Page 1

Operating Manual

MSA Cairns® XF1

Fire Helmet

Order No.: CH180A33- PQ730227/00

MSAsafety.com

Page 2

Thank you for purchasing your new MSA Cairns Fire Helmet. Welcome to the MSA Cairns Community of

Fire Helmet owners! Congratulations: you've just joined the thousands of Cairns Fire Helmet owners who

know why MSA Cairns is the market leading fire helmet in North America.Take these three steps to become

actively engaged with other helmet owners:

(1) Go to www.MSAsafety.com/registration and register your fire helmet for its lifetime warranty.

(2) Follow us on Facebook (facebook.com/MSAsafetyFire) and Twitter

(@MSAsafety, #lovemyCairns).

(3) Visit our active fire service brotherhood of MSA Cairns Fire Helmet owners at MSAFIRE.com

KEYWORD: CairnsCommunity.

The warranties made by MSA with respect to the product are voided if the product is not used and maintained

according to the instructions in this manual. Read and observe the DANGERS, WARNINGS and CAUTIONS

inside. If any information in this manual is unclear, or if you have any questions, contact MSA Customer

Service at 1-877-MSA-FIRE or visit our website at (MSAFIRE.com) before using this fire helmet.

1000 Cranberry Woods Drive

Cranberry Township, PA 16066

USA

Phone 1-800-MSA-2222

Fax 1-800-967-0398

For your local MSA contacts please go to our website www.MSAsafety.com

©

MSA 2018. All rights reserved

Page 3

Contents

1 Dangers, Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Description

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Attaching Ear Covers and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Ear Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Visor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Lighting Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Communication Headset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Donning the Helmet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .10

4.1 Pre-donning Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Donning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.1 Chinstrap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.2 Face Shield and Visor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Doffing the Helmet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Care and Maintenance

6.1 Routine Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.1 Fire Helmet Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.2 Impact Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.3 Ear Covers, Ratchet Cover, Chinstrap and Headband Liner (Soft Goods) . . . . . . . . . . . . . . . . . . . . . . 16

6.1.4 Chinstrap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.5 Face Shield and Visor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Advanced Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Routine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3.1 Fire Helmet Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3.2 Suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3.3 Impact Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.4 Ear Covers, Ratchet Cover and Headband Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 21

6.3.5 Headband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.6 Chinstrap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.7 Face Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.8 Visor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3.9 Edge Trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3.10 Reflective Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4 Advanced Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.1 Fire Helmet Disassembling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.2 Fire Helmet Resassembling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.5 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

US

MSA Cairns® XF1

3

Page 4

7 Replacement Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.1 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8 Warranty and Product Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 Contacting MSA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MSA Cairns® XF1

US

4

Page 5

Dangers, Warnings and Cautions

1 Dangers, Warnings and Cautions

WARNING!

Firefighting is an extremely dangerous activity. All personnel who have or will have the responsibility

for using or maintaining this fire helmet must follow the instructions in this manual carefully. This fire

helmet will perform as designed only if it is used and maintained according to the instructions. Otherwise, the fire helmet could fail to perform as designed, and personnel who rely on it for their safety can

sustain serious personal injury or death.

This fire helmet does NOT provide protection from all burns, injuries, diseases, conditions, or hazards.

Do not perform firefighting activities without the proper training and equipment.

Use extreme caution for all operations.

Use MSA Cairns

Occupational Safety and Health Program (current edition); CFR Title 29, Part 1910, Subpart I,

Personal Protective Equipment; NFPA 1971, Standard on Protective Ensembles for Structural and

Proximity Fire Fighting (current edition); and NFPA 1951, Standard on Protective Ensembles for Technical Rescue Incidents (current edition), as applicable.

This fire helmet provides LIMITED protection to the head when worn during structural, or rescue firefighting activities, as designated. Avoid exposure to flashovers, collapses, falls, and other conditions

that may exceed the protective capacity of the fire helmet.

If this fire helmet is exposed to heat, you may be BURNED with NO warning and NO sign of damage

to the fire helmet.

The NFPA-compliant face shield and/or the optional ANSI Z87 visor provide LIMITED protection to the

area they cover.

The visor provides LIMITED protection to the area covered. The visor is not certified according to

NFPA standards but meets the ANSI Z87.1 standard (most recent edition). The face shield MUST be

worn with the visor to maintain an NFPA compliant structural or rescue firefighting helmet ensemble.

Use adequate eye protection. Removal of NFPA-compliant eye protection voids the fire helmet's

NFPA certification.

To provide maximum protection and reduce the risk of injury, adjust the fire helmet with all components

in position to fit on the head properly and fasten the chinstrap securely.

The screw covers on both the lateral brackets for the impact cap must be snapped closed, covering

the screws underneath, to maintain optimal dielectric protection.

Do not use the helmet as a vehicular or sports helmet.

Follow the procedures in Section 6.3 "Routine Inspection" to inspect the fire helmet after EACH use.

Replace any part of the fire helmet that shows signs of wear or damage.

Use only components and accessories that are included with the original fire helmet or approved by

MSA. Using unauthorized components or accessories can adversely affect fire helmet performance.

Do not alter, paint, or attach any item that is not recommended by MSA to the fire helmet.

Do not use abrasive cleaners or solvents to clean the fire helmet.

Use only fire helmet markings (front identification shields, retro reflective trim) and fire helmet accessories (integrated lighting modules, communications headsets, etc.) that are supplied and/or

approved by MSA.

