Page 1

Operating Manual

Chillgard 5000

Refrigerant Monitor

Order No.: 10178535/01

CR 800000027642

MSAsafety.com

Page 2

WARNING!

Read this manual carefully before using the device. The device will perform as designed only if it is used and

maintained in accordance with the manufacturer's instructions. Otherwise, it could fail to perform as

designed and persons who rely on this device for their sa fety could sust ain serious pe rsonal injury or death.

The warranties made by MSA with respect to the product are voided if the product is not installed and used

in accordance with the instructions in this manual. Please pr otect yourself and your employees by following

the instructions.

Please read and observe the WARNINGS and CAUTIONS inside.

WARNING!

Make sure any personnel who will be installing, using, or maintaining this device have access to the user

manual. If electronic access to the user manual (through the supplied Chillgard 5000 CD or MSA website)

is not possible, print a copy of the manual and keep it in an accessible location near the device.

Failure to obey the following guidelines and/or incorrect inst allation, operation, servicin g, or maintenance of

the device can cause incorrect operation of the device. Personnel who rely on this product for their safety

can sustain serious personal injury or death.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

USA

Phone 1-800-MSA-2222

Fax 1-800-967-0398

For your local MSA contacts please go to our website www.MSAsafety.com

©

MSA 2017. All rights reserved

Page 3

Contents

1 MSA Permanent Instrument Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Exclusive Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Exclusion of Consequential Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Liability Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Description

3.1 Identifying Your Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Visible Alarming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Touchscreen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Optional Strobe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Audible Alarming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.1 Internal Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Optional External Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Optional External Alarm Activation and Silencing Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.5 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5.1 Digital Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5.2 Analog Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Receiving, Unpacking, and Inspecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Sample and Exhaust Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4.1 Tubing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4.2 Routing and Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4.3 End-of-Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.4 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4.5 Exhaust Venting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 21

4.5 Wiring and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Electrical Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.7 Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

US

5 Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 25

5.1 Language/Date & Time/Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.2 Point Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3 Gas Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4 Relay Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5 Communications Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.1 Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2 Routine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.1 Starting Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.2 Stopping Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chillgard 5000

3

Page 4

6.3 Zero Gas Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4 Span Gas Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5 Unsuccessful Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Routine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Dashboard Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Point Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 42

7.3 Point Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.3.1 Automatic Point Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.3.2 Manual Point Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.4 Predictive Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.5 Cautions, Warnings, and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.5.1 Non-Latching Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.5.2 Latching Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.6 Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.6.1 Noncritical Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.6.2 Critical Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.7 Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.7.1 All. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.7.2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.7.3 Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.7.4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 50

7.8 Edit Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 51

7.8.1 Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.8.2 Gas Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.8.3 Point Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.8.4 Relay Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.8.5 Communications Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.8.6 About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 58

8 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1 Flow Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.2 Sensor Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.3 Pump Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.4 Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.1 Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.1.1 Examine and Replace End-of-Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.1.2 Examine and Replace Internal Inline Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

9.1.3 Replace Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.1 Touchscreen Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.2 Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.1 Technical Specifications / Equipment Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.2 Gas Reading Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Chillgard 5000

US

4

Page 5

12 Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

13 Ordering Information

13.1 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

13.1.1 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.1.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.1.3 Installation and Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

13.1.4 Calibration Gas Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

14 Appendix A: Start-up Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

15 Appendix B: Installation of Optional Equipment

15.1 Strobe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

15.2 External Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

15.3 External Alarm Activation Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

15.4 External Alarm Silencing Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

16 Appendix C: Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

16.1 Alarm Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

16.2 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

16.3 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

17 Appendix D: Modbus Holding Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

17.1 Chillgard 5000 - Modbus RTU (Holding Registers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 79

17.2 RESET Button Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

17.3 Unit Status Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

17.4 Channel Status Flags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

17.5 Gas Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

18 Appendix E: BACnet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

18.1 Chillgard 5000 - BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

18.2 RESET Button Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

18.3 Unit Status Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

18.4 Channel Status Flags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

18.5 Gas Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

US

Chillgard 5000

5

Page 6

MSA Permanent Instrument Warranty

1 MSA Permanent Instrument Warranty

1.1 Warranty

MSA, the Safety Company warrants that this product will be free from mechanical defect or faulty

workmanship for a period of two (2) year s from the date of delivery, provided it is maintained and u sed

in accordance with MSA's instructions and/or recommendations.

This warranty does not apply to expendable or consumable part s whose normal life expectancy is less

than one (1) year, such as, b ut not limited to, nonrechargeable batteries, filament units, filter, lamps,

fuses, etc. MSA shall be released from all obligations under this warranty in the e vent that repairs or

modifications are made by persons other than its own or authorized service personnel or if the

warranty claim results from physical abuse or misuse of the product. No agent, employee, or representative of MSA has any authority to bind MSA to any affirmation, representation, or warranty

concerning the goods sold under this contract. MSA makes no warranty concerning components or

accessories not manufactured by MSA, but will pass on to the Purchaser all warranties of manufacturers of such components.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, AND IS STRICTLY LIMITED TO THE TERMS HEREOF. SELLER SPECIFICALLY

DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE.

1.2 Exclusive Remedy

It is expressly agreed that the Purchaser's sole and exclusive remedy for breach of the above

warranty , for any tortious co nduct of the Seller , or for any other cause of a ction, shall be the repair and/

or replacement at the Seller's option of any equipment or parts thereof, which after examination by the

Seller is proven to be defective. Replacement equipment and/or parts will be provided at no cost to

the Purchaser, F.O.B. Seller's Plant. Failure of the Seller to successfully repair any nonconforming

product shall not cause the remedy established hereby to fail of its essential purpose.

1.3 Exclusion of Consequential Damage

The Purchaser specifically understands and agrees that under no circumstances will the Seller be

liable to the Purchaser for economic, special, incidental, or consequential damages or losses of any

kind whatsoever, including but not limited to, loss of anticipated profits and any other loss caused by

reason of nonoperation of the goods. This exclusion is applicable to claims for breach of warranty,

tortious conduct, or any other cause of action against the Seller.

1.4 Liability Information

MSA accepts no liability in cases where the device has been used inappropriately or not as intended.

The selection and use of the device are the exclusive responsibility of the individual operator. Product

liability claims, warranties, and guarantees made by MSA with respect to the device are voided if the

device is not operated, serviced, and/or maintained in accordance with the instructions in this manual.

The warranties made by MSA with respect to the product are voided if the product is not used and

serviced in accordance with the instructions in this manual. Please protect yourself and others by

following them. We encourage our custome rs to write or call reg arding this eq uipment p rior to use o r

for any additional information relative to use or repairs.

US

Chillgard 5000

6

Page 7

Warnings and Cautions

2 Warnings and Cautions

The Chillgard 5000, hereafter also referred to as "the device", is a gas monitor intended for indoor u se

in mechanical equipment rooms or commercial spaces where refrigerant equipment, such as centrifugal chillers, is used. The device is specified to support compliance with federal, state, and local safety

codes that govern emissions.

WARNING!

