Page 1

Operating Manual

ALTAIR® 4X

Multigas Detector

Order No. 10106503/00

Page 2

Page 3

Declaration of Conformity

Manufactured by: Mine Safety Appliances Company

1000 Cranberry Woods Drive

Cranberry Township, PA 16066 USA

European authorized representative:

MSA AUER GmbH

Declaration of ConformityMSA

Thiemannstrasse 1

D-12059 Berlin

We declare that the

MSA ALTAIR 4X

complies with the provisions of the council directive 94/9/EC [ATEX].This declaration is

based on the EC-Type Examination Certificate FTZU 07 ATEX 0169 X in accordance

with Annex III of the ATEX Directive 94/9/EC. Quality Assurance Notification issued by

Ineris, Notified Body number 0080, in accordance with Annex IV of the ATEX Directive

94/9/EC.

We additionally declare that this product is in conformance with the

EMC Directive 2004/108/EC in accordance with the standards

DIN EN 50270:2006 Typ 2 and DIN EN 61000-6-3:2007

MSA AUER GmbH

Dr. Axel Schubert

R&D Instruments

GB

ALTAIR 4X

Berlin, May 2010

3

Page 4

MSAContents

Contents

1 Safety Regulations ................................................................................................. 6

1.1 Correct Use .................................................................................................. 6

1.2 Liability Information ....................................................................................... 7

1.3 Safety and Precautionary Measures to be Adopted ..................................... 7

2 Description ........................................................................................................... 10

2.1 Overview ..................................................................................................... 10

2.2 Device Hardware Interfaces ....................................................................... 11

2.3 On-Screen Indicators .................................................................................. 13

2.4 Battery Care ............................................................................................... 14

2.5 Viewing Optional Displays .......................................................................... 16

2.6 Sensor Missing Alarm ................................................................................. 20

2.7 Sensor End of Life Warning ........................................................................ 20

2.8 Sensor End of Life Indicator ....................................................................... 20

2.9 Monitoring Toxic Gases .............................................................................. 20

2.10 Monitoring the Oxygen Concentration ........................................................ 22

2.11 Monitoring Combustible Gases .................................................................. 23

3 Operation .............................................................................................................. 24

3.1 Environmental Factors ................................................................................ 24

3.2 Turning on the Device ................................................................................ 25

3.3 Measurement Mode [Normal Operation] .................................................... 30

3.4 Device Setup .............................................................................................. 32

3.5 Data Logging .............................................................................................. 36

3.6 Function Tests ............................................................................................ 37

3.7 Safe LED .................................................................................................... 37

3.8 Bump Test .................................................................................................. 37

3.9 Calibration .................................................................................................. 39

4

ALTAIR 4X

GB

Page 5

ContentsMSA

4 Maintenance ......................................................................................................... 44

4.1 Troubleshooting .......................................................................................... 45

4.2 Live Maintenance Procedure - Replacing and Adding a Sensor ................ 46

4.3 Cleaning ..................................................................................................... 48

4.4 Storage ....................................................................................................... 48

4.5 Scope of Delivery ....................................................................................... 48

5 Technical Specifications/Certifications ............................................................. 49

5.1 Technical Specifications ............................................................................. 49

5.2 Factory-set Alarm thresholds ...................................................................... 50

5.3 Certification ................................................................................................. 51

5.4 Performance Specification .......................................................................... 53

5.5 XCell Sensor Patents ................................................................................. 54

6 Ordering Information ........................................................................................... 55

7 Appendix ............................................................................................................... 56

7.1 Start Up Sequence [Power on] ................................................................... 56

7.2 Fresh Air Setup [FAS] ................................................................................. 57

7.3 Reset Screen Controls ............................................................................... 58

7.4 Bump Test .................................................................................................. 60

7.5 Options Setup ............................................................................................. 61

7.6 Sensor Setup .............................................................................................. 62

7.7 Calibrations ................................................................................................. 63

GB

ALTAIR 4X

5

Page 6

1 Safety Regulations

1.1 Correct Use

The ALTAIR 4X Multigas Detector is intended for use by trained and qualified personnel. It is designed to be used when performing a hazard assessment to:

- assess potential worker exposure to combustible and toxic gases and vapours

as well as low level of oxygen.

- determine the appropriate gas and vapour monitoring needed for a workplace.

The ALTAIR 4X Multigas Detector can be equipped to detect:

- Combustible gases and certain combustible vapours

- Oxygen-deficient or oxygen-rich atmospheres

- Specific toxic gases for which a sensor is installed.

While the device can detect up to 30 % oxygen in ambient air, it is

approved for use only up to 21 % oxygen.

MSASafety Regulations

It is imperative that this operating manual be read and observed when using the

product. In particular, the safety instructions, as well as the information for the use

and operation of the product, must be carefully read and observed. Furthermore,

the national regulations applicable in the user's country must be taken into account

for a safe use.

Danger!

This product is supporting life and health. Inappropriate use, maintenance or servicing may affect the function of the device and thereby seriously compromise the user's life.

Before use the product operability must be verified. The product must

not be used if the function test is unsuccessful, it is damaged, a competent servicing/maintenance has not been made, genuine MSA spare

parts have not been used.

Alternative use, or use outside this specification will be considered as non-compliance. This also applies especially to unauthorised alterations to the product and to

commissioning work that has not been carried out by MSA or authorised persons.

6

ALTAIR 4X

GB

Page 7

1.2 Liability Information

MSA accepts no liability in cases where the product has been used inappropriately

or not as intended. The selection and use of the product are the exclusive responsibility of the individual operator.

Product liability claims, warranties also as guarantees made by MSA with respect

to the product are voided, if it is not used, serviced or maintained in accordance with

the instructions in this manual.

1.3 Safety and Precautionary Measures to be Adopted

Attention!

The following safety instructions must be observed implicitly. Only in this

way can the safety and health of the individual operators, and the correct

functioning of the device, be guaranteed.

Check function each day before use

Safety RegulationsMSA

Before each use, check the function and calibration of the device. Otherwise there

is a danger that incorrect results will be displayed. The check is performed using a

suitable calibration gas.

Perform a bump test each day before use

Perform a bump test before each day's use to verify proper operation. The device

must pass the bump test. If it fails the test, perform a calibration before using the

device.

Perform a bump test more frequently if the device is subjected to physical shock or

high levels of contaminants. Also, perform a bump test more frequently if the tested

atmosphere contains the following materials, which may desensitize the combustible gas sensor and reduce its readings:

- Organic silicones

- Silicates

- Lead-containing compounds

- Hydrogen sulphide exposures over 200 ppm or exposures over 50 ppm for

one minute.

Check minimum concentration of a combustible gas

The minimum concentration of a combustible gas in air that can ignite is defined as

the Lower Explosive Limit [LEL]]. A combustible gas reading of "XXX” indicates the

atmosphere is above 100 % LEL or 5.00 % vol CH

ists. Move away from hazardous area immediately.

GB

ALTAIR 4X

, and an explosion hazard ex-

4

7

Page 8

MSASafety Regulations

Observe atmosphere

Do not use the device to test for combustible or toxic gases in the following atmospheres as this may result in erroneous readings:

- Oxygen-deficient or oxygen-rich atmospheres

- Reducing atmospheres

- Furnace stacks

- Inert environments

- Atmospheres containing combustible airborne mists/dusts.

Use the device only to detect gases/vapours for which a sensor is installed.

Make sure adequate oxygen is present.

Not to be used for gases having a flashpoint in excess of 38 °C

Do not use the device to test for combustible gases in atmospheres containing vapours from liquids with a high flash point [above 38 °C], as this may result in erroneously low readings.

Physical shock

Recheck calibration if device is subjected to physical shock.

Sensor maintenance

Do not block sensor openings as this may cause inaccurate readings. Do not press

on the face of the sensors, as this may damage them and cause erroneous readings. Do not use compressed air to clean the sensor holes, as the pressure may

damage the sensors.

Observe proper time for diplay stabilising

Allow sufficient time for device to display accurate reading. Response times vary

based on the type of sensor being utilized.

Observe proper battery maintenance

Use only battery chargers made available by MSA for use with this device; other

chargers may damage the battery pack and the device. Dispose of in accordance

with local health and safety regulations.

Use of the GALAXY Automated Test System is an alternate approved method for

charging ALTAIR 4X devices.

