Page 1

Operating Manual

Gallet F1XF

®

Helmet for Firefighters

Order No.: CH180454 - PQ730140/05

MSAsafety.com

Page 2

MSA Europe GmbH

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

info.ch@MSAsafety.com

www.MSAsafety.com

©

MSA 2019 All rights reserved

Page 3

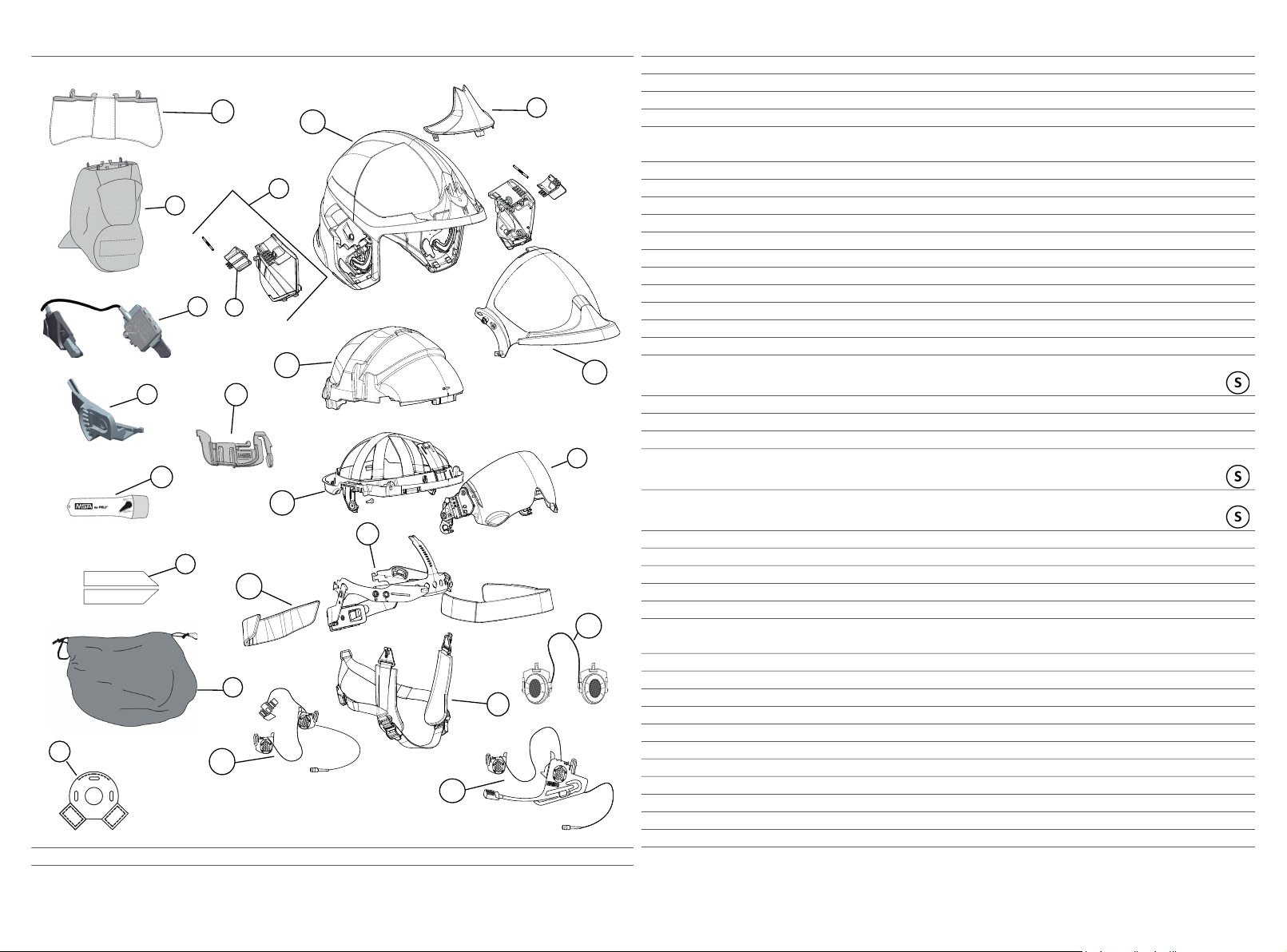

1

2

3

4

5

7

8

11

12

13

14

15

16

18

17

9

10

19

20

21

6

23

22

For other languages see chapter 6 of the respective manual.