Failure to obey these warnings can result in serious personal injury or death.

®

XF1 Fire Helmets within the guidelines of NFPA 1500, Standard on Fire Department

US

MSA Cairns® XF1

5

Page 6

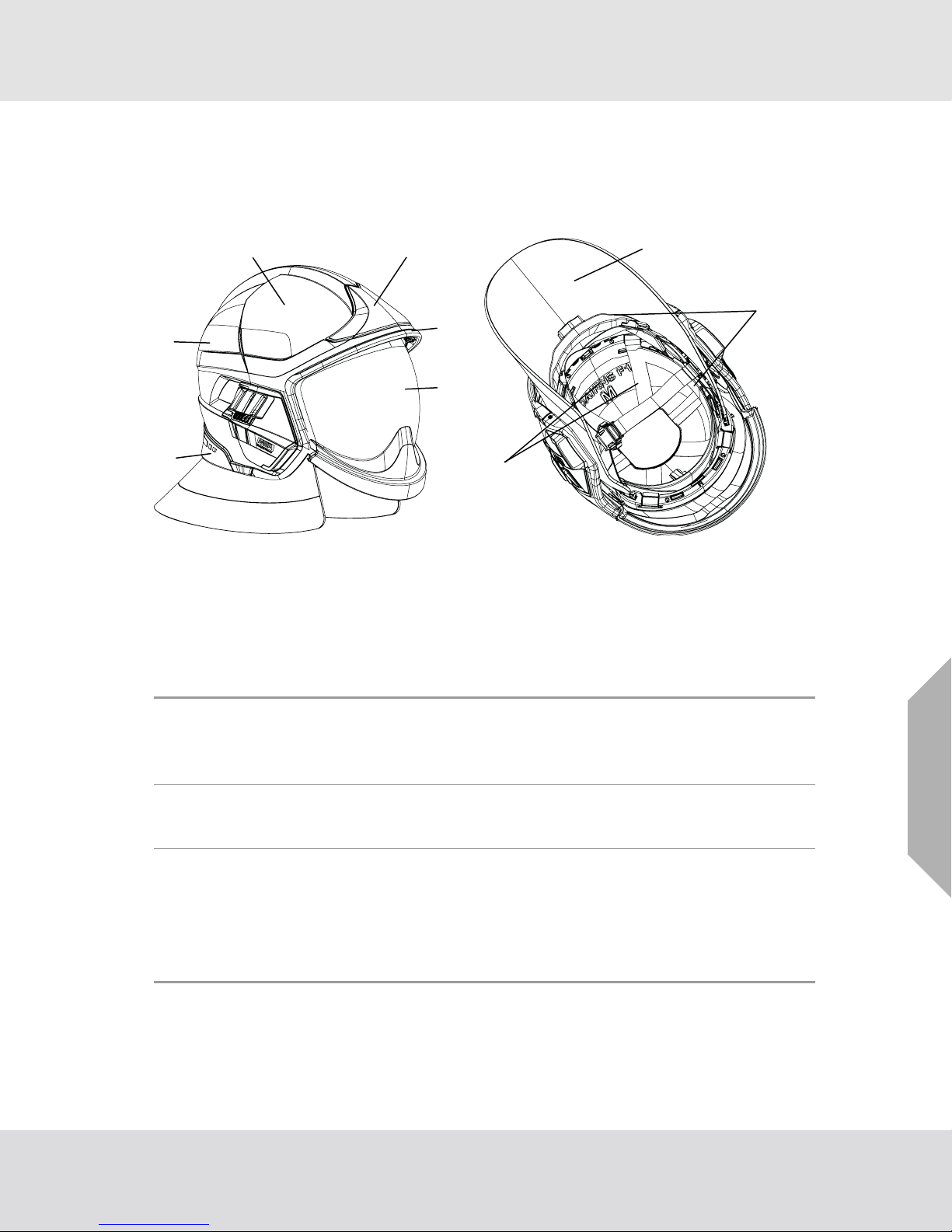

2 Description

1

6

5

2

3

4

9

8

7

2.1 Overview

The fire helmet consists of the following components:

Description

1 Shell 6 Reflective trim

2 Front plate 7 Ear covers

3 Front edge trim 8 Retention system (headband and chinstrap)

4 Face shield 9 Energy absorbing system (impact cap and suspension)

5 Rear edge trim

2.2 Technical Specifications

• Medium (M) for head sizes from 6-1/2 to 7-3/4 inches

Helmet sizes

Weight

(Helmet with face shield,

no options)

Options

(52 cm to 62 cm)

• Large (L) for head sizes from 7-1/8 to 8-1/8 inches

(57 cm to 65 cm)

• M: 3.5 lb ± 1 oz (1590 ± 30 g)

• L: 3.81 lb ± 1 oz (1730 ± 30 g)

• Integrated lighting module

•Visor

• Flexible Microphone Headset

Detailed information regarding the lighting module and the Flexible

Microphone Headset can be found in separate user manuals for

these devices.

US

MSA Cairns® XF1

6

Page 7

3 Attaching Ear Covers and Accessories

E

D

AB

C

F

3.1 Ear Covers

The helmet has 6 slots for installing the ear covers

(A, B, C, D, E and F).

Attaching Ear Covers and Accessories

(1) Place the ear covers upside down above the helmet.

(2) Insert the 2 clips marked in the central slots (A, B).

