Page 1

Chillgard® LC

Control Module

Instruction Manual

WARNING

"!

THIS MANUAL MUST BE CAREFULLY READ BY ALL

INDIVIDUALS WHO HAVE OR WILL HA VE THE RESPONSIBILITY

FOR INSTALLING, USING, MAINTAINING OR SERVICING THIS

PRODUCT. Like any piece of complex equipment, this prod uct

will perform as designed only if installed, used and serviced in

accorda nce with t he manufact urer’s in structi ons. OTHE RWISE ,

IT COULD FAIL TO PERFORM AS DESIGNED AND PERSONS

WHO RELY ON THIS PRODUCT FOR THEIR SAFETY COULD

SUST AIN SEVERE PERSONAL INJUR Y O R DEATH.

The warranties made by Mine Safety Appliances Company with respect to this product are

voided i f t he p r odu c t is n ot i nst a lle d , us ed an d s er vi ce d in a cc o rd ance w it h th e ins t ru cti o ns

in this manual. Plea se protec t yourself and others by follow ing them. We encourage our

customers to write or call regarding this equipment prior to use or for any additional

information relative to use or repairs.

MSA North America 1-800-MSA-INST or FAX (724) 776-8783

MSA International (412) 967-3354 or FAX (412) 967-3451

In Cana da 1-800-267-0672 or FAX (416) 663-5908

© Mine Safety Appliances Company 2008 - All Right s Reserved

This manual is available on the internet at www.msanet.com

Manufactured by

MSA NORTH AMERICA

PITTSBURGH, PENNSYLVANIA 15230

(L) REV 4 I MZ001-036 10036865

Page 2

MSA

Permanent Instrument Warranty

1. Warranty- Seller warrants that this product

will be free from mechanical defect or faulty

workmanship for a period of two years

from date of shipment, provided it is

maintained and used in accordance with

Seller’s instructions and/or

recommendations. This warranty does not

apply to expendable or consumable parts

whose normal life expectancy is less than

one (1) year such as, but not limited to,

non-rechargeable batteries, filament units,

filter, lamps, fuses etc. The Seller shall be

released from all obligations under this

warranty in the event repairs or

modifications are made by persons other

than its own or authorized service

personnel or if the warranty claim results

from physical abuse or misuse of the

product. No agent, employee or

representative of the Seller has any

authority to bind the Seller to any

affirmation, representation or warranty

concerning the product. Seller makes no

warranty concerning components or

accessories not manufactured by the

Seller, but will pass on to the Purchaser all

warranties of manufacturers of such

components. THIS WARRANTY IS IN

LIEU OF ALL OTHER WARRANTIES,

EXPRESSED, IM PL IED O R STAT UT ORY,

AND IS STRICTLY LIMITED TO THE

TERMS HEREOF. SELLER

SPECIFICALLY DISCLAIMS ANY

WARRANTY OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR

PURPOSE.

2. Exclusive Remedy- It is expressly agreed

that Purchaser’s sole and exclusive remedy

for breach of the above warranty, for any

tortious conduct of Seller, or for any other

cause of action, shall be the repair and/or

replacement at Seller’s option, of any

equipment or parts thereof, which after

examination by Seller is proven to be

defective. Replacement equipment and/or

parts will be provided at no cost to

Purchaser, F.O.B. Seller’s Plant. Failure of

Seller to successfully repair any

nonconforming product shall not cause the

remedy established hereby to fail of its

essential purpose.

3. Exclusion of Consequential Damage-

Purchaser specifically understands and

agrees that under no circumstances will

seller be liable to purchaser for economic,

special, incidental or consequential

damages or losses of any kind whatsoever,

including but not limited to, loss of

anticipated profits and any other loss

caused by reason of nonoperation of the

goods. This exclusion is applicable to

claims for breach of warranty, tortious

conduct or any other cause of action

against seller.

Page 3

Chillgard LC Control Module General Warnings and Cautions

General Warnings and Cautions

WARNING

"!

1. The Control Module described in this manual

must be installed, operated, and

maintained in strict accordance with the

labels, cautions, warnings, instructions, and

within the limitations stated.

anyone other than authorized MSA service

personnel, could cause the product to fail

to perform as designed, and persons who

rely on this product for their safety could

sustain serious personal injury or death.

2. The Control Module must not be installed in

outdoor areas or in locations where

explosive concentrations of combustible

gases or vapors might occur in the

atmosphere: Class 1, Group A, B, C, and D

areas as defined by the NEC. Because the

Control Module is not explosion-proof, it

must be located in non-hazardous areas.

3. Use only genuine MSA replacement parts

when performing any maintenance

procedures provided in this manual. Failure

to do so may seriously impair instrument

performance. Repair or alteration of the

Chillgard LC System, beyond the scope of

these maintenance instructions or by

Failure to comply with the above warnings can result in serious personal injury or death.

4. The Chillgard LC Control Module must be

installed, located and operated in

accordance to all applicable codes. These

codes include, but are not limited to, the

National Fire Prevention Code and National

Electric Code.

5 Protect the Chillgard LC Control Module from

vibration and heating; otherwise, improper

operation may result, which can result in

personal injury or death.

6. Do not exceed the relay contact ratings listed

in Section 1, TABLE B-1 Otherwise, relay

operation may fail, which can result in

personal injury or death.

Page 4

Chillgard LC Control Module Table of Contents

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-1. Chillgard LC System General Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

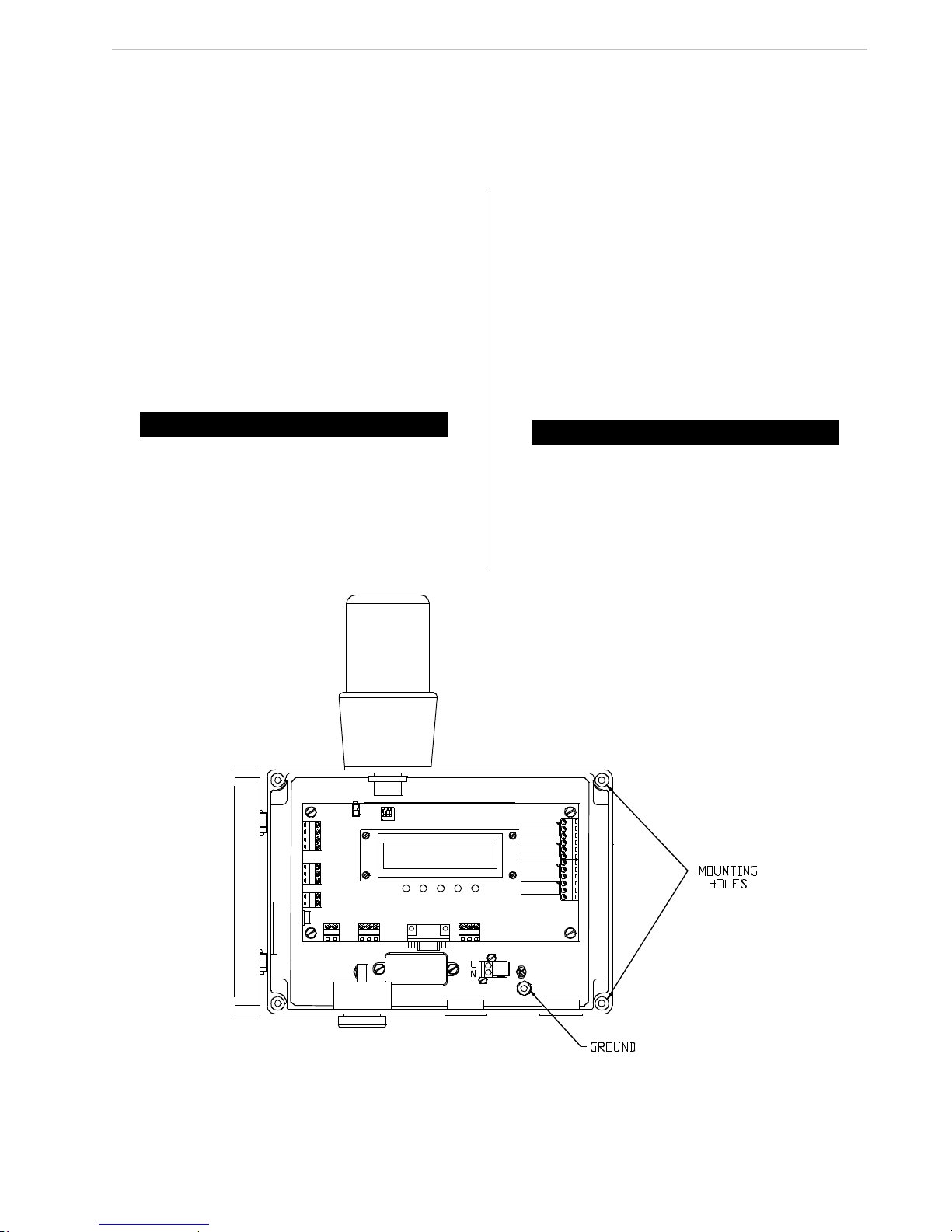

Figure 1-1. Chillgard LC Control Module Standard Version

(24 Volt AC/DC or 110/220 AC Version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Figure 1-2. Chillgard LC Control Module With Internal Transformer . . . . . . . . . . . . . . . . . . . . . 1-1

