

Special Conditions For Safe Use

This equipment uses an external non-metallic coating and may therefore generate an

ignition-capable level of electrostatic charge under certain extreme conditions. The

user should ensure that the equipment is not installed in a location where it may be

subjected to external conditions (such as high-pressure steam) which might cause a

build-up of electrostatic charge on non-conducting surfaces. Additionally, cleaning of

the equipment should be done only with a damp cloth.

In accordance with EN 60079-1:2014/ IEC 60079-1:Ed 7 Clause 11.3, the 4 x M6

housing retaining bolts are Class A2-70 304 Stainless Steel.

In accordance with EN 60079-1:2014/ IEC 60079-1:Ed 7 Clause 5.1, the flameproof

joints are not intended to be repaired.

1.3 System Integrity Verification

Commissioning Safety Systems

Before power up, verify wiring, terminal connections and stability of mounting for all integral

safety equipment including, but not limited to:

Power supplies

Control modules

Field detection devices

5

Page 14

Models FL3100H/3101H

Signaling / output devices

Accessories connected to field and signaling devices

After the initial application of power (and any factory specified warm-up period) to the safety

system, verify that all signal outputs, to and from devices and modules, are within the

manufacturers’ specifications. Initial testing should be performed per the manufacturers’

recommendations and instructions.

Proper system operation should be verified by performing a full, functional test of all component

devices of the safety system, ensuring that the proper levels of alarming occur.

Fault/Malfunction circuit operation should be verified.

Periodic Testing of Field Devices

Periodic testing should be performed per the manufacturers’ recommendations and

instructions. Testing procedures should include, but not be limited to:

Verify integrity of all optical surfaces and devices

For flame detectors, use the appropriate test lamp

When testing produces results outside of the manufacturers’ specifications, replacement of the

suspect device(s) should be performed as necessary.

Periodic System Verification

The following system verifications should be performed at least annually:

Verify wiring, terminal connections and stability of mounting for all integral safety equipment

including, but not limited to:

Power supplies

Control modules

Field detection devices

Signaling / output devices

Accessories connected to field and signaling devices

Proper system operation should be verified by performing a full, functional test of all component

devices of the detection system, ensuring that the proper levels of alarming occur.

Fault/Malfunction circuit operation should be verified.

Maintenance intervals should be independently established through a documented procedure,

including a maintenance log maintained by plant personnel or third party testing services.

6

Page 15

Models FL3100H/3101H

2.0 Product Description

2.1 General Description

Fire is usually manifested in heat (IR), smoke, light (visible), and flame (UV). Flame is the

gaseous region of a fire where vigorous combustion chain reactions take place. These

reactions emit radiation covering the Infrared, Ultraviolet and the Visible Spectral Regions.

The General Monitors’ Model FL3100H is an ultraviolet/infrared (UV/IR) flame detector (Figure

6). It detects the ultraviolet and infrared spectral regions of flame to produce a system which is

highly immune to false alarms caused by lightning, arc-welding, hot objects, and other sources

of radiation. The Model FL3101H is an ultraviolet (UV) flame detector (Figure 7). It only

responds to UV and has been optimized for speed of response.

Both units may be used with the General Monitors TA402A trip amplifier, FL802 controller, or

with other equipment, which accepts the 4 to 20 mA output. They may also be interfaced

directly with alarm/suppression devices or with switched input modules using integral relays. If

HART is used with the above controllers, you must use the special 1.25 mA to 20 mA mode.

NOTE: The Model FL802 is not CE Marked and, therefore, cannot be supplied to the EU.

The Models FL3100H and FL3101H features include:

Compact unitized design

Continuous optical path monitoring (COPM)

4-20 mA, alarm relays, and Modbus RTU RS-485 standard (Dual Modbus optional)

(HART optional)

Wide field of view

High false alarm immunity and visual indicators

Figure 6: Model FL3100H

7

Figure 7: Model FL3101H

Page 16

Models FL3100H/3101H

3.0 Installation

WARNING: Suitably skilled and competent personnel must carry out installation and

maintenance.

3.1 Tools Required

“T” Allen head wrench to remove detector head from detector base (included with flame

detector).

Flat head screwdriver maximum 3/16 in (5 mm) width for terminal block connections.

Adjustable wrench for conduit, or cable gland connections.

3.2 Choosing Product Locations

Several variables are involved in selecting the locations to install detectors to ensure proper

flame detection. There are no hard and fast rules defining the optimum location. Following are

some general suggestions that should be considered in regard to particular conditions at the

site where the unit(s) are being installed:

3.2.1 Detector Field of View

The FL3100H and FL3101H flame detectors have a maximum cone of vision of 120 and 140

maximum respectively. This cone has its vertex at the center of the detector (Figure 8 and

Figure 10).

3.2.2 Optical Sensitivity Range

The distance at which the detector will respond to a flame is a function of the intensity of that

flame. The maximum distance is 50ft (15.2m) for a heptane fire with a surface area of 1 sq. ft.

(0.093m2).

3.2.3 Environmental Factors

Mounting should be as free from shock and vibration as possible and convenient for visual

inspection and cleaning.

Detectors mounted in dirty atmospheric conditions will require frequent inspection, cleaning,

and sensitivity checking. Make sure the field-of-view of the detector is not obstructed by the

cover or nearby objects.

Observe the ambient temperature range for the specific model (Section 10.3.4). For outdoor

installations or other areas exposed to intense, direct solar radiation, the detector may reach

temperatures well above specifications. For these installations, a shade or cover may be

required to keep the detector temperature within specifications.