US

(3) Push the 4 pressure clips in order (C, D, E and

then F) until the clips lock.

MSA Cairns® XF1

7

Page 8

3.2 Visor

2

2

(b)(b)(b)

L

(a)(a)(a)

click

Attaching Ear Covers and Accessories

(1) Place the visor upside down above the

helmet.

(2) Insert the 2 clips simultaneously into the

dedicated slots.

(3) Lock the visor module by fixing the visor on

the shell connection pin (right and left).

The visor provides LIMITED protection to the area covered. The visor is not certified according to

NFPA standards but meets the ANSI Z87.1 standard (most recent edition). The face shield MUST be

worn with the visor to maintain an NFPA compliant structural or rescue firefighting helmet ensemble.

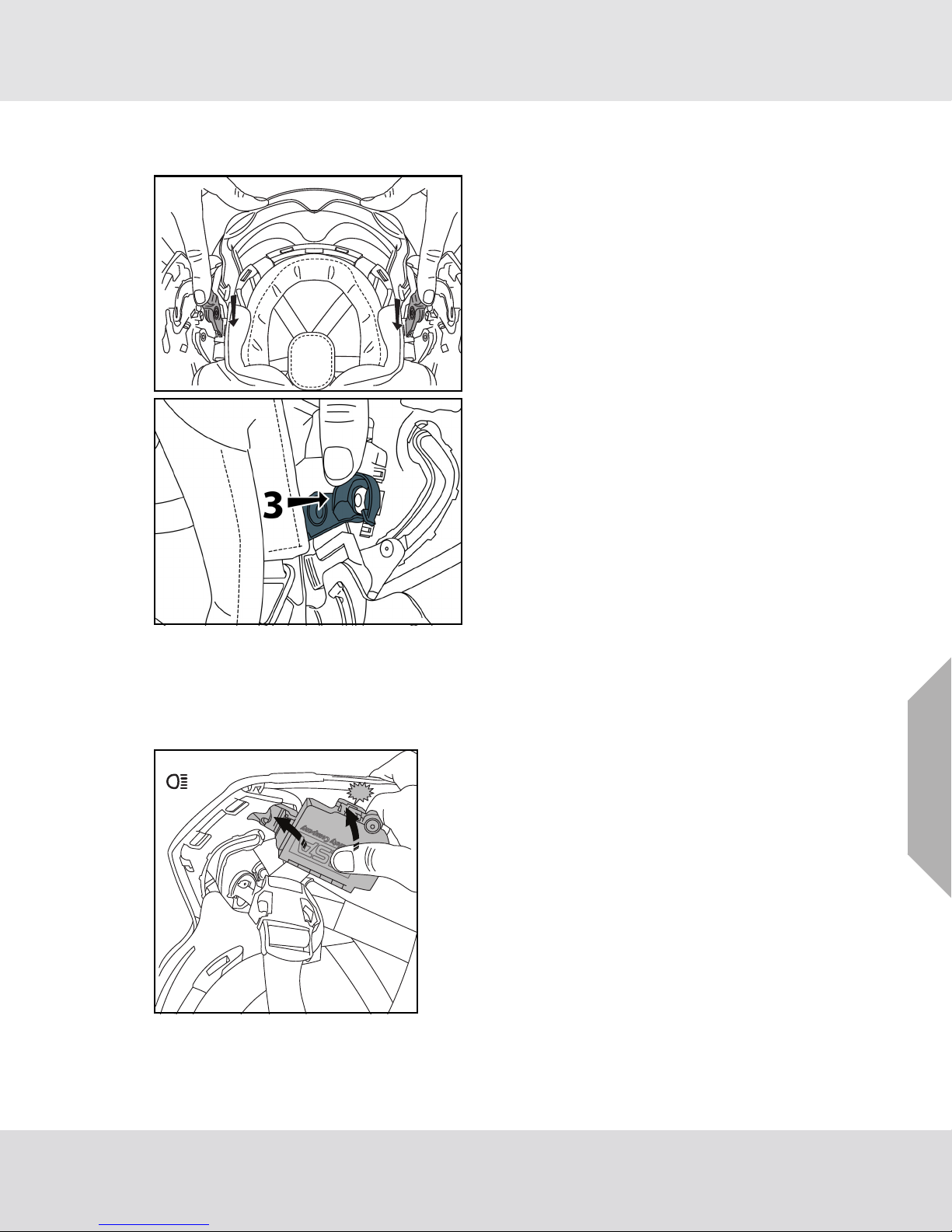

3.3 Lighting Module

US

(1) Place the helmet upside down with the face shield

towards you.

(2) Insert the left box (L) of the XF1 lighting module

into the space provided on the left side of the

helmet and firmly clip the box into place.

MSA Cairns® XF1

8

Page 9

Attaching Ear Covers and Accessories

(a)(a)(a)

(b)

(b)(b)

R

click

CLICK

(3) Repeat for the right box (R).

(4) Ensure that the lighting module cable is placed in

the indicated area.

(5) Refer to the lighting module user instruction

(MSAfire.com/Cairns) for details on operation.

3.4 Communication Headset

Refer to the Communication headset operating manual (MSAfire.com/Cairns).

If both the lighting module and XF1 flexible microphone headset are installed inside the helmet, disassemble the flexible microphone headset first and then disassemble the lighting module.

