The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Installation Manual

Signature Series

MHP15*A HEAT PUMP SPLIT SYSTEM

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

INSTALLATION INSTRUCTIONS

MHP15*A HEAT PUMP SPLIT SYSTEM

(R410A REFRIGERANT)

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury or death.

Table of Contents

Safety Precautions ......................................................2

Installation ...................................................................2

Electrical Connections.................................................5

Start-Up Procedure......................................................6

Operation.....................................................................7

Homeowner’s Information .........................................10

NOTE TO INSTALLING DEALER

These instructions and warranty are to be given to the

owner or displayed near the indoor air handler unit.

CAUTION

Improper installation, adjustment, alteration, service

installer or agency must use factory-authorized kits

or accessories when added to this products. Refer to

accessory kit.

NOTE

These instructions are intended as a general guide and

do not supersede national, state or local codes in any

way.

WARNING

result in hazards to you and others. Installation MUST

conform with local building codes and with the National

Electrical Code NFPA 70/ANSI C1-1993 or current

edition and Canadian Electrical Code Part 1 CSA C22.1.

WARNING

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than 1 disconnect switch. Lock out

and tag switch with a suitable warning label. Electrical

shock can cause personal injury or death.

Manufactured By

MRCOOL, LLC

Hickory, KY 42051

*P506318-03C*

(P) 506318-03C

Save these instructions for future reference

Page 1 of 11506318-03C mrcool.com

These units are designed for use in residential and

light commercial type buildings. Heat Pumps may only

be installed with indoor combinations listed in the Air

Conditioning, Heating and Refrigeration Institute (AHRI)

Inspect the unit for any damage before installation. If

damage is found, notify the transportation company

Safety Precautions

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations.

NOTE: Maximum liquid-line size is 3/8 in. O.D. for all

residential applications including long lines.

Outdoor Section

Zoning ordinances may govern the minimum distance the

condensing unit can be installed from the property line.

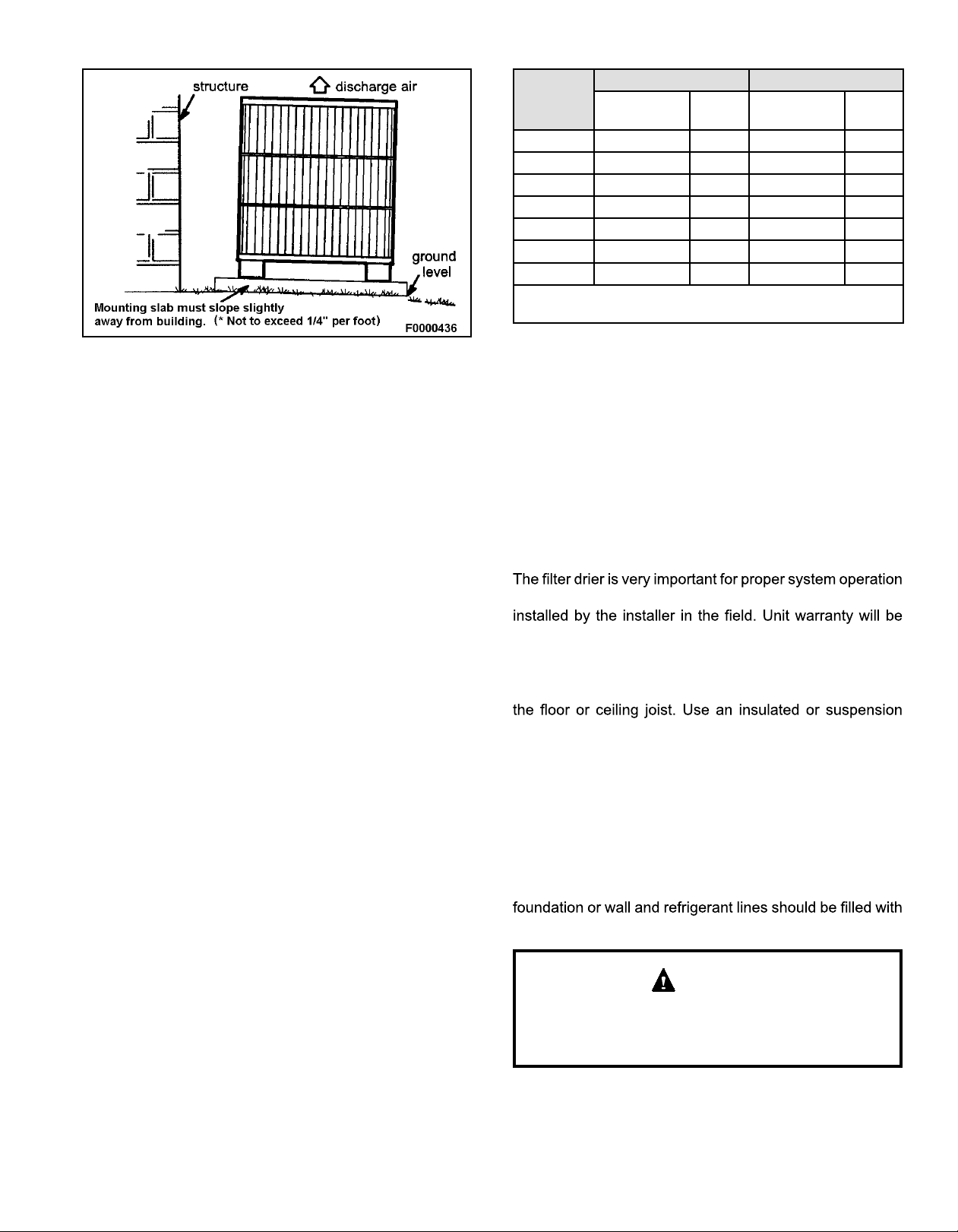

Install on a Solid, Level Mounting Pad

The outdoor section is to be installed on a solid foundation.