Termi n o l o g y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

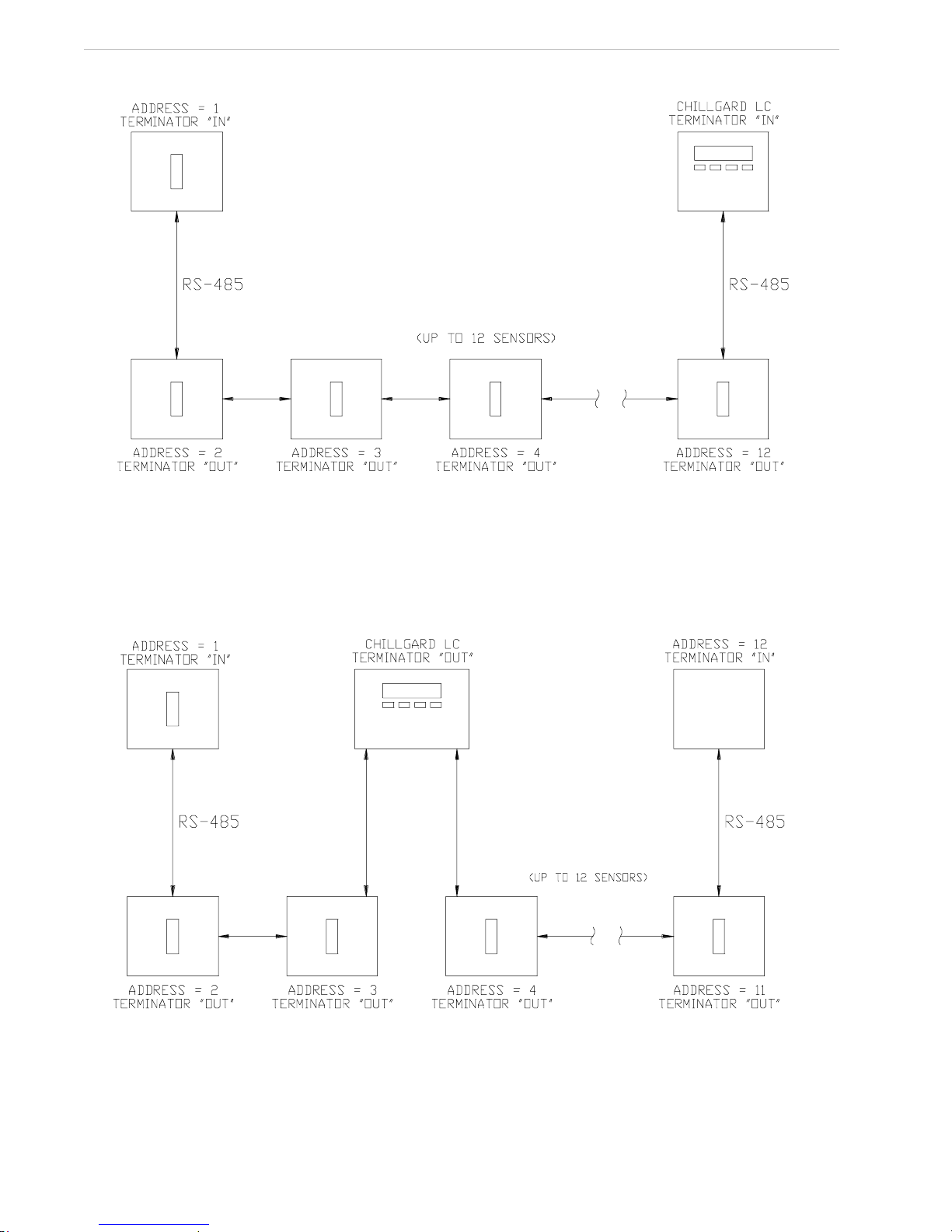

Connection of the Chillgard Instruments Using RS-485 Communications . . . . . . . . . . . . . . . . . . . . . . . 1-3

Multiple Sensor Modules with a Chillgard LC Control Module (Daisy Chain). . . . . . . . . . . . . . . . . . 1-3

Multiple Sensor Modules with a Chillgard LC Control Module (Two Branch). . . . . . . . . . . . . . . . . . 1-3

Figure 1-3. Connection of the Sensor and LC Instruments Using RS-485 Communications . . 1-3

Figure 1-4. Multiple Sensor Modules with a Chillgard LC Control Module (Daisy Chain) . . . . . 1-4

Figure 1-5. Multiple Sensor Modules with a Chillgard LC Control Module (Two Branch) . . . . . 1-4

Section 2

Insta llation and Set-u p . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Recei vi n g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpac ki n g th e S ystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

WARNIN G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

"

Initi a l In sp e c t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Location of the Control Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

" WAR N ING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

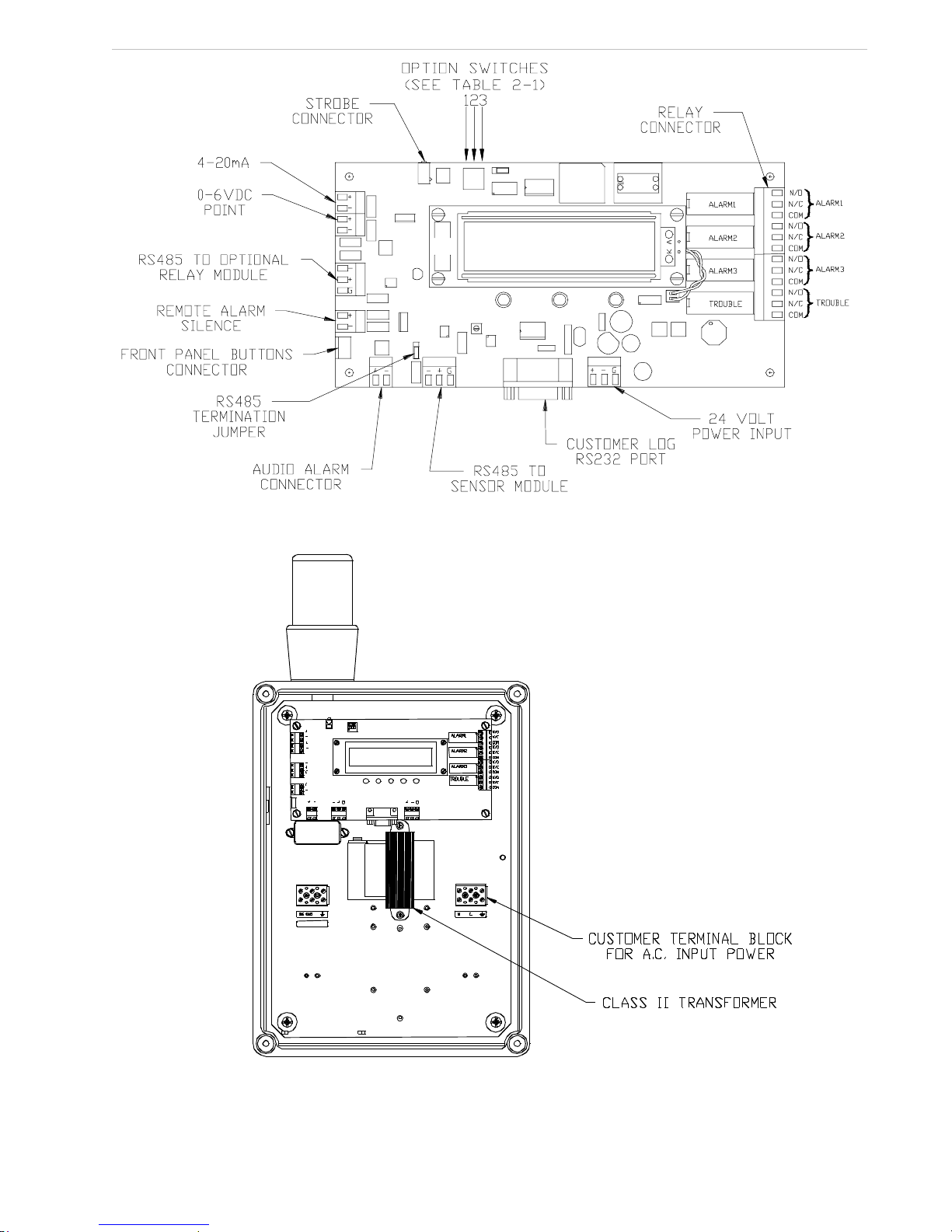

Figure 2-1. Basic LC Control Module with Door Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Wiring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Opening the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unit Po w e r Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

"!CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

" WAR N ING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Tabl e 2 -1 . Option S w i tc h Ta b l e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 2