8

ALTAIR 4X

GB

Page 9

Safety RegulationsMSA

Be aware of environmental conditions

A number of environmental factors may affect the sensor readings, including

changes in pressure, humidity and temperature.

Pressure and humidity changes also affect the amount of oxygen actually present

in the atmosphere.

Be aware of the procedures for handling electrostatically sensitive

electronics

The device contains electrostatically sensitive components. Do not open or repair

the device without using appropriate electrostatic discharge [ESD] protection. The

warranty does not cover damage caused by electrostatic discharges.

Be aware of the product regulations

Follow all relevant national regulations applicable in the country of use.

Be aware of the warranty regulations

The warranties made by Mine Safety Appliances Company with respect to the product are voided if the product is not used and maintained in accordance with the instructions in this manual. Please protect yourself and others by following them. We

encourage our customers to write or call regarding this equipment prior to use or for

any additional information relative to use or service.

GB

ALTAIR 4X

9

Page 10

2 Description

2.1 Overview

MSADescription

9

1 2

3

Fig. 1 device view

1 Communication

9

3

4

5

6

7

8

9

8 Display

10

11

12

10

2 Safe LED [green] and

Fault LED [yellow]

3 Sensor Inlets 10 Belt Clip

4 Horn 11 Charging Connection

T

5

6

7 ON/OFF Button

Button 12 Screws [4]

S

Button 13 Charge LED [red/green]

9 Alarm LEDs [4]

The device monitors gases in ambient air and in the workplace.

It is available with a maximum of three sensors, which can display readings for four

separate gases [one Dual Toxic Sensor provides both CO and H

S sensing capa-

2

bilities in a single sensor].

ALTAIR 4X

GB

Page 11

While the device can detect up to 30 % oxygen in ambient air, it is

approved for use only up to 21 % oxygen.

The alarm levels for the individual gases are factory-set and can be changed

through the Setup Menu. These changes can also be made through MSA Link software. Ensure that the latest version of the MSA Link software has been downloaded

from MSA’s website www.msanet.com.

If gas is present during Fresh Air Setup, the device will fail and enters

Measure mode.

2.2 Device Hardware Interfaces

Device operation is dialog driven from the display with the aid of the three function

buttons [→ Fig. 1].

DescriptionMSA

Button Definitions

Button Description

ON/OFF The ON/OFF button is used to turn device on or off and to confirm

user action selections.When the S button and the ON/OFF button

are pressed simultaneously for device start-up, the Options Setup

Mode displays.

T The T button is used to move forward through data screens in

measuring mode, or as page back and to decrease the values in

set-up mode. Holding this button for 3 seconds while in Normal

Measure Mode will activate the InstantAlert alarm.

S The S button is used to reset peak, STEL TWA and acknowledge

alarms [where possible] or access calibration in measuring mode. It

is also used as page up or to increase the values in set-up mode.

GB

ALTAIR 4X

11

Page 12

MSADescription

LED Definitions

LED Description

GREEN The Safe LED flashes once every 15 seconds to notify the user

that the device is on and operating.This option can be turned off

through the MSA Link software.

RED The red LEDs are visual indications of an alarm condition or any

type of error in the device.

YELLOW The yellow LED is a visual indication of an device fault condition.

This LED will be on with the following conditions:

- Device memory error

- Sensor Missing

- Sensor Error

RED/GREEN The Charge LED is a visual indication of charge status.

-RED:

is charging

- GREEN: complete charge

Vibrating Alarm

The device is equipped with a vibrating alarm.

Backlight

The backlight automatically activates when any button is pressed. The backlight remains on for the duration of the user-selected timeout. This on/off duration can be

set through MSA Link software.

Horn

The horn provides an audible alarm.

Operating Beep

This operating beep activates every 30 seconds by momentarily beeping the horn

and flashing the alarm LEDs under the following conditions:

- Operating beep is enabled

- Device is on normal Measure Gases page

- Device is not in battery warning

- Device is not in gas alarm

- Audible and visual options are enabled

12

ALTAIR 4X

GB

Page 13

2.3 On-Screen Indicators

Fig. 2 Display

1 Graphic Symbols 3 Gas Concentration

2 Gas Type

DescriptionMSA

1

2

3

COMB/EX

O2

CO

H2S

Alarm Symbol – Indicates alarm state.

Motion Alert – Indicates Motion Alert is active.

Bump Check Symbol – Indicates successful bump or cal.

Indicates required interaction.

Battery Condition – Indicates the battery charge level.

Sensor Labels.

Cal Gas Cylinder – Indicates cal gas must be applied.

No Gas Cylinder – Indicates cal gas should not be applied and device

must be exposed to fresh air.

Hourglass – Indicates user should wait.

GB

ALTAIR 4X

13

Page 14

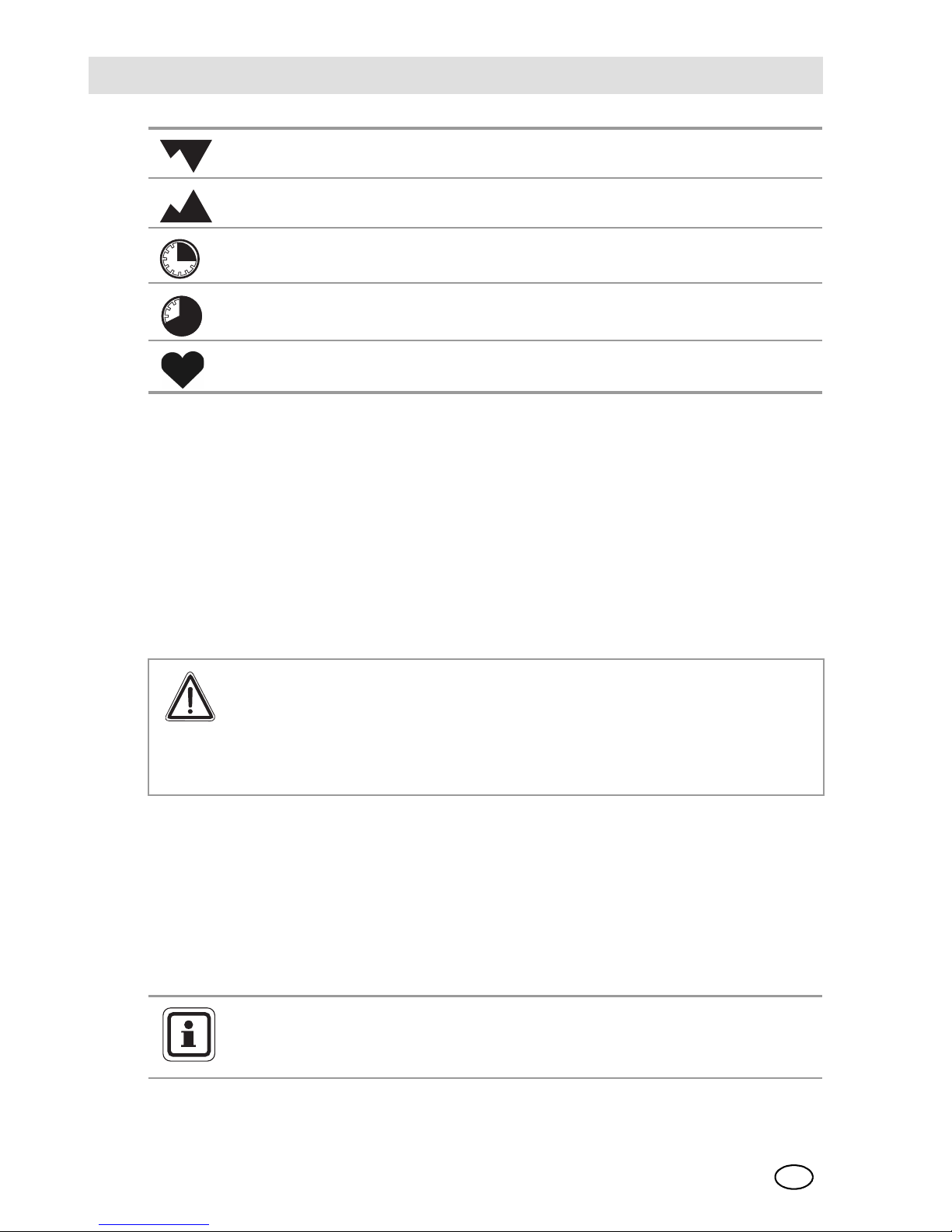

Minimum – Indicates a minimum value or low alarm.

