Page 1

Staring serial # Brass EZ-203000001001

Gray EZ-203250001001

OPERATING INSTRUCTIONS

AND

READ INSTRUCTIONS CAREFULLY: Read all information and instructions, including Gaslight

Warning Tag attached to light, before installation or use. Retain this guide for future reference.

OWNER’S MANUAL

INDOOR GASLIGHT

MHGLLP B

MHGLLP

Model

#

G

WARNING:

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance

— FOR YOUR SAFETY

you smell gas:

If

• Shut off gas to the appliance.

• Open windows.

• Don’t touch electrical switches.

• Extinguish any open flame.

• Immediately call your gas supplier.

— Service must be performed by a qualified service agency.

Attention installer:

C.S.A. regulations require that you leave these instructions with the appliance for the consumer.

.

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

05/08

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

20362

Re

v. L1

Page 2

• The design of Models MHGLLP B and MHGLLP G are C.S.A.

certified. Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1 (latest edition), and/or with CAN1-B149.2 (latest

edition) installation code for propane burning appliances and

equipment, and local codes.

IMPORTANT INFORMATION FOR USING

MR. HEATER INDOOR GASLIGHTS

• Use Gaslight only for purposes of illumination. Installation and

repair of equipment that operates on propane gas is a job for

experts. Do not attempt to install or repair your gaslight unless

you have been thoroughly trained and are experienced in such

matters. If your gaslight appears to be malfunctioning, turn it

to the “OFF” position and immediately contact your local dealer

or the Mr. Heater factory.

• After installation and before use, have qualified gas personnel

approve your installation and check for gas leaks using a leak

detector. Tubing, fittings, gaslight valve and any other gas

transporting component should be checked. Subjecting valve

assembly to testing pressures in excess of 6 PSI can damage

sealing grease which can cause leaks and voids warranty.

WARNING:

Use your gaslight in vented rooms only.

Carbon monoxide is produced by the incomplete

combustion of fuel.

WARNING:

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

THE STATE OF CALIFORNIA REQUIRES THE

FOLLOWING WARNING:

WARNING:

Combustion by-products produced when using this

product contain carbon monoxide, a chemical known to

the State of California to cause cancer and birth defects

(or other reproductive harm).

RECOMMENDED MAINTENANCE

The following matters should be dealt with as frequently as

necessary. If your gaslight has been out of use for a period of

time, examine it before lighting it.

Keep area clear and free from combustible materials, including

gasoline and other flammable vapors and liquids. Flow of

combustion air and ventilation air must not be obstructed.

Use propane gas only for models MHGLLP B and MHGLLP G.

Propane gas must be to this rating: 2500 to 2530 B.T.U. per cubic

foot. Mr. Heater propane gas orifices are manufactured to this

pressure rating only. See “Gaslight Rating Label.”

Propane gas supply tank and regulator. Gas supply tank must

not be overfilled. Regulator must be adjusted to operate at a

pressure of 11 inches of water column (27.9 cm) (6 oz. of mercury).

This same gas pressure must be maintained at the orifice of the

gaslight. Higher or lower pressures will cause the gaslight to

malfunction.

Copper gas tubing. Copper gas tubing must be internally tinned

to meet National Gas Code Standards unless otherwise directed by

local codes.

Orifice. All gaslights are equipped with standard propane orifices.

To use gaslights at elevations of 4500 feet or more above sea

level, order High Altitude Orifice, #20368 for propane gas.

WARNING:

Never touch drilled hole in orifice, as it is extremely

delicate. Use low-pressure compressed air to clean the

orifice. Pins, wire, even oil from hands, may disturb proper

gas flow. Replace orifice if in question.

Both MHGLLP B and MHGLLP G are ready to use with

PROPANE ONLY, at altitudes under 4,500 ft. The following

gas orifices are available for these other applications:

FUEL TYPE GAS ORIFICE

PROPANE (High Altitude) 20368

Valve Assembly. The valve assembly must be straight on the wall

bracket. Bracket can become cocked or bent when tightening

copper tubing, flare nut, etc. causing orifice to be aimed crooked.

Gas flow through the orifice must be aimed straight down the

center of the BBV.

CONTENTS

General Safety Instructions ......................................... 2

Recommended Maintenance ...................................... 2

Bunsen Burner Venturi (BBV) Cleaning Instructions .. . 3

Gaslight Location, Mounting & Assembly .................... 3

Mantle Installation & Lighting Instructions ................... 4

Optional OPK “3-In-1” Kit ............................................. 6

Parts List ..................................................................... 7

Limited Warranty ......................................................... 8

Mr. Heater | MHGLLP B MHGLLP G Operating Instructions and Owner’s Manual

When gaslight is operating properly, gas consumption is 2100

B.T.U. per hour. One “pound” of propane gas produces

approximately 10 hours of light.

Permanent screws that attach valve assembly to wallplate should

never be loosened or removed. Removing valve assembly from

wallplate will void warranty.