Avoid conditions that would allow ice build-up on the optical detector windows. Complete icing

over of the detector window(s) can result in fault conditions. Mount away from sources of

electrical noise where possible. A constant UV source detected by the unit will cause the

detector to go into FAULT after 9 – 10 minutes of exposure. The source must be removed or

the detector must be repositioned. (UV detectors can pick-up arc welding up to 2–3 miles

away). Users should be aware that any UV detector may be triggered by other sources of EMI,

for instance X-rays, sunlight, reflected sunlight, Gamma rays, lightning, arc welding, industrial

lighting, fluorescent lighting, etc., and due regard should be paid to the possible presence of

such radiation.

8

Page 17

Models FL3100H/3101H

Figure 8: FL3100H (UV/IR) Field of View

9

Page 18

Models FL3100H/3101H

Figure 9: FL3100H (UV/IR) Hydrogen Flame Detector Field of View

NOTE: Response Times and Field of View data have been derived by testing the Model

FL3100H flame detector with a flame from a round 6 inch diameter burner. The

hydrogen gas was supplied from a high pressure tank via a reducing regulator, set to

12 psi. This produces a flame 6 inches in height. The FL3100H-Hydrogen detector can

be tested by the TL105 as far as 40 feet. These are typical values and different results

may occur depending on the variation of each fire.

NOTE: The FL3100H-Hydrogen detector is not FM approved.

10

Page 19

Models FL3100H/3101H

0°

75°

70°

60°

45°

30°

15°

50'

45'

40'

35'

30'

25'

20'

15'

10'

15°

30°

45°

60°

70°

75°

+15°

0°

-15°

+30°

'

0

5

(±5°)

HORIZONTAL

SENSITIVIT Y

100%

75%, 50%

+75°

+70°

+60°

+45°

'

'

'

'

'

'

5

0

0

5

3

3

4

4

'

5

2

'

0

5

0

2

1

1

VERTICAL

0°

- 15°

- 30°

- 45°

- 60°

- 70°

- 75°

100%

50'

50'

50'

50'

50'

25'

<20'

TABLE CHART

50%

75%

40'

45'

40'

45'

40'

45'

45'

40'

45'

<15'

<20'

<15'

<20'

TABLE CHART

0°

100%

50'

50'

50'

50'

50'

25'

20'

100%

50'

50'

50'

50' 30'

<20' <15'

HORIZONTAL

± 15°

± 30°

± 45°

± 60°

± 70°

± 75°

VERTICAL

0°

+ 15°

+ 30°

+ 45°

+ 60°

+ 70°

+ 75°

75%

45'

45'

45'

45'

45'

<15'

75% 50%

45'

45'

45'

45'50'40'

<15'20'

<20'

<20'

50%

45'

45'

45'

45'

45'

<15'

<15'<15'

45'

45'

45'

45'

20'

-30°

-45°

-60°

-70°

(±5°)

VERTICAL

-75°

SENSITIVITY

100%

75%

50%

Figure 10: FL3101H (UV) Field of View

11

Page 20

Models FL3100H/3101H

3.3 Mounting and Wiring

WARNING: The conduit entries should be sealed per the Canadian Electrical Code

Handbook (Part 1, Section 18-154) or NEC 500-3d. An additional benefit of

conduit seals is the prevention of water entering the housing through the

conduit entry.

WARNING: Unused cable entry holes must be sealed with an approved stopping plug.

Red caps supplied by GM are for dust protection only and must not be left

on the unit when installed.

The FL3100H/FL3101H flame detectors should be mounted pointing downward so that

dust/moisture will not accumulate on the optical window(s). The detector(s) should be

mounted in locations which will inhibit people or objects from obscuring the detector’s

cone of vision.

Detectors should be mounted such that the conduit or cable gland entries are

pointed downward. See above warning for conduit entries. For cable glands and

stopping plugs, the threads should be sealed with Castrol EP and boots fitted over

the cable gland to prevent water ingress at the cable-to-gland junction. Mounting

hardware should be used as shown in Figure 12, and Figure 13.The overall

dimensions of the detector and mounting hardware are shown in Figure 15 and

Figure 16.

NOTE: General Monitors does not recommend the use of cable shoes or crimps on any

junction box or housing wiring terminals. Poor crimping can cause a bad

connection when the unit experiences temperature variations.

