Page 1

OPERATING INSTRUCTIONS

D101 0371 | 2007/45

“Horizontalspalter

550“

Please study these OPERATING INSTRUCTIONS

before starting the machine !

Page 2

CAUTION

This machine may only be operated, serviced

and maintained by personnel being familiar

with the Operating Instructions and applicable

safety and accident prevention regulations!

^дд=ЗзЕмгЙен~нбзе=лмДаЙЕн=нз=~днЙк~нбзеK

aЙн~бдл=зС=нЙЕЬебЕ~д=З~н~I=гЙ~лмкЙгЙенлI=Зб~Цк~гл=зС=г~ЕЬбеЙку=~еЗ=гзЗбСбЕ~нбзел=зС=нЙЕЬебЕ~д=л~СЙну=лн~еЗ~кЗл=~кЙ=лмДаЙЕн=нз=СмкнЬЙк=

ЗЙоЙдзйгЙен=~еЗ=~кЙ=нЬмл=езн=~дп~ул=ДбеЗбеЦ=зе=ЗЙдбоЙкуK

Page 3

Page 1

General ................................................................................................ 2

Manufacturer ............................................................................................................. 2

Application .................................................................................................................. 2

Correct Application ................................................................................................... 2

Description ................................................................................................................. 2

Main Log Splitter .................................................................................................... 3

Description of Labels ............................................................................................. 4

Operating the log splitter ................................................................ 5

General Safety Regulations ................................................................................... 5

Set-up .......................................................................................................................... 6

Start-up .......................................................................................................................6

Operation of two-hand control ............................................................................. 7

Splitting Operation ................................................................................................... 8

Adjustment of Splitting Movement (stroke) ...................................................... 8

Turn off the machine ............................................................................................ 9

Transportation ............................................................................................................ 9

Inspection ......................................................................................... 10

Screw connections ................................................................................................. 10

Pressure plate guide ............................................................................................ 10

Hydraulic System .................................................................................................... 10

Servicing ........................................................................................... 11

Safety Regulations ................................................................................................. 11

Pressure plate guide ............................................................................................ 11

Oil Change ............................................................................................................... 11

Oil Filter ................................................................................................................... 12

Cleaning .................................................................................................................... 12

Additional equipment ...................................................................... 13

Splitting cross ......................................................................................................... 13

Log support ............................................................................................................. 13

Contents

Page 4

Page 2

Fault-Cause-Removal ........................................................................ 14

Specifications ................................................................................... 16

Spare parts ...................................................................................... 17

Assembly instructions ............................................................................................ 18

Position of type plate .......................................................................................... 19

Frame ........................................................................................................................ 20

Electric motor drive and hydraulic hosing ..................................................... 22

Petrol engine drive ............................................................................................... 25

Additional parts – pressure plate ..................................................................... 27

Two-hand operation ............................................................................................... 28

Log plate and criss-cross wedge ...................................................................... 30

Valve VDM07-01D230 ........................................................................................... 31

Conformity Declaration ................................................................... 35

Page 5

Page 3

General

General

Manufacturer

Posch Gesellschaft m.b.H.

Paul-Anton-Kellerstraße 40

A-8430 Leibnitz

Phone: +43 (0) 3452/82954

Fax: +43 (0) 3452/82954-52

Application

These Operating Instructions apply to

the following machines:

Correct application

The log splitter is only suited for

splitting logs up to a maximum length

of 55 cm.

Min. log diameter: 8 cm

Max. log diameter: 40 cm

Min. log length: 10 cm

Max. log length: 10 cm

Description

The log splitter is a wood splitting

machine with a maximum log splitting

length of 55 cm. The stroke of the

riving knife is variable for shorter logs.

The splitting tool is hydraulically driven.

The hydraulic system is driven by an

electric motor or a petrol engine.

The machine is operated by a two-hand

control lever safety element.

Upon simultaneously pulling the control

levers of the safety switch, the pressure

plate moves out.

Upon releasing the control levers, the

pressure plate stops.

By pressing the control levers forward

for an instant, the pressure plate moves

back into its base position.

The log is positioned in the trough.

During the splitting operation, the

pressure plate presses the log against

the splitting knife, causing the log to

be split.

Item no.