US

MSA Cairns® XF1

9

Page 10

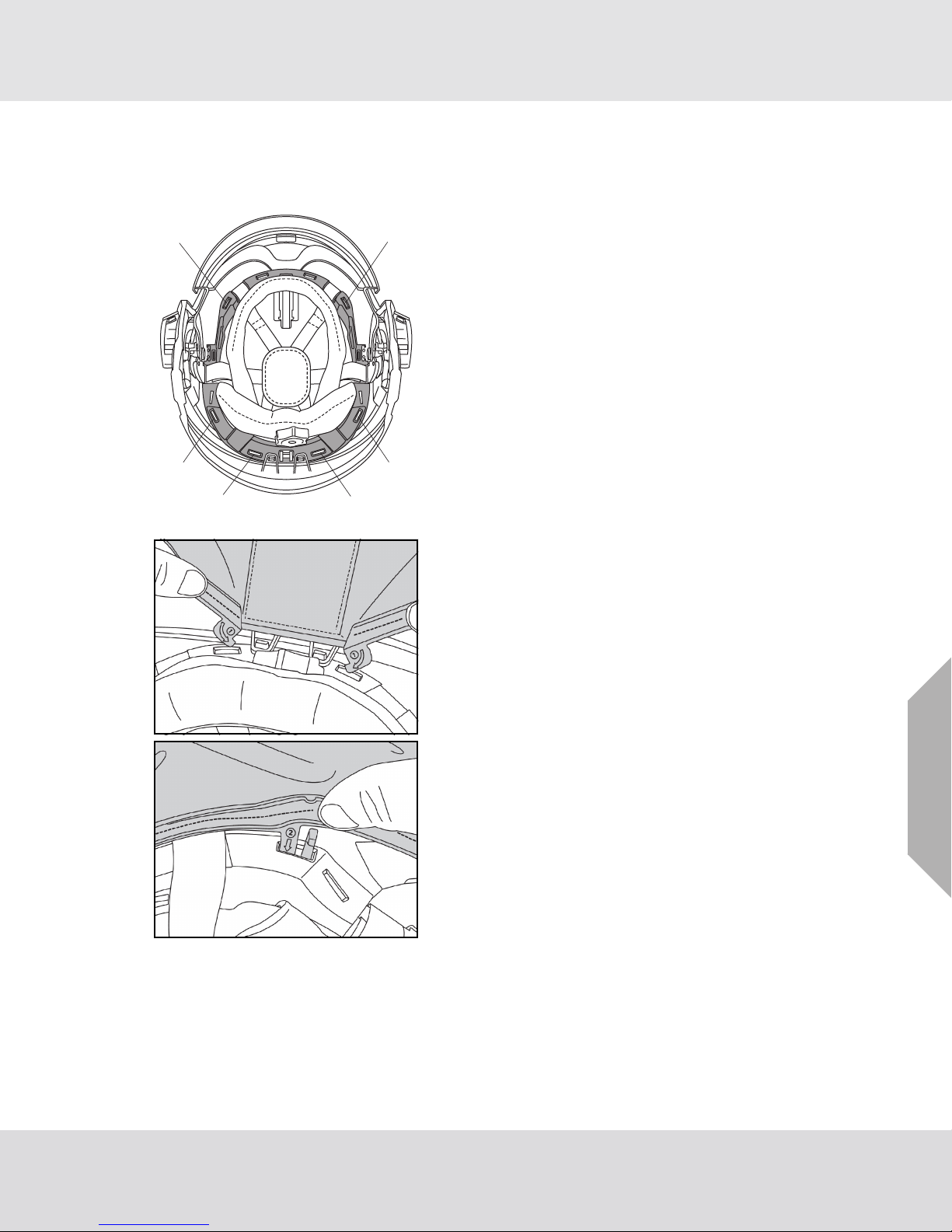

4 Donning the Helmet

4.1 Pre-donning Adjustments

Headband and Nape Strap Adjustments

Donning the Helmet

(1) Choose helmet size M or L (refer to Section 2.2

"Technical Specifications") according to your

head size.

(2) Adjust the front headband position by sliding the

headband up or down.

(3) Position the front headband inside the helmet to

avoid contact between headband and mask.

(4) Adjust nape strap/rear headband by rotating to

optimize fit on back of the head.

(5) Ensure that both the left and right side adjust-

ments are on the same setting so that the helmet

sits properly on the head.

US

MSA Cairns® XF1

10

Page 11

Donning the Helmet

4.2 Donning

WARNING!

To provide maximum protection, make sure to adjust the helmet properly. Tightening the ratchet

beyond its limits can cause damage to internal gears and result in reduced protection.

Failure to obey this warning can result in serious personal injury or death.

(1) Open the headband by turning the ratchet knob

counterclockwise (left).

(2) Position the chinstrap as shown before donning the

helmet.

(3) Put the helmet on your head.

(4) While holding the helmet down on your head, turn

the ratchet knob clockwise until the helmet feels

snug and comfortable.

(5) Lower the ear cover over your ears and over the

ratchet knob.

4.2.1 Chinstrap

WARNING!

Never wear the fire helmet without fastening and tightening the chinstrap.

Failure to obey this warning can result in serious personal injury or death.

The chinstrap is equipped with 3 adjustment points to allow quick and simple adjustment while the

helmet is on the head.

US

MSA Cairns® XF1

11

Page 12

Donning the Helmet

(1) Completely loosen the 3 adjustment points (chin-

strap buckle and 2 rear adjustments).