Figure 11: P/N 961-004 Swivel Elbow Drawing

12

Page 21

Models FL3100H/3101H

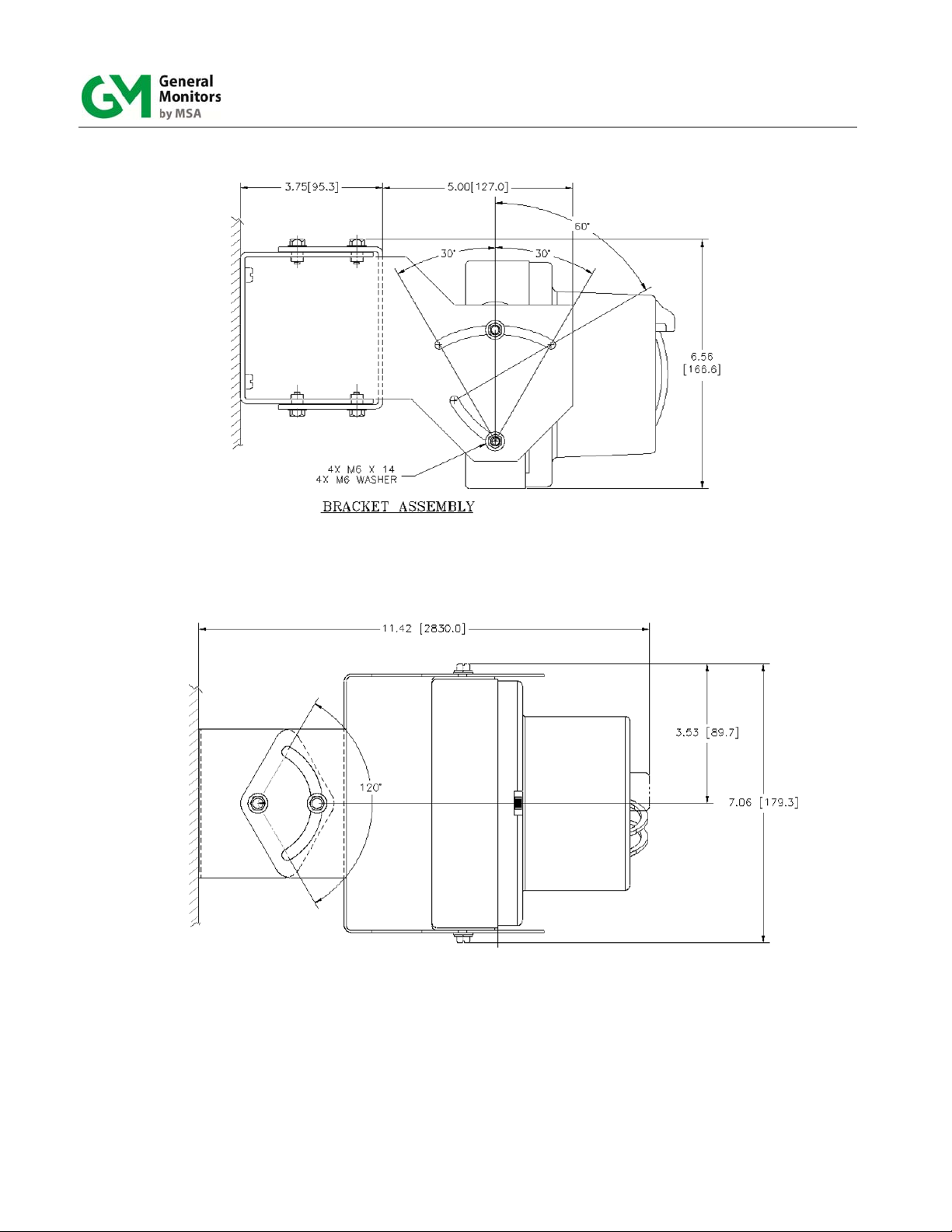

Figure 12: P/N 71072 Side View Mounting Bracket Drawing

Figure 13: P/N 71072 Top View Mounting Bracket Drawing

13

Page 22

Models FL3100H/3101H

Figure 14: P/N 71072 Rear View Mounting Bracket Drawing

14

Page 23

Models FL3100H/3101H

Figure 15: FL3100H and FL3101H Outline Drawing

[139.7]

5.0[127.0]

6.2[157.5]

.75[19.1]

2X 3/4 NPT ENTRY

5.5

1.50[38.1]

4X M6 X 1

2.94[74.7]

6.2[157.5]

1.63[41.4]

.75[19.1]

1.67[42.4]

Figure 16: FL3100H and FL3101H Outline Drawing

15

Page 24

Models FL3100H/3101H

Figure 17: FL3100H and FL3101H Field Terminations

16

Page 25

Models FL3100H/3101H

Figure 18: Detector Housing and Base

Term #

10

Terminal Block 2 Terminal Block 1

1

2

3

4

5

6

7

8

9

Term #

10

9

8

7

6

5

4

3

2

1

Figure 19: Terminal Block Operation

The optional HART signal will be on pin TB1- 5

17

Page 26

3.3.1 Terminal Connections

Models FL3100H/3101H

All wire connections are made through the base entries to the terminal block (Figure 19). The

terminal block accepts 14 AWG to 22 AWG (2.1 to 0.3 mm

2

) stranded or solid core wire. Each

wire should be stripped to .25 in (.64 cm). To connect the wire to the terminal block, insert the

conductor into the connection space as shown in Figure 19 and tighten the corresponding

screw terminal. There are twenty terminal connections. The following pages contain

descriptions and specifications for each connection.

WARNING: Relay contacts must be protected against transient and over-voltage conditions

(Figure 20).

H

H

Figure 20: Protection Circuits for Relay Contacts

3.3.2 Terminal Block TB2 – Alarm Relay Connections

TB2

Position

2 C Common Common

3 1 Normally Closed Normally Open

4 2 Normally Open Normally Closed

These connections are for the SPDT ALARM relay. The ALARM output is time delayed for 2, 4,

8 or 10 seconds. This time delay can be set by Modbus, HART, or by Dipswitch. The ALARM

output can be normally energized or normally de-energized, latching or non-latching, and these

options are also set via can be set by Modbus, HART, or by Dipswitch (Section 4.4). For all

relay connections see Figure 20.

North American Approved Applications: The ALARM relay contact ratings are 8A @ 250 VAC

and 8A @ 30 VDC resistive max.

European Union (EU) Approved Applications: The ALARM relay contact ratings are 8A, 30 V

RMS/42.4 V peak or 8A @ 30 VDC resistive max.

