Page 1

Locate the detector:

• indoors in a room area where air circulates freely

• indoors in an area near fittings where refrigerant leaks may occur

• on a flat, interior surface

• approximately 12-18 inches (30-45 cm) from floor

Do not locate the detector:

• near heat sources, such as appliances, direct sunlight or concealed pipes or chimneys

• on walls or structures subject to excessive vibration

• in areas where air does not circulate freely, such as behind doors or in corners.

3.2 Mounting the detector

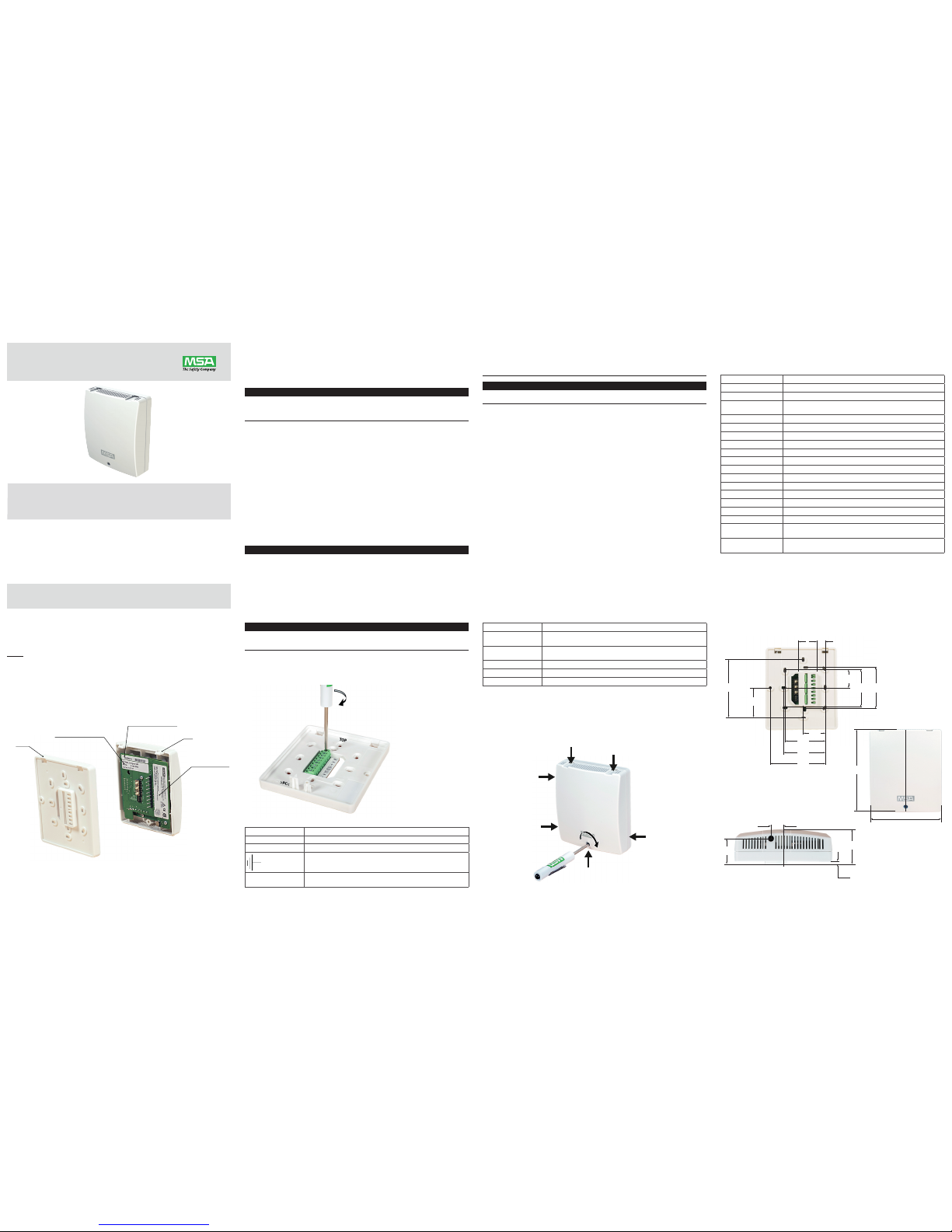

The detector consists of two basic parts, the base and the cover (Figure 1). The cover

incorporates the electronics with the sensing elements.