No Part Part. No

1a Aluminized neck curtain F1XF, 3 layers GA1116F

1b Nomex neck curtain F1XF GA1116C

1c Wool/Nomex neck curtain F1XF GA1116D

Integral Wool/Nomex neck curtain F1XF

2a

(Size Medium/Large)

GA1116B-M GA1116B-L

2b Integral aramid neck curtain F1XF GA1116E-M GA1116E-L

3 Lighting module F1XF GA1484

4 Torch lamp support F1XF (D: right/G: left) GA1485D GA1485G

5a Lamp XPS GA1488

5b Lamp XP LED GA1464

5c Lamp XS zone 0 GA1466

5d Lamp AS-R GA1481

6a Ocular visor kit F1XF, EN14458, clear GA1087A

6b Ocular visor kit F1XF, EN14458, tinted GA1087B

7a Face shield F1XF, EN14458, clear GA1086A

7b Face shield F1XF, EN14458, metalized GA1086B

8 Shell F1XF, Painted, (Size M: Medium/L: Large) GA1090-xxM GA1090-xxL

9 Kitfix F1XF GA1092A

10a Kitfix F1XF mobile GA1092B

10b Kitfix F1XF mobile, PN GA1092C

Suspension F1XF, EN443,

11

(Size M: Medium/L: Large)

GA1094-M GA1094-L

12 Impact liner F1XF, EN443, (Size M: Medium/L: Large)GA1095-M GA1095-L

13 Ratchet cradle F1XF GA1098A

14a Chinstrap F1XF, textile GA1128A

14b Chinstrap F1XF, leather GA1128B

15a Textile paddings, F1XF GA1129A

15b Leather paddings, F1XF GA1129B

Retroreflective stickers F1XF

16

(Size M: Medium/L: Large)

GA1136-xxM GA1136-xxL

17 Front plate F1XF GA1150-xx

18 Protective bag for helmet GA1382

19a Headset Bone Conductive Microphone F1XF GA010002A3X

19b Headset Bone Conductive Microphone F1XF 2ls GA010002A3AX

20a Headset Boom Microphone F1XF 1ls GA010002B3X

20b Headset Boom Microphone F1XF 2ls GA010002B3AX

21a Hearing F1XF Protect.Bone Conduct.Micro. GA010002C3X

21b Hearing Protection Boom Microphone F1xf GA010002D3X

21c Hearing Protection F1XF GA010002E3X

22 Set of 10 headset interfaces for F1XF GA1131

23 OSTEO interface for F1XF GA010007062

Page 4

1 Safety Regulations

1.1 Correct Use

The F1XF helmet - hereafter called helmet - is a safety helmet for the head intended for firefighters

operations, such as fire fighting in buildings and other structures, rescue interventions and other typical

tasks of fire brigades.

The helmet is designed for use with SCBA full face masks.

WARNING!

The safety intended to be provided by the helmet can only be ensured when it is properly assembled

and correctly fitted, removable parts shall not be worn separately.

WARNING!

This helmet is not suitable as a motorcycle helmet.

It is imperative that this operating manual be read and observed when using the product. In particular,

the safety instructions, as well as the information for the use and operation of the product, must be

carefully read and observed. Furthermore, the national regulations applicable in the user's country

must be taken into account for safe use.

Alternative use, or use outside this specification will be considered as non-compliance. This also

applies especially to unauthorized alterations to the product and to commissioning work that has not

been carried out by MSA or authorized persons.

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately or not as intended.

The selection and use of the product are the exclusive responsibility of the individual operator.

Product liability claims, warranties also as guarantees made by MSA with respect to the product are

voided, if it is not used, serviced or maintained in accordance with the instructions in this manual.

Safety Regulations

DANGER!

Before use the product operability must be verified. The product must not be used if the function test

is unsuccessful, it is damaged, a competent servicing/maintenance has not been made, genuine MSA

spare parts have not been used.

2 Description

The helmet provides protection of head and face against shocks, sharp objects, splatters of solid,

liquid, corrosive, chemical products (sulphuric acid, sodium hydroxide, p-xylene, butan-1-ol,

n-heptane…), molten metals, radiating heat, flames, electric current.

In situations where the conditions exceed those described in the specifications mentioned above, the

protection of the user is not guaranteed.