PEAK Symbol – Indicates a PEAK reading or high alarm.

STEL Symbol – Indicates a STEL alarm.

TWA Symbol – Indicates a TWA alarm.

Sensor life Symbol – Indicates the end of sensor life

2.4 Battery Care

Battery Life Indicator

The battery condition icon is continuously displayed in the upper right-hand corner

of the display. As the battery is depleted, battery icon segments blank until only the

battery icon outline remains.

MSADescription

Each indicator segment represents approximately 25 % of the total battery capacity.

Battery Warning

Attention!

If battery warning alarm activates while using the device, leave the area

immediately as the end of battery life is approaching.

Failure to follow this warning can result in serious personal injury or

death.

The nominal run-time of the device at room temperature is 24 hours. Actual runtime will vary depending on ambient temperature and alarm conditions. The runtime

of the device at -20 °C [-4 °F] will be approximately 14 hours.

The alarm levels for the individual gases are factory-set and can be changed

through the Setup Menu.

A Low Battery Warning indicates that a nominal 30 minutes of operation remain before the battery’s charge is depleted.

The duration of remaining device operation during a Low Battery

Warning depends on ambient temperatures.

14

ALTAIR 4X

GB

Page 15

DescriptionMSA

When the device goes into Low Battery Warning, the:

- battery life indicator flashes

- alarm sounds

- alarm LEDs flash

- display shows "Low Batt" and

- device repeats this warning every 15 seconds and continues to operate until it

is turned off or battery shutdown occurs.

Battery Shut Down

Attention!

If battery shutdown alarm activates, stop using the device as it no longer

has enough power to indicate potential hazards, and persons relying on

this product for their safety could sustain serious personal injury or

death.

The device goes into battery shutdown mode 60 seconds before final shutdown

[when the batteries can no longer operate the device]:

- On the display flashes "Low Batt" and

- Alarm sounds and lights flash; alarm cannot be silenced,

- No other pages can be viewed; after approximately one minute, the device

automatically turns off.

When battery shutdown condition occurs:

(1) Leave the area immediately.

(2) Recharge the battery.

GB

ALTAIR 4X

15

Page 16

MSADescription

Battery Charging

Warning!

Risk of explosion: Do not recharge device in hazardous area.

Attention!

Use of any charger, other than the charger supplied with the device, may

damage or improperly charge the batteries.

The charger is capable of charging a completely depleted pack in less than four

hours in normal, room-temperature environments.

Allow very hot or cold devices to stabilise for one hour at room temperature before attempting to charge.

- Minimum and maximum ambient temperature to charge the device is 10 °C

[50 °F] and 35 °C [95 °F], respectively.

- For best results, charge the device at room temperature [23 °C].

To Charge the Device

- Firmly insert the device into the charging cradle.

- The battery symbol will scroll through a progressively increasing number of segments and the charge LED will be red until 90 % of full charge has been obtained. Then the battery symbol will remain fully illuminated and the charge LED

will be green while the battery is trickle charged to its full capacity.

- If a problem is detected during charging, the battery symbol will flash and the

charge LED will be orange. Remove, then replace the device in the charging

cradle to reset the charge cycle.

2.5 Viewing Optional Displays

The Main Screen appears at device turn-on.

Optional displays can be viewed by pressing the T button to move to:

Bump Mode

(1) To select the Bump mode, press the ON/OFF button.

(2) To move forward, press the T button.

(3) To move backward to the Main page, press the S button.

16

ALTAIR 4X

GB

Page 17

DescriptionMSA

Peak Readings [PEAK page]

The peak icon [→ chapter 2.3] shows the highest levels of gas recorded by the device since turn-on or since peak readings were reset.

To reset the peak readings:

(1) Access the PEAK page.

(2) Press the S button.

Minimum Readings [MIN page]

This page shows the lowest level of oxygen recorded by the device since turn-on or

since the MIN reading was reset.

The minimum icon [→ chapter 2.3] appears on the display.

To reset the MIN reading:

(1) Access the MIN page.

(2) Press the S button.

Short Term Exposure Limits [STEL page]

Attention!

If the STEL alarm activates, leave the contaminated area immediately;

the ambient gas concentration has reached the preset STEL alarm level.

Failure to follow this warning will cause over-exposure to toxic gases and

persons relying on this product for their safety could sustain serious personal injury or death.

The STEL icon [→ chapter 2.3] appears on the display to show the average exposure over a 15 minute period.

When the amount of gas detected by the device is greater than the STEL limit:

- Alarm sounds

- Alarm LEDs flash

- STEL icon flashes.

To reset the STEL:

(1) Access the STEL page.

(2) Press the S button.

The STEL alarm is calculated over a 15 minute exposure.

GB

ALTAIR 4X

17

Page 18

STEL calculation examples:

Assume the device has been running for at least 15 minutes:

15 minute exposure of 35 ppm:

MSADescription

[15 minutes x 35 ppm]

= 35 ppm

15 minutes

10 minute exposure of 35 ppm and 5 minutes exposure of 5 ppm:

[10 minutes x 35 ppm] + [5 minutes x 5 ppm]

= 25 ppm

15 minutes

Time Weighted Average [TWA page]

Attention!

If the TWA alarm activates, leave the contaminated area immediately;

the ambient gas concentration has reached the preset TWA alarm level.

Failure to follow this warning will cause over-exposure to toxic gases and

persons relying on this product for their safety could sustain serious personal injury or death.

The TWA icon [→ chapter 2.3] appears on the display to show the average exposure since the device was turned on or since the TWA reading was reset. When the

amount of gas detected is greater than the eight-hour TWA limit:

18

- Alarm sounds

- Alarm LEDs flash

- TWA icon flashes.

To reset the TWA:

(1) Access the TWA page.

(2) Press the S button.

The TWA alarm is calculated over an eight-hour exposure.

ALTAIR 4X

GB

Page 19

TWA calculation examples:

1 hour exposure of 50 ppm:

DescriptionMSA

[1 hour x 50 ppm] + [7 hours x 0 ppm]

= 6.25 ppm

8 hours

4 hour exposure of 50 ppm and 4 hour exposure of 100 ppm:

[4 hours x 50 ppm] + [4 hours x 100 ppm]

= 75 ppm

8hours

12 hour exposure of 100 ppm:

[12 hours x 100 ppm]

= 150 ppm

8hours

Time Display

Current time appears on the display in a 12 hour format by default.

A 24-hour format can be selected using MSA Link.

Date Display

Current date appears on the display in the format: MMM-DD-YYYY.

Last cal page

Displays the device last successful calibration date in the format:

MMM-DD-YYYY

Cal due page

Displays the days until the device's next calibration is due [user selectable].

Motion Alert Activation

To activate or deactivate the Motion Alert feature, press the S button while the

Motion Alert Activation page is displayed. When the Motion Alert feature is active,

the Motion Alert symbol [→ chapter 2.3] will flash every 3 seconds. The device will

enter pre-alarm when no motion is detected for 20 seconds. This condition can be

cleared by moving the device.

After 30 seconds of inactivity, the full Motion Alert alarm is triggered. This alarm can

only be cleared by pressing the S button.

GB

ALTAIR 4X

19

Page 20

2.6 Sensor Missing Alarm

The device enters the Sensor Missing alarm if the instrument detects that an enabled O2 or Combustible sensor is not properly installed in the instrument or is not

functional.

For the O2 sensor, the sensor missing feature is checked when the instrument is

turned on and when leaving the Setup Mode.

The combustible Sensor Missing feature is continuously monitored.

If a sensor is detected as missing, the following occurs:

-"SENSOR ERROR" displays

- The flag above the sensor detected as missing flashes on the display

- Alarm sounds and lights flash.

- Yellow Fault LED is on solid.

- If there is a sensor error at startup, the device shuts off in 60 seconds.

2.7 Sensor End of Life Warning

MSADescription

If a sensor is nearing its end of life, the device will warn the user following a sensor

calibration. The sensor is still fully functional at this point, but the warning gives the

user time to plan for a replacement sensor and minimise downtime. The ♥ symbol

will be continuously displayed. For more details see chapter 3.9.