Install, operate, and maintain the device in strict accordance with its labels, cautions, warnings,

instructions, and stated limitations.

For any maintenance procedure provided in this manual, use only genuine MSA replacement parts.

Repair or alteration of the Chillgard 5000 system beyond the scope of these maintenance instructions

or by anyone other than authorized MSA service personnel can cause incorrect operation of the

device. For a list of approved part s and how to orde r them, refer to Section 13, "Ordering Information".

The device is intended for indoor use only. Do not use the device for outdoor applications.

Never operate the device without a connection to positive ground. Failure to connect the device to

positive ground can result in electrical shock. Electrical shock can cause damage to the device and

injury to personnel.

Make sure the device is not located in areas that contain a flammable mixture of gas and air. Otherwise, an explosion can occur.

The device is not intrinsically safe. Do not use the device in areas classified as hazardous or locati ons

where explosive concentrations of combustible gases or vapors can occur.

Failure to follow these warnings can result in serious bodily injury or death.

Chillgard 5000

US

7

Page 8

Warnings and Cautions

WARNING!

Make sure the device is installed in a clean, dry area that is protected from vibration, including but not

limited to a chiller, and heat sources.

Do not paint the device. Do not paint near any of the sample line inlets. If painting is don e ne ar the

device, make sure that paint is not deposited on the sample inlet fittings. Paint deposits can prevent

correct operation of the device.

Make sure the sample inlet lines to the device are clean and noncondensing.

Avoid any installation where condensatio n can collect. Cond ensation can clog or block sample lines,

which will prevent the device from receiving new or fresh gas samples in the area being monitored.

Install and maintain end-of-line filters in all sample inlet lines. Refer to Section 4.4.3, "End-of-Line

Filters".

The only absolute method of ensuring correct overall ope ration of a gas de tection instr ument is to do

a check with a known concentration of the gas for which it has been calibr ated. Do a calibration check

as part of the installation and initial setup. Refer to Section 6.1, "Initial Setup". Do routine calibration

checks thereafter. Refer to Section 6.2, "Routine Operation".

Install a circuit breaker for the incoming po we r con nection s of th e de vice. Pu t th e circuit b reake r in a

location that is easy to access and near the device. Clearly mark the circuit breaker as the disconnecting unit for the device.

Properly vent the exhaust of the Chillgard 5000 system to a safe area. Improper venting of the exhaust

can cause serious personal injury or death. Refer to Section 4.4.5, "Exhaust Venting".

To prevent unauthorized or untrained personnel from opening the device enclosure, install a locking

mechanism through the metal loop on either latch on the left side of the device (Fig. 2).

Perform periodic leak tests on all sample lines.

Do not exceed the relay contact rating listed in Section 11.1, "Technical Specifications / Equipment

Ratings". Otherwise relay operation may fail.

Failure to follow these warnings can result in serious bodily injury or death.

Chillgard 5000

US

8

Page 9

3 Description

The Chillgard 5000 provides continuous monitoring of refrigerant gas levels for up to 16 points in

nonhazardous areas. With the ability to read down to 1 ppm, the device provides a response to a

refrigerant leak, supporting the safety of personnel and the environment, and equipment efficiency.

The device uses patented Photoacoustic Infrared technology to allow the accurate measurement of

refrigerant gases with minimum interference from other vapors. The device monitors refrigerant gases

up to 1000 ppm with an ability to maintain a gas list through an internal refrigerant library.

The Chillgard 5000 minimizes unnecessary maintenance costs associated with calibration and

sensors by utilizing a centralized sample draw system. The device is factory calibrated for six specific

refrigerants, with the flexibility to adjust the gas of interest in the field.

The device offers three levels of alarm—caution, warning, and alarm—that are all configurable

through the intuitive touchscreen display. Fault and service notifications provide a lerts when servicing

is necessary . Audible and visual indications such as horns and strobes provide alerts about refrigerant

leaks.

Digital communications can be transmitted using the Modbus remote terminal unit (RT U) or BACnet™

master/slave token passing (MS/TP) protocol. Analog communications can be transmitted using a

4–20 mA or 0–10 Vdc current loop.

Description

The Chillgard 5000 requires minimal maintenance and incorporates predictive diagnostics that continuously check key detector components to ensure proper operation. When the device is insta lled, operated, and maintained according to MSA's recommendations, it provides reliable protection and longterm stability.

US

Chillgard 5000

9

Page 10

3.1 Identifying Your Unit

1

2

1

1

1

1

Fig. 1 Front of device

Description

17″ resistive touchscreen user interface

2 Power indicator

NOTE: Optional strobe not shown.

US

Fig. 2 Back of device

1 Mounting locations (10″ x 14 5/8″)

Chillgard 5000

10

Page 11

Fig. 3 Right side of device

1

3

4

2

1

1

2

2

1 AC power wiring cutout

2 Protective earth grounding cutout (optional)

3 Relay wiring cutout

4 Approval and unit identification label

Description

US

Fig. 4 Left side of device

1 Latches (lockable with padlock)

2 Signal wiring cutouts

Chillgard 5000

11

Page 12

Fig. 5 Bottom of device

1

1

2

3

4

5

1

2

3

3

4

3

1 Sample line identification labels

2 Internal alarm sounder

3 Calibration port

4 IP rated vent

5 Exhaust port (do not block)

Description

US

Fig. 6 Internal touchpoints

1 Fuses

2 AC wiring cover

3 Internal filters

4 ESD tie-off location

Chillgard 5000

12

Page 13

3.2 Visible Alarming Devices

The device provides visible alarm indicators through the touchscreen display and optional strobe.

3.2.1 Touchscreen Display

After the initial setup configuration, the touchscreen display shows a dashboard with the ma in function

buttons and tiles for the points that are enabled.

Notifications for all predictive warnings, alarms, and faults show on the dashboard.

3.2.2 Optional Strobe

The optional strobe provides a user-configurable visual indication of a gas leak.

For a list of approved parts and how to order them, refer to Section 13, "Ordering Information".

For installation instructions, refer to Section 15, "Appendix B: Installation of Optional Equipment".

3.3 Audible Alarming Devices

The device provides audible alarm indicators through the internal alarm and optional external horn.

3.3.1 Internal Horn

A horn inside the device provides an audible indicator of a gas leak. The level of sound output from

the internal horn is adjustable. To adjust the level of sound output, turn the soun der clockwise or counterclockwise.

Description

3.3.2 Optional External Horn

An optional external horn can be mounted in a location away from the device to provide an audible

indicator of a gas leak.

For a list of approved parts and how to order them, refer to Section 13, "Ordering Information".

For installation instructions, refer to Section 15, "Appendix B: Installation of Optional Equipment".

3.4 Optional External Alarm Activation and Silencing Stations

The device supports optional external stations for the activation and silencing of audible alarms.

Normally closed alarm activation and silencing switches can be wired in a single loop with a total

maximum loop length of 2500 ft (762 m).