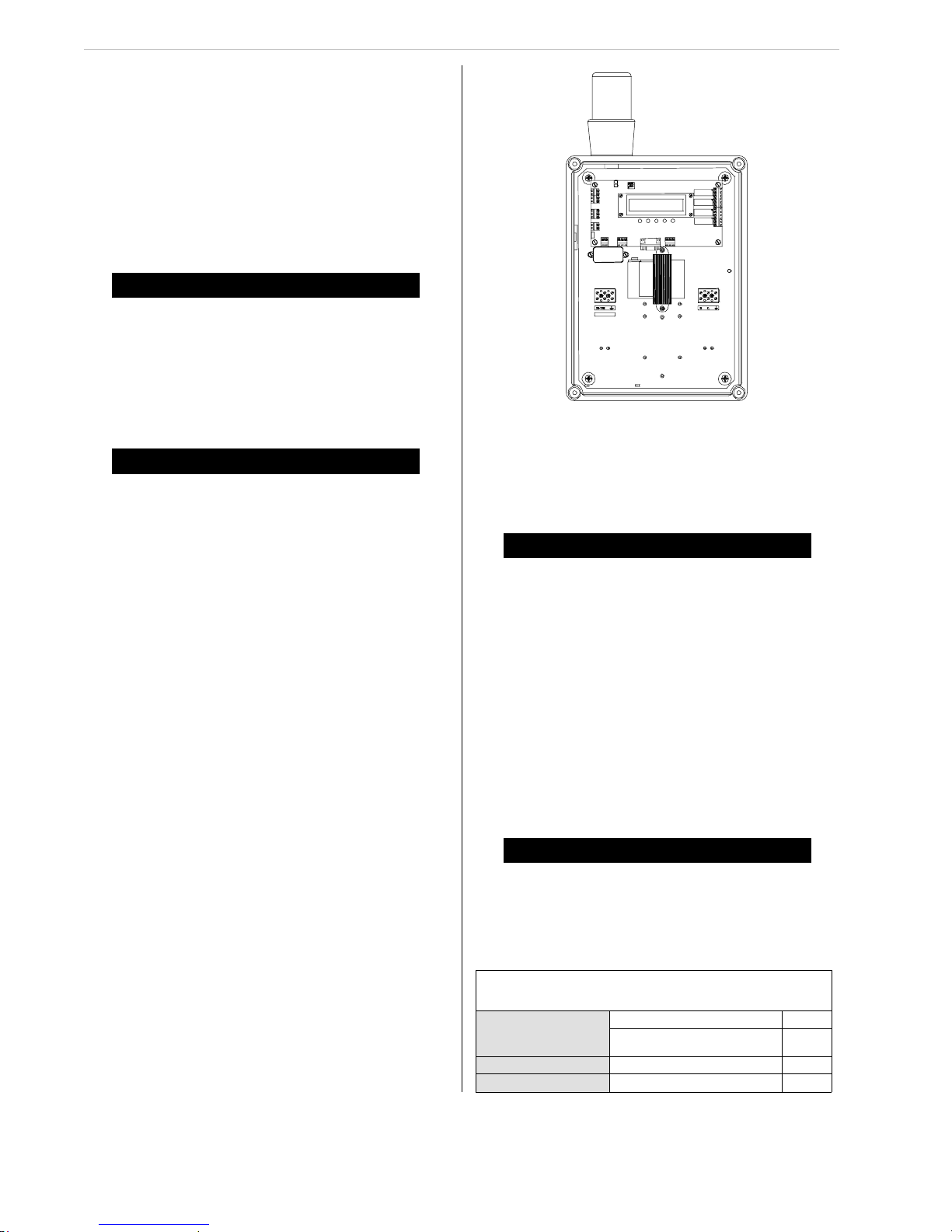

Figure 2-2. Transformer Version LC Control Module with Door Open . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3. Standard Version Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figu re 2-4. Tra n s fo r m e r V e rsion Wiring D i a g ra m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wirin g to th e Ch i l l g a r d Se n s o r s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

" WAR N ING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tabl e 2 -2 . C h i l l g a r d D ip Swi tch Pos i t i o n s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5. Chillgard LS Sensor Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-6. Chillgard M-100 Jumper Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Analog Signal Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

CAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

"!

Page 5

Table of Contents Chillgard LC Control Module

Relay Ou t p u ts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

CAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 7

"

Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setup Date, Time, and Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 7

"

Initi a l Cal i b ration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

WARNIN G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

"

Section 3

Displa y Sc reens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Figure 3-1. Display Screen Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2. Start-up and Normal Operation Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-3 Set-up Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-4 Span Calibration Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figu re 3-5 Zero C a li b r a ti o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 4

Figu re 3-6 Cali b ra t i o n Ch e ck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-7 Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-8 Data Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 6

Figu re 3-9 Alar m L e ve l Sc re e n. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figu re 3-10 Set u p Al a r m L a tching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figu re 3-11 Set u p Al a r m R e l a ys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figu re 3-12 Audi o A l a rm Scree n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-13 Analog Outputs and Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figu re 3-14 Set u p Ti mes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-15 Setup Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3- 9

Figu re 3-16 Revi e w L o g. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Section 4

Mainte na nce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Obtai n i n g R e p l a ce m e n t P a rts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

"!WARNING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Tabl e 4 -1 . R e p l a c e ment Pa rt s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

" WAR N ING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 1

Table 4-2. Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section 5

Data L oggi ng. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Numbe r of Data Poi n ts Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

User Se t u p Op ti o n s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Viewing Alarms/Events and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Figure 5-1. Log Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section 6

Calibr a t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diffu si o n V e rs i o n C a l ib r a t i o n. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Calib r a t i o n Equ i p ment - (FIGUR E 6 - 1 ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

"!WARNING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Page 6

Chillgard LC Control Module Table of Contents

Initial Calibration Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Figu re 6-1. Cal i b ra ti o n E q u i p ment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Calib r a t i o n Gu i d e l i n e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Calibration Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

"!WARNING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Figure 6-2. Applying Calibration Gas to the Chillgard LS Refrigerant Monitor. . . . . . . . . . . . . . 6-2

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Single or Four-Point Pumped Version Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Calib r a t i o n Equ i p ment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Tabl e 6 -1 . R P C a l i b ra ti o n G a s e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

" WAR N ING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Calibration Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Calib r a t i o n Gu i d e l i n e s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Figure 6-3. Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Figure 6-4. Using Zero Scrubber for Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Figure 6-5. Using Zero Gas Cylinder for Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Calibration Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

" WAR N ING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

" CA U TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Figure 6-6. Span Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

" CAU T ION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Appendix A

RS-232 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A- 1

RS-232 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table A-1. RS-232 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table A-2. Information Structure (Chillgard LC Control Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Tabl e A- 3 . Da t a St ru c t u r e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Tabl e A- 4 . Ala rm Stru c tu re . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table A-5. Alarms and Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B

Insta llation Ou t line Dra w ing. . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Figure B-1. Installation Outline Drawing for Standard Version . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Figu re B -2 . In stall a t i o n Ou tl i n e D ra w i n g fo r T r a n sformer Versi o n. . . . . . . . . . . . . . . . . . . . . . . B-3

Page 7

Chillgard LC Control Module Section 1, General Information

Section 1

General Information

Introduction

General Description

The Chillgard LC unit is a control module which

can communicate with up to eight Chillgard LS

or twelve Chillgard M100 Refrigerant Sens ors.

The Chillgard LC Control Module can be

installed remotely from the sensors, thus

enabling remote control of that Chillgard LS or

the Chillgard M100 Sensor.

The Chillgard LC comes in two major versions

based upon the power supply in the unit:

• 24 Volt AC/DC or 110/220 VAC version

• Internal Transformer version - 120 Volt input,

24 VAC output for powering Remote Sensor

Modules.

See FIGURES 1-1 and 1-2 to identify your unit.