2.8 Sensor End of Life Indicator

If the device cannot calibrate one or more sensors, the device will display

"SPAN ERR" followed by the Alarm symbol and ♥ symbol to indicate end of sensor

life. For more details see chapter 3.9.

2.9 Monitoring Toxic Gases

The device can monitor the concentration of the following toxic gases in ambient air:

- Carbon Monoxide [CO]

- Hydrogen Sulphide [H

The device displays the gas concentration in parts per million [PPM] or mg/m

the Measuring page until another page is selected or the device is turned off.

S]

2

3

on

20

ALTAIR 4X

GB

Page 21

DescriptionMSA

Attention!

If an alarm is triggered while using the device, leave the area

immediately.

Remaining on site under such circumstances can cause serious

personal injury or death.

GB

ALTAIR 4X

21

Page 22

The device has four gas alarms:

-HIGH Alarm

- LOW Alarm

- STEL Alarm

-TWA Alarm

If the gas concentration reaches or exceeds the alarm set point, the device:

- backlight turns on

- provides a vibrating alarm

- displays and flashes the Alarm symbol and either the Minimum icon

[LOW alarm] or the Maximum [PEAK] icon [HIGH alarm]

- enters an alarm state.

2.10 Monitoring the Oxygen Concentration

The device monitors the oxygen concentration in ambient air. The alarm set points

can be set to activate on two different conditions:

MSADescription

- Enriched - oxygen concentration > 20.8 % or

- Deficient - oxygen concentration < 19.5 %.

While the device can detect up to 30 % oxygen in ambient air, it is

approved for use only up to 21 % oxygen.

Attention!

If an alarm is triggered while using the device, leave the area

immediately.

Remaining on site under such circumstances can cause serious

personal injury or death.

When the alarm set point is reached for either of the above conditions:

- an alarm sounds

- alarm LEDs flash

- a vibrating alarm triggers

- device displays and flashes the Alarm icon and either the Minimum icon [Enriched alarm] or the Maximum icon [Deficient alarm] [→ chapter 2.3] along with

the corresponding oxygen concentration.

22

ALTAIR 4X

GB

Page 23

The LOW alarm [oxygen deficient] is latching and will not automatically

reset when the O

concentration rises above the LOW set point. To re-

2

set the alarm press the S button. If the alarm condition still exists, the

S button only silences the alarm for five seconds.

False oxygen alarms can occur due to changes in barometric pressure

[altitude] or extreme changes in ambient temperature.

It is recommended that an oxygen calibration be performed at the temperature and pressure of use. Be sure that the device is in known fresh

air before performing a calibration.

2.11 Monitoring Combustible Gases

The device can monitor these concentrations in ambient air:

- Methane

- Combustible gases

DescriptionMSA

The device displays the gas concentration in % LEL or % CH

on the

4

Measuring page until another page is selected or the device is turned off.

Attention!

If an alarm is triggered while using the device, leave the area

immediately.

Remaining on site under such circumstances can cause serious

personal injury or death.

The device has two alarm set points:

-HIGH Alarm

- LOW Alarm

If the gas concentration reaches or exceeds the alarm set point, the device:

- backlight turns on

- a vibrating alarm triggers

- displays and flashes the Alarm symbol and either the Minimum icon

[LOW alarm] or the Maximum [PEAK] icon [HIGH alarm]

- enters an alarm state.

GB

ALTAIR 4X

23

Page 24

When gas reading exceeds 100% LEL CH4, the device enters a

Lock Alarm state , the combustible sensor shuts down and displays

“xxx” in place of the actual reading. This state can only be reset by turning the device off and on in a fresh air environment.

Attention!

A combustible gas reading of "100” indicates the atmosphere is above

100% LEL CH

and an explosion hazard exists. Move away from con-

4

taminated area immediately.

In such cases, the device LockAlarm feature activates.

Check your national standard values for 100% LEL. Some countries use

5% vol and some use 4.4% vol as 100% LEL CH4.

MSAOperation

3 Operation

3.1 Environmental Factors

A number of environmental factors may affect the gas sensor readings, including

changes in pressure, humidity and temperature. Pressure and humidity changes affect the amount of oxygen actually present in the atmosphere.

Pressure Changes

If pressure changes rapidly [e.g., stepping through airlock], the oxygen sensor reading may temporarily shift and possibly cause the detector to alarm. While the percentage of oxygen may remain at or near 20.8 vol%, the total amount of oxygen

present in the atmosphere available for respiration may become a hazard if the

overall pressure is reduced by a significant degree.

Humidity Changes

If humidity changes by any significant degree [e.g., going from a dry, air conditioned

environment to outdoor, moisture laden air], oxygen readings can be reduced by up

to 0.5%, due to water vapour in the air displacing oxygen.

The oxygen sensor has a special filter to reduce the effects of humidity changes on

oxygen readings. This effect will not be noticed immediately, but slowly impacts

oxygen readings over several hours.

24

ALTAIR 4X

GB

Page 25

Temperature Changes

The sensors have built-in temperature compensation. However, if temperature

shifts dramatically, the sensor reading may shift. Zero the device at the work site

temperature for the least effect.

3.2 Turning on the Device

For more information, see the flow charts in [→ chapter 7].

Turn the device on with the ON/OFF button.

The device performs a self test and then goes to Fresh Air Setup:

- all display segments are activated

- audible alarm sounds

- alarm LEDs light

- vibrating alarm is activated.

During the self test, the device checks for missing sensors. In the case of a missing

sensor, the device displays the Sensor Missing screen and alarms until it is turned

off. Otherwise, the turn-on sequence continues.

OperationMSA

The device displays:

- Alarm & display self test

- Manufacturer name

- Device name

- Software version

- Sensor discovery

- Combustible gas type

- Toxic gas units

- Alarm set points [PEAK, MIN] [STEL, TWA]

- Calibration values

- Date and time display

- Last cal date [if activated]

- CAL due date [if activated]

- Fresh Air Setup option.

GB

ALTAIR 4X

25

Page 26

Screen Displays during Startup

During the startup sequence, all automatic page display timeouts are

preset to a range from two to four seconds.

Several sequences and screens occur during start up:

Device Self Test

The device performs a self test.

Device Name and Software version

Software version and device name display.

MSAOperation

Combustible Gas Type

Name of Combustible Gas Type displays, e.g. BUTANE.

NOTE: Combustible gas type can be changed manually through

the SENSOR SETUP menu or the MSA Link software.

26

ALTAIR 4X

COMB/EX

GB

Page 27

Toxic Gas Units

Name of Toxic Gas Units displays [ppm or mg/m3].

NOTE: Toxic units can only be modified through the MSA Link soft-

ware.

Alarm Set points

Alarm set points for all installed and activated sensors display.

LOW alarm set points display, followed by HIGH alarm set points.

NOTE: Alarm set points can be changed manually through the

Setup menu or the MSA Link software.

CO

OperationMSA

H2S

STEL and TWA Set points

The preset STEL and TWA values for installed and activated sensors display.

COMB/EX

CO

COMB/EX

CO

CO

O2

H2S

O2

H2S

GB

ALTAIR 4X

CO

H2S

27

Page 28

Calibration Values

MSAOperation

The preset STEL and TWA values for installed and activated sensors display.

Time and Date

The date displays in a month, day and year format.

NOTE: In the event that the battery is fully discharged, the time and

date reset. At startup, the user is prompted to enter the time and

date.

If the time and date information is missing, they are reset to

[Jan-01-2008] with time stamp [00:00].

Last CAL Date and CAL Due

NOTE: These display options can be set by MSA Link software. If

these options are not set, these screens are not displayed.

- By default Last Cal is activated.

COMB/EX

CO

O2

H2S

- By default Cal Due is deactivated.

Fresh Air Setup [FAS]

The FAS screen is prompted.

COMB/EX

CO

O2

H2S

28

ALTAIR 4X

GB

Page 29

OperationMSA

Fresh Air Setup [FAS]

The FAS is for automatic Zero calibration of the device.

The Fresh Air Setup has limits. The zero of any sensor that is outside of these limits

will not be adjusted by the FAS command.

Warning!