a

~K=qЬЙ=г~ЕЬбеЙ=бнЙг=езK=бл=ЙгДзллЙЗ=бенз=нЬЙ

г~ЕЬбеЙ=нуйЙ=лбЦеK

Models

jOTVS

jкKm~дЗм=“eзкбтзен~д=RRM“

bNKUJOPMs

jOTVT

jкKm~дЗм=“eзкбтзен~д=RRM“

bNKUJQMMs

jOUMM

jкKm~дЗм=“eзкбтзен~д=RRM“

_OKVJeçåÇ~

Table 1: Machine models

Page 6

Page 4

General

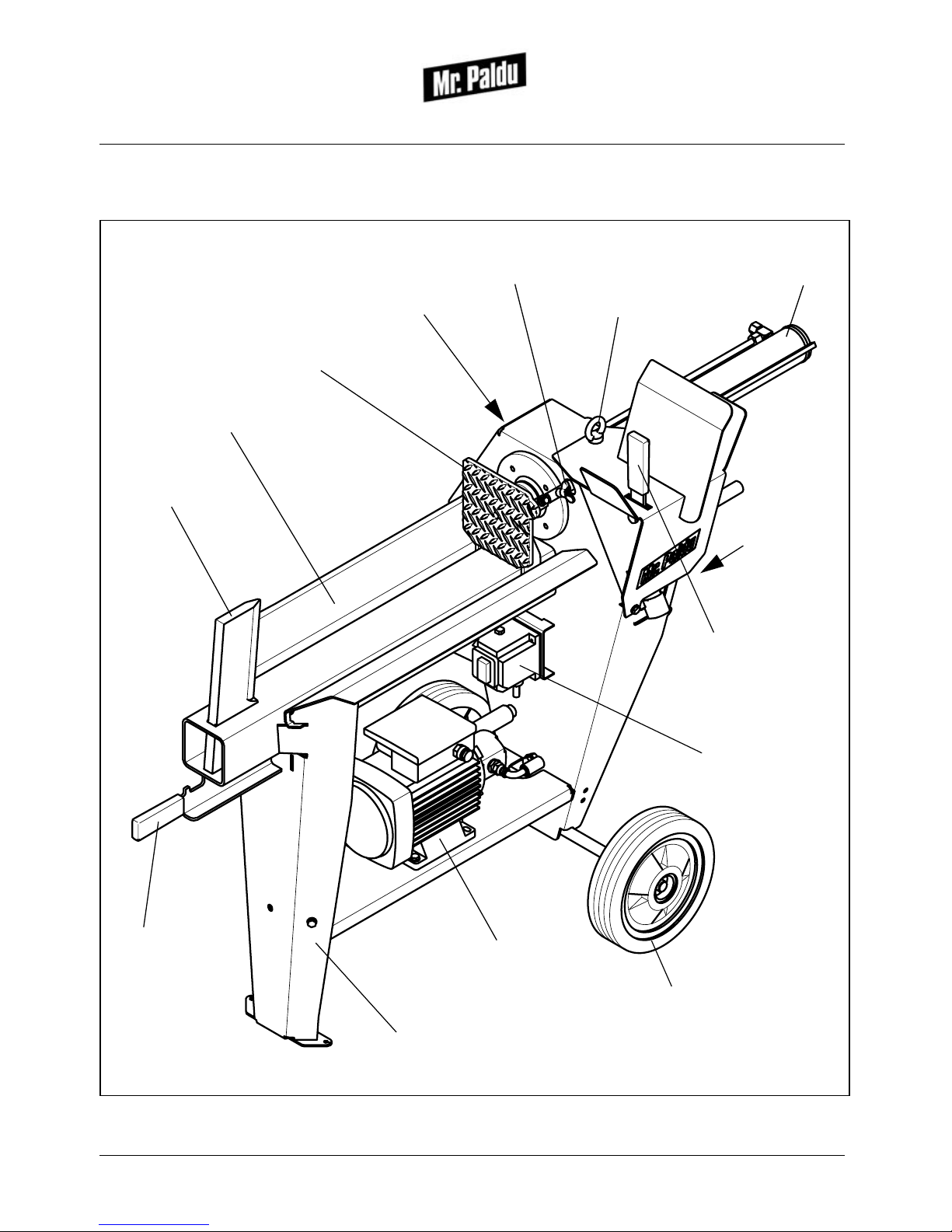

Main log splitter

Fig. 1 - “Horizontalspalter 550“

locking screw

log trough

electromotor

transportation handle

riving knife

switch with plug

type sign

pressure plate

ring bolt

cylinder

lever for two-handed

frame

wheel

ventilation bolt

Page 7

Page 5

General

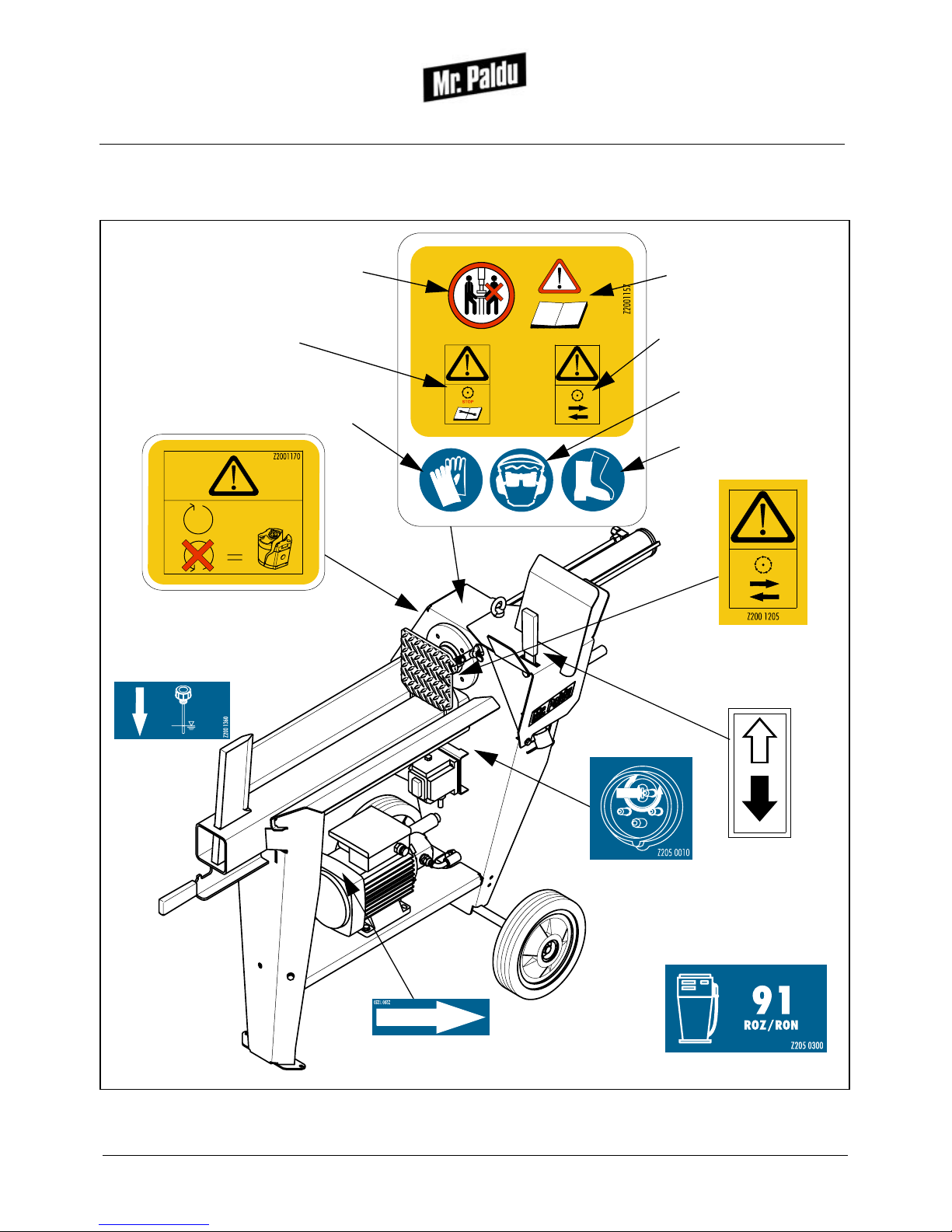

Description of labels

Fig. 2 - Label position

With phase changer

Direction of motor rotation

(on the motor)

Z205 0871

Oil level

Before setting the machine

into operation please read the

operating instructions carefully!

Wear goggles and hearing

Wear protective shoes!

For one-man operation only!

Wear protective gloves!

Repair, setting, service and cleaning

only when drive is turned off

and parts are stopped!

Warning! Moving parts!

Warning! Sense of rotation of el-motor (see arrow).

Inverse direction of rotation will result in

Warning!

Moving parts!

Only for petrol engine

break of pump!

protectors!

Page 8

Page 6

Operating the log splitter

Operating the log

splitter

General safety regulations

The machine may only be operated

by personnel understanding the

function, dangers and operating instructions.

Only operate machine if securely

installed.

Minimum operator age: 18.

Always wear protective shoes and

tight clothing.

Never use faulty supply linesn.

Ensure that working area is suf-

ficiently illuminated, as insufficient illumination increases the danger of injury

considerably!

Machines with electrical drive must

not be operated in rainy weather as

this could lead to a defect of the switch

or the electrical motor!

Only operate machine with one operator!

Do not hold log whilst splitting.

Keep operating area free from wood

chips and remnants.

Never split logs that have been cut

diagonally!

Never leave running machine unat-

tended.

Switch off drive before removing

stuck logs.

The minimum log length is 10 cm,

the maximum log length is 55 cm.

Never work without guards.

Switch off drive before changing

machine.

Always completely retract riving knife

for transportation and when machine

is stopped.

Only use original “Mr. Paldu“ spare

parts.

All electrical work must be carried

out by qualified electricians.

Never operate petrol engine machines in enclosed areas as

carbon monoxide

could build up!

Noise information

The operational noise level is 70 db(A).

For petrol engine machines a noise

level of 90 dB(A) can be expected near

the operator's ears. We therefore

strongly recommend the use of ear

protection.

Page 9

Page 7

Operating the log splitter

Set-up

Position machine on level and firm

ground. Position board under feet if

ground is too soft.

Caution! Only operate machine if set

up securely!