(2) Place helmet on head. Make sure that it is well

positioned.

(3) Close the chinstrap buckle.

(4) Tighten the chinstrap by pulling on the excess

chinstrap length.

(5) Secure the excess chinstrap length with the hook

and loop.

(4)

(6)

(6) Tighten the two rear adjustment straps by pulling

the excess strap length forward and slightly down

until a snug but comfortable fit is achieved.

4.2.2 Face Shield and Visor

WARNING!

Performance of the face shield and visor are obtained only in use position (low position).

Keep face shield and visor in standby position (stowed under the helmet shell) during the use of a

breathing apparatus (SCBA).

Do not wear a face shield over an SCBA face piece.

Visors worn over corrective lenses may transmit impacts which may damage the corrective

eyewear thus creating a hazard to the user.

Service life of face shield and visor depends on the conditions of use.

Any face shield or visor that has been scratched, dropped or damaged must be replaced.

Failure to obey these warnings can result in serious personal injury or death.

Face Shield

US

(1) Position by pushing it up or pulling it down as far as

it will go.

MSA Cairns® XF1

12

Page 13

Optional Visor

(1) Position by pushing it up or pulling it down.

(2) Tilt the visor towards the face by pushing the finger

spaces on either side of the visor for an optimal fit.

If further adjustment of the visor is needed to optimize the distance to the face:

(1) Unclip the yellow stopper.

Doffing the Helmet

(2) Clip the yellow stopper in positions (A), (B) or (C)

to optimize fit of the visor on the face.

5 Doffing the Helmet

(1) Loosen and unbuckle the chinstrap.

(2) While holding the helmet, turn the ratchet knob counterclockwise (to the left) to loosen the head-

band.

(3) Remove the helmet.

US

MSA Cairns® XF1

13

Page 14

Care and Maintenance

6 Care and Maintenance

WARNING!

Replace the helmet after it has withstood an impact, even if there is no visible damage.

Do not drop the fire helmet.

Avoid unnecessary impacts to the fire helmet which could damage the face shield and/or optional

visor (cracks/scratches).

Failure to obey these warnings can result in serious personal injury or death.

Carefully obey all of the procedures for cleaning, inspecting, repairing, and storing the fire helmet.

For additional guidance, refer to the current edition of NFPA 1851, which specifies the minimum selection, care, and maintenance requirements for structural and proximity firefighting protective ensembles and the individual ensemble elements, including fire helmets and interface components that are

compliant with NFPA 1971, Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting.

MSA Cairns® XF1

US

14

Page 15

Care and Maintenance

6.1 Routine Cleaning

WARNING!

Helmets that are dirty or soiled from firefighting activities may be contaminated with toxins that are

poisonous, pathogenic, toxic or carcinogenic. Failure to properly clean the helmet after each use

per the recommended cleaning procedures may result in injuries, illness, disease and/or death.

Helmets should be properly cleaned consistent with NFPA 1851 under the supervision of the

authority having jurisdiction and standard operating procedures.

Do not use cleaning solvents, oils, varnishes, or polishes other than those recommended in this

manual to clean or decontaminate fire helmets or fire helmet components.

Do not use abrasives, solvents, paint removers, acetone, paint or lacquer thinner, or any chlori-

nated organic solvents to clean the fire helmet shell. Use of these substances can degrade the

protective properties of the helmet shell.

Do not use equipment that produces mechanical action such as tumbling or agitation to machine-

wash or dry complete fire helmets.

Do not use forced hot air or put the fire helmet directly on a heat source to dry it.

Do not apply paint, stickers, cleaning products with a hydrocarbon base or solvents to the fire

helmet or visors to prevent damaging the materials of your helmet.

Failure to obey these warnings can result in serious personal injury or death.

• To prevent contamination after firefighting activities, clean the fire helmet after each use, before

inspection.

• Elements contaminated by CBRN agents must be handled according to decontamination and

disposal procedures set by the applicable authorities.

• Remove any fire helmet that has been exposed to chemical or biological contaminants from

service and clean it using the procedures in the Section 6.2 "Advanced Cleaning".

• For cleaning, use a solution of 1.5 oz (43 g) of mild detergent per 1 gal (3.8 L) of water at a

temperature no higher than 110 °F (43 °C).

• Do not use a fire helmet that is wet from use or cleaning. Allow all parts to air dry completely before

use.

• Do not use a heat source such as forced air to dry components more quickly. Do not tumble dry.

6.1.1 Fire Helmet Shell

• Wipe with mild detergent solution and a soft cloth. Do not use solvent based products or abrasive

materials.

6.1.2 Impact Cap

To clean the inside of the impact cap (when installed inside the fire helmet shell), wipe it with a soft

sponge or cloth dampened with a solution of warm water and mild detergent. Allow the impact cap to

air-dry completely. Do not use a heat source such as forced air to dry the impact cap more quickly. Do

not tumble dry.

US

MSA Cairns® XF1

15

Page 16

Care and Maintenance

C

6.1.3 Ear Covers, Ratchet Cover, Chinstrap and Headband Liner (Soft Goods)

(1) Remove the ratchet cover, headband liner and chinstrap (refer to Section 6.4.1 "Fire Helmet

Disassembling Procedure").

(2) Machine-wash the components with a mild liquid detergent at a temperature no higher than

110°F (43°C).