For a list of approved parts and how to order them, refer to Section 13, "Ordering Information".

For installation instructions, refer to Section 15, "Appendix B: Installation of Optional Equipment".

US

Chillgard 5000

13

Page 14

3.5 Communications

The device has both digital and analog outputs for use with external controllers or building management systems.

3.5.1 Digital Communication

The device is capable of Modbus RTU or BACnet MS/TP outputs. For setup instructions, refer to

Section 5.5, "Communications Output".

For a list of the registers that are available for exchange with the Modbus controller, refer to

Section 17, "Appendix D: Modbus Holding Registers".

For a list of the BACnet Objects that are available for exchange with the BACnet controller, refer to

Section 18, "Appendix E: BACnet Objects".

3.5.2 Analog Communication

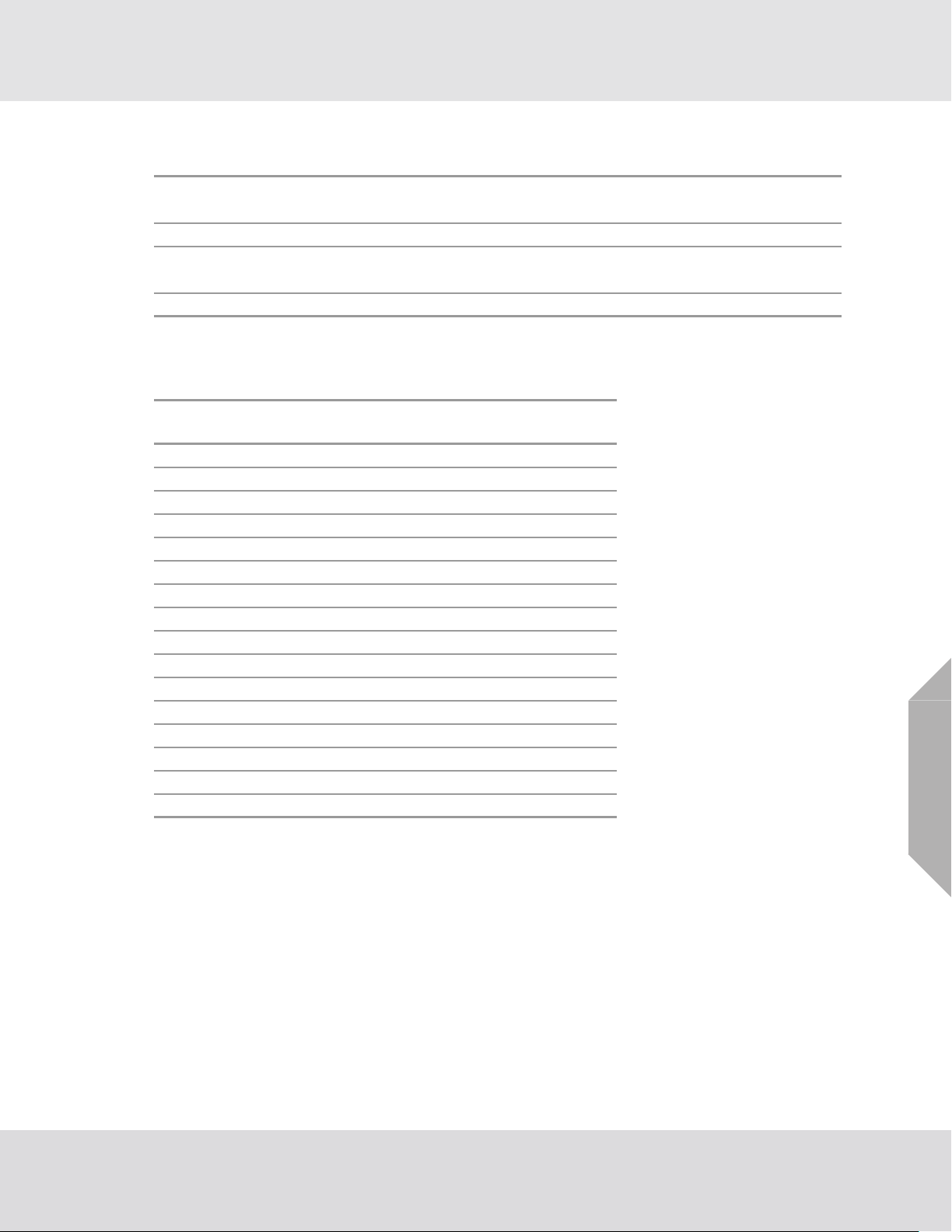

The device is capable of the following types of analog outputs:

• 4–20 mA, isolated, current sourcing

• 0–10 Vdc for gas sample point identification

Description

Scale Analog Output: 4–20 mA

Full scale is 1000 ppm.

Normal gas readings are at 4–20 mA. The reading is proportional to the detected gas concentration.

For the factory default of 100% full scale setting (0.016 mA = 1 ppm):

Output

(mA)

40

563

6125

7188

8250

9313

10 375

11 438

12 500

13 563

14 625

15 688

16 750

17 813

18 875

19 937

20 1000

Gas Concentration

(ppm)

US

Chillgard 5000

14

Page 15

Analog Output Settings

Warm-up Default = 3.5 mA

User adjustable between 0 and 3.75 mA

Calibration (nonconfigurable) 3.0 mA

Fault Default = 2.0 mA

User adjustable between 0.5 and 3.75 mA

Device over range (nonconfigurable) 21 mA

0–10 Vdc

The voltage output can be used to identify any active gas sample line.

Description

Sample Line

111.0

221.5

332.0

442.5

553.0

663.5

774.0

884.5

9- 5.0

10 - 5.5

11 - 6.0

12 - 6.5

13 - 7.0

14 - 7.5

15 - 8.0

16 - 8.5

While the device is in calibration mode, the output is 10 Vdc.

Vdc

4 or 8 pt system

Vdc

16 pt system

US

Chillgard 5000

15

Page 16

4 Installation

4.1 Warnings and Cautions

WARNING!

The device is intended for indoor use only. Do not use the device for outdoor applications.

A qualified electrician must do electrical wiring.

All wiring must comply with all applicable NEC/CEC and local electrical safety codes.

To prevent electrostatic discharge (ESD), connect an ESD wrist strap to the ESD connection point

inside the device enclosure before doing work inside the enclosure. ESD can cause damage to the

device.

Do not touch the electronic circuit boards.

Do not install or operate a device that has damage.

Disconnect ac power before opening the device enclosure. Failure to do so can result in electrical

shock. Electrical shock can cause damage to the device and injury to personnel.

Never operate the device without a protective ground. Operating the device without a prot ect ive

ground can result in electrical shock. Electrical shock can cause damage to the device and injury to

personnel.

The device is not intrinsically safe. Do not use the device in areas classified as hazardous or locati ons

where explosive concentrations of combustible gases or vapors can occur.

Make sure the device is not located in areas that contain a flammable mixture of gas and air. Otherwise, an explosion can occur.