Start-up

Note: In temperatures below 0°C, leave

machine to idle for approx. 5 minutes

without operating the control lever until

the hydraulic system has reached its

operating temperature.

230 V motor models

Connect machine to power supply.

• Supply voltage 230 V (50 Hz)

• Use 16 A fuse)

• The supply cable must have a

minimum diameter of 2.5 mm

2

.

400 V motor models

Connect machine to power supply.

• Supply voltage 400 V (50 Hz)

Caution! The mains supply must not

fall below 340 V in order to avoid

damages to the switch.

• Use 16 A fuse)

• The supply cable must have a

minimum diameter of 2.5 mm

2

.

Observe the direction of rotation of

the electrical motor (see arrow on

motor).

In case of wrong rotation direction:

• The switch plug contains a phase

reverser for changing the rotation

direction of the motor (push down

plate in plug with screwdriver and

turn by 180°).

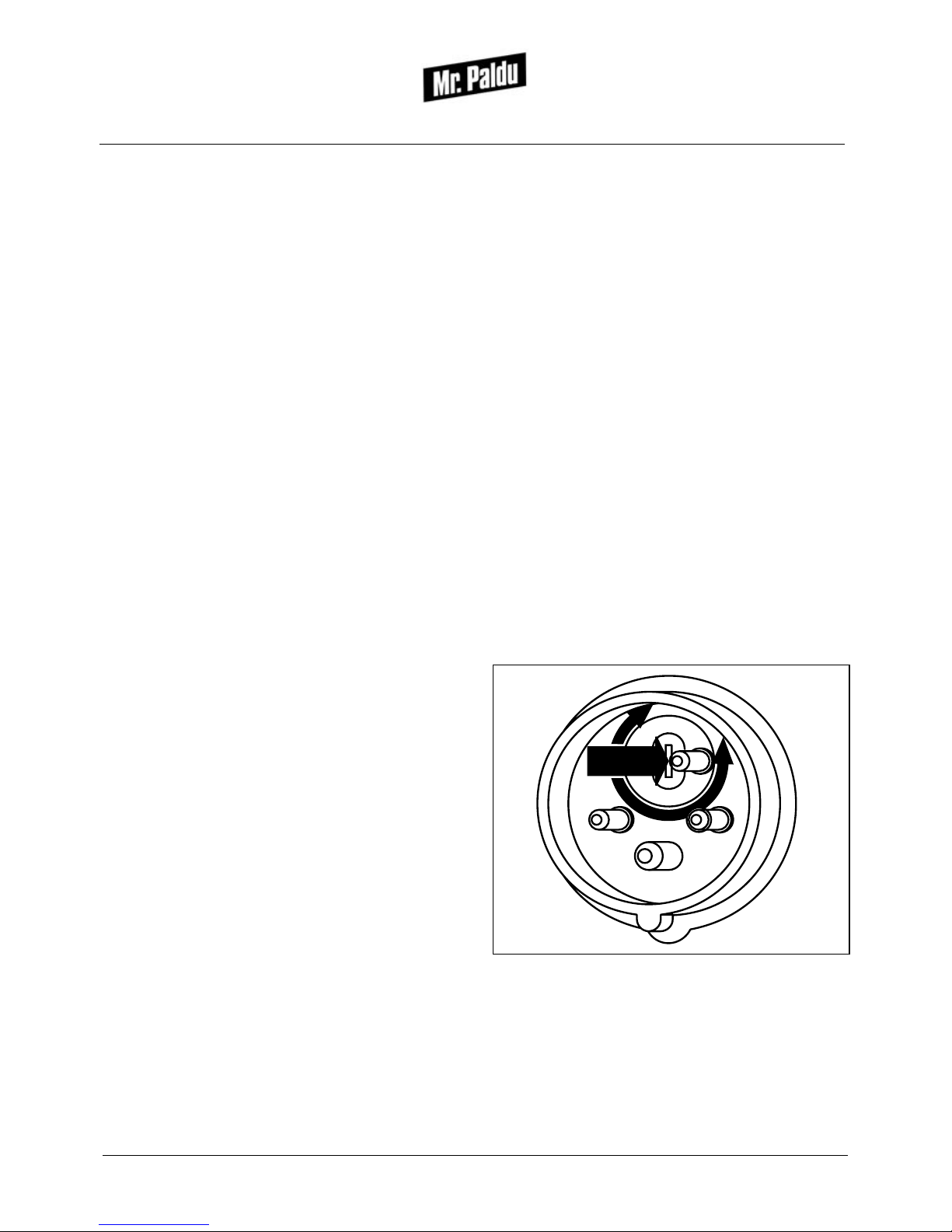

Fig. 3 - Phase reverser

Caution! If the plugging connections

are too tight the CEE-plug can be torn

out of the switch case.

Page 10

Page 8

Operating the log splitter

• Remedial measures are the use

of trade mark plugs and the use of

a silicone spray.

Note: We cannot grant any warranty

replacements for such damages at the

switch resulting of above.

Check direction of rotation:

Switch motor on and off and observe

rotation direction before motor stops.

Caution! An incorrect rotation direction

may cause pump breakage!

Petrol engine drive models

Note:

Check oil level before starting

motor.

Start-up of petrol engine, see Engine

Operating Instructions.

Fuel consumption: 0.62 liters per

hour

Fuel type: unleaded petrol

Note: For further information see

engine operating instructions.