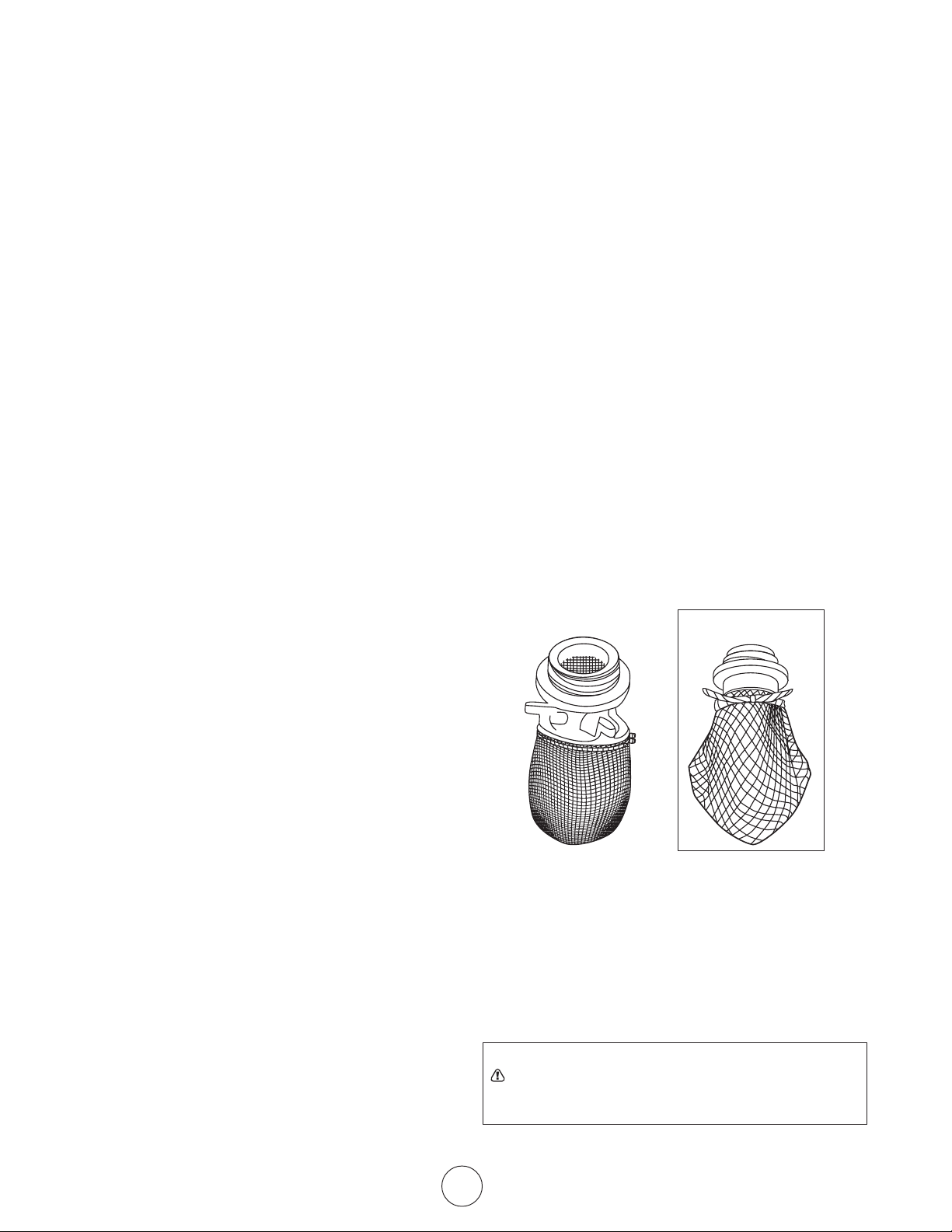

Mantles. Use Mr. Heater mantles which are designed for use with

propane gas only. Never use broken mantles. Inspect for carbon

deposits each time gaslight is used. Clean or replace defective

mantles immediately. Use proper ceramic burner head and mantle

combination. (Example: “Tie-on” type burner head, #20352, with tieon mantles, #20353. Or “Pre-formed” type burner head, #20337,

with pre-formed mantles, #20351.) Also see “Mantle Installation

and Lighting Instructions.”

2

Page 3

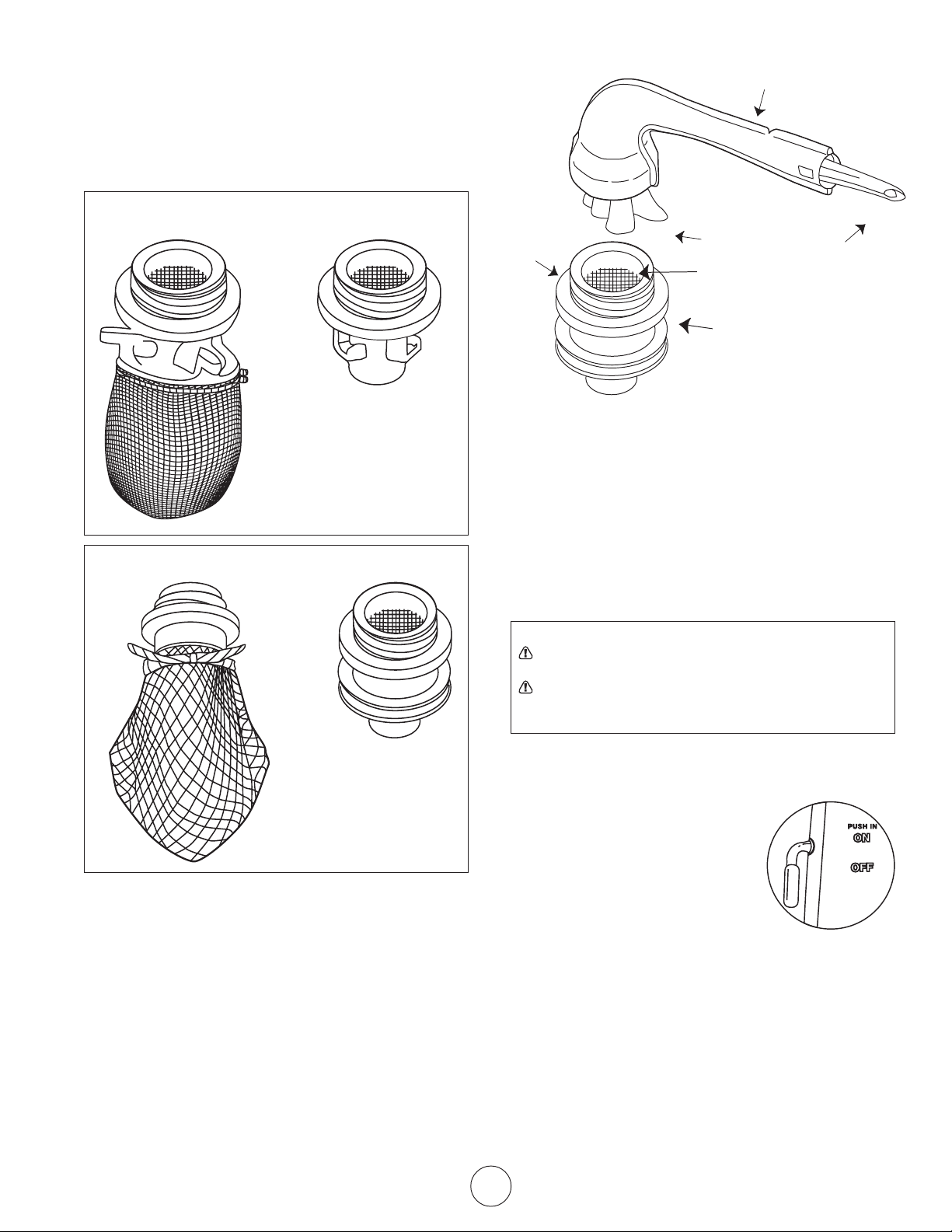

Burner Head Screen. Screen must be in threaded end of burner

head. Gaslight will not function properly if screen is missing.

Seal. Seal is placed on threaded end of burner head. Seal and

burner head should be screwed securely into Bunsen Burner

Venturi (BBV.) The seal must be replaced any time the burner head

is removed after the lamp has been used.

Included “Pre-formed” Mantle

Bunsen Burner Venturi (BBV)

Use “Pre-formed” type

burner head, #20337, with

pre-formed mantles, #20351

Optional “Tie-On” Mantle Not Included

Seal

Clean, dry cloth

Burner head screen

Burner head

BUNSEN BURNER VENTURI (BBV)

CLEANING INSTUCTIONS

1. Remove burner head.

2. Pull a clean, dry cloth through BBV to clean out foreign

material.

3. Replace seal. Reassemble burner head and tighten securely.

Note: Always replace seal if lamp has been previously lit.

GASLIGHT LOCATION, MOUNTING, &

ASSEMBLY

WARNING:

Read all instructions and Gaslight Warning Tag (attached

to light) before installing light.

Make sure that the gas supply is turned OFF at the supply

tank and that the gaslight valve handle is in the ‘OFF’

position.

Use “Tie-on” type burner

head, #20352, with tie-on

mantles, #20353

Bunsen Burner Venturi (BBV). Flow of combustion air and

ventilation air must not be obstructed. To ensure proper air flow

and gas mixture, the inside of the BBV must be clean and free of

any material that may potentially accumulate, such as spider webs,

insects, etc. Make a periodic visual check of the BBV. The BBV can

be cleaned by drawing a clean, dry cloth through it. It can also be

cleaned by blowing it out with compressed air. Never attach a

mantle directly to the BBV.

Plumbing Supplies

The following plumbing supplies are

needed for installation. They are available

from your local gas dealer.

Copper Tubing

Internally tinned copper tubing,

outside diameter, is recommended.

Copper tubing must be internally tinned

to meet National Fuel Gas Code unless

otherwise directed by local codes.

Fittings

If 3/8” copper tubing is used, a 3/8” Flare Male Connector x

1

/8 NPT Straight Fitting is required. Mr. Heater #20347 (included).

If Gaslight is to be connected from behind (through wall) a

1

/8 NPT Street Elbow (Male-Female), Mr. Heater #20348 (included)

must be used in addition to the Straight Fitting.

Permanent screws that attach valve assembly to wallplate should

never be loosened or removed. Removing valve assembly from

wallplate will void warranty.

Operating Instructions and Owner’s ManualMr. Heater | MHGLLP B MHGLLP G 07/07

3

3

/8”

Page 4

Location of Indoor Gaslight

Always mount gaslight on an open wall. Never mount gaslight in

a boxed-in or recessed area.