Failure to follow these warnings can result in serious bodily injury or death.

Installation

4.2 Receiving, Unpacking, and Inspecting

(1) Upon receipt of the device, inspect the shipping container for signs of damage. Report any

damage to the carrier and record the information on the delivery receipt.

(2) Carefully remove the device from its shipping container to avoid causing damage to sensitive

electrical components. If damage has occurred, file the appropriate claim with the shipping

carrier immediately.

(3) Review all contents of the shipping container to make sure all of the following components are

included:

a) Device

b) Instruction manual CD

c) End-of-line filters (quantity determined by number of ports ordered)

d) Remote horn (if equipped)

e) Protective foam

(4) Notify MSA of any shortages immediately.

(5) Keep the original packaging in case it is necessary to return the device for service.

(6) Release the two latches on the left side of the device.

(7) Open the enclosure.

US

Chillgard 5000

16

Page 17

(8) Carefully inspect the internal components and assemblies for damage or shortages. If damage

has occurred, file the appropriate claim with the shipping carrier immediately.

(9) Before installation and use, keep the device in a dry, secure place in the original shipping

container.

4.3 Mounting Guidelines

Do not mount the device directly to chiller, piping, or piping supports.

Mount the device:

• In a location that is easy to access and visible to personnel before they go into the are a being monitored.

• To a rigid surface that does not have vibration or mechanical shock.

• In a vertical position.

• Approximately 5 ft (1.5 m) above the ground (Fig. 7, Fig. 8).

• With at least 3 in. (7.62 cm) of clearance around all sides for proper ventilation, calibration, and

servicing. Make sure there is adequate space to connect the external wiring and sample line piping

(Fig. 8).

• With the appropriate hardware. Make sure the hardware is suitable for the mounting surface and

can withstand 70 lb (9 kg) without loosening or causing damage to the hardware or mounting

surface. Use all four mounting holes provided on the device (Fig. 9).

• Away from exposure to direct solar heating and other excessive heat sources.

• Away from wet or damp conditions.

• Away from areas that are dirty or exposed to oils or chemicals.

Installation

Fig. 7 Mounting location

Chillgard 5000

US

17

Page 18

Fig. 8 Front of device Fig. 9 Rear of device

Installation

4.4 Sample and Exhaust Lines

4.4.1 Tubing Material

The device can use hard and soft tubing. The following are acceptable tubing types:

US English System

¼ in. OD x 1/8 in. inside diameter (ID) Polyurethane tubing (ether based)

¼ in. OD x 3/16 in. ID Polyurethane tubing (ether based)

¼ in. OD Copper tubing

¼ in. OD Stainless steel tubing

SI Units

6 mm OD x 4 mm ID Polyurethane tubing (ether based)

6 mm OD Copper tubing

6 mm OD Stainless steel tubing

NOTICE

Use the appropriate tools to give a clean , smooth end to the tubing when it is cut.

US

Chillgard 5000

18

Page 19

4.4.2 Routing and Placement

MSA recommends the use of at least two gas-monitoring points per chiller for sufficient detection

monitoring. Due to installation and application variations, each system must be analyzed individually.

Do a smoke test of the mechanical room to determine the flow pattern and allow fo r optimal placement

of the sample lines. Ventilation smoke tubes for this use are available from MSA (P/N 458480) . For a

list of approved parts and how to order them, refer to Section 13, "Ordering Information".

Keep the total line length of a point, including the sample line and exhaust line, at less than 1200 ft

(366 m). Keep lines as short as possible to minimize the transport time of the device.

Transport Time

Line Length

(ft)

0 19s 19s 19s

50 19 s 19 s 19 s

100 19 s 19 s 19 s

150 19 s 19 s 19 s

200 19 s 19 s 19 s

250 19 s 19 s 19 s

300 1 m 35 s 2 m 51 s 5 m 23 s

350 1 m 35 s 2 m 51 s 5 m 23 s

400 2 m 51 s 5 m 23 s 10 m 27 s

450 2 m 51 s 5 m 23 s 10 m 27 s

500 2 m 51 s 5 m 23 s 10 m 27 s

4pts 8pts 16pts

Installation

*

Transport time is similar for all tubing configurations.

Typically, refrigerants collect near the floor. Install the sample points 12–18 in. (30–46 cm) above the

floor.

For installations where water condensation in the sample lines is likely, MSA recommends installing

a water trap filter such as a Parker P/N F504-01AHX67 or equivalent.

US

Chillgard 5000

19

Page 20

4.4.3 End-of-Line Filters

WARNING!

Failure to use and maintain end-of-line filters can cause inaccurate readings and damage to internal

components, and make additional ser vicing necessary.

Failure to follow these warnings can result in serious bodily injury or death.

Install an end-of-line filter (MSA P/N 711561) in each sample line to decrease contaminants in the

sample lines and device.

Do the following procedure to install end-of-line

filters:

(1) Remove the new end-of-line filter from the bag.

(2) Slide the end of the end-of-line filter with flexible

tubing onto the sample line tubing. Make sure

the arrow on the body of the filter (Fig. 10)

Fig. 10 End-of-line filter

points in the direction of air flow into the sample

line.

Installation

Examine and replace the end-of-line filters at regular intervals. The appropriate interval for replacement is determined by the environment of the installation.

For a list of approved parts and how to order them, refer to Section 13, "Ordering Information".

4.4.4 Connections

WARNING!

Install tubing with large enough bend radii to prevent kinking or pinching. Kinking or pinching of the

tubing can result in insufficient monitoring of an area.

Before connecting tubing to the device, clean all tubing with compressed air or nitrogen to remove

debris.

Failure to follow these warnings can result in serious bodily injury or death.

The device has Swagelok® compression fittings for connections to the sample and exhaust lines.

These fittings accept the hard and soft tubing specified in Section 4.4.1, "Tubing Material".

Do the following procedure to connect the sample and exhaust lines:

(1) Remove the cap from the compression fitting.

(2) Insert the tubing fully into the compression fitting and against the shoulder.

(3) Turn the nut until it is finger-tight on the tubing.

(4) Mark the nut at the 6 o'clock position.

US

(5) While holding the body of the fitting steady, tighten the nut 1 ¼ turns to the 9 o’clock position.

Chillgard 5000

20

Page 21

4.4.5 Exhaust Venting

The use of exhaust tubing reduces pump noise from the device.

Make sure to vent the exhaust of the device to the outside atmosphere (preferred) or a safe area.

Do not use inline or end-of-line filters in the exhaust line.

If possible, route the exhaust line so venting occurs to the outside atmosphere. Make sure to protect

the end of the exhaust tube from elements such as water, dirt, snow , ice, and insect s, which can cause

clogs and prevent efficient venting.

If exhaust venting occurs indoors, make sure to route the exhaust line to:

• An area that is not monitored for refrigerant gases

• An area away from personnel

WARNING!

Make sure to remove the cap from the exhaust port before operating the device. Failure to do so will

create back pressure that can result in inaccurate readings and damage to internal components.