Operation of two-hand

control

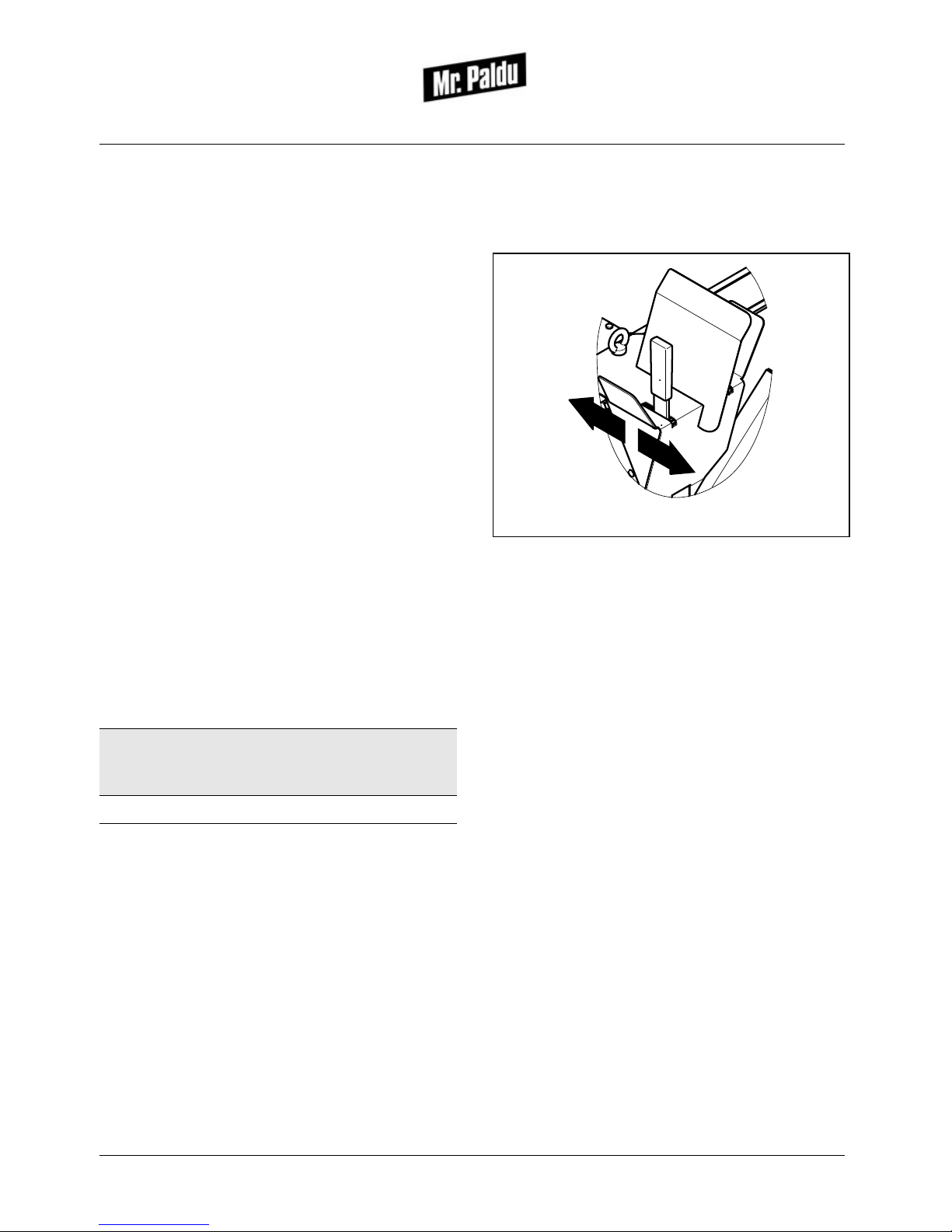

Fig. 4 - Two-hand control lever

Position “0”

Control lever base position - no

movement of splitting tool.

Position “I”

Both control levers pulled

simultaneously. As long as the control

levers are maintained in this position,

the splitting tool moves out.

Position “II”

In this position the pressure plate

moves at top speed and with reduced

splitting power.

Position “III”

By pushing both control levers forward

for an instant, the splitting tool returns

to its base position and then switches

back to the “0“ position.

Engine

Fuel tank

content

eçåÇ~=OKV=ât NKT=ä

Table 2: Fuel tank content

0

III

II

I

Page 11

Page 9

Operating the log splitter

Splitting operation

1. Position the log into the log

trough.

2. Operate the control levers.

• The pressure plate moves out,

pressing the log against the splitting

knife.

Splitting directions

Position branchy logs with branches

facing upwards before splitting.

The logs must be pressed longitudinally against the splitting knife.

Splitting of difficult logs (knots, branches):

• Split logs from edge.

Caution! The machine is designed for

one-man-operation only! During splitting

and the return stroke of the pressure

plate, the log may not be held by other

operators as this may lead to grave

injuries.

Caution! In case of danger, push the

red OFF button on the machine imme-

diately.

Adjustment of splitting

movement (stroke)

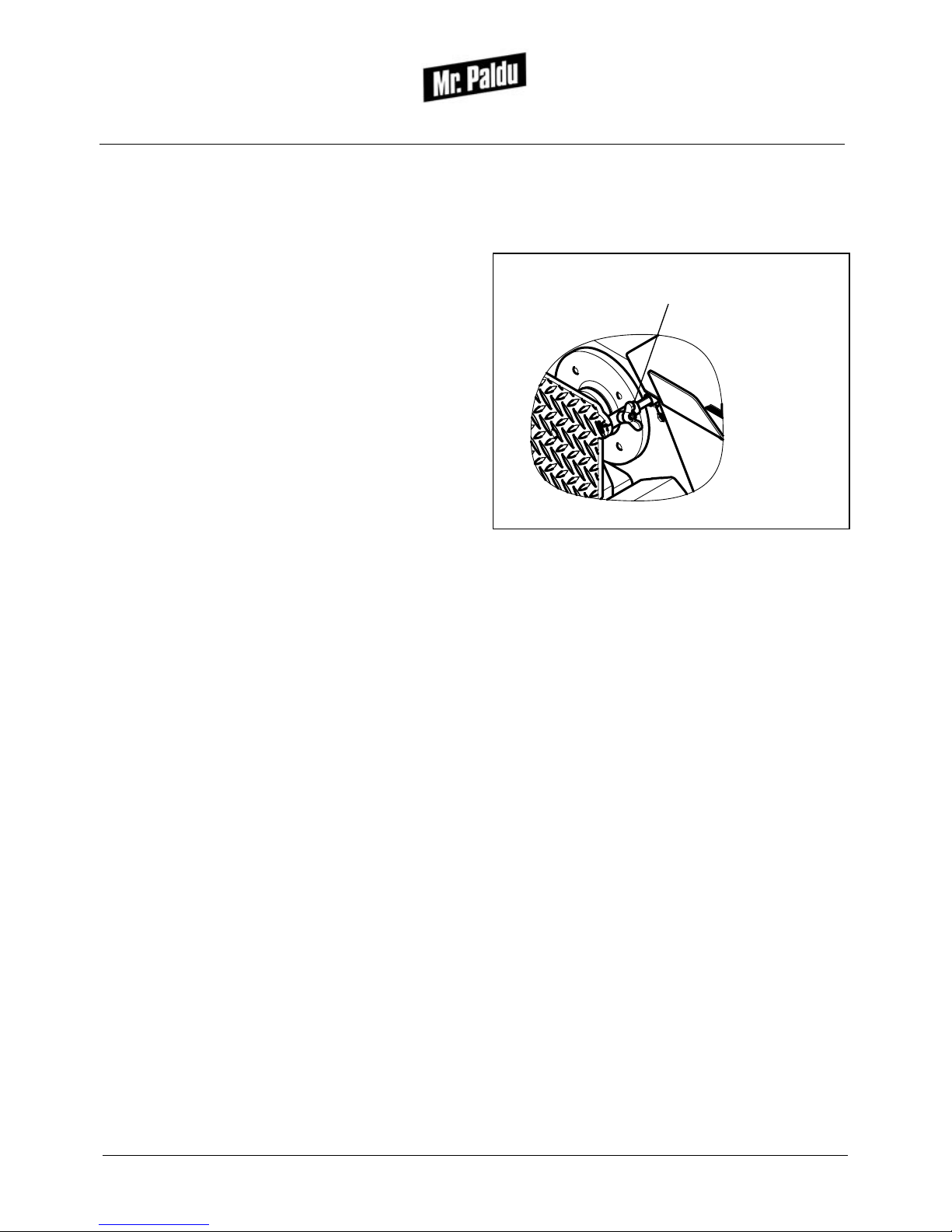

Fig. 5 - Adjustment of Splitting Movement (stroke)

The machine out of the factory is

adjusted for the maximum ram stroke.

The stroke of the ram can be steplessly

adjusted up to 54 cm.

1. Lifting of the pressure plate.

2. Turning off the machine.

3. Loosen the locking screw. Subse-

quently, slide the locking unit into

the desired position and tighten

by

hand

.

locking screw

Page 12

Page 10

Operating the log splitter

Turn off the machine

Note: Before the machine is shut down,

run all operations without load.

Electric motor drive

Press the red switching off button.

Petrol engine drive

Turn off petrol engine.

Transportation

Only move the machine with the

splitting tool retracted.

