Page 1

Page 2

Measurement principle

Oxygen (O2) = ZrO2 zirconium dioxide

COe (combustibles) = heated solid electrolyte

* total of flue gas combustibles

(CO + H2 + CxHy)

displayed as equivalent CO

STANDARD FEATURES

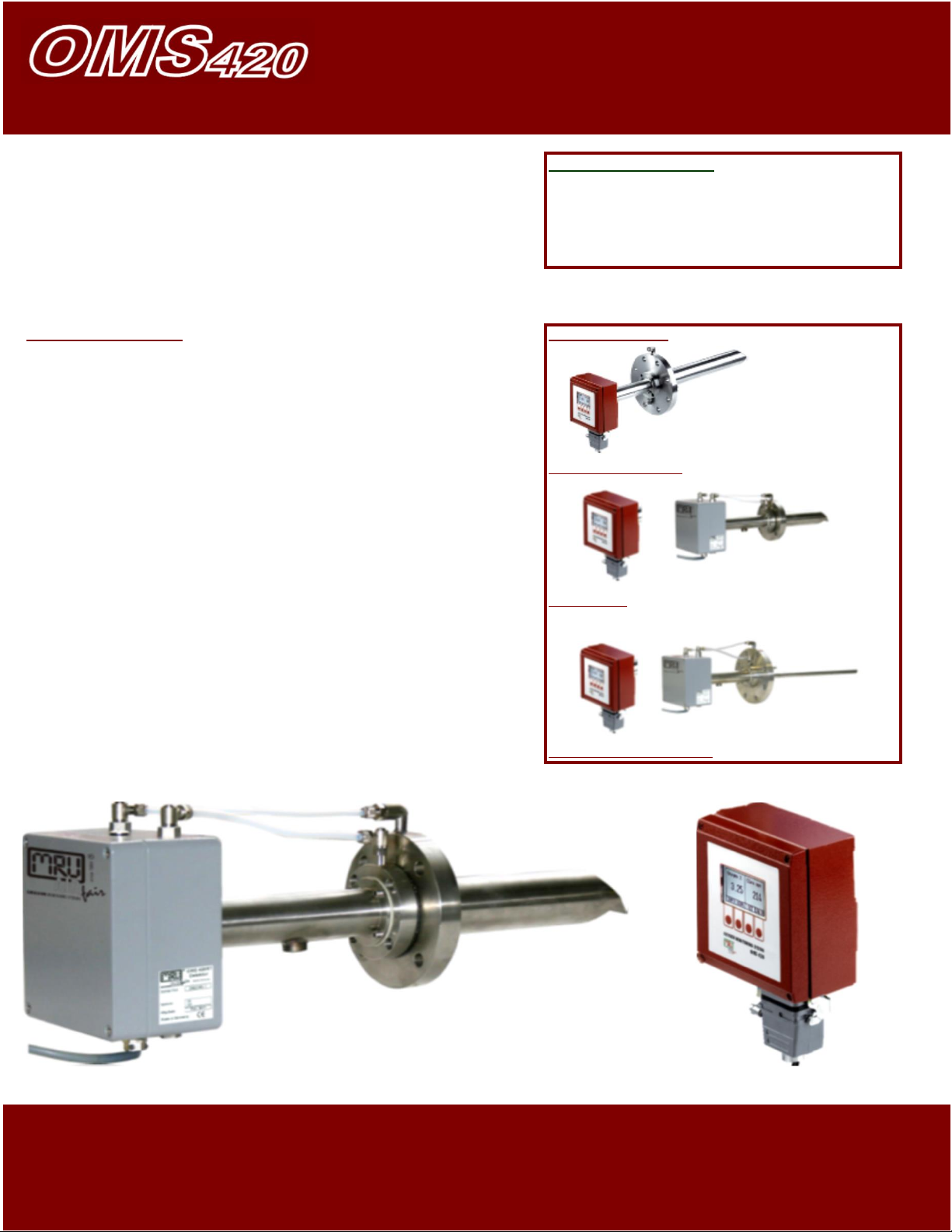

OMS 420 models

˃˃

Clean combustion (low dust)

with combustion temperatures up

to max. 1,800 °F

˃˃

Die cast aluminum enclosure with

electronics, keyboard, up-front display

OMS420 - compact

of O2 and COe

˃˃

Standard ANSI flange

(other flanges e.g. DIN on request)

Probe tube with Ø 2.4” and various

lengths.

