Page 1

Installer: Leave this manual with the appliance. Consumer: Retain this manual for future reference.

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

MR. HEATER

MODEL

MH25NG

MH25LP

GAS FIRED INFRA-RED WORKSHOP HEATER

READ INSTRUCTIONS CAREFULLY: Read and

follow all instructions. Place instructions in a

safe place for future reference. Do not allow

anyone who has not read these instructions to

assemble, light, adjust or operate the heater.

HEATSTAR

MODEL

HS25NG

HS25LP

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Shut off gas supply

• Do not try to light any appliance

• Do not touch an electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

WARNING: This is an unvented gas-fired heater. It uses air (oxygen) from the room in which it is installed.

Provisions for adequate combustion and ventilation air must be provided. Refer to Fresh Air for Combustion and

Ventilation section on page 3 of this manual.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operation, and maintenance instructions thoroughly before installing or

servicing this equipment. For assistance or additional information consult a qualified installer, service agency, or

gas supplier.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 · 216-916-3000

18673 Rev. D 06/06

Page 2

WARNINGS

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation, operation, and maintenance instructions thoroughly before installing or servicing this

equipment. For assistance or additional information consult a qualified installer, service agency, or

gas supplier.

WARNING: When used without fresh air, heater

may give off CARBON MONOXIDE, an odorless

poisonous gas. OPEN WINDOW AN INCH OR

TWO FOR FRESH AIR WHEN USING HEATER.

WARNING: This heater is equipped with a PILOT

LIGHT SAFETY SYSTEM. DO NOT TAMPER

WITH PILOT LIGHT SAFETY SYSTEM.

DANGER: Carbon monoxide poisoning may lead to

death.

Carbon Monoxide Poisoning:

Early signs of carbon monoxide poisoning resemble the

flu, with headaches, dizziness, or nausea. If you have

these signs, the heater may not be working properly. Get

fresh air at once! Have heater serviced. Some people are

more affected by carbon monoxide than others. These

include pregnant women, persons with heart or lung

disease or anemia, those under the influence of alcohol,

and those at high altitudes.

CAUTION

• Never connect gas valve or thermostat to line voltage

or a transformer.

• If the infra-red color of the grid becomes dull when the

building furnace is operating, consult gas supplier on

correct gas supply piping sizes.

• This heater is for indoor installation only!

WARNING: If heater shuts off, do not relight until

you provide fresh air. If heater keeps shutting off,

have it serviced. Keep burner and control clean.

Open door for 5 minutes.

Maintain clearances as shown in Figure 2 or on

heater nameplate.

• DO NOT USE MATCH OR OTHER FLAME

FOR LEAK TESTING.

• DO NOT EXCEED 1/2 PSI INLET PRESSURE

TO HEATER.

NOTE

Gasket binder material used in this heater assembly will

temporarily emit an odor and/or vapor. This condition will

clear up in approximately 20 minutes and thereafter will

not reoccur. Refer to Chapter 2 for ventilation.

TABLE OF CONTENTS

Chapter Title Page

I Introduction ............................................ 3

II Heater Installation .................................. 5

III Heater Operating Instructions ................. 10

IV Operator Maintenance Instructions ......... 12

V Replacement Parts List.......................... 15

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

2

Page 3

CHAPTER I

INTRODUCTION

1. EQUIPMENT

This heater is the consumer version of a highly successful, thoroughly tested, gas fired, infrared, industrial utility

heater.

This heater does not require an external electrical source

for operation.

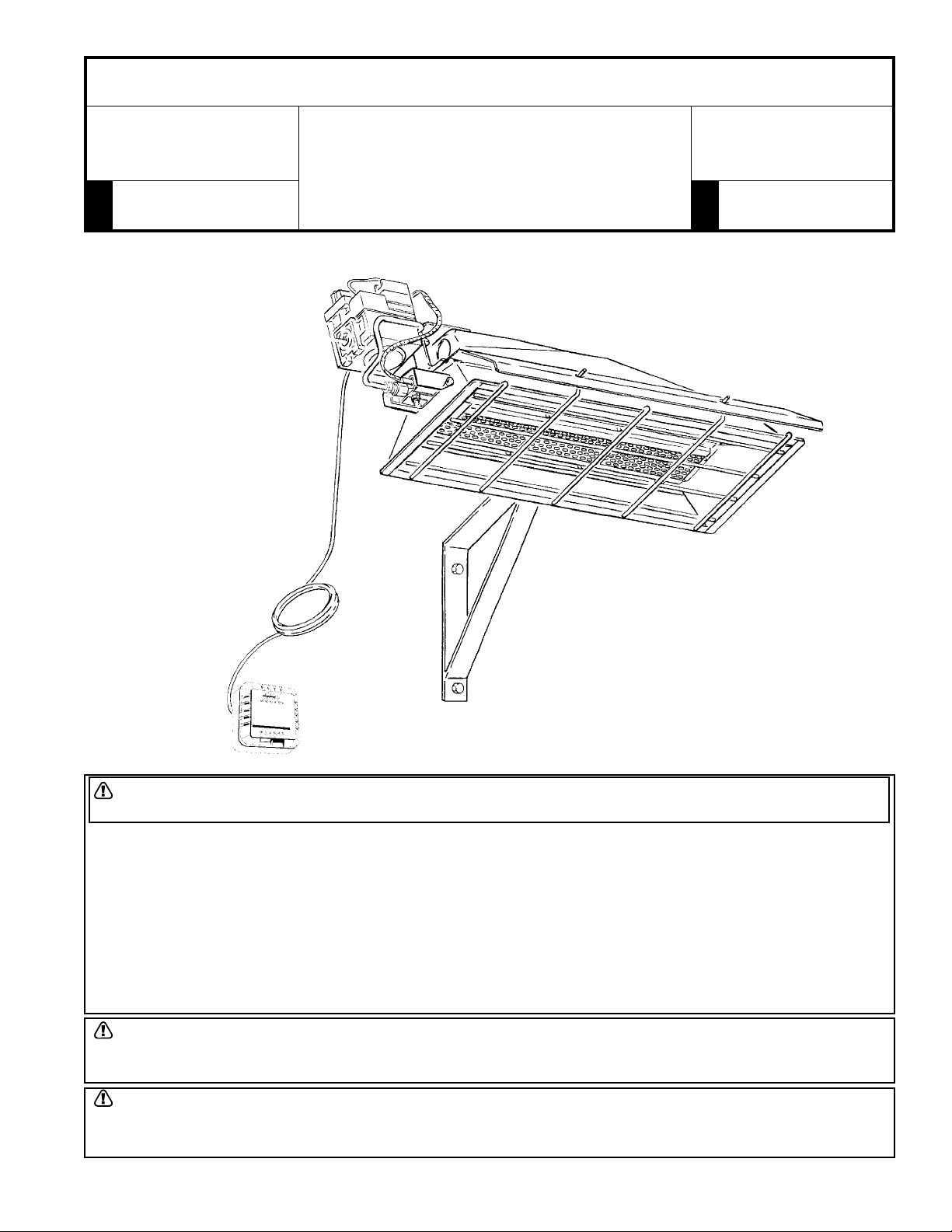

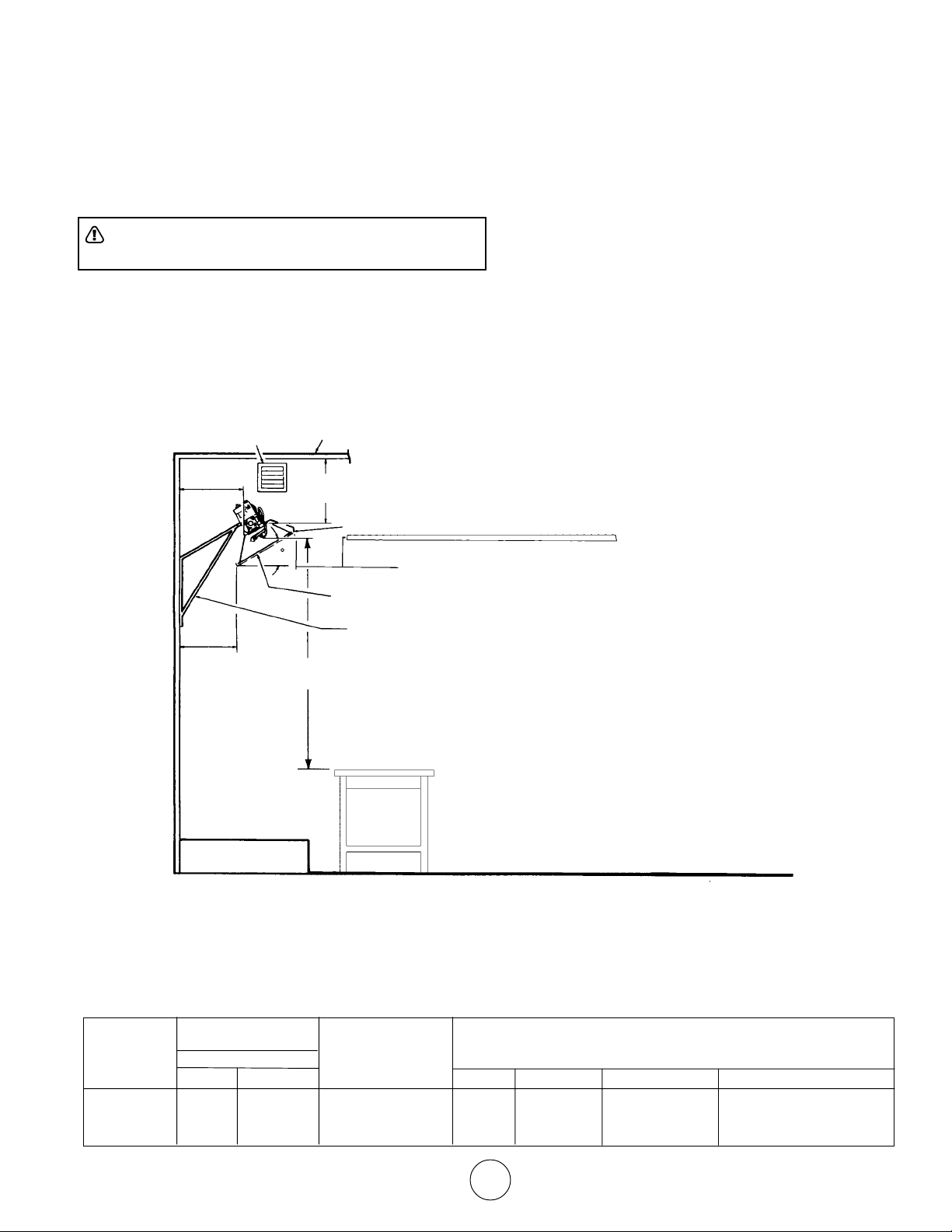

The major components of the heater and a typical

installation are identified in Figure 1. The basic heater

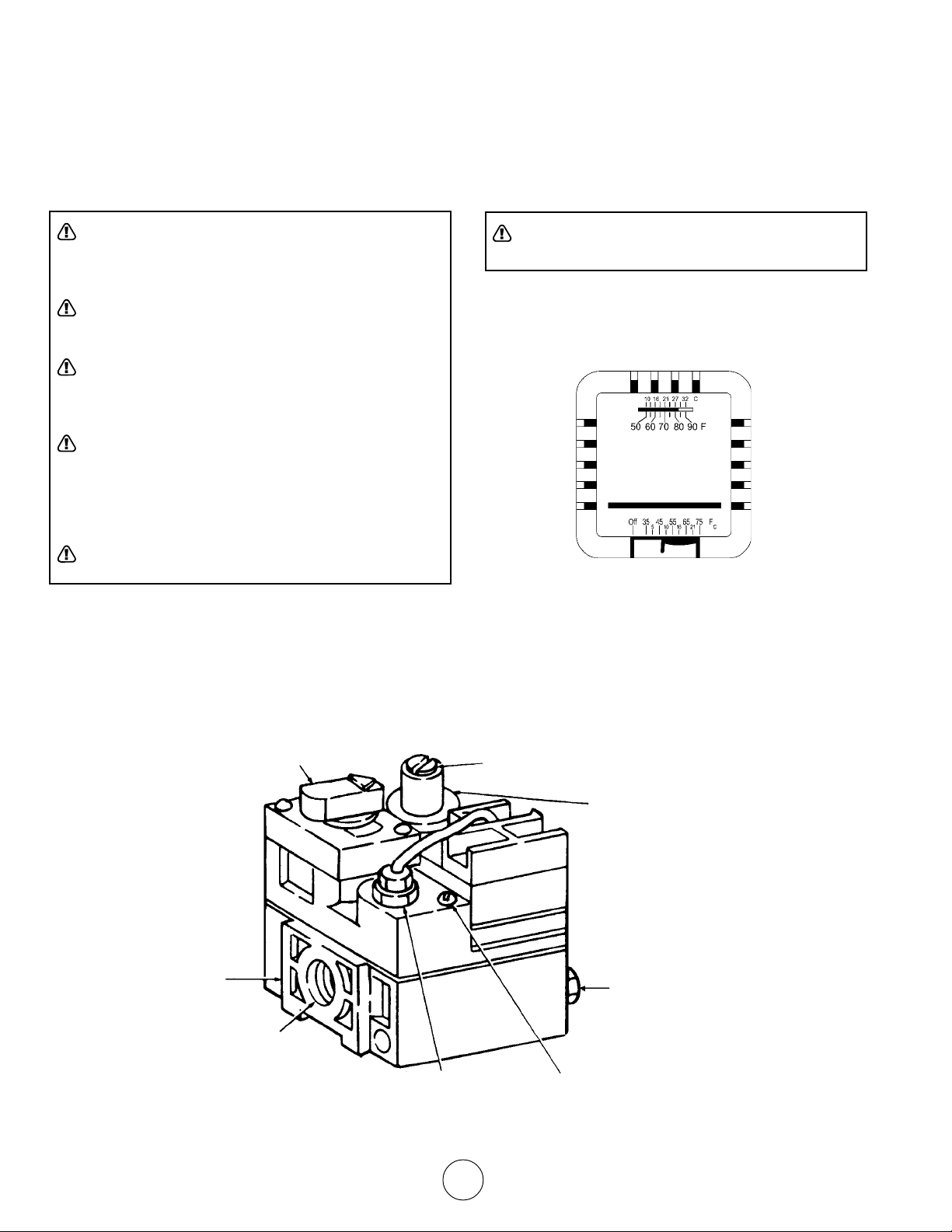

GAS CONTROL

VALVE

POWERPILE

GENERATOR

consists of the complete burner assembly, flue deflector,

grid, reflector assembly and face guard.