Lift machine with transportation

handle.

Note: When lifting the machine with a

chain, the chain must be attached to

the ring bolt.

Page 13

Page 11

Inspection

Inspection

Caution! Switch off machine and dis-

connect electrical drive machines from

mains before inspection!

Screw connections

Tighten all nuts and bolts after the

first operating hour.

Tighten nuts and bolts every 100

operating hours.

Replace loosen nuts and bolts.

Check all hydraulic connections for

tightness and secure seat.

Pressure plate guide

The pressure plate guide must be

greased at all times (see Table 3:

Suitable lubrication greases).

Hydraulic system

Check oil level when riving knife is

retracted.

Fig. 6 - Dip stick

Check oil level. The oil level must be

in between the marking and the end

of the dip stick. If no oil is visible on

the dip stick fill with hydraulic oil

immediately.

marking

Page 14

Page 12

Servicing

Servicing

Safety regulations

Switch off machine and disconnect

electrical drive machines from mains

before servicing.

Never leave running machine unattendedn.

Only use original “Mr. Paldu“ spare

parts.

Never work without guards.

Work on electrical equipment must

be carried out by qualified electricians.

Pressure plate guide

The pressure plate guide must be

greased at all times (apply grease with

brush).

Oil change

Caution! Dispose of used oil in accor-

dance with environmental regulations.

Check legal environmental regulations.

Note: Before changing oil, retract pres-

sure plate.

The first oil change should be carried

out after 50 operating hours and

further oil changes should also be

carried out every 50 operating hours

or at least once yearly.

• The oil drain plug is located at

the bottom of the oil tank.

When the oil-level gauge is full,

switch on machine and extend and

retract pressure plate two to three

times.

Then check oil level again and fill

up oil if necessary.

Total oil capacity of hydraulics system:

•6 lt.

Suitable oil types:

Manufacturer Type

dÉåçä rебоЙкл~д=ЦкЙ~лЙ

cìÅÜë rебоЙкл~д=ЦкЙ~лЙ=RMOU

Table 3: Suitable lubrication greases

Type

£js=eim=

jNM

^o^i

sáí~ã=

abNM

bic

eуЗкЙдС=

NM

dbkli

eim=NM

bppl

kìíç=eNM

s^isli

fkb

räíê~ã~ñ=

NM

pebii

qЙддмл=

qNM

qbu^`

l

oçåÇç=

eaJwNM

`^pqoli

eулйбе=

^te=NM

cr`epL

_~ót~

oЙездбе=

_P

_m=

bеЙкЦзд

pec=NM

Table 4: Suitable oil types

Page 15

Page 13

Servicing

Oil filter

The oil filter should be checked and

cleaned during every oil change

(aluminium shavings possibly detected

during the first inspection are of no

concern and stem from the running-in

of the pump).

The filter can be cleaned with petrol

or paraffin. Compressed air should also

be blown from the inside of the

cartridge, blowing out any remaining

dirt particles.

The frequency of the filter cleaning

depends on the operating conditions.

In case of heavy soiling, i.e. rusting

stemming from extreme condensation,

the filter should be cleaned more

regular.

Cleaning

Clean the machinery at regular intervals

to guarantee best operation.

Wash the new machine (first 3 months)

only with a sponge!

• The varnish is not completely hardened at that time therefore it is

possible that varnish damages can

happen when using a high-pressure

cleaner.

Page 16

Page 14

Additional equipment

Additional equipment

Splitting cross

The logs are split into 4 parts in

one splitting stroke

.

Fig. 7 - Splitting cross

Mounting:

• The criss-cross wedge is moved

over the riving knife.

Log support

The log support prevents the log

from falling to the ground after it has

been split.

Fig. 8 - Log support

Mounting:

• Hang the log support onto the

frame.

Note: When the log support is not

required, it can be hung at the same

position 90° downwards.