1. Fasten the base to a junction box or other support.

• The base has a number of openings to allow for mounting to various junction boxes.

CONFIGURATION LABEL

TOP

APPROVAL LABEL

BASE

SERIAL NUMBER LABEL

Figure 1: Base and Cover

2. Feed the power and signal wires through the rectangular opening in the base.

1 SAFETY REGULATIONS

1.1 Correct Use

MSA’s CHILLGARD® VRF Refrigerant Detector – hereafter referred to as detector – is

designed to detect the presence of the most common halogenated refrigerants, and

specifically calibrated to detect R410a.

WARNING

This manual must be carefully read by all individuals who have or will have the responsibility for

installing, using, or servicing the product. This product is supporting life and health. Incorrect use,

maintenance, or servicing may affect the function of the device and persons who rely on this product for

their safety could sustain loss of life or serious personal injury.

Furthermore, the national regulations applicable to the user’s country must be taken into

account for safe use of this product. Alternative use, or use outside of this specification will

be considered as non-compliance. This also applies especially to unauthorized alterations to

the product and to commissioning work that has not been carried out by MSA or authorized

persons.

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately or not

as intended. The selection and use of this product must be under the direction of a qualified

safety professional who has carefully evaluated the specific hazards of the site where it will

be used and who is completely familiar with the product and its limitations. The selection and

use of this product and its incorporation into the safety scheme of the site is the exclusive

responsibility of the employer.

Warranties, also known as guarantees, made by MSA with respect to the product are voided

if the product is not used, serviced, or maintained in accordance with the instructions in this

manual.

1.3 Safety and Precautionary Measures

WARNING

Carefully review the following safety limitations and precautions before placing this device in service.

Incorrect use can cause loss of life or serious personal injury.

• Install, operate, and maintain this instrument in strict accordance with its labels, cautions, warnings,

instructions, and within the limitations stated.

• Do not install this detector in outdoor areas or locations where explosive concentrations of

combustible gases or vapors might occur in the atmosphere. Do not paint this detector. Painting will

interfere with the sampling process of the detector. If painting is being done in an area where the

detector is located, exercise care to ensure that paint is not put or splashed on the detector.

WARNING

The unit must always be powered by either a suitable UL/CSA/IEC 60950 Certified power supply which is

isolated from line voltage by double insulation, or an appropriately rated UL Listed/CSA Certified Class 2

transformer. Failure to follow the above can result in serious personal injury or loss of life.

3. Connect the wires to the terminal connector located in the base, as indicated in Figure 2. The

terminal block on the base includes a label to identify the connections. Figure 3 shows the

wiring connection definitions. All units come with an analog and a digital output. The analog

output will be either current (mA) or voltage (V) and the digital output will be either BACnet

or Modbus. The choice is made based on the part number ordered.

Figure 2: Connecting Wires to Terminal Connector

Terminal Label Description

24V+ 24 V DC+ or AC Line

24V- 24 V DC- or AC Neutral

Circuit common/analog signal reference

GAS OUT

(mA or V)

For (mA) – Gas reading as current (4 - 20 mA = 0 - 1000 ppm)

For (V) – Gas reading as voltage (2 - 10 V = 0 - 1000 ppm)

• Protect this detector from vibration and heat; otherwise improper operation may result.

• Verify product operability. Do not use the detector if the function test is unsuccessful or the detector

is damaged.

• Ensure that all servicing is performed by MSA authorized technicians, using genuine MSA

replacement parts

CAUTION

Install this detector in as clean and dry area as possible and install splash shields to keep water and

other contaminants away from the detector; otherwise, damage can occur.

1.4 Warranty

1. Seller warrants that this product will be free from mechanical defect or faulty workmanship

for a period of 18 months from date of shipment, provided it is maintained and used in

accordance with Seller’s instructions and/or recommendations. This warranty does not apply

to expendable or consumable parts whose normal life expectancy is less than one (1) year

such as, but not limited to, non-rechargeable batteries, filament units, filter, lamps, fuses etc.

