Mr. Heater Heatstar HS50KT, MH50KT, MH75KT, MH125KT, MH175KT Owner's Manual

...

Serial Numbers 0117001 - 0148811

OPERATING INSTRUCTIONS AND OWNER’S MANUAL

MR. HEATER

M

MH50KT, MH75KT,

DO

E

L

125KT, MH175KT

MH

READ INSTRUCTIONS CAREFULLY: Read and

follow all instructions. Place instructions in a

sa

fe place for future reference. Do not allow

anyone who has not read these instructions to

assemble,

light, adjust or operate the heater.

HE

ATSTAR

M

HS50KT, HS75KT,

LEDO

HS

125KT, HS175KT

KEROSENE

FO

RCED-AIR HEATER

WARNING:

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

— Service must be performed by a qualified service agency.

This is an unvented portable heater. It uses air (oxygen) from the area in which it is used. Adequate

combustion

and ventilation air must be provided. Refer to page 3.

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

UL-733, &CSA/CAN3-B140.9.3

04/04 Revision L1 #70276ENERCO GROUP, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 216-881-5500

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF FIRE,

EXPLOSION, BURN, ASPHYXIATION, CARBON MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

WARNING:

NOT FOR HOME OR RECREATIONAL VEHICLE USE

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE AWAY FROM THE HEATER AS RECOMMENDED

BY THE INSTRUCTIONS NEVER USE THE HEATER IN

SPACES WHICH DO OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES, OR PRODUCTS SUCH AS

GASOLINE, SOLVENTS, PAINT THINNER, DUST PARTICLES OR UNKNOWN CHEMICALS.

WARNING:

The State of California requires the following warning:

COMBUSTION BY-PRODUCTS PRODUCED WHEN

USING THIS PRODUCT CONTAIN CARBON MONOXIDE,

A CHEMICAL KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND BIRTH DEFECTS (OR OTHER

REPRODUCTIVE HARM).

WARNING:

• DO NOT USE GASOLINE, NAPHTHA OR VOLATILE

FUELS.

• STOP HEATER BEFORE ADDING FUELS.

• ALWAYS FILL OUTDOORS AWAY FROM OPEN FLAME

• DO NOT USE EXTERNAL FUEL SOURCE.

• DO NOT OPERATE HEATER WHERE FLAMMABLE

LIQUIDS OR VAPORS MAY BE PRESENT.

• DO NOT START HEATER WHEN CHAMBER IS HOT

• DO NOT START HEATER WHEN EXCESS FUEL HAS

ACCUMULATED IN THE CHAMBER.

• DO NOT PLACE COOKING UTENSILS ON TOP OF THE

HEATER.

• PLUG ELECTRICAL CORD INTO A PROPERLY

GROUNDED THREE-PRONG RECEPTACLE.

50K & 75KT WARNING:

Not suitable for use on wood floors or other

combustible materials. When used the heater

should rest on a suitable insulating material at least

1 inch thick and extending 3 feet or more beyond

the heater in all directions.

