Page 1

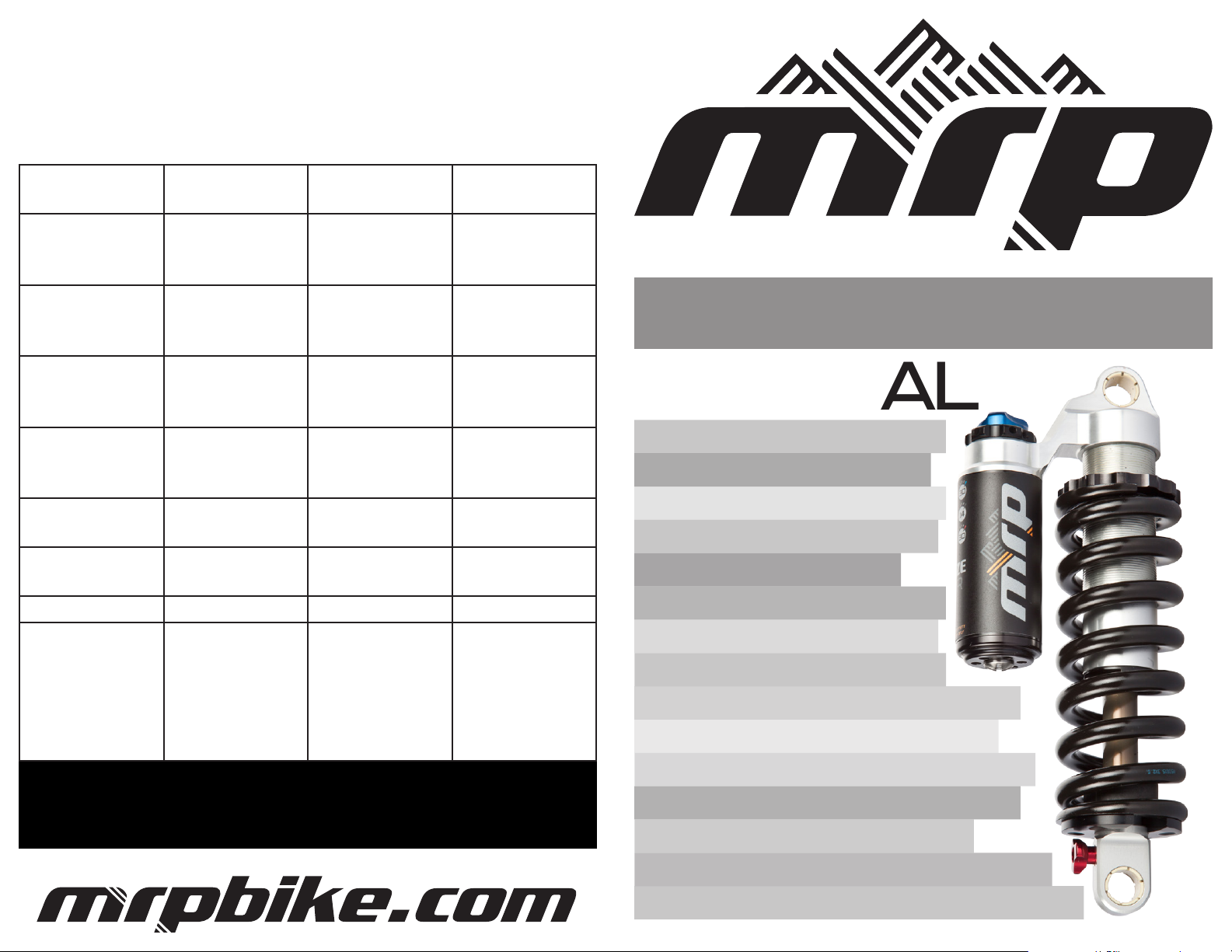

MAINTENANCE SCHEDULE

Maintenance frequency may vary depending on the number of hours the

shock is ridden and the condition under which it is ridden. Heat, violent

impacts, dust, mud, and adjustment settings are all factors that need to

be taken into consideration in determining the frequency of basic maintenance and oil changes.