Face Shield

The clear or gold coated face shield protects against various risks likely to arise during firefighting interventions, ambulance and emergency services, except respiratory and smoke and gas / vapour emission risks. The face shield resists the splatter of chemical products identical to those of the helmet

mentioned above.

Gallet F1XF

®

GB

3

Page 5

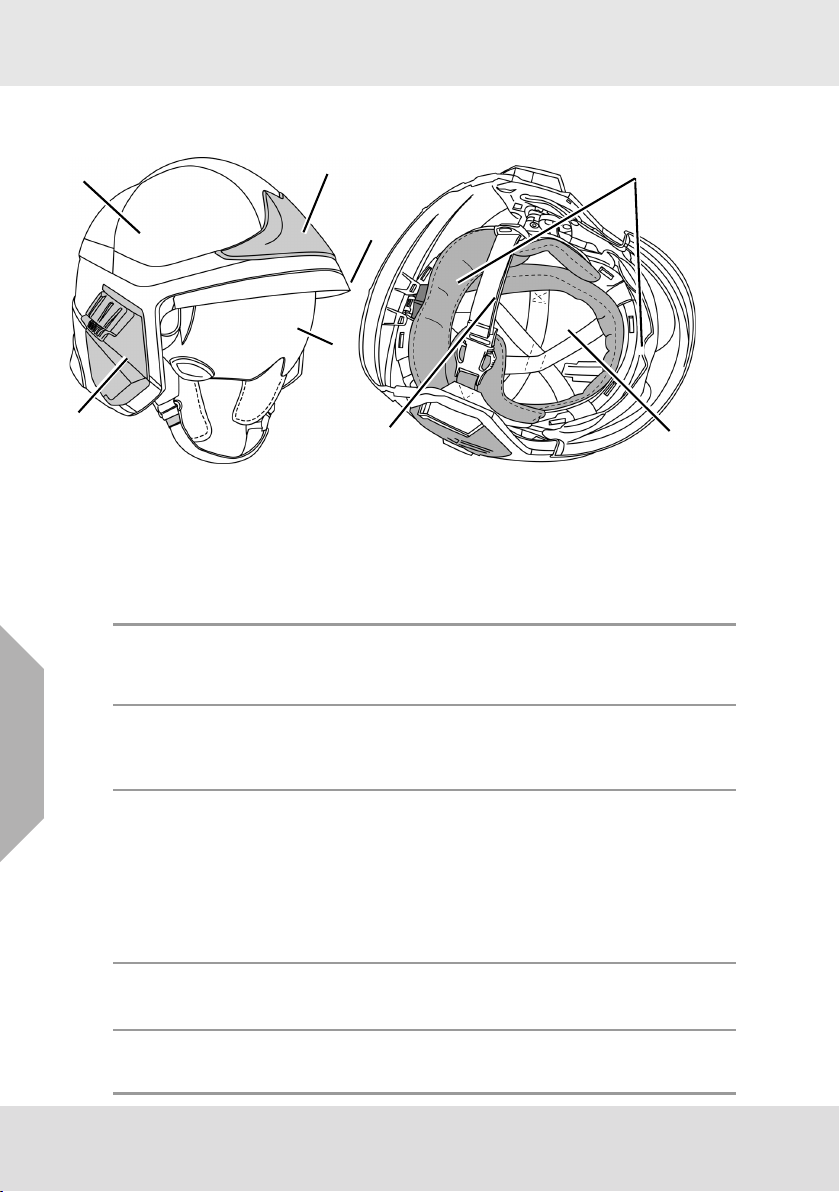

Description

1

2

5

4

6

3

8

7

2.1 Overview

1 Shell 5 Kitfix mask adaptor

2 Front plate 6 Inner ring with headband assembly

3 Face shield 7 Impact liner

4 Ocular visor 8 Chin strap

2.2 Technical Data

GB

The helmet consists of the following components:

• Medium (M) for head sizes from 52 cm to 62 cm (20.5 inches to

Helmet sizes

Weight

(Helmet with face

shield, no options)

Options

Warranty

•Helmet

• Options

Legal warranty

24.4 inches)

• Large (L) for head sizes from 57 cm to 65 cm (22.4 inches to

25.6 inches)

• M: 1450 ± 30 g

• L: 1580 ± 30 g

Weight changes when options are fitted on the helmet. Check manuals for

options for their exact weights.

