Page 1

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Owner & Installation

Manual

Signature Series

MGM*95SE*XA Gas Furnace

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Page 2

Gas Furnace

INSTALLATION INSTRUCTIONS

MGM*95SE*XA

Warm Air Gas Furnace

This manual must be left with the homeowner for future reference.

Table of Contents

2

3

Gas Piping 38

WARNING

MRCOOL, LLC

13

13

16

6

6

9

CAUTION

50

52

55

56

*F507276-C*

(P) 507276-05C

Save these instructions for future reference

507276-05C Page 1 of 57mrcool.com

Page 3

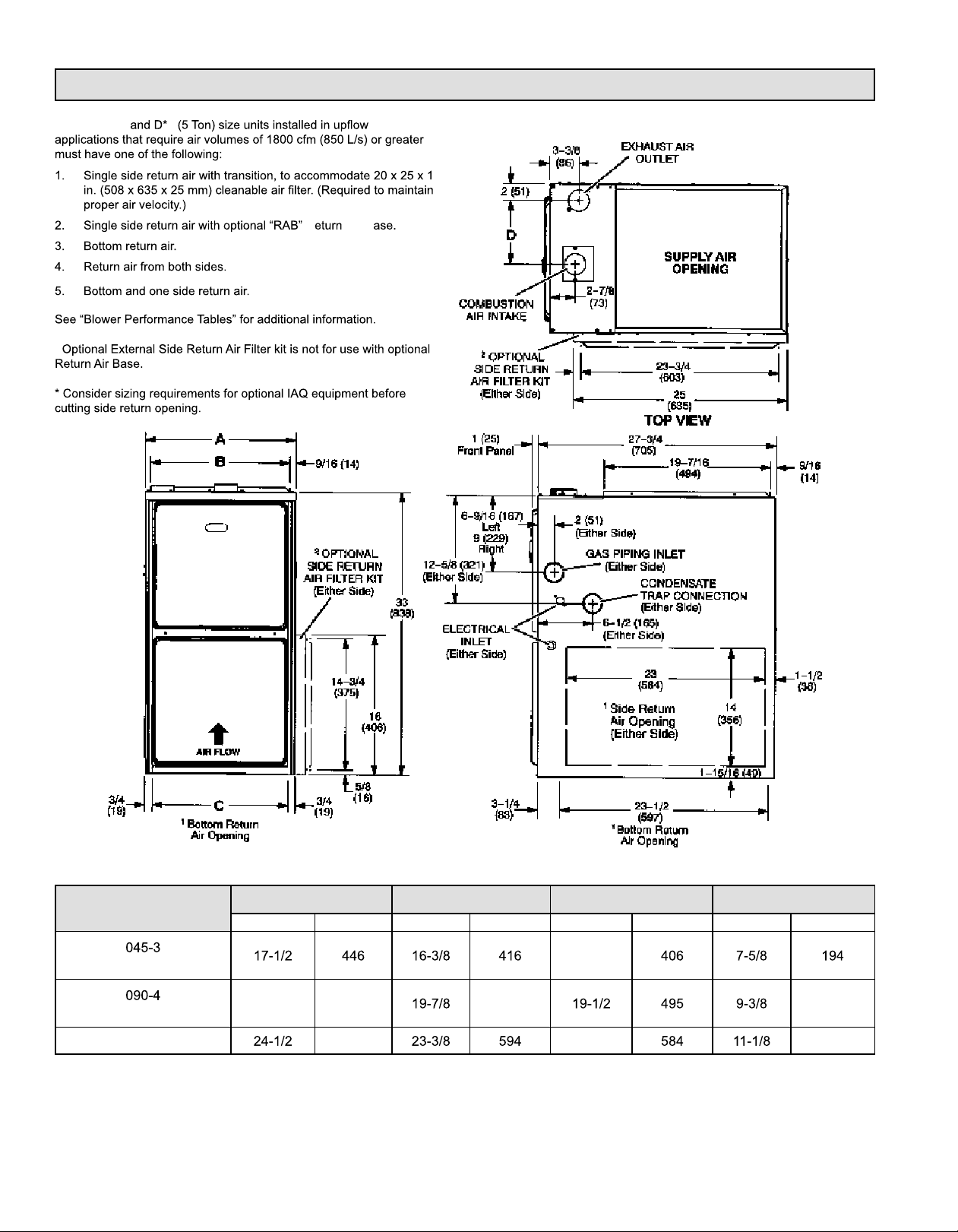

Unit Dimensions

1

NOTE - C*5 5

2

R Air B

Model

070-3

110-5

135-5

FRONT VIEW SIDE VIEW

A B C D

in. mm in. mm in. mm in. mm

16

21 533

622 23 283

505 238

507276-05CPage 2 of 57 mrcool.com

Page 4

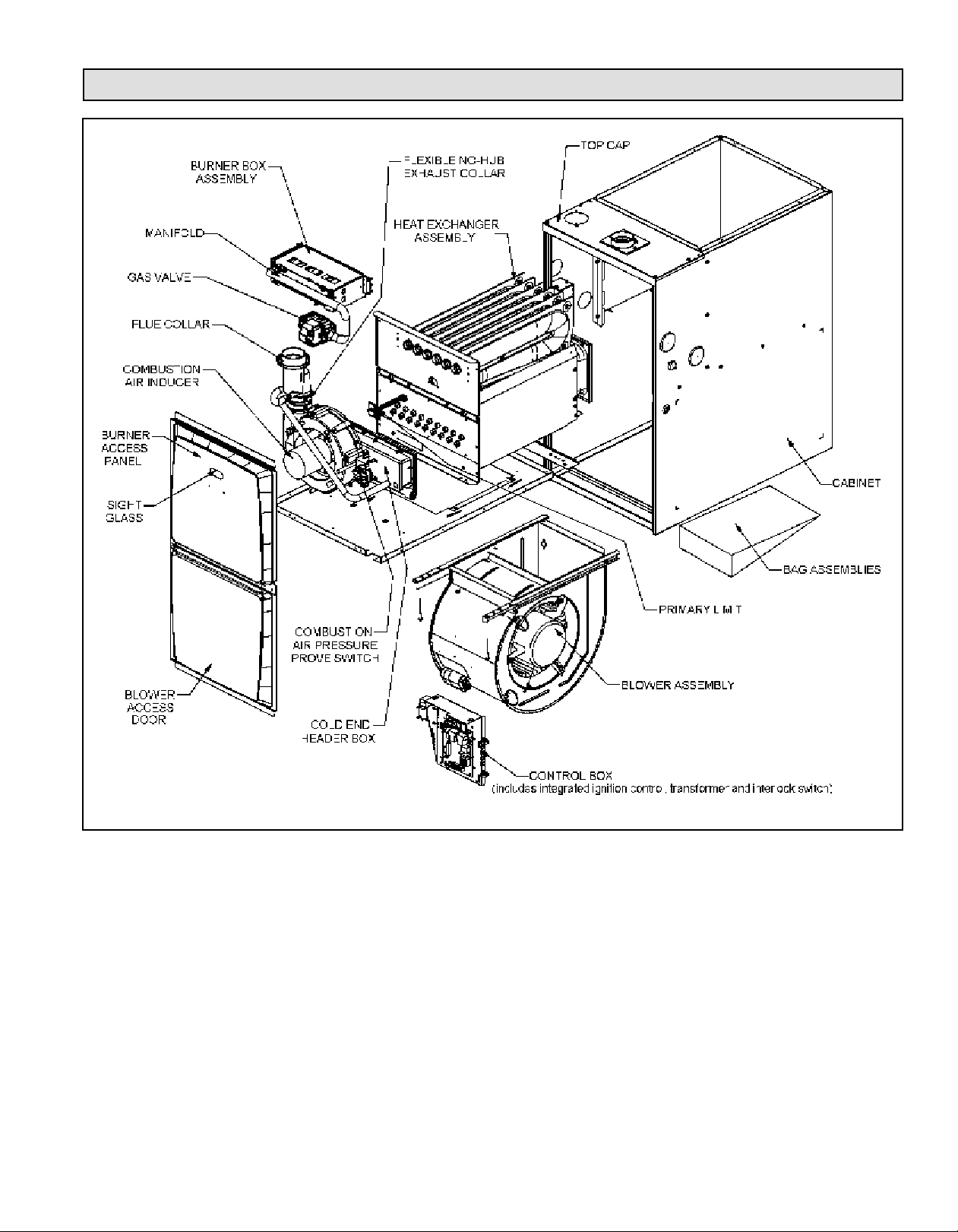

Parts Arrangement

Figure 1.

507276-05C Page 3 of 57mrcool.com

Page 5

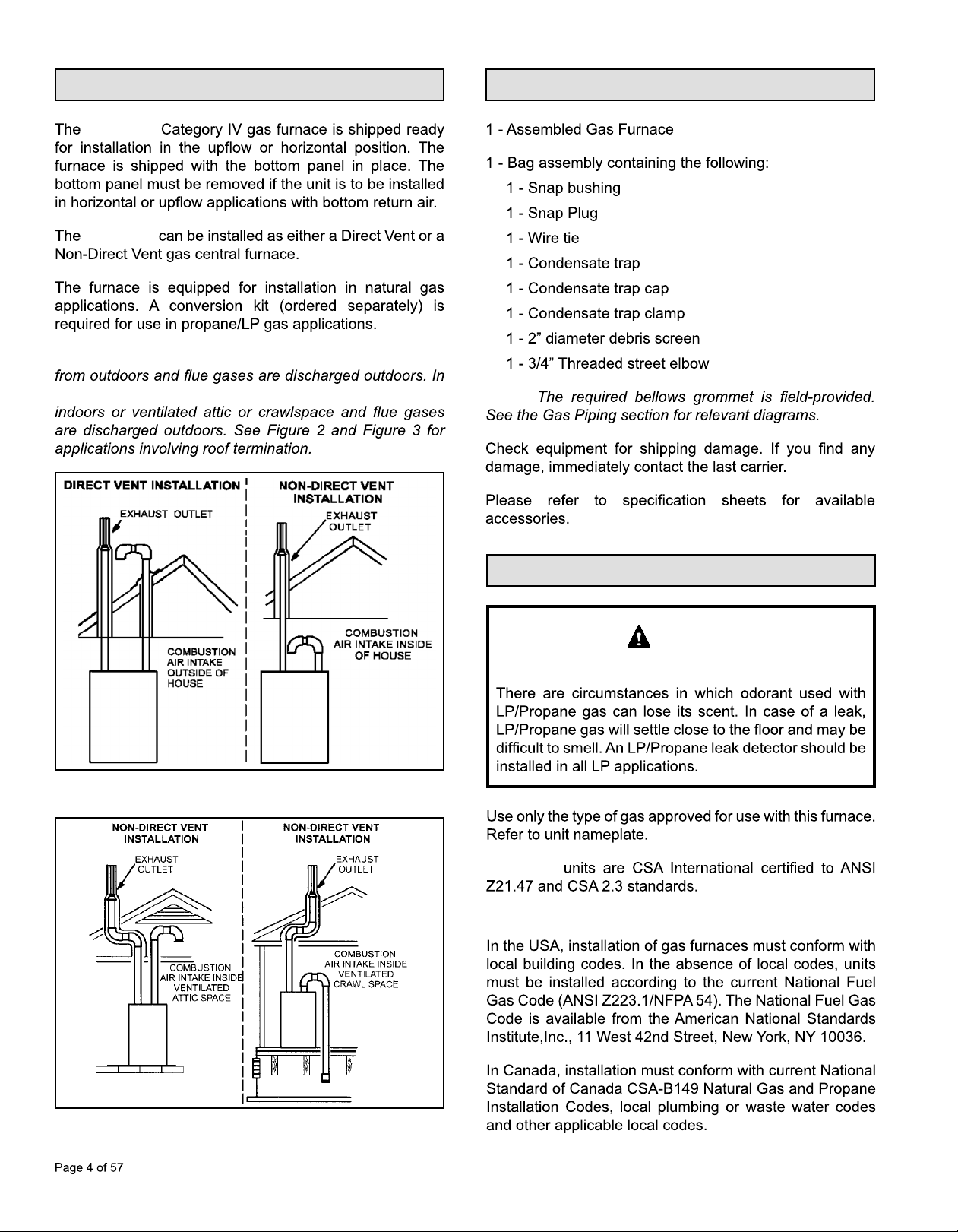

Gas Furnace

MG*95SE*XA

MG*95SE*XA

NOTE: In Direct Vent installations, combustion air is taken

Shipping and Packing List

Non-Direct Vent installations, combustion air is taken from

Figure 2.