AFTER EACH

USE

Clean under

the bottom-

out bumper

Clean shock

absorber

exterior

Check shaft

for damage

or rust

Check seal

head for leaks

or loosening

Check nuts for

loosening

Check DU

bushings

Check spring Inspect Inspect Inspect

Change oil,

piston and

wearband,

clean interior

parts, check

nitrogen

Yes Yes Yes

Yes Yes Yes

Inspect Inspect Inspect

Inspect Inspect/Replace Replace

Inspect Inspect Inspect

Inspect Inspect Inspect

END OF EACH

SEASON

Recommended

ANNUALLY

OWNER’S

MANUAL

IMPORTANT NOTE:

NOTE: MRP RECOMMENDS SENDING YOUR SHOCK EXCLUSIVELY TO MRP

OR A RECOMMENDED SERVICE CENTER FOR ALL YOUR OIL CHANGE AND

SEAL REPLACEMENT MAINTENANCE.

MORE TUNING INFORMATION AT

Page 2

Congratulations on your purchase of another cutting-edge

suspension product from MRP! Please read this manual completely

before you ride. It will help you to set your shock for optimum

performance.

IMPORTANT CONSUMER SAFETY INFORMATION

WARNING: RIDING A BIKE IS DANGEROUS. NOT

PROPERLY MAINTAINING OR INSPECTING YOUR BIKE

AND ITS COMPONENTS IS EVEN MORE DANGEROUS. IT

IS ALSO DANGEROUS TO NOT READ AND FOLLOW THESE

INSTRUCTIONS.

Thank you for choosing MRP. This owner’s manual is your

reference guide to using and fine-tuning your shock absorber for

optimum suspension performance and comfort. It also provides important

information about the proper maintenance of your shock. Carefully read

this manual before installing your shock. If you need further assistance,

our experienced team is able to advise and assist you to find the exact

set up to meet your personal needs.

The shock is an important part of your mountain bike and

this owner’s manual explains how to install and use it properly. We

recommend that it be installed by a qualified bicycle mechanic.

Improperly installed shocks might cause serious harm to you and may

severely damage your mountain bike. Never take any chances with

your safety. Before installing and using your new shock, carefully read

this owner’s manual to learn the correct installation and adjustment

procedures and avoid the consequences of an incorrect installation or

improper adjustment.

When your shock requires an oil change or other internal

maintenance, MRP and experienced suspension service centers are best

qualified to provide the necessary service or repairs.

WARRANTY:

MRP suspension products are the highest quality and as such are

warranted to be free from defects in materials and workmanship for a

period of one year from the date of purchase for the original purchaser.

If date of purchase cannot be verified by product registration or

proof of purchase then the warranty is one year from the date of

manufacture. On receipt of the product by MRP, if it is found to be

defective, MRP will determine replacement or repair of the product at

its sole discretion. MRP shall not be liable for any indirect, special or

consequential damages. Warranty does not apply to any product that

has been installed improperly or adjusted using methods not outlined

travel upon impacts or repetitive bumps, add more resistance by turning

the adjuster one click at a time until you bottom out only once in a while

upon major impacts.

INCREASING HIGH-SPEED COMPRESSION (MORE RESISTANCE

BEFORE BLOWING OFF)

To increase the high-speed compression threshold, thus increasing the level of force to activate the blow-off valve, turn the black highspeed compression adjuster knob clockwise (screw in). There are 22

clicks of high-speed compression adjustment. When the high-speed

setting gets too hard, the shock absorber will not be able to effectively

absorb impacts, thus making the ride harsh.

REDUCING HIGH-SPEED COMPRESSION (LESS RESISTANCE

BEFORE BLOWING OFF)

To reduce the high-speed compression thresholds, thus decreasing the level of force to activate the blow-off valve, turn the black highspeed compression adjuster knob counterclockwise (unscrew). When

the high-speed setting gets too soft, the suspension will use more travel

upon impacts and become more prone to bottoming out.

The goal is to run as little high-speed compression as possible to

have a plush and comfortable ride without bottoming out.

IMPORTANT NOTE:

WHEN TURNING THE HIGH-SPEED COMPRESSION ADJUSTMENT KNOB,

THE LOW-SPEED COMPRESSION ADJUSTMENT KNOB WILL FOLLOW ALONG

WITHOUT AFFECTING ITS SETTING.

CLEANING PROCEDURES

A well-maintained shock absorber will last longer and perform

better. For cleaning, use a gentle detergent and pay attention to areas

where debris can become lodged. Do not use any abrasive cleaning

products or high pressure washers.

CLEANING PROCEDURES:

1. Clean the threads under the preload ring using a soft brush

2. Clean around the rebound knob so that no foreign particles damage

the adjustment mechanism.