Wall Bracket Assembly (Ref. #1) must be mounted so that Heat

Deflector (Ref. #15) is a minimum of four inches from a

combustible surface, and outside of Globe (Ref. #13) is a minimum

of three inches from a combustible surface to either side or in

front. Mounting gaslights too close to a door may subject delicate

mantles to vibrations and could damage the mantle.

Assembly

First, remove all packaging materials from gaslight.

1. Remove Wall Bracket Assembly (Ref. #1) and visually identify

Valve Assembly (Ref. #2) and Orifice (Ref. #4). From center of

Orifice, measure a minimum of seven inches below an overhead

combustible surface and a minimum of ten inches from a

combustible surface at the front. These dimensions will provide the

minimum clearance to combustible surfaces for the Heat Deflector

and Globe. DO NOT TOUCH, DISTURB OR DAMAGE HOLE IN

ORIFICE, even oil from hands can interfere with proper gas flow.

If gas supply is to be connected through bottom of Valve Cover

(Ref. #27), remove Knockout tab (twist out using pliers) in valve

cover before proceeding.

2. Connect internally tinned copper tubing to Gas Inlet (Gas Inlet)

using proper fitting (See “Fittings” page 3). It is easier to connect

the tubing before fastening Wall Bracket Assembly to wall (also

Wall Bracket Assembly is less likely to be bent). Valve Assembly

(Ref. #2) must be straight on the Wall Bracket Assembly. Orifice

(Ref. #4) must aim into the center of the BBV (Ref. #28) for proper

air and gas mixture.

3. Fasten Wall Bracket Assembly to wall using four mounting

screws (Ref. #26) supplied. CAUTION; DO NOT OVER-TIGHTEN

SCREWS. The four Bosses (Mounting Bosses) on the Wall Bracket

Assembly must not be imbedded in the wall because air must

circulate behind the Wall Bracket Assembly to prevent scorching.

Replacement parts and accessories are available from your

local gas dealer or from Mr. Heater, Inc.

MANTLE INSTALLATION & LIGHTING

INSTRUCTIONS

Do not use defective mantles (holes, etc.) Replace defective

mantles immediately.

After installation and before use have qualified gas personnel

approve your installation and check for gas leaks using a leak

detector. Tubing, fittings, gaslight valve, and any other gas

transporting component should be checked. After gaslight has

been properly installed and thoroughly checked for leaks by

qualified gas personnel only:

1. Remove globe.

2. a. Pre-formed mantle: Grasp ceramic ring – do not touch

mantle itself. Hook legs into reverse “L” of the burner

head.

b. Optional Tie-on mantle: Loop the tie-on strings at the throat

of the mantle. Work fingertips into mantle throat and

enlarge the opening so that it will fit over the ceramic

burner head and seat in lower groove of burner head. Do

not tie the mantle to the BBV. Distribute puckers in the

mantle evenly around the burner head. Pull the ends of the

string snugly so that mantle and string are seated securely

in the burner head groove. Tie a double knot and clip off

excess string.

Optional “Tie-On”

Not Included

4. Attach Valve Cover Assembly (Ref. #27) to Wall Bracket

Assembly by engaging Slots (Slots) with Wall Bracket Assembly

Tabs (Assembly Tabs).

5. Carefully swing down the Valve Cover Assembly so that the

slots in the bottom of valve cover engage Lock Screws (Ref. #12).

Tighten Lock Screws.

6. Check the following dimensions:

Minimum of 4 inch clearance from top of Heat Deflector (Ref.

#15) to ceiling.

Minimum of 3 inch clearance from outer edge of Globe to

both sides and front.

Ensure 1

Holder (Ref. #16).

7. Loosen Globe Lock Screw (Ref. #14) and remove Globe. Be sure

that all packaging material has been removed. Attach mantle.

8. Attach Globe after installing mantle but before burn-off (See

“Mantle Installation and Lighting Instructions”) by engaging Tabs

(Globe Holder Tabs (2)) and inserting Globe so that Globe Lock

Screw can be tightened into the neck of the Globe. Do not overtighten.

1

/4 inch dimension between Heat Deflector and Globe

Mr. Heater | MHGLLP B MHGLLP G Operating Instructions and Owner’s Manual

3. Replace globe.

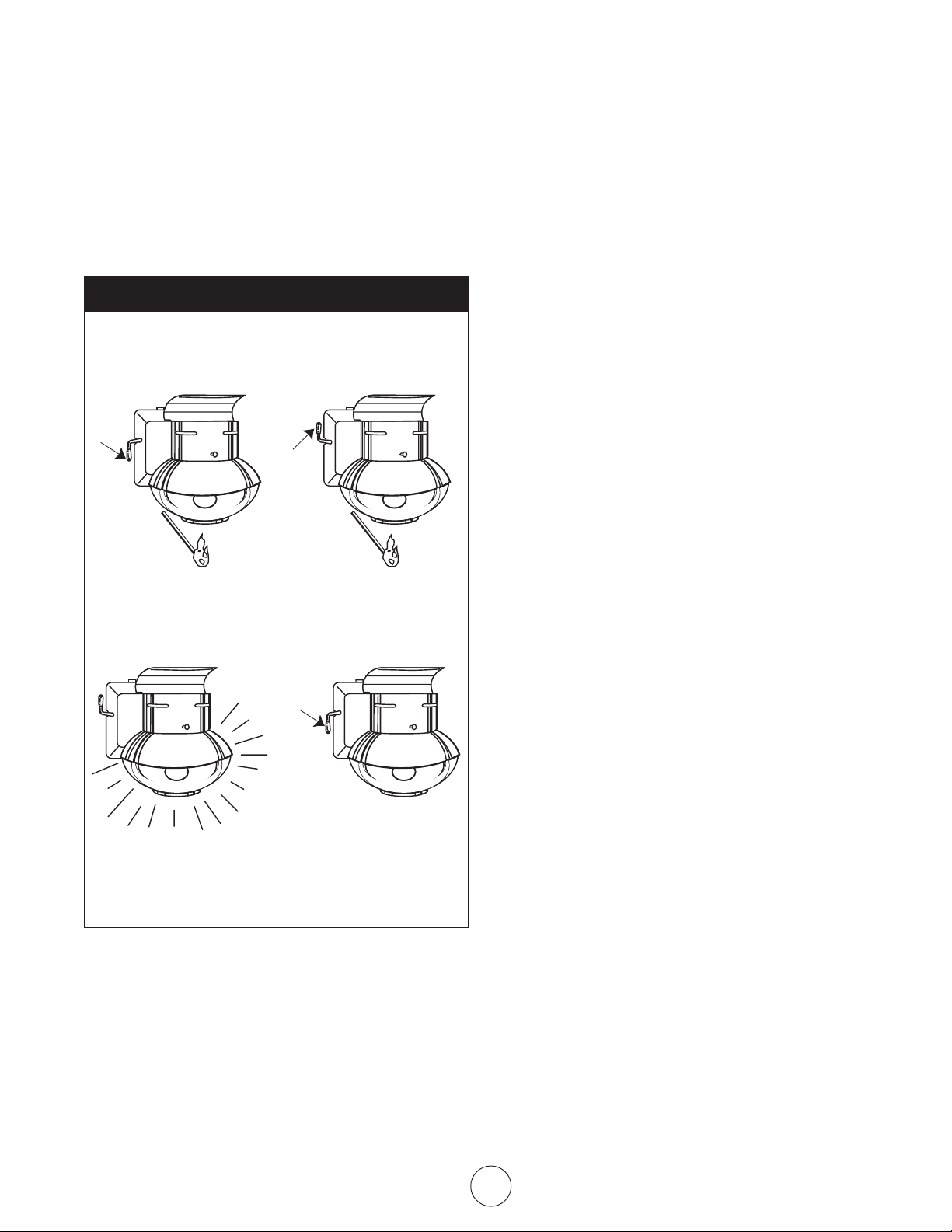

4. Mantle burn off: WITH GASLIGHT VALVE HANDLE IN THE

“OFF” POSITION, and in a well ventilated room, hold a lighted

match close to, but not touching, bottom of mantle. Remove

match when mantle begins to smolder. Allow fabric to burn

completely.