2. PURPOSE OF EQUIPMENT

WARNINGS

This heater is for indoor installation only.

This heater is designed to heat indoor areas. Do not

use for inhabited or small, enclosed areas.

This heater is an ideal selection when a simple and

easily installed method of heating a utility building is

required.

EXHAUST

VENT

THERMOSTAT

CABLE

THERMOSTAT

Figure 1. Heater Major Components

3. MODELS COVERED IN THIS MANUAL

Model MH25NG/HS25NG is for use where natural gas is

intended fuel source. Model MH25LP/HS25LP is for use

where propane gas is the intended fuel source.

4. MANUAL USE

• The procedures and information contained within

this manual will allow purchaser of this heater to

install and maintain the heater safely and

efficiently.

BASIC HEATER

WALL MOUNTING

BRACKET

• The cover and the following page provide a safety

summary that attempts to gather all the warnings used within the manual in one location.

• A table of contents is provided for easy reference

to any portion of the manual.

• Chapter 1 provides general information on the

use of this manual and on the heater.

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

3

Page 4

• Chapter 2 provides heater installation requirements

and information, such as: a) minimum distances

from heater components to combustible materials,

b) heater mounting requirements, c) venting

requirements, d) fuel supply requirements, e)

thermostat mounting.

• Chapter 3 covers startup, operation, and shutdown

of the heater.

• Chapter 4 provides operator maintenance instruc-

tions such as: troubleshooting, adjustments,

powerpile replacement and operator checks.

• Chapter 5 provides warranty and replacement

parts information.

5. GENERAL INFORMATION

• Your heater comes fully assembled and is tested

at the factory with the appropriate type of gas and

at the input pressures stated on the nameplate.

• Upon receipt and prior to attempting installation,

be sure to inspect the heater and its packaging for

damage and/or missing components. If damage is

found or missing components are suspected,

contact your dealer. See Chapter 5 for a complete

listing of items required for the safe and efficient

installation and use of this heater.

• Never attempt to operate the heater using a fuel

other than that specifically identified on the

nameplate.

• The installation of the heater must conform with all

local building codes or, in absence of governing

local codes, with the National Fuel Gas Code,

ANSI Z223.1 (NFPA 54). This code can be obtained from either the: Canadian Standards

Association, 8501 East Pleasant Valley Road,

Cleveland, OH 44131; or, NFPA, Battery March

Park, Quincy, MA 02269.

• Canadian installations must comply with CAN/

CGA-B149.1.2 gas code which can be purchased

from Canadian Gas Association, 55 Scarsdale

Road, Don Mills, Ontario M3B 2R3.

• Contact factory when appliance is to be installed at

high altitudes. Factory supply high altitude conversion kit with instructions and data plate.

• A plugged 1/8" N.P.T. Test Gage Connection is

provided on the heater gas control.

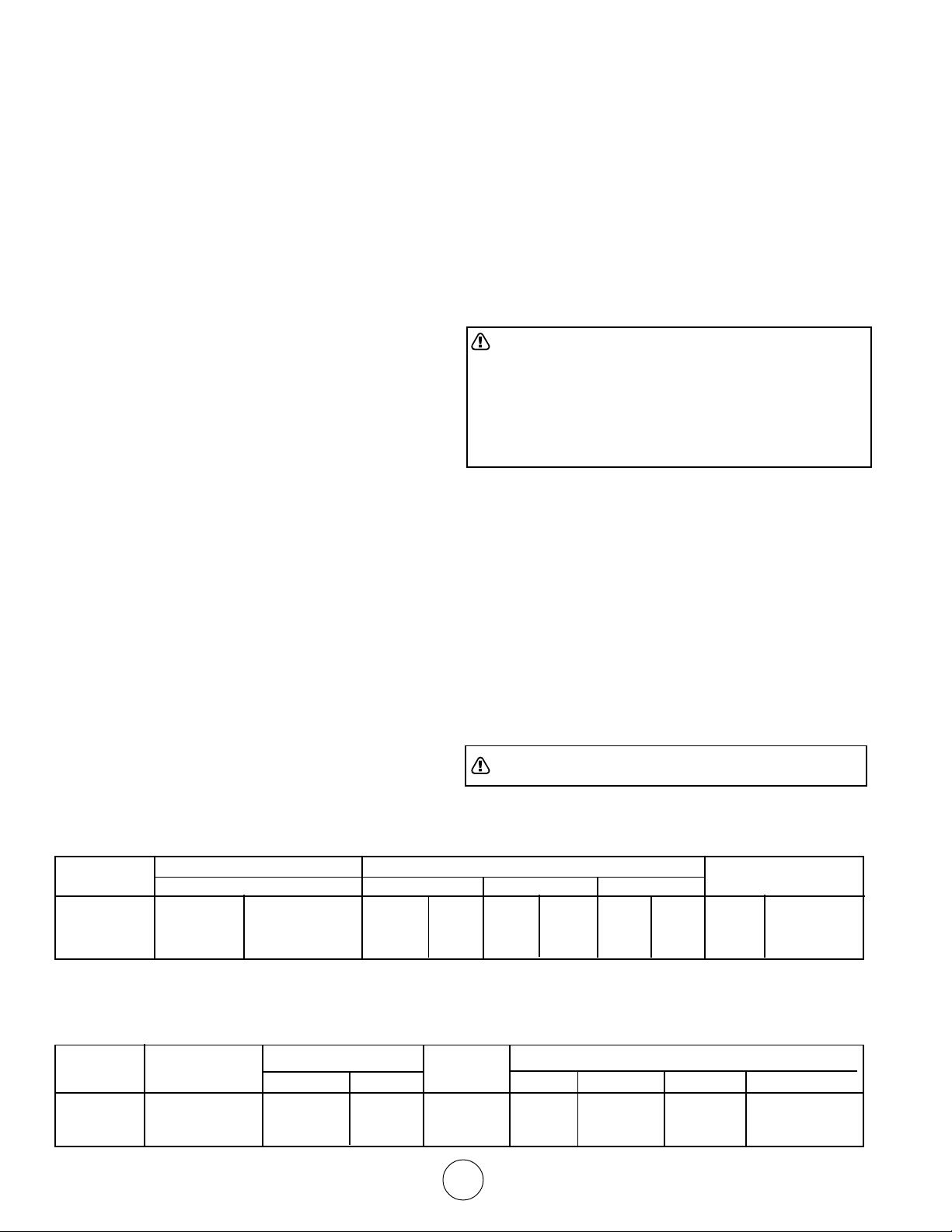

• See Tables 1 and 2 for heater specifications:

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause property damage,

injury or death. Read the installation, operation, and

maintenance instructions thoroughly before installing or

servicing this equipment. For assistance or additional

information consult a qualified installer, service agency,

or gas supplier.

• For additional information contact:

The factory.

• The following extra NFPA Manuals are helpful when

installing this heater in a location not anticipated in

this manual:

Number Related Subject

NFPA 88 Clearances to Combustible Surfaces

NFPA 409 Clearances to Combustible Surfaces

DO NOT EXCEED 1/2 PSI INLET PRESSURE TO HEATER

Table 1. BTU Ratings and Supply Pressures

MODEL BTU/HR. RATING GAS SUPPLY PRESSURE (W.C.) ORIFICE

NO. GAS MIN. MAX. MANIFOLD SIZE

NATURAL PROPANE NAT. L.P. NAT. L.P. NAT. L.P. NAT. L.P.

MH/HS25NG 25,000 — 7.0" — 14" — 6" — 45 —

MH/HS25LP — 22,000 — 11" — 14" — 10" — 55

Table 2. Heater Dimensions and Orifice Sizes

MODEL OPERATING ORIFICE SIZE INPUT SIZE

NO. PRESSURE BURNER PILOT BTU/H WIDTH LENGTH HEIGHT WEIGHT

MH/HS25NG 6.0"w.c. 45 .018 25.000 12-1/4" 29-3/4" 7" 20 lb.

MH/HS25LP 10"w.c. 55 .011 22,000 12-1/4" 29-3/4" 7" 20 lb.

