Page 1

Instruction Manual

Chillgard® RT

Refrigerant Monitor

Order No.: 814073/18

MSAsafety.com

Page 2

THIS MANUAL MUST BE CAREFULLY READ BY ALL INDIVIDUALS WHO HAVE OR WILL

HAVE THE RESPONSIBILITY FOR INSTALLING, USING OR SERVICING THE PRODUCT.

Like any piece of complex equipment, this instrument will perform as designed only if it

is installed, used and serviced in accordance with the manufacturer’s instructions.

OTHERWISE, IT COULD FAIL TO PERFORM AS DESIGNED AND PERSONS WHO RELY

ON THIS PRODUCT FOR THEIR SAFETY COULD SUSTAIN SEVERE PERSONAL INJURY

OR DEATH.

The warranties made by Mine Safety Appliances Company with respect to the product

are voided if the product is not used and serviced in accordance with the instructions in

this manual. Please protect yourself and others by following them. We encourage our

customers to write or call regarding this equipment prior to use or for any additional

information relative to use or repairs.

WARNING

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

USA

Schlüsselstrasse 12

8645 Rapperswil-Jona

Switzerland

For your local MSA contacts please go to our website www.MSAsafety.com

©

MSA 2016. All rights reserved

Page 3

1.

Warranty- Seller warrants that this product will be free from

mechanical defect or faulty workmanship for a period of eighteen

(18) months from date of shipment or one (1) year from installation,

whichever occurs first, provided it is maintained and used in

accordance with Seller’s instructions and/or recommendations.

This warranty does not apply to expendable or consumable parts

whose normal life expectancy is less than one (1) year such as,

but not limited to, non-rechargeable batteries, filament units, filter,

lamps, fuses etc. The Seller shall be released from all obligations

under this warranty in the event repairs or modifications are made

by persons other than its own or authorized service personnel or if

the warranty claim results from physical abuse or misuse of the

product. No agent, employee or representative of the Seller has

any authority to bind the Seller to any affirmation, representation or

warranty concerning the goods sold under this contract. Seller

makes no warranty concerning components or accessories not

manufactured by the Seller, but will pass on to the Purchaser all

warranties of manufacturers of such componen

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED, IMPLIED OR STATUTORY, AND IS STRICTLY

LIMITED TO THE TERMS HEREOF. SELLER SPECIFICALLY

DISCLAIMS ANY WARRANTY OF MERCHANT ABILITY OR OF

FITNESS FOR A PARTICULAR PURPOSE.

2.

Exclusive Remedy- It is expressly agreed that Purchaser's sole

and exclusive remedy for breach of the above warranty, for any

tortious conduct of Seller, or for any other cause of action, shall be

the repair and/or replacement at Seller's option, of any equipment

or parts thereof, which after examination by Seller is proven to be

defective. Replacement equipment and/or parts will be provided at

no cost to Purchaser, F.O.B. Seller's Plant. Failure of Seller to

successfully repair any non-conforming product shall not cause the

remedy established hereby to fail of its essential purpose.

3.

Exclusion of Consequential Damage- Purchaser specifically

understands and agrees that under no circumstances will seller be

liable to purchaser for economic, special, incidental or

consequential damages or losses of any kind whatsoever, including

but not limited to, loss of anticipated profits and any other loss

caused by reason of nonapplicable to claims for breach of warranty, tortious conduct or any

other cause of action against seller.

MSA Permanent Instrument Warranty

ts.

operation of the goods. This exclusion is

i

Page 4

General Warnings and Cautions

1.

The monitor and Relay Module described in this manual must be

installed, operated, and maintained in strict accordance with the

labels, cautions, warnings, instructions, and within the limitations

stated.

2.

The monitor must not be installed in outdoor areas or in locations

where explosive concentrations of combustible gases or vapors

might occur in the atmosphere: Class I, Group A, B, C, and D

areas as defined by the NEC. Because the monitor is not

explosion-proof, it must be located in non-hazardous areas.

3.

The Chillgard RT Refrigerant Monitor is designed to detect one

particular refrigerant gas or vapor at ambient atmospheric

pressures. The unit will not detect refrigerant gas at elevated

temperatures.

4.

High levels of or long exposure to certain compounds in the tested

atmosphere may contaminate the sensor. In atmospheres where

the system may be exposed to such materials, perform calibration

frequently to ensure dependable system operation and accurate

indications.

5.

Do not paint the Chillgard RT System. Also, do not paint near any

of the sample line inlets to ensure paint is not deposited on the

sample inlet fitting of the units. Such p

with the sampling process, whereby a sample of the atmosphere

being monitored is drawn into the Chillgard RT System.

6.

The only absolute method to assure the proper overall operation of

a gas detection instrument is to check it with a known

concentration of the gas for which it has been calibrated.

Consequently, a calibration check must be included as part of the

installation and as a routine inspection of the system.

7.

Perform periodic leak checks on all the sample lines and all flow

system components and fittings of the Chillgard RT System.

8.

Use only genuine MSA replacement parts when performing any

maintenance procedures provided in this manual. Failure to do so

may impair instrument performance. Repair or alteration of the

Chillgard RT System, beyond the scope of these maintenance

instructions or by anyone other than authorized MSA service

personnel, could cause the product to fail to perform as designed,

and persons who rely on this product for their safety could sustain

serious personal injury or death.

WARNING

aint deposits would interfere

ii

Page 5

9.

Properly vent the exhaust of the Chillgard RT System to a safe

area. Improper venting of the exhaust may cause serious personal

injury or death.

10.

Ensure the gas sample to the system is clean and non-condensing.

Install end-of-line filters in all sample inlet lines.

11.

Avoid any installation where condensation may form. Condensation

may possibly clog or block the sampling line; this will prevent the

instrument from receiving new or fresh gas samples from the area

being monitored.

12.

The Chillgard RT Refrigerant Monitor must be installed, located

and operated in accordance to all applicable codes. These codes

include, but are not limited to, the National Fire Prevention Code

and National Electric Code.

13.

The Chillgard RT Relay Module must be connected to proper main

voltages. Connection of improper voltages will cause the unit to

fail. The Chillgard RT Relay Module uses the same electrical

ground as the RT Monitor.

14.

Protect the Chillgard RT Relay Module from vibration and heating;

otherwise, improper operation may result, which can result in

personal injury or death.

15.

Do not exceed the relay contact ratings listed in Appendix B,

TABLE B-1 Otherwise,

relay operation may fail, which can result in

personal injury or death.

Failure to comply with the above warnings can result in

serious personal injury or death.

1.

Do not attempt to modify or adjust the sensing element.

CAUTION

iii

Page 6

Chapter 1

General Information ........................................ 1-1

Introduction ...................................................................... 1-1

Table 1-1. Chillgard RT System

General Operating Specifications .................... 1-2

Identifying Your Unit ........................................................ 1-3

Multipoint Sequencer .................................................... 1-3

Figure 1-1. Identifying your Unit ............................... 1-4

Figure 1-2. Single Point Sequencer Unit .................. 1-5

Figure 1-3. Four Point Sequencer Unit ..................... 1-5

Figure 1-4. Eight Point Sequencer Unit .................... 1-5

Beacon .......................................................................... 1-6

End of Sample Line Filters ........................................... 1-6

General Description ......................................................... 1-6

The Chillgard RT Unit: .................................................. 1-6

Figure 1-5. Chillgard RT Monitor

with Optional Beacon ...................................... 1-6

The Internal Multipoint Sequencer Unit: ....................... 1-7

Terminology ..................................................................... 1-8

Applications ..................................................................... 1-9

Sensor Selectivity* ........................................................... 1-9

Table 1-2. Typical Chillgard RT System for

R-11 Cross-Sensitivity Response Data ........... 1-9

Table 1-3. Typical Chillgard RT System for

R-12 Cross-Sensitivity Response Data ......... 1-10

Table 1-4. Typical Chillgard RT System for

R-22 Cross-Sensitivity Response Data

Table 1-5. Typical Chillgard RT System for

R-123 Cross-Sensitivity Response Data ....... 1-11

Table 1-6. Typical Chillgard RT System for

R-134a Cross-Sensitivity Response Data ..... 1-11

Table 1-7. Typical Chillgard RT System for

R-113 Cross-Sensitivity Response Data ....... 1-12

Table 1-8. Typical Chillgard RT System for

R-114 Cross-Sensitivity Response Data ....... 1-12

Table of Contents

......... 1-10

iv

Page 7

Table 1-9. Typical Chillgard RT System for

R-500 Cross-Sensitivity Response Data ....... 1-12

Table 1-10. Typical Chillgard RT System for

R-502 Cross-Sensitivity Response Data ....... 1-13

Table 1-11. Typical Chillgard RT System for

Ammonia*

Cross-Sensitivity Response Data .................. 1-13

Table 1-12. Typical Chillgard RT System for

R-404a Cross-Sensitivity Response Data ..... 1-14

Chapter 2

Installation and Set-up .................................... 2-1

Receiving ......................................................................... 2-1