This foundation should extend a minimum of 2” (inches)

beyond the sides of the outdoor section. To reduce the

possibility of noise transmission, the foundation slab

should NOT be in contact with or be an integral part of the

building foundation.

thoroughly and follow all warning or cautions attached to

the unit.

1. Always wear proper personal protection equipment.

2. Always disconnect electrical power before removing

panel or servicing equipment.

3. Keep hands and clothing away from moving parts.

4. Handle refrigerant with caution, refer to proper MSDS

from refrigerant supplier.

5. Use care when lifting, avoid contact with sharp edges.

Installation

NOTE: In some cases noise in the living area has been

traced to gas pulsations from improper installation of

equipment.

1. Locate unit away form windows, patios, decks, etc.

where unit operation sounds may disturb customer.

2. Ensure that vapor and liquid tube diameters are

appropriate to capacity of unit.

3. Run refrigerant tubes as directly as possible by

avoiding unnecessary turns and bends.

4. Leave some slack between structure and unit to

absorb vibration.

5. When passing refrigerant tubes through the wall, seal

opening with RTV or other silicon-based caulk.

6. Avoid direct tubing contact with water pipes, duct work,

Elevate Unit

CAUTION

Accumulation of water and ice in base pan may cause

equipment damage.

Elevate unit per local climate and code requirements to

provide clearance above estimated snowfall level and

ensure adequate drainage of unit. Use snow stand in areas

where prolonged freezing temperatures are encountered.

If conditions or local codes require the unit be attached to

pad or mounting frame, tie down bolts should be used and

fastened through knockouts provided in unit base pan.

Rooftop Installations

Mount on level platform or frame 6 inches above roof

surface. Place unit above a load-bearing wall and isolate

unit and tubing set from structure. Arrange supporting

members to adequately support unit and minimize

transmission of vibration to building. Ensure roof structure

and anchoring method is adequate for location. Consult

local codes governing rooftop applications.

Roof mounted units exposed to winds above 5 mph may

coil. The height should cover the face of the coil and the

length should be 6” from the access panel.

7. Do not suspend refrigerant tubing from joists and

studs with a rigid wire or strap which comes in direct

contact with tubing.

8. Ensure that tubing insulation is pliable and completely

surrounds vapor tube.

When outdoor unit is connected to factory-approved indoor

unit, outdoor unit contains system refrigerant charge for

operation with indoor unit of the same size when connected

check refrigerant charge using charging information

located on control box cover.

NOTE: Unit must be level to within ± 1/4 in./ft. per

Clearance Requirements

snow, or ice from roof or eaves cannot fall directly on unit.

506318-03CPage 2 of 11 mrcool.com

Figure 1.

Liquid Vapor

Capacity

-018 3/8” 3/8” 3/4” 3/4”

-024 3/8” 3/8” 3/4” 3/4”

-030 3/8” 3/8” 3/4” 3/4”

-036 3/8” 3/8” 7/8” 7/8”

-042 3/8” 3/8” 7/8” 7/8”

-048 3/8” 3/8” 7/8” 7/8”

-060 3/8” 3/8” 7/8” *1-1/8”

* Field supplied 7/8 x 1-1/8 connector required on both ends

of vapor tubing.

Connections

Dia.

Tube

Dia.

Connections

Dia.

Tube

Dia.

Table 1. Recommended Liquid & Vapor Tube

Diameters (in.)

DO LOCATE THE UNIT:

• With proper clearances on sides and top of unit

• On a solid, level foundation or pad

• To minimize refrigerant line lengths

DO NOT LOCATE THE UNIT:

• On brick, concrete blocks or unstable surfaces

• Near clothes dryer exhaust vents

• Near sleeping area or near windows

• Under eaves where water, snow or ice can fall directly

on the unit

• With clearance less than 2 ft. from a second unit

• With clearance less than 4 ft. on top of unit

Operating Ambient

The minimum outdoor operating ambient in cooling mode

is 55°F, and the maximum outdoor operating ambient in

cooling mode is 125°F. The maximum outdoor operating

ambient in heating mode is 66°F.

Refrigeration Line Sets

Use only refrigerant grade copper tubes. Split systems

may be installed with up to 50 feet of line set (no more than

20 feet vertical) without special consideration (see long

line set guidelines).

Be extra careful with sharp bends. Tubing can “kink” very

easily, and if this occurs, the entire tube length will have

to be replaced. Extra care at this time will eliminate future

service problems.

It is recommended that vertical suction risers not be upsized. Proper oil return to the compressor should be

maintained with suction gas velocity.

Filter Drier

and reliability. If the drier is shipped loose, it must be

void, if the drier is not installed.

Installation of Line Sets

DO NOT fasten liquid or suction lines in direct contact with

type of hanger. Keep both lines separate, and always

insulate the suction line. Long liquid line runs (30 feet or

more) in an attic will require insulation. Route refrigeration

line sets to minimize length.

DO NOT let refrigerant lines come in direct contact with

foundation. When running refrigerant lines through the

foundation or wall, openings should allow for a sound

and vibration absorbing material to be placed or installed

between tubing and foundation. Any gap between

It is important that no tubing be cut or seals broken until you

are ready to actually make connections to the evaporator

and to the condenser section. DO NOT remove rubber

plugs or copper caps from the tube ends until ready to

make connections at evaporator and condenser. Under no

circumstances leave the lines open to the atmosphere for

any period of time, if so unit requires additional evacuation

to remove moisture.

a vibration damping material.

CAUTION

If ANY refrigerant tubing is required to be buried by state

or local codes, provide a 6 inch vertical rise at service

valve.

Page 3 of 11506318-03C mrcool.com

Loading...

Loading...