Page 1

mr.steam

mr.steam

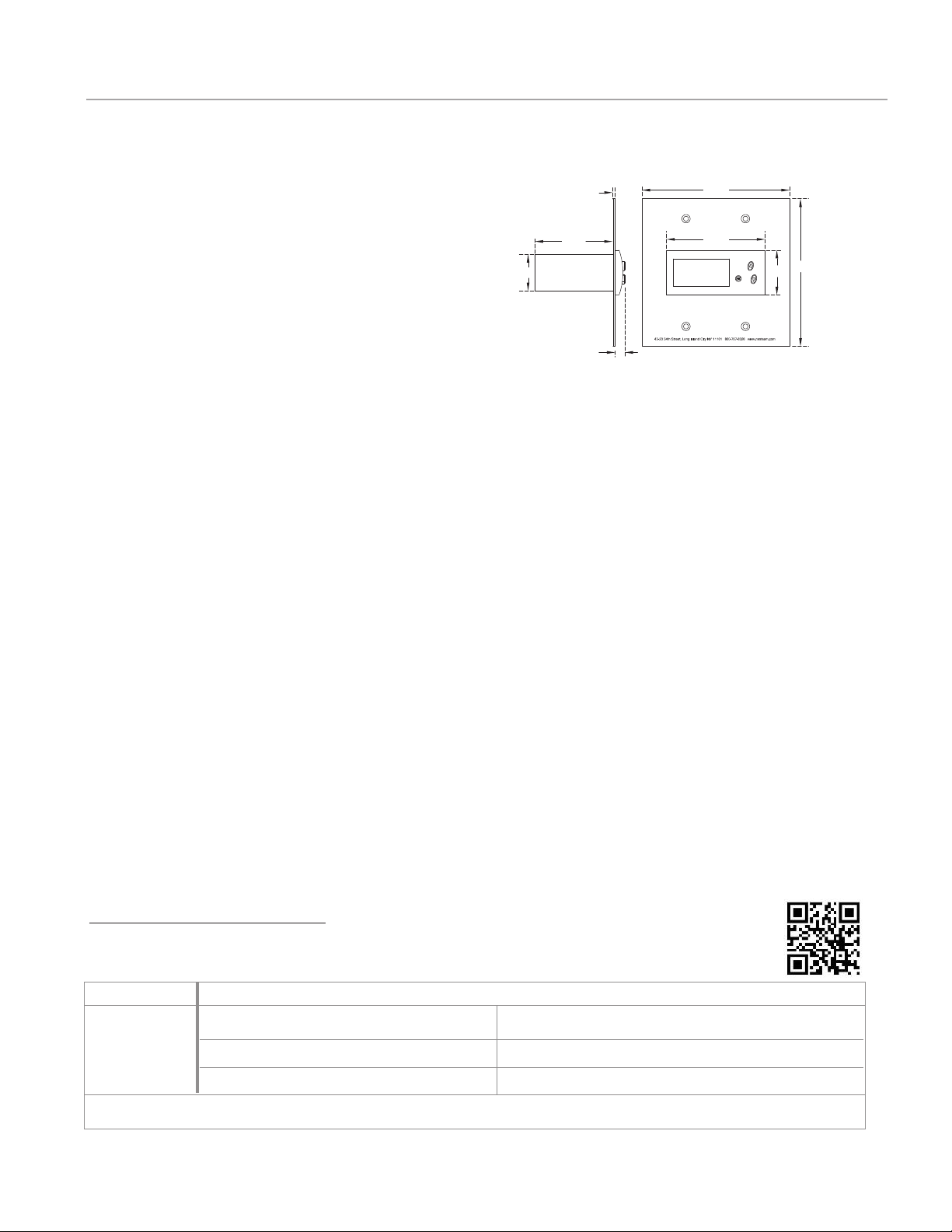

2.38”

.06”

.30”

1.11”

4.50”

3.00”

1.36”

4.50”

®

Technical Specifications

Digital1®Control Package

CU1-D1 KIT CONTENT

• Digital 1 Control (factory

installed on generator)

• Digital 1 Sensor

CU2-D1 KIT CONTENT

For CU 2000 - 4500 serving one room using two steam

solenoid valves and two steamheads.