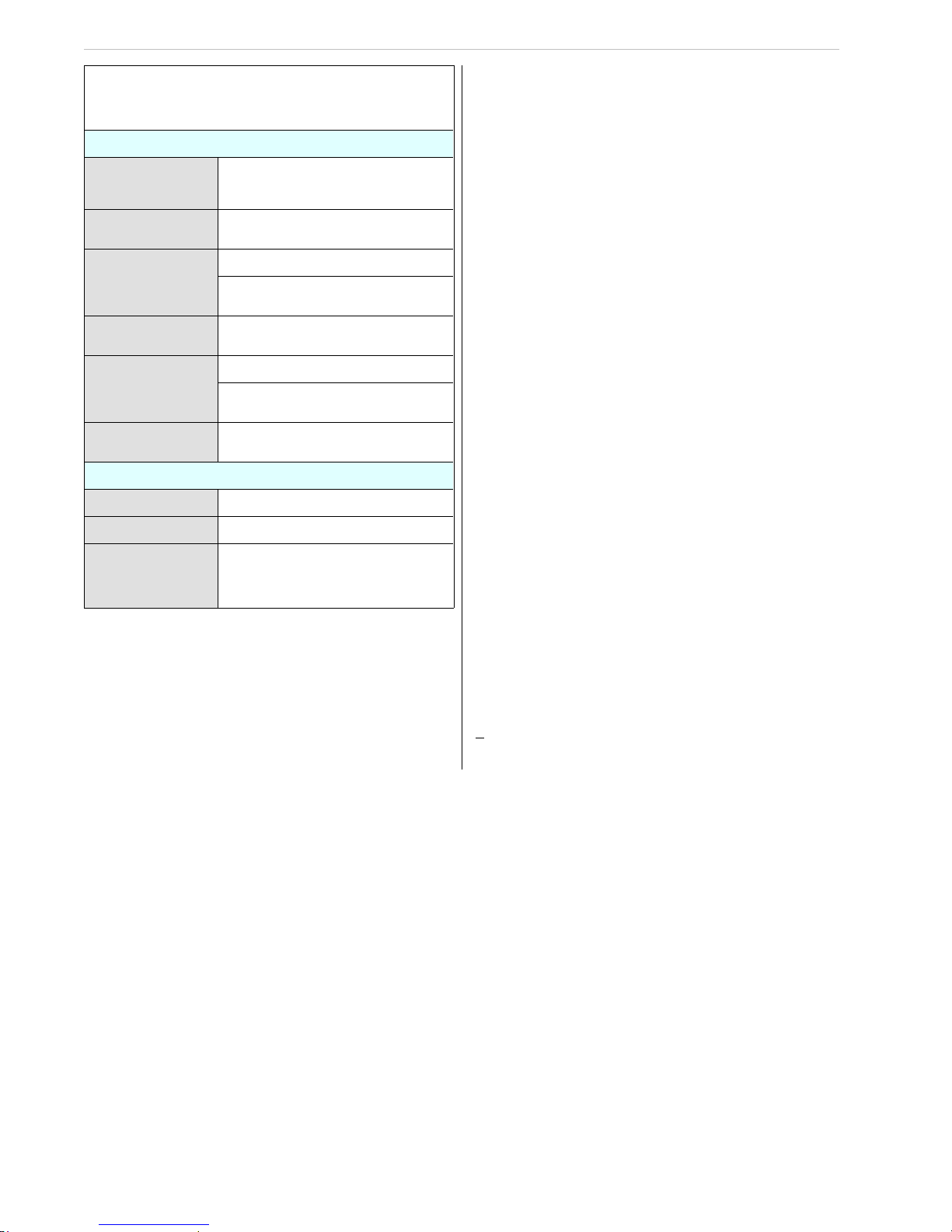

Table 1-1. Chillgard LC System

General Operating Specifications

OPERATING SPECIF ICATIONS

100 to 240 VAC, 50-60 Hz, 25 W

VOLTAGE RATING

POWER

REQUIREMENTS

TROUBLE RELAY

ALARM 1 RELAY

ALARM 2 RELAY

ALARM 3 RELAY

24 VDC +10% -0%

24 VAC

Transforme r Version: 120 V, 60 Hz, 75 VA

.15 am ps at 120 VAC;

.10 am ps at 240 VAC

0.6 am ps at 24 VAC

0.1 am ps at 24 VDC

Minimum wire size: #18 AWG

The LC Controller can power the

Chillgar d LS and seve n Chillgard

M-100 s ensors

Normally energized, Form C contact:

240 VAC, 5 amp resistive SPDT

One relay, Form C contacts: 240

VAC, 5 amps resistive SPDT

One relay, Form C contacts: 240

VAC, 5 amps resistive SPDT

One relay, Form C contacts: 240

VAC, 5 amps resistive SPDT

+10%

Figure 1-1. Chillgard LC Control Module

Standard Version

(24 Volt AC/DC or 110/220 AC Version)

ANALOG OUTPUTS

MAXIMUM OUTPUT

SIGNAL LOAD FOR

4-20 mA OUTPUT

4 to 20 mA sourcing, 500 ohm load ,

0-6 VDC, 2 K ohm load

600 ohms (includes wiring)

Figure 1-2. Chillgard LC Control Module

With Internal Transformer

1-1

Page 8

Section 1, General Information Chillgard LC Control Module

Table 1-1. Chillgard LC System

General Operating Specifications

OPERATING SPECIF ICATIONS

AUDIO ALARM

DRIVE OUTPUT

OPERATING

TEMPERATURE

STANDARD

VERSION

DIMENSIONS

STANDARD

VERSION WEIGHT

TRANSFORMER

VERSION

DIMENSIONS

TRANSFORMER

VERSION WEIGHT

TRANSPORT AND STORAGE CONDITIONS

TEMPERATURE -40

HUMIDITY 99% RH non-condensing

POLLUTION

DEGREE AND

INSTALLATION

CATEGORY

24 VDC 50-ohm load maximum

(availa ble only with non-beacon

models)

o

0 to 40

C (32 to 104oF)

7.5" high, 12.5" wide, 3.5" deep

19.05 cm high, 31.75 cm wide,

8.89 cm deep

3.5 pounds (1.59 kilograms)

14.7" high, 11.2" wid e, 5" deep

373 mm high, 284 mm wide,

127 mm deep

8.4 pounds (3.82 kilograms)

o

C to +60oC (-40oF to 140oF)

2

ZEROING- The process of placing a zero gas on

the unit during calibration.

SPAN- Full-scale or up-scale reading on

meter display.

SPANNING- The process of placing a full-scale or

span gas on the unit during calibrati on.

SPAN GAS VALUE- The gas concentration that

gives the instrument a full-scale or up-scale value.

This value is printed on the calibration gas

cylinder containing the gas.

FLOW RATE- Volume of gas drawn through the

sample line per minute.

EXHAUST GAS- Sample gas after it passes

through the sensor.

PUMP- The electric motor driven dev ice that

moves the gas sample to the refriger ant monitor.

ALARMS- The Chillgard LC System has three

alarms to alert the user at specific,

user-adjustable refrigerant gas concentrat ions.

(Level 1 = Caution, Level 2 = Warning and Level

3 = Alarm.)

RELATIVE HUMIDITY- The percent of water vapor

saturation in air at a given t emperature.

POINT NUMBER- The location or ar ea from which

a gas sample is drawn. Up to four , eight, or 12

areas, sequentially numbered from 1 to 12, can

be sampled.

Terminology

Become familiar with the following terminology.

ZERO- A zero (0) indication on the meter

display usually indicates fresh air ( no refrigerant

gas present).

FRESH AIR- Air that has no possibility of

containing refrigerant gas.

TEMPERATURE EFFECT- The gas response

displayed by the instrument (PPM) can change

+3 ppm for each degree (C) that the instrument is

operating above/below the temperature at which

the instrument was last calibrated.

1-2

Page 9

Chillgard LC Control Module Section 1, General Information

Connection of the Chillgard

Instruments Using RS-485

Communications

The Chillgard LC instrument acts as t he Master

device in the network. The LC inst rument initiates

and controls all communications on the network.

The LC instrument sends out commands and

requests for data from individual sens ors. When

the instruments are powered up, the LC unit

automatically detects the number and gas type of

all instruments on the network.

In a simple system using a single sens or module

and an LC Control module, the two m odules are

connected together; both units hav e the RS-485

terminators "IN" (FIGURE 1-3). Ref er to Section

2, Installation and Setup, for s etting the address

switches and FIGURES 2-2 and 2-3 f or the

location of the termination jumpers.

NOTE:Each sensor must have a different address.

The total length of the RS-485 cable cannot

exceed 1000 feet (304 meters).

MSA recommends Belden #9841

low-capacitance cable.

Multiple Sensor Modules with a

Chillgard LC Contro l Mo du le

(Daisy Chain)

See FIGURE 1-4.

NOTE:Up to eight Chillgard LS Sensors can be

connected to a Chillgard LC Controller.

(They must be addressed as Points 1

through 8.)

• LS1 devices can be on points 1 through 8.

• LS4 devices must be on point 1 and/or 5

and will also use the next three physical

addresses.

• LS4 on point 1 takes addresses 1, 2, 3, and 4.

• LS4 on point 5 takes addresses 5, 6, 7, and 8.

• LS4 cannot be on addresses 9, 10, 11, or 12.

Multiple Sensor Modules with a

Chillgard LC Contro l Mo du le

(Two Branch)

See FIGURE 1-5. Each end of the net work must

have the terminator IN; modules in t he middle

must have terminators OUT. RS-485 connec tions

from the Chillgard LC Control unit mus t have no

more than two terminations.

Figure 1-3. Connection of the Sensor and LC

Instruments Using RS-485 Communications

1-3

Page 10

Section 1, General Information Chillgard LC Control Module

Figure 1-4. Multiple Sensor Modules

with a Chillgard LC Control Module (Daisy Chain)

with a Chillgard LC Control Module (Two Branch)

1-4

Figure 1-5. Multiple Sensor Modules

Page 11

Chillgard LC Control Module Section 2, Installation and Set-Up

Section 2

Installation and Set-up

Receiving

Unpacking the System

To unpack the equipment:

1. Carefully remove the Chillgard LC Control

Module from its shipping container(s) in

order to prevent damage to sensitive

electrical components. If any damage is

found, report it to the shipper immediately.

WARNING

"

Do not install or operate a damaged unit. It

may not function properly and may not alert

you to any gas conditions.

2. Search through all packing material and

containers to avoid inadvertently discarding

usable or valuable parts. Report any

shortages immediately to MSA.

Initial Inspection

With the front door open, carefully inspect

components and assemblies inside the enclosure.

If damage or shortage is evident , advise and

promptly file the proper claim with t he carrier.

Location of the Control

Module

WARNING

"

Explosion Hazard!

Unit must not be located in areas that may

contain a flammable mixture of gas and air;

failure to follow this requirement can result

in death, serious injury, or equipment or

property damage.

Figure 2-1. Basic LC Control Module with Door Open

2-1

Page 12

Section 2, Installation and Set-Up Chillgard LC Control Module

Wiring Connections

Opening the Uni t

All wiring to the Chillgard LC unit is made via the

bottom entries. Open the unit to provide complete

access to all wiring connections.

Ensure that all wiring codes are followed. These

codes include, but are not limited t o, the National

Electrical Code.

CAUTION

"

Component Damage!

Monitor components must be protected from

splashing, spraying, or dripping water.

Failure to do so may cause damage to

internal components.

Unit Power W ir ing

!CAUTION

"

Instr ument Damage!

Correct powe r voltage mus t be connected to

the instrument. Failure to use cor rect voltage

may res ult in instrume nt damage.