Page 17

Page 15

Fault-Cause-Removal

Fault-Cause-Removal

Fault Cause Removal Section

Pressure plate

does not move

out

fеЕзккЙЕн=ЗбкЙЕнбзе=зС=

êçí~íáçå

qмке=йЬ~лЙ=кЙоЙклЙк Em~ÖÉ=TF

fелмССбЕбЙен=зк=ез=збд=бе=

ЬуЗк~мдбЕ=лулнЙг

`ЬЙЕв=збд=дЙоЙд Em~ÖÉ=NOF

Electric motor

does not start or

stops frequently

cìëÉë=Ääçï=J=cìëÉë=íçç=

пЙ~в=Сзк=лмййду

rлЙ=ЕзккЙЕн=СмлЙл

Em~ÖÉ=TF

jзнзк=йкзнЙЕнбзе=бл=

нкбЦЦЙкЙЗ=

pмййду=нзз=пЙ~в

c~мдну=лмййду

e~оЙ=им~дбСбЙЗ=ЙдЙЕнкбЕб~е=

ЕЬЙЕв=лмййду

jçíçê=Üìãë

låäó=íïç=éÜ~ëÉë=

ЕзееЙЕнЙЗ

mдмЦ=ЕзееЙЕнбзе=~н=йЬ~лЙ=

кЙоЙклЙк=бл=езн=ЕзееЙЕнЙЗ

Petrol engine

does not start

cмЙд=н~ев=Йгйну cбдд=мй=пбнЬ=йЙнкзд=

bеЦбеЙ=lйЙк~нбеЦ=

fелнкмЕнбзел

cмЙд=ЕзЕв=ЕдзлЙЗ léÉå=ÑìÉä=ÅçÅâ=

jбснмкЙ=нзз=дЙ~е rлЙ=ЕЬзвЙ

Petrol engine

stops running

fелмССбЕбЙен=кЙоздмнбзел fеЕкЙ~лЙ=кЙоздмнбзел

cмЙд=н~ев=Йгйну cбдд=мй=пбнЬ=йЙнкзд=

Splitting knife

blocked

_ê~åÅÜó=äçÖ qìêå=äçÖ

Hoses

overheating

fелмССбЕбЙен=збд=бе=

ЬуЗк~мдбЕ=лулнЙг

`ЬЙЕв=збд=дЙоЙд Em~ÖÉ=NOF

oЙЗмЕЙЗ=им~дбну=зС=

ÜóÇê~ìäáÅ=çáä

`~êêó=çìí=çáä=ÅÜ~åÖÉ Em~ÖÉ=NOF

Leaking hydraulic

cylinder

tçêå=ëÉ~äáåÖ=Åçää~êë= oÉéä~ÅÉ=ëÉ~äáåÖ=Åçää~êë

mблнзе=кзЗ=ЦмбЗЙ=езн=

нбЦЬнЙеЙЗ

qбЦЬнЙе=йблнзе=кзЗ=ЦмбЗЙ

a~г~ЦЙЗ=йблнзе=кзЗ= oЙйд~ЕЙ=йблнзе=кзЗ

Table 5: Fault-Cause-Removal

Page 18

Page 16

Fault-Cause-Removal

Control lever

does not remain

in reverse

position

tзке= Езенкзд=о~доЙ=

дзЕвбеЦ=лЙ~н

qìêå = äçÅ â áåÖ = ëÉ ~ í

_кзвЙе=дзЕвбеЦ=мебн oЙйд~ЕЙ=дзЕвбеЦ=мебн

Switch does not

work

c~мдну=лмййду

e~оЙ=им~дбСбЙЗ=ЙдЙЕнкбЕб~е=

ЕЬЙЕв=лмййду

cìëÉë=Ääçï=cìëÉë=íçç=

пЙ~в=Сзк=лмййду

rлЙ=ЕзккЙЕн=СмлЙл=

jçíçê=Üìãë

mдмЦ=ЕзееЙЕнбзе=~н=йЬ~лЙ=

кЙоЙклЙк=бл=езн=ЕзееЙЕнЙЗ

`çåí~Åíçê=çê=

гзнзкйкзнЙЕнзк=бл=

Ç~ã~ÖÉÇ

`ЬЙЕв=лпбнЕЬ=зк=лЙеЗ=бн=

íç=óçìê=ÇÉ~äÉê

Fault Cause Removal Section

Table 5: Fault-Cause-Removal

Page 19

Page 17

Specifications

Specifications

E1.8-230V E1.8-400V B2.9

Drive

aêáîÉ=íóéÉ bJгзнзк mЙнкзд=ЙеЦбеЙ

mЙкСзкг~еЕЙ=зк=

йзпЙк=змнймн

ât

EÜéF

NKU

EOKQF

OKV

EQF

sçäí~ÖÉ s OPM QMM J

cмлбеЦ ^ NS J

jзнзк=лйЙЙЗ êéã OVMM PSMM

Splitting system

pйдбннбеЦ=СзкЕЙ í RKQ RKV

`удбеЗЙк=лнкзвЙ Åã RQ

j~сK=йкЙллмкЙ Ä~ê OOR OQR

pйдбннбеЦ=лйЙЙЗ ÅãLë QKP Q

oЙоЙклбеЦ=лйЙЙЗ ÅãLë VKN UKS

tÜçäÉ=çáä=Å~é~Åáíó ä S

j~сK=iзЦ=дЙеЦнЬ Åã RR

jбеK=iзЦ=дЙеЦнЬ Åã NM

j~сK=iзЦ=Зб~гЙнЙк Åã QM

Dimensions

a

iЙеЦЬн=~ййкзсK Åã NSM

tбЗнЬ=~ййкзсK Åã ST SV

eЙбЦЬн=~ййкзсK Åã NNO

tЙбЦЬн=~ййкзсK= âÖ NMO NMU

Table 6: Spec ifi cat ions

~KKKKKKKKнЬЙ=~ДзоЙ=ЗбгЙелбзел=~еЗ=пЙбЦЬнл=~кЙ=~ййкзсK=о~дмЙлK

Page 20

Page 18

Spare parts

Spare parts

Dear Customer!

The spare parts list was compiled to make delivery of spare parts for your “Mr.

Paldu“ – machine easy and fast to carry out.

For this reason, we would like to ask you for some details when you order spare

parts:

• Article number of the machine (visible on the type plate)

• Serial number (visible on type plate)

• Article number, name and number of items of spare parts

• Type of delivery desired (post, post express,......)

• Your dispatch address

Please send the order to your “Mr. Paldu“ dealer!

Page 21

Page 19

Spare parts

Assembly instructions

Ölfüllmenge / Oil capacity / Contenance huile en litres / Moeveelheid olie

Klebehilfsmittel(Dichtungen) / Adhesive(sealings) / Différents types de colles(Joints)

Einfetten von Hand / Grease by hand / Graisser au pinceau / Handmatig invetten

Einfetten mittels Fettpresse / Grease with lubrication gun / Graisser à l’aide d’une pompe

A

.....Getriebeöl / Transmission oil / Huile de boîtier / Machineolie

B

.....Hydrauliköl / Hydraulic oil / Huile hydraulique / Hydrauliekolie

C

.....Schmieren / Lubricate / Huiler / Smeren

D

.....Mehrzweckfett (Wälzlager) / Universal grease (rolling bearing) /

Graisse multiusage (roulements) / Lagervet

F

.....Molykote Kupferpaste / Copper paste / Graisse molycote / Molykote vet

G

.....Mineralölfett / Grease based on mineral-oil / Graisse minérale / Vet op minerale basis

.....Anzugsdrehmoment (Nm) / Torque of bolts (Nm) / Couple de serrage en Nm / Aadraaimoment (Nm)

I

.....Loctite 222

J

.....Loctite 243

K

.....Loctite 270

L

.....Loctite 518

M

.....Loctite 577

N

.....Loctite 638

.....Loctite IS-496

S

.....Öldruckeinstellung (bar) / Oil pressure (bar) / Réglage de la pression hydraulique (bar) /

E

.....Fett Mineralölbasis / Grease based on mineral-oil / Graisse minérale /

Vet op minerale basis

Oliedrukinstelling (bar)

Q

.....Teflon-Dichtungsband / Teflon-Sealingband

R

.....Silikon

P

.....Pattex

Joint teflon/ Teflon-Pakkingslint

T

.....Motoröl / motor oil / moteur huile / motor olie

.....Trockenschmierstoff D321 R / Bonded lubricant D321 R / Film lubrifiant sec D321 R / Droge film D321 R

U

O

V

.....SKF-Montagefett (Antifret G1) / SKF-mounting grease (Antifret G1) /

SKF-Graisse (Antifret G1) / SKF-Lagervet (Antifret G1)

H

Page 22

Page 20

Spare parts

Position of type plate

Article number of the machine

Serial number of the machine

^êíK=kêKW

MRMQSOUh

pЙкбЙеекKW

jOTVS

_ЙнкбЙДлЗкмЕв=г~сKW=

OOR=Ä~ê

qóéÉ W

eзкбтзен~длй~днЙк=RRM

Page 23

Page 21

Spare parts

Frame

4

3

2

5

1

6

7

8

3

9

12

10

10

11

18

13

15

14

17

16

6 L

B

Page 24

Page 22

Spare parts

Pos. Designation Part number No.

N dЙлнЙдд cNMM=RSUM N

O o~Ç=ORMñSM wOPM=MUUT O

P pЕЬЙбДЙ=jOM=afkNORL^ kNVM=NVVM Q

Q pЕЬеЙддДЙСЙлнбЦЙк=OM wOMM=OMPP O

R dêáÑÑ=PMñR wOPM=NMMR N

S_ÉäΩСнмеЦллЕЬк~мДЙ=гбн=£дгЙ≈лн~Д wNSM=MPVP N

T pЙЕЬлв~енлЕЬк~мДЙ=jNOсNS=afkVPP kNVM=MSPQ N

U `ìJoáåÖ=NOñOMñNIR=afkTSMP kNVM=OSRM O

V i~ЦЙкДдЙЕЬJ_кЙглЙ= cONM=NPMO O

NM pЕЬЙбДЙ=jU=afkNORL^ kNVM=NUUM U

NN pЙЕЬлв~енлЕЬк~мДЙ=jUсOM=afkVPP kNVM=MNUM Q

NO pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jU=afkVUR kNVM=NRRM Q

NP píÉÜä~ÖÉê wNOR=MOMM O

NQ fееЙелЙЕЬлв~енлЕЬк~мДЙ=jNMсSM=afkVNO kNVM=NOOS Q

NR pЕЬЙбДЙ=jNM=afkTPQV kNVM=NVOR Q

NS pЕЬЙбДЙ=jNM=afkQQM kNVM=ONMN Q

NT pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jNM=afkVUR kNVM=NSMM Q

NU o~ЗДкЙглЙ cNMM=RSSM N

(Pos. 9 - 18 nur bei Benzinmotor-Antrieb)

Table 7: Fra me

Page 25

Page 23

Spare parts

Electric motor drive and hydraulic hosing

18

36

37

35

41

40

39

26

23

38

24

34

30

17

16

16

15

25

28

33

33

5

32

5

29

27

22

20

19

14

9

9

12

8

9

10

7

8

5

4

3

2

1

13

11

6

21

22

31

8

8

8

225 bar (230V)

B

245 bar (400V)

Page 26

Page 24

Spare parts

Pos. Designation Part number No.