• Neck curtain (4 types)

• Integrated lighting module

• Lamp bracket to fit a helmet mounted flashlight

• Ocular visor

• Communication headset

• Hearing protection with or without communication

Detailed information regarding the lighting module and the communication

headset can be found in the separate user manual for these devices.

2 years, parts and labour from the date of purchase

2 years, parts and labour from the date of purchase

For defects and hidden defects according to the conditions stipulated in articles 1641 and pursuant to the Civil Code (in France).

Different national regulations may apply.

4

Gallet F1XF

®

Page 6

2.3 Certifications/Approvals/Technical Specifications

The helmet meets the (EU) 2016/425 regulation and is certified according to EN 443:2008,

EN 16471:2014 and EN 16473:2014. Module D surveillance by: APAVE (0082), 8 rue Jean-Jacques

Vernazza, CS 60193, 13322 Marseille Cedex 16, France.

Standards and Directives for Helmet

INSPEC International Ltd. (0194), 56 Leslie Hough Way, Salford,

Certification

agencies

Standards and

directives:

Depending on the individual helmet configuration, optional EN 443:2008 requirements may be

marked on the helmet, as explained below:

Type B Indicates the protection zone assured by the helmet (area 1a -1b).

Type B3b Indicates the extended protection zone assured by the helmet (area 1a-1b and 3b)

E2 Indicates the electrical insulation of the damp helmet.

E3 Indicates a non-conductive surface of the shell.

*** / ** Indicates protection at low temperature down to -30°C/ -20°C

C

Marking

(Wheelmark):

Helmet

(EU) 2016/425 Personal protection equipment regulation

EN 443:2008

EN 16471:2014 "Helmets for wildland fire fighting" by BG BAU (0299).

EN 16473:2014 "Helmets for technical rescue" by BG BAU (0299).

Indicates a resistance to liquid chemical products. (sulphuric acid, sodium

hydroxide, p-xylene, butan-1-ol, n-heptane)

Meets 2014/90/EU Marine Equipment Directive (MED)

Greater Manchester, M6 6AJ, United Kingdom

BG BAU, DGUV Test (0299), Prüf- und Zertifizierungsstelle

FB PSA, Zwengenberger Straße 68, 42781 Haan, Germany

“Helmets for firefighting in buildings and other structures” by

INSPEC International Ltd. (0194).

Description

Standards and Directives for Visors

Certification

agency

Standards and

directives:

(+) or (=) Conforms to the additional requirements of firefighters or general use

-30 °C; 120 °C Extremes of temperature to which the visor has been tested (-30 °C & +120 °C)

Ω Complies with the electrical properties

A Resistance to high energy impact 190 ms-1

T Resistance to medium energy impact at extremes of temperatures

AT Resistance to high energy impact (190ms-1) at extremes of temperature

K Resistance to abrasion according EN 168: 2001, clause 15

N Resistance to fogging

2C-2.5 and 2C-1.2 UV filtering according to EN170:2002 for metalized and clear face shield

2-1.2 and 5-3.1 UV filtering according to EN170:2002 for clear and tinted ocular

Face shield:

Ocular visor

(EU) 2016/425 Personal protection equipment regulation

EN 14458:2004 Personal eye equipment

Visor type: Eye guard

Visor type : Face guard

INSPEC International Ltd. (0194), 56 Leslie Hough Way,

Salford, Greater Manchester, M6 6AJ, United Kingdom

BG BAU, DGUV Test (0299), Prüf- und Zertifizierungsstelle

FB PSA, Zwengenberger Straße 68, 42781 Haan, Germany

Gallet F1XF

®

GB

5

Page 7

Adjusting the Helmet

Radiant heat protection

%

Source Temperature (K)

35

40

45

50

55

60

65

70

75

1600 1800 2000 2200 2400 2450 2600 2800 3000 3200

GA1086A

GA1086B

The Declaration of Conformity can be found under the following link: https://MSAsafety.com/DoC.

Transmission

The protection against radiating heat ensured by the face shields varies with the temperature of the

heat source, see figure above. It is recommended to only use the face shield when the face shield can

reduce the heat exposure to the wearer's eyes to less than 100W/m2.

WARNING!

When fitted with another item of personal protective equipment or with an accessory, (other than as

supplied by the helmet manufacturer for use with this helmet) a helmet marked as complying with

EN 443 might no longer satisfy all clauses of the standard. Refer to information supplied by the helmet

manufacturer.