Alarm

Relays

Relay Contact

(De-Energized)

Table 1: TB2 Alarm Relay Connections

H

H

Relay Contact

(Energized)

18

Page 27

Models FL3100H/3101H

3.3.3 Terminal Block TB-2 Warning Relay Connections

TB2

Position

5 C Common Common

6 1 Normally Closed Normally Open

7 2 Normally Open Normally Closed

These connections are for the SPDT WARN relay. The WARN output is immediate on the

FL3100H/FL3101H. The WARN output can be normally energized or normally de-energized,

latching or non-latching, and these options are also set via Modbus, HART, or by Dipswitch

(Section 4.4).

The WARN relay contact ratings are 8A @ 250VAC and 8A @ 24VDC.

CAUTION: Inductive loads (bells, buzzers, relays, etc.) on dry relay contacts must be clamped

Warn Relays

Table 2: TB2 Warning Relay Connections

down as shown in Figure 20. Unclamped inductive loads can generate voltage

spikes in excess of 1000 Volts. Spikes of this magnitude may cause false alarms

and contact damage.

Relay Contacts

(De-Energized)

Relay Contacts

(Energized)

North American Approved Applications: The WARN relay contact ratings are 8A @ 250 VAC

and 8A @ 30 VDC resistive max.

European Union (EU) Approved Applications: The WARN relay contact ratings are 8A, 30 V

RMS/42.4 V peak or 8A @ 30 VDC resistive max.

3.3.4 Fault Relay

These connections are for the SPDT FAULT relay. The FAULT output configuration is normally

energized and non-latching. This is the standard configuration and it cannot be changed. The

FAULT circuit will be activated during the time-out function, a low power or loss of power

condition, and during a failed COPM check. During these conditions the FAULT relays will deenergize and the analog output signal will drop to 0 mA (2 mA for COPM faults) for the duration

of the FAULT.

TB2

Position

8 C C C

9 1 Normally Closed Normally Open

10 2 Normally Open Normally Closed

North American Approved Applications: The FAULT relay contact ratings are 8A @ 250 VAC

and 8A @ 30 VDC.

European Union (EU) Approved Applications: The FAULT relay contact ratings are 8A, 30 V

RMS/42.4 V peak or 8A @ 30 VDC resistive max.

Fault

Relays

Relay Contacts

(De-Energized)

Table 3: Fault Relay Connections

Relay Contacts

(Energized)

19

Page 28

Models FL3100H/3101H

3.3.5 Alarm Reset Terminal

The RESET, when activated, returns a latched ALARM and/or WARN output that is no longer

valid, to its original state. For this RESET function, place one contact of a normally open

momentary switch to TB1 Terminal 3 and the other contact to DC COM (the detector’s

common). To activate, just press and release the switch.

TB1

Position

3 RESET

4 TEST

5 0-20 mA

Table 4: Alarm Reset Terminal Connections

By connecting one contact of a normally open, momentary switch, to TB1 Terminal 4 and the

other contact to TB1 Terminals 9 and 10 (DC COM), the user can test the alarm outputs of the

flame detector by activating this switch for two to ten seconds depending on the alarm time

delay setting. The Alarm Test will activate the WARN and ALARM relay outputs as well as the

appropriate analog output. The flame detector will remain in this state until the switch is

released. Note: This function is also available via Modbus and HART.

NOTE: The latching WARN and/or ALARM will have to be RESET manually. The Alarm Test

feature cannot be daisy chained between two or more FL3100H/FL3101H flame

detectors.

Relays

3.3.6 Analog Output

The 0 to 20 mA output is a current signal that corresponds to the following signals:

Condition Current Modbus HART (Normal) HART (Special)

START UP:

0 to 0.2 mA 3.5 ± 0.1 mA 1.25 ± 0.1 mA

FAULT:

COPM Fault:

Ready:

IR (FL3100H only):

UV (FL3100H only):

WARN:

ALARM:

When HART is selected, the output current changes to comply with the HART Foundation

requirements. The HART Foundation does not specify current below 3.5 mA. In normal HART

mode, the actual current does not go below 3.5 mA. Modbus reports the analog output as if

HART was not there, meaning it reports 2.0 mA for COPM. This allows users to use a constant

Modbus program. The digital HART reports the actual current. When the alarm or warning

20

0 to 0.2 mA 3.5 ± 0.1 mA 1.25 ± 0.1 mA

2.0 ± 0.1 mA 3.5 ± 0.1 mA 2.0 ± 0.1 mA

4.05 ± 0.05 mA 4.05 ± 0.05 mA 4.05 ± 0.05 mA

8.0 ± 0.1 mA 8.0 ± 0.1 mA 8.0 ± 0.1 mA

12.0 ± 0.1 mA 12.0 ± 0.1 mA 12.0 ± 0.1 mA

16.0 ± 0.1 mA 16.0 ± 0.1 mA 16.0 ± 0.1 mA

20.0 ± 0.1 mA 20.0 ± 0.1 mA 20.0 ± 0.1 mA

Page 29

Models FL3100H/3101H

relays are latched, the highest output current is also latched. The output current will return to

4.0 mA after the relay reset is activated via Modbus, HART, or remote switch.

The HART special mode allows the current to go down to 1.25 mA. The HART will still function.

This mode must be used with GMI’s products that rely on 2 mA output for COPM and 1.5 for

offline and zero for fault (TA402A).

NOTE: The maximum analog output load is 600 ohms, including wiring.