CONTENTS

WARNINGS ................................................................................. 2

HEATER SPECIFICATIONS ............................................................ 3

OPERATING PRECAUTIONS ......................................................... 3

SAFETY PRECAUTIONS ................................................................ 3

OPERATING INSTRUCTIONS ........................................................ 4

MAINTENANCE, STORAGE AND SERVICE ................................... 5

WIRING DIAGRAM...................................................................... 6

PARTS LIST .................................................................................. 6

EXPLODED VIEW......................................................................... 7

WARRANTY ................................................................................ 8

INSTRUCTIONS FOR ORDERING PARTS ....................................... 8

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’s Manual

2

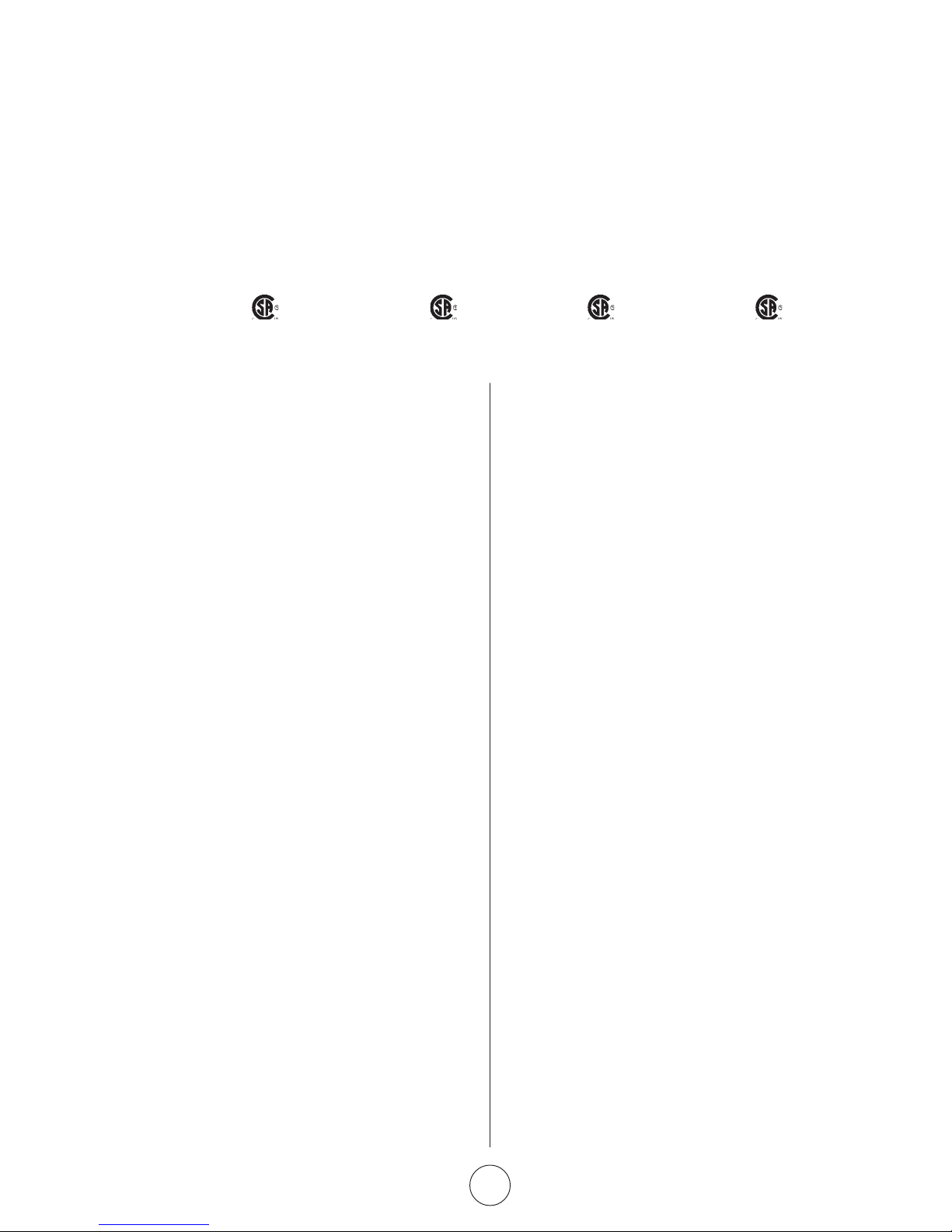

SPECIFICATIONS

Type of Fuel: For use with Kerosene or #1 Fuel Oil ONLY on ALL models.

Model ...................................... 50K ............................................. 75KT .......................................125KT ....................................... 175KT

Burn Rate:................................ 50,000 Btu/hr (15 kW) ...............75,000 Btu/hr (22 kW) ......... 125,000 Btu/hr (37 kW) ........... 175,000 Btu/hr (51 kW)

Fuel Rate:................................. 0.37 gal/hr (1.4 L/hr) ................. 0.55 gal/hr (2.1 L/hr) ............. 0.96 gal./hr (3.5 L/hr) ............. 1.3 gal/hr (5.0 L/hr)

Electrical Input: ........................ 115V, 60Hz, 3.5a......................... 115V, 60Hz, 4a ....................... 115V, 60Hz, 5.5a ...................... 115V, 60Hz, 5.5a

Line Protection:........................ 10 amps ...................................... 10 amps ................................. 20 amps ................................... 20 amps