The Seller shall be released from all obligations under this warranty in the event repairs or

modifications are made by persons other than its own or authorized service personnel or if the

warranty claim results from physical abuse or misuse of the product. No agent, employee or

representative of the Seller has any authority to bind the Seller to any affirmation, representation

or warranty concerning the goods sold under this contract. Seller makes no warranty

concerning components or accessories not manufactured by the Seller, but, to the extent

possible, will pass on to the Purchaser all warranties of manufacturers of such components.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED

OR STATUTORY, AND IS STRICTLY LIMITED TO THE TERMS HEREOF. SELLER

SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANT ABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE.

2. Exclusive Remedy - It is expressly agreed that Purchaser‘s sole and exclusive remedy for

breach of the above warranty, for any tortious conduct of Seller, or for any other cause of

action, shall be the repair and/or replacement at Seller‘s option, of any equipment or parts

thereof, which after examination by Seller is proven to be defective. Replacement equipment

and/or parts will be provided at no cost to Purchaser, F.O.B. Seller‘s Plant. Failure of Seller to

successfully repair any non-conforming product shall not cause the remedy established hereby

to fail of its essential purpose.

3. Exclusion of Consequential Damage - Purchaser specifically understands and agrees that

under no circumstances will seller be liable to purchaser for economic, special, incidental or

consequential damages or losses of any kind whatsoever, including but not limited to, loss of

anticipated profits and any other loss caused by reason of non-operation of the goods. This

exclusion is applicable to claims for breach of warranty, tortious conduct or any other cause

of action against seller.

4. This detector has no user-replaceable parts. Modification of the unit will void the warranty.

Terminal Label Description

DATA a

(BACnet or Modbus)

For BACnet – RS485 BACnet MSTP (a) connection

For Modbus – RS485 Modbus RTU (a) connection

DATA b

(BACnet or Modus)

For BACnet – RS485 BACnet MSTP (b) connection

For Modbus – RS485 Modbus RTU (b) connection

NO Relay – normally open (de-energized)

C Relay – common

NC Relay – normally closed (de-energized)

Figure 3: Wiring Connections

4. Align the top side tabs of the cover with the base and snap the cover onto the base, and

fasten the screw.

Note: Verify cover is securely attached to base by pulling on the top and bottom of

the cover as shown in Figure 4.

5. To remove the cover, remove the screw and pull the enclosure away from the base as show

in Figure 4.

Screw on

Grasp here and

pull to release

Snap on (2 places)

Pull on top

to verify

the attachment

Grasp here and

pull to release

Figure 4: Attaching or Removing the Cover

2 SPECIFICATIONS

This detector detects R410a with a number of output options. This includes analog output

(current or voltage) and RS-485 digital output (Modbus or BACnet). Check label provided on

the printed circuit board (Figure 1- shows the label).

Power Requirements 24 VDC ±20 %, 24 VAC ±20 %, 50/60 Hz, Class 2

Wiring 14 AWG max (up to 2.5 mm

2

), Class 2 copper wiring

Power Consumption Less than 5 watts

Output Options 4 to 20 mA sourcing, ≤500 Ohm load, 2-10 V, 10 K Ohm load,

RS-485: Modbus RTU, BACnet MS/TP

Operating Temp. 0 °C to 60 °C

Humidity 0 to 99 % non-condensing

Size 4.7” x 4.1” x 1.7” (11.9 cm x 10.4 cm x 4.3 cm)

Weight 0.51 lbs. (230 g)

Pressure Operating 10.2 to 15.7 PSIA (70 to 108 kPa)

Altitude 0-2000 m

Warm-up time 30 Minutes

Pollution Degree 2

Installation Category II

Range 0 to 1000 ppm

Minimum Detection 25 ppm

Response Time t50 less than 240 seconds

Repeatability ±10 ppm at 50 ppm

Linearity ±10 ppm from 25-50 ppm,

±20 % of reading from 50 to 1000 ppm

Relay Rated load: 1 A at 30 VDC, Max. operating current: 1 A,

Max. switching capacity: 30 W

3 INSTALLATION GUIDELINES

3.1 Locating the detector

Proper detector location is necessary to ensure accurate measurement of representative air

samples.