Unpacking the System .................................................... 2-1

Initial Inspection ............................................................ 2-1

WARNING ........................................................... 2-1

Location of the Monitor .................................................... 2-2

Instrument Location Guidelines .................................... 2-2

WARNING ........................................................... 2-2

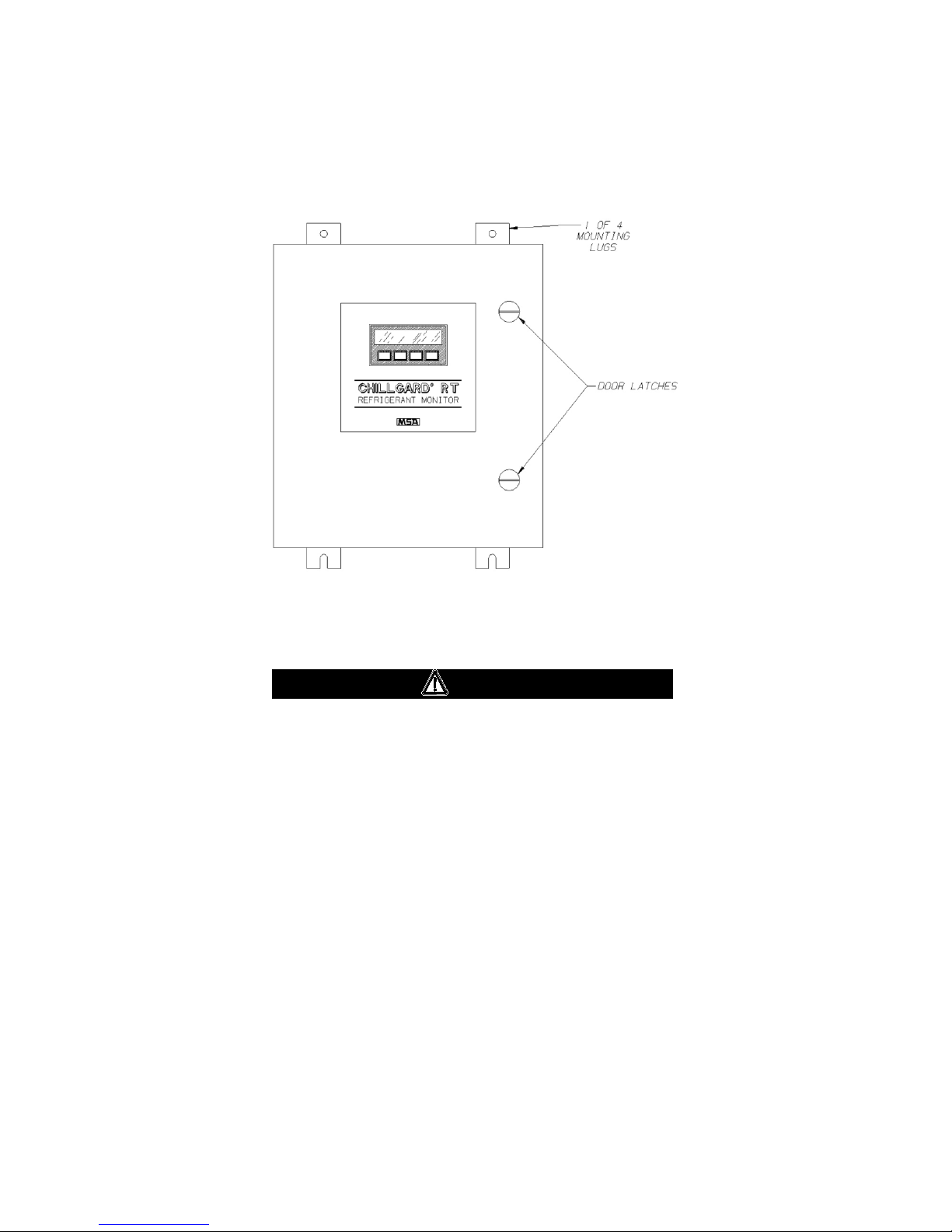

Figure 2-1. Front Door Latches ................................ 2-2

Guidelines for Locating the Sampling Point(s) ................ 2-3

Equipment Configuration .............................................. 2-3

Figure 2-2. Typical Monitor Installation .................... 2-4

Activity in the Room ...................................................... 2-5

CAUTION ............................................................. 2-5

Mounting the Unit ............................................................ 2-6

Sample System Installation ............................................. 2-6

WARNING ............................................................ 2-6

WARNING ............................................................ 2-6

Wiring Connections ......................................................... 2-7

Opening the Unit ........................................................... 2-7

CAUTION ............................................................. 2-7

CAUTION ............................................................. 2-7

Figure 2-3a. Mounting Dimensions ........................... 2-8

Figure 2-3b. Mounting Dimensions ........................... 2-9

Unit Power Wiring .......................................................... 2-10

Power Supply Wiring .................................................. 2-10

CAUTION ........................................................... 2-10

Figure 2-4. Primary Power Wiring .......................... 2-10

v

Page 8

Wiring the Chillgard RT Unit ....................................... 2-11

Analog Signal Output Wiring (FIGURE 2-5) ............... 2-11

4-20 mA ...................................................................... 2-11

0-10 VDC .................................................................... 2-11

RS 232 Output ............................................................ 2-12

Figure 2-5. Wiring Connections .............................. 2-12

Ferrite Bead Installation .............................................. 2-13

Figure 2-6. Ferrite Bead Installation ....................... 2-13

CAUTION ........................................................... 2-13

Optional Alarm Beacon ............................................... 2-14

Relay Outputs ............................................................. 2-14

Alarm Relays ............................................................... 2-14

Trouble Relay .............................................................. 2-15

Trouble Relay Connection Wiring ............................... 2-15

Remote Reset ............................................................. 2-15

Audible Alarm Output .................................................. 2-16

Auxiliary Input - Use UL Listed Devices ..................... 2-16

Initial Calibration ............................................................ 2-16

CAUTION ........................................................... 2-16

Multipoint Sequencer Operation .................................... 2-17

Chapter 3

Start-up and Initial Adjustments .................... 3-1

Figure 3-1a. Display Screen Overview ..................... 3-2

Figure 3-1b. Display Screen Overview Continued 3-3

Figure 3-2a. Start-up and

Normal Operation Screens .............................. 3-4

Figure 3-2b. Start-up and

Normal Operation Screens Continued ............ 3-5

Figure 3-3a. Setup Screens ...................................... 3-6

Figure 3-3b. Setup Screens Continued .................... 3-7

Figure 3-4. Span Calibration ..................................... 3-8

Figure 3-5. Zero Calibration ...................................... 3-9

Figure 3-6. Check Calibration ................................. 3-10

Figure 3-7. Diagnostic Screens .............................. 3-11

Figure 3-8. Diagnostic Screens .............................. 3-12

Figure 3-9. Diagnostic Screens .............................. 3-13

Figure 3-10. Data Screens ...................................... 3-14

vi

Page 9

Figure 3-11. Sequencer Set-up Screen .................. 3-15

Figure 3-12. Sequencer Set-up Screen .................. 3-16

Figure 3-13. Alarm Level Screen ............................ 3-17

Figure 3-14. Alarm Latching Screen ....................... 3-18

Figure 3-15. Alarm Latching Screen ....................... 3-19

Figure 3-16. Audio Alarm Screen ............................ 3-20

Figure 3-17. Analog Output Screen ........................ 3-21

Figure 3-18. Aux Alarm Screen ............................... 3-22

Figure 3-19. Auxiliary Alarm Screen ....................... 3-23

Figure 3-20. Setup Time ......................................... 3-24

Figure 3-21. Setup Log ........................................... 3-25

Figure 3-22. Setup Password ................................. 3-26

Figure 3-23. Review Log ......................................... 3-27

Figure 3-24. Review Data ....................................... 3-28

Chapter 4

Calibration ....................................................... 4-1

Introduction ...................................................................... 4-1

Calibration Equipment ..................................................... 4-2

Equipment needed: ....................................................... 4-2

Figure 4-1. Kit Components ...................................... 4-2

Table 4-1. RP Calibration Gases............................. 4-3

Chillgard RT identification ................................................ 4-3

CAUTION ............................................................ 4-3

Figure 4-2. Chillgard RT Models ............................... 4-4

Calibration Procedures .................................................... 4-5

Table 4-2.