3.3.7 Cable Requirements

For interfacing with 250 ohm input impedance devices, the following maximum cable lengths

apply (maximum 50-ohm loop):

Cable

AWG

Run

Feet

Cable

2

mm

Run

Meters

14 9000 2.50 2750

16

5800

1.50 1770

18 3800 1.00 1160

20 2400 0.75 730

22 1700 0.50 520

Table 5: Maximum Cable Requirements

3.3.8 Power

The supply voltage range is 20 to 36 VDC at the detector (low voltage is detected at

approximately 18.5 VDC).

TB1

Position

7 +24 VDC

8 +24 VDC

9 COM

10 COM

Table 6: Power Connections

The following maximum cable lengths apply for a +24 VDC supply (maximum 20 ohm loop):

Cable

AWG

Run

Meters

14 1370 2.5 4500

16 715 1.5 2340

18 470 1.00 1540

20 300 0.75 970

22 205 0.50 670

Connection

Cable

2

mm

Run

Feet

Table 7: Maximum Cable Lengths for +24 VDC Supply

21

Page 30

Models FL3100H/3101H

3.3.9 Modbus Interface

The Modbus interface is used to either query the unit’s status or to configure the unit. See

Section 5.0 for detailed information on Modbus RTU Protocol.

TB1

Position

1 DATA +

2 DATA -

Table 8: Connections for the Modbus Interface

NOTE: If Dual Modbus output is ordered, then the 0-20 mA and HART output is not available

and the wiring terminals for the second Modbus channels are as follows:

TB1

Position

5 DATA2 +

6 DATA2 -

Table 9: Connections for the Second Modbus Interface

Connection

Connection

3.3.10 Chassis Ground

This connection is available for use in wiring that requires a connection to chassis ground. It is

recommended the chassis be grounded at all times.

TB2

Position

1 CHAS GND

Connection

Table 10: Chassis Ground Connection

3.3.11 Connection to Fire Cards/Panels

For detectors wired together for monitoring via standard fire cards, GM will factory-fit EOL and

alarm resistors. If this special option is required, please specify at time of order and provide the

following information:

Specify one or two resistors (i.e. alarm only, or alarm resistor and EOL).

Specify value of resistors.

Where detectors are used in conjunction with a GM Model IN042 card, values would be 470ohm alarm resistor and 5.6K EOL. The EOL resistors are onboard the IN042, selectable by

DIP-switches.

NOTE: Contact General Monitors or an authorized representative for further details.

European Union (EU) Approved Applications: Interconnecting cables must have an overall

screen or screen and armor. Cables BS5308 Part 2, Type 2, or equivalents are suitable. Note

that the terms ‘screen’ and ‘shield’ are equivalent for the purpose of this manual. The cable

armor must be terminated in a suitable cable gland at the detector to ensure a positive

electrical connection.

22

Page 31

Models FL3100H/3101H

3.3.12 Cable Termination in the Non-Hazardous Area

The cable armor must be connected to safety earth in the safe area.

The cable screen (drain wire) must be connected to an instrument earth in the safe

area.

The power supply OV return must be connected to an instrument earth in the safe

area.

The interconnecting cables should be segregated from power and other noisy cables.

Avoid proximity to cables associated with radio transmitters, welders, switch mode

power supplies, inverters, battery chargers, ignition systems, generators, switch gear,

arc lights and other high frequency or high power switching process equipment. In

general, maintain separation of at least 1m between instrument and other cables.

Greater separations are required where long parallel cable runs are unavoidable. Avoid

running instrument cable trenches close to lightning conductor earthing pits.

Complete all cable insulation testing before connecting the cable at either end.

WARNING: Under no circumstances should equipment be connected or disconnected when

under power. This is contrary to hazardous area regulations and may lead to

serious damage to the equipment. Equipment damaged in this manner is not

covered under warranty.

23

Page 32

Models FL3100H/3101H

4.0 Operation

4.1 Checklist

Prior to starting the system verify the following:

Inhibit any external devices, such as automatic extinguishing fire suppression systems

or others, which you do not want activated.

Verify that the DIP-switch settings are set for the desired configuration.

Verify that the unit is properly mounted. Ensure the conduit/cable gland entries are

pointed downward.

Verify the field of view for each detector covers the area intended for flame detection.

Verify that the wiring is correct.

Verify that the power supply is connected properly. The detector is powered by +24

VDC (20 to 36 VDC voltage range). The detector will output a low voltage fault at 18.5

VDC or below.

4.2 Start Up

To start up the system, apply power to the flame detectors. Each detector will begin its self-test

start up sequence. For the first 10 seconds, the unit will output 0 mA, the fault relay stays deenergized, and the green and red LED will flash alternately. Each is on for about 300 ms. After

this 10-second period, the unit will output 4 mA, the fault relay will energize, the red LED will

turn off, and the green LED will turn on constant and briefly flash off every 5 seconds. The dual

Modbus version does not have a current output.

NOTE: If you ordered unit with three-color LED option, please refer to section 10.2.6 “Three-

color Visual Indicators” for the LED status.

4.3 System Test

To test the system, use the General Monitors Test Lamp Model TL105 (Section 7.3.2).