Failure to follow these warnings can result in serious bodily injury or death.

Installation

4.5 Wiring and Grounding

The Chillgard Wiring Diagram (Fig. 11) gives the details of the wiring requirements for the device.

WARNING!

Make sure the device chassis is connected to the earth ground at the ground bar.

Failure to follow these warnings can result in serious bodily injury or death.

NOTICE

Installations that require conformity to the CE mark must have a connection between the

Chillgard 5000 device and a nearby earth ground potential.

T o achieve this connection, inst all a 10 AWG or larger copper wire between the grounding lug terminal

strip on the right side of the Chillgard 5000 device and the grounding point (protective earth). The wire

length cannot be longer than 6 ft (2 m).

US

Chillgard 5000

21

Page 22

Installation

Fig. 11 Chillgard Wiring Diagram

Chillgard 5000

US

22

Page 23

4.6 Electrical Power Supply Requirements

WARNING!

A qualified electrician must do electrical wiring.

Wiring must comply with all applicable NEC/CEC and local electrical safety codes.

Make sure that the copper conductors used to connect to supply mains meet all NEC/CEC and local

electrical safety codes.

Never operate the device without a protective ground. Operating the device without a prot ect ive

ground can result in electrical shock. Electrical shock can cause damage to the device and injury to

personnel.

T o prevent electrical shock, the ci rcuit board cover must be in place when power is on. Electrical shock

can cause serious personal injury or death.

To prevent electrostatic discharge (ESD), connect an ESD wrist strap to the ESD connection point

inside the device enclosure before doing work inside the enclosure. ESD can cause damage to the

device.

Do not touch the electronic circuit boards.

Failure to follow these warnings can result in serious bodily injury or death.

Installation

The device uses a power supply that accepts inputs of 100–240 V ac, 50/60 Hz, 200 VA maximum.

Make sure the device is connected directly to the ac power source thr ough a dedicated circuit breaker .

Use an approved 3-conductor wire (minimum 16 AWG), rated 300 Va c at 221°F (105°C), to complete

the ac power connection.

Use only conduit hubs and hardware that are suitable for fiberglass enclosures.

Do the following procedure to connect electrical power:

(1) Disconnect electrical power.

(2) Install a circuit breaker for the incoming power connections of the device.

a) Put the circuit breaker in a location that is near the device and easy to access.

b) Clearly mark the circuit breaker as the disconnecting unit for the device.

(3) If applicable, remove the locking mechanism.

(4) Release the two latches on the left side of the device.

(5) Open the enclosure.

(6) Attach the ESD wrist strap to the ESD connection point inside the enclosure.

(7) Use a ¼-in. hex driver to remove the 4 hex nuts on the circuit board cover.

(8) Remove the circuit board cover.

US

(9) Remove the ac power wiring hole plug.

(10) Install conduit hubs that are suitable for fiberglass enclosures through the ac power wiring hole

plug openings.

(11) Put the ac power wiring through the conduit.

Chillgard 5000

23

Page 24

(12) Connect the ac power wiring to the L1 (HOT) and L2 (NEUTRAL) input terminals. Make sure the

connectors are seated securely.

(13) Connect the ac power ground wire to the ground bar so the device chassis ground is connected

to the earth ground.

(14) Make sure the wiring is not touching the sensor assembly.

(15) Install the circuit board cover.

(16) Use a ¼-in. hex driver to install the 4 hex nuts on the circuit board cover .

(17) Disconnect the ESD wrist strap from the ESD connection point inside the enclosure.

(18) Close the enclosure.

(19) Latch the two latches.

(20) If applicable, attach the locking mechanism.

(21) Supply electrical power to the device.

4.7 Relay Outputs

Refer to the Chillgard Wiring Diagram (Fig. 11 ) for details.

The Chillgard 5000 has the following five single-pole, double-throw (SPDT) relays. The relay contacts

are rated 8 A at 240 Vac/24 Vdc. Each relay can be connected as normally open (NO) or normally

closed (NC).

Installation

•Fault

•Alarm

• Warning

•Caution

•Horn

US

Chillgard 5000

24

Page 25

5Initial Setup

WARNING!

Make sure to remove the cap from the exhaust port before operating the device. Failure to do so will

create back pressure that can result in inaccurate readings and damage to internal components.

Failure to follow these warnings can result in serious bodily injury or death.

Remove the protective film from the touchscreen.

When power is supplied to the device, the green

power indicator LED (Fig. 1) illuminates and the

touchscreen shows a logo and a loading bar. The

loading bar indicates the status of the initializing

process.

If an error occurs during start-up, a pop -up identifies

the specific problem.

Initial Setup

5.1 Language/Date & Time/Passw o rd

(1) On the "Initial Setup" screen, select "Language/Date &

Time/Password".

(2) On the "Language Setup" screen, select the appro-

priate language, then select "Next".

When a language is selected, the change is instantaneous.

(3) On the "Date & Time Setup" screen, select the "Date"

tab.

US

The date format can be MM/DD/YYYY or DD/MM/YYYY

depending on the language setting.

Chillgard 5000

25

Page 26

Initial Setup

(4) Select the "Month/Day/Y ear" fields, and use the alpha-

numeric keypad pop-up to enter values. Select

to accept the values.

NOTE: An entry for the date is necessary to continue. If this

error pop-up shows, select "OK" to return to the previous

screen and supply a value.

(5) Select the "Time" tab.

(6) Select the "Hour/Minute" fields, and use the alphanu-

meric keypad pop-up to enter values. Select to

accept the values.

The time format can be 12 hours (AM/PM) or 24 hours

depending on the language setting.

(7) If applicable, select "AM" or "PM".

(8) Select "Next".

NOTE: A valid entry for the time is necessary to continue. If

this error pop-up shows, select "OK" to return to the

previous screen and supply a value.

US

Chillgard 5000

26

Page 27

Initial Setup

(9) On the "Password" screen, select "Disabled" or

"Enabled" to disable or enable password prote ction for

editable screens.

If password protection is disabled, the "Create Password" and "Verify Password" fields are inactive.

NOTE: If password protection is enabled, do the

following:

a) Select the "Create Password" field, and use the

alphanumeric keypad pop-up to enter a value.

Select to accept the value.

b) Select the "Verify Password" field, and use the

alphanumeric keypad pop-up to enter a value.

Select to accept the value.

(10) Select "Next".

If password protection is enabled, the "Password Required "

pop-up will show when any user tries to change an editable

screen.

(1 1) The "Initial Setup" screen shows a check mark beside

the "Language/Date & Time/Password" step to indicate that it is complete. Select "Continue" to go to the

point configuration setup.

US

Chillgard 5000

27

Page 28

5.2 Point Configuration

Initial Setup

NOTE: At initial setup, all points except Point 1 are disabled

by default and are inactive on the "Point Configuration"

screen. Configuration of Point 1 is required for device initialization.