3.3 Dimensions in mm [inch]

26.4

[1.040]

54.4

[2.140]

60.3

[2.373]

32

[1.260]

79.9

[3.147]

58.2

[2.290]

59.9

[2.360]

12.6

[0.496]

25.9

[1.020]

83.9

[3.304]

42.7

[1.680]

24.5

[0.964]

5

[0.197]

42.7

[1.681]

13.3

[0.523]

105

[4.132]

120

[4.723]

Figure 5: Installation Dimensions

MSAsafety.com

Operating Manual

Chillgard VRF

Order No.: 10176317/00

Page 2

4 OUTPUT ACTION

This detector is factory calibrated and ready for immediate use. Once power is applied, the

Red LEDs located at the top and bottom of the unit indicate status.

START-UP NORMAL

STATE

ALARM CALIBRATION

CHECK

FAULT

LED

STATE

Flash at

1 Hz

Flash every

60 seconds

Flash

fast at

3 Hz

Flash slow at 0.5Hz

(>=50 ppm fixed)

SOLID ON

Relay function:

Relay is normally energized, non-latching. It changes state upon alarm or fault condition.

During a sensor fault, the:

• current output is set to 2 mA or

• voltage output is set to 1 V

• digital output is defined in Register Map.

5 CONFIGURATION

All network communication uses serial framing (8 data bits, no parity, 1 stop bit) regardless of

protocol or Baud Rate. The serial framing cannot be changed.

Configuration Switches:

Switches Function

S300,S301,S302 Modbus address (Range = 1~255)

or

BACnet MAC address (Range = 0~127)

S303-1,S303-2,S303-3 Baud Rate

S303-4 Alarm level (ON (H) - default 50 ppm, OFF (L) - default 750 ppm)

S303-5 BACnet Instance Number setting

(OFF-(L) User’s setting, ON (H) factory setting)

S303-6 RS485 Termination match resistor (120 ohms).

ON position adds the resistor

Property Object Type

Device Analog Input Analog Values

Max APDU Length R

Segmentation

Support

R

APDU Timeout W(10~65535,65.535s)

Number APDU

Retries

W(0~10)

Max Master W(1~127)

Max Info Frames R

Device Address

Binding

R

Database Revision R

Active COV

Subscriptions

R

Present Value R R/W

Status Flags R R

Event State R R

Reliability R R

Out-Of-Service R R

Units R R

Priority Array R

Relinquish Default R

COV Increment W W

Modbus address

S300, S301and S302 are used to represent a value using the decimal number system for

Modbus address (Range = 1~255). S300 is hundreds number, S301 is tens digit number and

S302 is units digit number. The changes will only be valid after power reset. Invalid address

will cause an address fault.

BACnet MAC address

S300, S301 and S302 are used to represent a value using the decimal number system

for BACnet MAC address (Range = 0~127). S300 is hundreds number, S301 is tens digit

number, and S302 is units digit number. The changes will only be valid after power reset.

Invalid address will cause an address fault.

Baud Rate

S303-1, S303-2 and S303-3 are used to represent the Baud Rate configuration.

S303-1 S303-2 S303-3 Baud Rate

BACnet Modbus

OFF OFF OFF 9600

OFF OFF ON 19200

OFF ON OFF 38400

OFF ON ON 57600

ON OFF OFF 76800

ON OFF ON 115200

Alarm Level

There is one alarm whose value can be switched between two different levels. The factory

programmed alarm levels are: 50ppm when switch is in the ON (H) position, and 750ppm

when switch is in the OFF (L) position. The alarm values can be edited using a controller.

Any changes are valid immediately.

S303-4 Alarm Level

ON (H) Default 50 ppm

OFF (L) Default 750 ppm

BACnet Instance Number

Refer to the serial number label (Figure 1) for the default Instance Number (also Serial

Number). If switch S303-5 is ON (H) then the factory default is used and is unchangeable.

If S303-5 is OFF (L) then a user programmable Instance Number is used, although it is

initialized to the factory default.

5.2 Modbus RTU Connection

When connected to a Modbus network the following parameters must be set properly in

order to communicate with the Modbus controller:

• Modbus address

• Baud Rate

The following registers are available for exchange with the Modbus controller.