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

4

Page 5

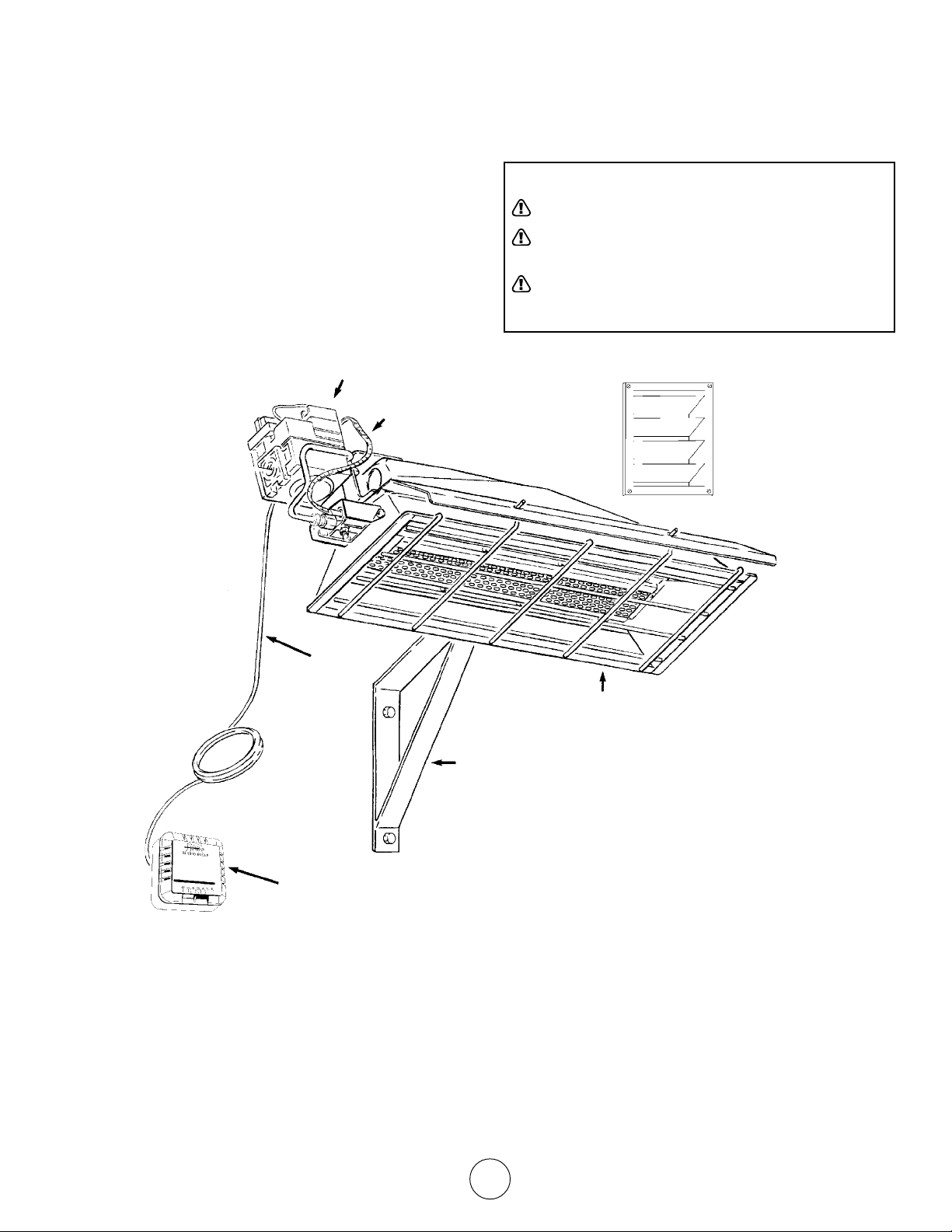

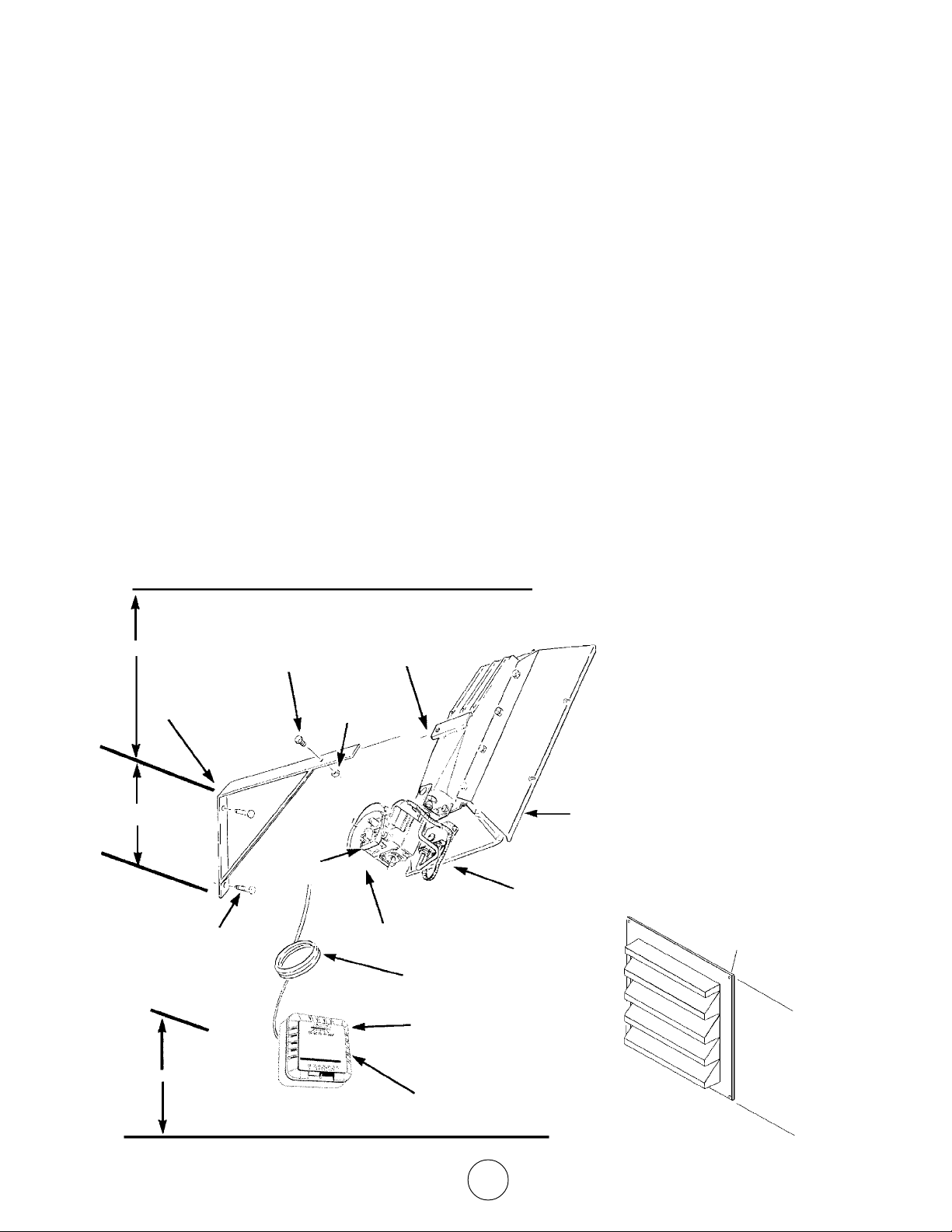

Provide adequate clearance to combustibles per Table 3 at

control end of heater for servicing and minimum on top and

sides for ventilation and combustion air supply.

A minimum clearance of 8’ above floor for public garages in

accordance with NFPA No. 88 most recent edition, or

Figure 1; whichever is larger.

Canadian installations in public garages must comply with

CGA 149B.1.9 most recent edition.

WARNING: Maintain clearances as shown in Figure 2

or on heater nameplate.

CHAPTER II

HEATER INSTALLATION

1. GENERAL INSTALLATION INFORMATION

AND REQUIREMENTS

• The required minimum clearances to combustible

surfaces are illustrated in Figure 2 and Table 3.

As shown on Figure 2, the front of the heater is

installed at the minimum required clearance to

combustible surfaces and toward open space,

and then the other sides must have a minimum

clearance of 16 inches to combustible surfaces.

16”

MINIMUM

14-1/2”

EXHAUST

VENT

30

CEILING

14”

MINIMUM

48”

MINIMUM

OPEN

WORKSHOP DOOR

16”

MINIMUM

HEATER

WALL

BRACKET

NOTE:

1. ONLY FLUE SIDE OF HEATER CAN

BE ELEVATED (30o).

2. HEATER SIDE REFLECTOR MUST

BE HORIZONTAL.

FLOOR LINE

Figure 2. Installation Clearances to Combustible Surfaces

Table 3. Installation, Ventilation and Mounting Information

BTU/HR. RATING NORMAL

MODEL GAS MOUNTING CLEARANCES TO COMBUSTIBLE SURFACES

NO. NAT. L.P. POSITION TOP SIDES BACK BELOW

MH/HS25NG 25,000 — 30

MH/HS25LP — 22,000 30

Model # MH25NG/LP HS25NG/LP

o

o

14" 16" 16" 48"

14" 16" 16" 48"

Installation instructions and Owner’s Manual

5

Page 6

• This heater may be mounted on any wall;

however, it is recommended that the heater be

mounted in the middle of the wall opposite any

overhead doors.

• When selecting installation locations for this

heater ensure that the opening of any exterior or

interior doors or windows will not violate minimum clearances or contact any heater components.

• If an overhead door is installed in the building,

verify that the heater is not installed in such a

way as to interfere with door operation and verify

that the door in its open position will not reduce

clearances below the minimum requirements.

Never mount the heater in such a way that

would position the heater above an opened

overhead door.

• In most cases the infiltration around your

uninsulated entry doors and windows will provide

enough air flow for efficient heater operation.

department at 1-800-251-0001.

The selection of the thermostat mounting location is

critical to efficient and effective heater operation.

• The thermostat should be mounted about 5 feet

above the floor where air can circulate freely

around it.

• The thermostat should not be mounted directly

to a cold exterior wall without an insulated

mounting block.

• The thermostat should not be mounted in direct

drafts.

• The thermostat should not be mounted directly

below the installed the heater.

• The thermostat should not be installed at a

distance that is farther from the heater than the

length of the thermostat cable.

Unrestricted air flow during heater operation is essential

to prevent the area above the installed heater from

overheating. If your workshop/utility building is tightly

insulated (including windows, doors, openings, etc.) the

following ventilating methods

must be followed:

• A single exhaust vent is supplied with your

heater for your convenience. This vent must be

located above the heater (preferably at the

highest point in the building interior) and it must

vent to the exterior of the building. An additional

vent is available from the factory for those having

a finished workshop or utility building.

• An intake vent, or equivalent, from the exterior of

the building and having an effective area of 75

square inches must be located below the heater

(preferably within 2 feet of the building’s floor).

• Openings equivalent to intake vent would be:

partially open doors and partially open windows.

• Openings of this size (5 inch by 13 inch, or 3

inch by 25 inch) will prevent dangerous heat

buildup above the heater.

Ensure that no gas lines or electrical wiring or conduits

will interfere with mounting of the heater to the wall.

Depending on local codes and requirements and the

installer’s skill level, the sizing and installation of gas

lines required to supply the heater may require the

assistance of a professional. If in doubt as to these

requirements, discuss the requirements of this manual

with the dealer from whom the heater was purchased

and your gas supplier, or call our customer service

2. HEATER MOUNTING INSTRUCTIONS

After selecting the heater installation location and the

thermostat location and after verifying and ensuring that

all of the above placement requirements are fulfilled,

mount the heater as follows:

A. Determine how you wish to install the vent based on

the construction of the building and your personal

preference. (i.e., do you wish the flanged (finished)

side on the interior or the exterior of the building or

do you want two vents so that both exterior and

interior will be finished?) If needed, order an

additional vent from the factory. Our address and toll

free phone number are on the rear cover of this

manual. Install the vent as follows:

1. See Figure 3 for dimensions and information on

the vent.

2. Select a place as high above the heater as

possible in accordance with the above requirements and ensure that the vent or vents will not

contact or interfere with existing building systems (i.e., ducts, wiring, plumbing, etc.)

3. Place the unfinished side of the vent against the

wall in its elected location and trace its dimensions on the wall with a pencil or other suitable

marker.

4. Cut or otherwise open a hole in the wall, or walls

for finished buildings, having the dimensions of

the unfinished side of the vent.

5. Install the vent or vents as desired and retain

with 4 suitable fasteners through the predrilled

holes in vent flange.

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

6

Page 7

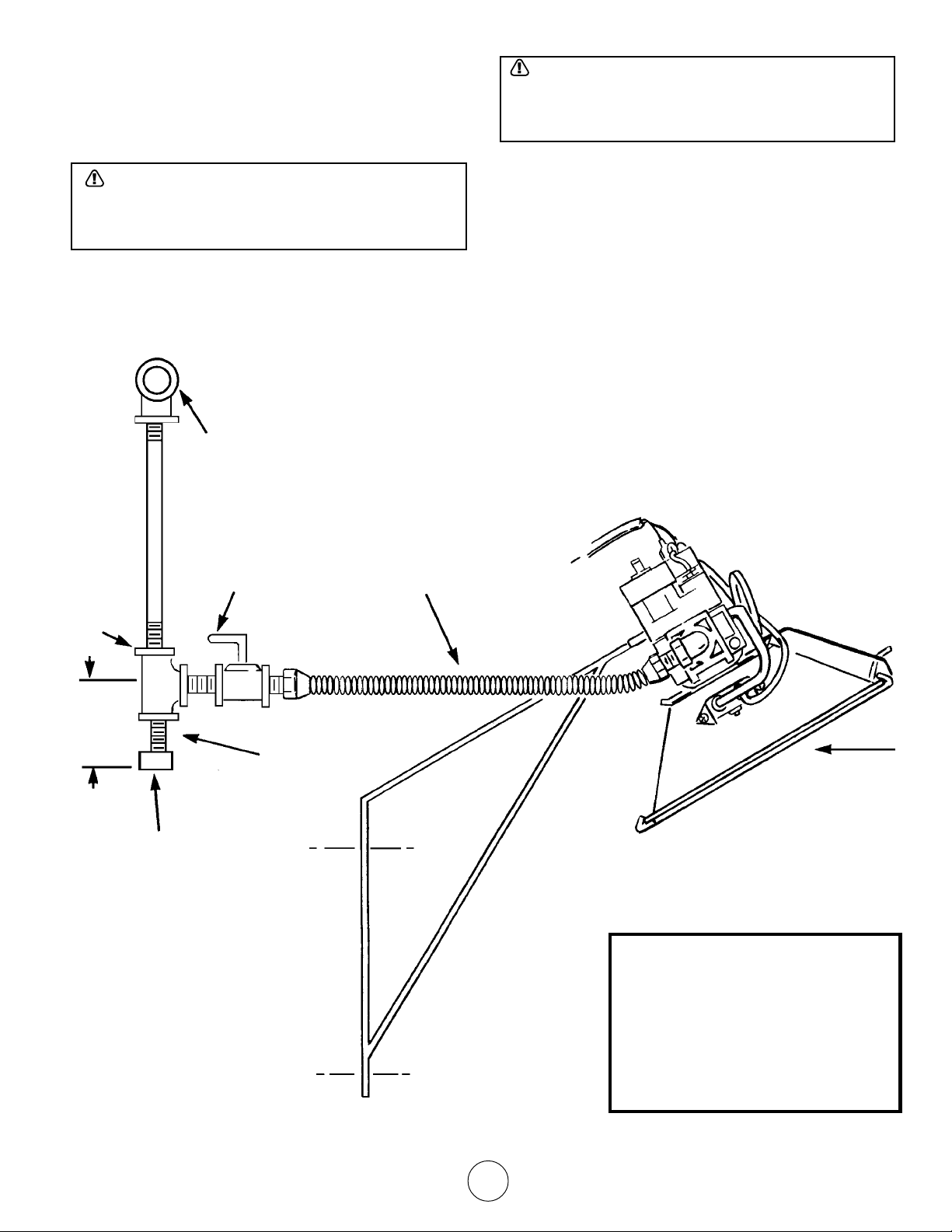

B. Prepare to install the heater wall mounting bracket

as follows:

1. If the wall mounting bracket is to be attached to

a stud and wallboard wall, refer to Figure 3 for

dimensions, locate a stud, and drill two 1/8" pilot

holes into the stud centerline. Use template for

simplified installation.