3 Adjusting the Helmet

3.1 Before Donning

GB

(4) Adjust rear headband by rotating to optimise

fit on back of the head.

6

(1) Choose helmet size M or L (see Technical

Data) according to your head size.

(2) Adjust front headband by sliding it up or

down.

(3) Position front headband inside the helmet to

avoid contact between headband and mask.

Gallet F1XF

®

Page 8

(5) Adjust wearing height with the Velcro

3.2 Donning

The following adjustments have to be carried out when the helmet is donned.

(1) Position the chin strap as shown before

Adjusting the Helmet

fasteners on the two rear suspension straps.

donning the helmet.

(2) Adjust head size:

(3) Check that the helmet is correctly adjusted:

The chin strap is equipped with 3 adjustment points to allow quick and simple adjustment while the

helmet is on the head.

Turn knob clockwise to tighten the ratchet

headband.

Turn knob anticlockwise to loosen the

ratchet headband.

The helmet should not fall off when the

head is leaning forward and the chin strap

is unfastened.

(1) Maximally loosen the 3 adjustment points.

(2) Place helmet on head. Make sure that it is well positioned.

(3) Close the buckle of the chin strap.

(4) Tighten the chin strap.

(5) Tighten the two rear adjustment straps until a tight but still

comfortable fit is achieved.

The wearing angle shown here is indicative.

It may vary slightly depending on user's head size and shape.

GB

Gallet F1XF

®

7

Page 9

Adjusting the Helmet

WARNING!

The helmet only meets the retention requirements of EN 443:2008 when the chin strap provided by the

helmet manufacturer is worn and adjusted according to the instructions.

3.3 Visors

WARNING!

Visors worn over non-designated corrective frames may transmit impacts which may damage the

corrective eyewear thus creating a hazard to the user.

Service life of visors is depending on the conditions of use.

Any face shield that has been scratched, dropped or damaged must be replaced.

The visor type "Face guard" will provide protection to the eyes and substantial areas of the face.

Performances of the visor are obtained only in use position (low position). Visors should be in

standby position (stored under the helmet shell) during the use of a breathing apparatus (SCBA).

Equipment not marked with "T" should only be used at non-extreme ambient temperatures.

Ensure that you are using an EN443 helmet with a visor marked "+" for structural firefighting.

Materials that come in contact with the wearer's skin could cause allergic reactions in susceptible

individuals.

Face Shield

(1) Position by pulling it completely up or down.

GB

Ocular Visor (optional)

(1) Position by pulling it up or down.

(2) Tilt the ocular visor towards the face for an optimal fit.

The ocular visor can be adjusted to optimize the distance between visor and face.

8

Gallet F1XF

®

Page 10

(1) Don helmet and pull down ocular visor.

4 Attaching the Accessories

4.1 Neck Curtains

2 types of neck curtain can be installed:

• Neck curtain for rear protection

• Integral neck curtain

Attaching the Accessories

(2) Unclip and clip the yellow stopper in positions

(A), (B) or (C) to optimize fit of the ocular visor

on the face.

The helmet has 8 slots for installing the neck curtain:

• 4 at the rear for the rear neck curtain (A, B, C, D).

• 4 more at the front for the integral neck curtain

(E, F, G, H)

(1) Place the neck curtain upside down

above the helmet.

(2) Insert the 2 clips marked in the central

slots.

Gallet F1XF

(3) Push the 2 pressure clips till locking.

For the integral neck curtain, repeat the operation for

the 4 front attachment points.

®

GB

9

Page 11

Attaching the Accessories

4.2 Ocular Visor

(3) Lock the ocular visor module by fixing it on

the shell plot (right and left).

4.3 Lighting Module

(1) Place the ocular visor upside down above

the helmet.

(2) Insert the 2 clips simultaneously into the

dedicated slots.

(1) Place the helmet upside down with the face

shield towards you.

(2) Insert the left box (L) of the F1XF Lightning

module into the space provided on the left

side of the helmet and clip into place.

GB

(3) Follow the same procedure for the right box

(R).

When the lighting module and F1XF boom microphone are both installed inside the helmet, always

disassemble the lightning module first, then the boom microphone.

10

Gallet F1XF

®

Page 12

(4) Ensure that the cable is placed in the indi-

CLICK

cated area.

