SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

1 / 108

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

2 / 108

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

3 / 108

Content

1. General Information .......................................................................................................... 6

1.1. Weather and environmental conditions ...................................................................... 6

1.2. Installation instructions ............................................................................................... 6

1.3. General important instructions for the plant operator ................................................. 6

2.1. Important information about the user’s operation manual .......................................... 7

11.1. General warning ......................................................................................................... 7

11.2. Safety Information ...................................................................................................... 7

11.3. Packing ...................................................................................................................... 9

11.4. Return of hazardous waste ........................................................................................ 9

11.5. Return of analyzer ...................................................................................................... 9

11.6. MRU guarantee conditions....................................................................................... 10

12. Analyzer Description ...................................................................................................... 11

12.1. Intended use ............................................................................................................ 11

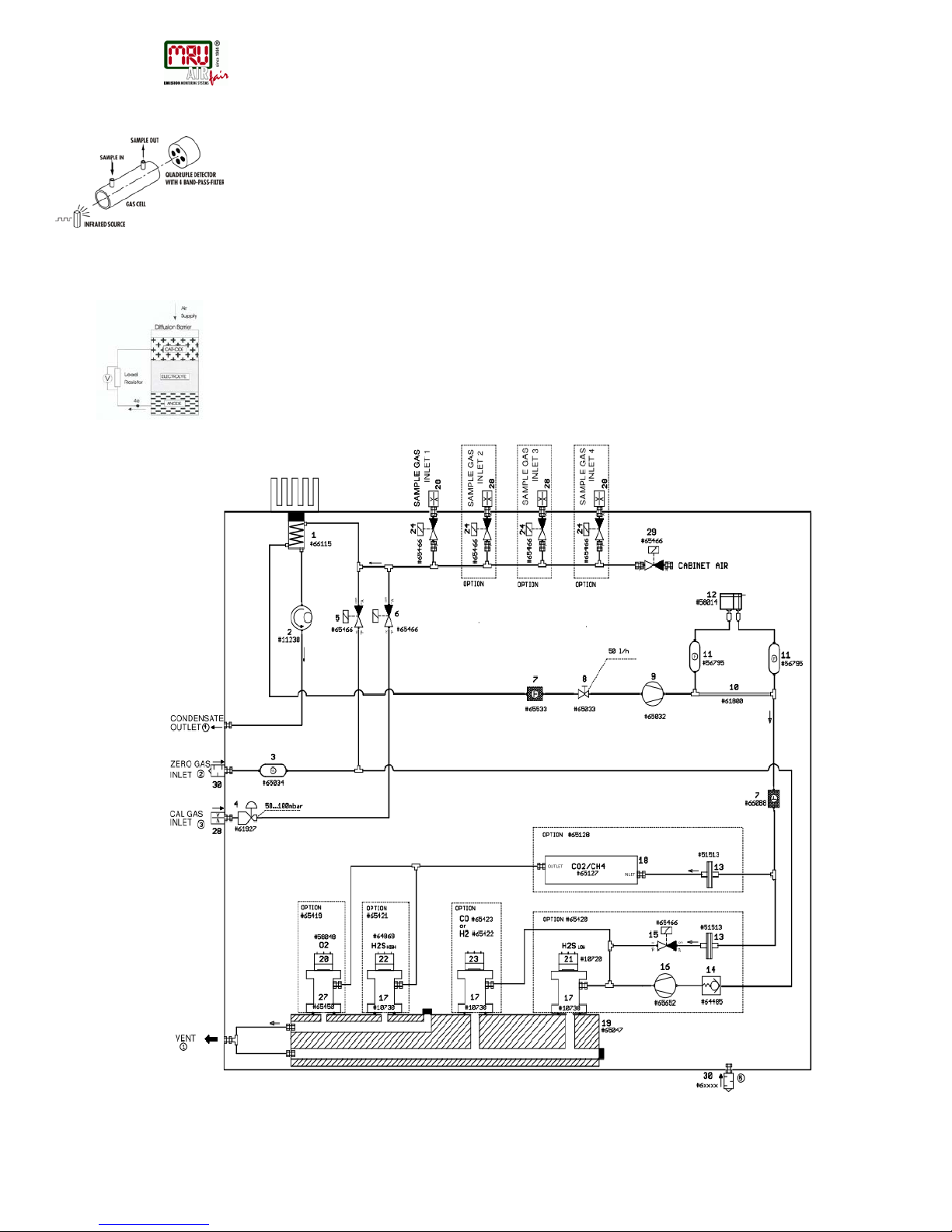

12.2. Principle of operation ............................................................................................... 12

12.3. Marking and range of application ............................................................................. 13

12.4. Possible applications and analyzer options ............................................................. 13

12.5. Features ................................................................................................................... 13

13. Overview of the SWG-100BIO Ex ................................................................................... 14

13.1. Scope of supply and delivery ................................................................................... 14

13.2. Material required for the installation (not scope of supply) ....................................... 14

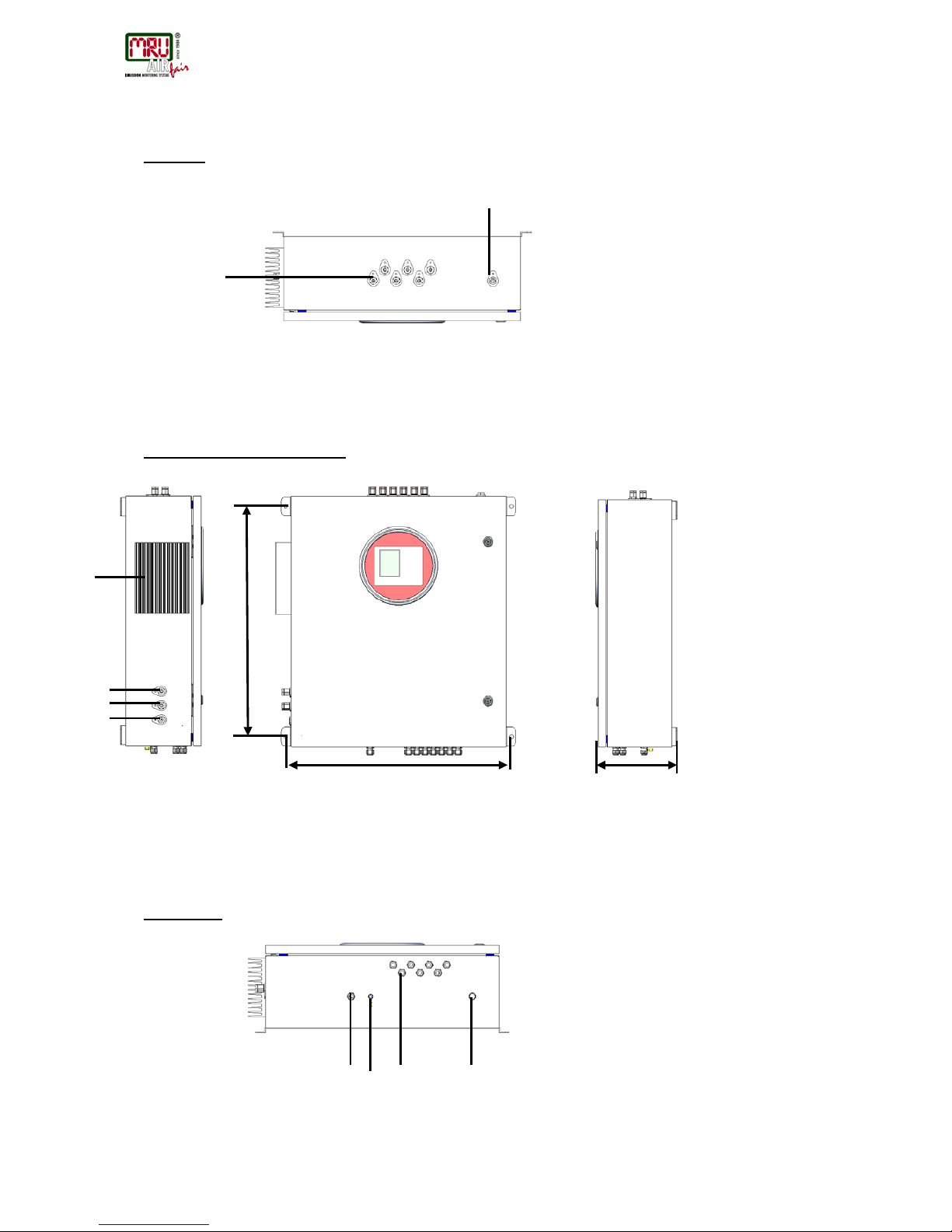

13.3. Dimensions and views of the analyser ..................................................................... 15

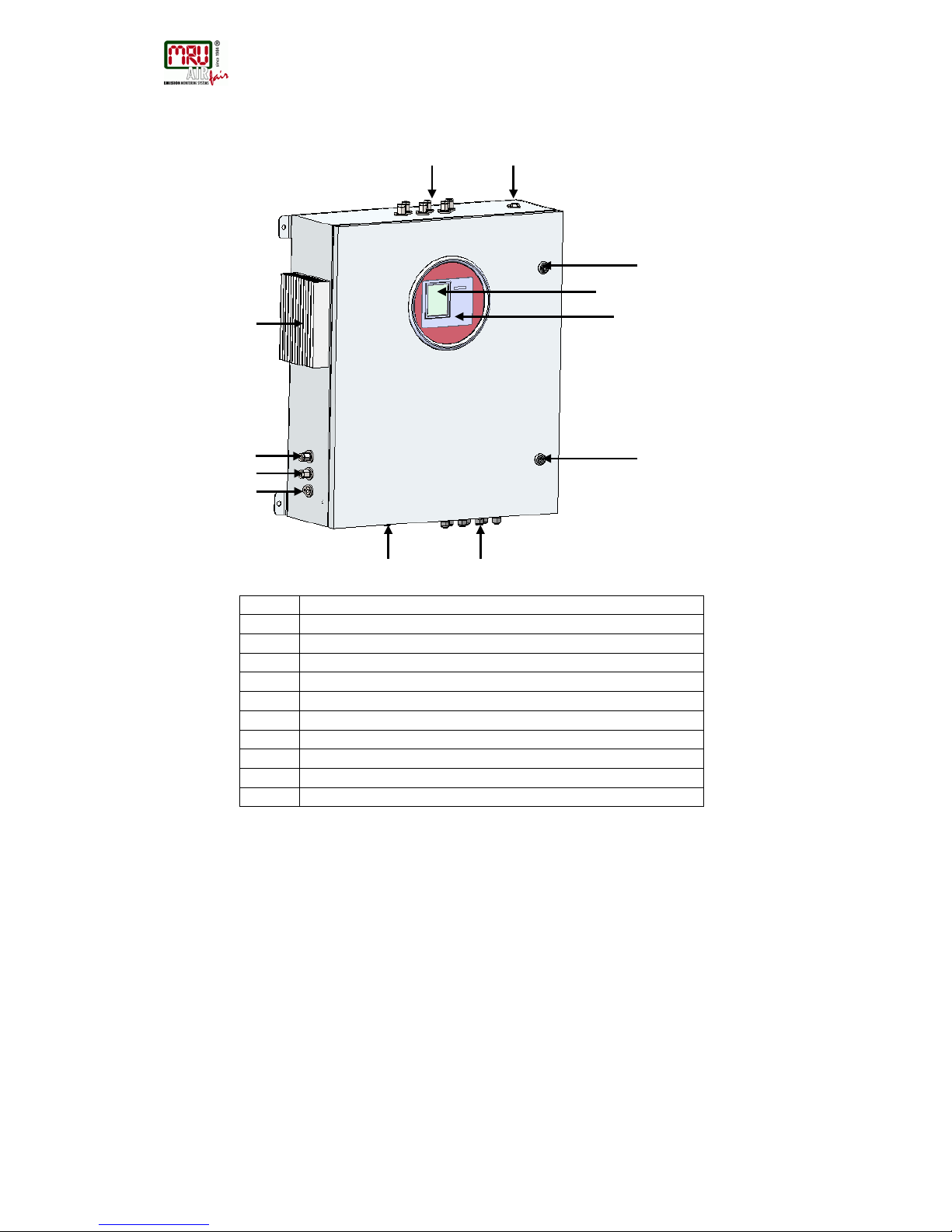

13.4. Position of the gas in and outlets ............................................................................. 16