3. Clean around the compression adjustment knobs delicately, be careful not to force water within the mechanism.

4. Use compressed air to clean beneath the bottom out bumper.

IMPORTANT NOTE:

DO NOT USE COMPRESSED AIR OR HIGH PRESSURE WATER WHEN

CLEANING THE SEAL HEAD AS THIS COULD POSSIBLY DAMAGE THE SEALS.

Page 3

plush and comfortable or

firm and fast rolling.

You should start

in the middle of the adjustment range. To adjust

properly, turn the adjuster one click at a time

RANGE ADJUSTER LOCATION

and take a test ride. The adjustment is more sensitive towards the fully in

position (slowest). When the low-speed setting gets too hard, the shock

absorber will not be able to absorb low-velocity impacts and weight

transfers, thus making the ride harsher. When the low-speed setting gets

too soft, the shock absorber will be too active, will wallow more under

pedaling and become more prone to bottoming out.

INCREASING LOW-SPEED COMPRESSION DAMPING (STIFFER

SUSPENSION)

To increase the low-speed compression damping, thus making

the suspension stiffer, turn the blue low-speed compression adjuster

knob clockwise (screw in). There are approximately 30 clicks of lowspeed compression adjustment.

REDUCING THE LOW-SPEED DAMPING (SOFTER SUSPENSION)

To reduce the low-speed compression damping, thus making the

suspension softer, turn the blue low-speed compression adjuster counterclockwise (unscrew).

HIGH-SPEED COMPRESSION

The Raze’s high-speed compression circuit is an adjustable

blow-off valve that momentarily relieves the pressure building up inside

the shock upon a harsh impact, instantly providing additional plushness then increasing resistance as needed. The adjustment controls the

level of force (threshold) required to open the blow-off valve upon fast

movements of the shock’s shaft (high velocity) which can be caused by

square-edged impacts, roots, rocks, potholes, vibrations or brake bumps.

When set properly, the high-speed compression circuit allows the wheel

to effectively absorb all impacts without bottoming out or using too much

travel.

Start with the adjustment in the fully open

position (completely

turned counterclockwise)

and take a test ride. If

you tend to bottom out

often or use too much

RANGE ADJUSTER LOCATION

in this manual. Warranty also does not cover products that have been

misused or products that have missing/altered serial numbers. The

product is not warrantied against damage in the appearance of the

product or for modifications not outlined in this manual. This warranty

does not cover breakage, bending, or damage that may result from

crashes, falls, or abuse. Normal wear and tear items such as; seals,

wipers, bushings, stanchion coating, stanchions, piston bands, foam

rings, bottom out and top out bumpers, or damage caused by lack of

proper maintenance as outlined in this manual is not covered by this

warranty.

What to do if you need warranty inspection or service:

1. Go to MRPbike.com and locate the warranty contact form in the

support section of the site. Alternatively, call or email MRP about the

troubles you are having and to set up a RA# (Return Authorization

Number).

2. Carefully pack and ship your product, be sure to insure the package

in case it is lost or damaged in transit. (Only the return shipping to

the customer is covered under warranty)

3. Wait for an email confirming MRP has received your shipment.

DISCLAIMER

BECAUSE MRP SUSPENSION PRODUCTS ARE DESIGNED FOR USE IN

RACING AND EXTREME RIDING CONDITIONS, MRP SUSPENSION CANNOT

GUARANTEE ANY OF ITS SUSPENSION PRODUCTS, OTHER THAN FROM

MANUFACTURING DEFECTS, BECAUSE WE HAVE NO CONTROL OVER

HOW THE PRODUCTS ARE USED AFTER INSTALLATION. IN ADDITION, THE

PURCHASER ASSUMES FULL RESPONSIBILITY TO THE EXTENT LEGALLY

PERMITTED FOR THE RISKS OF PERSONAL INJURY AND/OR DAMAGE TO THE

PURCHASER’S BIKE OR TO ANY THIRD PARTY THAT MAY BE INVOLVED IN AN

INCIDENT WITH THE PURCHASER.

MOUNTING HARDWARE

MRP uses 1/2” (12.7mm) DU bushings on both ends, which

is compatible with the original mounting hardware found on most

recent mountain bikes. Ordering new hardware with your shock is

recommended as this will ensure you have the proper hardware for your

shock and bike. If you contact MRP or your local MRP dealer, we can

verify that you can use the original mounting hardware that came with

your bike.