2. If the wall mounting bracket is to be attached to

a brick or masonry wall, refer to Figure 3 for

dimensions. Obtain two 1/4 inch (inside

diameter)expansion anchors and determine the

correct drill size to be used with them. Drill

the appropriate size holes in the brick or masonry to accept the anchors.

C. Place the wall mounting bracket on the wall and

align the two through holes on the bracket with the

pilot holes or anchors. Install 1/4 inch by 2-1/2 inch

lag screws through the bracket into the stud or

anchors. Tighten securely.

D. Locate heater mounting clip on back of heater and

select the 1/4" – 20 by 3/4" hex head bolt and 1/4" 20 hex nut.

E. Position the heater as shown in Figure 3 and slide

the heater mounting clip over the bracket and install

the bolt through the clip and bracket.

F. Thread the hex nut onto the bolt and tighten

securely.

G. Ensure that the selected thermostat location meets

all of the above requirements. Refer to the

instructions that come with the thermostat for

additional grounding information and mounting

instruction.

H. If the wall is of stud and wallboard construction, then

use the #6 by 1 inch sheet metal screws, included

with the thermostat, and mount the thermostat in the

selected location.

I. If wall is brick or masonry, the appropriate anchors

must be obtained to accommodate thermostat

mounting screws. Use the back plate of the

thermostat as a template to mark the hole locations,

drill appropriate size anchor holes, install the

anchors, securely attach the thermostat using the

mounting screws.

J. Connect thermostat wires to gas valve as shown in

Figure 4.

24” MIN

HEATER WALL

MOUNTING

BRACKET

9”

1/4” X 2-1/2” LONG

LAG SCREWS

(2 REQUIRED)

CEILING

HEATER

1/4”-20x3/4”

HEXHEAD BOLT

GAS

CONTROL

VALVE

Figure 3. Heater Mounting Information

MOUNTING

CLIP

1/4”-20

HEX NUT

FLUE

DEFLECTOR

HEATER

REFLECTOR

1/2” NPT GAS INLET

(DO NOT EXCEED 1/2 PSI)

THERMOSTAT CABLE

(SEE FIGURE 4)

58”

FLOOR

Model # MH25NG/LP HS25NG/LP

#6 X 1” SHEET METAL SCREWS

(2 REQUIRED - INCLUDED WITH

THERMOSTAT)

UNFINISHED

SIDE

THERMOSTAT (SEE INSTRUCTIONS

INCLUDED WITH THERMOSTAT

Installation instructions and Owner’s Manual

7

FINISHED

SIDE

FLANGE

PREDRILLED

HOLES

Page 8

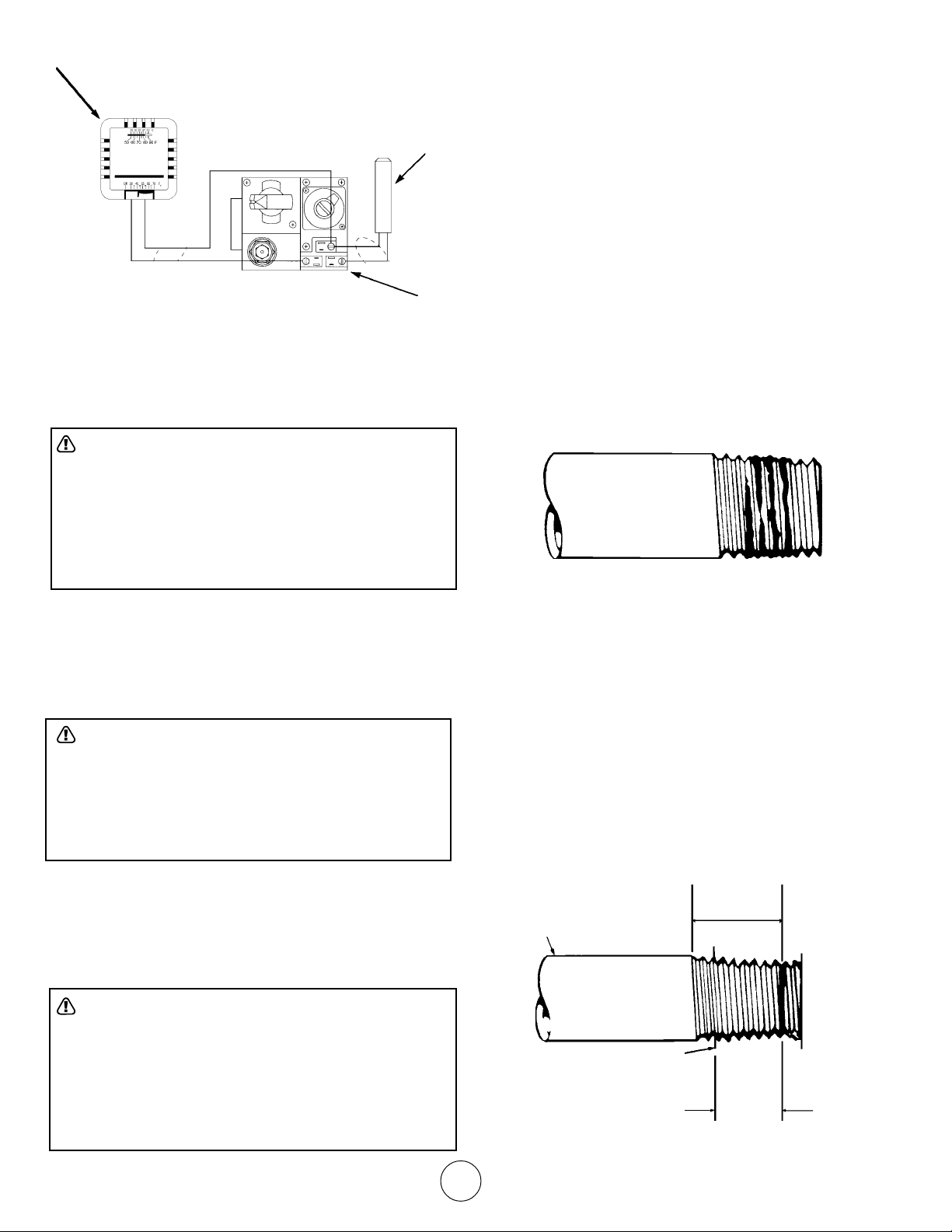

THERMOSTAT

• To ensure the best performance from your LP gas

heater, make sure the supply manifold pressure is

at least 1/2 psi (14 in W.P.).

POWERPILE GAS VALVE

POWERPILE GENERATOR

Figure 4. Connection Diagram

Refer to National Electrical Code NFPA70-1993 and for

Canadian installations to current CODE C22.1-

3. CONNECTING HEATER TO GAS SUPPLY

WARNING: Depending on local codes and require-

ments and the installer’s skill level, the sizing and

installation of gas lines required to safely and efficiently

supply the heater may require the assistance of a

professional. If in doubt as to these requirements,

discuss the requirements of this manual with the dealer

from whom the heater was purchased and your gas

supplier.

3.2 Piping Requirements

All piping installed must comply with local codes and

ordinances or with National Fuel Gas Code,

ANSI Z223.1 (NFPA 54), whichever takes precedence.

When installing piping, the following requirements must be

taken into consideration: Canadian installations must

comply with the B149.1.2 Gas Code.

• Use new properly reamed black pipe free from

chips.

• Apply a good quality pipe compound to all male

threads as shown in Figure 5 prior to assembly. If

LP gas is the fuel, ensure that pipe compound is

resistant to LP gas. Do not use Teflon™ tape.

USE MODERATE AMOUNT OF PIPE DOPE

LEAVE 2 THREADS BARE

3.1 Gas Supply Requirements

• See Tables 1 and 2 for gas supply minimum,

maximum, operating, and manifold pressures for

both heater models. Pressures are provided in

inches of W.C. (water column). Also, see heater

rating plates located on the heater.

WARNING: Model MH/HS25NG is designed to burn

natural gas and it comes equipped with a regulator. The

regulator is built into the gas valve. The maximum inlet

pressure to this regulator is 1/2 psi (14 in. W.C.) If gas

line pressure exceeds 1/2 psi, then an additional

regulator must be installed before the heater/regulator

to step down the pressure to a maximum of 1/2 psi.

• Most residential natural gas services provide a line

pressure of 4 oz. (6.9 in. W.C.). If in doubt consult

your natural gas supplier.

• To ensure the best performance from your natural

gas heater make sure the supply manifold pressure is at least 6" W.C.

WARNING: Model MH/HS25LP is designed to burn

liquefied petroleum (LP) gas and it comes equipped

with a regulator. The regulator is built into the gas valve.

The maximum inlet pressure to this regulator is 1/2 psi

(14 in. W.C.). If gas line pressure exceeds 1/2 psi, then

an additional regulator must be installed before the

heater/regulator to step down the pressure to a maximum of 1/2 psi.

Figure 5. Pipe Compound Application

• Male threads on pipe to be installed into gas valve

shall meet the requirements of Figure 6. Threads

longer than those shown in the figure may cause

gas valve distortion and malfunction.

• A sediment trap meeting the typical requirements

of Figure 7 shall be installed in the line to the gas

valve.

• A dedicated shutoff valve for the heater must be

installed in the gas supply line.

3.3 Piping Installation

While ensuring that all of the above gas supply require-

3/4” MAXIMUM

THREAD LENGTH

1/2” BLACK PIPE

GAS VALVE BODY

1/2” MAXIMUM

DEPTH OF INSERTS

INTO GAS VALVE

Figure 6. Gas Valve Connection Requirements

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

8

Page 9

ments and piping requirements are fulfilled, install piping

as follows:

A. In accordance with the above piping requirements,

assemble piping, sediment trap, shutoff valve, and

necessary fittings. Tighten all components securely.

WARNING: Failure to ensure that male threads on

pipe to be installed into gas valve meet the requirements of Figure 6 may cause gas valve damage,

distortion and malfunction.

B. Install a threaded nipple, prepared in accordance

with paragraph 3.2 into gas valve.

C. Connect gas piping to nipple installed in the gas

valve.

SUPPLY

LINE

WARNING: When testing gas piping use only a soap

and water solution. Do not use a match or other flame

for leak testing. If during leakage check gas is

smelled, turn off the gas supply and ventilate building.

D. Ensure the building is properly ventilated. Without

lighting the pilot light of the heater, open the gas

supply valve and pressurize the piping up to the

heater’s gas valve.

E. Using a brush, apply a soap and water solution to all

connections and look for bubbles indicating a leak. If

a leak is detected, turn off gas supply and tighten

connections. Retest and tighten connections until no

more leaks are found.

1/2”

TEE

3”

CAP

SHUTOFF

VALV E

NIPPLE

RIGID PIPE WITH

UNION OR A FLEXIBLE

CONNECTOR TO HEATER

HEATER

NOTE:

1. ONLY USE A PIPE COMPOUND

WHICH IS RESISTANT TO

LIQUIFIED GASES ON LP

INSTALLATIONS.

2. FITTINGS SHOWN ARE NOT

INCLUDED WITH HEATER.

Figure 7. Typical Piping Installation

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

9

Page 10

CHAPTER III

HEATER OPERATING

INSTRUCTIONS

NOTE

Gasket binder material used in this heater assembly

will temporarily emit an odor and/or vapor. This condition will clear up in approximately 20 minutes and

thereafter will not reoccur. Refer to Chapter 2 for

ventilation.

1. OPERATING SAFETY INSTRUCTIONS

WARNING: When used without fresh air, heater may

give off CARBON MONOXIDE, an odorless poisonous gas. OPEN WINDOW AN INCH OR TWO FOR

FRESH AIR WHEN USING HEATER.

WARNING: This heater is equipped with a PILOT

LIGHT SAFETY SYSTEM. DO NOT TAMPER WITH

PILOT LIGHT SAFETY SYSTEM.

WARNING: If heater shuts off, do not relight until you

provide fresh air. Open door for 5 minutes. If heater

keeps shutting off, have it serviced. Keep burner and

control clean.

WARNING: CARBON MONOXIDE POISONING MAY

LEAD TO DEATH. Early signs of carbon monoxide

poisoning resemble the flu with headache, dizziness

and/or nausea. If you have these signs, heater may

not be working properly. Get fresh air at once! Have

heater serviced.

WARNING: DO NOT USE MATCH OR OTHER

FLAME FOR LEAK TESTING.

CAUTION: If the infra-red color of the grid becomes

dull when the building furnace is operating, consult

gas supplier on correct gas supply piping sizes.

CAUTION: This heater is for indoor installation only!

2. HEATER STARTUP

WARNING: During heater startup ensure that

building is well ventilated.