Calibration Sequence Screens .............. 4-5

Figure 4-3a. Zero Calibration .................................... 4-6

Figure 4-3b. Zero Calibration Continued .................. 4-7

Figure 4-4. SPAN Calibration .................................... 4-8

Figure 4-5. Ammonia or R-404a Unit Calibration ..... 4-8

WARNING ........................................................... 4-9

vii

Page 10

Chapter 5

Maintenance .................................................... 5-1

General Maintenance ...................................................... 5-1

Obtaining Replacement Parts ......................................... 5-1

WARNING ........................................................... 5-1

Table 5-1. Replacement Parts ................................. 5-2

Troubleshooting Guidelines (see TABLE 5-2) ................. 5-3

Table 5-2. Troubleshooting Guidelines.................... 5-3

Chapter 6

Data Logging ................................................... 6-1

Log Size ........................................................................... 6-1

Last Values ...................................................................... 6-1

Number of Data Points Used .......................................... 6-1

User Setup Options ......................................................... 6-1

Viewing Alarms/Events and Data .................................... 6-1

Appendix A

Check List ....................................................... A-1

Appendix B

Relay Module .................................................. B-1

General Description………………………………………..B-1

Figure B-1. Relay…………..………………………….B-1

Figure B-2. Mounting the Relay Module…………….B-2

Specifications……………………………………………….B-3

Table B-1. Specifications…………………………….B-3

Figure B-3. Relay Module Main Power Connector

and Communication Cable Connector

Locations………………………………………...B-3

Communication Cable Connections…………………B-4

Figure B-4. Chillgard RT Relay Module Power

Wiring Diagrams for 120 Volts and

240 Volts ………………………………………..B-4

Figure B-5. Chillgard RT Refrigerant Monitor………B-4

viii

Page 11

Figure B-6. Typical Interface Modules………………B-5

Unpacking the Shipping Carton ...................................... B-6

Identifying the Unit .......................................................... B-6

Table B-2. Part Numbers and Supplied Relays .... B-6

Mounting Your Unit ............................................................... B-6

Electrical Connections for the Chillgard RT

Relay Module ....................................................................... B-6

Main Power Connections ................................................ B-6

CAUTION ................................................................... B-6

Communication Cable Connections ............................. B-7

WARNING .................................................................. B-7

CAUTION ................................................................... B-7

WARNING .................................................................. B-7

Communication Cable Connections

to the Chillgard RT Relay Module ................................... B-8

Communication Cable Connections

to the Chillgard RT Refrigerant Monitor .......................... B-8

Relay Wiring .................................................................... B-8

Operation ............................................................................. B-9

Front Panel ..................................................................... B-9

Power ............................................................................. B-9

Trouble ........................................................................... B-9

CAUTION ................................................................... B-9

WARNING .................................................................. B-9

Ready Indicator ............................................................. B-10

Chillgard RT Relay Module Relays ............................... B-10

The Common Horn Relay ............................................. B-10

The Trouble Relay ......................................................... B-10

The Discrete Caution, Warning and Alarm Relays ....... B-11

Applying Power ............................................................. B-11

Alarm Relay Configuration ............................................

Latching ......................................................................... B-11

Normally Energized/De-energized ................................ B-11

Operation ....................................................................... B-12

Reset Switch ................................................................. B-12

Trouble Relay ................................................................ B-12

Horn Operation .............................................................. B-13

Configuration ................................................................. B-13

Reset Switch ................................................................. B-13

B-11

ix

Page 12

Maintenance .................................................................. B-13

Troubleshooting ............................................................ B-14

Table B-3. Troubleshooting ................................. B-14

Obtaining Replacement Parts ..................................... B-14

Table B-4. Replacement Parts ............................ B-14

Appendix C

RS-232 Output ................................................ C-1

Introduction ...................................................................... C-1

Figure C-1. RS-232 Location

Table C-1. RS-232 Parameters ....................................... C-2

Three types of messages can be transmitted

from the RS-232 port: ................................................ C-2

Status............................................................................... C-3

Data Logged Value .......................................................... C-3

Alarm Events ................................................................... C-3

Table C-2. Status Message ........................................ C-4

Table C-3. Data Logging ............................................ C-5

RS-232 Output ................................................................ C-6

Table C-4. Alarm Logging........................................... C-6

Figure C-2. Typical RS-232 Wiring ............................ C-7

Remote Gas Sampling Channel Identification ................ C-8

Table C-5. Voltage Output

Corresponds to Channel ................................. C-8

Appendix D

Multi-refrigerant Capability* .......................... D-1

Introduction ...................................................................... D-1

Specifications .................................................................. D-1

Table D-1*. Multi-Refrigerant

Chillgard RT Refrigerant Monitor

Table D-2. Typical Cross Sensitivity

at 100 Parts Per Million (PPM) at 25°C

for the Chillgard RT Refrigerant Monitor

Calibrated at 1000 PPM R11

as Expressed in Response Factors ................ D-2

Identifying Your Unit ........................................................ D-2

x

...................... D-1

Page 13

Installation ....................................................................... D-2

Figure D-1. Label and RS-232 Location ................... D-3

Figure D-2. Calibration Label .................................... D-4

Figure D-3. Manufacture Date Label ........................ D-4

Initial Setup ............................................................... D-5

Calibration ....................................................................... D-5

Display Screens .............................................................. D-5

WARNING ............................................................. D-5

Figure D-4. Gas by Point Setup Screens ................. D-7

Figure D-5. Alarm Level Screens .............................. D-8

Figure D-6a. Alarm Level Screens ............................ D-9

Figure D-6b. Alarm Level Screens .......................... D-10

xi

Page 14

xii

Chillgard RT Refrigerant Monitor

Page 15

Chapter 1

CHILLGARD RT MONITORS EVALU ATED BY UNDERWRITERS LABORATORIES, INC.

R-11

R-502

R-12

R-123

R-113

R-22

R-114

R-134a

R-500

R-404a

General Information

Introduction

This manual provides instructions for the:

• Chillgard RT Monitor

• Chillgard RT unit with Multipoint Sequencer.

These instruments can provide continuous refrigerant gas monitoring

(see TABLE 1-1 for Operating Specifications).

All units listed below have been evaluated by Underwriters Laboratory.

The ammonia units have not been evaluated by Underwriters

Laboratories, Inc.

1-1

Page 16

Table 1-1. Chillgard RT System General Operating Specifications

PERFORMANCE SPECIFICATIONS

STABILITY

0-50 ppm, +1 ppm; ammonia is 2 ppm

51-1000 ppm, +10% of reading

SHORT TERM NOISE

+1 ppm peak over a 10-minute period;

ammonia* is +2 ppm

LINEARITY

0-50 ppm +1 ppm; ammonia* is +2 ppm

51-1000 ppm, +10% of reading

WARM-UP TIME (READY)

24 hours maximum; typical, 20 minutes at 70°F (21°C)

ambient

RESPONSE TIME

90% of a step-change and alarm condition

within 110 seconds

TRANSPORT TIME

500 FT (152 M) OF

SAMPLING TUBING LENGTH

13 minutes for a 90%

step change

OPERATING

TEMPERATURES

0°C to 50°C (32°F to 122°F)

TEMPERATURE EFFECT

+0.3%/°C of reading, +0.1 ppm/°C

RELATIVE HUMIDITY

0 to 95%, RH non-condensing

SAMPLE FLOW RATE

.75 liter per minute - minimum with maximum tubing

length; typically 1.2 to 1.5 liters per minute with no tubing

MAXIMUM SAMPLE OR

EXHAUST TUBING LENGTH

150 feet (46 m) with 1/8" (3.2 mm) ID tubing, 1/4" (6.4 mm)

0.18" (4.6 mm) ID tubing

OPERATING PRESSURE

ambient atmospheric

OPERATING SPECIFICATIONS

VOLTAGE RATING

100 to 240 VAC, 50-60 Hz

POWER REQUIREMENTS

.88 amps at 120 VAC;

.54 amps at 240 VAC

TROUBLE RELAY

Normally energized, Form C contact: 240 VAC,

8 amp resistive SPDT

WARNING RELAY

One relay, Form C contacts: 240 VAC,

8 amps resistive SPDT

CAUTION RELAY

One relay, Form C contacts: 240 VAC,

8 amps resistive SPDT

ALARM RELAY

One relay, Form C contacts: 240 VAC,

8 amps resistive SPDT

ANALOG OUTPUTS

4 to 20 mA sourcing, 1,000 ohm load, 0-10 V,

2 K ohm load

MAXIMUM OUTPUT SIGNAL

LOAD FOR 4-20 MA OUTPUT

1000 ohms (includes wiring)

AUDIO ALARM DRIVE

OUTPUT

10 VDC 20-ohm load maximum

(available only with non-beacon models)

SAMPLE TUBING

CONNECTIONS

1/4" (6.4 mm) OD

DIMENSIONS

18" high, 16" wide, 7" deep

45.7 cm high, 40.6 cm wide, 17.8 cm deep

SAMPLING TUBING LENGTH

150 FT (46 M) OF

OD (total of Inlet & Outlet); 500 feet (152 m) with

step change

105 seconds for a 90%

1-2

Page 17

WEIGHT OF CHILLGARD

RT WITH SEQUENCER

45 pounds (20 kg)

TRANSPORT AND STORAGE CONDITIONS

TEMPERATURE

-67°F to 158°F (-55°C to +70°C)

HUMIDITY

99% RH non-condensing

*This unit has not been evaluated by Underwriters Laboratories, Inc.