NOTE: It is normal for mantles to smoke during burn-off

procedure.

WARNING:

After burn-off, mantle is a chemical ash. It will break if

touched. Upon lighting of gaslight, it will shrink to its final

form.

5. Lighting of gaslight: Light gaslight only after mantle burn-off

4

Page 5

(Step 4) has been completely accomplished. Caution: Do not turn

gaslight to “ON” position until after lighting match. Do not touch

mantle with the match.

Note: When gaslight is newly installed, air may be present in the

gas line. Several matches may be required before the gaslight will

light. After a new mantle is ignited, allow it to burn for five to ten

minutes so it will shrink to its final form. Gaslight is now ready for

use.

6. Turning gaslight off: To turn off, simply move gaslight valve

handle to the “OFF” position.

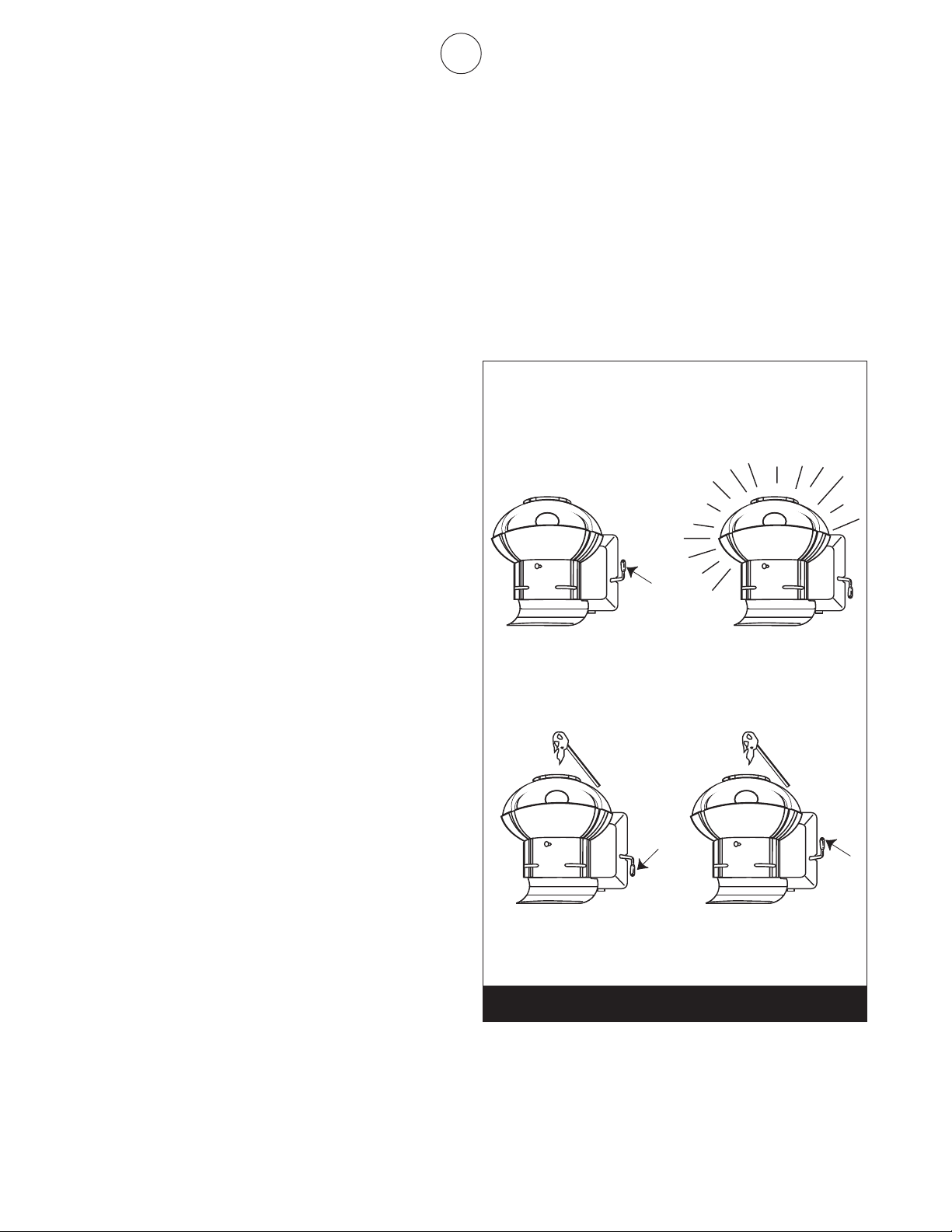

LIGHTING GASLIGHT

Light gaslight only after mantle burn-off (Step 4) has been

completely accomplished.

Caution: Do not turn

gaslight to “ON” position

until after lighting match.

When gaslight is burning

properly, flame is bright

white and has no visible

outlines.

Turn gaslight to “ON”

position. Do not touch

mantle with the match.

To turn off, simply move

gaslight valve handle to

the “OFF” position.