See the Lighting module user instruction delivered with the product for details on operation.

4.4 Lamp Bracket and Lamp

(1) Slide the lamp bracket along the shell shape.

Attaching the Accessories

(2) Insert the lamp into the lamp bracket from

the rear open side (A).

(3) Rotate, then press forward to secure the

attachment (B).

(4) Tilt the lamp up and down into the required

position.

(5) To remove the lamp, slightly press it

towards the helmet while sliding it to the

rear open side (A) of the lamp bracket.

Gallet F1XF

GB

®

11

Page 13

Maintenance and Cleaning

4.5 Mask Adapter (Kitfix)

Attach a mask using the "Kitfix" connector kits A.

To adjust mask tightness on helmet:

(1) Use a pair of pliers to remove the pin.

(2) Adjust the Kitfix to position (1) (2) or (3) (according to desired

mask tightness).

(3) Use the pin to lock the Kitfix in place (push it in completely).

(4) Test mask seal after attaching the mask if necessary.

5 Maintenance and Cleaning

The length of the useable life of this helmet will be affected by the type(s) of material used in its

construction and the environments in which the helmet is used and stored. Recommendations on this

topic should be sought from the manufacturer.

WARNING!

Do not apply paint, stickers, cleaning products with a hydrocarbon base or solvents to the helmet or

visors to prevent damaging the materials of your helmet.

Do not drop the helmet.

Prevent the helmet from impacts which could damage the shields (cracks/scratches).

GB

The parts in contact with skin have to be inspected regularly for cracks or wear that could

cause discomfort. Changing those parts regularly will maintain user comfort level.

To maximize helmet lifetime:

• Store the helmet in a proper storage bag and/or in a closed cabinet to avoid extended exposure

to cold, humidity, exhaust fumes, etc.

• Clean the helmet (shell and internal components) after use before storing.

Checks After Each Use

After each use, check every part of the helmet and especially all the fixing points:

• Correct anchor points used

• No evident wear

• No fractures or cracks

Check that the helmet fit is always correct.

12

Gallet F1XF

®

Page 14

Maintenance and Cleaning

Maintenance by a Trained Maintenance Specialist

Only trained people should perform the regular maintenance.

WARNING!

Replace any damaged parts only with original MSA parts, as only these original parts are authorized

and ensure the performance of the helmet.

Helmet absorbs the energy of a blow by partial destruction of, or damage to, the helmet. Even though

such damage may not be readily apparent, any helmet subjected to a severe impact should be

replaced.

Periodically, perform a complete check of the helmet with detailed inspection of each critical component. MSA provides upon request a Service and Maintenance manual which details conformity criteria

for all safety components of the helmet and parts replacement procedures.

MSA recommends that this complete control is performed at least every two (2) years, more regularly

in case of intensive use (every year for instance), or each time the helmet has been exposed to very

severe conditions (mechanical impact, very high temperature, direct flame contact, contact with

pouring metal or chemicals). In cases where frequency of use is very low and none of the mentioned

exposures and damages are recorded, an inspection should be performed at least every 4 years. Local

regulations may apply.

WARNING!

In case of visible damage identified during the daily check (before or after use), such as impacts, significant scratches, coating removal on the shell or visors, melted parts, broken parts, torn straps or

paddings, missing components, non-operational moving parts (such as visors or ratchet), etc., the

helmet should be taken to the trained maintenance technician or an MSA approved maintenance

center for complete control processing.

WARNING!

Components that are particularly critical to the safety of the product, such as suspension, shell and

impact liner, are marked with .

Treat such parts with special attention and care during inspection and assembly.

5.1 Cleaning

WARNING!

Do not use solvent-based products (acetone, alcohol etc.) or softeners.

Do not use abrasive materials.

The helmet must be completely dried before returning to service (max. drying temperature 40°C).

Plastic Components, Face Shield and Ocular Visor

• Use soapy water and a soft cloth.

Soft Goods (Chin Strap, Rear and Front Padding)

(1) Remove the textile or leather components (fastened with Velcro).

(2) Clean it as follows:

a) Textile chin strap + textile headband liner: 30°C with a mild detergent.

b) Leather chin strap + leather headband liner: Use soapy water and a lint-free soft cloth.