A. Open the gas supply valve or valves.

B. Set the thermostat to the OFF position.

See Figure 8.

FIGURE 8. THERMOSTAT CONTROLS

C. If the manual gas control knob on the gas valve is

not in the OFF position, partially depress the knob

and rotate to the OFF position. See Figure 9.

MANUAL GAS

CONTROL KNOB

WRENCH

BOSS

GAS

INLET

Model # MH25NG/LP HS25NG/LP

PRESSURE

REGULATOR

ADJUSTMENT

PILOTSTAT

POWER UNIT

PILOT FLOW ADJUSTING SCREW

(BENEATH COVER SCREW)

Figure 9. Gas Valve Components

Installation instructions and Owner’s Manual

10

STANDARD

PRESSURE

REGULATOR

PILOT GAS OUTLET

(PRESSURE TAPPING

DIRECTLY BENEATH)

Page 11

D. Wait 5 minutes to allow gas that may have

accumulated in the main burner to escape

(especially important after installation).

E. Turn the manual gas control knob to the PILOT

position.

F. Depress the manual gas control knob. Using a

match, light the pilot light. See Figure 10. Hold the

knob down for approximately 30 seconds to allow

any air in gas lines to pass through pilot and, once

pilot is lit, allow the thermocouple to heat up enough

to activate the safety valve in an open position.

G. Release manual gas control knob and turn to ON.

H. Reset thermostat to desired temperature.

DEPRESS TO

LIGHT

NOTE

During the initial startup of heater, an odor and,

perhaps, some vapor will come from the heater. This

is the gasket binding material emitting this odor and/

or vapor. After approximately 20 minutes, this odor will

disappear and not occur again.

3. HEATER SHUTDOWN

A. Turn thermostat to OFF.

B. Turn manual gas control knob on gas valve to PILOT

position.

C. Partially depress knob and rotate to the OFF

position.

D. Close gas supply valves.

GAS VALVE

PILOT BURNER

Figure 10. Lighting of Pilot Burner

Model # MH25NG/LP HS25NG/LP

11

LIGHT PILOT WITH MATCH

AS SHOWN

Installation instructions and Owner’s Manual

Page 12

CHAPTER IV

OPERATOR MAINTENANCE

INSTRUCTIONS

PROPER FLAME

ADJUSTMENT

3/8 TO 1/2 INCH

(10-13 MILLIMETERS)

1. TROUBLESHOOTING

A. Table 4 lists the common malfunctions which you may

find during the operation or maintenance of your heater.

B. For additional information, refer to Honeywell Field

Bulletin enclosed in the heater carton.

C. In the event results cannot be obtained after performing

all listed solutions, call the factory.

2. ADJUSTING THE PILOT FLAME

The pilot flame should envelop 3/8 to 1/2 in. (10 to 13

mm) of the tip of the thermocouple or generator.

Refer to Figure 11. To adjust:

PRESSURE REGULATOR ADJUSTMENT

MANUAL GAS

CONTROL KNOB

WRENCH

BOSS

Figure 11. Proper Flame Adjustment

A. Remove pilot adjustment cover screw. Refer to

Figure 12.

B. Turn inner adjustment screw clockwise to

decrease or counterclockwise to increase

pilot flame.

C. Always replace cover screw after adjustment and

tighten firmly to ensure proper operation.

(BENEATH COVER SCREW)

INSTALL LONG

SCREW IN

OUTSIDE CORNER

THERMOCOUPLE

GAS

INLET

PILOTSTAT

POWER UNIT

Figure 12. Top View of Standard Capacity Gas Control

Model # MH25NG/LP HS25NG/LP

STANDARD

PRESSURE

REGULATOR

(“A” MODEL)

STEP OPENING REGULATOR

PILOT GAS OUTLET

(PRESSURE TAPPING

DIRECTLY BENEATH)

PILOT FLOW ADJUSTING SCREW

(BENEATH COVER SCREW)

Installation instructions and Owner’s Manual

12

(“C” MODEL)

Page 13

Table 4. Trouble Shooting Chart

Below in chart form are various symptoms of a malfunctioning system, possible defects that will cause these symptoms

and suggested corrective measures. The chart assumes that the proper gas pressure is available to the heater and that

the lighting procedure is as stated on the plate attached to the heater.

SYMPTOMS CAUSES SOLUTIONS

burner light off very slow partially block pilot orifice replace

burner light off very slow infra-red partially blocked burner orifice replace

color stays dull

burner flash back low gas pressure correct line pressure

(roaring noise during operation or call your gas supplier

and ceramic grid surface will be

dark) damaged burner replace

ceramic grid or burner sooting up first check for damaged burner replace if damaged

(when new or after cleaning) orifice

pilot cannot be ignited blocked pilot orifice replace

pilot out of adjustment re-adjust pilot

if burner orifice is not damaged replace

then check for damaged manifold

gas cock not in position gas cock knob must be

turned to pilot and held

depressed

pilot gas flow adjustment open and adjust

screw may be closed (see Figure 12)

pilot lights but goes out defective thermocouple replace

defective control replace

pilot stays lit but main burner loose wire or improperly wired tighten connections, check

will not light wiring diagram

defective control replace

blocked burner orifice clean orifice or replace

failure to ignite main gas off open manual valves

3. REPLACING THE GAS VALVE UNIT

A. Remove the two gas valve unit wires at the gas

control valve labeled “PP”.

B. Unscrew gas valve from gas piping.

C. Reconnect gas valve and unit wires to terminals

“PP”. Be sure to leave thermostat wire on one

terminal.

4. FREQUENCY OF OPERATOR CHECKS

Intermittent use. Appliances that are used seasonally

air in gas line bleed gas line

loose wire connections tighten wire connections

dirty wire connections clean terminals and secure

terminals

should be checked before shutdown and again before the

next use.

Dusty, wet or corrosive environment. Since these

environments can cause the gas control to deteriorate

more rapidly, the system should be checked more often.

The gas control should be replaced if:

A. It does not perform properly on checkout or trouble

shooting.

B. The gas control knob Is hard to turn or push down, or

it fails to pop back up when released.

Model # MH25NG/LP HS25NG/LP

13

Installation instructions and Owner’s Manual

Page 14

IF SERVICE IS REQUIRED

PLEASE DO NOT RETURN THIS APPLIANCE TO YOUR STORE

For information regarding service, please call our Toll-Free Number:

1-800-251-0001.

Our office hours are 8:30 AM – 5:00 PM, Eastern Time Zone

Monday through Friday

Please include the model number, date of purchase, and description of

problem in all communication.

CHAPTER V

REPLACEMENT PARTS LIST

1.INTRODUCTION

This section of the manual will help you to obtain

efficient and dependable service from your heater and

enable you to order repair parts correctly.

A. Order parts by giving full model number and serial

number as it is stated on the name place attached

to the heater.

B. See Figure 13 to assist in locating parts.

C. Refer to Table 5 for part number and description.

2.WARRANTY

Enerco Group, Inc. warrants that Infra-Red Heaters

manufactured and sold will be free from defects in

material and workmanship.

Parts, assemblies, controls, etc. furnished by EGI

suppliers will carry a one (1) year warranty from date of

purchase.

The sole responsibility of EGI under this warranty shall be

to replace any part for which a written claim is made to

EGI WITHIN THE TIME LIMIT OF THIS WARRANTY,

WHICH IS RETURNED UPON REQUEST TO EGI –

F.O.B. Cleveland, Ohio – OR F.O.B. an EGI authorized

service facility and which is proved to be defective upon

inspection by EGI.

This warranty shall not apply to any part or product which

has been subjected to misuse or neglect, damaged by

accident, or rendered defective by reason of improper

installation. THIS WARRANTY IS IN LIEU OF ANY AND

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

and of any other responsibility of EGI for parts or products

sold by EGI, including consequential or special damages.

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

14

Page 15

1

11

12

8

20

21

3

18

19

2

22

15

5

6

7

10

16

17

4

13

14

9

Table 5. Replacement Parts List for Heater Models MH/HS25NG and MH/HS25LP

ITEM NO. STOCK NO. DESCRIPTION ITEM NO. STOCK NO. DESCRIPTION

1 02529A Burner Assembly Complete 12 05455 Orifice-Burner-Propane Gas

2 00377A Reflector Assembly 13 05576 Orifice-Pilot-Natural Gas

3 01357 Flue Deflector 14 05573 Orifice-Pilot-Propane Gas

4 16451 Pilot Tube 15 10358 Thermostat Cable

5 00024 Gas Valve-Natural Gas 16 11406 Pilot Burner N/G

6 00025 Gas Valve-Propane Gas 17 11405 Pilot Burner L/P

7 10367 Thermostat 18 04435A Grid Replacement

8 14405 Wall Mounting Bracket 19 12369 Gasket

9 04432 Face Guard 20 05354 Jamb Nut

10 09360 Thermocouple/Generator 21 05351 Connector

11 05445 Orifice-Burner-Natural Gas 22 98593 3/8” Close Nipple

23 19014 Intake Louver

23

ALL WARRANTY CLAIMS REQUIRE PROOF OF PURCHASE

Model # MH25NG/LP HS25NG/LP

15

Installation instructions and Owner’s Manual

Page 16

WARRANTY INFORMATION

Keep this warranty

Model ______________________

Serial No. ___________________

Date Purchased _______________

Always specify model and serial numbers when communication with the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable

is our standard written warranty. We make no other warranty, expressed or implied.

Enerco Group, Inc. warrants this product to be free from defects in materials and components for two (2)

years from the date of first purchase, provided that the product has been properly installed, operated and

maintained in accordance with all applicable instructions. To make a claim under this warranty the Bill of

Sale or cancelled check must be presented.

The warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s)

required to restore the heater to proper operating condition and an allowance for labor when provided by an

Enerco Group, Inc. Authorized Service Center. Warranty part(s) MUST be obtained through authorized

dealers of this product and/or Enerco Group, Inc. who will provide original factory replacement parts. Failure

to use original factory parts voids this warranty. The heater MUST be installed by a qualified installer in

accordance with all local codes and instructions furnished with the unit.

This warranty does not apply to parts that are not in original condition because of normal wear and tear of

parts that fail or become damaged as a result of misuse, accidents, lack of proper maintenance or defects

caused by improper installation. Travel, diagnostic cost, labor, transportation and any and all such costs

related to repairing a defective heater will be the responsibility of the owner.

TO THE FULL EXTENT ALLOWED BY THE LAW OF THE JURISDICTION THAT GOVERNS THE SALE

OF THE PRODUCT; THIS EXPRESS WARRANTY EXCLUDES ANY AND ALL OTHER EXPRESSED

WARRANTIES AND LIMITS THE DURATION OF ANY AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, TO TWO (2) YEARS OF ALL COMPONENTS

FROM THE FIRST DATE OF PURCHASE; AND ENERCO GROUP, INC.’S LIABILITY IS HEREBY LIMITED

TO THE PURCHASE PRICE OF THE PRODUCT AND ENERCO GROUP, INC. SHALL NOT BE LIABLE

FOR ANY OTHER DAMAGES WHATSOEVER INCLUDING INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states do not allow a limitation on how long an implied warranty lasts or an exclusion or limitation on

incidental or consequential damages, so the above limitation on implied warranties, or limitation on damages, may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights that very from state to

state. Always specify model and serial number when communication with the factory.

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135

216-916-3000 Toll Free Number 1-800-251-0001

www.mrheater.com

Mr. Heater is a registered trademark of Enerco Group, Inc.

© 2005, Enerco/Mr. Heater. All rights reserved

Model # MH25NG/LP HS25NG/LP

Installation instructions and Owner’s Manual

16

®

CAN 1-2.16-M81

ANSI Z83.6b-1993

Page 17

ANSI Z83.6b-1993

CAN 1-2.16-M81

®

16

Notice d’installation et guide d’utilisation

Modèle n° MH25NG/LP HS25NG/LP

© Enerco/Mr. Heater, 2005. Tous droits réservés.

Mr. Heater est une marque déposée d’Enerco Group, Inc.

www.mrheater.com

216 916-3000 Numéro sans frais 1 800 251-0001

ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135

communications avec l’usine.

droits qui varient selon la province ou l’État. Précisez toujours le modèle et le numéro de série dans vos

La présente garantie vous accorde des droits juridiques précis, et vous pourriez également avoir d’autres

ci-dessus sur les garanties implicites ou sur les dommages ne s’applique pas à vous.

exclusion ou une limitation sur les dommages accessoires et consécutifs; ainsi, il est possible que la limite

Certaines province ou certains États ne permettent pas une limite de durée de garantie implicite ni une

ACCESSOIRE OU CONSÉCUTIF.