A separate, dedicated power sourc e is

recommended for the refrigerant contr ol module to

ensure that the unit remains power ed when other

circuits are shut down for s ervicing, routine

maintenance or shift changes. Supply ear thground

is installed on lug first and all com ponent

earthgrounds are connected afterwards .

Standard Version

The control module uses a wide range power

supply which can accept AC power f rom 100 to

240 volts, 50 or 60 Hz. I f 24 Volt AC or DC is

available, power can be supplied directly to the

control board (FIGURE 2-3). The 24 V olt power

source used with this equipment must be

separated from mains by double or reinforc ed

insulation. If the 110/220 Volt power opt ion is

available, power can be supplied to terminal block

as shown in FIGURE 2-1.

Transformer Version

If the Chillgard LC unit contains t he internal

transformer, supply power as shown in

FIGURE 2-4. The resulting 24 VAC output from

the transformer can be used to power up to five

diffusion LS units or two pumped f our-point LS

units. However, voltage drop will occ ur over

extended line lengths with multiple sensors.

Ensure minimum required voltage is present at

the sensor terminals for each sensor module.

Figure 2-2. Transformer Version LC Control Module

with Door Open

WARNING

"

If insufficient voltage is supplied, unit could

display incorrect readings. check each

sensor module for minimum required voltage

at each unit.

With 18 AWG wire, a Chillgard LS Sensor Module

can be located a maximum distance of 450 feet

from the Chillgard LC Control Module. Two

Chillgard LS four-point Sensor Modules

daisy-chained from the Chillgard LC Contr ol

Module can be connected a maximum of 150 f eet

from the Chillgard LC Control Module. Wit h 18

AWG wire, seven Chillgard M-100 sensors can be

daisy-chained from the LC Control Module to a

distance of 1500 feet.

CAUTION

"

If the Chillgard LC transformer or other AC

power is used to power the Chillgard M-100

Sensor, the Chillgard M-100 AC power must

be isolated from the LC power for proper

operation.

Table 2-1. Option Switch Table

SWITCH 1

CUSTOMER RS232

PORT SPEED SET

SWITCH 2 N/A

SWITCH 3 N/A

19,200 BPS 8, N, 1 UP

9,600 BPS 8, N, 1 DN

2-2

Page 13

Chillgard LC Control Module Section 2, Installation and Set-Up

Figure 2-3. Standard Version Wiring Diagram

Figure 2-4. Transformer Version Wiring Diagram

2-3

Page 14

Section 2, Installation and Set-Up Chillgard LC Control Module

Wiring to t he Chil lgard Sens ors

The Chillgard LC Control Module can

communicate to up to 12 sample points.

Communication between these devices is

achieved through RS-485 modbus protocol

[see the Chillgard LS Instruc tion Manual

(P/N 10035164) and/or the Chillgard M-100

Instruction Sheet (P/N 10073591) for definition of

protocol]. This protocol allows for dais y-chaining

of the sensor modules to the c ontrol module. See

FIGURE 2-3 for wiring to the control m odule.

Addressing

Each sensor module must have a dist inct

address. The sensor module address swit ch is

used to specify the addresses of each sensor

module (FIGURE 2-5 and 2-6). The addresses

also determine the point number on the dis play.

WARNING

"

If the addresses of each sensor module are

not unique to each unit, the control modul e

may not recognize one or more of the sensor

modules.

The dip switch positions are shown in TABLE 2-2.

Table 2-2. Chillgard LS Dip Switch Positions

POINT ID

1100 0 0 0 -2101 1 0 0 -3102 0 1 0 -4103 1 1 0 -5104 0 0 1 -6105 1 0 1 -7106 0 1 1 -8107 1 1 1 --

1234

NOTE: 1 indicate s closed.

DIP SWITCH

For four-point sensor modules, there ar e two valid

dip switch settings: 100 and 104.

• If dip switch setting 100 is chosen, addresses

101 to 103 will be assigned to the four-point

unit and will not be available for use on other

units.

Figure 2-5. Chillgard LS Sensor Board Connections

2-4

Page 15

Chillgard LC Control Module Section 2, Installation and Set-Up

Figure 2-6. Chillgard M-100 Jumper Locations

2-5

Page 16

Section 2, Installation and Set-Up Chillgard LC Control Module

• If dip switch setting 104 is chosen, addresses

105 to 107 will be assigned to the four-point

unit and will not be available for use on other

units.

Analog Signal Output Wi r i ng

The unit has two availa ble analog outputs. The

4 to 20 mA analog output is software-se lectable

between 10% or 100% of full scale:

• 4-20 mA, isolated, current sourcing

• 0-6 VDC outputs, 0.5-Volt steps to indicate

point being monitored. For example, 1.5 V

represents point 3 at the milliamp output.

Analog output wiring should enter the unit through

the hole provided on the left side of the unit. The

maximum wire size that these connectors can

accept is Listed #12 AWG; t he maximum cable

length is 500 feet (166 meters) .

It is suggested that Listed #18 AWG, twisted-pair

wire be used. If shielded wire is nec essary,

ground the shields of all cables at t he receiving

end of the signal. Do not ground or connect the

shields at the Chillgard LC Control Module. See

FIGURE 2-2 for connecting the analog outputs.

CAUTION

"!

Bundle low voltage wiring together (lower than

30 volts), separate from high voltage wiring

(higher than 30 volts).

Optional Alarm Beacon

Your unit may have an optional alarm kit installed.

This kit is made up of a beac on on the top of the

unit. It is factory-wired so no additional wiring is

necessary; it lights when an Alar m 3 indication is

given by the instrument. Connection is made to

the strobe connector (FIGURE 2- 2). IP rating

shown on the strobe light applies t o the

strobe only.

Rela y Outputs

Alarm Relays

There are three alarm relay outputs:

• Alarm 1 (factory-set to trip at 50 ppm)

• Alarm 2 (factory-set to trip at 150 ppm)

• Alarm 3 (factory-set to trip at 1000 ppm;

300 ppm for R 123)

Each relay can be set up as latching/non-latching

and/or normally-energized/normally de-energized.

Contacts are Form C at 240 V olts AC 5 amps

resistive. User can adjust alarm trip points via the

front pane l (see Secti on 3, FIGURE 3-11).

Alarm Relay Connections Wiring

Three refrigerant level alarm relay out puts are

provided. All alarm relays are Form C, SPDT

relays which can be wired to either closed or

opened contacts in an alarm condition. Use copper

conductors only.

Each relay has contacts for:

• NORMALLY OPEN (NO)

• COMMON (COM)

• NORMALLY CLOSED (NC)

The function of each relay connec tor terminal is

indicated on FIGURE 2-2.

NOTE:The maximum wire size that these

connectors can accept is #12 AWG.

Fault Relay

There is one relay (the Fault r elay) within the unit

that indicates that a trouble or start-up condition

exists. This relay is configured from the factory

and operates differently than the alarm relays. It

operates in a normally-energized mode.

This relay is energ ized when the instrument is:

• normally operating,

• in the calibration mode, or

• in the setup condition.

The relay is de-energized when:

• a fault is detected,

• the unit is in the start-up state, or

• the main power is lost.

This means that power is no longer prov ided to

the relay coil. It is not pos sible to change the

configuration of the Trouble relay.

The relay connector function or ident ification:

• NORMALLY OPEN (NO),

• COMMON (COM),

• NORMALLY CLOSED (NC)

as marked in FIGURE 2-2 refers to the relay

contacts as if the relay is de-energized or in the

trouble condition. A relay contact is provided

between the Normally Closed (NC) and Common

(COM) position. This contact will be made in t he

event that main power to the unit is lost or any

other trouble condition exists.

2-6

Page 17

Chillgard LC Control Module Section 2, Installation and Set-Up

Remote Alarm Silence Switch

The audible alar m and latched ref rigerant level

alarms can be remotely reset throug h a switch t hat

has a momentary c ontact opening (normally clo sed

set of contac ts). Connections are made as shown in

FIGURE 2-3 with t he wiring entering the enclosure

through the hole on t he left side of the instrument.

The switch must have signal-level contacts , typically

gold plated. Th e maximum distan ce from the reset

switch to the co ntrol module, using 18 AWG wire, is

250 feet. The maximum wire size that these

connectors can accept is #12 AWG.

Audible Alarm Output

An outpu t is provided to drive the horn on the

bottom of the uni t (FIGURE 2-2).

CAUTION

"

All field wiring must be done in accordance

with national and local electrical codes.

Start-Up

The following steps outline the procedures t o

power-ON the Chillgard LC Control Module:

1. Before applying power to the unit, verify

proper power will be applied to the unit.

2. Turn the instrument ON at the circuit breaker

or fuse that supplies power to the

instrument. (The instrument does not have

a power switch.)

• A green LED indicates that power is ON

and communication is established to a

sensor module.

NOTE:The display will begin to indicate the gas

concentration of each point connected to the

Chillgard LC Control Module.

After power-ON, allow for unit s tabilization

(about 30 minutes) before checking calibration

of instrument.

Setup Date, Time, and

Logging

The data log on the LC unit must be

initialized by setting the date and time under the

Setup - Setup Time and Date Menu.

Setup logging next on the following menu:

1. Turn ON logging.

2. Set the log frequency.

3. Clear the log file to reset any readings.

4. Reset the LC unit to re-initialize the log to a

clean start.

" CAUTION

If this is not done, data recorded will not

have a time stamp and data review will not

be possible.