(1) On the "Point Configuration" screen, select "Point 1".

(2) Select "Next".

(3) On the "Point Configuration: Point #" screen, select

"Enable".

(4) Select the Name field, and use the alphanumeric

keypad pop-up to assign a name with up to

18 characters. Select to accept the value.

The entire 18 characters will only show on the "Point Detail"

screen. Only 10 characters will show on the "Point Configuration" screen.

(5) Select "Save".

(6) Repeat Step s (1) through (5) until all of the necessary

points have been configured.

(7) On the "Point Configuration" screen, select "Next".

(8) The "Initial Setup" screen shows a check mark beside

the "Point Configuration" step to indicate that it is

complete. Select "Continue" to go to the gas configuration setup.

US

Chillgard 5000

28

Page 29

5.3 Gas Configuration

Initial Setup

(1) On the "Select Gas" screen, select an empty gas slot.

NOTE: A maximum of six slots or gases can be configured.

NOTE: If "Next" is selected without configuring a gas, a

warning pop-up provides an alert that default settings will

be applied across all points.

To accept the default settings and bypass the gas configuration step, select "OK". Otherwise, select "Cancel" to

return to the "Select Gas" screen and select a gas slot.

(2) On the "Gases" tab of the "Configure Gas" screen,

select from the list of possible configurable gases. The

screen header changes to show the selected gas.

NOTE: When a gas is selected, the "Save" button becomes active. The interface does not automati-

cally move to the "Setpoints" tab.

If "Save" is selected without adjusting the setpoints for cautions, warnings, and alarms, the default

setpoint settings will be used for the selected gas.

(3) Select the "Setpoints" tab.

(4) Select the "Edit" button for Caution, Warning, or

Alarm, as applicable.

NOTE: If the "Setpoints" tab is selected but a gas has not

been selected, the options on the "Configure Gas" screen

will be inactive.

The options for the configuration settings for cautions,

warnings, and alarms are identical.

US

Chillgard 5000

29

Page 30

Initial Setup

(5) In the configuration pop-up, for "State", select

"Enabled" or "Disabled".

If "Disabled" is selected, all other options are inactive. Go to

Step (8).

(6) For "Setpoint", use the and buttons to adjust

the value.

(7) For "Action", select "Latching" or "Non-Latching".

NOTE: For a definition of latching and non-latching events,

refer to Section 7.5, "Cautions, Warnings, and Alarms".

For a list of default settings, refer to Section 16, "Appendix

C: Default Settings".

Use the scroll bar to see all of the configuration options.

(8) To associate an audible horn or a visual strobe with

the event, for "Alarm Indication", select the "Horn"

and/or "Strobe" check boxes.

(9) Select "Done" to accept the settings and return to the

gas-specific configuration screen, which shows the

updated settings.

(10) Repeat Steps (2) through (9) until all event setpoints

have been configured.

(11) Select the "Points" tab.

(12) Select the applicable checkbox to assign a point to the

gas.

NOTE: If the "Points" tab is selected but a gas has not been

selected, the options on the "Configure Gas" screen will be

inactive.

Only one gas can be assigned to a single point. Points th at

have already been assigned a gas are not available for

selection.

US

Chillgard 5000

30

Page 31

Initial Setup

(13) Select "Save".

(14) Repeat Steps (1) through (13) for each gas to be

configured.

NOTE: The "Reset" tab is not used during the initial setup.

For information about the "Reset" tab, refer to Section

7.8.2, "Gas Configuration".

(15) When all applicable gases have been configured,

select "Next".

(16) The "Initial Setup" screen shows a check mark beside

the "Gas Configuration" step to indicate that it is

complete. Select "Continue" to go to the relay configuration setup.

5.4 Relay Configuration

Each relay is mapped to a specific predetermined function; that is, fault, alarm, warning, caution, or

horn.

(1) On the "Configure Relays" screen, select "Edit" for the

function to configure.

NOTE: The options for the configuration settings for alarms,

warnings, cautions, and the horn are identical.

US

Chillgard 5000

31

Page 32

Initial Setup

The default setting for the internal fault relay is the energized state. To test the relay, do the following:

• Select "ON".

• Select "OFF".

(2) In the relay configuration pop-up, select the "Name"

field, and use the alphanumeric keyboard pop-up to

enter a value.

Relay names can have eight characters.

The title in the pop-up header changes to show the

assigned name.

(3) Select "Energized" or "De-energized" for the relay

state.

(4) Do the following to test the relay:

a) Select "ON".

b) Make sure the equipment connected to the relay

operates as expected.

c) Select "OFF".

(5) Select "Save". The updated settings for the relays

show on the "Configure Relays" screen.

(6) Repeat Steps (1) through (5) for each relay to be

configured.

(7) When all relays have been configured, select "Next".

US

Chillgard 5000

32

Page 33

(8) The "Initial Setup" screen shows a check mark beside

the "Relay Configuration" step to indicate that it is

complete. Select "Continue" to go to the output configuration setup.

5.5 Communications Output

There are three options availab le to supp o rt dig ital outpu ts.

For a list of the registers that are available for exchange with the Modbus controller, refer to

Section 17, "Appendix D: Modbus Holding Registers".

For a list of the BACnet Objects that are available for exchange with the BACnet controller, refer to

Section 18, "Appendix E: BACnet Objects".

Initial Setup

(1) On the "Digital" tab of the "Outputs" screen, select one

of the following:

(2) If "None" is selected, no digital communication is

configured.

(3) If "Modbus" is selected, do the following:

a) Select "Edit".

b) Select the "Device Address" field, and use the

alphanumeric keypad pop-up to enter a value.

Select to accept the value.

c) Select a baud rate for the connection.

US

d) Select the RS485 Termination check box.

e) Select "Done".

Chillgard 5000

33

Page 34

Initial Setup

(4) "If "BACnet" is selected, do the following:

a) Select "Edit".

b) Select the "MAC Address" field, and use the alpha-

numeric keypad pop-up to enter a value. Select

to accept the value.

c) Select the "Instance Number" field, and use the

alphanumeric keypad pop-up to enter a value.

Select to accept the value.

d) Select a baud rate for the connection.

Use the scroll bar to move through the list of available

options.

(5) Select the "Analog" tab.

(6) T o adjust the default values, select the applicable field,

and use the alphanumeric keypad pop-up to enter a

value. Select to accept the value.

(7) Select "Next".

For a list of default settings, refer to Section 16, "Appendix

C: Default Settings".

(8) The "Initial Setup" screen shows that all initial setup

steps are complete. Select "Finished" to confirm the

configuration settings and move to the "Initial Calibration" screen.

US

Chillgard 5000

34

Page 35

6Calibration

WARNING!

Make sure the device has been receiving power for at least 2 hours before performing a calibration.

Make sure to remove the cap from the exhaust port before operating the device. Failure to do so will

create back pressure that can result in inaccurate readings and damage to internal components.