Do not activate the Fresh Air Setup unless you are certain you are in

fresh, uncontaminated air; otherwise, inaccurate readings can occur

which can falsely indicate that a hazardous atmosphere is safe. If you

have any doubts as to the quality of the surrounding air, do not use the

Fresh Air Setup feature. Do not use the Fresh Air Setup as a substitute

for daily calibration checks. The calibration check is required to verify

span accuracy. Failure to follow this warning can result in serious personal injury or death.

If a battery charging cycle is interrupted before it is completed [4 hours

for a fully discharged battery], allow the device’s internal temperature to

stabilize for 30 minutes before performing a Fresh Air Setup.

COMB/EX

CO

Fig. 3 Fresh Air Setup

O2

H2S

GB

ALTAIR 4X

29

Page 30

If this option is enabled, the device displays "FAS?", prompting the user to perform

a Fresh Air Setup.

(3) Press the S button to bypass the Fresh Air Setup.

Z The Fresh Air Setup is skipped and the device goes to the Measuring page

[Main page].

(4) Press the ON/OFF button within 10 seconds to perform the Fresh Air Setup.

Z The device starts the FAS.

Z The screen shows a No Gas Symbol, a blinking hourglass, and all enabled

gas sensor readings.

Z At the end of the FAS Calibration, the device displays "FAS OK" or

"FAS ERR". along with the flags of the sensors that were outside of the

FAS limits. All sensors that are within the FAS limits will be zeroed.

3.3 Measurement Mode [Normal Operation]

In Normal Operation mode, the user can check the Minimum and Peak readings prior to clearing the STEL and TWA values or performing a Span and Zero Calibration.

MSAOperation

The following options pages can be executed from the Normal Operation screen:

Bump Page

This page allows the user to perform a bump

COMB/EX

O2

check.

CO

Peak Page

This page shows the peak readings for all sen-

COMB/EX

O2

sors.

CO

H2S

Min Page

This page shows the minimum reading for the

O2

oxygen sensor.

30

ALTAIR 4X

GB

Page 31

STEL Page

This page shows the calculated STEL readings of

the device.

TWA Page

This page shows the calculated TWA readings of

the device.

OperationMSA

CO

CO

H2S

Time / Date Page

This page shows actual time and date settings of

the device.

Motion Alert [optional]

This page allows the Motion Alert Feature to be

activated or deactivated.

Using the three device buttons, the user can navigate through each sub-menu in a

top/down sequence.

Refer to chapter 2.5 and in the appendix for detailed instructions on navigating

through these screens.

GB

ALTAIR 4X

31

Page 32

3.4 Device Setup

The setup menus can be accessed only when the device is turned on while pressing

and holding the S button.

This mode can only be activated at device turn-on.

The operation is as follows:

(1) Press and hold the S button while turning the device on.

Use the S and T buttons to enter the setup password.

The default password is "672".

(2) Press ON/OFF button to enter the setup menus.

Incorrect password: device enters the Measure mode.

Correct password: device continues/beeps three times.

The password can be changed through the MSA Link software.

MSAOperation

In the Setup mode:

- Press the ON/OFF button to store chosen value or go to the next page.

- Press S button to increase values by one or toggle a selection on or off.

- Press and hold S button to increase values by 10.

- Press T button to decrease values by one or toggle a selection on or off.

- Press and hold T button to decrease values by 10.

The following options are available by pressing the T and S buttons:

- Sensor Setup [SENSOR SETUP]

- Calibration Setup [CAL SETUP]

- Alarm Setup [ALARM SETUP]

- Setup Time and Date [TIME SET]

- EXIT

32

ALTAIR 4X

GB

Page 33

Sensor Setup

Each sensor can be turned on or off.

For more information, see the flow charts in [→ chapter 2.3].

OperationMSA

COMB/EX

CO

Fig. 4 Sensor Setup

O2

H2S

(1) To bypass this setup, press the T or S button; otherwise, continue as follows.

(2) Press the ON/OFF button to enter the submenu.

(3) Use the T or S button to change the option and confirm with the

ON/OFF button.

(4) Repeat this procedure for all other sensors.

(5) After setting the last sensor, continue to Calibration Setup.

Calibration Setup

The user can change and set the calibration values for each sensor.

It is also possible to select whether the Cal Due screen is displayed and set the

number of days until the next calibration is due.

For more information, see the flow charts in [→ chapter 2.3].

COMB/EX

CO

Fig. 5 Calibration Setup

GB

O2

H2S

ALTAIR 4X

33

Page 34

MSAOperation

(1) To bypass this setup, press the T or S button; otherwise, continue as follows.

(2) Press the ON/OFF button to enter the submenu.

Z The calibration gas concentration of the first sensor is shown.

(3) Press theT or S button to change the value.

(4) Press the ON/OFF button to store the value.

Z Setup screen for the next sensor is displayed.

(5) Repeat the procedure for all other sensors.

Z After setting the last sensor, the user is prompted to set CALDUE.

(6) Press the T or S button to enable or disable CALDUE.

Press the ON/OFF button to confirm the selection.

(7) If CALDUE is set on, press the T or S button to select the number of days

(8) Confirm with the ON/OFF button.

(9) After confirmation, continue to Alarm setup.

Alarm Setup

The user can switch all alarms on or off and change the alarm set points for each

sensor.

For more information, see the flow charts in [→ chapter 2.3].

See chapter 2.3 for alarm adjustment limits. The value of the High Alarm can only

be set to a value that is higher than the Low Alarm set point.

COMB/EX

CO

Fig. 6 Alarm Setup

O2

H2S

(1) To bypass this setup, press the T or S button; otherwise, continue as follows.

(2) Press the ON/OFF button to enter the submenu.

Z The calibration gas concentration of the first sensor is shown.

(3) Set alarms on or off by pressing the T or S button.

(4) Press the T or S button to change the value.

34

ALTAIR 4X

GB

Page 35

OperationMSA

(5) Press the ON/OFF button to store the value.

Z HIGH ALARM settings for the first sensor display.

(6) Press the T or S button to change the value.

(7) Press the ON/OFF button to store the value.

Z STEL ALARM settings [for toxic sensors only] display.

(8) Press the T or S button to change the value.

(9) Press the ON/OFF button to store the value.

Z TWA ALARM settings [for toxic sensor only] for display.

(10) Press the T or S button to change the value.

(11) Press the ON/OFF button to store the value.

(12) Repeat the procedure for all other sensors.

(13) After setting the last sensor, continue to Time and Date setup.

60% L.E.L. or 3.0% volume of methane is the maximum High Alarm set point that

can be programmed.

The combustible alarm can be turned off in the device setup.

When the combustible alarm is turned off, this is only indicated during startup of the

device: a startup screen will indicate that the combustible alarm is turned off. When

turned on, the combustible high alarm is latching.

The combustible alarm can be silenced momentarily by pressing the S button.

However, if the gas concentration causing the alarm is still present, the device will

go back into alarm.

GB

ALTAIR 4X

35

Page 36

MSAOperation

Setup Time and Date

This submenu is for setting date and time.

For more information, see the flow charts in [→ chapter 2.3].

Fig. 7 Date and Time Setup

(1) To bypass this setup, press the T or S button; otherwise, continue as follows.

(2) Press the ON/OFF button to enter the submenu.

(3) Set month by pressing theT or S button.

(4) Press the ON/OFF button to confirm month.

(5) Repeat this procedure for day, year, hours and minutes.

Z By default, time is displayed in 12 hour format.

Z The EXIT screen will be displayed next.

(6) Confirming this screen with the ON/OFF button exits the device setup.

Z If the sensors have not warmed up yet, the countdown is displayed.

Z The device then goes to Measuring mode.

3.5 Data Logging

Connecting device to PC

(1) Switch on the device and align the Datalink Communication port on the device

to the IR interface of the PC.

(2) Use the MSA Link software to communicate with the device.

See MSA Link documentation for detailed instructions.

36

ALTAIR 4X

GB

Page 37

3.6 Function Tests

Alarm Test

Turn on the device. Verify that:

- all LCD segments are activated momentarily

- alarm LEDs flash

- horn sounds briefly

- vibrating alarm triggers briefly.