**For UL2075 testing from 50°C to 61°C, the Temperature Effect is +0.6%/°C of reading

and +1 ppm/°C

For the Chillgard RT Remote Relay* unit option, see Appendix B, "Relay Module."

Th

e Chillgard RT Monitor is intended for indoor use in mechanical

equipment rooms housing air conditioning or refrigeration equipment or

for use in areas where bulk refrigerants are stored.

onitor uses infrared sensing technology, allowing accurate

The m

measurement of refrigerant vapors with minimum interference from

other vapors. Your Chillgard RT unit is factory-calibrated for a specific

refrigerant. It is extremely sensitive, capable of measuring down to 1

part per million (ppm). The unit monitors the signal and can operate

three alarm levels at software-selectable gas concentration values.

There is also a trouble indication to alert the operator when something

is wrong with the unit.

Identifying Your Unit

Multipoint Sequencer

The Chillgard RT Refrigerant Monitor is capable of monitoring different

types of refrigerants. However, each unit is factory-calibrated to detect

one type of refrigerant.

Check t

he label inside the front door to determine what gas your unit is

designed to detect (FIGURE 1-1). For specific guidelines on using the

RS232 function (serial communication port), see Appendix C. For

specific guidelines on the multi-refrigerant version of the Chillgard RT

Monitor, see Appendix D.

The uni

t monitors only one zone or location, but your instrument may

contain a Multipoint Sequencer capable of monitoring up to four or eight

different zones or locations. To determine the number of sampling

locations your particular unit is able to monitor, carefully tilt the unit and

count the number of inlet ports at the bottom of the case (FIGURE 1-2,

1-3 or 1-4).

1-3

Page 18

1-4

Figure 1-1. I

dentifying your Unit

Page 19

Figure 1-2. Single Point Sequencer Unit

Figure 1-3. Four Point Sequencer Unit

Figure 1-4. Eight Point Sequencer Unit

1-5

Page 20

Beacon

The optional beacon is mounted on top of the unit (FIGURE 1-5). It is

powered by the monitor’s internal DC voltage.

d of Sample Line Filters

En

End of sample line filters are required for proper unit operation; they

may be included in the shipping carton.

he end of sample line filters are not included, they must be

If t

purchased. Place an end-of-sample line filter (P/N 711561).

Fi

gure 1-5. Chillgard RT Monitor with Optional Beacon

General Description

The Chillgard RT Unit:

• Monitors refrigerant gases up to 1000 parts-per-million (ppm)

perates on the photo-acoustic principle, allowing refrigerant gas

• O

concentration measurement in a complex mixture of backgroun

gas

es

1-6

d

Page 21

• Allows refrigerant gas detection in applications where contaminants

or interferants preclude use of other techniques

• Provides a digital display; if it is a multi-point monitor, it also shows

the point number currently being sampled by the unit

• Is also used for applications requiring long-term stability and low

maintenance

• Is factory-calibrated to the full scale value of refrigerant gas

• Is compensated for the relative humidity of the gas to give

excellent zero stability and enable alarms at refrigerant gas levels

as low as 3 ppm.

• Operates over a wide temperature range

• Has front-panel windows for viewing:

• Gas concentration

• Diagnostics

• Alarm Conditions

• Is highly selective to enable operation in:

• Areas with varying humidity

• Areas containing other contaminants.

• Comes standard with:

• Four sets of relay contacts

• Two completely independent outputs:

0-10 V

4-20 mA

• One input: 4-20 mA, assignable to the ALARM relay

• RS 232 output (see Appendix C for more information).

The Internal Multipoint Sequencer Unit:

• Allows a single Chillgard RT unit to monitor up to four or eight

areas or locations, if equipped

• Each point is capable of sampling from remote areas up to 500

feet (152 m) from the Chillgard RT unit

• Contains all necessary flow components (excluding end-of-line filter

and sampling line) to properly sample four or eight areas and

indicate the gas or vapor concentrations.

1-7

Page 22

Terminology

Become familiar with the following terminology.

ZERO- A ze

air (no refrigerant gas present).

ZEROING- Th

calibration.

N- Full-scale or up-scale reading on meter display.

SPA

NNING- The process of placing a full-scale or span gas on the unit

SPA

during calibration.

N GAS VALUE- The gas concentration that gives the instrument a

SPA

full-scale or up-scale value. This value is printed on the calibration gas

cylinder containing the gas.

FLOW RATE- Vo

EXHAUST G

PUMP- T

the Chillgard RT Monitor.

ALARMS- T

at specific, user-adjustable refrigerant gas concentrations.

(Level 1 = Caution, Level 2 = Warning and Level 3 = Alarm.)

RELAT

given temperature.

ro (0) indication on the meter display usually indicates fresh

e process of placing a zero gas on the unit during

lume of gas drawn through the sample line per minute.

AS- Sample gas after it passes through the sensor.

he electric motor driven device that moves the gas sample to

he Chillgard RT System has three alarms to alert the user

IVE HUMIDITY- The percent of water vapor saturation in air at a

POINT N

drawn. Up to four or eight areas, sequentially numbered from 1 to 8,

can be sampled.

BYPA

drawn from the next area to be sampled. This feature reduces the

monitor response time when long sampling lines are used.

FRESH A

TEMPERAT

instrument (PPM) can change +0.3% for each degree (C) that the

instrument is operating above/below the temperature at which the

instrument was last calibrated.

UMBER- The location or area from which a gas sample is

SS- The Sequencer is a look-ahead system; bypass gas flow is

IR- Air that has no possibility of containing refrigerant gas.

URE EFFECT- The gas response displayed by the

1-8

Page 23

Applications

The Chillgard RT Monitor is factory-calibrated for a particular refrigerant

gas. When calibrated, the Chillgard RT System is used in a wide variety

of industrial applications, such as:

• detection of refrigerant gases leaking into the atmosphere

• ambient air monitoring for health and safety purposes

Sensor Selectivity*

The Chillgard RT Refrigerant Monitor is factory-calibrated for your

particular refrigerant gas (TABLE 1-3). The system is highly selective to

refrigerant gases in air; however, the system also responds to other

gases (interferants). See TABLES 1-2 through 1-11* for typical crosssensitivities. Actual cross-sensitivities vary from instrument to

instrument. *Typical cross-sensitivities not verified or investigated by UL.

NOTE: These cross-sensitivity values do not apply to a multi-refrigerant

unit where the optics have been adjusted to detect a variety of

refrigerants.

If it is not known whether the gas to be detected is an interferant gas,

contact MSA at 1-800-MSA-INST.