Do NOT do calibration with a constant-flow calibration gas regulator. Use only a demand-flow type

regulator (MSA P/N 710269). Failure to follow this warning can result in incorrect calibration, damage

to internal components, and inaccurate gas readings.

If the device does not pass calibration, remove it from service until the issue resulting in failed calibration is corrected and a successful calibration is achieved.

Failure to follow these warnings can result in serious bodily injury or death.

NOTE: During the calibration process, the device is not monitoring for gas.

Calibration is the process of applying a known quantity of g as to the device so it ca n adjust th e precision and accuracy of the measurements made during routine operating modes. This process ensures

that gas measurements are as accurate as possible.

Calibration

Although the Chillgard 5000 sensor is factory calibrated, it is recommended that calibration be

performed at initial startup and at regular intervals to ensure that the sensor is fully functional and

improve the accuracy of the device. Calibration accuracy is dependent on the type of cylinder used.

For optimal performance, calibrate with atmospheric background for given application.

There are two types of calibration: zero gas calibration and span gas calibration.

Zero gas calibration resets the baseline level reading to ze ro. Use the zero-gas scrubber with ambient

air for zero calibration.

Span gas calibration applies a known concentration of target gas so the accuracy and precision of the

detector can be adjusted to the known value. The known concentration of gas is ca lled a "span value"

because it represents the span, or reach, of the calibration curve from zero to that value (Fig. 12).

US

Fig. 12 Calibration curve

The device sensor is factory calibrated for many of the most commonly used refrigerant gases. The

sensor also has an extended pre-programmed library of additional refrigerant gases that can be used

to set up the device to detect other targeted refrigerant gases.

Chillgard 5000

35

Page 36

6.1 Initial Setup

Following the initial setup, an initial calibration must be completed to ensure sensor accuracy.

For a description of the dashboard, refer to Section 7.1,

"Dashboard Overview".

(1) On the "Initial Calibration" screen, select "Calibrate

Now".

(2) Go to Step (2) in Section 6.2, "Routine Operation".

NOTE: If "Calibrate Later" is selected, the dashboard

shows a notification on the "Calibration" button until the

initial calibration is completed.

Select "Calibrate" to re-open the "Initial Calibration" screen

and select "Calibrate Now".

Calibration

6.2 Routine Operation

WARNING!

Make sure to remove the cap from the exhaust port before operating the device. Failure to do so will

create back pressure that can result in inaccurate readings and damage to internal components.

Failure to follow these warnings can result in serious bodily injury or death.

6.2.1 Starting Calibration

(1) To start the calibration process, on the dashboard,

select "Calibrate".

(2) On the bottom of the device, remove the pin from the

calibration port.

US

Chillgard 5000

36

Page 37

(3) On the device touchscreen, select "Start".

6.2.2 Stopping Calibration

During some phases, when "Cancel" is available in the top left cor ner, the calibration process can be

stopped.

(1) To stop the calibration process, select "Cancel".

Calibration

(2) For zero-gas calibrations, disconnect the zero-gas

scrubber tubing from the calibration port, then select

"Next" on the device touchscreen.

(3) On the "Canceled" screen, select "Done".

(4) On the bottom of the device, install the pin in the cali-

bration port.

US

Chillgard 5000

37

Page 38

6.3 Zero Gas Calibration

Calibration

(1) Connect the zero-gas scrubber tubing to the calibra-

tion port.

(2) On the device touchscreen, select "Next".

A progress bar shows during the zero gas calibration.

(3) When zero gas calibration is complete, the "Results"

screen shows. Select "Continue" to go to the next

step.

(4) On the "Calibration Complete" screen, do one of the

following:

a) To continue with span gas calibration, select "Span

Gas Calibration". Go to Step (1) in the Span Gas

Calibration section below.

b) T o complete zero gas calibration without continuing

to the span gas calibration, select "Done", and go to

the next step.

c) To return to the "Results" screen, select "Back".

(5) On the bottom of the device, install the pin in the cali-

bration port.

(6) Remove the tubing from the calibration port.

US

Chillgard 5000

38

Page 39

6.4 Span Gas Calibration

Calibration

(7) Disconnect the zero-gas scrubber tubing from the cali-

bration port.

(8) On the device touchscreen, select "Next".

NOTE: To prevent zero-gas contamination, MSA recom-

mends using different regulators to do zero gas calibration

and span gas calibration.

(1) Close the cylinder valve.

(2) If applicable, remove the zero-gas cylinder or zero-

gas scrubber tubing from the calibration port.

(3) On the "Span Gas Calibration" screen, select the

applicable span gas.

NOTE: A maximum of seven gases show on the "Select

Gas" screen: six user-selected gases and one universal

gas (Synthetic R-134A).

(4) On the gas cylinder label, find the concentration for the

gas.

(5) On the "Set Span Gas Value" screen, to adjust the

concentration value to the value on the gas cylinder

label, either use the and buttons to increase or

decrease the value in 1 ppm increments, or select the

value field and use the alphanumeric keypad pop-up

to enter the value. Select to accept the value.

(6) To do the calibration with synthetic R-134A, select the

check box.

(7) Select "Next".

NOTE: The concentration value can be set between 10 and

500 ppm.

(8) Attach the span-gas cylinder tubing to the calibration

port.

US

(9) Open the span-gas cylinder valve.

(10) On the "Span Gas Calibration" screen, select "Start".

Chillgard 5000

39

Page 40

Calibration

A progress bar shows during the span gas calibration.

(11) When span gas calibration is complete, the "Results"

screen shows. Select "Continue".

(12) On the "Calibration Complete" screen, do one of the

following:

a) T o do a sp an gas calibration for another gas, select

"Select Another Gas". Repeat Steps (3) through

(11).

b) To return to the "Results" screen, select "Back".

c) "To go to the next step, select "Continue".

(13) Close the span gas cylinder valve.

(14) On the "Set Reminder" screen, select the applicable

button for the calibration interval. At the selected

interval, a pop-up will signal the need for calibration.

(15) Select "Next".

(16) On the bottom of the device, install the pin in the cali-

bration port.

(17) Remove the tubing from the calibration port.

US

Chillgard 5000

40

Page 41

(18) On the device touchscreen, select "Done".

6.5 Unsuccessful Calibrations

In the unlikely event that a problem occurs during a calibration process, the "Results" screen will show

the calibration status as "Unsuccessful".

Calibration

(1) On the "Results" screen, select "Continue".

(2) On the "Calibration Unsuccessful" screen, do one of

the following:

a) For zero gas calibrations:

To retry the zero gas calibration, select "Repeat

Calibration".

To return to the previous calibration values, select

"Close".

b) For span gas calibrations:

To do a span gas calibration for another gas, select

"Select Another Gas".

To retry the span gas calibration, select "Repeat

Calibration".

US

To return to the previous calibration values, select

"Close".

If "Close" is selected, on the dashboard, a gray check mark

indentifies the points that are affected by the unsuccessful

calibration. The gas readings for these sample points are

below the alarm threshold but may not be completely accurate.