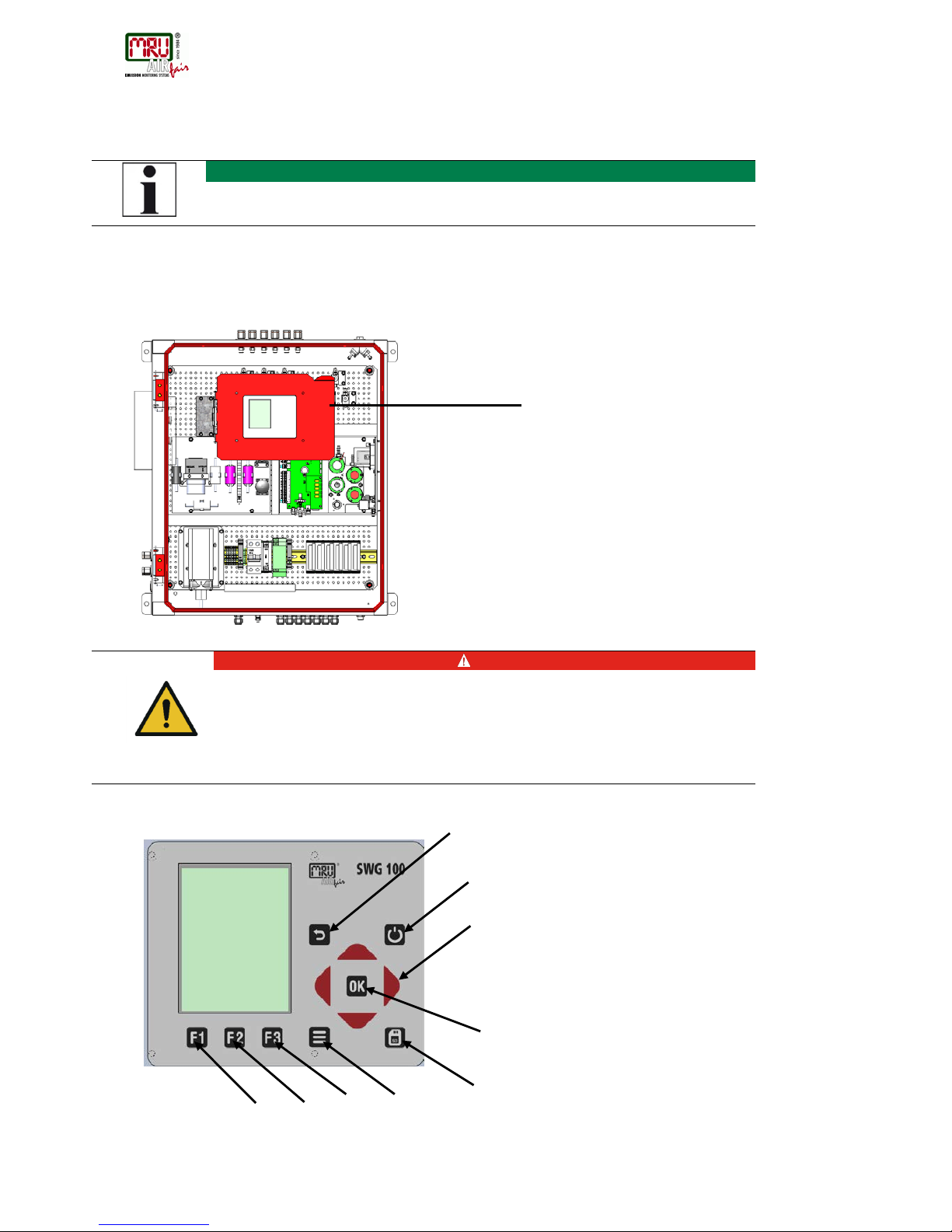

13.5. Operating unit: Display and keypad ......................................................................... 17

14.1. Measurement menu ................................................................................................. 19

15. Explosion protection systems of SWG100BIO-EX....................................................... 20

15.1. Electrical components .............................................................................................. 20

15.2. IP 65 cabinet ............................................................................................................ 20

15.3. CH

4

measurement of inside cabinet ......................................................................... 21

15.4. Remote Power Supply Box ...................................................................................... 24

16. Sample Gas measurement ............................................................................................. 27

16.1. Cycle configuration .................................................................................................. 27

16.2. H2Slow sensor protection (optional) ........................................................................ 32

17. Analyzer mounting and installation .............................................................................. 34

17.1. Content of your order ............................................................................................... 34

17.2. Installation rules to guarantee explosion protection ................................................. 34

17.3. Prerequisites for installation ..................................................................................... 34

17.4. Steps for the mechanical mounting and installation ................................................. 35

17.5. Mounting the analyser on a wall or steel rack .......................................................... 36

17.6. Correct tubing of the SWG100BIO-Ex ..................................................................... 37

18.1. Flow restrictor orifice (#65114) ................................................................................. 38

18.2. Installation of the power supply ................................................................................ 40

18.3. Installation of the external switch-off circuit .............................................................. 41

18.4. Connection of the I/O module .................................................................................. 43

19. Power up and commissioning the analyser ................................................................. 45

19.1. Power up the analyser ............................................................................................. 46

19.2. Check country and language ................................................................................... 47

19.3. Check date and time of the instrument .................................................................... 47

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

4 / 108

19.4. Configure sampling points ....................................................................................... 47

19.5. Configuration of the alarm relays ............................................................................. 48

19.6. Configuration of the Modbus .................................................................................... 50

19.7. Configuration of the external control (Option: IO module) ........................................ 52

19.8. Configuration of the analog outputs at the I/O module ............................................. 56

19.9. Configure alarm output of I/O module ...................................................................... 57

19.10. Configure the AUX-input on software-side: ......................................................... 59

20. Operating the analyser ................................................................................................... 60

20.1. Administrator PIN code ............................................................................................ 60

20.2. Power-On of analyser .............................................................................................. 60

20.3. Self-Test .................................................................................................................. 60

20.4. Main menu measurement ........................................................................................ 61

20.5. Data Storage ............................................................................................................ 63

20.6. Power-Down of analyzer .......................................................................................... 64

20.7. Backup/restore all individual user-settings ............................................................... 65

20.8. Default configuration ................................................................................................ 65

20.9. Update the firmware ................................................................................................. 67

21. Service and maintenance ............................................................................................... 70

21.1. Preparing and information about the maintenance .................................................. 70

21.2. Regular maintenance works by the operator ........................................................... 70

21.3. Position and overview of the service-parts............................................................... 71

21.4. Cleaning the surface of SWG100BIO-Ex. ................................................................ 77

21.5. Maintenance of the switch-off relay (K2) and the solenoid valve for CH4 supervision

77

22. Exchange of electrochemical sensors.......................................................................... 79

22.1. Analyzer calibration .................................................................................................. 86

23.1. Troubleshooting ....................................................................................................... 90

24. Technical specification .................................................................................................. 91

25. Declaration of conformity .............................................................................................. 95

26. APPENDIX ....................................................................................................................... 99

27. General information ........................................................................................................ 99

27.1. Special informationen about the Modbus Slave function ......................................... 99

27.2. Special informationen about the Profibus Slave function ....................................... 100

28. Defined registers to be read by the master ................................................................ 101

28.1. Analyser Status (address 0 and some mirror addresses) ...................................... 104

28.2. Analyser System Alarm (address 2 and some mirror addresses) .......................... 105

28.3. Spare parts list ....................................................................................................... 106

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

5 / 108

Inspect Shipment for Damage

Carefully inspect the entire shipment for damage in the presence of the shipper’s agent,

removing packaging material if necessary. Note any damage to packaging and/or goods on

Packing List and have it signed by the shipper’s agent prior to accepting the shipment. Submit

damage claim to MRU immediately.

NOTE: Damage claims not received by MRU within 3 days of receipt of shipment will not be

accepted.

The products described in this manual are subject to continuous development and improvement

and it is therefore acknowledged that this manual may contain errors or omissions. MRU

encourages customer feedback and welcomes any comments or suggestions relating to the

product or documentation.

Please forward all comments or suggestions to the Customer Feedback Department at the

following address:

MRU GmbH

Fuchshalde 8 + 12

74172 Neckarsulm / Obereisesheim

GERMANY

Fon (+49) 71 32 99 62 0 (Reception)

Fon (+49) 71 32 99 62 61 (Service)

Fax (+49) 71 32 99 62 20

Email: info@mru.de

Homepage: www.mru.eu

This manual is intended solely as a guide to the use of the product.

MRU shall not be liable for any loss or damage whatsoever arising from content errors or

misinterpretation of information’s from this manual or any mis-use resulting from the use of this

manual.

FOR MORE INFORMATIONS ABOUT COMPANY MRU PLEASE VISIT OUR WEBSITE

www.mru.eu

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

6 / 108

1. General Information

1.1. Weather and environmental conditions

The SWG100BIOGAS analyser is designed for operating ambient temperatures of +5°C to

+45°C (without cabinet heater) resp. -20°C to +45°C (with cabinet heater).

The SWG100BIO-Ex. is for designed for use in hazardous Zone 2, see the conformity marking

in the corresponding section.

In case of outdoor mounting it is important that the analyser is protected against rain and sun.

For extreme environmental conditions like high humidity, salty sea air, etc. further protective

measures are necessary. These should be clarified with the manufacturer (MRU).

Any additional protective measures for outdoor mounting have to be provided by the plant

operator. The manufacturer (MRU) is supporting the plant operator in choosing appropriate

protective measures.

1.2. Installation instructions

Installation instructions, which are described in chapter 17 of the operation manual, have to be

strictly carried out.

WARNING

Please check correct installation before powering up the analyzer!

Please operate the analyzer only in upright position!

1.3. General important instructions for the pla nt operator

To guarantee continuous operation of the SWG100 BIOGAS analyser, the functions, processes

and operation of the analyser have to be monitored regularly by the plant operator – especially

in case of any initial installation. Thus, it will be possible to take suitable measures to improve

the availability and life time of the analyser.

As the plant operator gains more experience concerning the maintenance requirements of the

analyser, the monitoring frequency may be reduced to more extended periods of time.

It is important that the filter-units, listed in chapter 10 of the operation manual, are checked

regularly and, if necessary, service parts are changed.

2.

ATTENTION

In case of not intended use the guarantee will void. Regular controls,

inspections and the exchange from polluted and exhausted filters by

the operator are also an important part of the determination “not

determined use”. See chapter 9 regular maintenance work.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

7 / 108

2.1. Important information about the user’ s oper ation manual

The users/operation manual is an important part of this delivery. It will explain how to use this

analyzer properly and sets forth safety and environmentally friendly procedures.

It is the responsibility of all users to read and familiarize themselves with this manual, paying

particular attention to the safety instructions.

The most important safety details are clearly marked with an attention sign.

Safety declarations

In this document the safety hints will be declared as follow:

DANGER

Identifies an immediate, impending hazard that, if ignored, will

result in severe bodily injuries or death.

WARNING

Identifies an immediate, impending hazard that, if ignored, may

result in severe bodily injuries, material damage or death.

CAUTION

Identifies a possibly dangerous situation that, if ignored, may result

in minor injuries.

9.

ATTENTION

Identifies a possibly harmful situation that, if ignored, may result in

damages to the device or its surroundings.

11.

NOTE

Identifies user tips and other especially important information.

11.1. General warning

DANGER

Any maintenance action must be done only, when the atmosphere is

verified to be not explosive.