3.7 Safe LED

The device is equipped with a green Safe LED. This green Safe LED flashes every

15 seconds under the following conditions:

- the SAFE LED feature is enabled

- device is in Measurement Mode [Normal Operation]

OperationMSA

- combustible reading is 0% LEL or 0.00% CH

- Oxygen [O2] reading is 20.8%

- Carbon Monoxide [CO] reading is 0 ppm or mg/m

- Hydrogen Sulphide [H2S] reading is 0 ppm or 0 mg/m

- no gas alarms are present [low or high]

- device is not in Low Battery warning or alarm

- CO, H

S, STEL and TWA readings are 0 ppm or 0 mg/m³.

2

3.8 Bump Test

Attention!

Perform a Bump Test before each day’s use to verify proper device

operation. Failure to perform this test can result in serious personal injury or death.

This test quickly confirms that the gas sensors are functioning. Perform a full calibration periodically to ensure accuracy and immediately if the device fails the

Bump Test. The Bump Test can be performed using the procedure below or automatically using the GALAXY Test Stand.

4

3

3

It is required that the device's sensitivity be tested before each day's use on a

known concentration of methane equivalent to 25 - 50% of full scale concentration.

Accuracy must be within 0 to +20% of actual. Correct accuracy by performing the

calibration procedure within this manual.

GB

ALTAIR 4X

37

Page 38

Equipment

See accessory section for ordering information for these components.

- Calibration Check Gas Cylinder

- 0.25 liters/min. Flow Regulator

- 1/8” ID Superthane Ester Tubing

- Calibration Cap

Performing a Bump Test

(1) From the normal measure screen press the

T button to display “BUMP TEST?”.

(2) Verify the gas concentrations displayed match

the Calibration Check Gas Cylinder. If they do

not, adjust the values through the Calibration

Setup menu.

COMB/EX

CO

MSAOperation

O2

H2S

(3) Attach the calibration cap to the device.

Z Insert tab on calibration cap into slot on de-

vice.

Z Press calibration cap as shown until it seats

onto device.

Z Press both side tabs down onto device until

they snap in.

Z Ensure that the calibration cap is properly

seated.

Z Connect one end of the tubing to the calibra-

tion cap.

Z Connect other end of tubing to the cylinder

regulator [supplied in the calibration kit].

38

ALTAIR 4X

GB

Page 39

(4) Press the ON/OFF button to start the bump test

then open the valve on the regulator. The hourglass will flash and the sensors will respond to

the gas.

After the Bump Test completes, the device momentarily displays “BUMP PASS” or

“BUMP ERROR” along with the label of any sensor that failed before returning to Measure

mode. If the device fails the Bump Test, perform

a calibration as described in chapter 3.9.

The √ symbol will be displayed in the Measure mode for 24 hours after a successful

Bump Test.

3.9 Calibration

COMB/EX

OperationMSA

O2

The device can be calibrated either manually using this procedure or automatically

using the GALAXY Test Stand.

Calibration must be performed using a flow regulator with a flow rate set to

0.25 litres per minute.

If a battery charging cycle is interrupted before it is completed [4 hours for a fully

discharged battery], allow the device’s internal temperature to stabilise for

30 minutes before performing a Calibration.

Under normal circumstances MSA recommends calibration at least

every six months, however, many European countries have their own

guidelines. Please check your national legislation.

GB

ALTAIR 4X

39

Page 40

MSAOperation

Fresh Air Setup and Zero Calibration

To skip the Zero procedure and move directly to the Calibration Span

procedure, push the S button. If no button is pushed for 30 seconds,

the device prompts user to perform a Span calibration before returning

to the Normal Operation mode.

(1) Press and hold the S button in Normal Operation mode for three seconds.

(2) If calibration lockout option is selected, enter password.

Z ZERO screen is then displayed.

YES NO

Password

correct?

40

ALTAIR 4X

GB

Page 41

- If calibration lockout option is NOT selected:

Z ZERO screen displays.

COMB/EX

O2

COMB/EX

OperationMSA

O2

(3) With the device exposed to fresh air,

press the ON/OFF button to confirm

the ZERO screen. A sensor refresh and

Zero Calibration will occur.

Alternatively press the S button to execute a Fresh Air setup [FAS].

See chapter 3.2 for more details.

After Zero calibration completes, the device

momentarily displays “ZERO PASS” or

“ZERO ERR” along with the flag of any sensor that failed.

CO

H2S

CO

CO

H2S

GB

ALTAIR 4X

41

Page 42

Span Calibration

To skip the Span procedure, push the S button.

If no button is pushed for 30 seconds, the device returns to the Measuring mode.

(1) Once the Zero is set, the SPAN

screen displays.

(2) Connect the appropriate calibra-

tion gas to the device.

COMB/EX

O2

COMB/EX

MSAOperation

O2

(3) Attach the calibration cap to the

device.

Z Insert tab on calibration cap

into slot on device.

Z Press calibration cap as

shown until it seats onto device.

Z Press both side tabs down

onto device until they snap into.

Z Ensure that the calibration

cap is properly seated.

Z Connect one end of the tubing

to the calibration cap.

Z Connect other end of tubing to

the cylinder regulator [sup-

plied in the calibration kit].

(4) Open the valve on the regulator.

(5) Press the ON/OFF button to cali-

brate [span] the device.

Z LEDs flash

CO

COMB/EX

H2S

O2

Z SPAN calibration starts.

42

ALTAIR 4X

GB

Page 43

OperationMSA

- After the SPAN calibration completes, the device momentarily

displays “SPAN PASS” or

COMB/EX

O2

COMB/EX

O2

“SPAN ERR” along with the label of

any sensor that failed then returns

to the Measuring mode.

CO

H2S

CO

H2S

If a sensor is nearing its end of life, this "SPAN PASS" indication will be followed by

the end of sensor life warning [♥ symbol]. The ♥ symbol, along with the gas type of

the sensor nearing its end of life, will blink for 15 seconds when the device returns

to measure mode. When in measure mode, the ♥ symbol is continuously displayed.

Finishing Calibration

(1) Close the valve on the regulator.

(2) Remove the calibration cap.

The calibration procedure adjusts the span value for any sensor that passes the ca-

libration test; sensors that fail calibration are left unchanged. Since residual gas

may be present, the device may briefly go into an exposure alarm after the calibration sequence is completed.

Autocalibration Failure

If the span calibration is unsuccessful:

- A sensor life indicator is displayed [Alarm symbol and ♥ symbol] to show the

sensor has reached its end of life and should be replaced.

- The device will remain in alarm state until the S button is pressed.

- The Alarm symbol and ♥ symbol will remain on the display until a successful

calibration or sensor in question is replaced.

A span calibration can fail for many reasons besides sensor at the end

of his life. If a span calibration failure occurs, items such as remaining

gas in the calibration cylinder, gas expiration date, security of the calibration cap, etc. should be verified and calibration should be repeated

prior to replacing the sensor.

GB

ALTAIR 4X

43

Page 44

4 Maintenance

If an error occurs during operation, use the displayed error codes to determine appropriate next steps.

The MSA warranty for sensors, rechargeable batteries, housing and

electronics is only valid if the device is annually maintained by the

manufacturer or an authorized person in accordance with the operating

manual.

Refer to EN 50073 [Guide for the selection, installation, use and maintenance of apparatus for the detection and measurement of combustible gases or oxygen].

MSAMaintenance

44

ALTAIR 4X

GB

Page 45

4.1 Troubleshooting

Problem Description Reaction

MaintenanceMSA

ERROR TEMP Temperature is below

-40°C or above 75°C.

ERROR EE EEPROM Memory error Contact MSA

ERROR PRG Flash Memory error Contact MSA

ERROR RAM RAM Memory error Contact MSA

ERROR UNK Unknown error Contact MSA

LOW

BATT

BATT

ALARM

ERROR CHARGE Charge error Device must be between 10° C

SENSOR ERROR Missing Sensor Verify if sensor is properly

Battery warning repeats

every 15 seconds.

Battery is completely

discharged.

Return device to normal

temperature range and recalibrate.

Contact MSA

Remove from service as soon as

possible and recharge battery

Device is no longer sensing gas.

Remove from service and

recharge battery.

and 36° C to charge.

Contact MSA if problem persists

installed

Device does not

turn on

&

Low battery Charge device

Sensor warning Sensor is near the end of its life

Sensor alarm Sensor has reached the end of its

life and cannot be calibrated. Replace sensor and recalibrate.

GB

ALTAIR 4X

45

Page 46

4.2 Live Maintenance Procedure - Replacing and Adding a Sensor

Warning!