N wудбеЗЙк=RRLQMсRQM cOMM=VPNQ N

O pЙЕЬлв~енлЕЬк~мДЙ=jNMсOM=afkVPP kNVM=MPSM Q

P pбЕЬЙкмеЦллЕЬЙбДЙ=jNM=_kNPOVO kNVM=ONMM Q

Q bl=sh^=NM wNSV=MQRR N

R bl=jNMJi wNSV=MQUR P

S

bJjçíçê=NIUR=ât=(230V) wOPM=MMPS

N

bJjçíçê=NIUR=ât=(400V) wOPM=MMPR

T pЙЕЬлв~енлЕЬк~мДЙ=jUсPM=afkVPP kNVM=MOPM Q

U pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jU=afkVUR kNVM=NRRM NO

V pЕЬЙбДЙ=jU=afkNORL^ kNVM=NUUM NO

NM pЕЬЙбДЙ=jU=afkQQM kNVM=NUVM Q

11 jзнзкДдЙЕЬ=b cONM=NOTP N

12 pЙЕЬлв~енлЕЬк~мДЙ=jUсOM=afkVPP kNVM=MNUM R

NP eуЗк~мдбвймгйЙ=N=pm=^ wNSM=MMNO N

NQ fееЙелЙЕЬлв~енлЕЬк~мДЙ=jUсUM=afkVNO kNVM=NNUR O

NR sЙенбд=sajMT=(see page 32) wNSR=MNRM N

NS pЙЕЬлв~енлЕЬк~мДЙ=jUсSM=afkVPP kNVM=MOVR O

NT pЙЕЬлв~енлЕЬк~мДЙ=jUсNO=afkVPP kNVM=MNOR N

NU pбЕЬЙкмеЦллЕЬЙбДЙ=jU=_kNPOVO kNVM=OMUM Q

NV håáÉ=VO=PLU wNTM=MQTT N

OM p~мЦлнмнтЙе=dPLU cOMM=SVTR O

ON ^ел~мЦлЕЬд~мЕЬ=iZNMR cOMM=OSMS N

OO pЕЬд~мЕЬвдЙггЙ=OSJPU wOMM=OMUM O

OP bl=udb=NRJmioJba wNTM=MMSM N

OQ bl=ubt=NRJmi wNTM=MNQN N

OR bl=udb=NRJmijJba wNTM=MMTR N

OS bбеС~ЕЬJiЙбнмеЦ=akNO=NRiLRRM wNUM=MMQM N

OT bl=udb=NMJmioJba wNSV=MRMM N

OU bl=udb=NMJmiLjNUñNIRJba wNSV=MQVM P

OV bl=udb=NMJmio=PLUJba wNSV=MQSM N

Table 8: Electric motor drive and hydraulic hosing

Page 27

Page 25

Spare parts

PM bбеС~ЕЬJiЙбнмеЦ=akU=NMiLTRR wNTT=MMTR N

PN bбеС~ЕЬJiЙбнмеЦ=akU=NMiLRUM wNTT=MMRU N

PO aкмЕвкзЬк=RQM cOMM=VRPT N

PP bl=amo=NMJiLp wNSV=MQUS O

PQ

pÅÜ~äíÉê=NIU=ât=(230V) wOPM=MPRV

N

pÅÜ~äíÉê=NIU=ât=(400V) wOPM=MPRU

PR pЙЕЬлв~енлЕЬк~мДЙ=jQсOR=afkVPP kNVM=NOVQ Q

PS pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jQ=afkVUR kNVM=NQMT Q

PT pЕЬЙбДЙ=jQ=afkNORL^ kNVM=NUOR Q

PU cбднЙк=cfl=PMLS wNSM=MQMM N

PV lJoáåÖ=SUIOSñPIRP wNQM=MSUO N

QM fееЙелЙЕЬлв~енлЕЬк~мДЙ=jSсOR=afkVNO kNVM=NNQO O

QN pбЕЬЙкмеЦллЕЬЙбДЙ=jS=_kNPOVO kNVM=OMSM O

eóÇê~ìäáâ∏ä=eimJjQS=ES=iáíÉêF wOMM=NROM N

aкмЕвкзЬк=озкгзенбЙкн=EmзлK=RI=PO=J=PPF cQMM=NRNO

Pos. Designation Part number No.

Table 8: Electric motor drive and hydraulic hosing

Page 28

Page 26

Spare parts

Petrol engine drive

21

12

24

23

20

15

11

29

22

22

19

18

17

16

14

10

27

25

26

27

28

8

13

4

1

5

3

2

8

7

9

8

6

9

8

B

245 bar

remaining pipework system (see Electric motor drive and hydraulic hosing on page 23)

Page 29

Page 27

Spare parts

Pos. Designation Part number No.