NOTE:

Safety Information

DANGER

DANGER OF EXPLOSION!

Figure 3.

MG*95SE*XA

Building Codes

507276-05Cmrcool.com

Page 6

Installation Locations

NOTE:

NOTE:

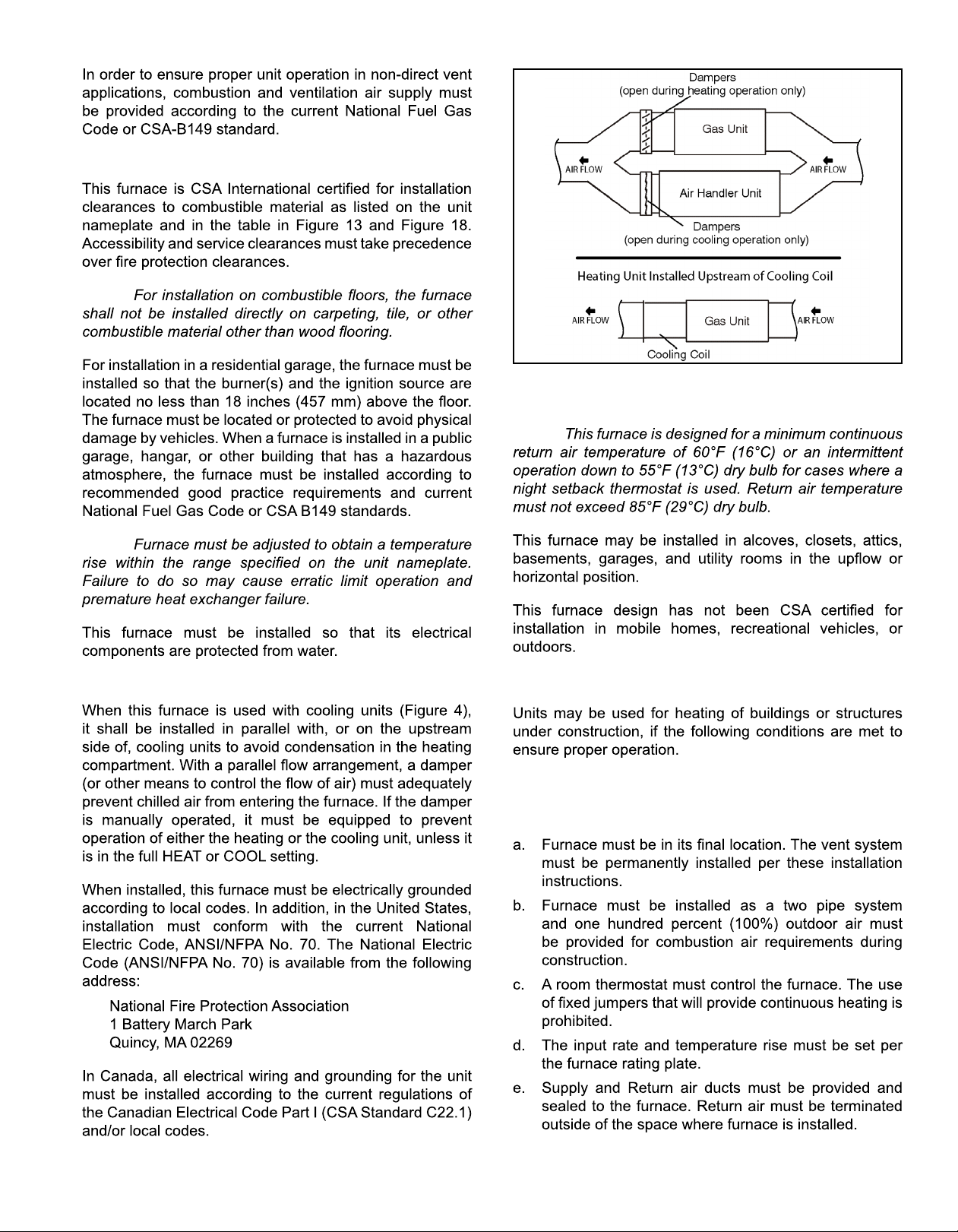

Figure 4. Heating Unit Installed Parallel to Air Handler

Unit

NOTE:

Installed in Combination with a Cooling Coil

Use of Furnace as a Construction Heater

DO NOT USE THE UNIT FOR CONSTRUCTION HEAT

UNLESS ALL OF THE FOLLOWING CRITERIA ARE

MET:

507276-05C Page 5 of 57mrcool.com

Page 7

COMPONENT FAILURE AS A RESULT OF FAILURE TO

•

•

NOTE:

•

•

•

CAUTION

General

•

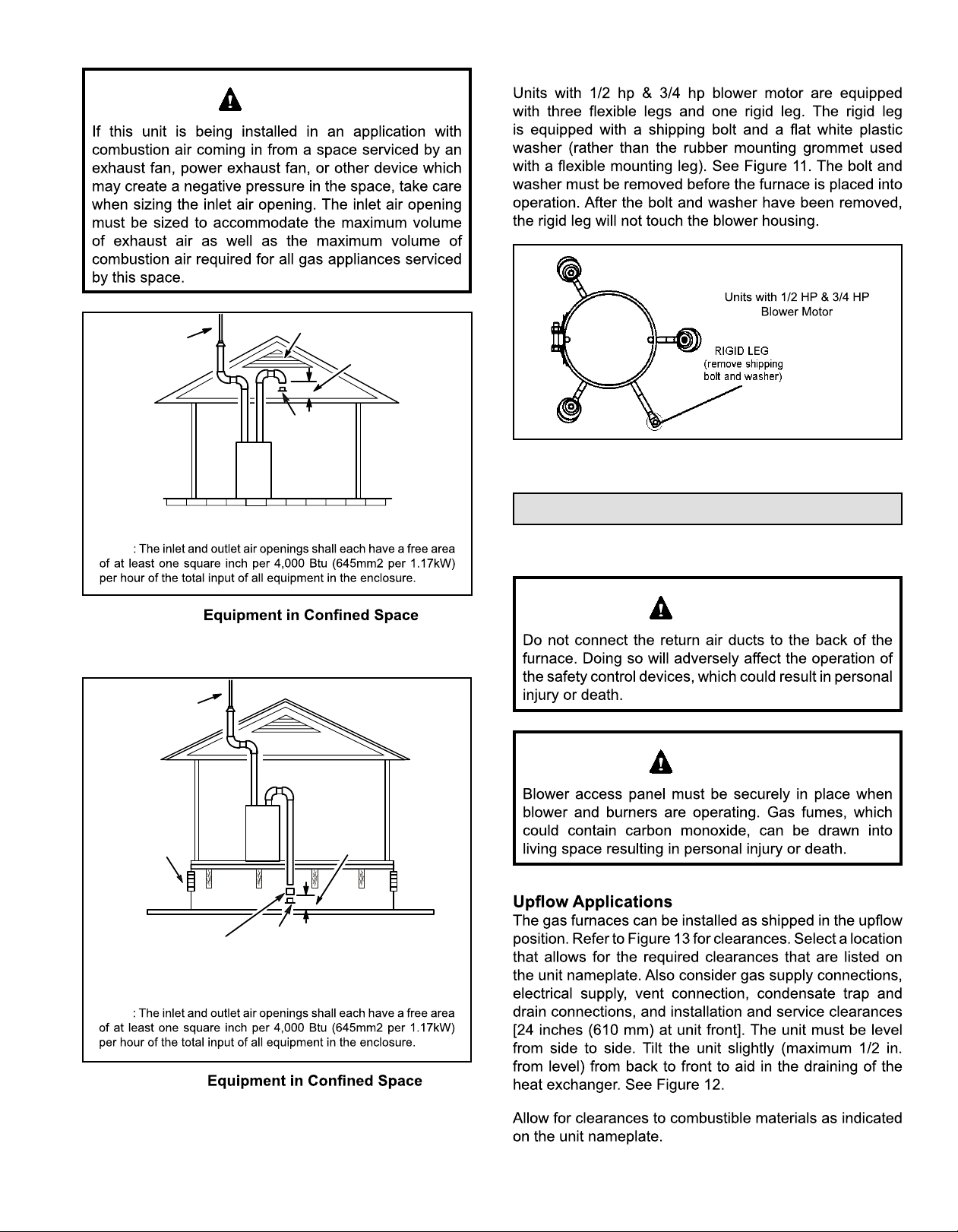

Combustion, Dilution & Ventilation Air

NOTE: In Non-Direct Vent Installations, combustion air is

•

•

507276-05CPage 6 of 57 mrcool.com

Page 8

WARNING

•

•

•

•

•

•

•

•

•

•

•

•

•

CAUTION

Air from Inside

507276-05C Page 7 of 57mrcool.com

Page 9

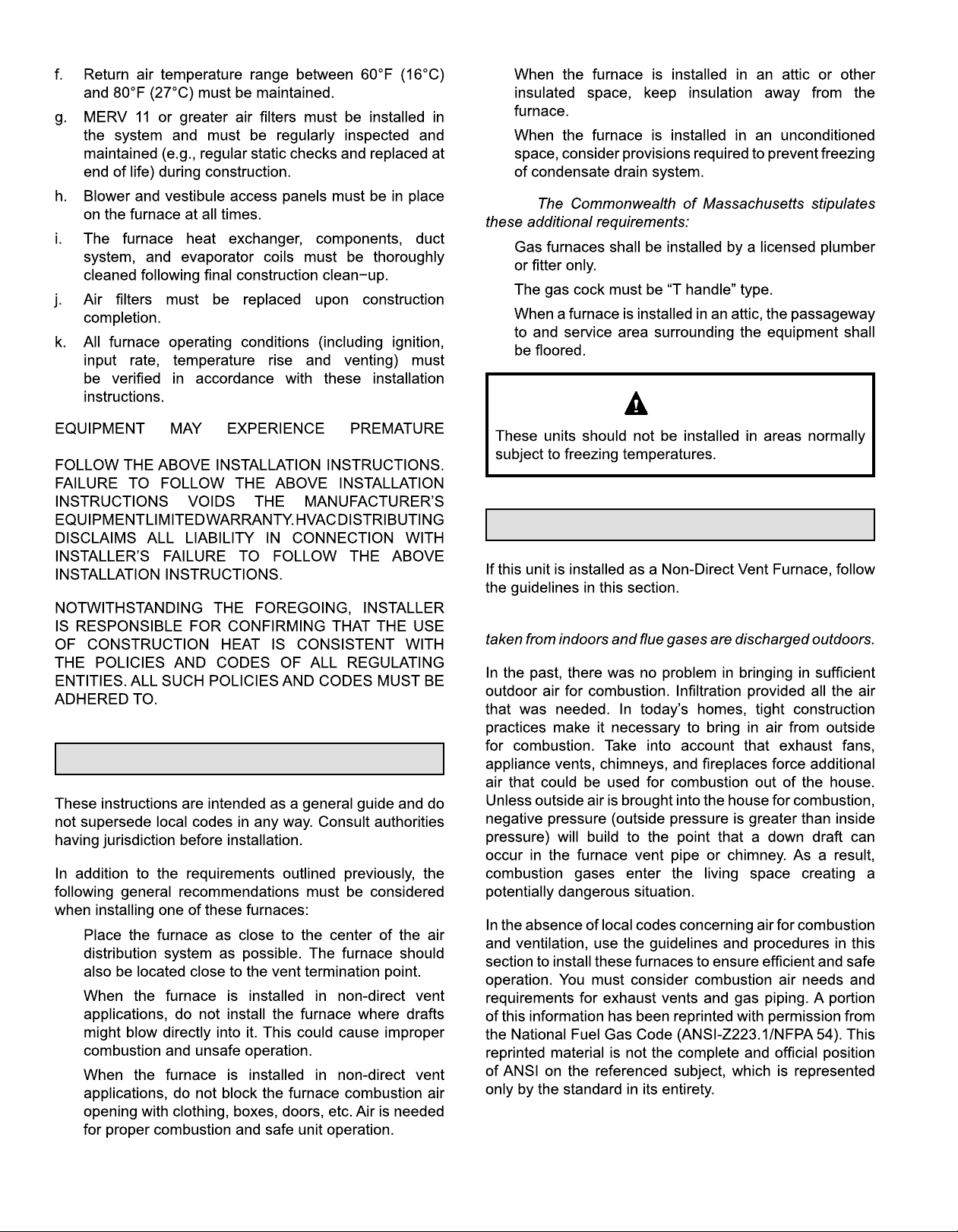

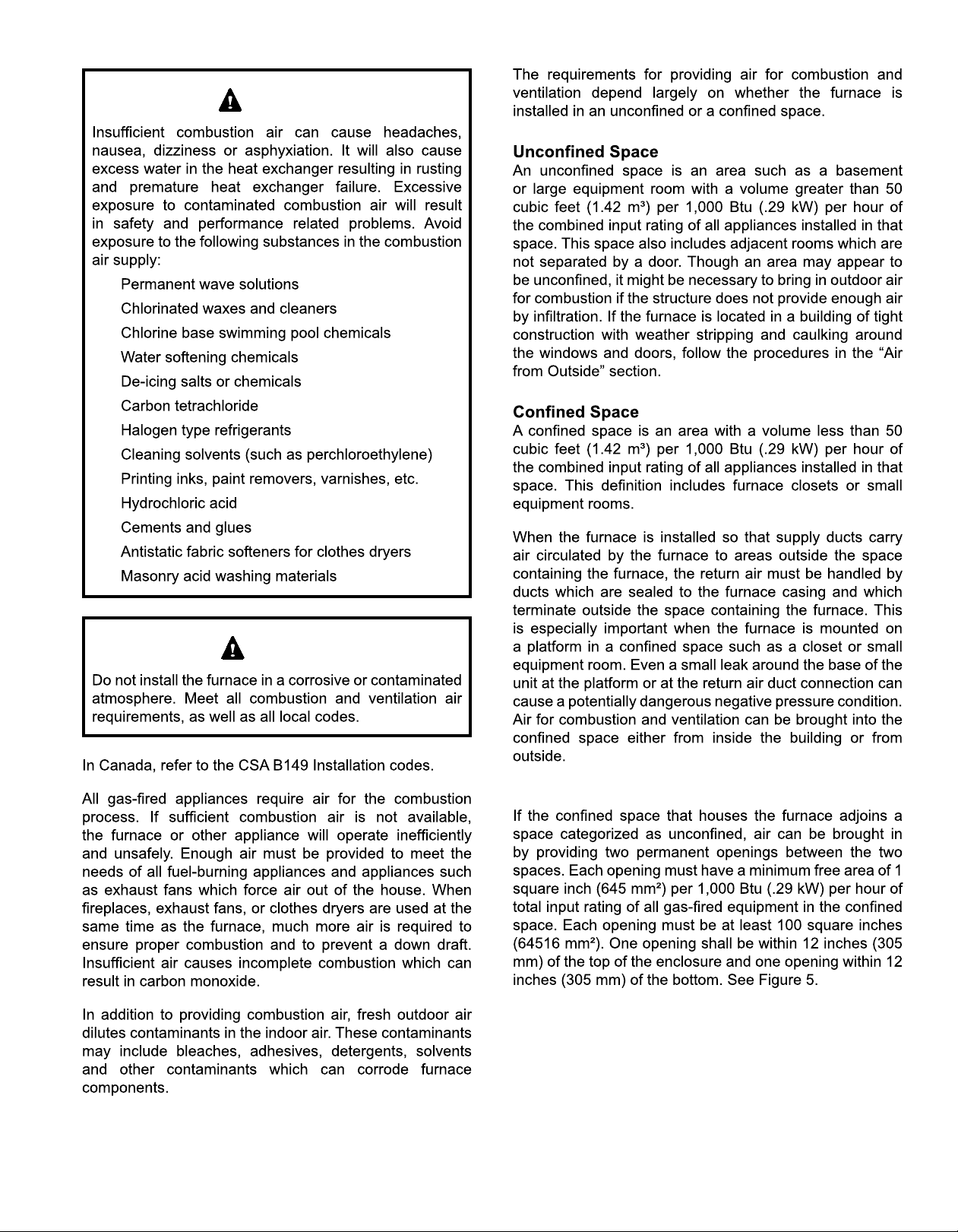

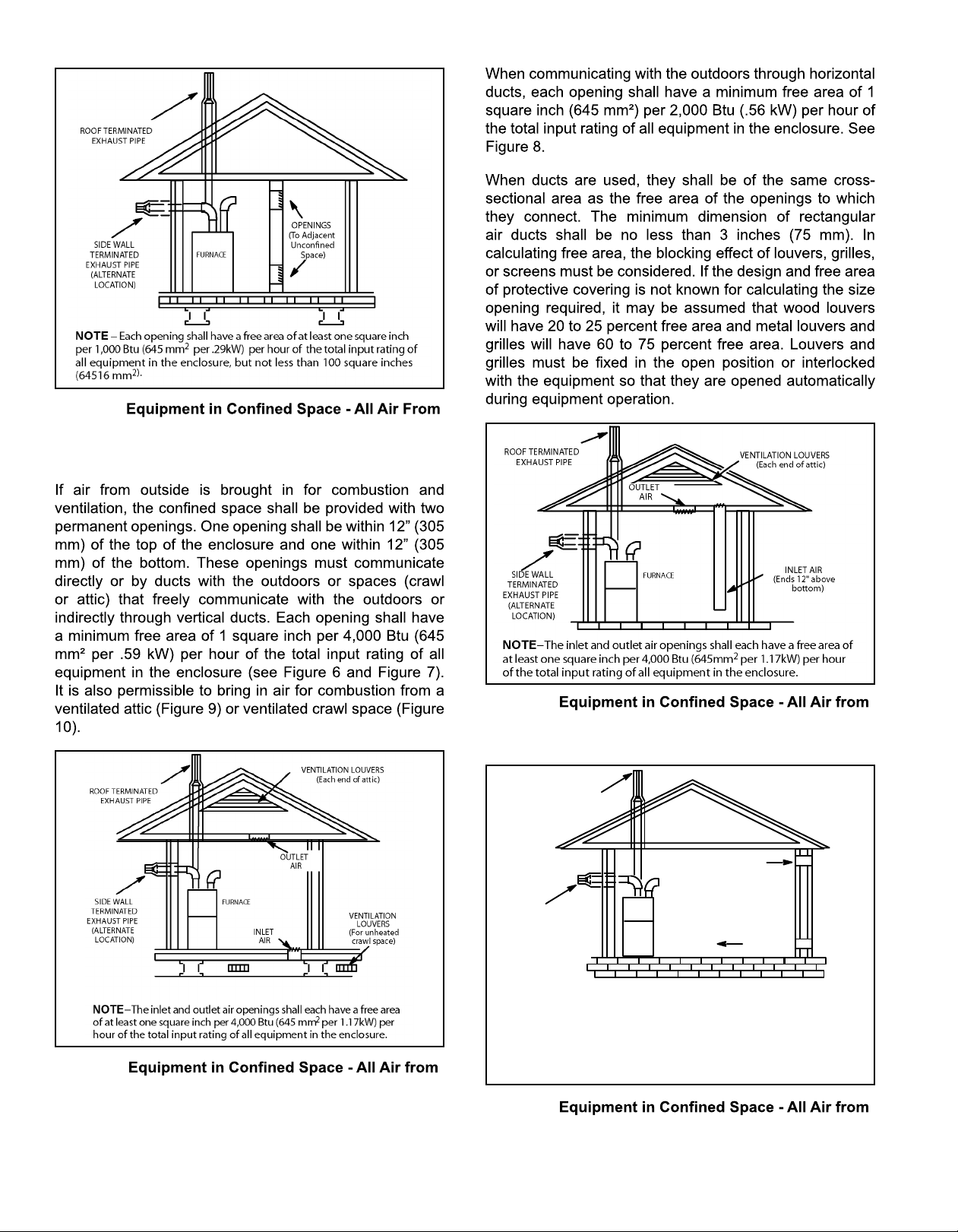

Figure 5.

Air from Outside

Inside

Figure 7.

ROOF TERMINATED

EXHAUST PIPE

Outside

(All Air through Ventilated Attic)

Figure 6.

Outside

(Inlet Air from Crawl Space and Outlet Air to

Ventilated Attic)

OUTLET AIR

SIDE WALL

TERMINATED

EXHAUST PIPE

(ALTERNATE

LOCATION)

NOTE−Each air duct opening shall have a free area of at least one

square inch per 2,000 Btu (645mm

input rating of all equipment in the enclosure. If the equipment room

is located against an outside wall and the air openings communicate directly with the outdoors, each opening shall have a free area

of at least 1 square inch per 4,000 Btu (645mm

hour of the total input rating of all other equipment in the enclosure.

FURNACE

INLET AIR

2

per .59kW) per hour of the total

2

per 1.17kW) per

Figure 8.