Remove and reinstall sensors carefully, ensuring that the components

are not damaged; otherwise device intrinsic safety may be adversely affected, wrong readings could occur, and persons relying on this product

for their safety could sustain serious personal injury or death.

Attention!

Before handling the PC board, ensure you are properly grounded; otherwise, static charges from your body could damage the electronics.

Such damage is not covered by the warranty. Grounding straps and kits

are available from electronics suppliers.

To add a sensor to an device that is not already equipped with a full array of sensors, remove the sensor plug from in front of the formerly unused sensor housing.

MSAMaintenance

While device case is open, do not touch any internal components with

metallic/conductive objects or tools.

Damage to the device can occur.

(1) Verify that the device is turned off.

(2) Remove the four case screws, and remove the case front while carefully not-

ing the orientation of the sensor gasket.

(3) Gently lift out and properly discard the sensor to be replaced.

Z Using fingers only, gently remove the toxic, combustible, or oxygen sensor

by gently rocking it while pulling it straight from its socket.

(4) Carefully align the new sensor contact pins with the sockets on the printed cir-

cuit board and pressing it firmly in place.

Z Insert the toxic sensor by placing it in the left-hand position of the sensor

holder.

Z Insert the O

sensor by placing it in the right-hand position of the sensor

2

holder.

Z Insert the combustible sensor by placing it in the middle position of the sen-

sor holder.

(5) Ensure groove in combustible sensor aligns with tab at top of holder.

Z If any sensor is not to be installed, ensure that a sensor plug is installed

properly in its place.

46

ALTAIR 4X

GB

Page 47

MaintenanceMSA

(6) If replacing sensor filters at this time:

Z Carefully peel off old filters taking care not to damage the inside of the case.

Z On new filters peel off backing exposing adhesive. Note proper orientation

of each filter and apply to inside of front case adhesive side against case.

Z Press filter into place taking care not to damage filter surface.

(7) Reinstall the sensor gasket in the case front.

(8) Ensure sensor gasket is properly installed.

(9) Re-install the screws.

(10) Turn on the device.

If the sensor replaced is the same as

the previous sensor:

If the sensor replaced is not the same

as the previous sensor or this sensor

channel was deactivated:

- The device starts up normally.

- The device automatically senses

that a new sensor is installed and

displays the "SENSOR DSCVRY"

- The device automatically senses

the difference and displays

"SENSOR CHANGE".

-"ACCEPT?" appears on the display.

screen.

Z Accept the change with

T button or reject with

S button.

Z Go into the sensor setup and

turn on the appropriate sensor

[→ chapter 3.4].

(11) Calibrate the device after the sensors have stabilised.

Danger!

Calibration is required after a sensor is installed; otherwise, the device

will not perform as expected and persons relying on this product for their

safety could sustain serious personal injury or death.

Allow sensors to stabilise at room temperature for at least 30 minutes

before calibration [→ chapter 3.9].

GB

ALTAIR 4X

47

Page 48

4.3 Cleaning

Clean the exterior of the device regularly using only a damp cloth. Do not use cleaning agents as many contain silicones which will damage the combustible sensor.

4.4 Storage

When not in use, store the device in a safe, dry place between 18 °C and 30 °C

[65 °F and 86 °F]. After storage, always recheck device calibration before use.

4.5 Scope of Delivery

Pack the device in its original shipping container with suitable padding. If the original container is unavailable, an equivalent container may be substituted.

MSAMaintenance

48

ALTAIR 4X

GB

Page 49

Technical Specifications/CertificationsMSA

5 Technical Specifications/Certifications

5.1 Technical Specifications

Weight 224 g [device with battery and clip]

Dimensions

112 x 76 x 33 mm – without fastening clip

[L x W x H]

Alarms Four gas alarm LEDs, a charge status LED, an audible alarm

and a vibrating alarm

Volume of

95 dBA at 30 cm typical

audible alarm

Display LCD display

Battery type Rechargeable Li polymer battery.

Li polymer battery must not be charged in Ex area.

Device run time 24 hours at 25 °C [77 °F]

Charging time ≥ 4 hours

The maximum safe area charging voltage U

= 6.7 VDC

m

Warm up time 2 min

Temperature

range

-10 °C to 50 °C [14 °F to 122 °F] Normal operating range

-20 °C to 50 °C [-4 °F to 122 °F] Extended operating range

10 °C to 35 °C [50 °F to 95 °F] while charging battery

Humidity range 15 % – 90 % relative humidity, non-condensing,

GB

Atmospheric

pressure range

Ingress

protection

Measuring

methods

5 % – 95 % RH intermittent

800 to 1200 mbar

IP 67

Combustible gases: Catalytic sensor

Oxygen: Electrochemical sensor

Toxic gases: Electrochemical sensor

ALTAIR 4X

49

Page 50

MSATechnical Specifications/Certifications

Combustible O

Measuring

range

0-100% LEL

0-5.00% CH

O2 0-30% Vol.

CO 0-1999% Vol.

4

The ppm to mg/m³ conversion is calculated at 20° C and at atmospheric

pressure.

5.2 Factory-set Alarm thresholds

Sensor LOW alarm HIGH alarm STEL TWA

LEL 10 % LEL 20 % LEL -- --

O

2

CO 25 ppm

H

S10 ppm

2

19.5 % 23.0 % -- --

[29 mg/m³]

[14.2 mg/m³]

[116 mg/m³]

[21.3 mg/m³]

100 ppm

15 ppm

2

CO H2S

0-999 mg/m³ 0-200 ppm

[0-284 mg/m³]

100 ppm

[116 mg/m³]

15 ppm

[21.3 mg/m³]

25 ppm

[29 mg/m³]

10 ppm

[14.2 mg/m³]

Sensor Min. alarm set point Max. alarm set po Auto-cal values

LEL 5 60 58%

O

2

CO 15 ppm

H

S5 ppm

2

5.0 29 15.0%

1700 ppm

[23.2 mg/m³]

[999mg/m³]

175 ppm

[7.1 mg/m³]

[205.9 mg/m³]

60 ppm

[69.9 mg/m³]

20 ppm

[28.4mg/m³]

While the device can detect up to 25 % oxygen in ambient air, it is approved for use only up to 21 % oxygen.

50

ALTAIR 4X

GB

Page 51

5.3 Certification

See device label for the approvals that apply to your specific device.

USA and Canada

USA See device label for the approvals that apply to

Canada See device label for the approvals that apply to

Europe Union

The product ALTAIR 4X complies with the following directives, standards or standardized documents:

Technical Specifications/CertificationsMSA

your specific device.

your specific device.

Directive 94/9/EC [ATEX]: II 1G Ex ia IIC T4, -40°C to +60°C, IP67

[Zone 0 with no combustible sensor installed]

II 2G Ex ia d IIC T4, -40°C to +60°C, IP67

[Zone 1 with combustible sensor installed]

CE 0080

Directive 2004/108/EEC [EMC]: EN50270 Type 2, EN61000-6-3

GB

ALTAIR 4X

51

Page 52

MSATechnical Specifications/Certifications

Other Countries

Australia/New Zealand TestSafe Australia

Ex ia s IIC T4, -40°C to +60°C, IP67 [Zone 0]

IECEx TestSafe Australia

Ex ia IIC T4, -40°C to +60°C,

[Zone 0 with no combustible sensor installed]

Ex ia d IIC T4, -40°C to +60°C,

[Zone 1 with combustible sensor installed]

European Community

The product ALTAIR 4 complies with the following directives, standards or standardised documents:

Manufacturer: Mine Safety Appliances Company

1000 Cranberry Woods Drive

Cranberry Township, PA 16066 USA

Product: ALTAIR 4X

Type of protection: EN 60079-0: 2006, EN 60079-1: 2004, EN 60079-11: 2007

Marking: III 2G Ex ia d IIC T4

-20 °C ≤ Ta ≤ +50 °C

Um 6,7 V

EC-Type Examination Certificate: FTZU 07 ATEX 0169 X

Quality Assurance Notification: 0080

Year of Manufacture: see Label

Serial Nr.: see Label

EMC Conformance according to the Directive 89/336/EC

EN 50270: 2006 Type 2, EN 61000-6-3: 2007

52

ALTAIR 4X

GB

Page 53

5.4 Performance Specification

Combustible Gas

Technical Specifications/CertificationsMSA

Range 0 to 100 % LEL or 0 to 5 % CH

Resolution 1 % LEL or 0.05 % vol CH

4

4

Reproducibility 3 % LEL, 0 % to 50 % LEL reading

or 0.15 % CH

, 0.00 % to 2.50 % CH

4

4

[normal temperature range]

5 % LEL, 50 % to 100 % LEL reading

or 0.25 % CH

, 2.50 % to 5.00 % CH

4

4

[normal temperature range]

5 % LEL, 0 % to 50 % LEL reading

or 0.25 % CH4, 0.00 % to 2.50 % CH

4

[normal temperature range]

8 % LEL, 50 % to 100 % LEL reading

or 0.4 % CH4, 2.50 % to 5.00 % CH

4

[normal temperature range]

Response time 90 % of final reading in less than or equal to 25 sec [pentane]

and 10 sec [methane] [normal temperature range]

Oxygen

The oxygen sensor has built-in temperature compensation. However, if temperature shifts dramatically, the oxygen sensor reading may shift. Zero the device at a

temperature within 30 °C [86 °F] of the work place temperature for the least effect.