OMS420RT

˃˃

Connector for back purge

compressed air.

˃˃

Connecting tube with reference

air inlet with small flange, Ø 3.9"

˃˃

Rugged industrial plug for power supply

and data transfer

OMS420HT High Temp.

(analog 4 … 20 mA, digital RS 485)

OMS 420-RT (remote display and control unit)

Display and control unit

IN - SITU O2 MONITOR

IN-SITU real time analysis

Oxygen (O2) and combustibles (COe)*

Page 3

Combustion-optimization diagram:

Save millions $ a year (in large power plants)

Save energy and fuel consumption

Connecting

tube

OMS control

unit and

Power supply and data

Fitting for back-purge

Probe tube

ANSI flange

Test gas inlet

The essential advantage

of the OMS 420 system

easy servicing, inspecting or

repairing the unit:

The OMS 420 transmitter

contains the electronics, display

and keyboard, the connection

tube and the small flange (Ø

3.9") are mounted on the ANSI

flange using just 4 screws.

Simply loosen the 4 screws and

change the transmitter in

minutes…

… simple and economical

replacement!

Page 4

TECHNICAL SPECIFICATIONS

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Warm up time

min. 30 minutes

Measuring range

0.1 ... 25.0 % Vol.-% O2

0 ... 1,000 ppm COe (option combustibles measurement)

Accuracy

O2: ±0.2 % or ± 5 % of reading, whichever is larger

COe: ±50 ppm or ±10 % of reading, whichever is larger

Flange

ANSI flange: Ø 230mm / probe tube: Ø 60mm,

up to max. 13' (4.0 m) length or flange DN80 PN16

Flange

DN65 PN6 flange: Ø 216 mm / probe tube: Ø 60 mm

up to max. 13' (4.0 m) length or flange DN80 PN16

Flange temperature

min. +160 °F ... max. +300 °F

(condensation at the flange must be avoided)

Response time T90

<10 seconds

Analog outputs

2 x current loop 4 … 20 mA, with galvanic isolation

linearized for both 0 … 25 % O2 and 0 ... 1,000 ppm COe

(user definable settings in 0.5% steps are possible)

Digital output

galvanic isolated RS 485 ( with Modbus protocol)

Power supply

18 ... 24 Vdc (for model OMS 420), 90 ... 100 W

100 ... 240 Vac (for model OMS 420 RT and HT) max. 100 W

Power supply

18 ... 24 Vdc, 90 ... 100 W

Electronic of transmitter

with local microprocessor, display and 4 push-buttons

Calibration inlet

with test gas fitting for 6/4 mm tube cal. gas supplied manually

or automatically by pneumatic unit PU 420

Back purge inlet

min. 87 PSI … 116 PSI (6 … 8 bar) compressed air with quick connector for 8 mm tube

Ambient temperature

-70 °F ... +130 °F

of electronics

Enclosure

Die cast aluminum, 6.3" x 6.3" x 2.4" and probe tube, Ø 2"

Protection class

IP 65

Weight

7.7 lbs. (without probe and flange)

OPTIONS

COe measurement

PROBE TUBE AND SENSOR CHAMBER BLOW BACK SYSTEM. Compressed air is required!!

Blow back timing and duration are user definable. Recommended for

applications with high particulates, such as coal-fired power plants.

Automatic calibration for span and offset, using pneumatic unit PU 420

Application with high temperatures up to approx. 3,100 °F with ceramic tube and ejector (model HT)

Remote control and display unit

(max. cable length = approx. 33’ - model RT) for applications with ambient temperature >120 °F

MRU Instruments, Inc.

Houston, Texas 77044

Tel.: (832) 230 - 0155

Fax: (832) 230 - 1553

info@mru-instruments.com

www.mru-instruments.com

Loading...

Loading...