11.2. Safety Information

The following safety procedures must be followed at all times. They are significant and essential

part of this manual. Failure to follow safety procedures can result in the loss of your warranty

claims.

Biogas or other similar gases (landfill gas, bio-methane, coal seam gas etc) is containing

flammable gas component CH4 and toxic gas component as well (H2S and CO2).

Analyzers is continuously sampling a certain volume (approx 50l/h) of the sample gas, and is

venting it to ambient air.

For this reason, there are two aspects which must be considered:

1) toxicity danger of sample gas

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

8 / 108

2) flammable (explosion) danger of sample gas

1) Inhaling toxic gases is harmful to health and can even cause death in some cases.

• It is the responsibility of analyzer user to ensure that person is skilled and trained

in safety aspects of gases being analyzed and procedures to follow while using this

instrument.

• Local regulations for possible exposition to toxic gases have to be known and obeyed

by the user of the analyzer

• Using a personal gas detector inside the biogas plant is highly recommended since

H2S in higher (very dangerous) concentration cannot be detected by human nose.

Only small concentrations around few ppm can be detected by human nose

• CO2 gas is heavier than air and therefore operator shall avoid working at underground

or confined spaces. Beside of that CO2 is also odorless!

• It is not allowed using the biogas analyzer in confined space or rooms

without forced ventilation.

• Sample gas exiting the analyzer will flow in the ambient air and only outdoor use

or forced ventilation rooms are suitable for using the biogas analyzer

2) Regarding flammable gases (e.g. CH4 methane) and hazardous area of operating the

instruments, user must also be able to recognize the area classification and be aware of using

the instrument there. This area classification is country specific, please observe and notice it.

• Stationary analyzers are allowed to be mounted in hazardous area zone 2 only if they

have the certificate of compliance. These instruments shall never be located in

confined places or rooms without forced ventilation.

Only trained personnel should carry out installation of stationary instrument and/or

maintenance, service and repair. Opening the stationary analyzer cabinet can expose

personnel to injuries and shocks from mains voltage!

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

9 / 108

Safety regulations

The analyzer may only be used as indicated in this manual. Our analyzers are checked

according to the following regulations:

VDE 0411 (EN61010) and DIN VDE 0701 before they leave the MRU GmbH factory.

MRU technical products are designed and manufactured according to DIN 31000/ VDE 1000

and UVV = VBG 4 of the professional guilds for fine mechanics and electrical engineering.

MRU GmbH assures that the analyzer complies to the essential requirements of the legal

regulations of the member states of the electro-magnetic compatibility (89/336/EWG) and to the

low-voltage regulations (3/23/EWG).

Specific safety regulations

No part of the analyzer, or any other metal parts & accessories shall be used as electric

conductors.

The analyzer shall not be used in or under water.

The analyzer shall not be placed near or directly exposed to open fire or heat.

The analyzer shall avoid dropping.

CAUTION

Moisture or condensate, being pumped out of the condensate outlet

port can be slightly acidic.

In case of skin contact IMMEDIATELY: clean affected parts of the body.

Avoid getting liquid in eyes.

Please carefully clean all parts that come into contact with the

condensate.

11.3. Packing

Packing regulation of 12.07.1991

If your local waste facility does not accept MRU packing materials for disposal, you may return it

to MRU or our local sales representative. Packing materials returned to MRU must be returned

prepaid.

11.4. Return of hazardous waste

Waste Disposal/Returns/Warranty MRU GmbH is required to accept the return of hazardous waste such as electro-chemical

sensors that cannot be disposed of locally. Hazardous waste must be returned to MRU prepaid.

11.5. Return of analyzer

MRU GmbH is required to accept the return, for proper disposal, of all analyzers delivered after

13th of August 2005. Analyzers must be returned to MRU prepaid.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

10 / 108

11.6. MRU guarantee conditions

MRU granted of the analyzer SWG100 BIOGAS a guarantee of 12 month.

1. 6 month on MRU spare parts.

2. The term of the guarantee conditions starts as of the invoice date.

3. Excluded from the guarantee conditions are damages, which occurred by:

• Improper use.

• Improper application.

• Improper mounting.

• Deliberate or negligent destructions.

• External influence for example fall, hits, solvents, acids, gases, by normal wear or

transport damages. This applies also for defects, which are caused from high pollution

and/or moisture (condensate) in the gas route or on the sensors.

4. As well excluded from the guarantee conditions are typical consumable- and spare parts.

5. The guarantee condition denatured immediately, if no original consumable parts are installed.

The guarantee is only for original MRU consumable parts and sensors.

6. With the replacement of the type plate or the serial- number of the devices all guarantee

conditions will be invalid.

7. The service of a guarantee conditions will not enlarge the guarantee time. Demands because

of consequential damages are excluded.

8. The transport costs for round trip takes the consignor or the warrantee.

9. MRU reserves the right, to determine individual conditions or exceptions. These will be

separated informed.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

11 / 108

12. Analyzer Description

12.1. I nte nded use

The instrument is intended for analyzing the composition of biogases / biomethane / landfill

gases and determine the concentration of several components like CH4, CO2, O2 and H2S.

The instrument may optionally be equipped to monitor several sites in time sharing technique

(cyclical one by one sampling).

In particular, the instrument is not foreseen to serve as a gas detector or as a safety device.

In case of not intended use the guarantee will void. Regular controls, inspections and the

exchange from polluted and exhausted filters by the operator are also an important part of the

determinations “not determined use”- see chapter 9 regular maintenance work.

The SWG-100BIO Ex. is an extractive measuring system. It has maximal 4 sample gas inlets, to

measure the gas concentration from 4 different sample points, one by one. It has an internal

gas pump to suck the sample gas from the sampling points. After the measurement, the sample

gas is vented through the sample gas outlet (Vent).

All sample points are equipped with a flow restrictor orifice, which allows also sampling the gas

from the higher-pressure gas pipe of the engine, while limiting the maximum amount of gas in

case of internal cabinet piping leakage.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

12 / 108

12.2. P r inciple of operation

• Sample gas from one or more sampling points is fed into the analyzer by dedicated

ports. Internally mounted electric valves select one point at a time to feed sample gas

to the analysis unit.

• The instrument is equipped with a non-dispersive infrared (NDIR) bench for analysis of

CO2 and CH4. Two separate infrared detectors for each CO2 and CH4 are included,

each operating with a different optical path length and stabilized by referring to a

reference detector. The IR source is a highly efficient and stable IR emitter, pulsed at a

frequency of several Hertz. By design NDIR technique offers good stability and

selectivity together with long life time of sensor (only limited by corrosion or dust, which

can be prevented or removed by regular servicing the instrument).

• The instrument is optionally equipped with a number of electro-chemical sensors ECS

in order to detect gas components like oxygen O2 or H2S. Those sensors offer a

reliable and effective way to detect the target gases. They are typically of limited life

time (several years) but may be easily replaced once the end-of-life is reached.

• In regular time intervals (user settable), the instrument automatically switches to purge

the sensors with fresh (ambient) air for re-adjust the zero point.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

13 / 108

12.3. Ma r king and range of application

The SWG100BIO-EX was designed for use in hazardous area with potentially explosive

atmosphere and was certificated by ATEX directive:

EX-Protection: [EX] II 3G Ex nA nC IIC T3 Gc

Certification no.: EPS 16 ATEX 1xxx X

The SWG100BIO-EX is operating in a temperature range of -20°C … +45°C with intern cabinet

heater.

The specifications of the analyzer are:

Main power supply: 230 VAC / 50 Hz

Power consumption: 36 VA

Protection class: IP65

Fuses: 230 VAC/ 50Hz / 6 A

Data output interface: 4…20 mA / analog outputs

RS485 Modbus RTU

12.4. Possible applications and analyzer options

The bi ogas analyzer SWG100 is the industrial measuring solution to be used at all hazardous

zone 2 areas of::

• biogas (anaerobic digestion) plants

• cogeneration heat and power engines (CHP)

• municipal or industrial waste water treatment sites

• coal seam gas sites (coal bed methane)

• food and animal waste processing plants

• biomethane (gas to grid) plants

• landfill sites

12.5. Features

This analyzer can be equipped with additional options and/or additional accessories to full fill

multiple other measuring tasks such as

• H2S

low measurement with protected EC cell using cutoff solenoid valve and air

purge pump

• H2S

high measurement with EC cell

• H2 measurement with EC cell

• CO measurement with EC cell

• Multiple sampling point switchover from 2x up to maximum 4x sites

• Module with 4 channel analog outputs/inputs 4-20mA, with 2x “fail safe” alarm

relays

• Converter module of RS485 into Profibus

• Cabinet heater for freeze protection

Ask our sales representatives for available options and accessories or check out our MRU

website.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

14 / 108

13. Overview of the SWG-100BIO Ex

13.1. S cope of supply and delivery

The delivery contains the follow components:

• SWG-100BIO Ex analyser, with a stainless steel case.

• A stainless-steel thread filter for the zero gas inlet, with a G1/8 inch male thread.

• Flow restrictor orifices for the sample gas inlets, with a G1/8 inch female thre ad. The

number of flow restrictors is depended from the number of gas sample inlets.

• A fitting for the gas outlet (vent), with a G1/4 inch male thread.

• Mounting material.

• Optional: Flame arresters for the sample gas inlets, with a G1/4 inch male thread.

13.2. Material required for the installation (not scope of supply)

Material for tubing or hosing the sample gas inlets and outlet.

• For the sample gas inlets: Flexible PTFE tube or stainless steel tubing with a

diameter of 4/6 mm. It could be necessary to install a heated sample line on the tubes,

to protect the sample gas from freezing.

• For the sample gas outlet (Vent): Flexible PTFE tube with a diameter of 8/10 mm. It

could be necessary to install a heated sample line on the flexible tube, to protect the

vent gas pipe for freezing.

• For the condensate outlet: Flexible tube with a diameter of 4/6 mm. It could be

necessary to heat the condensate tube to prevent that the condensate for freezing.

Power supply lines and signal lines

• Cable for power supply: Cable type: H 07 RN-F 5 G 0,75 mm²

• Signal lines for 4…20 mA analog outputs.

• Signal lines for Modbus RTU digital transfer.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

15 / 108

13.3. Dimensions and views of the analyser

Top view:

Front view / left view / right view

Bottom view

642 mm

630 mm

223 mm

1 2 1 2 3 4 1

2 3 4

Reference:

1. Sample gas inlets G1/8 inch female thread.

2. Sample gas outlet G1/4 inch female thread

Reference:

1. Heat sink of gas cooler unit

2. Calibration gas inlet G1/8 inch female thread

3. Zero gas inlet G1/8 inch female thread

4. Condensate outlet G1/8 inch female thread

Reference:

1. Cable gland M16 for power supply

2. PE bolt for earthing cable

3. Cable gland M16 for I/O modules

4. Breather drain

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

16 / 108

13.4. P osition of the gas in and outlets

1

Display (color, with backlight)

2

Keypad

3

Sample biogas inlet ports (1 to max 4 ), female G1/8” threads

4

Cabinet lock

5

Inlet cable glands M16 for I/O modules

6

Inlet cable gland M16 for mains power supply

7

Heat sink for gas cooler unit

8

Condensate outlet port, female G1/8” thread

9

Zero gas inlet port, female G1/8” thread

10

Calibration gas inlet port, female G1/8” thread

11

Vent outlet port, female G1/4” thread

1

2

3

4

4 5 6

7

11

8 9 10

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

17 / 108

13.5. Operating unit: Display and keypad

14.

NOTE

Operation of the keypad is intrinsically safe.

All commissioning can be carried out with the control-unit.

The operating-unit can only be operated when the cabinet door is open.

DANGER

Explosion hazard

In case of system alarm, after analyser has auto-shut-

off itself, the

cabinet might contain an explosive atmosphere. Any ignition source

must be avoided when opening the door.