Outside

507276-05CPage 8 of 57 mrcool.com

Page 10

WARNING

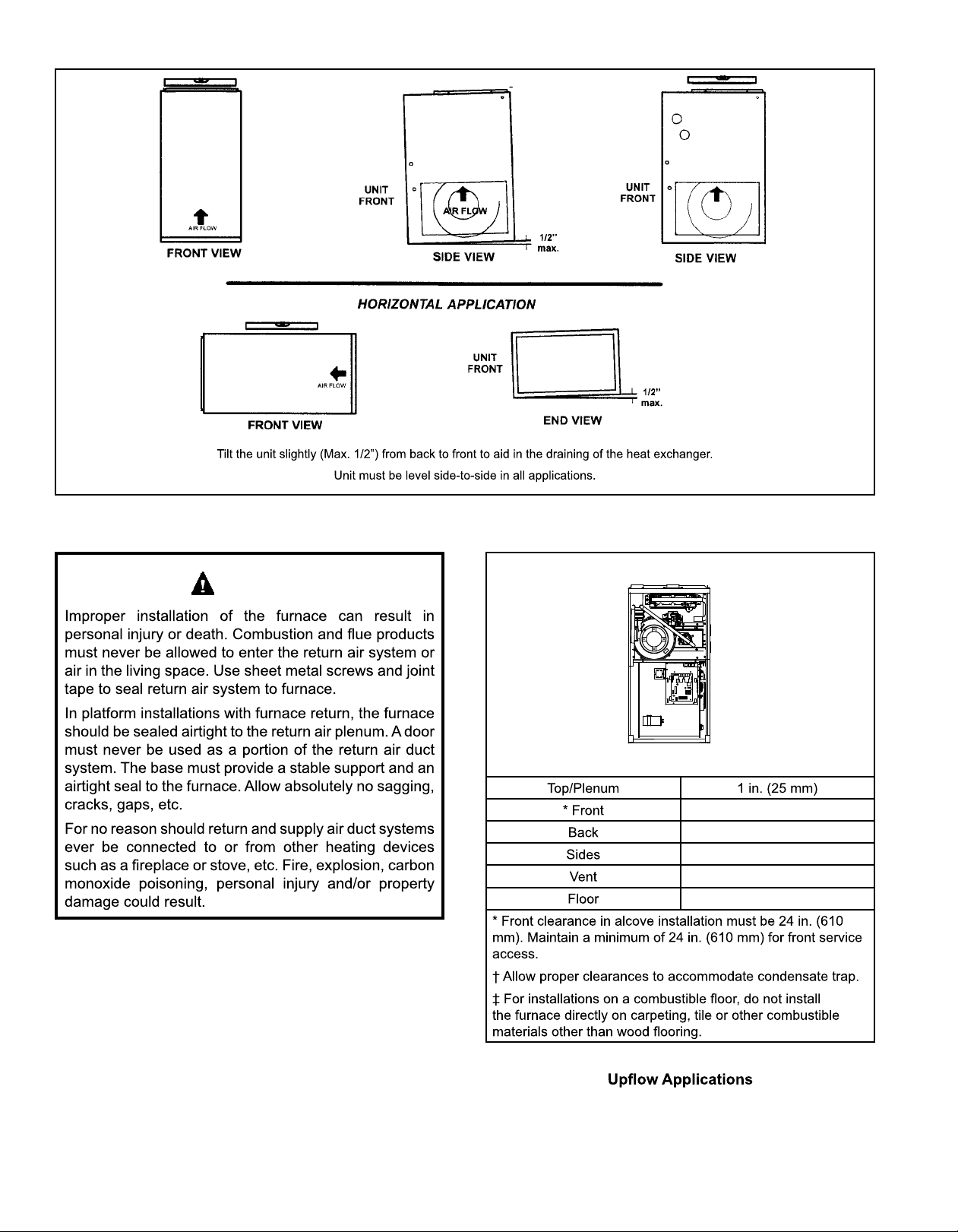

Shipping Bolt Removal

Roof Terminated

Exhaust Pipe

Ventilation Louvers

*Intake Debris

Screen

(Provided)

Furnace

Inlet Air

(Minimum 12 in.

(305mm) above

Attic Floor)

* See Maximum Vent Lengths table

NOTE

Figure 9.

(Inlet Air from Ventilated Attic and Outlet Air to

Outside)

Roof Terminated

Exhaust Pipe

Figure 11.

Installation

Setting Equipment

WARNING

Inlet Air

Minimum

Ventilation

Louvers

(Crawl Space)

Coupling or

3 in. to 2 in.

Transition

(Field Provided)

Furnace

12 in. (305mm)

above Crawl

Space Floor

*Intake Debris Screen Provided

* See Maximum Vent Lengths table

NOTE

Figure 10.

(Inlet Air from Ventilated Crawl Space and Outlet Air

to Outside)

507276-05C Page 9 of 57mrcool.com

WARNING

Page 11

WARNING

Figure 12. Setting Equipment

Top

Left Side

Right Side

Bottom (Floor)

Top/Plenum 1 in. (25 mm)

*Front 0

Back 0

Sides 0†

Vent 0

Floor 0‡

*Front clearance in alcove installation must be 24 in. (610 mm).

Maintain a minimum of 24 in. (610 mm) for front service access.

†Allow proper clearances to accommodate condensate trap.

‡For installations on a combustible

on carpeting, tile or other combustible materials other than wood

ooring.

oor, do not install the furnace directly

0

0

0†

0

0‡

Figure 13. Installation Clearances

507276-05CPage 10 of 57 mrcool.com

Page 12

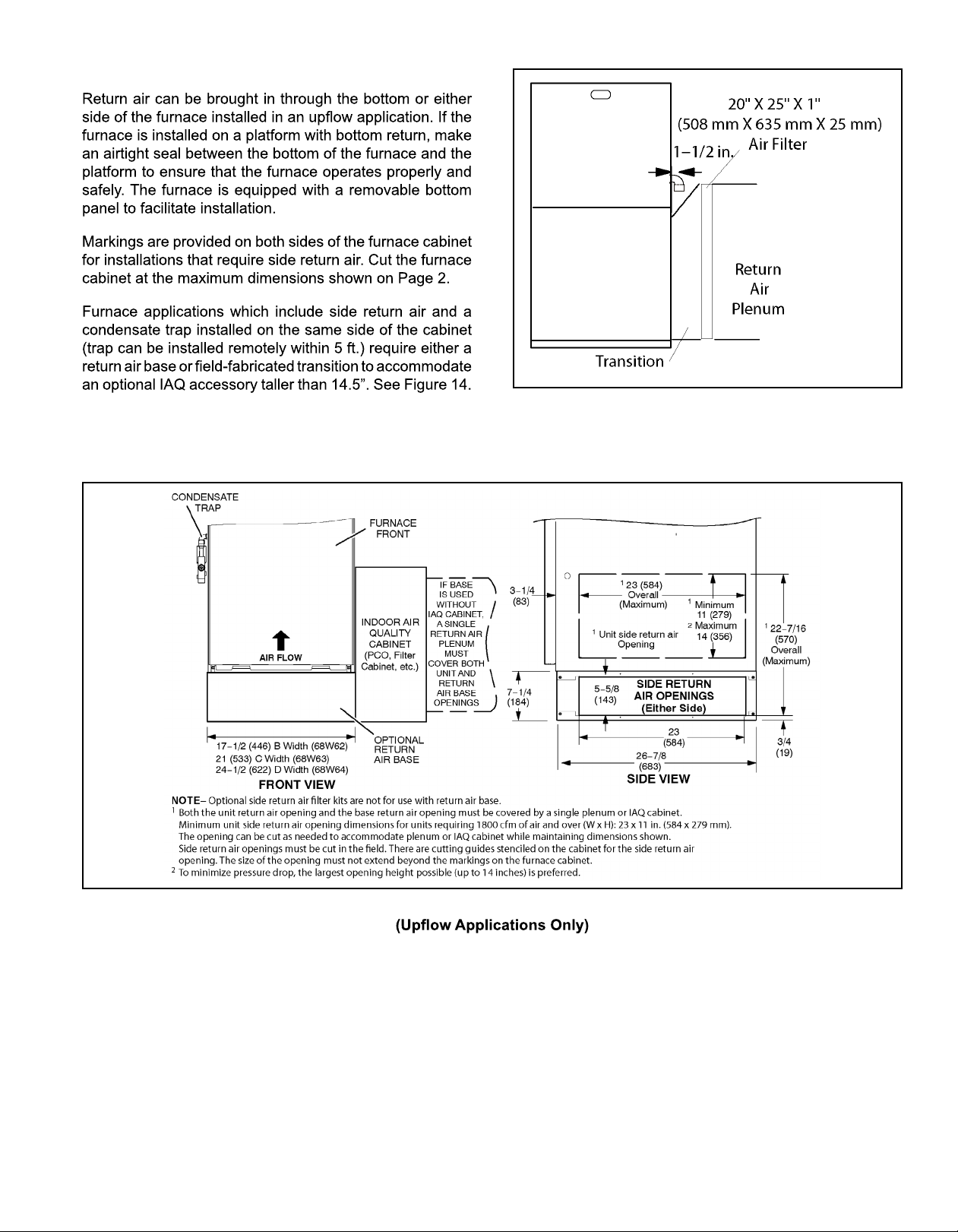

Return Air Guidelines

Figure 14. Side Return Air

(with Transition and Filter)

Figure 15. Optional Return Air Base

507276-05C Page 11 of 57mrcool.com

Page 13

Right−Hand Discharge

dnEthgiRdnEtfeL

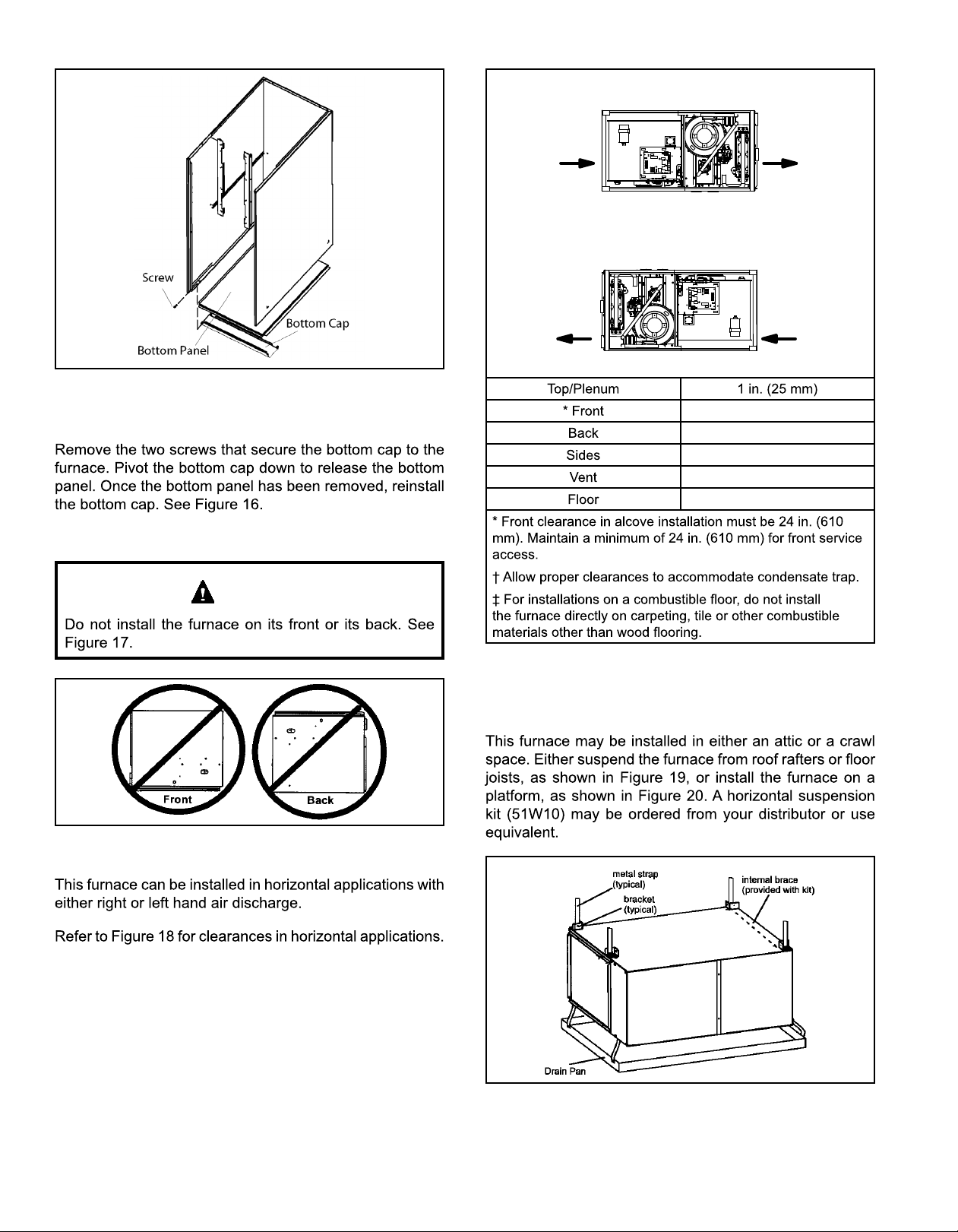

Figure 16. Removing the Bottom Panel

Removing the Bottom Panel

Horizontal Applications

WARNING

Air

Flow

Air

Flow

Bottom (Floor)**

Left−Hand Discharge

Top

dnEthgiRdnEtfeL

Air

Flow

Air

Flow

Bottom (Floor)**

Top 0

Front* 0

Back 0

Ends 0

Vent 0

Floor 0‡

* Front clearance in alcove installation must be 24 in. (610 mm).