• Digital 1 Control (factory installed on generator)

• Two ¾" Steam Solenoid Valve

and ¾" Steamhead

DIGITAL 1 CONTROL INSTALLATION

•

Digital 1 Control uses 120V, 1PH control voltage supply.

• If Digital 1 Control is not factory installed on generator,

refer to PUR 100376 for installation instructions.

OPERATING PARAMETERS

• Operating Temperature Range 80-120°F (26.5 - 49°C)

• Backup Temperature shut off fixed at 130°F (54.5°C)

BACKUP TEMPERATURE SHUT-OFF

•

In the event room conditions or environment cause the

temperature to reach 130 °F (54.5 °C) the Digital 1

Control will shut off power to the steam bath generator.

• The Digital 1 control will reset when the temperature

in the room reaches normal operating range.

TEMPERATURE SENSOR INSTALLATION

• Locate sensor on a wall inside the steam room five

(5) feet above the floor

• Do NOT locate the Digital 1 sensors near or above the

steamhead(s) as this may cause direct steam emission

to interfere with steam room temperature regulation.

• Do NOT route sensor cable with power wiring, next

to electric motors or any other location subject to

electrical noise.

• One ¾" Steam Solenoid

alve and ¾" Steamhead

V

• Acrylic Shield

• Sensor Cover

• Digital 1 Sensor

• Two Acrylic Shields, one

for each steamhead

• Sensor Cover

The Digital 1 Control maintains selected room temperature

and features a high limit shut-off. Provides Steam-On-De-

®

mand

for consistent room temperature comfort and control.

STEAMHEAD INSTALLATION

1. For steam rooms constructed of tile, marble or similar nonporous heat-resistant materials for the enclosure, locate

steam head 12 inches above steam room floor and install

Mr.Steam PN CU-103985 acrylic shield on each steamhead.

IMPORTANT: For Steam rooms using acrylic, fiberglass or other

non-heat resistant materials used for steam room enclosure, install each steamhead 20-30 inches above the floor.

2. Locate each steamhead away from bather seating area and

away from traffic patterns as required to prevent incidental

contact with steamhead or direct steam emissions.

3. NOTE: To preserve the steamhead finish, do not use wrench

or other tools to tighten. Use of proper thread sealant and

hand tightening is usually sufficient.

4. Apply a bead of silicone around the steamhead where it

meets the wall as required to prevent moisture damage.

ACRYLIC SHIELD

Apply a small bead of silicone in the grooves on the top and bottom of the steamhead. Place an Acrylic Shield (PN 103985) over the

steamhead until the tabs engage the grooves in the steamhead.

STEAM SOLENOID VALVE INSTALLATION

The steam solenoid valve is powered by the CU Steam Generators 120 VAC control circuit.

• The steam solenoid valve:

• Should be plumbed as close as practical to the steam room

• Must be installed outside the steam room

• Must remain accessible for service

• Shall be plumbed horizontally

FOR ILLUSTRATIVE PURPOSES ONLY. IMPORTANT NOTE: FOR SAFE AND TROUBLE FREE INSTALLATION

visit mrsteam.com or scan the QR code before installation to download the Installation, Operation and Maintenance

Manual or refer to the manual provided with the unit.

MODEL PROJECT INFORMATION

CU1-D1

CU1-D2

Notes:

mr.steam

43-20 34th Street, Long Island City, NY 11101 tel: 1 800 76 STEAM fax: 718 472 3256

9410 S. La Cienega Blvd. Inglewood CA 90301 tel: 1 800 72 STEAM fax: 310 216 2944

Location:

Architect:

Engineer:

®

Sussman-Automatic Corp®

Contractor:

Submitted By:

Date:

hello@mrsteam.com www.mrsteam.com

TS0054 REV 7.14

Loading...

Loading...