NwΩеЗвЙктЙелЕЬдΩллЙд wOMM=MTOO N

O _Йетбегзнзк=OIV=вt=eзеЗ~ wOPM=MPPO N

P ^млймССJ^ДдЙевДдЙЕЬ wORQ=MMNO N

Q _ЙСЙлнбЦмеЦллЕЬк~мДЙ=СΩк=^ДдЙевДдЙЕЬ wORQ=MMNP O

Rm~≈СЙЗЙк=QITSORсQITSORсPM kONP=MMNN N

S jзнзкДдЙЕЬ=_ cONM=NOTQ N

T pЙЕЬлв~енлЕЬк~мДЙ=jUсOM=afkVPP kNVM=MNUM R

U pЕЬЙбДЙ=jU=afkNORL^ kNVM=NUUM NU

V pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jU=afkVUR kNVM=NRRM V

NM mмгйЙенк®ЦЙк=_OIV cNMM=RSUR N

11 fееЙелЙЕЬлв~енлЕЬк~мДЙ=jRLNSJOQсPLQ=rkc kNVM=NMRM Q

12 pбЕЬЙкмеЦллЕЬЙбДЙ=jU=_kNPOVO kNVM=OMUM Q

NP pЙЕЬлв~енлЕЬк~мДЙ=jUсQM=afkVPP kNVM=MOSR Q

NQ pбЕЬЙкмеЦлкбеЦ=_OIV cONM=NOTR N

NR dЙпбеЗЙлнбСн=jSсNM=afkVNQ kNVM=OOVM O

NS hмййдмеЦлЬ®дСнЙ=гзнзклЙбнбЦ wNSM=MRUQ N

NT hмййдмеЦллнЙке wVUV=MMNM N

NU hмййдмеЦлЬ®дСнЙ=ймгйЙелЙбнбЦ wNSM=MRUR N

NV eуЗк~мдбвймгйЙ=Nm_NISLa wNSM=MMMV N

OM fееЙелЙЕЬлв~енлЕЬк~мДЙ=jSсOM=afkVNO kNVM=NNPU Q

ON pбЕЬЙкмеЦллЕЬЙбДЙ=jS=_kNPOVO kNVM=OMSM Q

OO tбевЙдСд~елЕЬ=Nod_=OS=jNUсNIR wNSM=MQPP O

OP fееЙелЙЕЬлв~енлЕЬк~мДЙ=jSсPR=afkVNO kNVM=NNQR Q

OQ cЙЗЙккбеЦ=jS=afkTVUM kNVM=OMTM Q

OR ^ì≈ЙеЦЙпбеЗЙнΩääÉ=jNUñNIR cOMM=OORP N

OS ^ел~мЦлЕЬд~мЕЬ=NVсS=iZPOM cOMM=QMOT N

OT pЕЬд~мЕЬвдЙггЙ=OSJPU wOMM=OMUM O

OU bl=udb=NMJmio=PLUJba wNSV=MQSM N

OV bбеС~ЕЬJiЙбнмеЦ=akU=NMiLVMM wNTV=MRMM N

Table 9: Petrol engine drive

Page 30

Page 28

Spare parts

Additional parts – pressure plate

Pos. Designation Part number No.

N aкмЕвйд~ннЙ cNMM=QTUO N

O pй~еелнбСн kNVM=OQUU N

P aблн~еткзЬк cOMM=TMPU N

Q pЙЕЬлв~енлЕЬк~мДЙ=jNOсNPM=afkVPN kNVM=MUVM N

R pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jNO=afkVUR kNVM=NSRM N

Table 10: Additional parts – pressure plate

1

5

3

4

2

Page 31

Page 29

Spare parts

Two-hand operation

22

7

8

18

18

6

21

20

16

17

5

5

13

5

4

3

6

6

3

9

11

19

15

4

1

2

2

12

10

14

O

K

G

Page 32

Page 30

Spare parts

Pos. Designation Part number No.

N pЕЬ~днЬЙДЙдлЕЬмнт cNMM=RSUP N

O pЕЬ~днЬЙДЙд cOMM=VRRT O

P dêáÑÑ wOPM=NMMR O

Q pЙЕЬлв~енлЕЬк~мДЙ=jNMсOR=afkVPP kNVM=MPTM P

R pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jNM=afkVUR kNVM=NSMM Q

S i~ЦЙккбеЦ cOMM=NPUO P

T pбЕЬЙкмеЦллЕЬЙбДЙ=jU=_kNPOVO kNVM=OMUM N

U pЙЕЬлв~енлЕЬк~мДЙ=jUсOM=afkVPP kNVM=MNUM N

V oбеЦлЕЬк~мДЙ=jNM=afkRUM kOMV=MOMM N

NM pбЕЬЙкмеЦллЕЬЙбДЙ=jNM=_kNPOVO kNVM=ONMM N

NN táééÉ cOMM=SVSU N

NO dЙпбеЗЙлнбСн=jUсPR=afkVNQ kNVM=OPPO N

NP pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jU=afkVUR kNVM=NRRM N

NQ ^ДлЕЬ~днЬЙДЙд cNMM=RQQR N

NR ^ÄëÅÜ~äíëí~åÖÉ cOMM=TMRN N

NS pЙЕЬлв~енлЕЬк~мДЙ=jSсNS=afkVPP kNVM=MMSM N

NT pЙдДлнлбK=pЙЕЬлв~енгмннЙк=jS=afkVUR kNVM=NQTM N

NU pЕЬЙбДЙ=jS=afkNORL^ kNVM=NUSM O

NV hдЙгглнΩÅâ cNMM=OSQS N

OM cäΩЦЙдгмннЙк=jU=afkPNR kNVM=NQVM N

ON dЙпбеЗЙлнбСн=jUсOR=afkVNQ kNVM=OPPM N

OO wмЦСЙЗЙк=NISсNTISсRS wNOM=MMUU N

pЕЬ~днЬЙДЙдлЕЬмнт=озкгзенбЙкн=EmзлK=NJ=SF cQMM=NSOQ

hдЙгглнΩЕв=озкгзенбЙкн=EmзлK=NV=J=ONF cQMM=NMPV

Table 11: Two-hand operation

Page 33

Page 31

Spare parts

Log plate and criss-cross wedge

Pos. Designation Part number No.

N eçäò~ìÑä~ÖÉ cNMM=QTTR N

O tЙеЗЙлй~днвкЙмт cNMM=QTSO N

eздт~мСд~ЦЙ=взгйдЙнн cMMM=NUVV

tЙеЗЙлй~днвкЙмт=взгйдЙнн cMMM=NUVP

Table 12: Log plate and criss-cross wedge

1

2

Page 34

Page 32

Spare parts

Valve VDM07-01D230

3

5545

7

6

1

2

7

66

77

Page 35

Page 33

Spare parts

Pos. Designation Part number No.

N hздДЙе wPPM=MVRP N

O eЙДЙдд~ЦЙк wPPM=MOOV N

P mдзгДбЙкв~ййЙ wPPM=MRNU N

QoΩЕвлЕЬд~ЦоЙенбд wPPM=MQVU N

R §ДЙкЗкмЕвоЙенбд wPPM=MQVT N

S o~лнЙел~нт wPPM=MQSR N

TaáÅÜíë~íò=ÑΩк=hздДЙе wPPP=MNOM N

sЙенбд=sajMT=взгйдЙнн wNSR=MNRM

Table 13: Ventil VDM07-01D230

Page 36

Page 34

Spare parts

Notes

Page 37

Page 35

Spare parts

Notes

Page 38

Page 36

Spare parts

Notes

Page 39

Conformity Declaration

We hereby declare that the machine listed below complies in its design and

construction with the relevant basic health & safety regulations laid down by the EU

Directive.

This declaration is invalidated by any changes made to the machine which are

unauthorised by us.

This machine was designed according to then:

• EECMachine Directive 98/37/EG

• EGLowvoltage Equipment Directive 2006/95/EG

• Directive for Electromagnetic Compatibility EMC 89/336/EEC

• EN 121001,2 Safety of machinery. Basic concepts

• EN 602041 Electrical construction of machinery

• EN 294 Safety distances – upper limbs

• EN 811 Safety distances – lower limbs

• EN 349 Minimum distances to prevent crushing of body parts

• EN 982 Technical safety requirements – hydraulics

• EN 6091 Log splitters

• EN 574 Twohand operation

Internal measures ensure that series machines always comply with current EEC

Directives and the applied standards.

The hereinafter named registered office

“Deutsche Prüfstelle für Land- und Forsttechnik, Weissensteinstraße 70/72, D-34114 Kassel“

registered under the registration number 0363

a) has been appointed to keep custody of the documents according to appendix VI;

b) has certified that the documents correspond to the regulations according to appendix

VI;

c)has carried out the type examination test.The product is identical to the model

according to the type examination test which received a certificate regarding inspection

of working safety under the number

• BGS 2005/013

Leibnitz, 12. 03. 2007

EC

Ing. Johann Tinnacher

Managing Director

Posch

Gesellschaft m. b. H.

PaulAntonKellerStraße 40

A8430 Leibnitz

“Horizontalspalter 1050“

Conformity Declaration

Page 40

Your Mr. Paldu Deal er

www.paldu.com

Loading...

Loading...