Table 1-2. Typical Chillgard RT System for

R-11 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-11

Acetone 100 14

Methyl Ethyl Ketone 100 32

Methanol 1000 130

iso-Propanol 500 400

Methylene Chloride 100 0

Xylene 100 0

Ammonia 50 0

R 113 100 25

R 11 100 100

R 22 100 30

R 12 983 490

R 134 A 100 20

R 123 100 3

Propane 0.6% 18

Ethylene 500 20

TEST CONDITIONS: Calibrated 0-1000 PPM R-11 in N2; Temperature: 25°C

1-9

Page 24

Ta

ble 1-3. Typical Chillgard RT System for

R-11 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-12

Acetone 100 3

Methyl Ethyl Ketone 1000 25

Methanol 1000 2

Methylene Chloride 1000 14

Trichloroethylene 1000 167

Ethyl Acetate 1000 22

Xylene (ortho-Xylene) 1000 5

R113 100 35

R11 100 5

R22 100 1

R12 100 100

R134A 100 2

R114 100 45

TEST CONDITIONS: Calibrated 0-1000 PPM R-12 in N

Temperature - 25°C

2;

Table 1-4. Typical Chillgard RT System for

R-22 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-22

Acetone 100 <1

R11 100 16

R123 100 35

R134A 100 25

R1132A 100 40

R22 100 100

R113 100 39

TEST CONDITIONS: Calibrated 0-1000 PPM R-22 in N2; Temperature: 25°C

1-10

Page 25

Table 1-5. Typical Chillgard RT System for

R-123 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-123

Acetone 100 22

Methyl Ethyl Ketone 500 48

Methanol 100 2

iso-Propanol 100 5

Methylene Chloride 1000 14

Trichloroethylene 1000 4

Ethyl Acetate 100 42

Xylene (ortho-Xylene) 1000 5

Ammonia 910 7

Natural Gas 1000 5

R113 100 80

R11 100 <1

R22 100 4

R12 100 8

R134A 100 140

R123 100 100

TEST CONDITIONS: Calibrated 0-1000 PPM R-123 in N2; Temperature: 25°C

Table 1-6. Typical Chillgard RT System for

R-134a Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-134a

R113 100 17

R11 100 2

R22 100 1

R134A 100 100

R123 100 8

TEST CONDITIONS: Calibrated 0-1000 PPM R-134a in N2; Temperature: 25°C

1-11

Page 26

Ta

ble 1-7. Typical Chillgard RT System for

R-113 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-113

R11 100 1

R12 100 10

R22 100 5

R123 100 125

R134A 100 175

R114 100 155

R113 100 100

TEST CONDITIONS: Calibrated 0-1000 PPM R-113 in N2; Temperature: 25°C

Table 1-8. Typical Chillgard RT System for

R-113 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-114

R11 100 105

R12 100 50

R22 100 35

R113 100 30

R123 100 3

R134a 100 20

R114 100 100

TEST CONDITIONS: Calibrated 0-1000 PPM R-114 in N2; Temperature: 25°C

Table 1-9. Typical Chillgard RT System for

R-500 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-500

R11 100 8

R22 100 0

R113 100 41

R114 100 60

R123 100 2

R134a 100 7

R502 100 5

R500 100 100

TEST CONDITIONS: Calibrated 0-1000 PPM R-500 in N2; Temperature: 25°C

1-12

Page 27

Table 1-10. Typical Chillgard RT System for

R-502 Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-502

R11 100 25

R22 100 160

R123 100 60

R134a 100 40

R502 100 100

TEST CONDITIONS: Calibrated 0-1000 PPM R-502 in N2; Temperature: 25°C

Table 1-11. Typical Chillgard RT System for

Ammonia* Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM AMMONIA

Acetone 1000 45

Methyl Ethyl Ketone 100 25

Methane 2.5% 5

Iso-Propanol 1000 725

Methylene Chloride 1000 12

O-Xylene 100 7

NH

3

R11 500 50

R22 550 15

R12 100 65

R134a 100 130

R123 100 20

Propane 0.6% 50

Pentane 0.75% 100

Ammonia 100 100

TEST CONDITIONS: Calibrated 0-1000 PPM Ammonia in N2; Temperature: 25°C

*This gas has not been evaluated by Underwriters Laboratories,Inc.for the Chillgard RTunit.

100 100

1-13

Page 28

Ta

ble 1-12. Typical Chillgard RT System for

R404a Cross-Sensitivity Response Data

GAS CONCENTRATION (PPM) EQUIVALENT PPM R-404a

R11 100 <1

R12 100 3

R22 100 2

R113 100 30

R123 100 40

R134a 100 56

TEST CONDITIONS: Calibrated 0-1000 PPM R-404a in N2; Temperature: 25°C

1-14

Page 29

Chapter 2

Installation and Set-up

Receiving

Upon receipt of the unit, inspect the shipping carton for signs of visible

damage. Report any damage to the carrier and note it on the delivery

receipt. The unit must be stored in a dry, secure place prior to its

installation and use. Store unit in the original shipping carton.

Unpacking the System

To unpack the equipment:

1.

Carefully remove the Chillgard RT Monitor from its shipping

container(s) in order to prevent damage to sensitive electrical

components. If any damage is found, report it to the shipper

immediately.

Do not install or operate a damaged unit. It may not function

properly and may not alert you to any gas conditions.

2.

Search through all packing material and containers to avoid

WARNING

Inadvertently discarding usable or valuable parts. Report any

shortages immediately to MSA.

The contents of the shipping carton are:

• instrument

• manual

• end-of-line filters (may be purchased separately).

Retain the original packing form for re-use in the event the unit

must be returned for service.

3.

Using a screwdriver, loosen the two latches on the Chillgard RT

door (FIGURE 2-1) by turning 1/4 turn counterclockwise.

4.

Open the front door.

Initial Inspection

With the front door open, carefully inspect components and assemblies

inside the enclosure. If damage or shortage is evident, advise and

promptly file the proper claim with the carrier.

2-1

Page 30

Fi

gure 2-1. Front Door Latches

Location of the Monitor

WARNING

This unit must not be located in areas that may contain a

flammable mixture of gas and air; otherwise, an explosion

may occur.

The monitor performance is dependent on its location and sensing pickup location(s). Follow the guidelines listed below before mounting the

monitor.

Instrument Location Guidelines

1.

Select a location where personnel will see the front panel or the

ional beacon before they enter the equipment room or the area

opt

where the monitoring point is located.

2.

Mount the unit vertically; do not mount the unit to structures subject

to vibration and shock, such as piping and piping supports.

3.

Do not locate the unit near an excessive heat source or in wet and

p locations.

dam

2-2

Page 31

4.

Do not mount unit where it will be exposed to direct solar heating.

5.

For proper cooling, allow at least three inches (7.6 cm) clearance

around all surfaces except for the mounting surface.

6.

Mount the unit so the front panel is easily seen and accessed for

service and calibration.

Guidelines for Locating the Sampling Point(s)

Due to the wide variation in equipment room layouts, each situation

must be analyzed individually. A sampling point may be remotely

located up to 150 feet (46 m) from the monitor (500 feet [152 m] if

0.180" (4.6 mm) I.D. tubing is used) in an area where refrigerant

vapors are most likely to leak or accumulate (FIGURE 2-2).

NOTE: The 150 and 500 feet (46 and 152 m) allowances refer to the

total sample and exhaust line length for each sample point.

Equipment Configuration

The equipment arrangement in the room can also have an impact on

the most effective place to sample. As a general guideline:

• If there is one chiller in the room, sample at the perimeter of unit.

• For two chillers, sample between them.

• With three or more chillers, multiple monitors or a single monitor

with a multi-point sampling system should be used. Airflow patterns

must always be considered.

2-3

Page 32

Figure 2-2

option have one sampling port; those with sequencer have four or eight ports)

. Typical Monitor Installation (Monitors without sequencer

2-4

Page 33

Activity in the Room

The expected activities in the room must also be considered when

determining the sensing point. Refrigerants will concentrate near the

floor. Typically, sampling 12-18 inches (30.5-45.7 cm) above the floor

is sufficient for

someone working close to the floor. If it is expected that an occupant’s

breathing zone may be less than 12-18 inches (30.5-45.7 cm) off the

floor, locate the sampling point accordingly.

early warning and to provide adequate protection for

NOTE: S

elect sampling locations which result in the shortest possible

line length in order to reduce transport time.

Consider t

he following guidelines when selecting the location for the

sampling point(s).

1.

Most refrigerants are heavier than air and sink to the floor or

accumulate in low areas.

2.

Ammonia gas is lighter than air and tends to rise to the ceiling.

3.

Place the end of the sampling line in an area that provides the

nstrument with a representative sample; ventilation Smoke Tubes

i

(P/N 458480) are useful in determining air flow patterns in ambient

sampling areas.

4.

Properly exhaust the instrument to a safe area or to outside

mosphere.

at

5.

Ensure the sampling area is free of particulate matter and

ondensing moisture; ensure sample lines will not draw moistur

c

up

into the line.

NOTE: Th

e sample gas must be adequately filtered before

ent

ering the instrument. End-of-sample-line filters must be

used with the unit. These filters must be installed at the

end of all sample lines.

6.

Ensure the end of the sampling line is unobstructed to allow the

ample to flow freely to the instrument.

s

7.

Keep sample lines as short as possible to reduce transport time.

e

Ensure that tubing radii are wide enough to prevent kinking

or bending. Otherwise, an obstruction may occur, preventing

the instrument from sampling the intended area.

CAUTION

2-5

Page 34

8.

DO NOT:

• back-pressure the exhaust line or

• connect it to a vacuum source or

• install a flow meter in the exhaust line.

ALWAYS :

connect an exhaust line that is vented to a safe area or an

outside atmosphere.

Mounting the Unit

The instrument has four mounting lugs (FIGURE 2-1). Securely mount

the unit to a wall or support, using appropriate hardware.