Min. Operating Voltage: .......... 110V ............................................110V ....................................... 110V ......................................... 110V

Pressure Setting: ...................... 3.5 psig (24 kPa) ........................ 4.2 psig (29 kPa) .................... 5.0 psig (34 kPa) ...................... 5.8 psig (40 kPa)

Max. Outlet Temperature:........ 1300oF (704oC) ............................1300oF (704oC) .......................1300oF (704oC) ......................... 1300oF (704oC)

Fuel Tank Capacity: .................. 4 gallons (15.1 L) ........................6 gallons (22.7 L) ................... 14 gallons (53 L) ...................... 14 gallons (53 L)

Ignition: ................................... Direct Spark, Continuous............ Direct Spark, Continuous ....... Direct Spark, Continuous ......... Direct Spark, Continuous

Spark Generator: ..................... Igniter 13 kV, 10ma .................... Igniter 13 kV, 10ma ................Igniter 13 kV, 10ma .................. Igniter 13 kV, 10ma

Primary Safety Control:............ Solid State Control...................... Solid State Control ................. Solid State Control ................... Solid State Control

Certification:

OPERATING PRECAUTIONS

This is a kerosene, direct-fired, forced air heater. It's intended use

is primarily temporary heating of buildings under construction,

alteration or repair.

Direct-Fired means that all of the combustion products enter the

heated space. Even though this heater operates very close to 100

percent combustion efficiency, it still produces small amounts of

carbon monoxide. Carbon monoxide (called CO) is toxic. We can

tolerate small amounts but not a lot. CO can build up in a heated

space and failure to provide adequate ventilation could result in

death. The symptoms of inadequate ventilation are:

• headache

• dizziness

• burning eyes and nose

• nausea

• dry mouth or sore throat

So, be sure to follow advice about ventilation in these operating

instructions.

Forced Air means that a blower or fan pushes the air through

the heater. Proper combustion depends upon this air flow;

therefore, the heater must not be revised, modified or operated

with parts removed or missing. Likewise, safety systems must not

be circumvented or modified in order to operate the heater.

When the heater is to be operated in the presence of other

people the user is responsible for properly acquainting those

present with the safety precautions and instructions, and of the

hazards involved.

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT operate

a damaged heater.

2. DO NOT modify the heater or operate a heater which has

been modified from its original condition.

3. Use only Kerosene. Never use gasoline, naphtha, paint

thinner, alcohol or other fuels of any kind.

4. For indoor use only. Not for use where exposed to weather.

5. Use in well ventilated areas, provide at least 2 sq. ft. (0.19

sq. m.) of opening near the floor and 2 sq. ft. (0.19 sq. m.)

near the ceiling directly to outdoors. Increase air openings as

marked for each additional heater.

6. Always keep combustibles, like paper and wood at least 8

ft. (2.4 m) from the heater outlet and 3 ft. (1.0 m) from the

top, sides and inlet. Locate 10 ft. (3.0 m) from canvas or

plastic coverings and secure them to prevent flapping

movement.

7. Caution: Due to the high surface and exhaust temperatures,

adults and children must observe clearances to avoid burns

or clothing ignition. Do Not Touch. Keep Children, Clothing,

and Combustibles away.

8. Install the heater such that it is not directly exposed to

water spray, rain and / or water.

9. Never use in areas normally for habitation and /or where

children may be present.

10. Operate only on a stable, level surface. (MH50K & MH75KT

– See wood floor warning).

11. Do not use with duct work. Do not restrict inlet or exit.

12. Use only with electrical power specified. The electrical

connection and grounding must comply with National

Electrical Code – ANSI/NFPA 70 (USA) and CSA C22.1

Canadian Electrical Code, Part 1 (Canada).

13. Use only a properly grounded 3-prong receptacle or

extension cord.

14. Do not move, handle, or service while hot or burning.

15. Use only in accordance with local, state (provincial) or

National requirements, ordinances and codes.

OPERATING INSTRUCTIONS

UNPACKING

1. Remove all protective material which may have been applied

to the heater for shipment.

2. Remove heater from carton.

3. Check the heater for possible shipping damage. If any

damage is found immediately notify the dealer from whom

you purchased the heater.