Modbus Objects:

REGISTER

NAME

PDU

ADDRESS

LOGICAL

ADDRESS

Property RANGE

Gas

Concentration

0x0000 1 Read 0 to 1000 (ppm)

Gas Number 0x0001 2 Read R-410A=34

Active Alarm

Level

0x0002 3 Read ( ppm )

Fault and Device

State

0x0003 4 Read Device Fault 80 (MSB)

Address Fault 8 (MSB)

Concentration

Alarm

10 (LSB)

Warm Up

Complete

0 (LSB)

High Alarm Level 0x0004 5 Read/Write 750 default

range = 25-1000

Low Alarm Level 0x0005 6 Read/Write 50 default

range = 25-1000

Room TEMP. (°C) 0x0008 9 Read

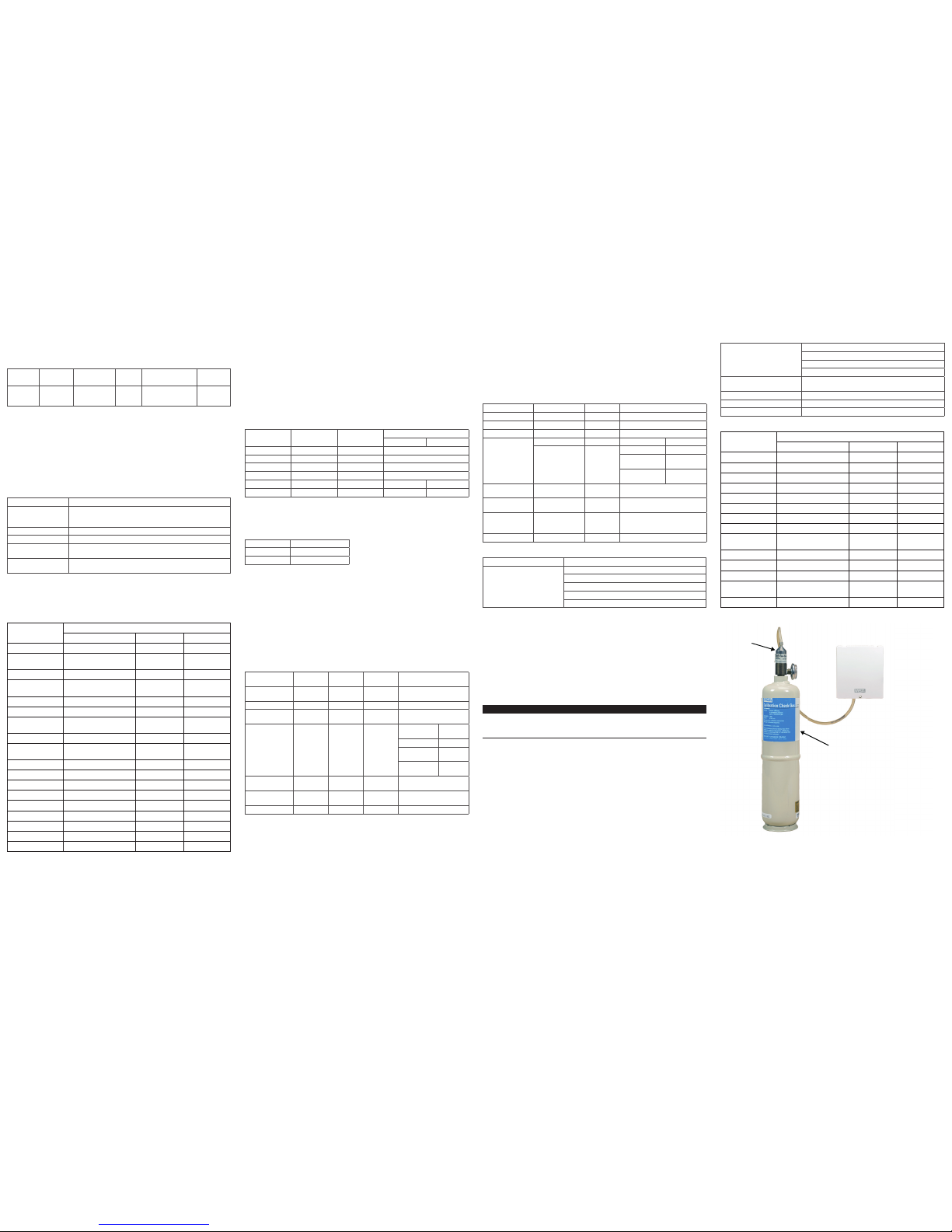

6 CALIBRATION CHECK

This detector with Photoacoustic infrared technology is designed to operate with a stable

baseline for years of operation. However, a unit must be checked periodically to verify

that it detects refrigerant gas. The calibration check can be done with the following MSA

equipment:

• (P/N 603806) Polyurethane Tubing

• (P/N 467895) 0.25 LPM regulator

• (P/N 10077766) Gas cylinder, 100ppm R410A in Nitrogen

5.1 BACnet Connection

When connected to a BACnet network, the following parameters must be set properly in

order to communicate with the BACnet controller:

• MAC address

• Instance Number

• Baud Rate

This monitor is configured for and connected to a BACnet network and has the following

BACnet Objects available for exchange with the BACnet controller.