Range 0 to 30 vol.% O

Resolution 0.1 vol.% O

Reproducibility 0.7 vol.% O2 for 0 to 30 vol.% O

Response time

<10 second [normal temperature range]

2

2

2

[90% of final reading]

GB

ALTAIR 4X

53

Page 54

Carbon Monoxide

Data is presented as the indicated output in PPM which will result from

the application of the test gas.

Range 0 - 999 ppm [0-999 mg/m3] CO

Resolution 1 ppm [1.2 mg/m3] CO,

Reproducibility ±5 ppm [5.8 mg/m

3

] CO or 10 % of reading,

whichever is greater [normal temperature

range]

±10 ppm [11.6 mg/m3] CO or 20 % of reading,

whichever is greater

[extended temperature range]

Response time 90% of final reading in less than or equal to

15 seconds [normal temperature range]

MSATechnical Specifications/Certifications

Hydrogen Sulphide

Range 0 - 200 ppm [0 to 284 mg/m3] H2S

Resolution 1 ppm [1.4 mg/m3] H2S,

Reproducibility ±2 ppm [2.8 mg/m3] H2S or 10 % of reading,

Response time 90% of final reading in less than or equal to

5.5 XCell Sensor Patents

Combustible sensor Part No.10106722 Patent Pending

for 3 to 200 ppm [4,3 to 284 mg/m3] H2S

whichever is greater [normal temperature

range]

3

0 to 100 ppm [0 to 142 mg/m

±5 ppm [7,1 mg/m

3

] H2S or 10 % of reading,

] H2S,

whichever is greater

[extended temperature range]

15 seconds [normal temperature range]

O

sensor Part No.10106729 Patent Pending

2

54

ALTAIR 4X

GB

Page 55

6 Ordering Information

Description Part No.

SS Suspender Clip 10069894

Ordering InformationMSA

58L quad gas mix [1.45% CH

, 15% O2, 60 ppm CO, 20 ppm H2S] 10053022

4

Universal pump probe [UL] 10046528

Universal pump probe [CSA] 10055576

Universal pump probe [AUS] 10047594

Universal pump probe [ATEX] 10047596

Calibration assembly [cap, tube, connector] 10089321

Charging cradle assembly 10086638

North American Power Supply with Charge Connector 10092233

Global Power Supply with Charge Connector 10092938

Charging cradle assembly with Power supply [[North America] 10087368

Charging cradle assembly with Power supply [Australia] 10089487

Charging cradle assembly with Power supply [Europe] 10086638

Vehicle Charging cradle assembly 10095774

MSA Link Software CD-Rom 10088099

JetEye IR adapter with USB connector 10082834

Combustible sensor replacement kit 10106722

O

sensor replacement kit 10106729

2

CO/H

S Two Toxic sensor replacement kit 10106725

2

Single CO sensor replacement kit 10106724

Single H

S sensor replacement kit 10106723

2

Front Housing with integrated dust filters [charcoal] 10110030

Front Housing with integrated dust filters [fluorescent] 10110029

Main board w/ battery pack 10089161

LCD Frame assembly [frame LCD, zebra strips, screws] 10110061

Sensors gasket, socket head cap screws [4x], self tapping [2x] 10110062

[2x] CD Manual ALTAIR 4 x 10106623

GALAXY, QuickCheck and additional accessories are available on request.

GB

ALTAIR 4X

55

Page 56

7 Appendix

7.1 Start Up Sequence [Power on]

From Power on

(Press

)

MSAAppendix

CO

H2S

CO

H2S

COMB/EX

O2

CO

H2S

COMB/EX

CO

COMB/EX

COMB/EX

CO

CO

O2

H2S

H2S

COMB/EX

COMB/EX

O2

CO

H2S

COMB/EX

56

O2

CO

H2S

Begin Normal

Operation

ALTAIR 4X

GB

Page 57

7.2 Fresh Air Setup [FAS]

AppendixMSA

From Start Up Sequence

Press

Press key

YES

Press

or wait 10 seconds

NO

FAS OK?

GB

ALTAIR 4X

57

Page 58

7.3 Reset Screen Controls

MSAAppendix

From Normal Operations

(Main Page)

CAL Mode

To Calibration

Press

Hold

for 3 seconds

Button?

Press

BUMP Page

Button ?

Press

Perform BUMPMeasure

Hold

for 5 seconds

Press

Instrument off

58

To Bump

ALTAIR 4X

To Next

Page

GB

Page 59

From previous

page

AppendixMSA

Press

Press

COMB/EX

CO

Button ?

Button ?

CO

O2

H2S

Press

O2

Press

H2S

Press

Press

COMB/EX

CO

O2

H2S

O2

Press

Press

Main Page

Press

Button ?

Press

CO

H2S

Button ?

Press

Press

CO

H2S

CO

H2S

To Time

and Date

GB

ALTAIR 4X

59

Page 60

7.4 Bump Test

MSAAppendix

From Normal Operations

(Main Page)

Press

Button ?

COMB/EX

CO

O2

H2S

No Button

PASS?

COMB/EX

H2S

60

ALTAIR 4X

GB

Page 61

7.5 Options Setup

AppendixMSA

From

Date/Time

Setup

COMB/EX

CO

O2

H2S

To Sensor

Setup

Password

Correct?

From

Alarm

Setup

COMB/EX

CO

To CAL

Setup

NOYES

Button?

or

Setup

O2

H2S

From

CAL

Setup

To Main

Page

GB

To Time/

Date Setup

ALTAIR 4X

COMB/EX

CO

To Alarm

Setup

O2

H2S

61

Page 62

7.6 Sensor Setup

MSAAppendix

Combustible

O

2

From

Setup Options

Set Sensor with

Confirm Sensor with

COMB/EX

O2

COMB/EX

or

O2

CO

H2S

CO

H2S

To Options

Menu

CO

H2S

62

ALTAIR 4X

GB

Page 63

7.7 Calibrations

AppendixMSA

From Measure Page when

is held for 3 seconds

ZERO CAL

Press

Press

Perform

ZERO CAL?

SPAN CAL

Perform

ZERO CAL?

Press

Press

Press

CO

GB

CAL COMPLETE

COMB/EX

O2

CO

H2S

ALTAIR 4X

Return to

Normal Operation

63

Page 64

Alarm Setup

MSAAppendix

From Setup Options

Set Alarms

on or off

Combustible

O

2

COMB/EX

Set Alarms with

Confirm Alarms with

COMB/EX

O2O2

or

CO

H2S

64

COCO COCO

H2SH2S H2S

ALTAIR 4X

H2S

To

Time/Date

Setup

GB

Page 65

Time and Date Setup

AppendixMSA

From Options Setup

To Exit Setup

GB

ALTAIR 4X

65

Page 66

Thank you for reading this data sheet.

For pricing or for further information, please contact us at our UK Office, using the details

below.

UK Office

Keison Products,

P.O. Box 2124, Chelmsford, Essex, CM1 3UP, England.

Tel: +44 (0)330 088 0560

Fax: +44 (0)1245 808399

Email: sales@keison.co.uk

Please note - Product designs and specifications are subject to change without notice. The user is responsible for determining the

suitability of this product.

Loading...

Loading...