PRODUIT; ENERCO GROUP, INC. NE SERA RESPONSABLE D’AUCUN AUTRE DOMMAGE INDIRECT,

RESPONSABILITÉ D’ENERCO GROUP, INC. EST PAR LA PRÉSENTE LIMITÉE AU PRIX D’ACHAT DU

DEUX (2) ANS POUR TOUS LES COMPOSANTS À PARTIR DE LA DATE DU PREMIER ACHAT; ET LA

DE TOUTES LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’APTITUDE À L’USAGE À

CETTE GARANTIE EXPRESSE EXCLUT TOUTE AUTRE GARANTIE EXPRESSE ET LIMITE LA DURÉE

AVEC TOUTE LA RIGUEUR DE LA LOI DU TERRITOIRE GOUVERNANT LA VENTE DU PRODUIT,

toutes les dépenses reliées à la réparation d’un radiateur défectueux seront à la charge du propriétaire.

mauvaise installation. Les frais de déplacement, de diagnostic, de main-d’œuvre et de transport, ainsi que

ou endommagées en raison d’un usage abusif, d’un accident, ou bien d’un entretien inadéquat ou d’une

Cette garantie ne s’applique pas aux pièces soumises à une usure normale ni aux pièces défectueuses

locaux et à la notice d’installation fournie avec l’appareil.

cette garantie. Le radiateur DOIT être installé par un installateur qualifié conformément à tous les codes

rechange originales de l’usine. Le défaut d’utiliser des pièces originales de l’usine aura pour effet d’annuler

auprès des détaillants autorisés de ce produit et/ou d’Enerco Group, Inc., qui fournira les pièces de

centre de réparations autorisé par Enerco Group, Inc.. Les pièces garanties DOIVENT être obtenues

pièces requises pour rétablir le bon fonctionnement du radiateur et, s’il y a lieu, celui de la main-d’œuvre du

La garantie ne protège que l’acheteur initial auprès du détaillant. Cette garantie couvre le coût de la ou des

garantie, un contrat de vente ou un chèque annulé doit être présenté.

utilisé et entretenu conformément aux directives applicables. Pour faire une réclamation en vertu de cette

deux (2) ans à partir de la date de l’achat initial, à la condition que ce produit ait été correctement installé,

Enerco Group, Inc. garantit ce produit contre tout défaut de matériel et de fabrication pour une période de

applicable est notre garantie écrite standard. Nous n’offrons aucune autre garantie, expresse ou implicite.

Nous nous réservons le droit de modifier ces spécifications en tout temps sans préavis. La seule garantie

Précisez toujours le modèle et le numéro de série dans vos communications avec l’usine.

Date de l’achat _______________

Numéro de série ___________________

Modèle ______________________

Conservez cette garantie

RENSEIGNEMENTS SUR LA GARANTIE

Page 18

combustion

brûleur

Notice d’installation et guide d’utilisation

15

PREUVE D’ACHAT

23 19014 Évent à lames

Modèle n° MH25NG/LP HS25NG/LP

TOUTES LES RÉCLAMATIONS EN VERTU DE LA GARANTIE REQUIÈRENT UNE

11 05445 Orifice-brûleur-gaz naturel 22 98593 Raccord simple 3/8 po

10 09360 Thermocouple/générateur 21 05351 Connecteur

9 04432 Grille de protection 20 05354 Contre-écrou

8 14405 Support mural 19 12369 Joint d’étanchéité

7 10367 Thermostat 18 04435A Grille de rechange

5 00024 Soupape de gaz-gaz 16 11406 Veilleuse GN naturel

5 00024 Soupape de gaz-gaz 16 11406 Veilleuse GN naturel

4 16451 Tube de veilleuse 15 10358 Câble du thermostat

3 01357 Déflecteur de gaz de 14 05573 Orifice-veilleuse-gaz propane

2 00377A Ensemble de réflecteur 13 05576 Orifice-veilleuse-gaz naturel

1 02529A Ensemble complet de 12 05455 Orifice-brûleur-gaz propane

CLATURE CLATURE

N° D’ARTICLE N° DE NOMEN- DESCRIPTION N° D’ARTICLE N° DE NOMEN- DESCRIPTION

MH/HS25NG et MH/HS25LP

Tableau 5 Liste des pièces de remplacement pour les modèles de radiateurs

14

13

23

17

16

9

2

19

18

4

10

22

20

12

7

6

5

15

21

8

11

3

1

Page 19

14

Notice d’installation et guide d’utilisation

dommages consécutifs ou spéciaux.

des pièces ou des produits vendus par EGI, incluant les

IMPLICITE, et toute autre responsabilité d’EGI en regard

REMPLACE TOUTE AUTRE GARANTIE EXPRESSE OU

raison d’une mauvaise installation. CETTE GARANTIE

accidentellement endommagés ou défectueux en

un produit négligés ou dont on a fait un usage abusif,

Cette garantie ne protège aucunement une pièce ou

pièce est défectueuse.

EGI autorisé, si EGI détermine après inspection que la

Cleveland, en Ohio – OU FOB à un centre de réparations

ÊTRE RETOURNÉE SUR DEMANDE À EGI – FOB à

PÉRIODE DE GARANTIE, CETTE PIÈCE DEVANT

réclamation écrite est soumise à EGI DURANT LA

consiste à remplacer toute pièce pour laquelle une

En vertu de cette garantie, la seule responsabilité d’EGI

.

Modèle n° MH25NG/LP HS25NG/LP

garantie d’un (1) an à partir de la date d’achat.

fournis par les fournisseurs d’EGI comportent une

Les pièces, les ensembles, les commandes, etc.,

fabrication.

fabriqués et vendus contre les défauts de matériel et de

Enerco Group, Inc. garantit les radiateurs à infrarouge

2. GARANTIE

description des pièces

C. Reportez-vous au tableau 5 pour le numéro et la

B. Consultez la figure 13 pour repérer les pièces.

sur la plaque signalétique du radiateur.

complet du modèle et le numéro de série indiqués

A. Pour commander les pièces, indiquez le numéro

commander les pièces correctement.

rendement fiable et efficace de votre radiateur et à

La présente section du manuel vous aidera à obtenir un

1. INTRODUCTION

LISTE DES PIÈCES DE RECHANGE

CHAPITRE V

problème dans toutes vos communications.

Veuillez inclure le numéro de modèle, la date de l’achat et la description du

du lundi au vendredi

Nos heures d’ouverture sont de 8 h 30 à 17 h, HE,

numéro sans frais : 1 800 251-0001.

Pour plus de renseignements sur les réparations, veuillez appeler notre

NE RETOURNEZ PAS CET APPAREIL À VOTRE MAGASIN

SI UNE RÉPARATION EST NÉCESSAIRE

Page 20

Notice d’installation et guide d’utilisation

13

remonte pas lorsque relâché.

de la commande de gaz, ou si le bouton ne

B. Il est difficile de tourner ou d’enfoncer le bouton

l’inspection ou du dépannage.

A. Elle ne fonctionne pas correctement lors de

La commande de gaz doit être remplacée si :

doit être inspecté plus souvent.

détérioration rapide de la commande de gaz, le système

Puisque ce type d’environnement peut entraîner une

Environnement poussiéreux, humide ou corrosif.

fils de raccordement encrassés nettoyer et serrer les bornes

fils de raccordement relâchés serrer les fils de raccordement

air dans la conduite de gaz purger la conduite de gaz

orifice du brûleur bloqué nettoyer l’orifice ou remplacer

commande défectueuse remplacer

Modèle n° MH25NG/LP HS25NG/LP

et avant leur mise en fonction à la saison suivante.

saisonnière doivent être inspectés avant leur mise à l’arrêt

Usage intermittent. Les appareils utilisés sur une base

L’UTILISATEUR

4. FRÉQUENCE DES INSPECTIONS PAR

le fil du thermostat sur une borne.

soupape aux bornes «PP». Assurez-vous de laisser

C. Reconnectez la soupape de gaz et les fils de la

B. Dévissez la soupape de gaz du tuyau.

de gaz.

A. Déposez les deux fils étiquetés «PP» à la soupape

3. REMPLACEMENT DE LA SOUPAPE DE GAZ

allumage impossible gaz secteur coupé ouvrir les robinets manuels

ne s’allume pas le schéma de câblage

mais le brûleur principale inadéquats mais le brûleur principal

la veilleuse demeure allumée fils de raccordement relâchés ou serrer les connexions, vérifier

tourné à PILOT et tenu enfoncé

commande défectueuse remplacer

la veilleuse s’allume puis s’éteint thermocouple défectueux remplacer

la veilleuse est peut-être fermée (voir la figure 12)

la vis de réglage du débit de gaz à ouvrir et régler

robinet de gaz pas en position le bouton du robinet doit être

impossible d’allumer la veilleuse orifice de la veilleuse bloqué remplacer

est endommagé

endommagé vérifier si le collecteur

si l’orifice du brûleur n’est pas remplacer

neufs ou viennent d’être nettoyés)

noirs de suie (alors qu’ils sont est endommagé

grille en céramique ou brûleur vérifier d’abord si l’orifice du brûleur remplacer si endommagé

brûleur endommagé remplacer

grille en céramique est sombre)

radiateur et la surface de la

(fonctionnement bruyant du ou appeler le fournisseur en gaz

retour de flamme du brûleur pression insuffisante du gaz corriger la pression dans la conduite

demeure terne

I la couleur de l’infrarouge veilleuse

allumage très lent de la veilleuse, obturation partielle de l’orifice de la remplacer

veilleuse, veilleuse mal réglée régler de nouveau la veilleuse

allumage très lent de la veilleuse obturation partielle de l’orifice de la remplacer

SYMPTÔMES CAUSES SOLUTIONS

procédure d’allumage est conforme à celle indiquée sur la plaque rattachée au radiateur.

les mesures correctives suggérées. Le tableau suppose que la pression du gaz combustible est appropriée et que la

Le tableau suivant présente différents symptômes d’un système défectueux, les causes possibles de ces symptômes et

Tableau 4. Tableau de dépannage

Page 21

DIRECTEMENT EN DESSOUS)

(DÉRIVATION DE PRESSION

SORTIE DE GAZ DE VEILLEUSE

(MODÈLE «C»)

PROGRESSIVE

RÉGULATEUR À OUVERTURE

Notice d’installation et guide d’utilisation

(MODÈLE «A»)

STANDARD

DE PRESSION

RÉGULATEUR

12

vue du dessus

COUVERCLE)

Figure 12. Commande de gaz de capacité standard –

VEILLEUSE

VEILLEUSE (SOUS LA VIS DU

VIS DE RÉGLAGE DU DÉBIT DE LA

DU CAPTEUR DE

DE GAZ

ENTRÉE

Modèle n° MH25NG/LP HS25NG/LP

BLOC D’ALIMENTATION

LE COIN EXTÉRIEUR

LONGUE VIS DANS

INSTALLEZ UNE

pour l’augmenter.

flamme

(SOUS LA VIS DU COUVERCLE)

PRESSION

RÉGLAGE DU RÉGULATEUR DE

fonctionnement de la veilleuse.

réglage en la serrant bien pour assurer le bon

C. Remettez toujours la vis du couvercle après le

et dans le sens antihoraire

pour réduire la flamme de la veilleuse

horaire

B. Tournez la vis de réglage interne dans le sens

veilleuse. Voir la figure 12.

A. Déposez la vis du couvercle de réglage de la

Figure 11. Réglage approprié de la

MANOEUVRE

BOSSAGE DE

GAZ MANUELLE

COMMANDE DE

BOUTON DE

ou du générateur. Voir la figure 11. Pour le réglage :

13 mm (3/8 à 1/2 po) de la pointe du thermocouple

La flamme de la veilleuse doit envelopper 10 à

2. RÉGLAGE DE LA FLAMME DE LA VEILLEUSE

de régler le problème, appelez l’usine.

C. Si toutes les solutions énumérées ne permettent pas

technique Honeywell inclus dans la boîte du radiateur.

B. Pour plus de renseignements, consultez le bulletin

le fonctionnement ou l’entretien de votre radiateur.

A. Le tableau 4 énumère les défaillances courantes durant

1. DÉPANNAGE

THERMOCOUPLE

(3/8 À 1/2 POUCE)

10 À 13 MILLIMÈTRES

LA FLAMME

APPROPRIÉ DE

RÉGLAGE

L’UTILISATEUR

À L’INTENTION DE

DIRECTIVES D’ENTRETIEN

CHAPITRE IV

Page 22

Notice d’installation et guide d’utilisation

11

Figure 10. Allumage de la veilleuse

Modèle n° MH25NG/LP HS25NG/LP

QU’INDIQUÉ

AVEC UNE ALLUMETTE TEL

ALLUMER LA VEILLEUSE

VEILLEUSE

REMARQUE

GAZ

SOUPAPE DE

D. Fermez les robinets d’alimentation en gaz.

position OFF (arrêt).

C. Enfoncez légèrement le bouton et tournez-le à la

la position PILOT (veilleuse).

B. Tournez le bouton de commande manuelle du gaz à

A. Mettez le thermostat hors fonction (OFF).

3. ARRÊT DU RADIATEUR

20 minutes, elles disparaîtront définitivement.

du liant pour joint d’étanchéité. Au bout d’environ

radiateur. Cette odeur et/ou cette vapeur proviennent

peut-être un peu de vapeur seront dégagées par le

Au démarrage initial du radiateur, une odeur et

ALLUMER

ENFONCER POUR

H. Réglez le thermostat à la température désirée.

et mettez-le à ON (ouvert).