BACnet Objects:

Object Name Instance Number Property RANGE

Gas Concentration 1 ( default ) Read 0 to 1000 (ppm)

Gas Number 2 ( default ) Read R-410A=34

Active Alarm Level 3 ( default ) Read ( ppm )

Fault and Device

State

4 ( default ) Read Device Fault 80 (MSB)

Address Fault 8 (MSB)

Concentration

Alarm

10 (LSB)

Warm Up

Complete

0 (LSB)

High Alarm Level 5 ( default ) Read/Write 750 default

range = 25-1000

Low Alarm Level 6 ( default ) Read/Write 50 default

range = 25-1000

Instance Number 7 ( default ) Read/Write Default value:

Serial Number Label (Figure 1)

Range: 0~4194302

Room TEMP. (°C) 8 ( default ) Read

BACnet Protocol Implementation Conformance Statement (PICS):

Device Profile BACnet Application Specific Controller (B-ASC)

Data Sharing Read Property-B (DS-RP-B)

Read Property Multiple-B (DS-RPM-B)

Write Property-B (DS-WP-B)

Write Property Multiple-B (DS-WPM-B)

COV-B(DS-COV-B)

A calibration check of the sensor requires a supply of:

• ZERO GAS (air or nitrogen). It may be possible to use ambient air if user is certain it does

not contain refrigerant gas or an interfering component

• SPAN GAS Cylinder comprised of refrigerant gas of appropriate concentration

6.1 Calibration Check Procedure

To verify proper sensor operation:

1. If the active alarm level is lower than the concentration of calibration gas, please be aware

that the relay may activate. You may modify the active alarm level via Modbus or BACnet

or you may switch to the alternate alarm level using switch S303-4 (refer to Alarm Level

section above).

2. If appropriate, deactivate any equipment connected to the outputs, or disconnect the wiring

of the outputs.

CAUTION

If any control instruments connected to this detector are wired to external devices (e.g., horns, exhaust

fans, and fire suppression systems), these devices may activate during the following procedures.

To prevent activating these devices while adjusting this monitor, disconnect the wiring to the control

device. Return all wiring to the control device when the calibration procedure is completed.

3. With the tubing connected to the regulator and cylinder, place tubing in the opening at the

bottom of this unit (see Figure 6).

4. Open the regulator and apply gas. This process may take up to five minutes.

5. If the unit is operating properly:

• The Red LED:

• illuminates when concentration level > Calibration Check level or Active Alarm level

• is visible through the upper and lower enclosure vents.

• the relay will activate if the Active Alarm level is exceeded.

6. Turn off regulator and remove tubing from opening.

7. Allow gas level to return to normal.

8. Reactivate any equipment connected to the outputs or reconnect the wiring to the outputs.

9. Remember to restore any alarm level settings that may have been changed for the Calibration

Check.

Device Management Dynamic Device Binding-B (DM-DDB-B)

Dynamic Object Binding-B (DM-DOB-B)

Device Communication Control-B (DM-DCC-B)

Reinitialize Device-B (DM-RD-B)

Data Link Layer Options MS/TP Master (Clause 9),

Baud Rates: 9600, 19200, 38400, 57600, 76800, 115200

Static device binding Supported NO

Character Sets Supported ISO 10646 (UTF-8)

Segmentation Capability NO

BACnet Standard Object Types supported:

Property Object Type

Device Analog Input Analog Values

Object Identifier R R R

Object Name R R R

Object Type R R R

System Status R

Vendor Name R

Vendor Identifier R

Model Name R

Firmware Revision R

App Software

Revision

R

Protocol Version R

Protocol Revision R

Services Supported R

Object Type

Supported

R

Object List R

.25 LPM

REGULATOR

467895

SPAN OR ZERO

GAS CYLINDER

Figure 6: Applying Calibration Gas

Loading...

Loading...