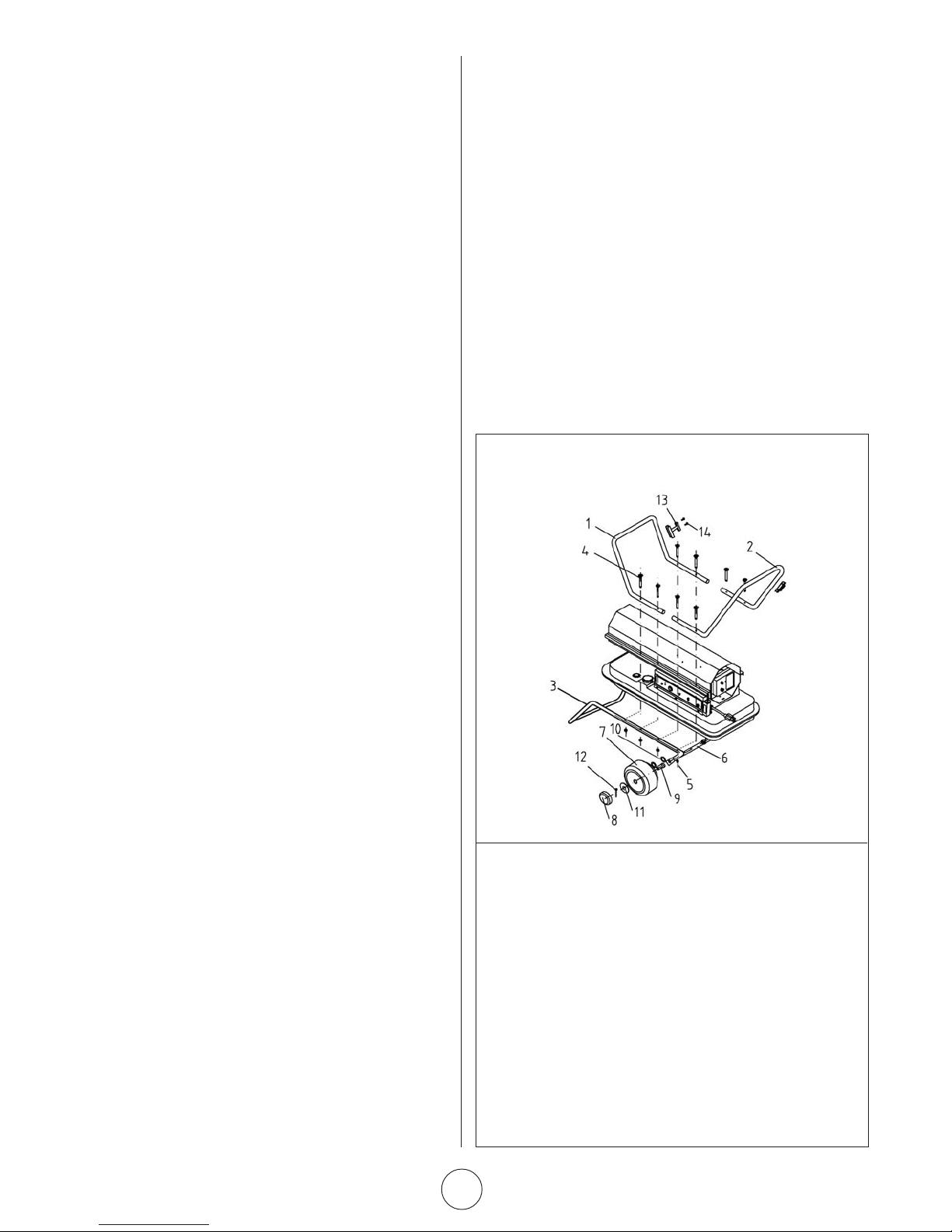

ASSEMBLY (For 125,000 and 175,000 BTU/hr models only)

Wheel and handles are found in the shipping carton along with

mounting hardware. The wheels, axle and mounting hardware

are in a package. Tools required are a 5/16" nutdriver, 3/8"

open or adjustable wrench and standard pliers.