Maintain a minimum of 24 in. (610 mm) for front service access.

**An 8" service clearance must be maintained below the unit to provide

for servicing of the condensate trap.

‡For installations on a combustible

on carpeting, tile or other combustible materials other than wood

ooring.

oor, do not install the furnace directly

0

0

0†

0

0‡

Figure 17.

Figure 18. Installation Clearances

Horizontal Applications

Suspended Installation of Horizontal Unit

Figure 19. Typical Horizontal Application

507276-05CPage 12 of 57 mrcool.com

Page 14

NOTE:

Filters

NOTE:

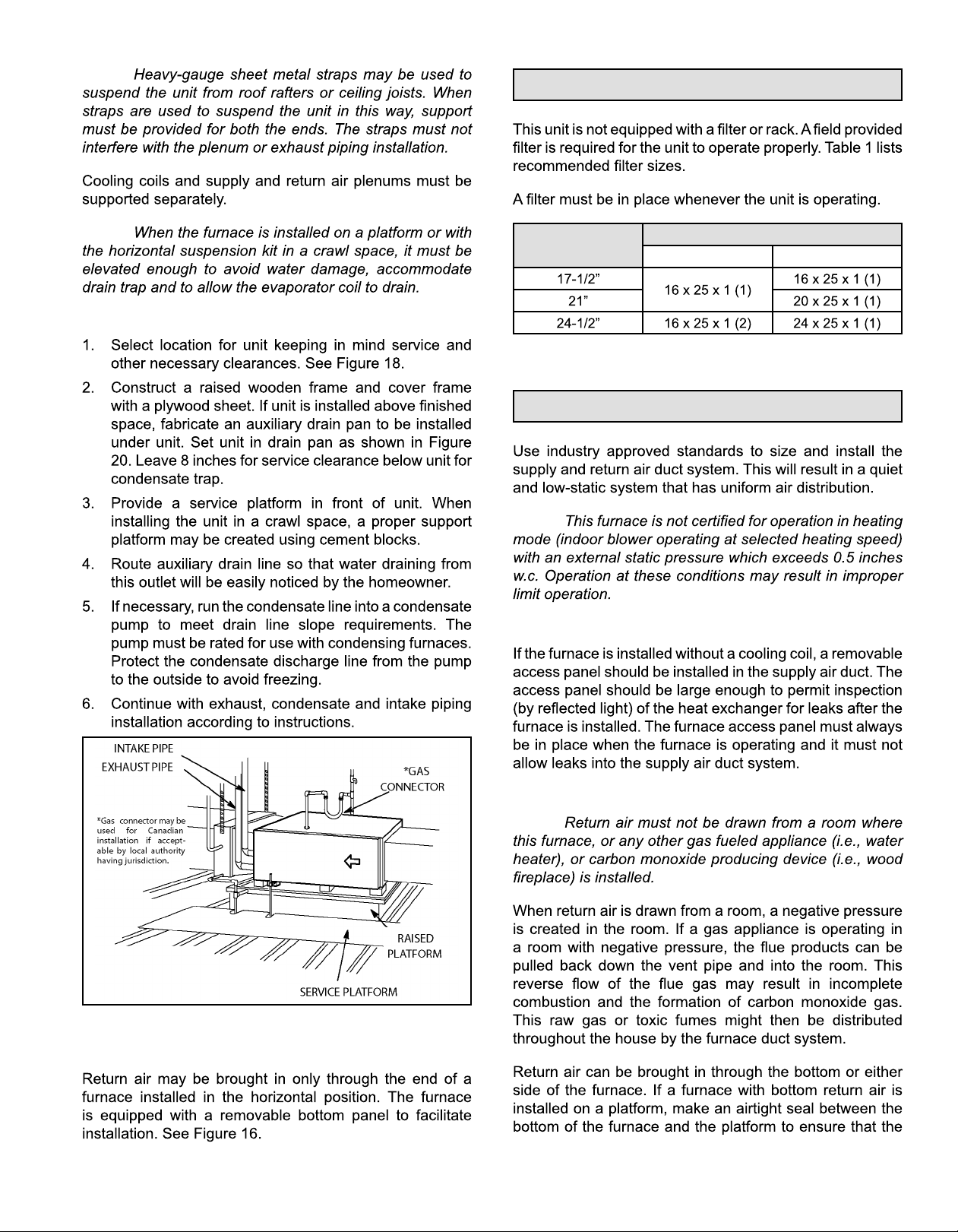

Platform Installation of Horizontal Unit

Furnace Cabinet

Width

Duct System

NOTE:

Supply Air Plenum

Filter Size

Side Return Bottom Return

Table 1.

Figure 20.

Return Air - Horizontal Applications

507276-05C Page 13 of 57mrcool.com

Return Air Plenum

NOTE:

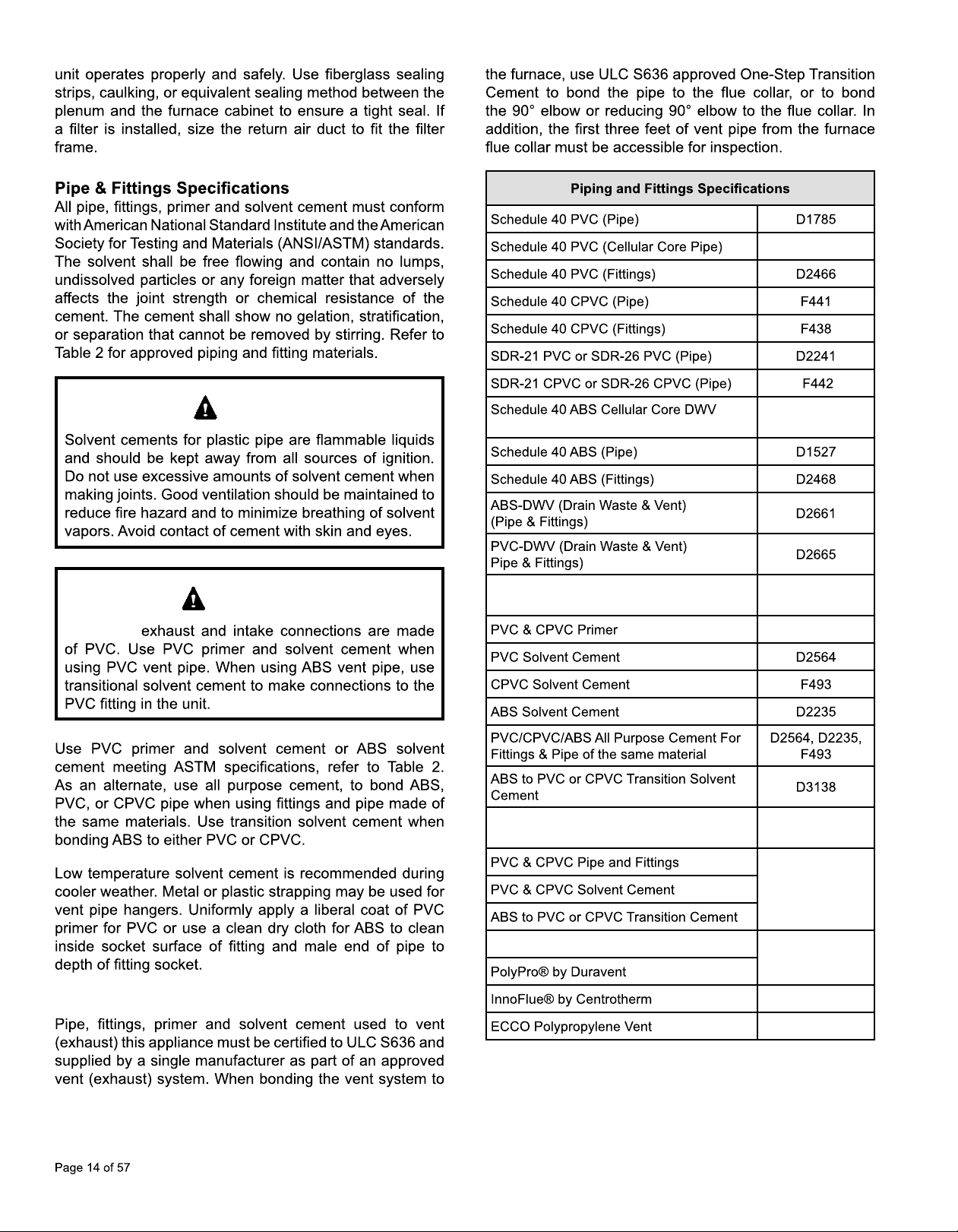

Page 15

F891

MGM95*E

CAUTION

IMPORTANT

(Pipe)

PRIMER & SOLVENT CEMENT

CANADA PIPE & FITTING & SOLVENT

CEMENT

F628

ASTM

SPECIFICATION

F656

MARKING

Canadian Applications Only

POLYPROPYLENE VENTING SYSTEM

TM

Table 2.