G. Relâchez le bouton de commande manuelle de gaz

ouvrir la soupape de sécurité.

thermocouple de se réchauffer suffisamment pour

fois la veilleuse allumée, pour permettre au

conduites de gaz de se rendre à la veilleuse et, une

30 secondes pour permettre à l’air présent dans les

figure 10. Tenez le bouton enfoncé pendant environ

Avec une allumette, allumez la veilleuse. Voir la

F. Enfoncez le bouton de commande manuelle de gaz.

la position PILOT (veilleuse).

E. Tournez le bouton de commande manuelle de gaz à

(particulièrement important après l’installation).

gaz accumulé dans le brûleur principal

D. Attendez 5 minutes pour permettre la dissipation du

Page 23

10

Notice d’installation et guide d’utilisation

VEILLEUSE

COUVERCLE)

LA VEILLEUSE (SOUS LA VIS DU

VIS DE RÉGLAGE DU DÉBIT DE

DIRECTEMENT EN DESSOUS)

(DÉRIVATION DE PRESSION

SORTIE DE GAZ DE VEILLEUSE

PRESSION STANDARD

RÉGULATEUR DE

PRESSION

RÉGULATEUR DE

RÉGLAGE DU

DU CAPTEUR DE

D’ALIMENTATION

BLOC

Modèle n° MH25NG/LP HS25NG/LP

Figure 9. Composants de la soupape de gaz

DE GAZ

ENTRÉE

MANOEUVRE

BOSSAGE DE

GAZ MANUELLE

COMMANDE DE

BOUTON DE

position OFF. Voir la figure 9.

enfoncez-le légèrement et tournez-le à la

soupape de gaz n’est pas à la position OFF,

C. Si le bouton de commande manuelle sur la

THERMOSTAT

FIGURE 8. COMMANDES DU

(fermé). Voir la figure 8.

B. Réglez le thermostat à la position OFF

en gaz.

A. Ouvrez le ou les robinets d’alimentation

ventilé.

radiateur, assurez-vous que le bâtiment est bien

AVERTISSEMENT : Durant le démarrage du

2. DÉMARRAGE DU RADIATEUR

l’intérieur seulement!

ATTENTION : Ce radiateur doit être utilisé à

la taille des tuyaux à utiliser pour l’alimentation en gaz.

adressez-vous à votre fournisseur en gaz pour connaître

s’atténue lorsque la fournaise de l’immeuble fonctionne,

ATTENTION : Si la couleur de la grille infrarouge

POUR VÉRIFIER LES FUITES.

D’ALLUMETTES NI AUCUNE AUTRE FLAMME

AVERTISSEMENT : NE PAS UTILISER

immédiatement à l’air libre! Faites inspecter le radiateur.

radiateur ne fonctionne peut-être pas correctement. Allez

et nausée. Si vous ressentez ces symptômes, le

de la grippe, soit maux de tête, étourdissements

monoxyde de carbone ressemblent aux symptômes

MORT. Les signes avant-coureurs d’intoxication au

MONOXYDE DE CARBONE PEUT CAUSER LA

AVERTISSEMENT : L’EMPOISONNEMENT AU

et la zone de commande propres.

continuellement, le faire réparer. Garder le brûleur

porte pendant cinq minutes. Si le radiateur s’éteint

ventiler la pièce avant de le rallumer. Ouvrir la

AVERTISSEMENT : Si le radiateur s’éteint,

VEILLEUSE.

PAS MODIFIER LE SYSTÈME DE SÉCURITÉ À

SYSTÈME DE SÉCURITÉ À VEILLEUSE. NE

AVERTISSEMENT : Ce radiateur est doté d’un

RADIATEUR EST UTILISÉ.

LAISSER ENTRER L’AIR FRAIS LORSQUE LE

CENTIMÈTRES (UN POUCE OU DEUX) POUR

inodore. OUVRIR LA FENÊTRE DE TROIS À CINQ

MONOXYDE DE CARBONE, un gaz toxique

sans l’apport d’air frais nécessaire, il produira du

AVERTISSEMENT : Si le radiateur est utilisé

REMARQUE

Voir le chapitre 2 pour l’aération.

d’environ 20 minutes et ne se reproduiront plus.

de la vapeur. Ces émanations cesseront au bout

radiateur émettra temporairement une odeur et/ou

Le liant pour joint d’étanchéité utilisé dans ce

1. CONSIGNES DE SÉCURITÉ

RADIATEUR

NOTICE D’UTILISATION DU

CHAPITRE III

Page 24

9

Notice d’installation et guide d’utilisation

Modèle n° MH25NG/LP HS25NG/LP

Figure 7. Installation type de la tuyauterie

LE RADIATEUR.

NE SONT PAS INCLUS AVEC

2. LES RACCORDS ILLUSTRÉS

INSTALLATIONS AU GPL.

AUX GAZ LIQUÉFIÉS SUR LES

JOINT QUI EST RÉSISTANTE

1. N’UTILISEZ QU’UNE PÂTE À

REMARQUE :

BOUCHON

RACCORD

RADIATEUR

(3 po)

7,6 cm

RADIATEUR

RACCORD FLEXIBLE AU

RACCORD UNION OU

TUYAU RIGIDE AVEC

D’ARRÊT

SOUPAPE

disparaissent.

connexions jusqu’à ce que toutes les fuites

connexions. Testez de nouveau et serrez les

coupez l’alimentation en gaz et serrez les

indiquant une fuite. Si vous détectez une fuite,

toutes les connexions et vérifiez s’il y a des bulles

E. Avec un pinceau, mettez de l’eau savonneuse sur

jusqu’à la soupape de gaz du radiateur.

d’alimentation en gaz et pressurisez les tuyaux

allumer la veilleuse du radiateur, ouvrez le robinet

D. Assurez-vous que le bâtiment est bien ventilé. Sans

aérer le bâtiment.

de gaz est détectée, couper l’alimentation en gaz et

y a des fuites. Si, durant un test de fuite, une odeur

utiliser d’allumettes ni aucune flamme pour vérifier s’il

du savon pour tester les conduites de gaz. Ne pas

AVERTISSEMENT : Utiliser uniquement de l’eau et

1/2 po

EN TÉ

RACCORD

D’ALIMENTATION

CONDUITE

dans la soupape de gaz.

C. Raccordez la conduite de gaz au raccord installé

gaz.

indiquée au paragraphe 3.2, dans la soupape de

B. Installez un raccord fileté, préparé de la manière

soupape de gaz.

d’entraîner une distorsion et une défaillance de la

conformes aux exigences de la figure 6, ils risquent

inséré dans la soupape de gaz ne sont pas

AVERTISSEMENT : Si les filets mâles du tuyau

nécessaires. Serrez bien tous les composants.

sédiments, la soupape d’arrêt et les raccords

tuyauterie, assemblez les tuyaux, la grille à

A. Conformément aux exigences ci-dessus pour la

Page 25

la soupape de gaz

SOUPAPE DE GAZ 1/2 PO

D’INSERTION DANS LA

PROFONDEUR MAXIMALE

SOUPAPE DE GAZ

CORPS DE LA

FILET 3/4 PO

LONGUEUR MAXIMALE DU

dans la conduite d’alimentation en gaz.

• Une soupape d’arrêt du radiateur doit être installée

conduite menant à la soupape de gaz.

types de la figure 7 doit être installée dans la

• Une grille à sédiments conforme aux exigences

distorsion et la défaillance de la soupape de gaz.

ceux de la figure, les filets peuvent entraîner la

exigences de la figure 6. S’ils sont plus longs que

la soupape de gaz doivent être conformes aux

• Les filets mâles du tuyau qui sera inséré dans

Figure 5. Application de la pâte à joint

LAISSEZ 2 FILETS DÉNUDÉS

PÂTE À JOINT

UTILISEZ UNE QUANTITÉ MODÉRÉE DE

au GPL. N’utilisez pas de ruban TeflonMC.

du GPL, assurez-vous que la pâte à joint résiste

figure 5, avant l’assemblage. Si le combustible est

tous les filets mâles, comme il est indiqué à la

• Appliquez une pâte à joint de bonne qualité sur

alésés et non ébréchés.

• Utilisez des tuyaux noirs neufs adéquatement

8

Notice d’installation et guide d’utilisation

Figure 6. Exigences relatives au raccordement de

TUYAU NOIR 1/2 PO

comme suit :

l’alimentation en gaz et à la tuyauterie, installez les tuyaux

En vous assurant de respecter les exigences relatives à

3.3 Installation des tuyaux

Figure 4. Schéma de câblage

THERMOPILE

Modèle n° MH25NG/LP HS25NG/LP

pression à un maximum de 3,4 kPa (1/2 lb/po²).

installé avant le radiateur/régulateur pour réduire la

3,4 kPa (1/2 lb/po²), un régulateur additionnel doit être

(14 po) CE. Si la pression de la conduite de gaz excède

vers ce régulateur est de 3,4 kPa (1/2 lb/po²) ou 355 mm

soupape de gaz. La pression d’aspiration maximale

équipé d’un régulateur. Le régulateur est intégré à la

pour brûler des gaz de pétrole liquéfiés (GPL) et est

AVERTISSEMENT : Le modèle MH/HS25LP est conçu

d’admission est d’au moins 152 mm (6 po) CE.

au gaz naturel, assurez-vous que la pression

• Pour obtenir un rendement optimal de votre radiateur

consultez votre fournisseur de gaz naturel.

de 175 mm (6,9 po) CE. En cas de doute,

naturel fournissent une pression de canalisation

• La plupart des services d’alimentation en gaz

3,4 kPa (1/2 lb/po²).

régulateur pour réduire la pression à un maximum de

régulateur additionnel doit être installé avant le radiateur/

conduite de gaz excède 13,4 kPa (1/2 lb/po²), un

(1/2 lb/po²) ou 355 mm (14 po) CE. Si la pression de la

d’aspiration maximale vers ce régulateur est de 3,4 kPa

régulateur est intégré à la soupape de gaz. La pression

pour brûler du gaz naturel et est équipé d’un régulateur. Le

AVERTISSEMENT : Le modèle MH/HS25NG est conçu

signalétiques sur le radiateur.

(colonne d’eau). Consultez également les plaques

fournies en pouces et en millimètres de CE

modèles de radiateurs. Les pressions sont

fonctionnement et d’admission pour les deux

d’alimentation en gaz minimum, maximum, de

• Consultez les tableaux 1 et 2 pour les pressions

3.1 Exigences relatives à l’alimentation en gaz

radiateur et votre fournisseur en gaz.

avec le distributeur auprès duquel vous avez acheté le

exigences, discutez des exigences du présent manuel

du radiateur. Si vous avez des doutes quant à ces

gaz requises pour l’alimentation sûre et efficace

pour le calibrage et l’installation des conduites de

celui-ci peut devoir faire appel à un professionnel

au niveau local et les compétences de l’installateur,

AVERTISSEMENT : Selon les codes et exigences

GAZ

3. CONNEXION DU RADIATEUR À L’ALIMENTATION EN

Code canadien de l’électricité en vigueur, C22.11993, et, pour les installations canadiennes, le

Voir le Code national de l’électricité, NFPA70-

B149.1.2.

canadiennes doivent se conformer au code sur les gaz

lors de l’installation de la tuyauterie : les installations

exigences suivantes doivent être prises en considération

ANSI Z223.1 (NFPA 54), selon celui qui a préséance. Les

et ordonnances locaux ou au National Fuel Gas Code,

Toute la tuyauterie installée doit être conforme aux codes

3.2 Exigences relatives à la tuyauterie

THERMOPILE

SOUPAPE À GAZ DE LA

ou 355 mm (14 po) CE.

d’admission est d’au moins 3,4 kPa (1/2 lb/po²)

radiateur à GPL, assurez-vous que la pression

• Pour obtenir un rendement optimal de votre

THERMOSTAT

Page 26

CÔTÉ FINI

PRÉPERCÉS

TROUS

REBORD

Notice d’installation et guide d’utilisation

CÔTÉ NON FINI

7

Modèle n° MH25NG/LP HS25NG/LP

PLANCHER

AVEC LE THERMOSTAT)

INSTRUCTIONS INCLUSES

THERMOSTAT (VOIR LES

147 CM (58 PO)

AVEC LE THERMOSTAT)

(2 REQUISES – INCLUSES

VIS À TÔLE Nº 6 X 1 PO

RADIATEUR

RÉFLECTEUR DU

COMBUSTION

DE GAZ DE

DÉFLECTEUR

(VOIR LA FIGURE 4)

CÂBLE DU THERMOSTAT

[1/2 LB/PO²])

(NE PAS DÉPASSER 3,4 KPA

ENTRÉE DE GAZ 1/2 PO NPT

FIXATION

BRIDE DE

2 1/2 PO (2 REQUISES)

LONGUES 1/4 PO X

VIS TIRE-FOND

DE GAZ

COMMANDE

DE

SOUPAPE

23 CM (9 PO)

1/4 PO-20

ÉCROU HEX.