Keypad for operation of control unit.

1 2 3 4 5

6 7 8

9

Control unit

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

18 / 108

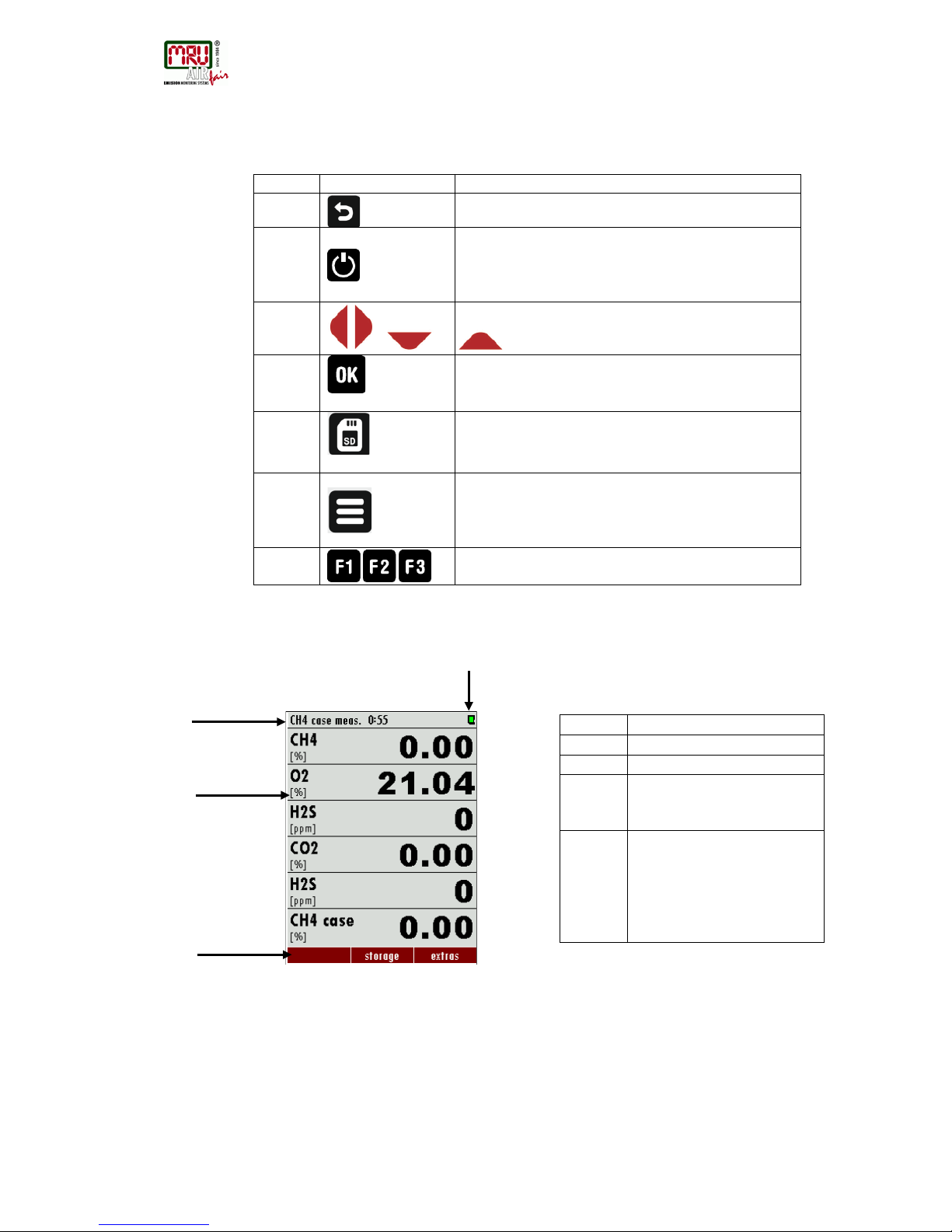

All information required to operate the analyser is displayed as shown below.

Number

Symbol

Description

1

ESC : abort or return to the menu above

2

Prepare Power-Down: Press this key before you

disconnect mains. The analyser will store changed user

settings and other operational data and will purge the

sensors 3 , , ,

Arrow keys: context dependent functions, e.g. scroll in

between lines, change values, change view.

4

OK : confirmation key, select a marked menu point.

5

Screen shot : press this key in order to store a screen

shot of the current display contents onto the SD card.

6

Menu key: Will show all available functions in the

window that is currently in use – also those which have

an individual key on the key pad like the printer and the

three function keys.

7-9

Function Keys : Activates the functions seen on the

display (2 function key bar)

All information required to operate the analyser is displayed as shown below.

Number

Function

1

Menu bar

2

Function key bar

3

Display panel

- Menu

- Measurement value,

4

SD-Card in the slot

- Indication green readand write access

- Indication yellow only read

access (SD-Card write

protected)

1 2 3

4

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

19 / 108

14.1. Measurement menu

The measurement menu is the main root of the menus. Here you can see the current

measurement values, the current sampling point number and the status of the zeroing process

while it's active. Via pressing the function keys F1-F2-F3 you can reach other menus:

- F1: Menu Sample Point Switching

- F2: Menu Storage

- F3: Menu Extras

Menu Memory all tasks for the management of the data memory available.

Menu Extras all the other available tasks – for management and customizing your

analyzer.

Please read chapter 5 for

details.

Please read chapter 5 for

details.

Please read chapter 5 & 6

for details.

No matter which menu is currently active you will return to the measurement menu by pressing

the ESC key several times.

SWG 100 BIOGAS

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

20 / 108

15. Explosion protection systems of SWG100BIO-EX

The explosion protection of SWG100 Bio-EX is based on the nA and nC type of protection as

indicated in the ATEX declaration. Following aspects have to be followed.

Any action not in line with the guidelines below may violate the explosion protection of the

SWG100 BIO-Ex and may results in danger and explosion hazard

WARNING

The following chapter explains with which protection systems

the SWG100BIO-

Ex. is equipped. If one of the explained

protection systems is triggered, the user must do the following

actions to prevent an ignition inside the analyser cabinet.

• Only staffs with a “hot permit” are allowed to restart the

analyser in service.

• The staff must have a certified flammable gas detector to

monitor the ambient atmosphere.

• The cabinet door shall not be opened by force in order to

prevent ignition sparks.

•

The entire cabinet must be checked for absence of

flammable gas with a certified combustible gas detector.

• It is not allowed to restart the analyser in service, until the

cause of system alarm is remedied.

•

Exchange disconnected flexible tubes. Never use

exhausted tubes again.

15.1. Electrical components

All components in the SWG100 BIO-EX are selected and qualified to meet the requirements of

the given type of protection (nA or nC). Make sure that any change to the instrument during it’s

life time are in line with the requirements of this type of protection. No change to the wiring or

change of components are allowed without prior information about the impact on the type of

protection of these changes. Always ask feedback of MRU for the intended changes.

15.2. IP 65 cabinet

The SWG100BIO-Ex. has an IP 65 cabinet. The cabinet prevents explosive gases and dust to

penetrate inside. Prevention from dust is a basic requirement to the type of protection.

Therefore, it is required to always operate the instrument with the door being closed. Perform a

visual inspection in regular time intervals to verify the housing and the seals of the door and

window are not damaged.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

21 / 108

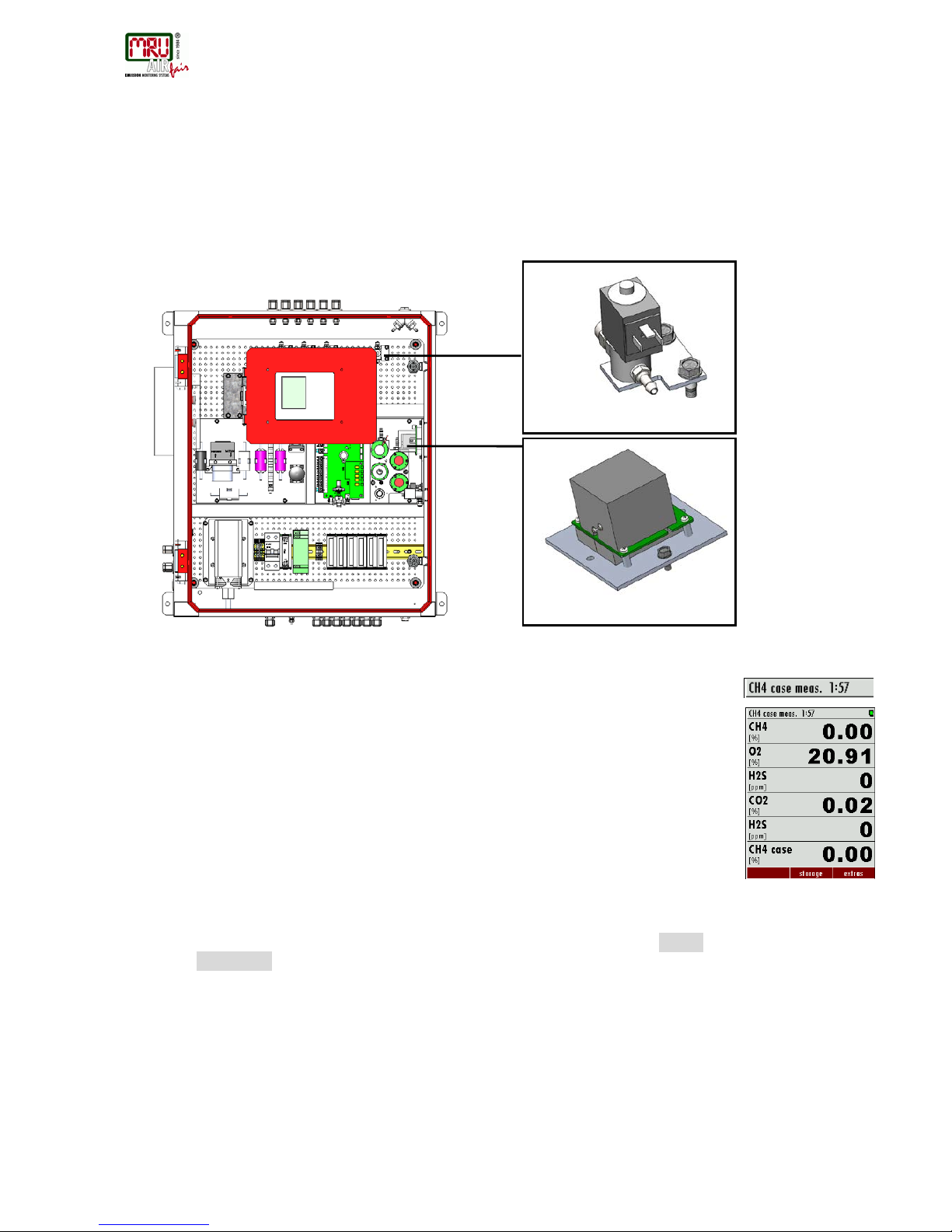

15.3. CH4 measurement of inside cabinet

While the components internal to the instrument are verified to meet the type of protection, it is

nevertheless required to monitor the cabinet to prevent explosive atmosphere being present.

Therefore SWG100 BIO-EX implements a regular monitoring of the CH4 content inside the

cabinet with the help of the CH4-NDIR bench used for biogas measurement.

In case an explosive atmosphere is detected inside the cabinet, the SWG100BIO-EX outputs an

alarm signal to the remote power supply box, which interrupts the power supply of the full

instrument.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

23 / 108

Desciption of the CH4 cabinet monitoring

The main parts of the system are following:

• The CH4/CO2 NDIR- bench.

• A solenoid valve, which feeds the atmosphere inside the case to t he CH4/CO2 NDIR

bench.

The figure below shows the position of the two components.

• The CH4 cabinet measurement is inforced after each air purging phase / zero point.

This phase takes 2 minutes and is called 'CH4 case measurement'. During this phase

the menu indication bar will indicate 'CH4 case meas.' and a count-down starts.