4.4 User Selectable Options/Factory Defaults

All settings on the Models FL3100H and FL3101H are done via a DIP switch on the

Power/Relay Board or via Modbus or HART which will override the dipswitch settings. To set

these options, remove the detector head from the base assembly and locate the DIP switch

(Figure 21). On the DIP switch, ON/CLOSED means the switch is pushed in on the side labeled

ON or CLOSED (opposite the OPEN side). OFF/OPEN means the switch is pushed in on the

side with the number corresponding to the switch position or the side labeled OPEN. Refer to

Table 11 for the switch assignments. The settings for the WARN and ALARM outputs have

been covered in Section 3.3. The time delay specifies the amount of time a WARN condition

persists before an ALARM condition will occur. If the HART option is ordered the current you

desire must be selected (1.25 mA or 3.5 mA). Factory default is 3.5 mA to 20 mA. HART

current is only HART or Modbus selectable, not DIP switch selectable.

24

Page 33

Models FL3100H/3101H

Option Off On

1. 100% Sens – 1 ft2@ 50 ft 1, 2

2. 75% Sens – 1 ft2 @ 35 ft 2 1

3. 50% Sens – 1 ft2 @ 25 ft 1 2

4. 2 Second ALARM Time Delay 3 4

5. 4 Second ALARM Time Delay 3, 4

6. 8 Second ALARM Time Delay 4 3

7. 10 Second ALARM Time Delay 3, 4

8. ALARM non-latching 5

9. ALARM latching 5

10. WARN non-latching 6

11. WARN latching 6

12. ALARM normally energized 7

13. ALARM normally de-energized 7

14. WARN normally energized 8

15. WARN normally de-energized 8

Table 11: DIP Switch Options

Figure 21: DIP switch Location

25

Page 34

Models FL3100H/3101H

5.0 Modbus Interface

Standard FL3100H or FL3101H flame detectors include a single Modbus that is referenced as

Comm 1. A dual Modbus feature is optional, which includes two independent communications

channels referenced as Comm 1 and Comm 2.

NOTE: If the dual Comm option is ordered, the analog output and HART will not be available.

5.1 Baud Rate

The Baud Rate is a selectable setting via the Modbus communications interface. The

selectable baud rates are 19.2K, 9600, 4800, or 2400 bits per second.

5.2 Data Format

The Data Format is a selectable setting via the Modbus communications interface. The

selectable data formats are as follows:

Data Bits Parity Stop Bit Format

8 None 1 8-N-1

8 Even 1 8-E-1

8 Odd 1 8-O-1

8 None 2 8-N-2

Table 12: Data Format

5.3 Modbus Read Status Protocol (Query/Response)

5.3.1 Modbus Read Query Message

Byte Modbus Range Referenced to FL3100H / FL3101H

1st Slave

Address

2nd Function

Code

3rd Starting

Address Hi**

4th Starting

Address Lo**

5th No. of

Registers Hi

6th No. of

Registers Lo

7th CRC Lo 00-FF (Hex) CRC Lo Byte

8th CRC Hi 00-FF (Hex) CRC Hi Byte

*: Address 0 is reserved for broadcast mode and will not be supported at this time.

NOTE

1-247 * FL3100H / FL3101H ID (Address)

(X = 0 or 1 Model Type)

03 Read Holding Registers

00 Not Used by FL3100H / FL3101H

00-FF (Hex) FL3100H / FL3101H Commands

00 Not Used by FL3100H / FL3101H

01 No. of 16 Bit Registers

Table 13: Modbus Query Messages

NOTE**: Start Address can be a maximum of 247 Address Locations (0000-0x00F7)

26

Page 35

Models FL3100H/3101H

5.3.2 Modbus Read Response Message

Byte Modbus Range

1st Slave

Address

2nd Function

Code

3rd Byte Count 02 – FF (Hex) No. of Data Bytes

4th Data Hi 00-FF (Hex) FL3100H / FL3101H Hi Byte

5th Data Lo 00-FF (Hex) FL3100H / FL3101H Lo Byte

6th CRC Lo 00-FF (Hex) CRC Lo Byte

7th CRC Hi 00-FF (Hex) CRC Hi Byte

Table 14: Modbus Read Response Messages

NOTE: Address 0 is reserved for broadcast mode and will not be supported at this time.

* (Decimal)

1-247

03 or 04 Read Holding Registers

Referenced to FL3100H,

FL3100H1

FL3100H / FL3101H ID (Address)

Status Data

Status Data

5.4 Modbus Write Command Protocol (Query/Response)

5.4.1 Modbus Write Query Message

Byte Modbus Range

1st Slave Address

2nd Function Code 06 Preset Single Register

3rd Register Address

**

Hi

4th Register Address

Lo**

5th Preset Data Hi 00-FF (Hex) FL3100H / FL3101H Hi Byte

6th Preset Data Lo 00-FF (Hex) FL3100H / FL3101H Lo Byte

th

7

8th CRC Hi 00-FF (Hex) CRC Hi Byte

*: Address 0 is reserved for broadcast mode and will not be supported at this time.

NOTE

NOTE**: Start Address can be a maximum of 247 Address Locations (0000-0x00F7).

CRC Lo 00-FF (Hex) CRC Lo Byte

Table 15: Modbus Write Query Message

*

1-247

(Decimal)

00 Not used by FL3100H /

00-FF (Hex) FL3100H / FL3101H Commands

Referenced to FL3100H /

FL3101H

FL3100H / FL3101H ID

(Address)

FL3101H

Command Data

Command Data

27

Page 36

Models FL3100H/3101H

5.4.2 Modbus Write Response Message

Byte Modbus Range

1st Slave Address 1-247*

(Decimal)

2nd Function Code 06 Preset Single Register

3rd Register Address

Hi**

4th Register Address

Lo**

5th Preset Data Hi 00-FF (Hex) FL3100H / FL3101H Hi Byte

6th Preset Data Lo 00-FF (Hex) FL3100H / FL3101H Lo Byte

7th CRC Lo 00-FF (Hex) CRC Lo Byte

8th CRC Hi 00-FF (Hex) CRC Hi Byte

Table 16: Modbus Write Response Message

NOTE*: Address 0 is reserved for broadcast mode and is not supported at this time.