1/4 PO-20x3/4 PO

HEXAGONALE

BOULON À TÊTE

RADIATEUR

PLAFOND

RADIATEUR

MURAL DU

SUPPORT

Figure 3. Directives de montage du radiateur

61 CM (24 PO) MIN.

comme il est indiqué à la figure 4.

J. Connectez les fils du thermostat à la soupape de gaz

montage.

ancrages, fixez le thermostat au moyen des vis de

grandeur appropriée pour les ancrages, posez les

l’emplacement des trous, percez des trous d’une

thermostat comme gabarit pour marquer

montage du thermostat. Utilisez la plaque arrière du

vous les ancrages appropriés en fonction des vis de

I. Si le mur est en brique ou en maçonnerie, procurez-

à l’emplacement sélectionné.

incluses avec le thermostat, et montez le thermostat

de revêtement, utilisez des vis à tôle nº 6 de 1 po,

H. S’il s’agit d’un mur à poteaux de cloison et panneaux

instructions de montage.

plus de renseignements sur la mise à la terre et les

documentation accompagnant le thermostat pour

indiquées précédemment. Reportez-vous à la

thermostat est conforme à toutes les exigences

G. Assurez-vous que l’emplacement choisi pour le

bien.

F. Vissez l’écrou hexagonal sur le boulon et serrez-le

la bride et le support.

radiateur sur le support, puis insérez le boulon dans

figure 3 et faites glisser la bride de fixation du

E. Positionnez le radiateur comme il est indiqué à la

1/4 po – 20 x 3/4 po et l’écrou hexagonal 1/4 po – 20.

radiateur et sélectionnez le boulon à tête hexagonale

D. Repérez la bride de fixation du radiateur à l’arrière du

ancrages. Serrez bien les vis.

2 1/2 po par le support dans le poteau ou les

les ancrages. Insérez des vis tire-fond de 1/4 po x

deux trous du support sur les trous d’implantation ou

C. Placez le support mural sur le mur et alignez les

ancrages dans la brique ou la maçonnerie.

Percez les trous appropriés pour recevoir les

interne et déterminez la taille du foret à utiliser.

ancrages à expansion de 1/4 po de diamètre

pour les dimensions. Procurez-vous deux

brique ou de maçonnerie, consultez la figure 3

2. Si le support mural doit être fixé à un mur de

l’installation.

du poteau. Utilisez le gabarit pour simplifier

d’implantation de 3,2 mm (1/8 po) au centre

repérez le poteau et percez des trous

consultez la figure 3 pour les dimensions,

poteaux de cloison et panneaux de revêtement,

1. Si le support mural doit être fixé à un mur à

radiateur comme suit :

B. Préparez-vous à installer le support mural du

Page 27

6

Notice d’installation et guide d’utilisation

Modèle n° MH25NG/LP HS25NG/LP

les trous aménagés sur le rebord de la prise.

les au moyen de 4 attaches appropriées dans

5. Installez la ou les prises tel que désiré et fixez-

côté non fini de la prise.

le bâtiment est fini) ayant les dimensions du

4. Taillez un trou dans le mur (ou dans les murs si

d’un autre marqueur approprié.

dimensions sur le mur au moyen d’un crayon ou

à l’emplacement choisi et tracez ses

3. Placez le côté non fini de la prise contre le mur

etc.).

(c.-à-d. les conduites, le câblage, la tuyauterie,

n’entravent les systèmes existants du bâtiment

assurez-vous que la ou les prises ne touchent ni

conformément aux exigences ci-dessus et

2. Sélectionnez un endroit le plus haut possible

renseignements sur la prise.

1. Voir la figure 3 pour les dimensions et d’autres

présent guide. Installez la prise comme suit :

de téléphone sans frais figurent à l’endos du

prise à l’usine. Notre adresse et notre numéro

l’extérieur?) Au besoin, commandez une autre

vous deux prises finies à l’intérieur et à

l’intérieur ou l’extérieur du bâtiment ou désirezexemple, voulez-vous que le côté fini soit sur

fonction de vos préférences personnelles. (Par

prise selon la construction du bâtiment et en

A. Déterminez comment vous désirez installer la

des conduites de gaz requises pour l’alimentation du

appel à un professionnel pour le calibrage et l’installation

compétence de l’installateur, celui-ci peut devoir faire

Selon les codes et exigences locaux et le niveau de

le montage du radiateur sur le mur.

électrique et aucun conduit de câble électrique n’entrave

Assurez-vous qu’aucune conduite de gaz, aucun câble

au-dessus du radiateur.

empêcheront les surchauffes dangereuses

13 po) ou 8 cm par 64 cm (3 po par 25 po)

• Des ouvertures de 13 cm par 33 cm (5 po par

partiellement ouvertes.

extérieure sont : les portes et les fenêtres

• Les ouvertures équivalentes à une prise d’air

(2 pi) du plancher du bâtiment).

radiateur (préférablement à moins de 60 cm

485 cm² (75 po²) doit être aménagée sous le

du bâtiment et ayant une surface efficace de

• Une prise d’air, ou l’équivalent, de l’extérieur

une prise additionnelle auprès de l’usine.

ou un bâtiment utilitaire fini peuvent se procurer

l’extérieur du bâtiment. Ceux qui ont un atelier

à l’intérieur du bâtiment) et elle doit donner à

radiateur (préférablement au point le plus haut

Cette prise doit être située au-dessus du

avec votre radiateur pour plus de commodité.

• Une prise de ventilation par aspiration est fournie

été respectées, montez le radiateur comme suit :

que toutes les exigences relatives à l’emplacement ont

et l’emplacement du thermostat, et après vous être assuré

Après avoir choisi l’emplacement d’installation du radiateur

RADIATEUR

2. INSTRUCTIONS DE MONTAGE DU

câble du thermostat.

ne doit pas être supérieure à la longueur du

• La distance entre le thermostat et le radiateur

directement sous le radiateur installé.

• Le thermostat ne doit pas être monté

les courants d’air.

• Le thermostat ne doit pas être monté dans

sans bloc de montage isolé.

directement sur un mur extérieur froid

• Le thermostat ne doit pas être monté

ce que l’air puisse circuler librement autour.

(5 pieds) au-dessus du plancher et de façon à

• Le thermostat doit être monté à environ 1,5 m

radiateur.

est critique pour le fonctionnement efficace et efficient du

Le choix de l’emplacement de montage du thermostat

service à la clientèle au 1 800 251-0001.

radiateur et votre fournisseur en gaz, ou appelez le

avec le distributeur auprès duquel vous avez acheté le

exigences, discutez des exigences du présent manuel

radiateur. Si vous avez des doutes relativement à ces

doivent être respectées :

fonctionne de manière efficace.

fournira suffisamment d’air pour que le radiateur

des portes d’entrée et des fenêtres non isolées

ventilation suivantes

les portes, les ouvertures, etc.), les méthodes de

est doté d’une isolation complète (incluant les fenêtres,

installé ne surchauffe. Si votre atelier/bâtiment utilitaire

pour empêcher que la zone au-dessus du radiateur

Il est essentiel de permettre la libre circulation de l’air

• Dans la plupart des cas, l’infiltration d’air autour

à levage vertical ouverte.

qu’il se trouve au-dessus d’une porte roulante

montez jamais le radiateur de manière à ce

minimales lorsque la porte est ouverte. Ne

ments ne sont pas inférieurs aux valeurs

de la porte et assurez-vous que les dégageinstallé de manière à nuire au fonctionnement

installée, vérifiez que le radiateur n’est pas

• Si une porte roulante à levage vertical est

lorsqu’on les ouvre.

contact avec des composants du radiateur

dégagement minimales et n’entrent pas en

n’empiètent pas sur les distances de

ou les fenêtres intérieures ou extérieures

de ce radiateur, assurez-vous que les portes

• Lors du choix des emplacements d’installation

échéant.

portes roulantes à levage vertical, le cas

l’installer au milieu du mur situé en face des

quel mur; cependant, il est recommandé de

• Ce radiateur peut être monté sur n’importe

Page 28

5

Notice d’installation et guide d’utilisation

Modèle n° MH25NG/LP HS25NG/LP

LIGNE DU PLANCHER

DOIT ÊTRE HORIZONTAL.

2. LE RÉFLECTEUR LATÉRAL DU RADIATEUR

).

(30

o

DU RADIATEUR PEUT ÊTRE REMONTÉ

1. SEUL LE CÔTÉ GAZ DE COMBUSTION

14 po 16 pouces 16 pouces 48 po

14 po 16 pouces 16 pouces 48 po

REMARQUE :

MINIMUM

40 CM (16 POUCES)

o

o

MURAL

SUPPORT

RADIATEUR

MH/HS25LP — 22 000 30

MH/HS25NG 25 000 — 30

NAT. GPL NORMALE HAUT CÔTÉS ARRIÈRE DESSOUS

MODÈLE GAZ DE MONTAGE DISTANCE DES SURFACES COMBUSTIBLES

EN BTU/H POSITION

PUISSANCE

Tableau 3. Renseignements sur l’installation, la ventilation et le montage

Figure 2. Distances entre l’installation et les surfaces combustibles

MINIMUM

120 CM (48 PO)

30

(14 1/2 PO)

37 CM

PORTE

40 cm (16 pouces) des surfaces combustibles.

les autres côtés doivent être éloignés d’au moins

combustibles et orienté vers l’espace ouvert, et

à la distance minimale requise des surfaces

à la figure 2, le devant du radiateur est installé

et dans le tableau 3. Comme il est indiqué

surfaces combustibles sont illustrées à la figure 2

• Les distances minimales par rapport aux

L’INSTALLATION

ET EXIGENCES RELATIVEMENT À

1. RENSEIGNEMENTS GÉNÉRAUX

RADIATEUR

INSTALLATION DU

CHAPITRE II

DE L’ATELIER OUVERTE

MINIMUM

35 CM (14 PO)

PLAFOND

MINIMUM

(16 POUCES)

40 CM

ASPIRATION

VENTILATION PAR

PRISE DE

à la figure 2 ou sur la plaque signalétique du radiateur.

AVERTISSEMENT : Respectez les distances indiquées

149B.1.9 de l’ACG.

doivent être conformes à la dernière édition de la norme

Les installations canadiennes dans des garages publics

si cette hauteur est supérieure.

dernière édition de la norme NFPA n° 88, ou à la figure 1,

du plancher pour les garages publics conformément à la

Il faut une hauteur minimum de 2,4 m (8 pi) au-dessus

en air de ventilation et de combustion.

dégagement minimum en haut et sur les côtés pour l’apport

de la commande du radiateur pour l’entretien, ainsi qu’un

combustibles, conformément au tableau 3, à l’extrémité

Prévoir une distance appropriée par rapport aux matériaux

Page 29

4

Notice d’installation et guide d’utilisation

GAZ MIN. MAX. COLLECTEUR L’ORIFICE

Modèle n° MH25NG/LP HS25NG/LP

MH/HS25LP 10 po CE 55 0,011 22 000 12 1/4 po 29 3/4 po 7,0 po 20 lb

MH/HS25NG 6 po CE 45 0,018 25 000 12 1/4 po 29 3/4 po 7,0 po 20 lb

NEMENT BRÛLEUR VEILLEUSE (BTU/H) LARGEUR LONGUEUR HAUTEUR POIDS

FONCTION- ENTRÉE

MODÈLE PRESSION DE TAILLE DE L’ORIFICE DIMENSIONS

Tableau 2. Dimensions du radiateur et tailles des orifices

MH/HS25LP — 22 000 — 11 po — 14 po — 10 po — 55

MH/HS25NG 25 000 — 7,0 po — 14 po — 6 po — 45 —

NATUREL PROPANE NAT. GPL NAT. GPL NAT. GPL NAT. GPL

MODÈLE PUISSANCE EN BTU/H PRESSION D’ALIMENTATION EN GAZ (CE) TAILLE DE

Tableau 1. Puissances en BTU et pressions d’alimentation

combustibles

combustibles

DÉPASSER 3,4 KPA (1/2 LB/PO²)

LA PRESSION D’ENTRÉE AU RADIATEUR NE DOIT PAS

NFPA 409 Distance par rapport aux surfaces

NFPA 88 Distance par rapport aux surfaces

Numéro Sujet connexe

prévu dans le présent manuel :

le radiateur doit être installé à un emplacement non

• Les guides NFPA suivants sont également utiles si

l’usine.

• Pour plus de renseignements, communiquez avec :

un fournisseur en gaz qualifié.

installateur, un fournisseur de services d’entretien ou

renseignements supplémentaires, adressez-vous à un

de cet appareil. Pour obtenir de l’assistance ou des

de procéder à l’installation, l’entretien ou la réparation

notices d’installation, d’utilisation et d’entretien avant

blessures ou même la mort. Lisez complètement les