• During this phase, all solenoid valves are closed and the solenoid valve, which feeds

the gas from inside the cabinet, will open. The first 90 seconds of the CH4 monitoring

is used to feed the inside cabinet atmosphere to the NDIR bench. Only in the last 30

seconds the CH4/CO2 NDIR- bench detects the CH4 concentration. During this

time the measured CH4 values will be shown also as life values.

• The CH4 concentration is displayed as CH4 % concentration as well as CH4

concentration in % LEL in the measurement menu (see screenshots below).

• If the CH4 concentration rises over an user defined value, an alarm will be triggered for

2 minutes. After the 2 minutes the analyser will power down to prevent an explosion.

• The CH4 alarm threshold can be set in the general menu (find on the path: EXTRAS /

GENERAL MENU).

• If the user must perform maintenance works on the analyser and the alarm appears, it

is possible to delay the power down for 1 hour to max 2 hours. The alarm menu can be

closed with the key F1 or ESC. The alarm is still active, the user will see a flashing red

'OFF' on the menu indication bar.

Solenoid valve for CH4 monitoring

CH4 / CO2 NDIR-bench

Menu screen in the „CH4

case meas.” mode

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

24 / 108

•

Self test of the CH4/CO2 NDIR- bench

The CH4/CO2 NDIR-bench being a part of the SWG100BIO-EX protection system, is requir ed

to be monitoring itself. In case the bench is supposed to be not working correctly, the alarm

output is activated as well, which will lead to a power down of the instrument.

This self test is performed regularly and intrinsically by the biogas sample gas measurement

itself. The analyser detects the CH4 concentration on all installed sample gas inlets. If the CH4

concentrations of all inlets are below 5 Vol.%, the alarm is triggered. The user has the

possibility to manually delay the power-down in 1 hour intervals (max. 24 hours), in case the

missing CH4 is known to be due to the sample gas composition. Do not delay the alarm if there

is any doubt on the NDIR bench’s performance. The alarm is still active, the user will see a

flashing red 'OFF' on the menu indication bar.

In case the user needs to pause the self test supervision for a limited time interval, this can be

done for a couple of hours (min.2:00:00 max.24:00:00) in order to prevent a switch-off alarm. To

pause the function, select to the path: EXTRAS / CH4 SENSOR S UPERVISION. The following menu will

appear. With F3 the supervision function can be switched off and on. In the screen a countdown

appears. This countdown shows when the paused CH4 sensor supervision will restart. With the

right/ left arrow keys the countdown can be set up until 24 hours.

After power-on the CH4 sensor supervision will start as soon as all sample gas inlets have been

measured once and not earlier than 1 hour operation.

15.4. Remote Power Supply Box

When the SWG100BIO-EX outputs an alarm (due to internal CH4 detected or due to failed self

test) it is required to switch off the instrument completely by means of an external power supply

box, which shall be located in safe area, in the power supply distribution cabinet.

Screen after a delay was added

Right / left arrow keys

to set the

countdown up or down.

General menu: Menu-

point to set the LEL Level

Switch off alarm. The user has 2 minutes

before the SWG100BIO-Ex power down.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

25 / 108

The Remote Power Supply Box as optionally supplied by MRU, has a switch-off contactor (K1),

with 3 m ake contacts (normally open). The power contactor K1 is activated after the analyser is

powered on by pushing the power-on button until the green LED is light-on. In case of an

SWG100BIO-EX alarm, the power contactor K1 is deenergized. The circuit diagram shows the

correct wiring of the power co ntact or inst a lled in the remote power supply box.

For more information see chapter 20.3

The circuit diagram of above pictured device must be implemented by user as part of the safety

concept.

User can either use the remote power supply box as offered by MRU, or install inside the power

distribution cabinet a similar circuit (see diagram in chapter 20.3) using a power contactor and

push-start button.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

27 / 108

16. Sample Gas measurement

16.1. Cycle configuration

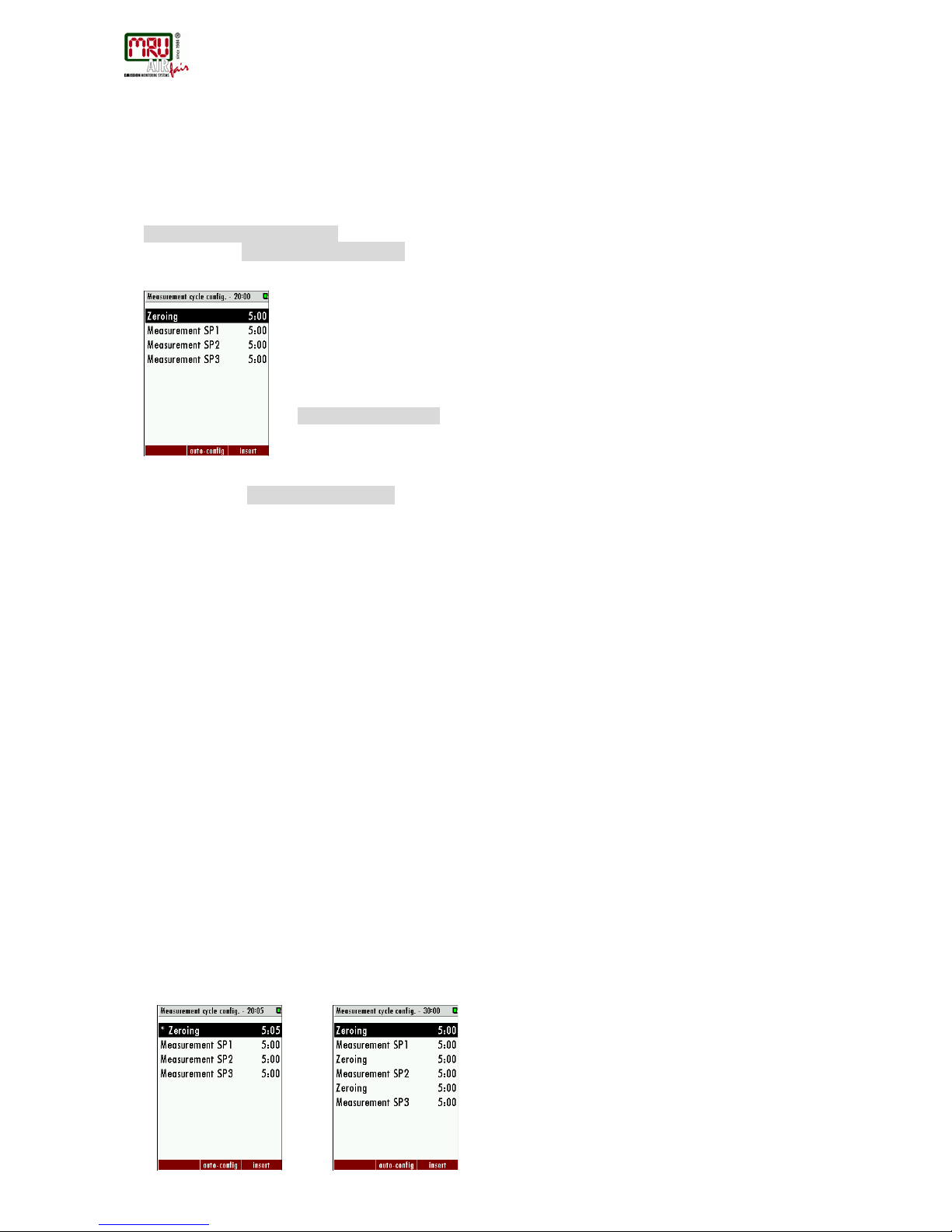

Path and default setting

EXTRA/ MEASUREMENT CYCLE CONFIG.

When the menu “MEASUREMENT CYCLE CONFIG.” is selected the user definable setting for the measurement cycle will

appear (see screenshot below).

General information

The menu point “CYCLE CONFIGURATION” allows the user to configure an individual measurement cycle. Every

installed sample point can be configured. For the configuration the user has the following phases, which can be

selected:

• Zeroing.

• Purging.

• Stand-by.

• Measurement SPx (SPx stands for Sample point 1, 2…).

The configuration is performed with the three function keys F1, F2 and F3.

• F1: Delete a phase.

• F2: Make an Auto-config.

• F3: Insert a new phase.

• OK: View/change phase details

• Left/right: Change the phase type.

Auto configuration

With F2 the “Auto-config.” can be selected. The user can select one of two default cycle configurations.

• One zeroing / cycle.

• One zeroing / sample point.

The first program is for applications where the different measurement points have almost the same gas

concentrations. The zeroing is not necessary at every change of the measur eme nt SPX.

The second program is for applications where the different measurement points have different gas

concentrations. A zeroing is recommended after every measurement point change.

The screenshots below show the “One zeroing / cycle” and “One zeroing / sample point” in comparison.

Screenshot shows default setting, when

the „MEASUREMENT CYCLE CONFIG.” will be

started the first time.

The two auto-configurations, which can be selected.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

Depending on the analyser type, the first or the first and second phase cannot be deleted, deactivated or moved

to another position.

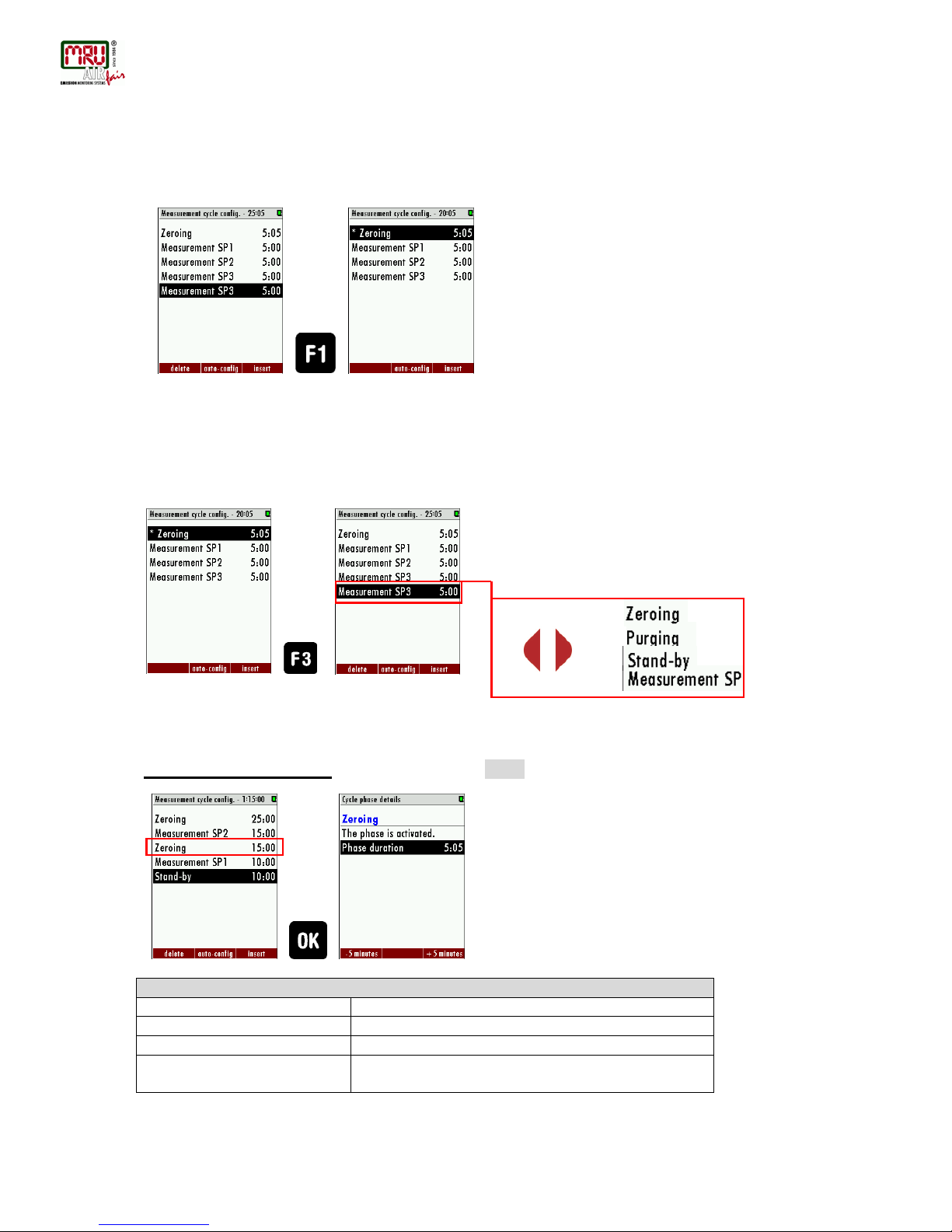

Delete a phase

With F1 a phase can be deleted. To do this, select the phase, which should be deleted and press F1.