Initial Calibration

WARNING

"

Calibrate after installation; otherwise, false

or erroneous readings can result.

See Chillgard LS Instruction Manual

(P/N 10035164) for calibration or c alibration check

instructions. See Chillgard M100 Instruc tion Sheet

(P/N 10073591) for calibration or c alibration check

instructions.

2-7

Page 18

Chillgard LC Control Module Section 3, Display Screens

Section 3

Display Screens

All instrument operation is performed via the front

panel which consists of four keys and a two-line

by 20-character LCD display. There is no reason

to open the unit for set-up, calibration or

diagnostic testing of the instr ument. The most

commonly used, self-explanatory screens appear

on the following pages. Simply follow the

on-screen menus. The step-by step approac h

guides you through each operation.

• The Display Screen Overview (FIGURE 3-1)

shows a general system function flow. See

the following FIGURES for specific Display

Screen details:

• Start-up and Normal Operation Screens

(FIGURE 3-2)

• Calibration Screens

(FIGURES 3-4 through 3-5)

• Information Screens

(FIGURES 3-7 through 3-8 and

FIGURE 3-16)

• Set-up Screens

(FIGURES 3-3 and 3-10 through 3-15).

3-1

Page 19

Section 3, Display Screens Chillgard LC Control Module

3-2

Figure 3-1. Display Screen Overview

Page 20

Chillgard LC Control Module Section 3, Display Screens

Figure 3-2.

Start-up and Normal Operation Screens

Figure 3-3.

Set-up Screens

3-3

Page 21

Section 3, Display Screens Chillgard LC Control Module

Figure 3-4.

Span Calibration Screens

3-4

Figure 3-5.

Zero Calibration

Page 22

Chillgard LC Control Module Section 3, Display Screens

Figure 3-6.

Calibration Check

Figure 3-7.

Diagnostics Menu

3-5

Page 23

Section 3, Display Screens Chillgard LC Control Module

Figure 3-8.

Data Screens

Figure 3-9.

Alarm Level Screen

3-6

Page 24

Chillgard LC Control Module Section 3, Display Screens

Figure 3-10.

Setup Alarm Latching

Figure 3-11.

Setup Alarm Relays

3-7

Page 25

Section 3, Display Screens Chillgard LC Control Module

Figure 3-12.

Audio Alarm Screen

3-8

Figure 3-13.

Analog Outputs and Password

Page 26

Chillgard LC Control Module Section 3, Display Screens

Figure 3-14.

Setup Times

Figure 3-15.

Setup Logging

3-9

Page 27

Section 3, Display Screens Chillgard LC Control Module

3-10

Figure 3-16.

Review Log

Page 28

Chillgard LC Control Module Section 4, Maintenance

Section 4

Maintenance

General Maintenance

Under normal operation conditions, the Chillgard

LC Control Module requires minimal maintenance.

Obtaining Replacement Parts

To obtain replacement parts, address t he order or

inquiry to:

MSA North America

P.O. Box 427, Pittsburgh, PA 15230

or call, toll-free, 1-800-MSA-INST.

WARNING

"!

Use only genuine MSA replacement parts

when performing any maintenance

procedures. Failure to do so may seriously

impair unit performance. Repair or alteration

of the Chillgard LC Control Module, beyond

the scope of these instructions or by anyone

other than authorized MSA service

personnel, could cause the product to fail

to perform as designed and persons who

rely on this product for their safety could

sustain serious personal injury or death.

Table 4-1. Replacement Parts

PART PART NO.

Mounting Panel, Chillgard LC 10033888

RFI Filter 10034402

Display Assembly, Chillgard LC 10039866

Transfo rmer, Chillg ard LC 10039 002

Printe d Circuit Boar d Assembly, Co ntrol 10033 233

Printed Circuit Board, Membrane Switch 10034274

Strobe Light, red, 2 4 VDC 63467 4

Buzzer 637123

Horn 10034190

WARNING

"

Hazardous Voltage!

Disconnect all electric power, including

remote disconnects before servicing. follow

proper lockout/tagout procedures to ensure

the power cannot be inadvertently energized.

Failure to disconnect power before servicing

could result in death or serious injury.

4-1

Page 29

Section 4, Maintenance Chillgard LC Control Module

Table 4-2. Troubleshooting Guidelines

TROUBLE DESCRIPTION SOLUTION

1. Check AC power to unit.

2. Verify AC power to unit is wired properly.

3. Check for loose wires on terminal barrier input.

Unit will not turn ON No power

4. Check wiring to the unit power supply.

Remove power supply cover and chec k fuse; replace if necessary.

5. Check input cable to mai n board on power supply.

6. Check for 24 VDC power supply output.

7. Check communications

1. Check that plu g is co nn ected to circuit board

Beacon will not light Beacon alarm

Under-range failed

Calibrati on failed

Zero limi t is

minus 20

ppm

Coefficients

out of range

2. Beacon is controlled by Al arm 3; ch eck that the unit has exceeded Alarm 3.

3. Replace beacon asse mbly.

1. Adjust display zero to 0.0 via the keypad with zero air or zero scrubber applied.

2. Check the zero air cylinder; replace if necessary.

3. Check the zero scrubber; replace if necessary.

1. Replace zero scrubber or change zero air supply.

2. Check span gas supply.

3. Check all tubing, filters and fittings for leaks.

4. For sequencer units, make sure the unit is locked on the selected sample port used for

calibration.

5. Leak test the flow system.

6. Return to MSA for service.

4-2

Page 30

Chillgard LC Control Module Section 4, Maintenance

Table 4-2. Troubleshooting Guidelines

TROUBLE DESCRIPTION SOLUTION

1. Remove all input lines to the sensor module.

Attach one line at a time to check for sample input.

Check all end of line filters. Sample flow failure is always the present point

being sampled .

Sensor fl ow failed

Leaky o r blocked

sample lin e

2. Che ck opera t io n of all manifold samp le valv es .

3. Leak test the flow system.

4. Return the unit to MSA for service.

Sensor te mperature

range fa iled

Infrared source failed

in sens or module

Memory protect

External reset failed

Display failure

Checks for

tempera ture rang e of

o

over 67

Checks the power of

source assembly

Checks checksum of

setup a nd cal valu es

Checks the external

reset butto n

Display

communications

C

1. Sensor temperature exceeded; mount unit in a lower temperature location.

1. Check the co nnection of the IR source into the motherboard.

2. Replac e op t ic al be nc h.

3. Return to MSA for service.

1. Replace the control board

2. Return to MSA for service.

1. If not used, check for jumper.

2. If used, verify switch is wired norma lly closed.

1. Repower unit.

2. Check for broken or cracked display.

3. Replace display.

Audio al arm failure Audio ala rm

No data in th e

Data Log

Unit fails startup

Loggin g not set

Password is set

inadvertently

1. Check output terminal s.

2. Check f or faulty horn bu zzer.

1. See Chapte r 2, "Initial Calibration"

1. Call MSA for service

4-3

Page 31

Chillgard LC Control Module Section 5, Data Logging

Section 5

Data Logging

The Chillgard LC unit allows 798 sets of data and

events to be logged. This data is eit her the

maximum or average of the concentration

calculated. The structure of t he data stored and

transmitted is shown in Appendix C. The

download can be initiated by sending the ASCII

character "L" or "0x4C." Datalog information can

be downloaded by connecting to the RS232 por t

(see FIGURE 2-3).

Number of Data Points Used

If the unit is only a single point monitor or all but

one point is inactive, the value is recorded

continuously. With four points active, 12 values

per point are evaluated every hour . The number

of values can be considerably lower if the monitor

enters extended dwell because of high gas

concentrations.

User Setup Options

Concentrations are recorded either every 15

minutes or hourly (FIGURE 3-15). If the logging

function is turned OFF, the cl ock/calendar chip is

stopped to save battery ener gy.

• Before logging can be used, the user must:

1. Turn logging ON.

2. Select an interval of 15 minutes or

one hour for readings to be logged.

3. Clear the log.

4. Restart the hardware.

Setting any value starts the c lock/calendar. Hours

or days may be skipped or repeat ed. The log can

be cleared in the Setup Menu.

Viewing Alarms/Events

and Data

From the Review Events Screen, the user can

view just alarms, just events, or both. The latest

event is presented first. When the memory is

filled, the oldest entries are ov erwritten.

From the Review Data Screen, the us er can view

the recorded concentrations. The particular point

must be selected. Again, the lates t data is

presented first; when the memory is f illed, the

oldest entries are overwritten.

The log entry number displays to giv e the user a

sense of where in the log they ar e located

(FIGURE 5-1).

Figure 5-1. Log Description

5-1

Page 32

Chillgard LC Control Module Section 6, Calibration

Section 6

Calibration

Two calibration procedures are available:

1. Diffusion for non-pumped sensors like a

single-point, non-pumped Chillgard LS

Module

2. Pumped for sensors which incorporate a

pump to draw air through tubing to the

sensor.

NOTE:The Chillgard M-100 sensor can be

cal-checked, but does not require calibration.

Diffusion Version Calibration

Calibra ti on Equipment - (FIGURE 6-1)

Calibration of the monitor requires a supply of:

• ZERO GAS (air or nitrogen) It may be

possible to use ambient air if you are sure it

does not contain any possible interferant

gases or contaminants.

• SPAN GAS (A known refrigerant

concentration) that measures approximately

10% of the full-scale calibration of the unit.