WARNING

Do not mount the unit directly to a chiller; the vibration may

affect the operation of the monitor, resulting in incorrect

readings.

Sample System Installation

1.

Remove all caps on the sample inlets and exhaust of the Chillgard

RT Monitor (FIGURE 2-3).

WARNING

Failure to remove any caps from the unit gas inlet or exhaust

fittings prevents gas sampling and may cause an undetected

toxic and hazardous gas build-up and a flow trouble

indication.

2.

Route the 1/4" (6.4 mm) OD tubing into the areas to be monitored.

NOTE: For

Refrigerant Units:

1/4" (6.4 mm) O

D rigid copper tubing with compression

type fittings is recommended for most refrigerants.

Soldered connections on the sample line(s) should be

avoided due to the possibility of the monitor being

sensitive to the solvents in the soldering flux paste.

For Ammonia Units:

It i

s recommended that stainless steel tubing and filters be

used. Do not use copper or brass for tubing or connection

components as they are not compatible with ammonia.

3.

After the line(s) are installed and BEFORE they are connected to

onitor:

the m

2-6

Page 35

a.

Clean lines with compressed air or nitrogen to remove any

debris.

b.

Perform a leak-check to assure they are free of leaks.

c.

Connect the line(s) to the sample port(s) on the monitor.

d.

Install the end-of-line filters.

NOTE: \All unused sample inlet(s) must be plugged or have an

end-of-line filter installed to avoid debris entering the unit.

To disable these unused lines, refer to the setup screen

shown in FIGURE 3-11.

4.

Install all tubing ends to the inlet fittings of the unit. Mark the

location identity of each individual tubing on the tubing or on the

inside of the instrument itself (FIGURE 2-3).

5.

Connect the exhaust fitting to tubing which is routed to an area

where refrigerant gases may be safely dispersed.

Ensure that each and every sample tubing has an end-of-line

filter on it; otherwise, damage to the internal components

may result.

CAUTION

Wiring Connections

Opening the Unit

All wiring to the Chillgard RT unit is made via the side entries. Open the

unit to provide complete access to all wiring connections.

Ensure that all wiring codes are followed. These codes include, but are

not limited to, the National Electrical Code.

Do not open the Chillgard RT unit door unless the equipment

is protected from splashing, spraying, or dripping water;

otherwise, damage to the internal components may result.

CAUTION

2-7

Page 36

2-8

Figure 2-3a. Mounting Dimensions

Page 37

Figure 2-3b. Mounting Dimensions

2-9

Page 38

Unit Power Wiring

A separate, dedicated power source is recommended for the refrigerant

monitor to ensure that the unit remains powered when other circuits are

shut down for servicing, routine maintenance or shift changes.

The mo

nitor uses a wide range power supply which can accept AC

power from 100 to 240 volts, 50 or 60 Hz. The power wiring should

enter the unit through one of the openings on the right side of the

enclosure. Connections are made to the screw terminals labeled L1, L2,

ACN and GND, located in the upper right side of the unit (FIGURE 2-4).

The maximum wire size that these connectors can accept is #12 AWG.

The i

ncoming power provided to the monitor determines the

configuration of the fuse(s) and wiring to the main power terminal block.

FIGURE 2-4 shows the fuse and wire connections for various voltages.

gure 2-4. Primary Power Wiring

Fi

Power Supply Wiring

1.

Using a screwdriver, loosen the two latches on the enclosure door

(FIGURE 2-1).

2.

Open the front door.

3.

Determine the power requirements for your Chillgard RT unit,

ensuring the power i

current capa

city specifications.)

s clean and reliable. (Refer to TABLE 1-1 for

If unsure of your power available, contact your facility

engineer or safety officer. If incorrect power is applied,

damage may occur to the instrument.

2-10

CAUTION

Page 39

Wiring the Chillgard RT Unit

4.

Route power wiring through one of the entries in the side of

the unit.

NOTE: Power wiring should be separated from relay wiring.

5.

For single fuse 100/120 Volts AC power connection, connect the:

• power wire to L1

• neutral wire to ACN

• ground wire to

6.

For double fuse 220/240 Volts AC power connection, connect

power wires to L1 and L2 and ground wire to

terminal

terminal.

Analog Signal Output Wiring (FIGURE 2-5)

The Chillgard RT unit has two available analog outputs. Each analog

output is software-selectable between 10% or 100% of full scale:

• 4-20 mA, isolated, current sourcing

• 0-10 VDC

These voltage and current outputs are proportional to the displayed

refrigerant concentration. Connections are made to terminal strip J17

located on the lower left side of the main circuit board (FIGURE 2-5).

Analog output wiring should enter the unit through the hole provided on

the left side of the unit. The terminal portion of the connector can be

removed from the circuit board for easier connection. The maximum

wire size that these connectors can accept is Listed #12 AWG; the

maximum cable length is 500 feet (152 m).

It is suggested that Listed #18 AWG, twisted-pair wire be used. If

shielded wire is necessary, ground the shields of all cables at the

receiving end of the signal. Do not ground or connect the shields at the

Chillgard RT Monitor.

4-20 mA

The 4-20 mA output sources current to a separate return. Connections

are made to

terminals 2 (I+) and 3 (RTN) on terminal strip J17.

1-10 VDC

The 0-10 VDC output sources voltage to 2 K ohms maximum load.

Connections are made to terminals 4 (V+) and 5 (COM) on terminal

strip J17.

2-11

Page 40

The voltage output can be programmed to correspond to the channel

presently being sampled. The front-panel screen shows:

1V/PT IF OUT = 1-10V

(indicating one volt per point if output equals one to 8 volts).

When enabled, and the unit is monitoring from:

• channel 1:

the voltage output is one volt

• channel 2:

the voltage output changes to two volts.

RS 232 Output

• See Appendix C for wiring information.

2-12

Figure 2-5. Wiring Connections

Page 41

Ferrite Bead Installation

Some models are shipped with ferrite beads. Follow the instructions

below for proper installation.

• The input and output signals must be connected by using twisted,

shielded wire pairs.

• The shield or its drain wire (FIGURE 2-6) must be connected to the

grounding terminal on the power supply plate.

• Each unit is supplied with Thora-Electronik #16-28-9 or equivalent

ferrite (P/N 10017468).

• The shield must also be connected to ground at the receiving

equipment.

• The RS 485 communications lines to the relay module must be

wired in a similar manner. See Appendix B for more information on

the relay module.

Bundle low voltage wiring together (lower than 30 volts),

separate from high voltage wiring (higher than 30 volts).

CAUTION

Figure 2-6. Ferrite Bead Installation

2-13

Page 42

Opt

ional Alarm Beacon

Your unit may have an optional alarm kit installed. This kit is made up of

a beacon on the top of the unit. It is factory-wired so no additional wiring

is necessary; it lights when any alarm indication is given by the

instrument. This function parallels the audible alarm output (when the

horn sounds, the beacon will light).

Relay Outputs

Alarm Relays

There are three alarm relay outputs:

aution (factory-set to trip at 9 ppm)

• C

• Warning (factory-set to trip at 29 ppm)

• Alarm (factory-set to trip at 700 ppm)

elay can be set up as latching/non-latching and/or normally-

Each r

energized/normally de-energized. Contacts are Form C at 240 Volts AC

8 amps resistive. Connect wiring to Terminal Strip J29. User can adjust

alarm trip points via the front panel (see Section 3, FIGURE 3-13).

NOTE: R

esponse time equals 90% of a step change and alarm

condition within 110 seconds.

Alarm R

Three r

are Form C, SPDT relays which can be

elay Connections Wiring

efrigerant level alarm relay outputs are provided. All alarm relays

wired to either closed or opened

contacts in an alarm condition.

elay has contacts for:

Each r

• N

ORMALLY OPEN (NO)

• COMMON (COM)

• NORMALLY CLOSED (NC)

The f

unction of each relay connector terminal is shown on FIGURE 2-5.

Relay w

iring should enter the unit through one of the openings on the

right side of the unit. Connections are made at the internal terminal strip

labeled J29, located on the right side of the circuit board (FIGURE 2-5).

The terminal portion of the connector can be unplugged from the circuit

board for easier wire connections.

NOTE: Th

e maximum wire size that these connectors can accept is

#12 AWG.

2-14

Page 43

Trouble Relay

There is one relay (the Trouble relay) within the unit that indicates that a

trouble or start-up condition exists. This relay is configured from the

factory and operates differently than the alarm relays. It operates in a

normally-energized mode.

This relay is energized when the instrument is:

• normally operating,

• in the calibration mode, or

• in the setup condition.