Insert a phase

With F3 a new phase is inserted in the measurement cycle. With the right/left arrow keys the different phase

types can be selected.

In the title-bar the entire cycle time is shown. It is called “Measurement cycle config.”

With OK the “Cycle phase details” can be shown and changed.

Configuration of the phase details

In this chapter the different cycle phase details will be explained.

Zeroing (Cycle phase details): In the cycle phase detail “ZEROING” the zeroing time can be configured.

ZEROING

Measuring site valves

Valves closed

Zeroing valve

Valve open

Duration

2min to 1 h

Recommendation

5min., in general not to be changed by user as depending

only on analyzer internal setup

+

=

Screenshot shows how a

phase can be deleted. In

this example the last phase

“Measurement SP3” is

deleted.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

29 / 108

Measurement SPX (Cycle phase details): In the cycle phase details of “Sample point X” the measurement time

and the suction delay can be configured. Each sample point can be configured individually. In the cycle phase

details the following times can be set:

MEASUREMENT SPx

Measuring site valves

Valve of selected site is open, others closed

Zeroing valve

Valve closed

Duration

Phase duration: 2 min. to 24 h

Suction/response time: 30 sec. to 1h

Pure measurement: calculated

H2S-low: Activated/protect (Optional)

Stand-by (cycle phase details): In the cycle phase details “Stand-by” the sleep mode time can be configured. In

the cycle phase details the following times can be set:

• Phase duration: Entire Stand-by time (Purging time + Quiet time = Phase time).

• Purging time: The time, to purge the analyser with ambient air, through the zero gas inlet.

• Quiet time: The time, where the analyser is in the pure stand-by mode.

STAND-BY

Measuring site valves

Valves closed

Zeroing valve

Valve closed

Duration

Phase duration: 2 min to 24h

Purging time: 30 sec. to 1h

Quiet time: calculated

• Purging (cycle phase details): The purging is a separate configuration point to purge the analyser with ambient

air through the zero gas inlet. It can be helpful, if the analyser must switch between a sample point with different

sample gas concentrations.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

PURGING

Measuring site valves

Valves closed

Zeroing valve

Valve open

Duration

30 sec. to 1 h

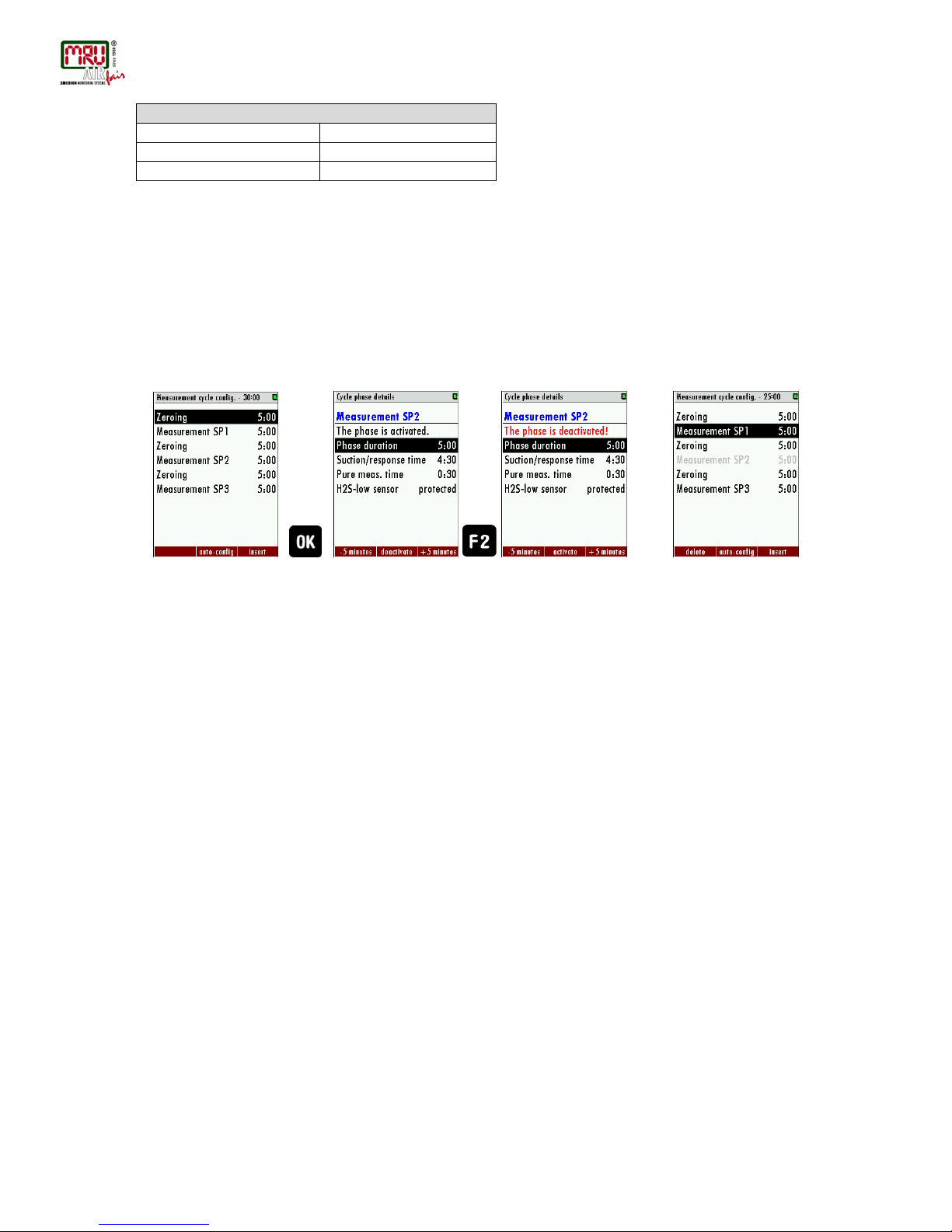

Activated/deactivated a phase

The user has the opportunity to deactivate a phase in the measurement configuration cycle. This could be

necessary for example if a sample point is temporarily not in use. The activation and deactivation of a phase can

be done in the cycle phase details of the concerning phase.

Example for the deactivation of a phase

In this example the “Measurement SP2” will be deactivated. The deactivated phase is grey out.

=

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

31 / 108

Or

F1/F3

Or

F1/F3

Or

F1/F3

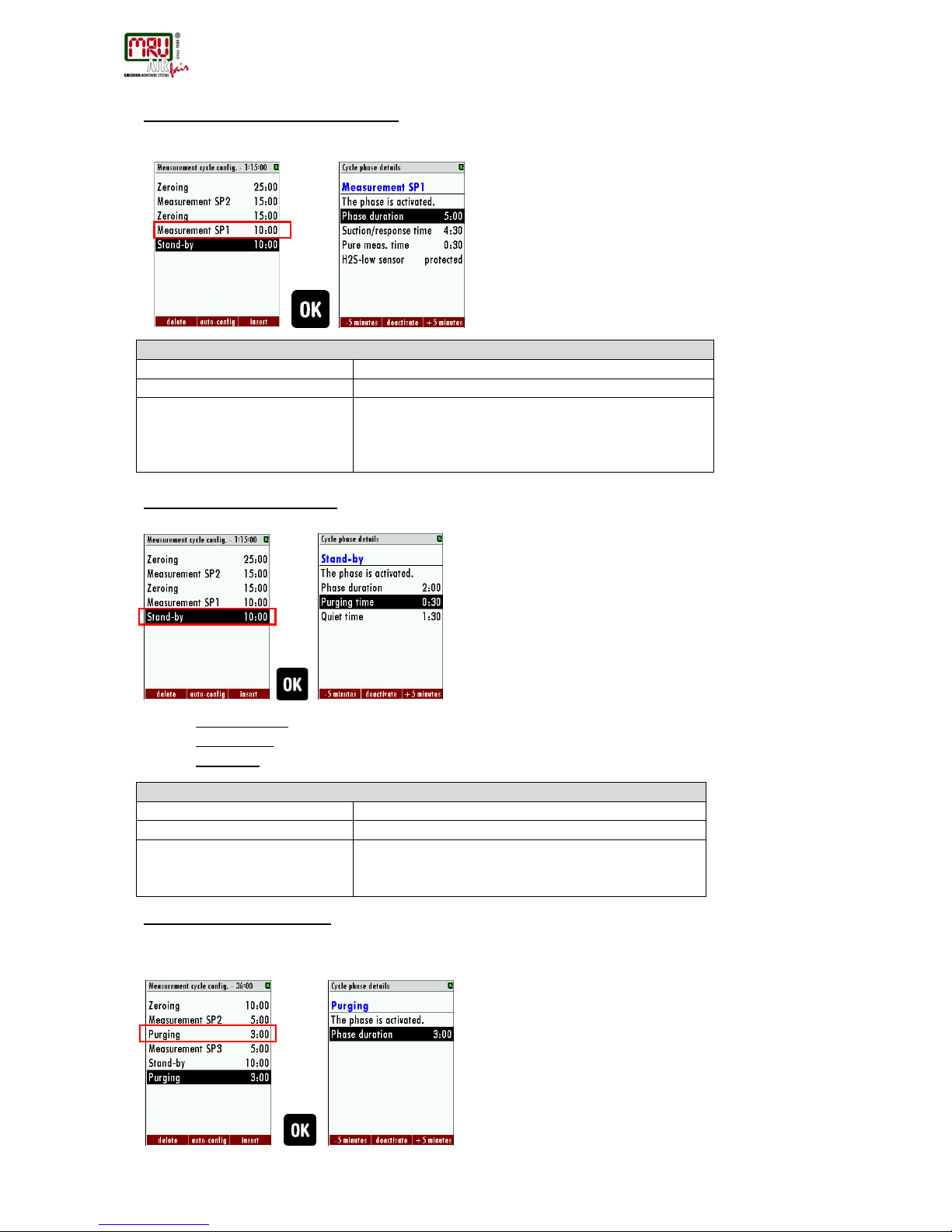

Example for a measurement cycle configuration

In this chapter an individual measurement cycle should be created with the features described

at the chapters below.

The measurement cycle should have the following sequence:

Following points must be done to configure the individual measurement cycle:

1. Open the measurement cycle config. menu: Path: EXTRA/ MEASUREMENT CYCLE CONFIG.

2. The default measurement cycle will appear. Open the cycle phase detail of the first

zeroing and adjust the phase duration at 25 min.

3. Leave the cycle phase detail and select the second point. Switch with the left/right

arrow keys until the measurement SP2 is selected.

4. Open with the OK key the cycle phase detail of the measurement SP2. Adjust the

duration-phase at 15 min. and the suction/response time until the pure meas. time has

the value of 3 min. Use for this operation the arrow keys.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

32 / 108

Or

F1/F3

Or

F1/F3

Or

F1/F3

Or

F1/F3

5. Leave the cycle phase detail and select the next phase. Select with the left/right

arrow keys the phase “zeroing” and go in the cycle phase detail. Adjust the phase-

duration at 15 min. and leave the cycle phase detail.