Gallet F1XF

®

GB

13

Page 15

Maintenance and Cleaning

Neck Curtains

Neck curtains made of Nomex, wool:

• Cleaning at 30°C with a mild detergent

Integral Aramid neck curtain:

• Cleaning at 60°C with a mild detergent.

Aluminized neck curtain:

• Manual cleaning at 30°C with soapy water,

using a sponge.

See the Cleaning and Care Guidelines by using the following link:

https://msa.webdamdb.com/bp/#/folder/1777763/98866226

Chin Strap Disassembly before Cleaning

GB

(1) Unlock metallic trapezoid (chin strap 3rd

point) from the hook by pushing it.

(3) Push each clip forward and raise it on the

back.

Chin Strap Assembly after Cleaning

(1) Insert both clips into the slots vertically.

(2) Rotate the clips on right and left side of the

chin strap 90 degrees towards the rear of the

helmet.

(2) Rotate clips 90 degrees towards the rear and

push them in.

14

Gallet F1XF

®

Page 16

Maintenance and Cleaning

(3) Rotate the clips 90 degrees forward into

the wearing position.

Attachment of the 3rd point (at the back)

(4) Insert the metallic trapezoid and lock it in

the hook by pulling it vertically.

5.2 Transport

Helmet with Visor(s)

Store the visor(s) inside the helmet (out of use position), store the helmet in a MSA Gallet protective

bag (GA1382).

Visor as Spare Part

The visors have to be kept in their plastic bags until they are mounted on the helmet.

5.3 Discard

The helmet must be treated as ordinary industrial waste/non-hazardous waste according to local regulations. For further information contact MSA.

GB

Gallet F1XF

®

15

Page 17

Spare Parts, Accessories and Options

6 Spare Parts, Accessories and Options

No Part Part. No

1a Aluminized neck curtain F1XF, 3 layers GA1116F

1b Nomex neck curtain F1XF GA1116C

1c Wool/Nomex neck curtain F1XF GA1116D

2a Integral Wool/Nomex neck curtain F1XF (Size Medium/Large) GA1116B-M GA1116B-L

2b Integral aramid neck curtain F1XF GA1116E-M GA1116E-L

3 Lighting module F1XF GA1484

4 Torch lamp support F1XF (D: right/G: left) GA1485D GA1485G

5a Lamp XPS GA1488

5b Lamp XP LED GA1464

5c Lamp XS zone 0 GA1466

5d Lamp AS-R GA1481

6a Ocular visor kit F1XF, EN14458, clear GA1087A

6b Ocular visor kit F1XF, EN14458, tinted GA1087B

7a Face shield F1XF, EN14458, clear GA1086A

7b Face shield F1XF, EN14458, metalized GA1086B

8 Shell F1XF, Painted, (Size M: Medium/L: Large) GA1090-xxM GA1090-xxL

9 Kitfix F1XF GA1092A

10a Kitfix F1XF mobile GA1092B

10b Kitfix F1XF mobile, PN GA1092C

Suspension F1XF, EN443,

11

(Size M: Medium/L: Large)

12 Impact liner F1XF, EN443, (Size M: Medium/L: Large) GA1095-M GA1095-L

13 Ratchet cradle F1XF GA1098A

14a Chinstrap F1XF, textile GA1128A

14b Chinstrap F1XF, leather GA1128B

15a Textile paddings, F1XF GA1129A

15b Leather paddings, F1XF GA1129B

GB

16 Retroreflective stickers F1XF (Size M: Medium/L: Large) GA1136-xxM GA1136-xxL

17 Front plate F1XF GA1150-xx

18 Protective bag for helmet GA1382

19a Headset Bone Conductive Microphone F1XF GA010002A3X

19b Headset Bone Conductive Microphone F1XF 2ls GA010002A3AX

20a Headset Boom Microphone F1XF 1ls GA010002B3X

20b Headset Boom Microphone F1XF 2ls GA010002B3AX

21a Hearing F1XF Protect.Bone Conduct.Micro. GA010002C3X

21b Hearing Protection Boom Microphone F1XF GA010002D3X

21c Hearing Protection F1XF GA010002E3X

22 Set of 10 headset interfaces for F1XF GA1131

23 OSTEO interface for F1XF GA010007062

GA1094-M GA1094-L

16

For illustrations of parts see fold-out page.

Gallet F1XF

®

Page 18

For local MSA contacts, please visit us at MSAsafety.com

Loading...

Loading...