Page 4

Before installing your mounting hardware check the direction

the piggy back should face on your frame. This is important so not

to damage your frame also for frames that require different mounting

hardware sizes for each end of the shock. Start with the steel sleeve and

insert it through (the correct side) the bushing in the eyelet and center

it on the eyelet as best as you can. Take the frame spacers and insert

the provided seals into the flanged side of the sleeve. With the seals

installed slide the frame spacers over the sleeve so that the seal rests

against the eyelet of the shock.

SPRING REMOVAL & INSTALLATION

To remove the spring, start by turning the preload adjuster ring

counterclockwise to remove all preload until the spring become loose.

Push down on the spring retainer clip then slide it off the shock, being

careful not to damage the shaft with the sharp sides of the spring clip.

Once the clip is removed, you can slide the spring off the shock.

IMPORTANT NOTE:

ALWAYS MAKE SURE THAT THE END OF THE SPRING’S COIL IS ALIGNED ON

THE OPPOSITE SIDE OF THE SLOT IN THE SPRING RETAINING CLIP. THIS WILL

PREVENT THE SPRING FROM BENDING THE CLIP.

PRELOAD

Spring preload is the compression applied to the shock’s spring

when at rest, using the preload adjuster ring. The preload adjustment is

used to achieve the optimal amount of sag and proper ride height.

INCREASING THE PRELOAD:

To increase the preload on your spring, turn the preload ring

clockwise. Increasing the preload will increase the ride height, thus

reducing the sag. This will result in a more responsive ride. Be careful not

to apply too much preload. This can cause “coil binding”, which is when

the coils of the spring rub against each other under compression. This

can damage the spring, the shock, and can be dangerous for the rider.

REDUCING THE PRELOAD:

To reduce the preload on your spring, turn the preload ring

counter-clockwise. Reducing the preload will decrease the ride height,

thus increasing the sag. This will result in a more comfortable ride. Make

sure to apply enough preload so the spring is firmly held in place and

does not spin freely on the shock.

IMPORTANT NOTE:

IF MORE THAN 5MM OF PRELOAD (5 TURNS) IS NEEDED TO ACHIEVE PROPER

SAG, IT IS RECOMMENDED TO CHANGE TO A HIGHER SPRING RATE. IF SAG

IS NOT ENOUGH WITHOUT ANY PRELOAD APPLIED TO THE SPRING, IT IS

RECOMMENDED TO CHANGE TO A LIGHTER SPRING RATE.

REBOUND

The rebound adjustment controls the speed the shock will return

to its initial extended state after being compressed upon an impact. If the

rebound adjustment is set properly, the rear wheel should keep maximum

traction by tracking the ground without catapulting the rider off the bike.

You should start in the middle of the adjustment range. To adjust

properly, turn the adjuster one click at a time and take a test ride. The

adjustment is more

sensitive towards the

fully in position (slowest).

When the rebound

setting gets too slow, the

shock absorber will not

have time to resume to

its initial position when a

RANGE ADJUSTER LOCATION

series of close bumps is encountered. In this case, the bike will run out

of travel (packing), possibly bottoming out, and may give the impression

of the compression being too soft. When the rebound adjustment is set

too fast, the rear end of the bike will kick and move from side to side after

hitting a series of close bumps and the rider will feel catapulted by the

bike.

INCREASING THE REBOUND DAMPING (SLOWER RETURN):

To increase the rebound damping, thus making the shock return

slower upon an impact, turn the rebound adjuster knob clockwise (screw

in). There are approximately 30 clicks of rebound adjustment.

REDUCING THE REBOUND DAMPING (FASTER RETURN):

To reduce the rebound damping, thus making the shock return

faster upon an impact, turn the rebound adjuster knob counterclockwise

(unscrew).

IMPORTANT NOTE:

MRP’S REBOUND VALVING IS TUNED IN SUCH A WAY THAT IT PROVIDES

MORE DAMPING (SLOWER RETURN) WHEN DEEP WITHIN THE STROKE TO

PREVENT THE RIDER FROM BEING CATAPULTED OFF THE BIKE UPON MAJOR

IMPACTS.

LOW-SPEED COMPRESSION

The low-speed compression adjustment controls the damping

level (resistance) for slow movement of the shock’s shaft (low velocity),

such as under pedaling, when cornering and when preloading the suspension for jumping. The low-speed compression damping level provides

the overall stiffness feeling of the bike’s suspension, making it either

Loading...

Loading...