Chillgard 5000

41

Page 42

Routine Operation

7 Routine Operation

WARNING!

Make sure to remove the cap from the exhaust port before operating the device. Failure to do so will

create back pressure that can result in inaccurate readings and damage to internal components.

Failure to follow these warnings can result in serious bodily injury or death.

7.1 Dashboard Overview

After the initial setup, the dashboard shows the main function buttons and tiles for the point s that are

enabled.

A green box around the tile identifies the point currently being sampled.

Point tiles are titled by name, not number.

When 2–4 points are enabled, large tiles show the point

name, number, current gas reading, and status.

7.2 Point Details

When 5–8 points are enabled, medium tiles show the poin t

name, number, current gas reading, and status.

When 9–16 points are enabled, small tiles show the point

name, number, current gas reading, and status.

To see details about a specific point, on the dashboard,

select the point tile. A detail pop-up opens.

To close the detail pop-up and return to the dashboard,

select the X at the top right corner.

To hold and lock onto a point for an extended period manually, in the point detail pop-up, select "Hold".

US

Chillgard 5000

42

Page 43

Routine Operation

7.3 Point Hold

7.3.1 Automatic Point Hold

During routine operation, when any sample point detects gas that results in a caution/warning/alarm

(C/W/A), the device automatically holds that sample point for an additional four gas measurement

cycles to analyze the point further and provide more data. When the additional four measurement

cycles are complete, the device goes to the next point and resumes routine sample times.

When the sampling cycle returns to the point that triggered the automatic hold, the automatic hold

state continues unless the non-latching event no longer exists (that is, the gas concentration

decreases below the C/W/A threshold) or the latching alarm event has been reset.

7.3.2 Manual Point Hold

To set the duration of the Hold feature, use the and

buttons.

T o disable the point alarm for the dura tion of the hold, select

the "Disable Alarm" checkbox.

To activate the Hold feature, select "Hold".

To cancel the Hold feature, select "Cancel" or the X at the

top right corner.

NOTE: The Hold feature can only be applied to one point at

a time. During the hold duration for the selected point, the

"Hold" button is inactive for all other points until the hold

duration for the selected point has completed.

7.4 Predictive Warnings

When a point goes above the acceptable thresh old for flow rate, sensor performa nce, or pump performance, a predictive warning pop-up shows on the dashboard.

US

Predictive warnings indicate that it may be necessary to do troubleshooting or replace a part, not that

there is a critical issue with the flow rate, sensor, or pump.

Chillgard 5000

43

Page 44

Routine Operation

To acknowledge the predictive warning and return to the dashboard, select "Acknowledge".

Acknowledging the predictive warning triggers a notification

that shows on the "Diagnostics" button on the dashboard.

A corresponding notification also shows on the "Diagnostics" screen. For information about diagnostics, refer to Section 8, "Diagnostics".

7.5 Cautions, Warnings, and Alarms

Cautions, warnings, and alarms can be triggered by non-latching or latching events. Non-latching

events do not require user interaction for resolution. Latching even ts require user interaction for resolution.

When an event occurs, a pop-up shows on the dashboard.

7.5.1 Non-Latching Events

Non-latching events do not require user interaction for resolution. For a non-latching event, if the gas reading goes

below the caution, warning, or alarm threshold before

"Acknowledge" is selected, the pop-up disappears from the

dashboard, the background of the point tile on the dashboard changes from red to white, the event is catalogued in

the Event Log, and a notification shows on the "Event Log"

button on the dashboard.

For information about the Event Log, refer to Section 7.7, "Event Log".

A corresponding notification of the event shows on the "Diagnostics" screen. For information about

diagnostics, refer to Section 8, "Diagnostics".

US

Chillgard 5000

44

Page 45

7.5.2 Latching Events

Routine Operation

Latching events require user interactio n for reso lution. F or

a latching event, "Acknowledge" must be selected on the

pop-up to return to the dashboard. If a horn is enabled for

the point, selecting "Acknowledge" silences the horn, but

the event is not yet resolved. The point tile shows in red on

the dashboard to indicate the unresolved event.

Select the point tile with the event to see a detail pop-up.

While the gas reading is above the event threshold, the

"Reset" button on the detail pop-up is hidden, and the even t

cannot be resolved.

When the gas reading goes below the event threshold, the

"Reset" button is active.

Select "Reset" to resolve the event and return to the dashboard. The point tile on the dashboard shows in it s nor mal

state, and the event is considered resolved.

A corresponding notification of the event shows on the "Diagnostics" screen. For information about

diagnostics, refer to Section 8, "Diagnostics".

US

Chillgard 5000

45

Page 46

Routine Operation

7.6 Faults

WARNING!

If the device is in critical fault mode, the device will not be monitoring for gas.

Failure to follow these warnings can result in serious bodily injury or death.

There are two types of faults: noncritical and critical.

Alarm events have priority over fault events. If a point has an alarm during a fault event, the po int tile

on the dashboard shows in red to indicate the alarm, not in yellow to indicate the fault.

Faults can be acknowledged and reset th rough th e pop-up

if it is a channel related fault.

If the fault is system related, it is acknowledged and reset

through the fault tab in the event log. Once the rese t is initiated on the system related faults, it will reset all of the faults

concurrently.

For faults related to the display, the system will notify the

user upon reset.

7.6.1 Noncritical Faults

When a noncritical fault occurs, a pop-up with a yellow

background signals the event on the dashboard.

If multiple faults occur simultaneously, the pop-up shows

the faults as line items.

To acknowledge the event and return to the dashboard,

select "Acknowledge".

If the fault can be related to a single or multiple points, the

associated point tiles show on the dashboard with a yellow

background.

US

Chillgard 5000

46

Page 47

Routine Operation

If the fault cannot be related to a single point or multiple points, the dashboard shows in a norma l state.

To see the details about a specific point, on the dashboard, select the point tile.

To see the details about the fault itself, go to the Event Log, "Faults" tab. Refer to Section 7.7, "Event

Log".

7.6.2 Critical Faults

WARNING!

If the device is in critical fault mode, the device will not be monitoring for gas.

Failure to follow these warnings can result in serious bodily injury or death.

A critical fault causes the following to occur:

• The fault relay trips.

• The device cannot monitor for gas.

• The 4–20 mA output decreas es to the user -specified

fault level.

• All modules except the main board and display shut

down.

• All point tiles show on the dashboard with a yellow background and a black X icon.

NOTE: If more than four events occur, use the scroll bar to

see the entire list of faults.

To acknowledge the events collectively and return to the

dashboard, select "Acknowledge".

US

Chillgard 5000

47

Page 48

7.7 Event Log

7.7.1 All

Routine Operation

On the dashboard, select the "Event Log" button.

The "All" tab shows a list of all types of events for the

device.

The last 25 events show in chronological order. When there

are 25 events in the list and a new event occurs, the oldest

event is deleted to make space for the new event to show.