Page 1

Page 2

●

small power plants, small gas turbines

●

food industry steam boilers

●

cogeneration heat and power engines (CHP)

●

bio methane and methane boilers

●

waste incinerators, ovens and kilns

●

ethanol and palm oil plants and more

●

industrial heaters and dryers

SWG 100 - CEM - Instrument main features are:

˃˃

field replaceable, plug & play pre-calibrated sensors

˃˃

very compact industrial design, for up to 6 gas simultaneous measurement

˃˃

use low cost but reliable electrochemical cells for O2, CO, NO, NO2, SO2

and infrared module (NDIR) for CO2 measurement

˃˃

advanced sample gas preparation for fast and reliable measurements

˃˃

flexible platform can be used for various combustion applications

˃˃

direct and continuous/discontinuous measurement, with pressure and temperature

compensation of all main flue gas parameters

˃˃

external measurements (temperature, pressure, etc.) by reading of ext. standard signal

˃˃

simple installation, ready to run delivery and easy to maintain

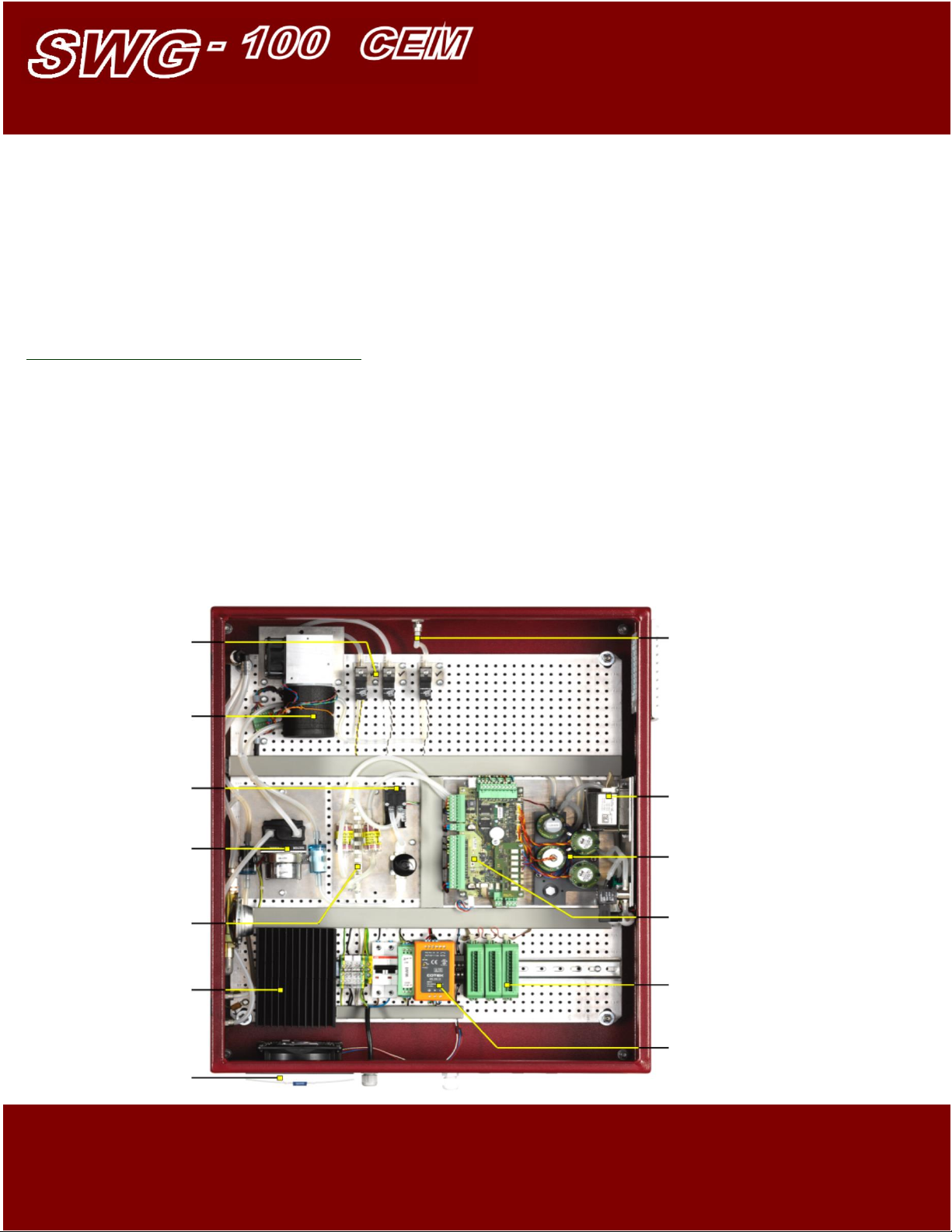

Auto-Zero and

Sample gas inlet with heated or

Auto-Cal solenoid valves

unheated gas sampling line

Gas cooler Peltier type

Gas sampling pump

NDIR bench for CO2

measurement

Condensate draining

EC cells for O2/CO /NO/NO2/SO2

with cut-off and purge for CO cell

Internal sample

flow monitoring

Main pcb

Modules with analog

Cabinet heater 200W

outputs 4 channel 4-20 mA,

freeze protection

RS485 and 2x alarm relays

Universal power supply

Continuous monitored

90-240 Vac 47-63 Hz / 90 W

ventilation fan with alarm

The complete, ready to use emissions analyzer SWG 100 CEM is the low cost solution

to be used with a wide variety of industrial emissions monitoring applications:

Page 3

The MRU continuous emission monitoring analyzer SWG 100 CEM, is designed for use in the harsh industrial

environment of different combustion sites, where flue gas emissions must be continuously monitored.