ULCS636

ULC-S636

ULC-S636

ULC-S636

507276-05Cmrcool.com

Page 16

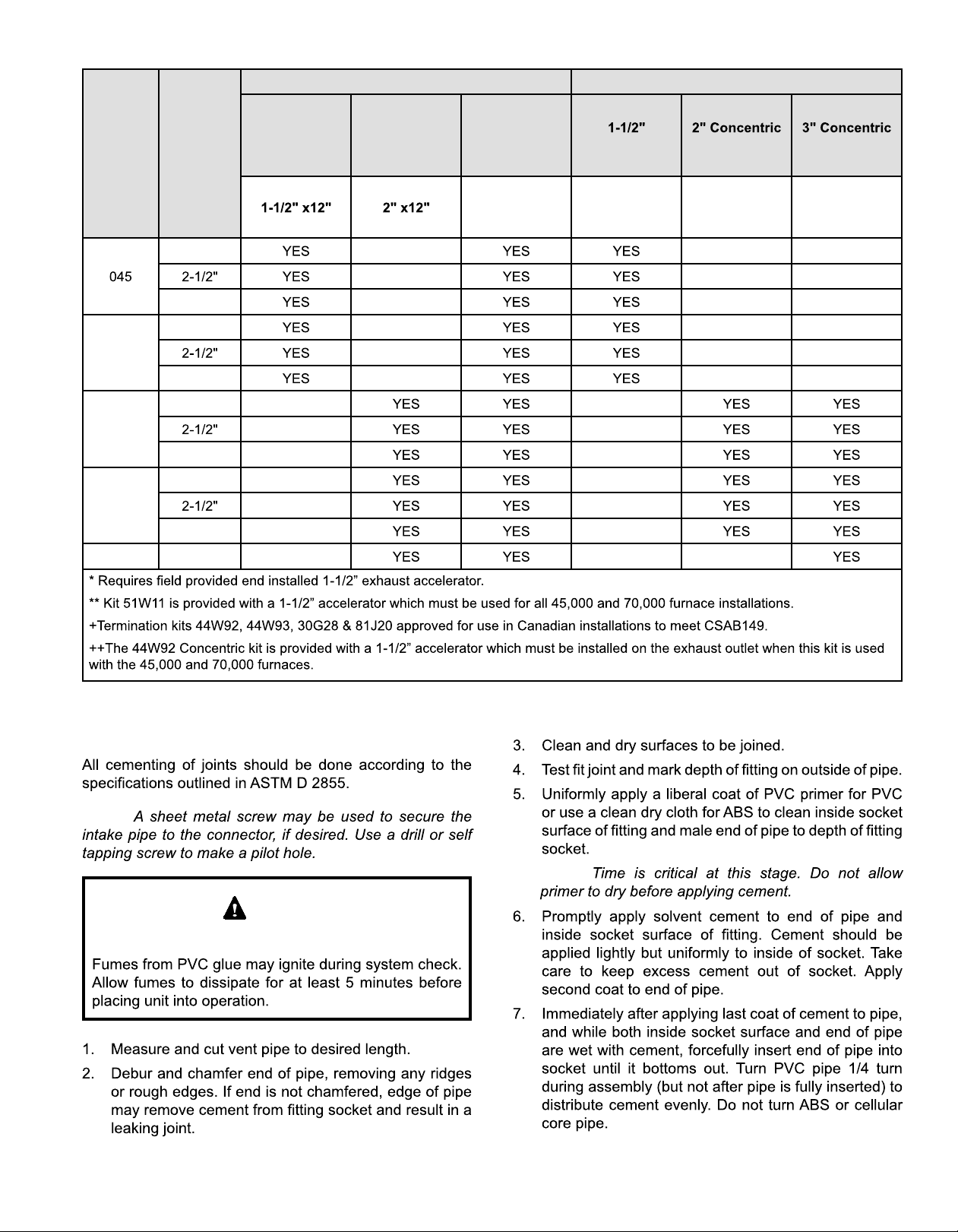

STANDARD CONCENTRIC

Capacity

070

090

110

135 3

VENT

PIPE DIA.

(in.)

2

3

2

3

2

3

2

3

Outdoor

Exhaust

Accelerator

(Dia. X Length)

Outdoor

Exhaust

Accelerator

(Dia. X Length)

Flush Mount

Kit

51W11**

Concentric Kit Kit Kit

71M80

OR

+44W92++

69M29

OR

+44W92++

60L46

OR

44W93+

Joint Cementing Procedure

NOTE:

DANGER

DANGER OF EXPLOSION!

Table 3. Outdoor Termination Kits Usage

NOTE:

507276-05C Page 15 of 57mrcool.com

Page 17

NOTE:

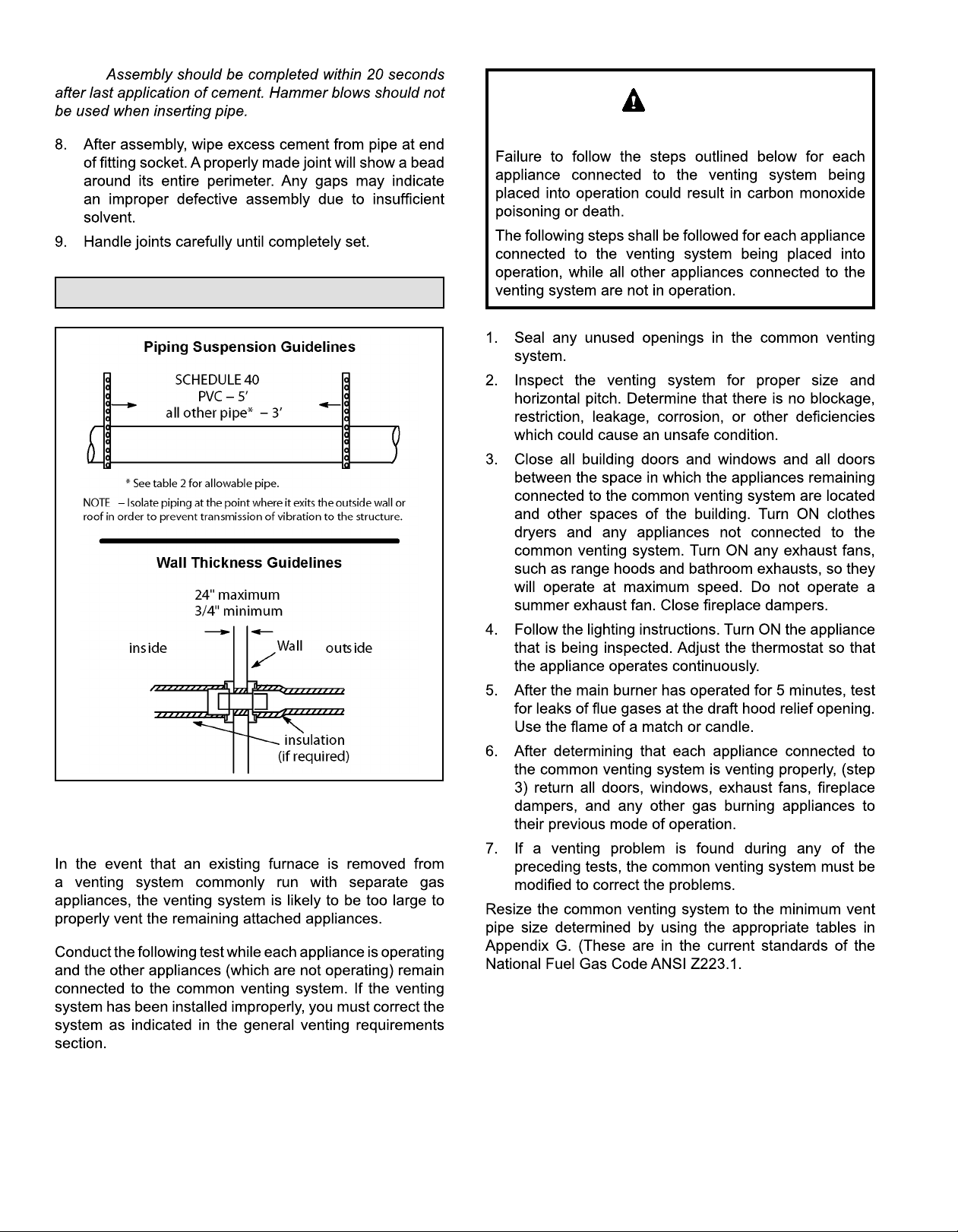

Venting Practices

WARNING

CARBON MONOXIDE POISONING HAZARD

Figure 21.

Removal of the Furnace from Common Vent

507276-05CPage 16 of 57 mrcool.com

Page 18

CHIMNEY

OR GAS

VENT

(Check sizing

for remaining

appliance)

REPLACING FURNACE THAT

Vent Piping Guidelines

WAS PART OF A COMMON

VENT SYSTEM

NOTE: In non-Direct Vent installations, combustion air is

In Direct Vent installations, combustion air is taken from

FURNACE

(Removed from

from common

vent system)

If this gas furnace replaces a furnace which

was commonly vented with another gas appliance,

the size of the existing vent pipe for that gas

appliance must be checked. Without the heat of the

original furnace flue products, the existing vent pipe

is probably oversized for the single water heater or

other appliance. The vent should be checked for

proper draw with the remaining appliance.

Exhaust Piping

WATER

HEATER

Figure 22.

OPENINGS

(ToAdjacent

Room)

MRCOOL, LLC

NOTE:

NOTE:

CAUTION

CAUTION

507276-05C Page 17 of 57mrcool.com

Figure 23.

Page 19

IMPORTANT

Capacity Min. Vent Length*

Furnace capacity?

1

045, 070,

090, 110,

135

135 **

Table 4.

Which termination?

2

Which needs most

3

elbows?

How many?

4

Desired pipe size?

5

Standard or

Concentric?

See Table 3

Intake or

Exhaust?

2”, 2-1/2”

or 3”

What is the altitude?

6

Use Table 5 to find

7

max pipe length.

Figure 24.

507276-05CPage 18 of 57 mrcool.com

Page 20

MG*M95SE*XA Maximum Allowable Intake or Exhaust Vent Length in Feet

Number

of 90°

Elbows

Used

10 31 16 65 50 18 87 87 68 68

Number

of 90°

Elbows

Used

10 31 16 65 50 18 87 87 68 68

045 070 090 110 135 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 25 20

2 20 15 71 56

3 15 10 66 51 29 9 100 85 53 28 122 122 103 103 99

10 61 95 80 23 117 117 98 98

5 56 19 90 75 18 112 112 93 93 89

6 51 36

7 31 9 80 65 33 8 102 102 83 83 79

8

9 36 21 70 55 23 92 92 73 73 69

045 070 090 110 135 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 25 20

2 20 15 71 56

3 15 10 66 51 29 100 85 53 28 122 122 103 103 99

10 61 95 80 23 117 117 98 98

5 56 19 90 75 18 112 112 93 93 89

6 51 36

7 31 9 80 65 33 8 102 102 83 83 79

8

9 36 21 70 55 23 92 92 73 73 69

Capacity Capacity Capacity Capacity

76 61 39 19 110 95 63 38 132 132 113 113 109

105 90 58 33 127 127 108 108

85 70 38 13 107 107 88 88

26 75 60 28 97 97 78 78

Capacity Capacity Capacity Capacity

76 61 39 110 95 63 38 132 132 113 113 109

105 90 58 33 127 127 108 108

85 70 38 13 107 107 88 88

26 75 60 28 97 97 78 78

Table 5A.

507276-05C Page 19 of 57mrcool.com

Page 21

MG*M95SE*XA

Maximum Allowable Intake or Exhaust Vent Length in Feet

Number

of 90°

Elbows

Used

10 23 8 55

Number

of 90°

Elbows

Used

10 23 8 55

045 070 090 110 135 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 25 20

2 20 15 63

3 15 10 58

10 53 38 22 85 70 19 101 101 85

5

6

7 38 23 7 70 55 29 86 86 79 79 70

8 33 18

9 28 13 60

045 070 090 110 135 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 25 20

2 20 15 63

3 15 10 58

10 53 38 22 85 70 19 101 101 85

5

6

7 38 23 7 70 55 29 86 86 79 79 70

8 33 18

9 28 13 60

Capacity Capacity Capacity Capacity

68 53 37 17 100 85 59 116 116 109 109 100

32 12 95 80 29 111 111 95

27 7 90 75 106 106 99 99 90

33 17 80 65 39 96 96 89 89 80

28 12 75 60 91 91 75

65 50 81 81 65

19 76 76 69 69 60

71 71 55

Capacity Capacity Capacity Capacity

68 53 37 100 85 59 116 116 109 109 100

32 95 80 29 111 111 95

27 90 75 106 106 99 99 90

33 17 80 65 39 96 96 89 89 80

28 12 75 60 91 91 75

65 50 81 81 65

19 76 76 69 69 60

71 71 55

Table 5B.