The relay is de-energized when:

• a fault is detected,

• the unit is in the start-up state, or

• the main power is lost.

This means that power is no longer provided to the relay coil. It is not

possible to change the configuration of the Trouble relay.

The relay connector function or identification:

• NORMALLY OPEN (NO),

• COMMON (COM),

• NORMALLY CLOSED (NC)

as marked in FIGURE 2-5 refers to the relay contacts as if the relay is

de-energized or in the trouble condition. A relay contact is provided

between the Normally Closed (NC) and Common (COM) position. This

contact will be made in the event that main power to

any other trouble condition exists.

the unit is lost or

Trouble Relay Connection Wiring

The Trouble relay wiring should enter the unit through one of the entries

on the right side of the unit. Connections are made at the internal

terminal strip labeled J29, positions 1, 2 and 3 (located on the right side

of the circuit board - FIGURE 2-5). The terminal portion of the connector

can be unplugged from the circuit board for easier wire connections.

The maximum wire size that these connectors can accept is #12 AWG.

Remote Reset

The audible alarm and latched refrigerant level alarms can be remotely

2-15

Page 44

reset through a switch that has a momentary contact opening (normally

closed set of contacts). Connections are made to terminal strip J16,

terminals 1 and 2 with the wiring entering the enclosure through the

hole on the left side of the instrument. The switch must have signallevel contacts, typically gold plated. The maximum distance from the

reset switch to the monitor, using 18 AWG wire, is 250 feet (76 m). The

maximum wire size that these connectors can accept is #12 AWG.

Audible Alarm Output

An output is provided to drive the piezo-electric horn on the bottom of

the unit (FIGURE 1-5). This output is available for customer use,

provided that the beacon is not installed.

Auxiliary Input - Use UL Listed Devices

A 4-20 mA analog input can be made to the monitor from another

device such as another refrigerant monitor or an oxygen monitor. The

input wiring should be brought into the enclosure through the hole on

the left side of the instrument and connected to terminals 3 (AUX) and 4

AWG,

(GND) on terminal strip J16. It is recommended that Listed #18

twisted pair wire be used; maximum wire length is 250 feet (76 m). The

maximum wire size that these connectors can accept is Listed #12

AWG. Shielded wire is necessary. Ground the shields of all cables at the

transmitting end of the signal. Do not ground or connect the shield at

the Chillgard RT Refrigerant Monitor.

All field wiring must be done in accordance with national and

local electrical codes.

CAUTION

Initial Calibration

Calibrate after installation; otherwise, false or erroneous

readings can result.

The initial calibration is the same as the routine calibration. Refer to

Section 4 for this procedure.

2-16

WARNING

Page 45

Multipoint Sequencer Operation

In the sequencer setup screens, unneeded points can be de-activated

by using the RIGHT ARROW key and selecting the point to be deactivated.

• When the change key is pressed, the number in the display

goes blank.

• After pressing OK, the display shows a dark diamond to indicate

which points are de-activated (see FIGURE 3-11).

In the sequencer setup screens, the monitor can be locked on a single

point by pressing CHANGE before the RIGHT ARROW key.

• After pressing the RIGHT ARROW key and OK, only the selected

point is indicated.

• After an hour (if no buttons are pushed), the monitor returns to

normal sequencer operation (see FIGURE 3-12).

When calibrating:

• the gas inlet point can be selected.

• an inactive point can be selected.

After leaving calibration:

• the monitor returns to the previous sequencer setup (FIGURE 3-4).

Chillgard RT operation with a sequencer has a normal dwell time of 30

seconds per sample line, or four measurement cycles.

To improve monitor performance in noisy environments and eliminate

false alarms

was established.

• The factory value for this threshold is 30%.

• The threshold value is used with the Caution Alarm setpoint to

due to high noise, a user-selectable parameter "threshold"

determine when additional readings must be made on the

current sample line to confirm actual concentration at the

sample point.

• The allowable adjustment range for the threshold value is

30% to 70%.

• If this value is greater or equal to the product of the threshold and

the Caution Alarm value, the monitor dwells for an additional 60

seconds or eight more measurement cycles.

• Raising the threshold above 30% prevents false alarms but also

requires greater gas concentrations to cause the Caution Alarm to

trip (see FIGURE 2-7).

2-17

Page 46

Chapter 3

Start-up and Initial Adjustments

Before applying power to the Chillgard RT Refrigerant Monitor, follow

the Appendix A check list. This will help ensure that the instrument is

properly configured for operation.

nstrument operation is performed via the front panel which consists

All i

of four keys and a two-line by 20-character vacuum fluorescent display.

There is no reason to open the unit for set-up, calibration or diagnostic

testing of the instrument. The most commonly used, self-explanatory

screens appear on the following pages. Simply follow the on-screen

menus. The step-by step approach guides you through each operation.

• Th

e Display Screen Flow Overview (FIGURE 3-1a and 3-1b)

shows a general system function flow. See the following FIGURES

ecific Display Screen details:

for sp

• Star

• Calibration Screens (FIGURES 3-4 through 3-6)

• I

• Set-up Screens (FIGURES 3-3 and 3-11 through 3-22).

t-up and Normal Operation Screens

(FIGURE 3-2a and 3-2b)

nformation Screens (FIGURES 3-7 through 3-10 and

IGURES 3-23 and 3-24)

F

3-1

Page 47

Figure 3-1a. Display Screen Overview

3-2

Page 48

Figure 3-1b. Display Screen Overview Continued

3-3

Page 49

Figure 3-2a. Start-up and

Normal Operation Screens

3-4

Page 50

3-5

Figure 3-2

b. Start-up and

Normal Operation Screens Continued

Page 51

Figure 3-3a. Setup Screens

3-6

Page 52

3-7

Fi

gure 3-3b. Setup Screens Continued

Page 53

Figure 3-4. Span Calibration

3-8

Page 54

3-9

Fi

gure 3-5. Zero Calibration

Page 55

Figure 3-6. Check Calibration

3-10

Page 56

3-11

Figure 3-7

. Diagnostic Screens

Page 57

Figure 3-8. Diagnostic Screens

3-12

Page 58

3-13

Figure 3-9

. Diagnostic Screens

Page 59

Figure 3-10. Data Screens

3-14

Page 60

Figure 3-11. S

3-15

equencer Set-up Screen

Page 61

Figure 3-12. Sequencer Set-up Screen

3-16

Page 62

3-17

Figure 3-13. A

larm Level Screen

Page 63

Figure 3-14. Alarm Latching Screen

3-18

Page 64

3-19

Figure 3-15. A

larm Latching Screen

Page 65

Figure 3-16. Audio Alarm Screen

3-20

Page 66

3-21

Figure 3-17. A

nalog Output Screen

Page 67

Figure 3-18. Aux Alarm Screen

3-22

Page 68

3-23

Figure 3-19. A

uxiliary Alarm Screen

Page 69

gure 3-20. Setup Time

Fi

3-24

Page 70

3-25

Figure 3-2

1. Setup Log

Page 71

Figure 3-22. Setup Password

3-26

Page 72

3-27

Fi

gure 3-23. Review Log

Page 73

Figure 3-24. Review Data

3-28

Page 74

Chapter 4

Calibration

Introduction

As with any type of gas monitor, the only true check of its performance

is to apply gas directly to the sensor. The frequency of the calibration

gas test depends on the operating time and exposures of the sensors.

New monitors should be calibrated more often until the calibration

records prove stability. The calibration frequency can then be reduced to

the schedule set by the safety officer or plant manager.

Perform t

calibration adjustments. Calibration frequency may increase for a variety

of reasons. If calibration cannot be performed at any step, STOP;

consult MSA at 1-800-MSA-INST.

he calibration procedure regularly and maintain a log of

4-1

Page 75

Calibration Equipment

Equipment needed:

• Calibration Kit (MSA ATO #50; FIGURE 4-1)

• A SPAN gas cylinder

• Optional ZERO gas cylinder.

• A ZERO gas cylinder may not be needed.

• For ammonia units, zero gas cylinder must be used.

Item 1 - Tube and Tee Assembly

(P/Ns 603806 and 636866)

- Connector Assembly

Item 3

(P/N 711533)

NOTE: When used with older models

of Chillgard Monitors, the nut

end of the connector must be

cut off to fit into the Chillgard

sample inlet.

- Zero Gas Scrubber (P/N 803873)

Item 5

NOTE: Replace protective caps after use.

Item 2 - 1.5 LPM Flow Controller

(P/N 478358)

Item 4 - Span Gas Scrubber

(P/N 803874)

NOTE: Replace protective caps

after use.