6. Switch to the next point and select with the left/right arrow key the measurement

SP1. Go in the cycle phase detail of the measurement SP1. Here adjust the durationphase 10 min. and the pure measurement time: 5 min.

7. At last push F3 key for insert a new phase and select with the left/right arrow key the

“Stand-by” phase. Go into the cycle phase detail and adjust the Purging time at 3 min.

and the Quiet-time at 10 min.

Leave the menu and safe the adjustments. The individual configuration is done.

16.2. H2Slow sensor protection (optional)

The instrument may be optionally equipped with a H2S

low

sensor. As this sensor typically shows

limited life time when experiencing high H2S concentrations, some precautions are taken to

protect the sensor:

• The instrument is equipped with a cut-off solenoid valve and air purge pump to protect

the H

2Slow

sensor, without impacting the results of all other sensors.

• The purge unit is always activated after 3-10 minutes of active sensor measuring time.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

33 / 108

• The measuring time of the H2S

low

sensor may be limited to less than 10 minutes by

user setting

• The H

2Slow

sensor may optionally not be included in all measuring cycles of sampling

points. Instead the user may configure that the H

2Slow

sensor is active only added at

some of the measurement cycles.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

34 / 108

17. Analyzer mounting and installation

17.1. Content of y our or der

Your analyzer is delivered in a carton box and is protected with special edged protectors.

Please do preserve the packing of your analyzer, for possible back shipment.

17.2. I nstallation rules to guarantee explosion protection

The SWG100BIO-Ex. has an ATEX Class 2 certification. To guarantee, that the analyser can be

operated safely in this area, please follow the rules during the mounting and the operation of

the analyser.

17.3. Prerequisites for installation

DANGER

Explosion hazard

Before start the mounting and installation work, detect the atmosphere

with a certificate gas detector.

CAUTION

Only educated staff should mounting the analyzer on the stack.

NOTE

Important

The mounting should be done in pairs.

A measurement point must conform some criterions:

• The measurement place must be safeguarding and easily accessible.

• The measurement place must have enough space for installation and

maintenance works.

• The place should be protected for direct sunlight, rain and squalls.

• The area around the analyzer must have enough space.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

35 / 108

17.4. S teps for the mechanical mounting and installation

The graphic below shows the single steps, which must be done to mount the SWG100BIO Ex.

analyser correctly into the application

Mounting the analyser on a wall or a steel rack

Installation of the power supply

Installation of the sample gas tubing

Installation of the Modbus RTU (optional)

Installation of the I/O modules

Installation of the external switch-off circuit

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

36 / 108

17.5. Mounting the analyser on a wall or steel rack

The analyzer can be mounted indoor or outdoor. The device is designed for the mounting on

wall or on steel rack. The follow sketch shows the dimensions, which the analyzer needs for the

correct mounting.

DANGER

Explosion hazard

Before start the mounting and installation work, make sure to have a

“hot permit” and monitor at all time the ambient atmosphere with a

certified flammable gas detector.

CAUTION

Only operate the analyzer in an upright position. Only power the

device up after it is correctly mounted.

General installation rules

• Mount the device on a solid wall or steel rack.

• Be sure, that the air circulation is not obstructed.

• Let enough room for the tubing or piping.

For outdoor installation

Ensure that the analyzer is mounted on a rain and sun protected place (weather shade).

4x M8 bolts

(by user)

642 mm

630 mm

D:4x 10,20 mm

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

37 / 108

For indoor installation:

Ensure that the analyzer is installed on a dry and clean place. Be sure that the room is

permanently vented with fresh air (forced ventilation).

Connect the VENT gas-outlet of the device to ambient by using adequate tube with min Ø8mm

ID.

17.6. Corr ect tubing of the SWG100BIO-Ex

The analyzer uses two different fitting diameters. The position and the diameters of the different

connectors will be shown in the sketch below:

DANGER

Explosion hazard

Before start the mounting and installation work, make sure to have a

“hot permit” and monitor at all time the ambient atmosphere with a

certified flammable gas detector.

CAUTION

Do not cover the breather drain!

18.

NOTE

All connectors of the analyzer use female threads.The analyzer may be

connected by tubing or piping.

Distance, which should be fulfilled

Min. 40 cm

Min. 30 cm

Min. 50 cm

Do not cover the

breather drain.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

38 / 108

Top-side

On the top of the analyzer are the sample gas-inlets. Sample gas inlet 1 is the default gas inlet

port. The analyzer may be equipped with up to 3 additional sample gas inlet ports from different

sampling sites. The following sketch shows the position of the different sample gas inlets.

18.1. Flow restrictor orifice (#65114)

To measure any biogas applications, the analyzer can be equipped with a flow restrictor orifice

(see picture).

Picture: Flow restrictor orifice with intern filter.

Information

The copper seal of the nozzle is intended only for single use.

Connection the flow restrictor orifice with the gas inlets

Fitting type: G 1/8 inner ISO parallel thread for tubing with 6/4 mm flexible tube.

Information

Use PTFE strips to tighten the fitting inside the thread!

The flow restrictor orifices are installed on the sample gas inlets and on the calibration gas inlet.

G1/8“ out ISO parallel thread

G1/8“ ISO parallel thread

Sinter filter

O-ring

Nozzle

Male connector G1/8“

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

39 / 108

Left-side

CAUTION

Be sure, that the heat sink has enough distance to the next wall.

CAUTION

Be sure that the Zero gas inlet feeds fresh, clean air.

Heat sink:

Do not cover the heat

sink from the gas

cooling- unit.

1

2

3

1

Calibration gas inlet

Fitting: 1/8 in. ISO parallel thread.

Zero gas inlet:

Fitting: 1/8 in. ISO parallel thread.

Condensate outlet (Option:

65408)

Fitting: 1/8 in. ISO parallel thread.

Reference:

1. Fitting for PTFE tubing 4/6 mm G1/8” thread

2. Flow restrictor orifice G1/8” thread.

3. Zero gas filter G1/8” thread

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

40 / 108

18.2. I nstallation of the power supply

DANGER

Explosion hazard

Before start the mounting and installation work, make sure to have a

“hot permit” and monitor at all time the ambient atmosphere with a

certified flammable gas detector.

DANGER

Electric shock.

Electricity may cause death. Only educated staff should be allowed for

mounting and installation job.

100-230 Vac/ 47-60 Hz/ 300W

Fuse 4A slow (by user)

N

L

PE

Pre-fuse

N

L

PE

Cable gland (M16):

For cables with Ø 3,5-10 mm.

Remote power supply circuit

to guarantee power down the analyser in

case of hazard. (See chapter

20.3)

K2 switch off relay

G5

G5

2

~

~

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

41 / 108

18.3. Installation of the external switch-off circuit

The remote power supply box itself is not explosion protected at all. Therefore it must be

installed in safe area.

WARNING

Safety installation

The external electric contactor K1 is a part of the safety installation. It is

required to be installed by user when power supplying the analyser.

The circuit diagram below shows the correct wiring of the remote

power supply box.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

42 / 108

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

43 / 108

18.4. Conne ction of the I/O module

DANGER

Explosion hazard

Before start the mounting and installation work, make sure to have a

“hot permit” and monitor at all time the ambient atmosphere with a

certified flammable gas detector.

DANGER

Electric shock.

Electricity may cause death. Only educated staff should be allowed for

mounting and installation job.

NOTE: analog output current 4-20mA load resistor is max. 500Ohm

analog output does not require power supply since it is sourcing the current

alarm relays Out1 and Out2 contacts are “fail safe” type:

open contact in case of alarm or power failure

closed contact for normal operation

Cable glands (M16):

For cables with

Ø 3,5-10 mm.

Signal cable

for I/O modul

RS-485

Out 1

Out 2

Out 3

Out 4

Out 1

Out 2

20mA Alarm

+ + +

-

- - -

4

3

2 1 4 3 2

1

+

+

-

+

In +/- 30V

12V

0V

PT1000

TH-

TH+

Temperature input

In 20mA

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

44 / 108

Plug connector definition:

WARNING

Electric voltage

Power the system down and protect for reconnecting, before start maintenance

work.

Slit screws

Stripping length: 7 mm

Tightening torque min.-max.: 0,5-0,6 Nm

Conductor cross sections, which can be used:

Type of electric line

Conductor cross section min.-max.

Solid

0,2-2,5 mm² (30-12 AWG)

Stranded

0,2-2,5 mm² (30-12 AWG)

Solid with ferrule (with/ or without plastic)

0,25-2,5 mm²

Information for cables, which go through the cable gland M16:

It is recommended to use only electric lines with ferrules.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

45 / 108

19. Power up and commissioning the analyser

After installation of the analyzer few steps should be processed in order to operate the

instrument properly.

The graphic below shows the few steps, which should be done, to power up the analyser

correctly.

START

Supervise the atmosphere with an external certified combustion gas

detector.

Open the case door of the analyser

Power up the circuit breakers

Press the power switch from the remote power supply box.

The analyser will start.

Make the analyser commissioning on the operation unit.

- Language

- Date and time of the instrument

- Configure sample points

- Configure analog in and outputs of the I/O modules

- Configure the alarm relays

- Configure the Modbus RTU.

CLOSE and LOCK the cabinet door of analyser

END OF PROCESS

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

46 / 108

19.1. Power up the analyser

1. Open the case door of the analyser.

2. Power up the circuit breaker. See figure below.

3. Press the power switch of the remote power supply box. Wait until the system is ready

for operation. The green LED on the remote power supply box will glow .

4. The analyser will start and firmware will boot. Wait until the first Self-Test is completed.

Power up the circuit breaker.

Q1

Q1

L

N

Press for 3 sec.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

47 / 108

19.2. Check country and language

Important note:

In case the analyzer shows a language, you don't understand, you ma y swap the language to

English by pressing the menu key and selecting the function 'Set English language'.

Use the menu EXTRAS – GENERAL SETTINGS.

The analyzer will automatically set some country-typical things like the language, the date

format, the temperature unit, the daylight-saving time function and the CSV-export settin gs .

19.3. Che ck date and time of the instrument

The analyzer stores automatically measurement values including timestamps. Therefore, the

instruments' system clock should be set correctly.

Use the menu EXTRAS – GENERAL SETTINGS – DATE & TIME.

In case the date & time is not correct, press the key F2=modify, change date & time and then

press the key F2=store.

Note:

According to the selected country (see previous chapter) the analyzer automatically switch the

daylight-saving time in spring and autumn. This function is active for most European countries.

Whenever the daylight-saving time is currently active, then you'll see a '*' in the time line of the

menu, thus 'Time *' instead of 'Time'.

19.4. Configure sampling points

The analyzer measures at least one sample point. Optional it can measure up to 10 sample

points automatically or manually. Remote sample switching is also possible by using 4 relays

contacts connected to the 1-st I/O module

Use the F1 key in the main measurement menu SAMPLE POINT CONFIGURATION

Set suction delay and measuring time for each sample point according to your needs.

Note:

You may use the function 'auto-config', which will install typical settings. Then check the

settings and modify them if needed.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

19.5. Configuration of the alarm relays

On the main PCB there is one “system alarm” relay with “fail safe” NC contact. The following errors will turn the

relay from NC to NO.

1. Main board is offline (internal RS485 bus communication failure)

2. Main board is in the “bootloader” phase

3. Gas leakage inside analyzer cabinet (CH4 > 20% to 50% LEL)

4. Condensate alarm (contacts resistance < 35kΩ)

5. Low fan rotation (speed rotation < 900U/min)

6. Sample flow alarm (sample flow < 20 l/hr)

7. Gas cooler high alarm (temperature > +10°C)

8. Gas cooler low alarm (temperature < +2°C)

9. Cabinet high temperature (> +55°C)

10. Cabinet low temperature (< +5°C)

Errors 1 to 5 alarm will force a measurement stop (all analog outputs are on hold or at 2mA, depending on

configuration).