507276-05CPage 20 of 57 mrcool.com

Page 22

Maximum Allowable Exhaust Vent Lengths with Furnace Installed in a Closet or Basement Using Ventilated Attic or Crawl

Space for Intake Air in Feet

Number

of 90°

Elbows

Used

10 21 6 50 50 28 68 67

Number

of 90°

Elbows

Used

10 21 6 50 50 28 68 67

045 070 090 110 135 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 25 20

2 20 15 61

3 15 10 56 19 85 85 63 28 103 102 83 83 79

10 51 36 80 80 58 23 98 97 78 78

5 31 9 85 75 53 18 93 92 73 73 69

6

7 36 21 65 65 8 83 82 63 63 59

8 31 16 60 60 38 3 78 77 58 58

9 26 11 55 55 33 73 72 53 53

045 070 090 110 135 045 070 090 110 135 045 070 090 110 135 045 070 090 110 135

1 25 20

2 20 15 61

3 15 10 56 19 85 85 63 28 103 102 83 83 79

10 51 36 80 80 58 23 98 97 78 78

5 31 9 85 85 53 18 93 92 73 73 69

6

7 36 21 65 65 8 83 82 63 63 59

8 31 16 60 60 38 3 78 77 58 58

9 26 11 55 55 33 73 72 53 53

Capacity Capacity Capacity Capacity

66 51 29 9 95 95 73 38 113 112 93 93 89

90 90 68 33 108 107 88 88

26 70 70 13 88 87 68 68

Capacity Capacity Capacity Capacity

66 51 29 95 95 73 38 113 112 93 93 89

90 90 68 33 108 107 88 88

26 70 70 13 88 87 68 68

Table 5C.

507276-05C Page 21 of 57mrcool.com

Page 23

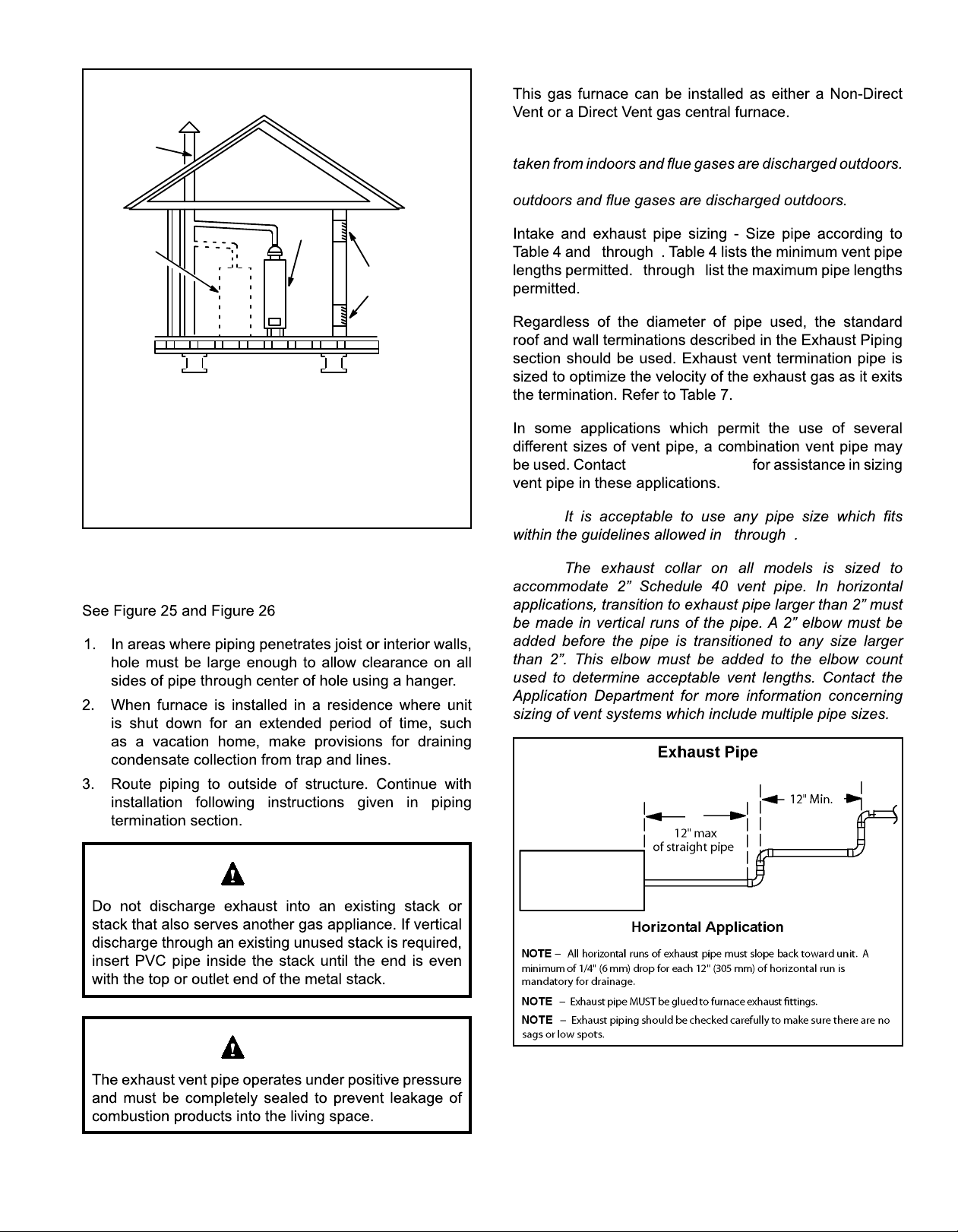

Figure 25.

Figure 26.

507276-05CPage 22 of 57 mrcool.com

Page 24

Intake Piping

Figure 27.

Figure 28.

507276-05C Page 23 of 57mrcool.com

Page 25

Figure 29.

CAUTION

Figure 30.

Ventilation Louvers

Roof Terminated

Exhaust Pipe

*Intake Debris

Screen

(Provided)

Furnace

Inlet Air

(Minimum 12 in.

(305mm) above

Attic Floor)

* See Maximum Vent Lengths table

NOTE:

Figure 31.

(Inlet Air from Ventilated Attic and Outlet Air to

Outside)

507276-05Cmrcool.com

Page 26

Roof Terminated

Exhaust Pipe

Ventilation

Louvers

(Crawl Space)

Furnace

NOTE:

Inlet Air

Minimum

12 in. (305mm)

above Crawl

Space Floor

NOTE:

Coupling or

3 in. to 2 in.

Transition

(Field Provided)

*Intake Debris Screen Provided

* See Maximum Vent Lengths table

NOTE:

Figure 32.

(Inlet Air from Ventilated Crawl Space and Outlet Air

to Outside)

General Guidelines for Vent Terminations

IMPORTANT

IMPORTANT

For Canadian Installations Only:

507276-05C Page 25 of 57mrcool.com

Page 27

Maximum Allowable Exhaust Vent Pipe Length (in ft.) without Insulation in Unconditioned Space For Winter Design

Winter Design Temperatures

1

2

1

ºF (ºC)

Vent Pipe

Diameter

Unit Input Size

045 070 090 110 135

PVC

2

PP PVC2PP PVC2PP PVC2PP PVC2PP

18 16 31 28 50 30 30

13 56

9 9 18 18 35 35 52 52

9 8 18 16 32 29 30 30

5 13

8 8 19 19 26 26 30 30

5 3 12 10 22 19 30 27

7 15 22

10 10 16 16 18 18

Conditioned

Space

Table 6.

Conditioned

Space

Pipe Insulation

Unconditioned

Space

Exhaust

Pipe

Intake

Pipe

Figure 33. Insulating Exhaust Pipe in an Unconditioned Space

507276-05CPage 26 of 57 mrcool.com

Page 28

VENT TERMINATION CLEARANCES

FOR NON-DIRECT VENT INSTALLATIONS IN THE US AND CANADA

INSIDE CORNER

DETAIL

G

D

A

E

B

L

C

Fixed

F

Closed

Operable

B

Operable

B

B

VENT TERMINAL

AIR SUPPLY INLET

US Installations

A =

Clearance above grade, veranda,

porch, deck or balcony

B =

Clearance to window or

door that may be opened

C =

Clearance to permanently

closed window

Vertical clearance to ventilated soffit

D =

located above the termin

al within a

12 inches (305mm) or 12 in. (305mm)

above average snow accumulation.

4 feet (1.2 m) below or to side of opening;

1 foot (30cm) above opening

* 12”

* Equal to or greater than soffit depth.

horizontal distance of 2 feet (610 mm)

from the center line of the terminal

E =

F =

G =

Clearance to unventilated soffit

Clearance to outside corner

Clearance to inside corner

H =

tended above meter / regulator assembly

I =

Clearance to service regulator

vent outlet

J =

Clearance to non-mechanical air

* Equal to or greater than soffit depth.

* No minimum

3 feet (.9m) within a height 15 feet (4.5m)

*

above the meter / regulator assembly

* 3 feet (.9m)

4 feet (1.2 m) below or to side of opening;

1 foot (30 cm) above opening

pliance

K =

ply inlet

L =

Clearance above paved sidewalk or

paved driveway located on public property

M =

Clearance under veranda, porch, deck or balcony

1

In accordance with the current ANSI Z223.1/NFPA 54 Natural Fuel Gas Code

2

In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

† A vent shall not terminate directly above a sidewalk or paved driveway that is

located between two single family dwellings and serves both dwellings.

‡ Permitted only if veranda, porch, deck or balcony is fully open

on a minimum of two sides beneath the floor. HVAC Distributing recommends

avoiding this location if possible.

3 feet (.9m) above if within 10 feet

(3m) horizontally

7 feet (2.1m)†

*12 inches (305mm)‡

H

B

Fixed

Closed

A

J

I

M

AREA WHERE TERMINAL

IS NOT PERMITTED

1

Canadian Installations

2

12 inches (305mm) or 12 in. (305mm)

above average snow accumulation.

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

* 12”

* Equal to or greater than soffit depth.

* Equal to or greater than soffit depth.

to outside corner * No minimum to outside corner

**

3 feet (.9m) within a height 15 feet (4.5m)

above the meter / regulator assembly

3 feet (.9m)

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

6 feet (1.8m)

7 feet (2.1m)†

12 inches (305mm)‡

*For clearances not specified in ANSI Z223.1/NFPA 54 or CSA

B149.1, clearance will be in accordance with local installation

codes and the requirements of the

lation instructions.”

K

Figure 34.

507276-05C Page 27 of 57mrcool.com

Page 29

VENT TERMINATION CLEARANCES

FOR DIRECT VENT INSTALLATIONS IN THE USA AND CANADA

INSIDE CORNER

DETAIL

G

D

A

E

B

L

C

Fixed

F

Closed

Operable

B

Operable

B

A

B

VENT TERMINAL

AIR SUPPLY INLET

US Installations

A =

B =

Clearance above grade, veranda,

porch, deck or balcony

Clearance to window or

door that may be opened

12 inches (305mm) or 12 in. (305mm)

above average snow accumulation.