Figure 4-1. Kit Components

4-2

Page 76

alibration Kit contains a ZERO gas scrubber which can be used in

The C

place of a ZERO gas cylinder if the ambient air around the Chillgard RT

contains little or no refrigerant.

CAUTION

The zero gas scrubber must be replaced periodically. The

frequency of replacement depends on the concentration of

the ambient refrigerant vapors.

The SPAN or ZERO cylinders (if needed) may be included with the

Calibration Kit; cylinders shown in TABLE 4-1 are available from MSA:

Table 4-1. RP C

DESCRIPTION CONCENTRATION PART NO.

R-11 in Nitrogen 100 PPM 803499

R-12 in Nitrogen 100 PPM 804866

R-123 in Nitrogen 100 PPM 803498

R-134A in Nitrogen 100 PPM 803500

R-22 in Nitrogen 100 PPM 804868

R-113 in Nitrogen 100 PPM 804870

Pentane in Nitrogen 0.75% 804532

substitute for Ammonia

Zero Air for CHILLGARD RT only 100% 10028042

R-11 in Nitrogen 30 PPM 812785

R-12 in Nitrogen 30 PPM 812823

R-113 in Nitrogen 30 PPM 813368

R-114 in Nitrogen 30 PPM 813369

R-123 in Nitrogen 30 PPM 812784

R-134a in Nitrogen 30 PPM 812787

R-22 in Nitrogen 30 PPM 812786

R-500 in Nitrogen 30 PPM 813370

R-502 in Nitrogen 30 PPM 813371

Nitrogen as substitute)

alibration Gases

100 PPM 803500 R-404a (use R-134a in

Become familiar with the Calibration Kit components (FIGURE 4-1).

Chillgard RT identification

You must identify your unit as a single-point monitor or a multi-point

monitor for proper calibration gas connection. Refer to FIGURE 4-2 to

help identify your unit.

4-3

Page 77

Figure 4-2. Chillgard RT Models

4-4

Page 78

Calibration Procedures

Table 4-2. Calibration Sequence Screens

#

PRESS

RESULT

1

ANY KEY

BRINGS UP MENU

2

CAL

BRINGS UP CAL MENU

3

USER

ALLOWS ADJUSTMENTS

4

ZERO

ALLOWS ZERO CALIBRATION

5

NEXT

PROMPT: ALARMS ARE NOW OFF

6

NEXT

PROMPT: SAMPLE POINT 1 TO BE USED

7

NEXT

PROMPT: APPLY ZERO GAS

8

NEXT

PROMPT: ADJUST OR OK READING

9

OK

PROMPT: REMOVE ZERO GAS

10

SPAN

PROMPT: GO INTO SPAN CALIBRATION

11

NEXT

PROMPT: ALARMS ARE OFF NOW

12

NEXT

PROMPT: SAMPLE POINT 1 TO BE USED

13

NEXT

PROMPT: APPLY SPAN GAS

14

NEXT

PROMPT: ADJUST OR OK READING

15

OK

PROMPT: REMOVE SPAN GAS

16

NEXT

PROMPT: ALARMS ARE NOW ACTIVE

Before calibrating the Chillgard Monitor, leak-check the sample line(s)

connected to the monitor:

1.

Temporarily block the sample inlet at the end-of-line filter(s) and

rify that the monitor gives a trouble alarm.

ve

• If the monitor is a Multipoint Sequencer, the trouble alarm

will not activate until the blocked sampling point is selected by

the Sequencer.

2.

After checking for leaks, remove the sampling line for the

hillgard inlet.

C

• On Multipoint Monitors, use sample inlet Point 1.

3.

Attach the Calibration Kit connector assembly to the inlet.

4.

Before applying gases, familiarize yourself with the calibration

screens by stepping the monitor through the whole sequence.

Press the keys in the following order:

17 NEXT RETURNS TO NORMAL OPERATION

• When this sequence is done with zero and span gases, adjust

the zero and span readings (if necessary) in TABLE 4-2 steps

#9 and #15, respectively.

4-5

Page 79

• I

f adjustments are needed, press ADJ to access the UP, DOWN

and ENTER keys; enter the zeroing and spanning adjustments.

4.

Zeroing the Monitor:

When zero gas is required, attach a zero gas scrubber or zero gas

cylinder to the connector as shown in FIGURE 4-3.

NOTE: U

5.

Spanning the Monitor:

se only the zero gas cylinder on monitors calibrated

f

or ammonia.

When span gas is required, a span gas cylinder must be attached

to the connector as shown in FIGURE 4-4.

Figure 4-3a

. Zero Calibration

4-6

Page 80

N

OTE: The span gas must be appropriate for monitor calibration.

For many applications, a span gas cylinder of the

refrigerant of interest is available from MSA. If a span gas

cylinder of the specific refrigerant is not available, MSA has

determined an appropriate synthetic span gas. See

TABLE 4-1 for calibration cylinders available from MSA. If

a synthetic span gas is used (such as pentane for

ammonia monitors or use R134a for 404a calibration),

refer to the calibration label on the inside of the monitor

door (FIGURE 4-5).

he unit to the value given on the "synthetic span" label shown

Set t

in FIGURE 4-5.

4-7

Figure 4-3b. Zero Calibration Continued

4-7

Page 81

Figure 4-4. SPAN Calibration

Figure 4-5. Ammonia or R-404a Unit Calibration

4-8

Page 82

6.

Perform the TABLE 4-2 sequence.

a.

Apply zero gas when requested.

• Allow enough time for a stable reading.

b.

Accept (OK) or adjust ("ADJ") and enter a zero reading.

c.

Apply span gas when requested.

• Allow enough time for a stable reading.

d.

Accept (OK) or adjust ("ADJ") and enter the correct span

reading.

7.

Remove the connector assembly and re-attach the sampling line to

onitor inlet.

the m

WARNING

If the sampling line is not re-attached, the monitor cannot

sample from the remote location. During calibration, the

alarm relays do not activate; ensure that a hazardous

condition does not exist when calibrating the CHILLGARD

RT system.

4-9

Page 83

Chapter 5

Maintenance

General Maintenance

Under normal operation conditions the Chillgard RT Monitor requires

minimal maintenance. The end-of-sample-line filter(s) should be

examined regularly for dirt/dust build-up and replaced when necessary.

If the filter(s) become severely clogged with dust, the flow rate will

eventually fail and a flow alarm will occur. If the end-of-sample-line

filters are used and serviced correctly, the filters installed inside the

monitor should rarely require replacement; however, these internal

filters must be inspected periodically.

Obtaining Replacement Parts

To obtain replacement parts, address the order or inquiry to:

MSA Corporate Center

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

or call, toll-free, 1-800-MSA-INST.

WARNING

Use only genuine MSA replacement parts when performing

any maintenance procedures. Failure to do so may seriously

impair unit performance. Repair or alteration of the Chillgard

RT Monitor, beyond the scope of these instructions or by

anyone other than authorized MSA service personnel, could

cause the product to fail to perform as designed and

persons who rely on this product for their safety could

sustain serious personal injury or death.

5-1

Page 84

Ta

ble 5-1. Replacement Parts

PART PART

NO.

Internal Filter, Single Point 711561

Internal Filters, all Multipoint and single-point Ammonia 655533

Filter, End-of-Line 711561

Ammonia Unit, Filter, End-of-Line 655652

2.0 amp, 250 volt Fuse 638091

Display 655786

Front Panel Printed Circuit Board Assembly (grey ribbon cable) 10014705

Power Supply 637394

Pump Assembly 711479

Low Flow Switch 637824

Polyurethane Tubing, 1/4" (6.4 mm) OD, 1/8" (3.2 mm) ID 603806

Polyethylene Tubing, 1/4" (6.4 mm) OD, 0.17" (4.3 mm) ID 29264

Nylon Tubing, 1/4" (6.4 mm) OD, 0.180" (4.6 mm) ID 29207

*Teflon®-Lined Tubing 603876

Equalization Valve 711371

Strobe, Beacon Assembly 634674

Gasket, Beacon Assembly 711168

Connector, Beacon Assembly 637523

Sonalert 629693

Zero Gas Scrubber 803873

Span Gas Scrubber 803874

Front Panel Printed Circuit Board Assembly (black/orange cable) 711386

Printed Circuit Board, Membrane Switch, Keypad 711340

Label, Keypad 711374

*Trademark of E. I. DuPont Co.

5-2

Page 85

Troubleshooting Guidelines (see TABLE 5-2)

Unit will not turn ON

No power

1.

Check AC power to unit.

on power supply if necessary.

Table

5-2. Troubleshooting Guidelines

TROUBLE DESCRIPTION SOLUTION

2. Verify AC power to unit is wired properly.

3. Replace L1 and/or L2 fuse.

4.

Check for loose wi