NOTE**: Start Address can be a maximum of 247 Address Locations (0000-0x00F7).

00 Not used by FL3100H / FL3101H

00-FF (Hex) FL3100H / FL3101H Commands

Referenced to FL3100H /

FL3101H

FL3100H / FL3101H ID (Address)

Command Data

Command Data

5.4.3 Function Codes Supported

Function Code 03 or 04 (Read Holding Registers) is used to read status from the slave unit.

Function Code 06 (Preset Single Register) is used to write a command to the slav e unit.

5.5 Exception Responses and Exception Codes

In a normal exchange, the master device sends a query to the FL3100H / FL3101H. The

FL3100H / FL3101H receives the query and returns a normal response to the master. If a

normal communications error occurs, there are 4 possible responses from the FL3100H /

FL3101H:

1. If the FL3100H / FL3101H does not recognize the query due to a communications

error, then no response is returned from the FL3100H / FL3101H and the master

device will eventually process a timeout condition for the query.

2. If the FL3100H / FL3101H receives the query, but detects a communication error

(CRC, etc.), then no response is returned from the FL3100H / FL3101H and the master

device will eventually process a timeout condition for the query.

3. An exception code is returned when the FL3100H / FL3101H receives the query

without a communications error, but cannot process it due to reading or writing to a

non-existent or illegal Function Code, Illegal Command Starting Address or Register

Address, or Illegal Data Value. The exception response message has two fields that

differentiate it from a normal response. See the next section for more information.

28

Page 37

Models FL3100H/3101H

5.5.1 Exception Responses

Byte Modbus Range

1st Slave Address 1-247* (Decimal) FL3100H / FL3101H ID (Address)

2nd Function Code 83 or 86 (Hex) MSB is set with Function Code

3rd Exception Code 01 - 06 (Hex) Appropriate Exception Code (See

4th CRC Lo 00-FF (Hex) CRC Lo Byte

5th CRC Hi 00-FF (Hex) CRC Hi Byte

Table 17: Exception responses

5.5.1.1 Exception Code Field

In a normal response, the FL3100H / FL3101H returns data and status in the data field,

requested in the query from the master. In an exception response, the FL3100H / FL3101H

returns an exception code in the data field, which describes the condition that caused the

exception. Below is a list of exception codes that are supported by the FL3100H / FL3101H:

Code Name Description

01 Illegal Function The function code received in the query is not an

allowable action for the FL3100H / FL3101H.

02 Illegal Data Address The data address received in the query is not an

allowable address for the FL3100H / FL3101H.

03 Illegal Data Value A value contained in the query data field is not an

allowable value for the FL3100H / FL3101H.

04 Slave Device Failure An unrecoverable error occurred while the

FL3100H / FL3101H was attempting to perform the

requested action.

05 Acknowledge The FL3100H / FL3101H has accepted the request

and is processing it, but a long duration of time will

be required. This response is returned to prevent a

timeout error from occurring in the master.

06 Device Busy The FL3100H / FL3101H is engaged in processing

a long-duration program command. The master

should retransmit the message later when the slave

is free.

Referenced to FL3100H /

FL3101H

below)

Table 18: Exception Code Field

29

Page 38

Models FL3100H/3101H

5.6 Command Register Locations

5.6.1 Operational Mode Commands

See section number listed below and reference Section 5.7 for details of each register.

NOTE: The FL3100H has Modbus error reporting. The optional dual Modbus has error

reporting for each channel. It can also provide simultaneous block mode.

R - indicates Read Only Access R/W - indicates Read/Write Access

Parameter Function Type Scale Access

Analog 0-20 mA Current Output Value 16-Bit R 0000 40001

Mode Indicates Fire Status Mode Value (0-11) R 0001 40002

Status/Error Indicates Error Bit 16-Bit R 0002 40003

UV/IR Only Indicates Detection of UV

Only or IR Only (FL3100H

only)

Model Type Identifies the Model

FL3100H / FL3101H

Software

Rev

COPM Fault UV/IR COPM Fault Bit 2-Bit R 0006 40007

Override Override Dipswitch Settings Bit 1-Bit R/W 0007 40008

Options Indicates Unit Options Bit 8-Bit R/W 0008 40009

Comm 1

Address

Not Used 000A 40011

Comm 1

Baud Rate

Comm 1

Data Format

UV

Sig Count

IR

Sig Count

UV Fault

Total

IR

Fault Total

Remote

Reset

Indicates the Software

Revision

Unit Address Decimal

Baud Rate

(2400, 4800, 9600,19.2K)

Data Format

(8N-1, 8E-1, 8O-1, 8N-2)

Indicates No. of UV Signal

Pulses within 500 ms

Indicates No. of IR Signal

Pulses within 500 ms

Indicates Total No. of UV

COPM Faults

Indicates Total No. of IR

COPM Faults

Remotely Resets the Alarm

and Warn Relays

Bit 2-Bit R 0003 40004

Decimal 310X R 0004 40005

ASCII 2-Char R 0005 40006

(1-247)