See TABLE 5-3 for available refrigerant gas

cylinders.

Relative humidity may have a small effec t on the

output of the unit. If dry gas is used, Nafion

Tubing (P/N 813628) can be used t o humidify the

sample stream going to the monitor.

Both ZERO gas and SPAN gas must be carefully

applied to the unit to avoid press urizing the

internally mounted optical bench.

See Chillgard LS manual (P/N 10035164) TABLE

5-2, Calibration Accessories Parts List, for the

appropriate calibration parts and calibr ation gases

available for the Chillgard LS Refrigerant M onitor.

WARNING

"!

Exercise care during the span calibration

to ensure that the unit can accurately detect

refrigerant gas. Improper calibration can

cause improper readings across the

full-scale range of the monitor.

0.25 LPM Flow Controller P/N 478359

Calibratio n Adapter P/N 10034395

Figure 6-1. Calibration Equipment

Initial Calibration Procedures

Refer to FIGURES 3-4 and 3-5 for cal ibration

menus.

During the initial calibration procedures, alarm

relays of any connected contr ol instrumentation

may activate. Disconnect or dis able any

equipment or alarms.

The following equipment is required for initial

calibration:

• Tubing Assembly with calibration adapter

(FIGURE 6-1)

• Calibration Gas

• Flow Controller (0.25 LPM) (FIGURE 6-1)

Preparation for Calibration

To verify the instrument is operating properly and

to make initial calibration adjustments, perform the

following:

1. Remove the light gray cover to open the

enclosure on the Chillgard LS and LC.

6-1

Page 33

Section 6, Calibration Chillgard LC Control Module

CAUTION

"

Component Damage!

Monitor components must be protected from

splashing, spraying, or dripping water.

Failure to do so may cause damage to

internal components.

2. Deactivate the equipment connected to the

outputs, or disconnect the wiring to the

outputs.

3. Replace lid on the enclosures.

CAUTION

"

If any control instruments connected to the

Chillgard LS or Chillgard LC Refrigerant

Monitor are wired to external devices (e.g.,

horns, exhaust fans, and fire suppression

systems), these devices may activate while

adjustments or repairs are performed during

the following procedures.

To prevent activating these devices while

adjusting the Chillgard LC Monitor,

disconnect the wiring from the relay. Return

all wiring to the relay when the calibration

procedure is completed.

Calibrat io n Gu id e lin e s

Once the Chillgard LS Refrigerant Monitor is

operating, perform periodic calibration c hecks to

ensure proper instrument operation.

Perform calibration to monitor long-term changes

(drift) in both the ZERO and SP AN readings. If

there is an unacceptable change in either of

these readings, make adjustments to obt ain

proper readings.

When routine calibration does not res tore proper

readings, perform the procedures out lined under

"Initial Calibration."

If following Calibration procedures fails t o restore

proper readings of the instrument, see Chillgard

LS manual (P/N 10035164) Section 4,

"Troubleshooting Guidelines" for guidelines to

correct the instrument.

Keep written records of the c alibration readings

obtained and any adjustments made. Analysis of

these records enables review and c ontrol of the

time between checks.

Check a new Chillgard LS Refrigerant M onitor

installation at least once a week by performing

the steps outlined in the following section.

Calibration Check Procedure

The calibration check procedure involves chec king

the SPAN and ZERO readings on t he instrument.

Figure 6-2. Applying Calibration Gas

to the Chillgard LS Refrigerant Monitor

During the calibration check procedure, any

control instrumentation connected to t he Chillgard

LS Refrigerant Monitor may activate. Disconnect

or disable any equipment or alarms connect ed to

the monitor during the calibration pr ocedure.

Applying Calibration Gases to the Instrument

Arrange Span and Zero gas cylinders wit h

regulator, tubing, and cal cap as shown in

FIGURE 6-2. Refer to FIGURE 3-6 for t he

calibration menus.

WARNING

"!

Refrigerant Hazard!

During calibration, the Chillgard LS Monitor

is not sampling and monitoring the intended

area. Exercise caution in the area as

appropriate. Failure to do so may result in

death or serious personal injury.

1. Lock the Chillgard LC Control Module to the

point being calibrated.

• Only the point being calibrated displays.

2. Perform the Zero Calibration first.

• Use Nitrogen, not room air, to calibrate

the zero point and avoid any

contamination.

6-2

Page 34

Chillgard LC Control Module Section 6, Calibration

• Be sure sure to apply gas to the sensor

for three minutes.

3. Enter the CAL - USER - ZERO - NEXT CHANGE Menu to select the point to be

calibrated (see FIGURE 3-5).

4. Press OK on the correct point;

then, press NEXT.

5. After a reading displays, press ADJ; then,

press UP or DN to return the displayed gas

value to 0 ppm.

6. Perform Span Calibration using the

appropriate sensor gas at 100 ppm.

• Be sure to apply gas for three minutes.

7. Enter the CAL - USER - SPAN - NEXT CHANGE Menu to select the point to be

calibrated (see FIGURE 3-4).

8. Press OK on the correct point;

then, press NEXT.

9. Press ADJ; then, press UP or DN to set the

span to the gas concentration of the type

being used (100 ppm).

10. Close the regulator valve and remove the

span gas cylinder from the sampling tubing.

11. Remove the calibration cap and return to

normal operation.

Calibration Equipment

Equipment needed:

• Calibration Kit (MSA ATO #50; FIGURE 6-3)

• A SPAN gas cylinder

• Optional ZERO gas cylinder.

• A ZERO gas cylinder may not be needed.

The Calibration Kit contains a ZERO gas scrubber

which can be used in place of a ZERO gas

cylinder if the ambient air around t he Chillgard LS

contains little or no refrigerant.

Relative humidity may have a small effec t on the

output of the unit. If dry gas is used, Nafion

Tubing (P/N 813628) can be used t o humidify the

sample stream going to the monitor.

CAUTION

"

The zero gas scrubber must be replaced

periodically. The frequency of replacement

depends on the concentration of the ambient

refrigerant vapors.

The SPAN or ZERO cylinders (if needed) m ay be

included with the Calibration Kit; cy linders shown

in TABLE 6-1 are available from MSA.

CAUTION

"

Equipment Failure!

Do not leave any alarm device or equipment

disabled or disconnected during normal

operation of the instrument; otherwise, the

equipment will not function as intended

when the instrument detects an alarm

situation. Failure to do so may result in

serious personal injury.

Single or Four-Point

Pumped Version Calibration

Introduction

As with any type of gas monit or, the only true

check of its performance is t o apply gas directly

to the sensor. The frequency of the calibration

gas test depends on the operating time and

exposures of the sensors. New monitors should

be calibrated more often until the c alibration

records prove stability. The c alibration frequency

can then be reduced to the sc hedule set by the

safety officer or plant manager.

Perform the calibration procedure regularly and

maintain a log of calibration adjustments.

Calibration frequency may increase for a variety

of reasons. If calibration cannot be performed at

any step, STOP; consult MSA at 1-800-MSA-INST.

Table 6-1. RP Calibration Gases

DESCRIPTION CONCENTRATION PART NO.

R-11 in Nitrogen 100 ppm 803499

R-12 in Nitrogen 100 ppm 804866

R-123 in Nitrogen 100 ppm 803498

R-134A in

Nitrogen

R-22 in Nitrogen 100 ppm 804868

Become familiar with the Calibration Kit

components (FIGURE 6-3).

Exercise care during the span calibration

to ensure that the unit can accurately detect

refrigerant gas. Improper calibration can

cause improper readings across the

full-scale range of the monitor.

100 ppm 803500

WARNING

"

Calibration Procedures

Preparation for Calibration

To verify the instrument is operating properly and

to make initial calibration adjustments, perform the

following:

1. Remove the light gray cover to open the

enclosures on the Chillgard LS and LC

Monitors.

6-3

Page 35

Section 6, Calibration Chillgard LC Control Module

Tube and Tee Asse mbly

(P/Ns 6038 06 and 636866 )

Connector Assembly (P/N 711533)

Zero Gas Scrubber (P/N 803873)

(Replace protective caps after use)

Figure 6-3. Kit Components

CAUTION

"

Component Damage!

Monitor components must be protected from

splashing, spraying, or dripping water.

Failure to do so may cause damage to

internal components.

2. Deactivate the equipment connected to the

outputs, or disconnect the wiring to the

outputs.

CAUTION

"

1.5 LPM Flow Controller

(P/N 4783 58 )

Span Ga s Scrubb er (P/N 803874)

(Replace protective caps after use)

1. Temporarily block the sample inlet at the

end-of-line filter(s) and verify that the

monitor gives a Fault alarm.

2. After checking for leaks, remove the sampling

line for the Chillgard LS inlet.

3. Attach the Calibration Kit connector assembly

to the in l e t.

Calibrat io n Gu id e lin e s

Once the Chillgard LS Refrigerant Monitor is

operating, perform periodic calibration c hecks to

ensure proper instrument operation.

If any control instruments connected to the

Chillgard LS or LC Refrigerant Monitor are

wired to external devices (e.g., horns,

exhaust fans, and fire suppression systems),

these devices may activate while

adjustments or repairs are performed during

the following procedures.

To prevent activating these devices while

adjusting the Chillgard LC Refrigerant

Monitor, disconnect the wiring from the relay.

Return all wiring to the relay when the

calibration procedure is completed.