(3) Allow the components to air-dry completely. Do not use a heat source such as forced air to dry

components more quickly. Do not tumble dry.

(4) Reassemble all soft goods into the fire helmet.

6.1.4 Chinstrap

Chinstrap Disassembly before Cleaning

(1) Unlock metallic trapezoid (chinstrap 3rd point) from the

hook by pushing it (first A then B).

(2) Rotate the clips on right and left side of the chinstrap

90 degrees towards the rear of the helmet (C).

(3) Push each clip forward (D) and raise it on the back (E).

US

MSA Cairns® XF1

16

Page 17

Chinstrap Assembly after Cleaning

F

Care and Maintenance

(4) Detach the crown pad to release the crown strap.

(5) Detach the hook-and-loop tab on each side of the

headband liner behind the ear (near the ratchet).

(6) Remove the chinstrap from the helmet.

(1) Attach the crown pad to the suspension to position

the crown strap.

(2) Place the crown pad straps between the plastic

headband and the headband liner.

(3) Secure the straps in place by reattaching the head-

band liner to the plastic headband using the hookand-loop tabs.

(4) Insert both clips (F) into the slots vertically.

US

MSA Cairns® XF1

17

Page 18

Care and Maintenance

I

(5) Rotate clips 90 degrees towards the rear (G) and

push clips in (H).

(6) Rotate the clips 90 degrees forward into the wearing

position (I).

Attachment of the 3rd point (at the back)

(7) Insert the metallic trapezoid and lock it in the hook by

pulling it vertically (first K then J).

6.1.5 Face Shield and Visor

• Wipe with mild detergent solution and a soft cloth. Do not use solvent based products or abrasive

materials.

• Allow the face shield or visor to air dry completely. Do not use a heat source such as forced air to

dry the impact cap more quickly. Do not tumble dry.

US

MSA Cairns® XF1

18

Page 19

Care and Maintenance

6.2 Advanced Cleaning

WARNING!

Only a manufacturer-trained organization, verified organization, or verified Independent Service

Provider (ISP) can perform advanced cleaning.

Failure to follow the recommended cleaning procedures can result in illness or disease.

Do not use cleaning solvents, oils, varnishes, or polishes to clean or decontaminate fire helmets

or fire helmet components. If it is necessary to use a stronger cleaning agent than what is recommended in this manual, contact MSA Customer Service at 1-877-MSA-FIRE.

Do not use abrasives, solvents, paint removers, acetone, paint or lacquer thinner, or any chlori-

nated organic solvents to clean the fire helmet shell. Use of these substances can degrade the

protective properties of the helmet shell.

Do not use equipment that produces mechanical action such as tumbling or agitation to machine-

wash or machine-dry complete fire helmets.

Do not use forced hot air or put the fire helmet directly on a heat source to dry it.

Do not use a fire helmet that is wet from use or cleaning. Allow all parts to dry completely before

use.

Do not apply paint, stickers, cleaning products with a hydrocarbon base or solvents to the fire

helmet or visors to prevent damaging the materials of your helmet.

Failure to obey these warnings can result in serious personal injury or death.

• For advanced cleaning, perform the procedures in Routine Cleaning Sections 6.1.1 "Fire Helmet

Shell" through 6.1.5 "Face Shield and Visor", followed by the procedures in this section.

(1) Don protective gloves.

(2) Remove all detachable components and accessories from the fire helmet. Wash and air-dry

them separately.

(3) Immerse the entire fire helmet in a solution of 1.5 oz (43 g) of mild detergent per 1 gal (3.8 L) of

water at a temperature no higher than 110°F (43 °C).

(4) Use a soft brush to remove dirt and other debris from the fire helmet.

(5) Rinse the fire helmet and accessories thoroughly with water.

(6) Use a clean cloth dampened with water to wipe the fire helmet and accessories.

(7) Put the fire helmet in a clean, safe place to air-dry. Do not use a heat source such as forced air

to dry components more quickly. Do not tumble dry.

US

MSA Cairns® XF1

19

Page 20

Care and Maintenance

6.3 Routine Inspection

WARNING!

Failure to follow the recommended inspection procedures can reduce fire helmet performance and

result in serious personal injury, disease, illness, or death.

Do not use a fire helmet that has damage.

Do not attempt to test the fire helmet. The performance properties of the fire helmet and its components cannot be properly tested by a user in the field.

Failure to obey these warnings can result in serious personal injury or death.

Clean the fire helmet per section 6.1 "Routine Cleaning" prior to inspection.

Inspect the fire helmet after each use for the following signs of damage from impact and thermal exposure. If any of these conditions exist, remove the fire helmet from service immediately and repair or

replace it as applicable.

After each use, check every part of the fire helmet and, especially the attachment points.

• No evident wear

• No fractures or cracks

• Continued, proper fit

WARNING!

Replace the helmet after it has withstood an impact, even if there is no visible damage.

Ensure the screw covers on both the lateral brackets for the impact cap are snapped closed, covering

the screws underneath, to maintain optimal dielectric protection.

In case of visible damage identified during the routine inspection (before or after use), such as

impacts, significant scratches, coating removal on the shell or visors, melted parts, broken parts, torn

straps or padding, missing components, non-operational moving parts (such as visors or ratchet), etc.,

the fire helmet should be taken to the trained maintenance technician or an MSA approved maintenance center.

Failure to obey these warnings can result in serious personal injury or death.