Operating Instructions and Owner’s ManualMr. Heater | MHGLLP B MHGLLP G 07/07

5

Page 6

OPTIONAL OPK “3-IN-1” KIT

Item #: F220370

Suspends the gaslights in single, double or triple pendants

Mr. Heater | MHGLLP B MHGLLP G Operating Instructions and Owner’s Manual

6

Page 7

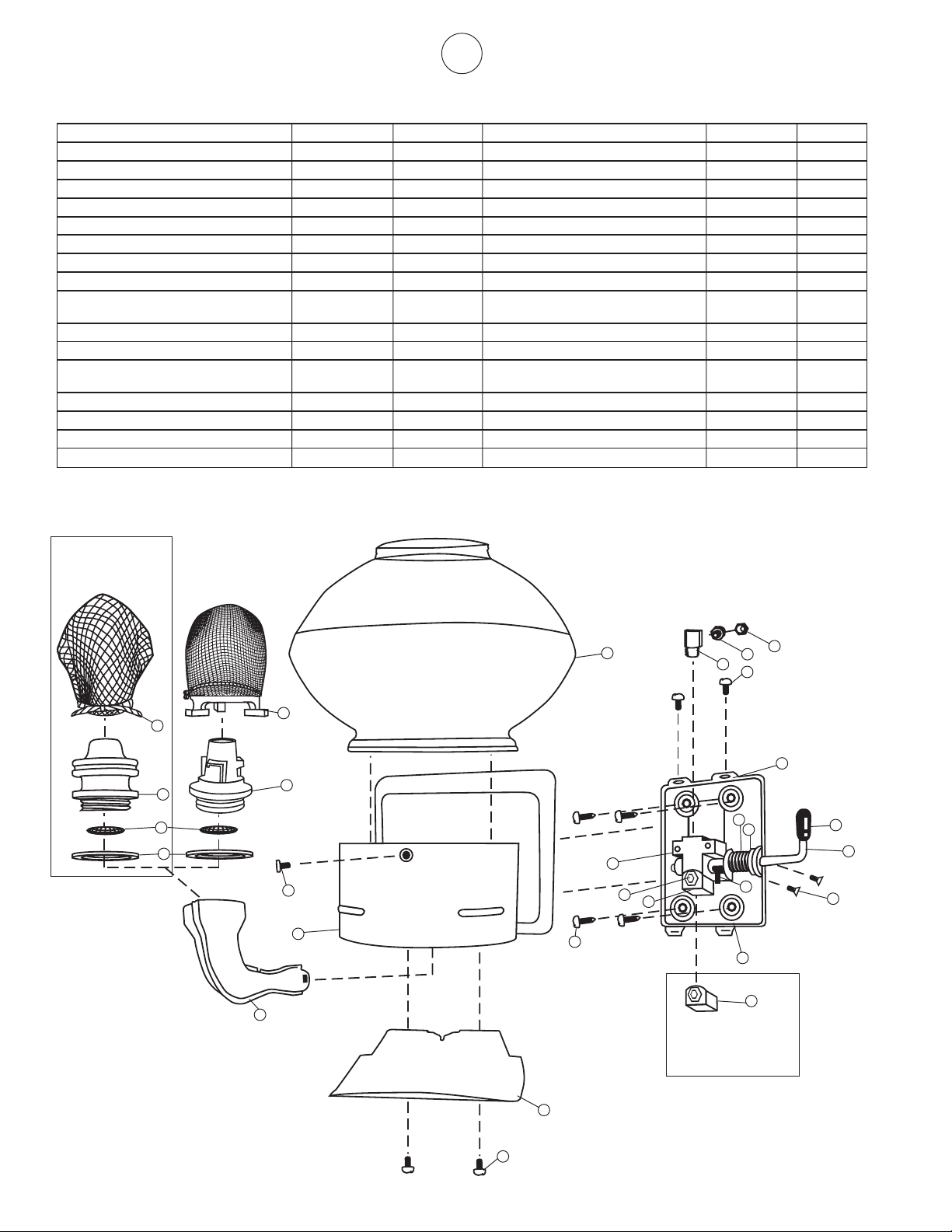

Optional

High Altitude

Orifice

30

1

12

15

28

26

16

9

5

7

10

6

8

11

12

25

24

23

3

4

2

13

14

18

29

19

20

21

22

Optional

“Tie-On”

REF NO. STOCK NO. DESCRIPTION REF NO. STOCK NO. DESCRIPTION

1 20311 Wall Bracket Assembly 16 20315 Globe Holder Brass

2 20314 Valve Assembly 16 20320 Globe Holder Gray

3 20312 Control V alve 18 20339 Ceramic Fiber Gasket

4 20313 Orifice 20338 Burner Head Assembly (Preformed Mantle)

5 20316 On/Off Lever 19 20337 Ceramic Burner Head (Preformed Mantle)

6 20317 Washer 20 20351 Preformed Mantle

7 20321 Plastic Handle 20381 Burner Head Assembly (Tie-on Mantle)

8 20322 Spring 21 20352 Ceramic Burner Head (Tie-on Mantle)

9 20323 Screw 22 20353 Tie-on Mantle

10 20324 On/Off Lever Bracket 2 3 20346 3/8 S.A.E. Flare Nut

11 20326 Wall Mounting Bracket 24 20347 3/8 S.A.E. Flare x 1/8 NPT Male Connector

12 20327 Philips Pan Head Screw Type AB 4.2x7.5 25 20348 1/8 Female x 1/8 Male NPT 90 Degree Elbow

13 20331 Half Frosted Pyrex Globe 26 20349 Philips Pan Head Screw Type A M4x13

14 20332 Globe Lock Screw Brass 4x12.5 28 20342 Bunsen Burner Venturi

14 20386 Globe Lock Screw Gray 4x12.5 29 20336 Burner Head Screen

15 20333 Heat Deflector 30 20368 High Altitude Orifice15

Includes items #18, 29, & 19

Includes items #18, 29, & 21

Operating Instructions and Owner’s ManualMr. Heater | MHGLLP B MHGLLP G 07/07

7

Page 8

OPERATING INSTRUCTIONS

Model #

AND OWNER’S MANUAL

WARNING:

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS COULD

CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE AVAILABLE FROM MR. HEATER

LOCAL DEALER OR DIRECT FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE AGENCY.

MHGLLPG

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any Mr. Heater local dealer or direct

from the factory

FOR INFORMATION REGARDING SERVICE

Please call Toll-Free 800-251-0001 www.mrheater.com

Our office hours are 8:30 AM – 5:00 PM, EST, Monday through Friday.

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or workmanship,

under normal and proper use in accordance with product instructions of Enerco Group, Inc., for a

period of one year from the date of delivery to the buyer. Enerco Group, Inc., at its option, will

repair or replace products (except globe, gaskets and/or mantles which are considered

consumable parts) returned by the buyer to the factory, transportation prepaid within said one

year period and found by the Company to have imperfections in material or workmanship.

MHGLLP B

If a part is damaged or missing, call our Technical Support Department at 800-251-0001.

Address any Warranty Claims to the Service Department, Enerco Group, Inc., 4560 W. 160TH

ST., CLEVELAND, OHIO 44135. Include your name, address and telephone number and include

details concerning the claim. Also, supply us with the purchase date and the name and address

of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no other

warranties, express or implied. Specifically there is no warranty of fitness for a particular

purpose and there is no warranty of merchantability. In no event shall the Company be liable for

delay caused by imperfections, for consequential damages, or for any charges of the expense of

any nature incurred without its written consent. The cost of repair or replacement shall be the

exclusive remedy for any breach of warranty. There is no warranty against infringement of the

like and no implied warranty arising from course of dealing or usage of trade. This warranty will

not apply to any product which has been repaired or altered outside of the factory in any respect

which in our judgment affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may have other rights which vary from state to state.

Enerco Group, Inc. reserves the right to make changes at any time, without notice or

obligation, in colors, specifications, accessories, materials and models.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

Mr. Heater is a registered trademark of Enerco Group, Inc.

© 2003, Enerco/Mr. Heater. All rights reserved

Mr. Heater | MHGLLP B MHGLLP G Operating Instructions and Owner’s Manual

CAN 1-2.15-M83

ANSI Z21.42a 2004

8

Page 9

8

Mr. Heater | MHGLLP B MHGLLP G Guide d’utilisation et instructions de fonctionnement

© Enerco/Mr. Heater, 2003. Tous droits réservés.

Mr. Heater est une marque déposée de Enerco Group Inc.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • (216) 916-3000

aux modèles.

préavis ni obligation, aux couleurs, aux spécifications, aux accessoires, aux matériaux et

Enerco Group Inc. se réserve le droit d’effectuer des modifications en tout temps, sans

vous pourriez avoir d’autres droits qui varient selon la province ou l’État.

concernent peut-être pas. La présente garantie vous accorde des droits juridiques précis, mais

subséquents. Par conséquent, les limitations ou exclusions ci-dessus mentionnées ne vous

Certains États ou provinces ne permettent pas d’exclure ou de limiter les dommages indirects ou

que ce soit sur l’état de l’appareil ou son fonctionnement, selon notre jugement.

aucun produit qui a été réparé ou modifié par d’autres que le fabricant si cela influe de quelque façon

usages du commerce ou de la façon habituelle d’échanger. La présente garantie ne s’applique à

aucune garantie contre une transgression de ce genre ni aucune garantie tacite découlant des

réparation ou du remplacement sera le seul recours possible en cas de violation de garantie. Il n’y a

des dépenses encourues sans son consentement écrit, quelle que soit leur nature. Le coût de la

ne sera tenue responsable des retards causés par des défectuosités, ni des dommages indirects, ni

à un usage particulier ni aucune garantie concernant la qualité marchande. En aucun cas l’entreprise

autre garantie, expresse ou tacite. Plus précisément, il n’y a aucune garantie concernant l’adéquation

Ce qui est énoncé ci-dessus constitue la responsabilité totale de l’entreprise. Il n’existe aucune

nom et l’adresse du détaillant auprès duquel vous avez acheté le produit.

téléphone ainsi que les détails de la réclamation. Indiquez-nous également la date d’achat et le

4560 W. 160TH ST., CLEVELAND, OHIO 44135, USA. Indiquez vos nom, adresse et numéro de

Adressez toute réclamation relative à la garantie à Service Department, Enerco Group, Inc.,

au 1 800 251-0001.