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’s Manual

3

1. Assemble the wheels onto the wheel support frame as

follows:

a. Install one of the cotter pins into the hole on one end of

axle.

b. Slide the large washer, then wheel onto the axle next to

the cotter pin.

c. Slide a small washer, spacer, small washer onto the axle

next to the wheel.

d. Slide the partially assembled axle through the wheel

support frame.

e. Slide the small washer, spacer, and small washer onto

the axle next to the wheel support.

f. Slide the wheel then large washer onto the axle and

hold in place with the remaining cotter pin.

g. Install the caps over the larger washers to finish the

wheel assembly.

2. Position the heater on the wheel support frame assembly

with the exit end over the wheels.

3. Use eight screws and nuts to attach the handles to the top of

the tank flange. The screws will go through the handles,

tank flange and wheel support frame. Install the nuts and

finger tight only until all nuts are installed.

4. Tighten all the nuts.

5. Attach cord caddies to handles using No. (14) & No. (5)

screws and nuts.

PREPARING FOR OPERATION

1. Check the heater for possible shipping damage. If any is

found, immediately notify the factory.

2. Follow all of the "Precautions".

3. Fill the fuel tank with clean kerosene. In extremely cold

weather, condensation may develop in the tank and it is

recommended that a tablespoon of de-icer be added for each

gallon (4 liters) of fuel in the tank. When filling the heater, use

at least 2 gallons (8 liters) of fuel. Be sure heater is level and

do not overfill. Use a funnel or can with a long fill spout.

IMPORTANT: Before filling fuel tank the first time or after

extended storage periods, drain the fuel tank of any moisture

or condensation.

4. Locate heater at a safe distance from combustible materials.

ModelS 50K & 75KT is not suitable for use on wood floors or

other combustible materials. When used, the heater should

rest on suitable insulating material at least 1 inch thick and

extending 3 ft. or more beyond the heater in all directions.

START

1. 50K: Plug the heater into a grounded 115V, 60 Hz, 1 Ø

outlet.

75KT, 125KT & 175KT: Turn thermostat to lowest

setting, make sure “On/Off” switch is “Off”. Plug the

heater into a grounded 115V, 60 Hz, 1 Ø outlet. Turn

thermostat to highest setting. Start heater by push

toggle switch to “On” position (light signifies switch is

in “ON” position). Adjust thermostat to desired setting.

Heater will cycle on/off as heat is required.

For all models: In cold weather, starting may be

improved by holding a finger over the end of the

pressure adjusting screw until the heater starts. This unit

is equipped with a circuit breaker located near the power

cord. If the unit does not start, check to see that the

reset button is pressed in.

STOP

1. 50K: Unplug heater from power source.

75KT, 125KT & 175KT: Push “On/Off” switch to “Off”

position. For extended shutdown, unplug heater from

power source.

RESTART AFTER SAFETY SHUTDOWN (50K, 75KT, 125KT

& 175KT)

1. Wait 5 minutes.

2. Press reset button.

Handle assembly for 125KT 175KT only.

ITEM PART NO. DESCRIPTION QTY

1 M4365 Handle, Front 1

2 M4338 Handle, Rear 1

3 M4339 Wheel Support Frame 1

4 M6977 Machine Screw Blk (long) 8

5 M6037 Kep Nut Blk 12

6 M8746 Axle 1

7 M8752 Wheel 2

8 M8751 Cap 2

9 M8748 Spacer 2

10 M8747 Washer, Small 4

11 M8749 Washer, Large 2

12 M8750 Cotter Pin 2

13 M8754 Ext. Cord Caddy 2

14 M7336 Machine Screw Blk (Small) 4

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’s Manual

4

MAINTENANCE AND STORAGE

WARNING. To prevent personal injury, unplug the heater

from the wall outlet before servicing.

For maximum efficiency and trouble-free service, make the

following periodic maintenance, cleaning and inspections.

DAILY SCHEDULE

1. GENERAL. Make general visual inspection of heater for loose

or damaged parts. Check nuts and bolts to insure against

looseness caused by vibration or rough handling. Damaged

parts should be repaired or replaced before using heater

again. Check heater operation to be sure it is operating

normally (See "Servicing" section for description of normal

operation).