6.3.1 Fire Helmet Shell

If any of the following conditions exist, replace the entire fire helmet ensemble.

• Any cracks

• Blisters or bubbles

6.3.2 Suspension

If any of the following conditions exist, replace the suspension:

• Straps have missing, cut, fraying, or broken stitching

• Straps are torn or abraded

• Straps are brittle or discolored

• Suspension attachment clips are broken, brittle, whited, or discolored

US

MSA Cairns® XF1

20

Page 21

Care and Maintenance

6.3.3 Impact Cap

If any of the following conditions exist, replace the applicable part:

• Cracks in the foam or plastic liner

• Depressions or dents in the foam equal to or larger than a thumbnail

• Punctures, blisters, or discoloration due to impact, excessive heat, or normal wear

• Separation of foam from the black liner

• Screw covers on the lateral brackets will not stay closed, or are broken or missing

6.3.4 Ear Covers, Ratchet Cover and Headband Liner

If any of the following conditions exist, replace the applicable part:

• Missing, cut, or broken stitching

• Torn, discolored charred, perforated or seared

• Missing or broken fasteners for ear cover

6.3.5 Headband

If any of the following conditions exist, replace the headband:

• Brittle, torn, cracked, or broken

•Holes

• Able to open ratchet by tugging on nape arms (rather than turning the knob)

6.3.6 Chinstrap

If any of the following conditions exist, replace the chinstrap:

• Frayed, missing, or broken parts

• Missing, cut, frayed, or broken stitching

• Clogged or worn-out hook-and-loop fastener

• Brittle, broken, or missing quick-release buckle

• Broken or cracked attachment points

• Webbing is torn or abraded

• Webbing is brittle or discolored

6.3.7 Face Shield

If any of the following conditions exist, replace the face shield or mounting hardware:

• Blistered, bubbled, cracked, charred or otherwise damaged hardware or lens

• Lens will not stay in the stowed position and/or cannot be adjusted

6.3.8 Visor

If any of the following conditions exist, replace the visor or attachment clips, as applicable:

• Blistered, bubbled, cracked, or charred lens

• Broken quick-connect attachment clips

• Lens will not stay in the stowed position and/or cannot be adjusted

US

MSA Cairns® XF1

21

Page 22

Care and Maintenance

6.3.9 Edge Trim

If any of the following conditions exist, replace the edge trim:

•Broken

• Edge trim pulled away from brim

6.3.10 Reflective Trim

If the reflective trim is charred, partially detached, nonreflective, and/or missing, replace it.

6.4 Advanced Inspection

WARNING!

Only a manufacturer-trained organization, verified organization, or verified Independent Service

Provider (ISP) can perform advanced inspection.

Failure to obey this warning can result in serious personal injury or death.

Advanced inspection includes all of the items listed for 6.3 "Routine Inspection" as well as the

following items. After the fire helmet is put into service, do an Advanced Inspection of all protective

ensemble elements at least every 12 months, or whenever a routine inspection removes the

ensemble from service, whichever occurs first.

NOTICE

For the purposes of replacement (according to NFPA 1851, Standard on Selection, Care, and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting) and

warranty, the manufacturing date for the fire helmet ensemble is based on the oldest original part

shipped as a component of the complete compliant fire helmet ensemble, irrespective of the manufacturing date of the replaced parts.

Disassemble the fire helmet using the instructions in Section 6.4.1 "Fire Helmet Disassembling Procedure"and inspect all components for the conditions listed in Section 6.3 "Routine Inspection".

US

MSA Cairns® XF1

22

Page 23

6.4.1 Fire Helmet Disassembling Procedure

8

7

5

1

2

3

4

6

9

10

11

12

Care and Maintenance

Fig. 1 Exploded view

1 Reflective trim 7 Impact cap

2 Shell 8 Suspension including lateral brackets and screw covers

3 Front plate 9 Headband

4 Front edge trim 10 Headband liner and ratchet cover

5 Rear edge trim 11 Chinstrap

6 Face shield 12 Ear cover

The following instructions enable a complete disassembling of the fire helmet for individual component

inspection.

(1) Turn the fire helmet upside down.

(2) Remove the ear cover.

US

(3) Remove the headband liner and the ratchet cover.

MSA Cairns® XF1

23

Page 24

Care and Maintenance

(4) Remove the chinstrap as described in Section 6.1.4 "Chinstrap".

(5) Remove the headband assembly:

a) Release the 2 rear attachments by sliding them through the wider area of the groove.

b) Slide the yellow front part out of its rail.

c) Release the front attachment by bringing them in a vertical position to get out of the slots.

(6) If necessary, remove the energy absorption system (impact cap + suspension) from the shell:

a) Move the side clips by detaching them from the shell connection pin.

b) Lift and remove screw covers on the lateral bracket for the impact cap on both sides.

c) Using a Torx 20 tool, remove the two attachment screws.

d) Unclip the rear of the suspension and slide the energy absorption system out of the helmet

shell.

(7) If necessary, separate the impact cap from the suspension:

a) Remove the attachment clip (front).

b) Gently pull the impact cap out of the suspension ring.

(8) If necessary, remove the face shield:

a) Move the face shield in the in-use position.

b) Unlock the upper face shield’s clips by rotating them at 180° (facing the opposite direction from

the engraved lock), using a Torx 15 tool.

c) Push the visor inwards, so that the upper clips get out of the rail and rotate the top of the visor

away from the helmet.

d) Slide the lower clips towards the top of the rail pushing the visor inwards to release the visor

from the helmet.