Errors 5 to 10 will be displayed as warning message only; analog outputs of active sampling point are live, all

others are on hold.

ATTENTION

Analyzer system alarm relay is a potential-free contact, which max. 24VDC/VAC and

a current of 1A (max.)

Connection of the alarm relay: Potential-free

Max. 24VDC/VAC, 1 A (max.)

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

49 / 108

Plug connector definition for the system alarm relay

Slit screws

Stripping length: 7 mm

Tightening torque min.-max.: 0,5-0,6 Nm

Conductor cross sections, which can be used:

Type of electric line

Conductor cross section min.-max.

Solid

0,2-2,5 mm² (30-12 AWG)

Stranded

0,2-2,5 mm² (30-12 AWG)

Solid with ferrule (with/ or without plastic)

0,25-2,5 mm²

Information for cables, which go through the cable gland M16:

It is recommended to use only electric lines with ferrules.

Following analyzer errors will produce a system alarm (open contact of System Alarm relay)

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

19.6. Configuration of the Modbus

The Mobdbus connector can be found on the PCB-mainboard (see sketch below).

NOTE: for specification of Modbus (RTU) data transfer over RS485, please observe appendix.

User RS-485 (Modbus RTU)

Plug connector definition for the system alarm relay

Slit screws

Stripping length: 7 mm

Tightening torque min.-max.: 0,5-0,6 Nm

Conductor cross sections, which can be used:

Type of electric line

Conductor cross section min.-max.

Solid

0,2-2,5 mm² (30-12 AWG)

Stranded

0,2-2,5 mm² (30-12 AWG)

Solid with ferrule (with/ or without plastic)

0,25-2,5 mm²

Information for cables, which go through the cable gland M16:

It is recommended to use only electric lines with ferrules.

Configuration at the analyzer

1. Open the path EXTRAS/ GENERAL SETTINGS.

2. Press F3 “Modbus”.

3. The Modbus store settings will be open. The user can commission the slaves settings.

A B GND

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

51 / 108

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

19.7. Configuration of the external control (Option: IO module)

This feature requires an I/O module (optional) and the function must be activated.

This feature can be used for the external control of the analyzer. With the help of the external control follow

operations can be done:

• Externally controlled sampling point selection,

• Stand-by.

The commands will be given by a 4-bit binary number, which will be built through four external signals. The pins

for the signal are shown in the sketch below. It exists two different types to set the four pins:

• Potential free relay contacts.

• 4-20 mA signal inputs.

• Through one 4...20mA input.

The settings-menu can be found at the path: EXTRAS/GENERAL SETTINGS-> EXTERNAL CONTROL.

The user can set three different types for the external control. The types can be found at the sketch below.

Connection of the external control via relay contact

This feature can be used for externally controlled sampling point selection, zeroing and stand-by, using external

potential free relay contacts, see also diagram in $4.4

The relay contacts build a 4-bit binary number: RC4 - RC3 - RC2 - RC1 open=0, closed=1.

Let us tell this number 'status number'.

- - -

-

RC4

RC3

RC2

RC1

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

53 / 108

Connection of the external control via 4-20 mA input signals

The signal inputs built a 4-bit binary number: I4 – I3 – I2 – I1: 0-11 mA=open=0; 11/12-20 mA=closed=1.

Connection of the external control via one 4-20 mA input signal

The user has the opportunity to control the analyzer with only the firs t 4-20mA input (see sketch below). The

different commands will be given by the changing of the current signal. The offset-signal is 4 mA. Every 1 mA

step describes a condition of for the external control. Overall the analyzer can take 16 different statuses. The first

status is by 5 mA (4 mA+1 mA) the second is by 6 mA (4 mA + 2 mA) and so on until the 20 mA signal is

reached.

The connection of the one 4-20 mA signal is a two-wire connection.

- - -

-

I4 + I3

I2

I1

+ + +

-

+

I1

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

Configuration at the analyzer

1. Open the path: EXTRAS/GENERAL SETTIN GS.

2. Switch the menu-point “External control” from “OFF” to “Relais”/“4x mA” or “ 1 x mA” (dependent from

the connected signal input.). When the external control is activated an arrow symbol will appear at the

title line.

3. If a valid input state (>0) is present, an arrow in the title line will appear. The analyzer is now slave and

will perform the measurement until it gets another command from the master unit. Some external control

settings can be configured. This can be found at the path: EXTRA/GENERAL SETTINGS then F2= ext.crtl.

The user has the opportunity to set the zeroing time, suction/response time and stand-by purge time.

Case 1: Stand-by

The Stand-by modus will be activated if the input state is higher than the number of sample points (example: 4

sample points and input state 5…15). The Stand-by modus has the following pass:

- Purging with zero gas (for the configured duration)

- Standby until the input state is below or equal the number of sample points (e.g. 4 sample points and input state

1.4)

Case 2: External control of a sample point

-Zeroing: First the zeroing will be done. The duration of the zeropoint can be set at the menu ext. crtl. (see point

“configurated at the analyzer” in the same chapter).

-Gas sampling: The gas sampling is for purging the entire system and give the analyzer enough time for

response. (Response time). To set the suction/ response time, see point “configurated at the analyzer” in the

same chapter.

-Measurement: The measurement will be started after the response/ suction time is finished. It will be only abort,

if the user changes the status of the external signal sources. The chart below shows the possible statues, which

can be set at the analyzer:

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

55 / 108

Status of external signal source Status number Description

RC4/I4 RC3/I3 RC2/I2 RC1/I1 I [mA] - -

0 0 0 0 4 0 Automatic sampling point switching

0 0 0 1 5 1 Analyzer is sampling the point SP1 (*1, *2)

0 0 1 0 6 2 Analyzer is sampling the point SP2 (*1, *2)

0 0 1 1 7 3 Analyzer is sampling the point SP3 (*1, *2)

0 1 0 0 8 4 Analyzer is sampling the point SP3 (*1, *2)

0 1 0 1 9 5 Analyzer is sampling the point SP4 (*1, *2)

0 1 1 0 10 6 Analyzer is sampling the point SP5 (*1, *2)

0 1 1 1 11 7 Analyzer is sampling the point SP6 (*1, *2)

1 0 0 0 12 8 Analyzer is sampling the point SP7 (*1, *2)

1 0 0 1 13 9 Analyzer is sampling the point SP8 (*1, *2)

1 0 1 0 14

10

Analyzer is sampling the point SP9 (*1, *2)

1 0 1 1 15

11

Analyzer is sampling the point SP10 (*1, *2)

1 1 0 0 16

12

Analyzer is “stand-by” (*3)

1 1 0 1 17

13

Analyzer is “stand-by” (*3)

1 1 1 0 18

14

Analyzer is “stand-by” (*3)

1 1 1 1 19

15

Analyzer is “stand-by” (*3)

(*1): Whenever the selected sample point will be changed, then the analyzer will start a zeroing before measuring

the new sample point.

(*2): Not only status numbers 4 to 15, but all status numbers larger than the number of installed sample points will

start the “stand-by” (example: when you have 4 sample points, then status numbers 5 to 15 will trigger “standby”).

(*3): When the status number changes to a “stand-by“ number, then the analyzer will purge the sensors, then it

will close all solenoid valves and switch off the gas pump. When the status number changes back to a value less

or equal to the number of installed sample points, then a “set to zero” cycle will start and afterwards the selected

sample point will be measured.

Note: The “stand-by” status can easily be used to initiate just a zeroing without any “stand-by” and without

changing the sample point.

Example : - status number=1 (for any time period, recommended max. 1 hour)

- status number=15 (for a few seconds, recommended min. 10 seconds)

- status number=1 (for any time period, recommended max. 1 hour)

After installation and power-up of the analyzer few steps should be processed in order to operate the instrument

properly.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

19.8. Configuration of the analog outputs at the I/O module

Each I/O module provides 4 channel analog 4-20mA outputs, which are able to provide the measuring values via

8 wire cable to a remote PLC or DCS.

1. Use the menu EXTRAS – ANALOG OUTPUT CONFIGURATION.

2. At the menu the user can:

a. Select the sample point.

b. The measurement item.

c. The measurement unit.

d. The equivalent concentration for 4 mA and for 20 mA.

Assign measuring value and the min and max value to each analog output channel.

Note:

You may use the function 'auto-config', which will install typical settings. Then check the settings and modify them

if needed.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

57 / 108

19.9. Configure alarm output of I/O module

Each I/O module provides 2 alarm relay contacts (see previous page) normally open contacts (fail safe type)

which will send alarm status via 4 wire cable to a remote PLC or DCS.

Use the menu EXTRAS – ALARM OUTPUT CONFIGURATION.

The screenshot below, shows how the menu looks like:

Assign sampling point, measuring value, threshold value and the alarm direction (LO alarm, when below

threshold or HIGH alarm when above threshold).

ATTENTION

You may use the fuction ‘auto-config’, which will install typical settings. Then check the

settings and modify them if needed.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

Test the alarm outputs of the IO module

Use the menu EXTRAS/ ALARM OUTPUT CONFIGURATION

Open the submenu TEST (F2).

The following screenshot will appear. With F2 all alarm outputs in the entire analyzer can be activated.

With the help of a multimeter, it is possible to test the different alarm outlets. The sketch below shows how to

measure the alarm outputs.

#

Calm

Alarm

1

NC

NO

ATTENTION

With the test modus for the alarm outputs of the IO module, the alarm relays at the IO

modules and the relay at the PCB mainboard can be activated.

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm

59 / 108

19.10. Configure the AUX-input on software -side:

1. Open the menu point AUX input configuration which can be found under the path: EXTRAS/

AUX INPUT CONFIGURATION.

2. All possible inputs are listed in the following screen. Every IO module is able to load four

signals.

3. To configure an AUX input on the software side, select an AUX-input with the arrow keys

and confirm it with OK.

4. The screen AUX INPUT DETAILS appears. In this menu the AUX-input can be given a name

(Meas. item) and a unit (under Meas. unit) which can be selected with the arrow keys. The

measurement item can be named by the user. To set the measurement unit rotates with

the left/ right arrow keys.

5. Important for the AUX-inputs is the measurement range. The range is set with the two

points “Minimum 4 mA” and “Maximum 20 mA”.

6. Before the menu is left, a request to safe the configuration will appear.

SWG100 BIOGAS User Manual

MRU GmbH, D-74172 Neckarsulm

60 / 108

20. Operating the analyser

20.1. Administrator PIN code

All functions and menus which may disturb the analyser’s normal measurement can be

protected against unauthorized access by activating the administrator PIN code request.

We highly recommend activating this function, when unauthorized persons could access the

analyzer.

The PIN code is: F1 - F1 - F3 - F2 - Up - Down

The PIN code request can be activated and deactivated in the menu Extras/General settings:

The deactivation of the PIN code request requires at least one time PIN code input.

Once the user has input the correct administrator PIN code the analyser will stay in

administrator mode (password free) for 10min after last time key acting. Each key acting will

trigger another 10min password free operation.

20.2. Power-On of analyser

When the analyser is connected with mains (Power-On) it will start the system boot process

which usually takes very few seconds. Then the display will show the self-test menu.

20.3. Self-Test

The first menu to be displayed after Power-On is the self-test menu. The analyser won't leave

this menu before all sub-systems will be connected and the gas cooler (option) has reached the

target operation temperature.

During the self-test phase

• the gas pump is switched off

• all analog outputs will deliver 2mA

• all alarm outputs will have alarm status (open contacts)

Usually the self-test will be left automatically as soon as all conditions for measurement are

satisfied. Then the first zeroing will be started.

If one of the internal RS485 bus participants are issuing alarm (faulty) status, the user can still

leave the self-test manually by pressing F2='forward' (PIN code requested), even if not all subsystems or the gas cooler are ready.

NOTE: this is for service purpose only!

SWG100BIO Ex. User Manual

MRU GmbH, D-74172 Neckarsulm