Si une pièce est endommagée ou manquante, téléphonez à notre service de soutien technique

ayant des défauts de pièce ou de main-d’œuvre.

fabricant, transport prépayé, dans la dite période de un an et considérés par l’entreprise comme

manchons qui sont considérés comme des pièces consommables) retournés par l’acheteur au

son choix, réparera ou remplacera les produits (à l’exception du globe, des joints et/ou des

pour une période d’un an à compter de la date de livraison à l’acheteur. Enerco Group, Inc., à

conditions d’utilisation normale et adéquate, conformément aux instructions de l’entreprise,

L’entreprise garantit ce produit contre tout défaut de pièce ou de main-d’œuvre, dans des

GARANTIE LIMITÉE

MHGLLP G

MHGLLP B

Modèle no.

toutes vos communications avec nous.

Veuillez indiquer le numéro du modèle, la date d’achat et la description du problème dans

Nos heures d’ouverture sont de 8 h 30 à 17 h (HNE), du lundi au vendredi.

Appelez sans frais au 1 800 251-0001 • www.enerco-mrheater.com

POUR OBTENIR DES RENSEIGNEMENTS SUR LE SERVICE

directement du fabricant.

ACHAT : Il est possible d’acheter les accessoires chez tous les détaillants Mr. Heater ou

INFORMATIONS SUR LA COMMANDE DE PIÈCES :

ET DOIVENT ÊTRE INSTALLÉES PAR UN FOURNISSEUR DE SERVICES D’ENTRETIEN QUALIFIÉ.

DISPONIBLES CHEZ VOTRE DÉTAILLANT MR. HEATER OU DIRECTEMENT CHEZ LE FABRICANT

RISQUE DE CAUSER DES BLESSURES ET LA MORT. LES PIÈCES DE RECHANGE SONT

N’UTILISEZ QUE LES PIÈCES DE RECHANGE DU FABRICANT. L’UTILISATION D’AUTRES PIÈCES

AVERTISSEMENT :

FONCTIONNEMENT

ET INSTRUCTIONS DE

GUIDE D’UTILISATION

Page 10

7

07/07

Guide d’utilisation et instructions de fonctionnementMr. Heater | MHGLLP B MHGLLP G

15 20333 Réflecteur de chaleur 30 20368 Ajutage haute altitude

14 20386 Vis de blocage du globe gris 4 x 12,5 29 20336 Crépine de bec de brûleur

14 20332 Vis de blocage du globe laiton 4 x 12,5 28 20342 Venturi du bec Bunsen

13 20331 Demi-globe en verre givré 26 20349 Vis à tête bombée Philips type A M4x13

12 20327 Vis à tête bombée Philips type AB 4,2 x 7,5 25 20348 1/8 femelle x coude mâle 90 degrés 1/8 NPT

11 20326 Support de montage mural 24 20347 3/8 S.A.E. Évasement x raccord mâle 1/8 NPT

10 20324 Support de manette marche/arrêt 2 3 20346 3/8 S.A.E. Écrou évasé

9 20323 Vis 22 20353 Manchon à cordon

8 20322 Ressort 21 20352 Bec de brûleur en céramique (manchon à cordon)

Comprend les articles no. 18, 29 et 21

7 20321 Manette en plastique 20381 Bec de brûleur (manchon à cordon)

6 20317 Rondelle 20 20351 Manchon préformé

5 20316 Levier marche/arrêt 19 20337 Bec de brûleur en céramique (manchon préformé)

Comprend les articles no. 18, 29 et 19

4 20313 Ajutage 20338 Bec de brûleur (manchon préformé)

3 20312 Robinet de commande 18 20339 Joint en fibre de céramique

2 20314 Robinet 16 20315 Porte-globe gris

1 20311 Support mural 16 20320 Porte-globe en cuivre

No.DE RÉF . No. DE STOCK DESCRIPTION No. DE RÉF. No. DE STOCK DESCRIPTION

option

Cordon en

22

21

29

18

13

20

19

2

14

16

28

26

4

3

25

24

12

8

6

10

1

30

en option

23

11

7

5

9

haute altitude

Ajutage

15

12

Page 11

6

Mr. Heater | MHGLLP B MHGLLP G Guide d’utilisation et instructions de fonctionnement

Suspend les lumiéres du gaz en pendants simples, doubles ou triples.

No. DE STOCK: F220370

KIT FACULTATIF D’OPK “3-IN-1”

Page 12

5

07/07

Guide d’utilisation et instructions de fonctionnementMr. Heater | MHGLLP B MHGLLP G

d’arrêt (OFF).

du robinet à la positon

gaz, tournez la manette

Pour éteindre la lampe à

pas de contours visibles.

blanche, et ne présente

flamme est lumineuse et

brûle correctement, la

Lorsque la lampe à gaz

avec l’allumette.

pas le manchon

marche (ON). Ne touchez

lampe à gaz à la position

Tournez le robinet de la

allumette.

avant d’avoir allumé une

robinet de la lampe à gaz

Attention : n'ouvrez pas le

manchon (étape 4).

N’allumez la lampe à gaz qu’après le brûlage complet du

ALLUMAGE DE LA LAMPE À GAZ

la position d’arrêt (OFF).

6. Pour éteindre la lampe à gaz, tournez la manette du robinet à

à être utilisée.

pour qu’il prenne sa forme définitive. La lampe à gaz est alors prête

l’allumage d’un manchon neuf, laissez-le brûler de cinq à dix minutes

peuvent être nécessaires pour allumer la lampe à gaz. Après

peut y avoir de l’air dans la canalisation de gaz. Plusieurs allumettes

Remarque : lorsque l’installation de la lampe à gaz est récente, il

Page 13

4

allumette. Ne touchez pas le manchon avec l’allumette.

n'ouvrez pas le robinet de la lampe à gaz avant d’avoir allumé une

qu’après le brûlage complet du manchon (étape 4). Attention :

5. Allumage de la lampe à gaz : n’allumez la lampe à gaz

gaz, il prend sa forme définitive.

casse dès qu’on le touche. Lors de l’allumage de la lampe à

Après le brûlage, le manchon est une cendre chimique. Il se

Mr. Heater | MHGLLP B MHGLLP G Guide d’utilisation et instructions de fonctionnement

AVERTISSEMENT :

la procédure de brûlure-de.

NOTE : C'est normal pour les manteaux pour fumer pendant

brûler complètement.

l’allumette lorsque le manchon commence à brûler. Laissez le tissu

enflammée près du bas du manchon, sans y toucher. Retirez

ÉTANT FERMÉ, et dans une pièce bien aérée, tenez une allumette

4. Brûlage du manchon : LE ROBINET DE LA LAMPE À GAZ

3. Replacez le globe.

cm

entre le réflecteur de chaleur et le

3

col de celui-ci. Ne serrez pas trop.

globe de façon que la vis de blocage puisse être serrée dans le

engageant les languettes du porte-globe [2] et en insérant le

rubrique Instructions d’installation du manchon et d’allumage) en

8. Fixez le globe après le manchon mais avant son brûlage (voir la

Fixez le manchon.

globe. Assurez-vous que tout le matériau d’emballage a été retiré.

7. Desserrez la vis de blocage du globe (réf. 14) et retirez le

porte-globe (réf. 16).

Ménagez un écart de

globe, les deux côtés et le devant.

Dégagement minimal de 7,5 cm entre le bord extérieur du

de chaleur (réf. 15) et le plafond.