(9) If necessary, remove the edge trim:

a) Using a Torx 10 tool, remove the rear edge trim attachment screw

b) Using a Torx 10 tool, remove the two front edge trim attachment screws

c) Gently separate the rear and front edge trims in their attachment area and pull out the trims

from the shell.

6.4.2 Fire Helmet Resassembling Procedure

The following instructions enable a complete reassembling of the fire helmet if fully disassembled.

(1) Install the rear and front edge trim and lock them with their respective screws using a Torx 10 tool

US

(2) Install the face shield:

a) Insert the lower clips in the lower rail, and pull them to the end of the sliding rail (corresponding

to the in-use position of the face shield), leaving the upper clips outside the helmet shell.

b) Rotate the top of the visor towards the helmet and gently push the visor inwards to insert the

upper clips in their location.

c) Lock the upper clips rotating them at 180° (facing the engraved lock), using a Torx 15 tool.

MSA Cairns® XF1

24

Page 25

Care and Maintenance

(3) Attach the impact cap to the suspension and lock the attachment clip.

(4) Install the energy absorption module inside the helmet shell:

a) Install the inner module, sliding it inside the shell until rear locating clips are properly posi-

tioned in their lugs

b) Lock the inner module using 2 new screws to ensure proper locking.

c) Press the screw covers firmly back over the screws to ensure a tight seal on each lateral

bracket for the impact cap until the covers are secured.

(5) Install the headband assembly:

a) Attach the black side parts, inserting them vertically in their slot, and rotate them once the

attachment clip is properly inserted.

b) Insert and slide the yellow front part through its rail.

c) Complete the installation by inserting the 2 rear attachment points through the mounting

groove.

(6) Install the chinstrap as described in Section 6.1.4 "Chinstrap".

(7) Install the headband liner and ratchet cover.

(8) Install the ear covers as described in Section 3.1 "Ear Covers".

6.5 Storage

WARNING!

Do not store equipment that is not explicitly authorized by MSA in or on the fire helmet. The storage

of gloves, wedges, lights, and other equipment in or on the fire helmet can dramatically change the

protective capacity of the fire helmet.

Failure to obey this warning can result in serious personal injury or death.

• Clean the fire helmet (shell and internal components) after use before storing.

• Store the fire helmet in a clean, dry area where it is not exposed to heat, cold, or sunlight.

• Store the fire helmet in a proper storage bag and/or in a closed cabinet to avoid extended exposure

to cold, humidity, exhaust fumes, etc.

• When not in use, store the fire helmet with the ratchet suspension set to its smallest size.

• Store the face shield and visor (if applicable) inside the fire helmet (stowed position).

US

MSA Cairns® XF1

25

Page 26

Replacement Parts and Accessories

7 Replacement Parts and Accessories

Please see our catalog, visit MSAFIRE.com or contact your authorized MSA fire service distributor for

a full line of genuine MSA accessories and replacement parts.

7.1 Replacement Parts

Description Part Number

Clear face shield XF1 GA1156

Edge trim XF1, Large size (rear + front edge trim) GA1165-L

Edge trim XF1, Medium size (rear + front edge trim) GA1165-M

Impact cap XF1, (Size M: Medium / L: Large) GA1157-M / GA1157-L

Suspension XF1, (Size M: Medium / L: Large) GA1158-M / GA1158-L

Headband Assembly XF1 GA1161

Kit, Headband liner and ratchet cover XF1 GA1162

Chinstrap XF1 GA1160

Front plate GA1150-xx

Kit, reflective material (lime-yellow) XF1 GA1153

Ear cover XF1 GA1159

Kit, Screws, Edge Trim XF1, 50/package GA1163

Kit, Screws M4x12 TBC steel, 50/package GA1027

Lateral brackets with screw cover (L&R) GA1166

7.2 Accessories

Description Part Number

Lighting module GA1484

Ocular visor kit XF1 GA1087C

Headset Boom Microphone 1 LS GA010002H3

Headset Boom Microphone 2 LS GA010002H3A

US

MSA Cairns® XF1

26

Page 27

Warranty and Product Registration

8 Warranty and Product Registration

Refer to ID 3600-72-MC (MSA Cairns 10-Year Warranty and Terms of Sale).

Registering your new fire helmet is important! Registering your new fire helmet will help MSA provide

quicker, more efficient service and support. Your product registration can help ensure you get the most

out of your warranty, especially if your fire helmet was a gift and you don't have a proof of purchase

date.

Registering your product will solidify the start date on your warranty period and eliminate confusion

and frustration if you ever have to take advantage of your warranty.

Finally, in the unlikely event a safety notification or warranty service is required, MSA will have the

ability to contact you. Your completed registration also helps us to keep you updated on support,

service, product information and promotions/special offers.

To register your new MSA Cairns Fire Helmet, go to http://us.msasafety.com/productRegistration

9 Contacting MSA

Keep these instructions in a safe place so you can refer to them in the future. For questions regarding

the operation of this fire helmet or suggestions and comments about it, contact Customer Service at

1-877-MSA-FIRE.

.

MSA Cairns® XF1

US

27

Page 28

For local MSA contacts, please visit us at MSAsafety.com

Because every life has a purpose...

Loading...

Loading...