Before calibrating the Chillgard LS Monitor,

leak-check the sample line(s) connected t o the

monitor:

6-4

Perform calibration to monitor long-term changes

(drift) in both the ZERO and SP AN readings. If

there is an unacceptable change in either of

these readings, make adjustments to obt ain

proper readings.

When routine calibration does not res tore proper

readings, perform the procedures out lined under

"Initial Calibration."

If following Calibration procedures fails t o restore

proper readings of the instrument, see Section 5,

"Troubleshooting Guidelines" for guidelines to

correct the instrument.

Keep written records of the c alibration readings

obtained and any adjustments made. Analysis of

Page 36

Chillgard LC Control Module Section 6, Calibration

these records enables review and c ontrol of the

time between checks.

Calibrat ion Equipment

Calibration of the monitor requires a supply of:

• ZERO GAS (nitrogen) It may be possible to

use ambient air if you are sure it does not

contain any possible interferant gases or

contaminants.

• SPAN GAS (A known gas concentration that

measures approximately 10% of the full-scale

calibration of the unit.

Carefully apply both ZERO gas and SPAN gas t o

the unit to avoid pressurizing t he internally

mounted sensing cell. See TABLE 5-2,

"Calibration Accessories Parts List" for the

appropriate calibration parts and calibr ation gases

available for the Chillgard LS Refrigerant M onitor.

Figure 6-4. Using Zero Scrubber for Zero Calibration

Figure 6-5. Using Zero Gas Cylinder

for Zero Calibration

6-5

Page 37

Section 6, Calibration Chillgard LC Control Module

Calibration Check Procedure

The calibration check procedure involves chec king

the SPAN and ZERO readings on t he instrument.

During the calibration check procedure, any

control instrumentation connected to t he Chillgard

LS Refrigerant Monitor may activate. Disconnect

or disable any equipment or alarms connect ed to

the monitor during the calibration pr ocedure.

Zeroi ng the M o nitor

When zero gas is required, att ach a zero gas

scrubber or zero gas cylinder to the connector as

shown in FIGURES 6-4 and 6-5.

WARNING

"

If the sampling line is not re-attached, the

monitor cannot sample from the remote

location.

CAUTION

"

During calibration, the Chillgard LS

Refrigerant Monitor is not sampling and

monitoring the intended area. Exercise

caution in the area as appropriate.

6-6

Figure 6-6. Span Calibration

Page 38

Chillgard LC Control Module Section 6, Calibration

Assemble this setup when calibrating a Chillgar d

LS-4 sensor. Be sure that the pressure well outlet

is at least six inches long t o minimize dilution by

the outside air. This pressure well allows for a

flow outlet when the flow regulator has a higher

flow than the Chillgard LS-4 sensor. Tr ying to limit

the flow from the regulator is quite difficult and

may lead to under-pressurization of the Photo

acoustic Bench. If this under -pressurization

occurs, concentration readings f rom that sensor

will be low.

1. Lock the Chillgard LC sensor onto the first

sampler address of the Chillgard LS-4

sensor (point 1 or point 5).

2. Remove any sampling tubes from the first

point; calibration gases will be applied

directly to the sampler.

3. Perform Z ero Calib r a tion firs t.

• Use Nitrogen, not room air, to calibrate

the zero point and avoid any

contamination.

• Be sure sure to apply gas to the sensor

for three minutes.

4. Enter the CAL - USER - ZERO - NEXT CHANGE Menu to select the point to be

calibrated (point 1 or point 5).

(See FIGURE 3-5.)

5. Press OK on the correct point;

then, press NEXT.

6. After a reading displays, press ADJ; then,

press UP or DN to return the displayed gas

value to 0 ppm.

7. Perform Span Calibration using the

appropriate sensor gas at 100 ppm.

• Be sure to apply gas for three minutes.

8. Enter the CAL - USER - SPAN - NEXT CHANGE Menu to select the point to be

calibrated. (See FIGURE 3-4.)

9. Press OK on the correct point; then, press

NEXT.

10. Press ADJ then UP or DN to set the span to

the gas concentration of the type being

used (100 ppm).

11. Close the regulator valve and remove the

SPAN gas cylinder from the sample tubing.

12. Remove tubing from the sensing cell on the

unit.

13. Re-connect or enable all equipment and

alarm devices connected to any control

equipment monitoring the Chillgard LS

Refrigerant Monitor.

CAUTION

"

Do not leave any alarm device or equipment

disabled or disconnected during normal

operation of the instrument; otherwise, the

instrument will not function as intended

when it detects an alarm situation.

6-7

Page 39

Chillgard LC Control Module Appendix A, RS-232 Output

Appendix A

RS-232 Output

Introduction

The instrument is ready to monitor; however, it is

necessary to configure the unit to your specific

requirements. Your Chillgard LC Control Module

may be connected to Multi-Point Sequenc er(s)

and/or multi-sensor modules, enabling your unit to

sample from up to 12 individual sampling locat ions.

Your unit also contains several ot her features

described in this appendix:

• RS-232 output

• Password protection

• Sampling point identification.

RS-232 Output

The RS-232 output broadcasts certain information

about the Chillgard LC Control Module (TABLE

A-3). This output conforms t o the specification for

RS-232 signal levels and is capable of driving its

signal up to 200 feet when using low c apacitance

RS-232 cable.

Connection to the RS-232 output is v ia a 9-pin

sub "D" female connector.

Table A-1. RS-232 Parameters

9600 Bau d or 19,200

COMMUNICATION

PARAMETERS

The log data is an array of s tructures. The array

size is 792 and the structure lengt h is 22 bytes.

The first byte is a sync character "R" followed by

23,760 bytes. The first s tructure is the Log

Information.

(See TABLE 2-1)

8 bits

No parity

One stop bit

Table A-2. Information Structure

(Chill ga r d LC C ontrol Module)

ITEM

Total 30

DESCRIPTION VALUE OR TYPE

NO.

0 Monitor type ASCII "R" 1

1 Monitor Type ASCII "L" 1

2 Monitor Type ASCII "C" 1

3 Scale char 0x0 3 1

4 ID Number unsigne d integer 2

5 Year (0 - 99)* bcd number 1

6 Month (1 - 12) bcd number 1

7 Date (1 - 31) bcd number 1

8 Hour (0 - 23) bcd number 1

9 Minute (0 - 59) bcd number 1

10 Average or Max char 1

Point 1 Gas

11

Type

Point 2 Gas

12

Type

Point 3 Gas

13

Type

Point 4 Gas

14

Type

Point 5 Gas

15

Type

Point 6 Gas

16

Type

Point 7 Gas

17

Type

Point 8 Gas

18

Type

Point 9 Gas

19

Type

Point 10 Gas

20

Type

Point 11 Gas

21

Type

Point 12 Gas

22

Type

23 Sequencer Points char 1

24 Log Index unsigned inte ger 2

*The base/year is 2000.

The last stru cture is filled with 0xff .

char 1

char 1

char 1

char 1

char 1

char 1

char 1

char 1

char 1

char 1

char 1

char 1

SIZE

(BYTES)

The information structure is followed by data and

event structures. Data s tructures are always

identified by Alarm/Event value of 0x01. Empty

structures have Alarm/Event v alue of 0x00.

A-1

Page 40

Appendix CA RS-232 Output Chillgard LC Control Module

Table A-3. Data Structure

ITEM

NO.

1 Alarm or Event char = 0x00 1

2 Year* bcd 1

3 Month bcd 1

4Date bcd 1

5Hour bcd 1

6Minute bcd 1

7 Conce ntration P oint 1 integer 2

8 Conce ntration P oint 2 integer 2

9 Conce ntration P oint 3 integer 2

10 Concentration Point 4 integer 2

11 Concentration Point 5 integer 2

12 Concentration Point 6 integer 2

DESCRIPTION

VALUE OR

TYPE

SIZE

(BYTES)

Table A-4. Alarm Structure

ITEM

Total 30

DESCRIPTION VALUE OR TYPE SIZE (B YTES)

NO.

Alarm or

1

Event

2Year bcd 1

3Month bcd 1

4Date bcd 1

5Hour bcd 1

6Minute bcd 1

7 Point (1 - 12) c har 1

8spaces 0x00 15

*The base/year is 2000.

char 1

Table A-5. Alarms and Events

DATA CONCENTRATION 0x01

LOG_ALARM 1 0x02

ALARMS

LOG_ALARM 2 0x04

13 Concentration Point 7 integer 2

14 Concentration Point 8 integer 2

15 Concentration Point 9 integer 2

16 Concentration Point 10 integer 2

17 Concentration Point 11 integer 2

18 Concentration Point 12 integer 2

Total integer 30

*The base/ye ar is 2000.

EVENTS

LOG_ALARM 3 0x08

LOG_WARMUP 0x10

LOG_READY 0x20

LOG_FAULT 0x40

LOG_CAL_SETUP 0x80

A-2

Page 41

Chillgard LC Control Module Appendix B, Installation Outline Drawing

Appendix B

Installation Outline Drawing

B-1

Page 42

Appendix B, Installation Outline Drawing Chillgard LC Control Module

B-2

Figure B-1. Installation Outline Drawing

for Standard Version

Page 43

Chillgard LC Control Module Appendix B, Installation Outline Drawing

Figure B-2. Installation Outline Drawing

for Transformer Version

B-3

Loading...

Loading...