Hex

Value (0-3) R/W 000B 40012

Value (0 - 3) R/W 000C 4001 3

Value 16-Bit R 000D 40014

Value 16-Bit R 000E 40015

Value 16-Bit R 000F 40016

Value 16-Bit R 0010 40017

Bit 1-Bit R/W 0011 40018

(01F7)

R/W 0009 40010

REG

Addr

Master

I/O

Addr

Refer to

Section

30

Page 39

Models FL3100H/3101H

Parameter Function Type Scale Access

Remote

Alarm Test

Clear

COPM

Faults

NOT Used 0014 40021

Serial

Number

Serial

Number

NOT Used 0017-

Optional

HART

All “1” or “0” HART Test 0 off 1, 2 Bit 2 Bit R/W 001E 40031

Not Used 001F 40032

Comm 1

Register

errors

Comm 1

Bus Activity

Rate %

Comm 1

Function

Code Errors

Comm 1

Starting

Address

Errors

Comm 1

Total

Receive

Errors

Comm 1

RXD CRC

Errors

Comm 1

RXD CRC

Errors

Comm 1

Overrun

Errors

Remotely Activates Alarm

Test

Clears UV/IR COPM Fault

Counters

Serial Number Upper Value 16 bit R 0015 40022

Serial Number Lower Value 16 bit R 0016 40023

HART Enable Bit 1 bit R/W 001D 40030

Total # of Register Errors

Bus Activity Rate in %

Of this Addressed Node vs.

Other Addressed Nodes

Total # of Function Code

Errors

Total # of Starting

Addresses

Errors

Total # of Comm 1

Receive Errors

Total # of RXD CRC

Errors

Total # of RXD CRC

Errors

Total # of Overrun Errors

Bit 1-Bit R/W 0012 40019

Bit 1-Bit R/W 0013 40020

Value 16-Bit R 0020 40033

Decimal

Hex

Value 16-Bit R 0022 40035

Value 16-Bit R 0023 40036

Value 16-Bit R 0024 40037

Value 16-Bit R 0025 40038

Value 16-Bit R 0026 40039

Value 16-Bit R 0027 40040

(0100%)

(0-64)

R 0021 40034

REG

Addr

1C

Master

I/O

Addr

40024-

40029

Refer to

Section

31

Page 40

Models FL3100H/3101H

Parameter Function Type Scale Access

Comm 1

Parity

Errors

Comm 1

Framing

Errors

Comm 1

UART errors

Comm 1

Total

Receive

Errors

Comm 1

Clear UART

Comm1

Clear Stats

HART

Current

Range

Comm 2

Address

Total # of Parity Errors Value 16-Bit R 0028 40041

Total # of Framing

Errors

Total # of UART errors Value 16 Bit 002A 40043

Total # of Comm 1

Receive Errors

Clear UART errors Bit 1-Bit R/W 002C 40045

Clear Comm Stats Bit 1-Bit R/W 002D 40046

3.5 ma to 20 ma

1.25 ma to 20 ma

Unit Address Decimal

Value 16-Bit R 0029 40042

Value 16-Bit R 002B 40044

Bit 1-Bit R/W 002E 40047

Hex

(1-247)

(01-F7)

R/W 002F 40048

REG

Addr

Master

I/O

Addr

Refer to

Section

Comm 2

Baud

Rate

Comm 2

Data

Format

Not Used 0032 40051

Input

Voltage

Voltage at

the alarm

input

Voltage at

the Reset

input

The position

of the dip

switch

Not used 0037

Indicates present Baud Rate

(2400, 4800, 9600, 19.2K)

Indicates present Data

Format

(8N-1, 8E-1, 8O-1, 8N-2)

Indicates the 24 volts Value 16-Bit R 0033 40052

Indicates alarm test input

voltage

Indicates reset input voltage Value 16-Bit R 0035 40054

Dip Switch Data Bits 16-Bit R 0036 40055

Value (0-3) R/W 0030 40049

Value (0-3) R/W 0031 40050

Value 16-Bit R 0034 40053

40056

003F

40064

32

Page 41

Models FL3100H/3101H

Parameter Function Type Scale Access

EVENT

LOGGING

USER

INFO

Comm 2

Register

errors

Comm 2

Bus Activity

Rate %

Comm 2

Function

Code Errors

Comm 2

Starting

Address

Errors

Comm 2

Total

Receive

Errors

Comm 2

RXD CRC

Errors

Comm 2

RXD CRC

Errors

Comm 2

Overrun

Errors

Comm 2

Parity

Errors

Comm 2

Framing

Errors

Comm 2

UART errors

Not Used 0083 40132

Comm 2

Clear UART

Comm2

Clear Stats

Event logging

See Section 6.0

User Information Value 16-Bit R/W 0068

Total # of Register Errors

Bus Activity Rate in %

Of this Addressed Node vs.

Other Addressed Nodes

Total # of Function Code

Errors

Total # of Starting

Addresses

Errors

Total # of Comm 2

Receive Errors

Total # of RXD CRC

Errors

Total # of RXD CRC

Errors

Total # of Overrun Errors

Total # of Parity Errors Value 16-Bit R 0080 40129

Total # of Framing

Errors

Total # of UART errors Value 16-Bit R 0082 40131

Clear UART errors Bit 1-Bit R/W 0084 40133

Clear Comm Stats Bit 1-Bit R/W 0085 40134

Value 0040

Value 16-Bit R 0078 40121

Decimal

Hex

Value 16-Bit R 007A 40123