The analyzer can be installed in outdoor or indoor locations, can sample dry or wet flue gas, pressurized or

low pressure flue gas, even from a long distance sampling point.

The analyzer system can be configured with different gas sampling probes and sampling lines to optimize the

sample gas preparation.

SWG 100 - CEM

standard

option

Basic analyzer for wall or rack mounting, IP54 protection, aluminum

cabinet with anti-corrosive red structural lacquer and fan ventilation

Condensate separator and automatic condensate draining pump

Gas sampling probe

Monitored ambient air ventilation, with alarm display for fan rotation failure

HD-GW heated, with

Sample gas pump and internal sample flow

borosilicate quartz

monitoring with alarm in case of filter clogging

filter element

Solenoid valve for auto-zero with ambient air and

for auto-calibration with span gas

1/8” threads for all sample gas, zero gas and

calibration gas inlets, fittings for DN6/4mm tube

3.5” TFT color, backlit display and keyboard,

password protected operation

RS485 digital data transfer (Modbus RTU)

Universal power supply 90 - 240 Vac /47-63 Hz / 90 W

Gas sampling probe LD

O2 measurement with long-life EC cell

unheated, with

CO measurement with protected EC cell using

in-situ sintered

cut-off solenoid valve and air purging pump

metal filter

NO measurement with EC cell

NO2 measurement with EC cell

SO2 measurement with EC cell

CO2 measurement using infrared (NDIR) module

Thermoelectric gas cooler (Peltier) with constant dew point

and automatic condensate draining pump

Heated gas sampling probe model HD, with ceramic filter

and back-purge, for flying ash type flue gases

Gas sampling line

Heated gas sampling probe model HD-GW, with

Teflon, heated with

quartz glass wool filter for acid mist flue gases

temperature regulation

Unheated gas sampling probe model LD, for clean

combustions, using in-situ sintered metal filter

Heated gas sampling lines, from 5 to 75 m length, with temperature

regulation by analyzer or by internal thermostat, with single or

dual PTFE 4/6 mm tube

Module with 4 channel analog outputs/inputs 4-20 mA,

with 2x “fail safe” alarm relays

Converter module of RS485 into Profibus

Thermoelectric

Cabinet heater for freeze protection

gas cooler

Peltier type

•••••••••••

•

Page 4

TECHNICAL SPECIFICATIONS

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Measurement components

Measuring range

Accuracy

Measuring method

O2

Oxygen

0 ... 25 %

0,2 % abs.

electrochemical

CO

Carbon monoxide

0 ... 10,000 ppm

±10 ppm or 3 % reading

electrochemical

NO

Nitric oxide

0 ... 4,000 ppm

± 5 ppm or 3 % reading

electrochemical

NO2

Nitrogen dioxide

0 ... 1,000ppm

± 5 ppm or 3 % reading

electrochemical

SO2

Sulfur dioxide

0 ... 4,000ppm

±10 ppm or 3 % reading

electrochemical

CO2

Carbon dioxide

0 ... 40 %

±0,3 % or 3 % reading

NDIR

Zero drift

Negligible with automatic zeroing

Drift

Less 0.2 % of range per month

Calculated component

True NOx : NO + NO2

Calc. NOx = 1.05*NO (if NO2 is not measured)

All emissions relevant mg/Nm3; user selectable O2 referencing

Combustion efficiency (fuel type depending), heat loss, dewpoint

HMI human machine interface

3.5” TFT color and backlit display

Keyboard and password protected operation

I/O module with 4channel, analog out 4-20 mA, floating, max. load 500 R

and 2 alarm relays, potential free contacts 24 Vdc/5 A

SD-card for data and event logging

RS485 digital interface (Modbus RTU)

DIN-rail RS485 / ProfiBus converter

Sample preparation

Gas sampling probe HD, heated ceramic filter with back-purge, or gas sampling probe HD-GW,

heated quartz wool filter, or gas sampling probe LD, non-heated with in-situ sintered filter

Heated or non-heated DN4/6 mm PTFE sampling line

Thermoelectric gas cooler (Peltier type) with const.+5 °C dewpoint

Teflon particulate filter, internal Viton hosing

Controlled and regulated gas sampling pump

Constant gas sample flow of 50 l/h

Sample inlet pressure: -200 mbar to + 200 mbar

Sample venting: atmospheric pressure

Cabinet dimensions

Aluminum with anti-corrosive structural painting

27.55" x 23.61" x 8.26" (700 x 600 x 210 mm) ( H x W x D ) for wall or rack mounting

Weight / Protection

55lbs (25kg) / IP54

Ambient temperature

+5°C…+45°C standard, +5°C…+55°C with Vortec cooler, -10°C…+45°C with cabinet heater

Installation site

Indoor or outdoor (rain and sun shade is mandatory user scope of supply)

Cabinet conditioning

Continuous, monitored fan ventilation

Cabinet heater 200 W

Cabinet Vortec cooler (requires 0,5m3/min clean and dry compressed air)

Power supply

Universal 90 - 240 Vac / 47 - 63 Hz / 90 W (300 W with cabinet heater)

MRU Instruments, Inc.

Houston, Texas 77044

Tel.: (832) 230 - 0155

Fax: (832) 230 - 1553

info@mru-instruments.com

www.mru-instruments.com

Loading...

Loading...