2. FILTERS. Dirty air or fuel filters will cause an imbalance in the

air-fuel mixture. The best indication that this condition exists

is an increase in odors or difficulty getting your heater to

ignite. This heater should never be operated without the

filters in place. If required, clean filters as described under

"500 Hours" and "Annual Schedules".

500 HOUR SCHEDULE

1. AIR INTAKE FILTER. Remove and wash the filter element with

a mild detergent, dry thoroughly and replace. Do not oil the

filter element. If your heater is used where there is

considerable dust or dirt, clean as often as necessary

(approximately every 50 hrs.).

2. REMOVE DUST. Clean heater twice a season (more often

under dusty conditions). Remove accumulated dust from the

transformer, burner, motor and fan blades with compressed

air. Wipe area clean with a clean dry cloth. Inspect area to

insure all foreign materials are removed, especially around

the burner and combustion area.

3. CAD CELL. Clean the glass portion of the cad cell with a soft

dry cloth.

4. NOZZLE. Accumulation of dirt from fuel and carbon from the

compressor vanes will eventually fill up the passages in the

nozzle, resulting in reduction of fuel and air flow. Pressure

will gradually increase giving improper fuel-air mixture and

excess odor and smoke. If this occurs, replace the fuel nozzle.

5. FUEL TANK. Clean twice a season (during frequently used

periods, clean twice a month). Drain and flush the fuel tank

with clean fuel oil.

ANNUAL SCHEDULE

1. AIR OUTPUT FILTER. Remove the air output filter and tap the

contaminated side gently on a solid object to remove

contaminates. Compressed air or liquids should not be used

to clean this filter. Reinstall cleaned filter in filter body in the

same position as it was when removed. If the filter appears

extremely dirty, replace it with a new filter of the same type.

When replacing the filter cover, be sure the gasket is firmly in

place and the screws in the filter cover are tight to prevent air

leaks.

2. FUEL FILTER. Remove the fuel filter from fuel line and direct

compressed air through the filter in the opposite direction of

fuel flow. Safety glasses should be worn when using

compressed air.

3. AIR AND FUEL LINES. If the air or fuel lines are removed

during cleaning, be sure all connections are tight before

operating unit.

4. AIR PRESSURE SETTING. The air pressure has been properly

set at the factory. If the air pressure is out of adjustment, it

will most likely be caused by dirty air filters, a partially

plugged nozzle, an air leak in the system or improperly set

pressure. If adjustment becomes necessary, first determine

the proper pressure setting for your heater which is printed

on the serial label located on the fuel tank. Remove the plug

from the air filter cover and attach an accurate pressure

gauge calibrated to a maximum reading of 15 PSI. Start the

heater and note the pressure reading. If the pressure is low,

slowly turn the pressure adjusting screw in (Clockwise) until

the correct pressure is obtained. If the air pressure is high,

turn the adjusting screw out (counterclockwise) until the

pressure is correct. When correct pressure is reached, unplug

the heater, remove the gauge and replace the plug.

STORAGE

Store the heater in a dry location free from fumes or dust.

At the end of each heating season, clean the heater as described

in the MAINTENANCE section. Drain and flush the fuel tank with

clean fuel. The manufacturer recommends completely filling the

tank with fuel for extended storage to minimize condensation

inside the tank.

SERVICING

A hazardous condition may result if a heater is used that has been

modified or is not functioning properly. When the heater is

working properly:

* The flame is contained within the heater.

* The flame is essentially yellow.

* There is no strong disagreeable odor, eye burning or other

physical discomfort.

* There is no smoke or soot internal or external to the heater.

* There are no unplanned or unexplained shut downs of the

heater.

The parts lists and wiring diagram show the heater as it was

constructed. Do not use a heater which is different from that

shown. Heater performance is effected by air pressure setting. If

there is any uncertainty about the air pressure setting, have it

checked.

A heater which is not working right must be repaired, but only by

a trained, experienced service person.

In-warranty products will be repaired with no charge for either

parts or labor. Please include a brief statement indicating date,

place of purchase, the nature of the problem and proof of

purchase.

Out-of-warranty products will be repaired with a charge for parts

and labor.

Enerco Group, Inc. | Kerosene Forced Air Heater Operating Instructions and Owner’s Manual

5

Loading...

Loading...