Dégagement minimal de 10 cm entre le dessus du réflecteur

6. Vérifiez les tolérances suivantes :

blocage (réf. 12). Serrez les vis de blocage.

languettes au bas du couvercle s’engagent dans les vis de

5. Abaissez délicatement le couvercle de robinet pour que les

(en option)

Manchon à cordon

un double nœud et couper le cordon en excès.

soient bien engagés dans la gorge du bec du brûleur. Faites

les extrémités du cordon pour que le manchon et le cordon

également autour du bec du brûleur. Tirez fermement sur

le manchon sur le VBB. Répartissez les plis du manchon

s’engage dans la gorge inférieure de celui-ci. Ne serrez pas

qu’elle s’adapte sur le bec du brûleur en céramique et

dans la gorge du manchon, agrandissez l’ouverture pour

à la gorge du manchon. En insérant l’extrémité des doigts

b. Manchon à cordon en option : nouez les cordons d’attache

du bec du brûleur

toucher au manchon. Accrochez les pattes dans le L inversé

2. a. Manchon préformé : saisissez la bague en céramique sans

1. Retirez le globe.

fuites recherchée par un technicien qualifié en appareils à gaz :

lampe à gaz correctement installée et la présence éventuelle de

composants transportant le gaz doivent être vérifiés. Une fois la

fuites. Le tuyau, les raccords, le robinet de la lampe et les autres

et de vérifier s’il y a des fuites de gaz à l’aide d’un détecteur de

technicien qualifié en appareils à gaz d’approuver votre installation

Après l’installation et avant l’utilisation, demandez à un

immédiatement tout manchon défectueux.

N’utilisez pas de manchon défectueux (trous, etc.). Remplacez

MANCHON ET D’ALLUMAGE

INSTRUCTIONS D’INSTALLATION DU

chez votre détaillant local ou auprès de Mr. Heater, Inc.

Des pièces de rechange et des accessoires sont disponibles

engageant les encoches et les languettes du support mural.

4. Fixez le couvercle du robinet (réf. 27) au support mural en

éviter le roussissement.

mur parce que l’air doit circuler derrière le support mural pour

bosses du support mural ne doivent pas être incrustées dans le

fournies. ATTENTION : NE SERREZ PAS TROP LES VIS. Les quatre

3. Fixez le support mural avec les quatre vis de montage (réf. 26)

et un mélange gazeux appropriés.

(réf. 4) doit viser le centre du VBB (réf. 28) pour un débit d’air

(réf. 2) doit être perpendiculaire au support mural. L’ajutage

le support mural a moins de chance d’être courbé). Le robinet

raccorder le tuyau avant de fixer le support mural au mur (de plus,

l’aide d’un raccord approprié (voir Raccords, page 3). Il est facile de

2. Raccordez le tuyau étamé intérieurement à l’entrée de gaz à

pièces avant de poursuivre.

robinet (réf. 27), retirez la pièce détachable du couvercle avec des

Si l’arrivée de gaz doit être raccordée par le bas du couvercle de

bon débit du gaz.

TROU DE L’AJUTAGE; même le sébum de la peau peut nuire au

TOUCHEZ PAS, NE MODIFIEZ PAS ET N’ENDOMMAGEZ PAS LE

chaleur et du globe par rapport aux surfaces combustibles. NE

dimensions procurent un dégagement minimal du réflecteur de

et un minimum de 25 cm devant une surface combustible. Ces

mesurez au moins 18 cm sous une surface combustible supérieure

robinet (réf. 2) et l’ajutage (réf. 4). À partir du centre de l’ajutage,

1. Retirez le support mural (réf. 1) et identifiez visuellement le

Retirez d’abord tout le matériau d’emballage de la lampe à gaz.

Assemblage

le manchon à des vibrations qui risquent de l’endommager.

montage d’une lampe à gaz trop près d’une porte peut soumettre

de 7,5 cm de toute surface combustible sur le côté ou le devant. Le

combustible et que l’extérieur du globe (réf. 13) soit à un minimum

de chaleur (réf. 15) soit à un minimum de 10 cm de toute surface

Le support mural (réf. 1) doit être monté de sorte que le réflecteur

jamais la lampe à gaz dans une partie encastrée du mur.

Montez toujours la lampe à gaz sur un mur ouvert. Ne montez

Emplacement de la lampe à gaz pour l’intérieur

Page 14

/8po et un

3

3

Guide d’utilisation et instructions de fonctionnementMr. Heater | MHGLLP B MHGLLP G 07/07

la plaque murale annule la garantie.

doivent jamais être desserrées ou retirées. Retirer le robinet de

Les vis permanentes qui fixent le robinet à la plaque murale ne

(inclus), doit être utilisé en plus du raccord droit.

/8, Mr. Heater numéro 20348

1

un coude mâle-femelle NPT de

Si la lampe à gaz est raccordée par l’arrière (à travers le mur),

20347 (inclus).

/8 doivent être utilisés. Mr. Heater numéro

1

/8 po est utilisé, un joint conique mâle de

3

raccord droit NPT de

Si un tube de

Raccord

du gaz (National Gas Code).

répondre aux normes du code national

de gaz en cuivre doit être étamé pour

des codes locaux, l’intérieur du tuyau

recommandé. Sauf indication contraire

de

/8po de diamètre extérieur, est

3

Ne fixez jamais de manchon directement au VBB.

peut aussi être nettoyé en soufflant de l’air comprimé à l’intérieur.

peut être nettoyé en y faisant passer un chiffon sec et propre. Il

d’araignées, des insectes, etc. Vérifier régulièrement le VBB. Le VBB

propre et sans corps pouvant s’accumuler, comme des toiles

d’air et un mélange gazeux appropriés, l’intérieur du VBB doit être

et de ventilation ne doivent pas être obstrués. Pour garantir un débit

Venturi du bec Bunsen (VBB). L’écoulement de l’air de combustion

Un tuyau en cuivre étamé à l’intérieur,

Tuyau en cuivre

de gaz.

vous les procurer auprès de votre détaillant

nécessaires pour l’installation. Vous pouvez

Les articles de plomberie suivants sont

Articles de plomberie

numéro 20353

un manchon à cordon,

cordon, numéro 20352, avec

Utilisez un bec de brûleur à

position fermé (OFF).

réservoir de gaz et si le robinet de la lampe à gaz est en

Vérifiez si l’alimentation en gaz est fermée au niveau du

de la lampe à gaz (fixée à la lampe) avant de l’installer.

Lisez toutes les instructions et l’étiquette d’avertissement

AVERTISSEMENT :

Bec de brûleur

Crépine du bec de brûleur

Chiffon sec et propre

DE LA LAMPE À GAZ

EMPLACEMENT, MONTAGE ET ASSEMBLAGE

allumée.

Remarque : remplacez toujours le joint si la lampe a déjà été

bien.

3. Replacez le joint. Remontez le bec du brûleur et vissez-le

retirer tous les corps étrangers.

2. Passez un chiffon sec et propre à travers le VBB pour

1. Retirez le bec du brûleur.

numéro 20351

INSTRUCTIONS DE NETTOYAGE

VENTURI DE BEC BUNSEN (VBB)

Joint

Manchon à cordon (en option)

avec un manchon à cordon,

type préformé, numéro 20352,

Utilisez un bec de brûleur de

Manchon préformé inclus

Venturi du bec Bunsen (VBB)

bec du brûleur est retiré après une utilisation de la lampe.

du bec Bunsen (VBB). Le joint doit être remplacé chaque fois que le

Le joint et le bec du brûleur doivent être bien vissés dans le venturi

Joint. Un joint est placé sur l’extrémité filetée du bec du brûleur.

l’absence de la crépine.

filetée du bec du brûleur. La lampe à gaz ne fonctionne pas bien en

Crépine du bec de brûleur. La crépine doit se trouver à l’extrémité

Page 15

2

Instructions d’installation du manchon et d’allumage.

avec un manchon préformé, numéro 20351). Voir aussi la rubrique

numéro 20353, ou bec de brûleur de type préformé, numéro 20337,

bec de brûleur à cordon numéro 20352 avec un manchon à cordon

Utilisez la bonne combinaison bec de brûleur-manchon. (Exemple :

Nettoyez ou remplacez immédiatement tout manchon défectueux.

présence de dépôt de carbone à chaque utilisation de la lampe.

le gaz propane. N’utilisez jamais de manchon cassé. Recherchez la

Manchons. Utilisez seulement des manchons Mr. Heater conçus pour

plaque murale annule la garantie.

doivent jamais être desserrées ou retirées. Retirer le robinet de la

Les vis permanentes qui fixent le robinet à la plaque murale ne

Mr. Heater | MHGLLP B MHGLLP G Guide d’utilisation et instructions de fonctionnement

Garantie limitée ........................................................... 8

Liste des pièces.......................................................... 7

Instructions d’installation du manchon et d’allumage .. 4

à gaz............................................................................ 3

Emplacement, montage et assemblage de la lampe

Instructions de nettoyage du venturi du bec Bunsen ... 3

Entretien recommandé ............................................... 2

Instructions générales en matière de sécurité ............ 2

TABLE DES MATIÈRES

approximativement 10 heures d’éclairage.

est de 2 100 BTU par heure. 0,5 kg de gaz propane produit

Lorsque la lampe à gaz fonctionne correctement, sa consommation

directement vers le centre du VBB.

position prévue. Le gaz circulant par l’ajutage doit être dirigé

cuivre ou de l’écrou évasé, de sorte que l’ajutage soit dévié de sa

support peut être déformé ou courbé par le serrage du tuyau en

Robinet. Le robinet doit être perpendiculaire au support mural. Le

PROPANE (haute altitude) 20368

TYPE DE COMBUSTIBLE AJUTAGE DE GAZ

peuvent être utilisés pour ces applications :

altitudes inférieures à 1 371 mi. Les ajutages suivants

fonctionner avec du gaz PROPANE UNIQUEMENT à des

Les modèles MHGLLP B et MHGLLP G sont prévus pour

circulation du gaz. En cas de doute, remplacer l’ajutage.

fil et même le sébum de la peau peuvent entraver la

basse pression pour nettoyer l’ajutage. Des broches, du

étant extrêmement délicat. Utilisez de l’air comprimé sous

Ne touchez jamais le trou percé dans l’ajutage, celui-ci

AVERTISSEMENT :

numéro 20368 pour gaz propane.

supérieure à 1 371 mètres, commandez un ajutage haute altitude

propane standard. Pour utiliser une lampe à gaz à une altitude

Ajutage. Toutes les lampes à gaz sont munies d’ajutages de

aux normes du code national du gaz (National Gas Code).

l’intérieur du tuyau de gaz en cuivre doit être étamé pour répondre

Tuyau de gaz en cuivre. Sauf indication contraire des codes locaux,

La lampe fonctionnera mal si la pression est inférieure ou supérieure.

même pression doit être maintenue à l’ajutage de la lampe à gaz.

une pression de colonne d’eau de 27,9 cm (6 oz de mercure) La

le réservoir de gaz. Le régulateur doit être réglé pour fonctionner à

Réservoir de gaz propane et régulateur. Ne remplissez pas trop

Consultez l’étiquette d’estimation de lumiére du gaz.

lampe Mr. Heater sont conçus pour cette pression uniquement.

entre 2 500 et 2 530 BTU par pied cube. Les orifices du brûleur de la

MHGLLP G. Le rendement du gaz propane utilisé doit être compris

N’utilisez que du gaz propane avec les modèles MHGLLP B et

ventilation ne doivent pas être obstrués.

ou vapeurs inflammables. L’écoulement de l’air de combustion et la

matériaux combustibles, y compris d’essence ou d’autres liquides

Maintenez les alentours de la lampe propres et libres de

examinez-la avant de l’allumer.

Si vous n’avez pas utilisé la lampe à gaz pendant un certain temps,

Procédez aux opérations suivantes aussi souvent que nécessaire.

ENTRETIEN RECOMMANDÉ

(ou d’autres risques pour la reproduction).

comme cause de cancer et d’anomalies congénitales

produit chimique reconnu par l’État de la Californie

combustion contenant du monoxyde de carbone, un

L’utilisation de cet appareil crée des sous-produits de

AVERTISSEMENT :

SUIVANT :

L’ÉTAT DE CALIFORNIE EXIGE L’AVERTISSEMENT

d’appareil ou de tout autre appareil.

liquides ou vapeurs inflammables à proximité de ce type

N’entreposez et n’utilisez pas d’essence ou d’autres

AVERTISSEMENT :

incomplète du combustible.

Du monoxyde de carbone est produit par la combustion

aérées.

Utilisez la lampe à gaz uniquement dans des pièces

AVERTISSEMENT :

fuites et annuler la garantie.

endommager la graisse d’étanchéité, ce qui peut provoquer des

le robinet à des pressions d’essai supérieures à 6 lb/po2 peut

composants transportant le gaz doivent être vérifiés. Soumettre

Le tuyau, les raccords, le robinet de la lampe à gaz et les autres

vérifier s’il y a des fuites de gaz à l’aide d’un détecteur de fuites.

qualifié en appareils à gaz d’approuver votre installation et de

• Après l’installation et avant l’utilisation, demandez à un technicien

ou le fabricant Mr. Heater.

la et communiquez immédiatement avec votre détaillant local

matière. Si votre lampe à gaz semble mal fonctionner, fermezcomplètement formé et d’avoir une certaine expérience en la

d’installer ou de réparer votre lampe à gaz à moins d’être

propane doivent être confiées à des experts. N’essayez pas

L’installation et la réparation d’appareils fonctionnant au gaz

• Utilisez la lampe à gaz uniquement pour l’éclairage.

MR. HEATER POUR L’INTÉRIEUR

L’UTILISATION DES LAMPES À GAZ

RENSEIGNEMENT IMPORTANT POUR

appareils de combustion du propane, et aux codes locaux.

et/ou au code d’installation CAN1-B149.2 (dernière édition) des

national des gaz combustibles) ANSI Z223.1 (dernière édition),

l’absence de codes locaux, au National Fuel Gas Code (code

CSA. L’installation doit être conforme aux codes locaux ou, en

• La conception des modèles MHGLLP B et MHGLLP G est certifiée

Page 16

07/07 20362 Rév. L1ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-916-3000

l’appareil.

La

réglementation de la CSA exige que vous laissiez ces instructions destinées au consommateur avec

À l’attention de l’installateur :

– L’entretien doit être effectué par un fournisseur de services d’entretien qualifié.

• Appelez immédiatement votre fournisseur de gaz.

• Éteignez toute flamme nue.

• Ne touchez à aucun commutateur électrique.

• Ouvrez les fenêtres.

• Fermez l’arrivée de gaz de l’appareil.

vous percevez une odeur de gaz :

Si

– POUR VOTRE SÉCURITÉ

type d’appareil ou de tout autre appareil.

– N’entreposez et n’utilisez pas d’essence ou d’autres liquides ou vapeurs inflammables à proximité de ce

matériels, des blessures et des pertes de vie.

dommages

avec exactitude risque d’entraîner une explosion ou un incendie causant des

Le fait de ne pas respecter les instructions données dans le présent guide

AVERTISSEMENT :

LAMPE À GAZ INTÉRIEURE

son utilisation. Conserver ce guide pour référence future.

ou

instructions, y compris l’étiquette d’avertissement fixée sur la lampe à gaz, avant son installation

LISEZ SOIGNEUSEMENT LES INSTRUCTIONS : Lisez tous les renseignements et toutes les

MHGLLP G

MHGLLP B

de modèle

o

Numér

Gray EZ-203250001001

Starting Serial # Brass EZ-203000001001

CTIONNEMENT

FON

INSTRUCTIONS DE

ET

GUIDE D’UTILISATION

Loading...

Loading...