6 inches (152mm) for appliances <10,000

Btuh (3kw), 9 inches (228mm) for ap-

pliances > 10,000 Btuh (3kw) and <50,000

Btuh (15kw), 12 inches (305mm) for ap-

pliances > 50,000 Btuh (15kw)

C =

D =

Clearance to permanently

closed window

Vertical clearance to ventilated soffit

located abo

ve the terminal within a

horizontal distance of 2 feet (610mm)

* 12”

* Equal to or greater than soffit depth * Equal to or greater than soffit dept

from the center line of the terminal

E =

F =

G =

H =

Clearance to unventilated soffit

Clearance to outside corner

Clearance to inside corner

Clearance to each side of center line ex-

tended above meter / regulator assembly

I =

Clearance to service regulator

vent outlet

J =

Clearance to non-mechanical air

supply inlet to building or the com-

bustion air inlet to any other ap-

pliance

* Equal to or greater than soffit depth * Equal to or greater than soffit depth

* No minimum to outside corner

*

3 feet (.9m) within a height 15 feet (4.5m)

above the meter / regulator assembly

*

3 feet (.9m)

6 inches (152mm) for appliances <10,000

Btuh (3kw), 9 inches (228mm) for ap-

pliances > 10,000 Btuh (3kw) and <50,000

Btuh (15kw), 12 inches (305mm) for ap-

pliances > 50,000 Btuh (15kw)

K =

Clearance to mechanical air sup-

ply inlet

L =

Clearance above paved sidewalk or

paved driveway located on public property

M =

Clearance under veranda, porch, deck or balcony

1

In accordance with the current ANSI Z223.1/NFPA 54 Natural Fuel Gas Code

2

In accordance with the current CSA B149.1, Natural Gas and Propane Installation Code

† A vent shall not terminate directly above a sidewalk or paved driveway that is located

between two single family dwellings and serves both dwellings.

‡ Permitted only if veranda, porch, deck or balcony is fully open on a minimum of

two sides beneath the floor. HVAC Distributing recommends avoiding this location

if possible.

3 feet (.9m) above if within 10 feet

(3m) horizontally

* 7 feet (2.1m)

*12 inches (305mm)‡

H

Fixed

Closed

J

B

I

M

K

AREA WHERE TERMINAL

IS NOT PERMITTED

1

Canadian Installations

2

12 inches (305mm) or 12 in. (305mm)

above average snow accumulation.

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 inches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

* 12”

h

* No minimum to outside corner

*

3 feet (.9m) within a height 15 feet (4.5m)

above the meter / regulator assembly

3 feet (.9m)

6 inches (152mm) for appliances <10,000

Btuh (3kw), 12 i

nches (305mm) for

appliances > 10,000 Btuh (3kw) and

<100,000 Btuh (30kw), 36 inches (.9m)

for appliances > 100,000 Btuh (30kw)

6 feet (1.8m)

7 feet (2.1m)†

12 inches (305mm)‡

*For clearances not specified in ANSI Z223.1/NFPA 54 or CSA

B149.1, clearance will be in accordance with local installation

codes and the requirements of the gas supplier and these

installation instructions.”

Figure 35. Vent Termination Clearances for Direct Installations

507276-05CPage 28 of 57 mrcool.com

Page 30

Details of Intake and Exhaust Piping

Terminations for Direct Vent Installations

NOTE: In Direct Vent installations, combustion air is taken

NOTE:

Inches (MM)

8” (203MM) MIN

12” (305MM) ABOVE

AVERAGE SNOW

ACCUMULATION

3” (76MM) OR

2” (51MM) PVC

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES

3” (76MM) MIN.

SIZE PER EXHAUST PIPE

TERMINATION SIZE

REDUCTION TABLE

UNCONDITIONED

ATTIC SPACE

1/2” (13MM) FOAM

INSULATION IN

UNCONDITIONED

SPACE

Figure 36. Direct Vent Roof Termination Kit

(15F75 or 44J41)

Capacity Exhaust Pipe Size

Termination

Pipe Size

90

110

135

Table 7. Exhaust Pipe Termination Size Reduction

NOTE:

Figure 37.

Figure 38.

507276-05C Page 29 of 57mrcool.com

Page 31

NOTE − FIELD−PROVIDED

REQUIRED TO ADAPT

LARGER VENT PIPE SIZE

* WALL

SUPPORT

C1

REDUCER MAY BE

TO TERMINATION

C1

A

E

D

B

Intake

Elbow

STRAIGHT

APPPLICATION

D

B

A

EXTENDED

APPLICATION

FIELD FABRICATED WALL TERMINATION

A− Minimum clearance

above grade or average

snow accumulation

B− Maximum horizontal

separation between

intake and exhaust

C1 -Minimum from end of

exhaust to inlet of intake

C2 -Minimum from end of

exhaust to inlet of intake

D− Maximum exhaust

pipe length

E− Maximum wall support

distance from top of each

pipe (intake/exhaust)

D

B

* Use wall support every 24” (610 mm). Use two

wall supports if extension is greater than

24” (610 mm) but less than 48” (1219 mm).

NOTE − One wall support must be within 6” (152 mm)

from top of each pipe (intake and exhaust) to prevent

movement in any direction.

C2

D

B

C2

A

E

A

2” (51mm)

Vent Pipe

12” (305 mm)

12” (305 mm)

3” (76mm)

Vent Pipe

12” (305 mm)

6” (152 mm)6” (152 mm)

8” (203 mm)8” (203 mm)

6” (152 mm)6” (152 mm)

20” (508 mm)

6” (152 mm)6” (152 mm)

ALTERNATE TERMINATIONS (TEE & FORTY−FIVE DEGREE ELBOWS ONLY)

2” (51MM)

Vent Pipe

12” (305 mm) Min. 12” (305 mm) Min.

6” (152 mm) Min.

24” (610 mm) Max.

9” (227 mm) Min.

12” (305 mm) Min.

16” (405 mm) Max.

6” (152 mm) Max.

Front View of

Intake and Exhaust

Intake

Exhaust

Intake

Elbow

B

C

A

E

B

Exhaust

D

3

D

1

12”

C

A− Clearance above

grade or average snow

accumulation

B− Horizontal

separation between

intake and exhaust

C− Minimum from

end of exhaust to

inlet of intake

D− Exhaust pipe length

E− Wall support distance

from top of each pipe

(intake/exhaust)

2

A

D

B

1

C

2

A

D

E

B

C

1

12”

2

A

1

The exhaust termination tee should be connected to the 2” or 3” PVC flue pipe as shown in the illustration.

Do not use an accelerator in applications that include an exhaust termination tee.

The accelerator is not required.

2

As required. Flue gas may be acidic and may adversely affect some building materials. If a side wall vent

termination is used and flue gases will impinge on the building materials, a corrosion-resistant shield

(24 inches square) should be used to protect the wall surface. If optional tee is used, the protective shield

is recommended. The shield should be constructed using wood, sheet metal or other suitable material.

All seams, joints, cracks, etc. in affected area, should be sealed using an appropriate sealant.

3

Exhaust pipe 45° elbow can be rotated to the side away from the combustion air inlet to direct exhaust

away from adjacent property. The exhaust must never be directed toward the combustion air inlet.

3” (76MM)

Vent Pipe

6” (152 mm) Min.

24” (610 mm) Max.

9” (227 mm) Min.

12” (305 mm) Min.

20” (508 mm) Max.

6” (152 mm) Max.

Figure 39.

507276-05CPage 30 of 57 mrcool.com

Page 32

Figure 40.

Figure 42.

Figure 43.

8” - 12”

(203MM - 305MM)

3”-8”

(76MM-203MM)

STRAIGHT-CUT OR

ANGLE-CUT IN DIRECTION

OF ROOF SLOPE

Figure 41.

507276-05C Page 31 of 57mrcool.com

Minimum 12” (305MM)

above chimney top

plate or average snow

accumulation

INTAKE PIPE

INSULATION (optional)

SHEET

METAL TOP

PLATE

INSULATE

TO FORM

SEAL

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

3” - 8”

(76MM-

203MM)

ALTERNATE

INTAKE PIPE

EXTERIOR

PORTION OF

CHIMNEY

* SIZE TERMINATION PIPE

PER EXHAUST PIPE TERMINATION

SIZE REDUCTION TABLE

Figure 44. Direct Vent Application Using Existing

Chimney

Page 33

Direct Vent Applications

12” (305MM)

ABOVE AVE.

SNOW

ACCUMULATION

3” (76MM) OR

2” (51MM) PVC

PROVIDE SUPPORT

FOR EXHAUST LINES

SIZE PER EXHAUST PIPE

TERMINATION SIZE

REDUCTION TABLE

UNCONDITIONED

ATTIC SPACE

SIZE TERMINATION

PER EXHAUST PIPE

TERMINATION SIZE

REDUCTION TABLE

* Use wall support every 24” (610 mm). Use two supports of extension is greater than 24”

(610 mm) but less than 48” (1219 mm).

Figure 47.

Termination Extended

STRAIGHT-CUT OR

ANGLE-CUT IN DIRECTION

OF ROOF SLOPE

Figure 45.

SIZE TERMINATION

PER EXHAUST PIPE

TERMINATION SIZE

REDUCTION TABLE

Figure 46.

15F75 or 44J41)

Termination

Minimum 12” (305MM)

above chimney top

plate or average snow

Figure 48.

accumulation

SHEET

METAL TOP

PLATE

INSULATE

TO FORM

SEAL

* SIZE TERMINATION PIPE

PER EXHAUST PIPE TERMINATION

SIZE REDUCTION TABLE

Chimney

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

EXTERIOR

PORTION OF

CHIMNEY

507276-05CPage 32 of 57 mrcool.com

Page 34

Exhaust through Crawl Space Vent Option

Exhaust from

Furnace

To Termination

Figure 49.

2” or 3”

Sanitary Tee

1/2” PVC

Drain Stub

Drain Trap

Assembly

Rubber Boot (51W18)

Drain Plug (15Z70)

Clamp

(51W18 Only)

From

Furnace

Downflow Furnace

Exhaust

To Vent

Termination

Drain Trap

(assembled)

Exhaust from

Furnace

To Termination

* Kit 51W18 is shown.

Figure 50. Crawl Space Vent Pipe Drain Trap

Assembled Incorrectly

24” max.

KIT 51W18 (USA)

KIT 15Z70 (Canada)

NOTE:

NOTE:

Figure 51.

507276-05C Page 33 of 57mrcool.com

* Kit 51W18 is shown.

Basement Floor

To Termination

1/2” PVC to

Code-Approved

Drain

Page 35

Condensate Piping

NOTE:

NOTE:

NOTE:

CAUTION

Figure 52.

CAUTION

507276-05Cmrcool.com

Page 36

Figure 53. Condensate Trap Locations

Figure 54.

Switch

WARNING

507276-05C Page 35 of 57mrcool.com

Page 37

Figure 55. Condensate Trap Locations

Figure 56. Unit with Cooling Coil Using Separate

Drain

Figure 58. Evaporator Coil Using a Common Drain

Figure 57. Evaporator Coil Using a Common Drain

507276-05CPage 36 of 57 mrcool.com

Page 38

Figure 59.

507276-05C Page 37 of 57mrcool.com

Page 39

Gas Piping

IMPORTANT

CAUTION

Leak Check

WARNING

NOTE:

IMPORTANT

Figure 60.

IMPORTANT

WARNING

FIRE OR EXPLOSION HAZARD

507276-05CPage 38 of 57 mrcool.com

Page 40

Figure 61. Gas Piping

Figure 62. Gas Piping

Horizontal Applications

507276-05C Page 39 of 57mrcool.com

Page 41

Nominal

Iron Pipe

inches

(mm)

1 680 375 320 285 260 220 205 195

2 3950 2750 2200 1900 1680 1520 1300 1220 1150

3 11000 7700 6250 5300 3900 3700 3250

Internal

Diameter

(mm)

10

(3.048)20(6.096)30(9.144)40(12.192)50(15.240)60(18.288)70(21.336)80(24.384)90(27.432)

175 120 97 82 73 66 61 57 53 50

360 250 200 170 151 138 125 118 110 103

950 770 660 580 530

2100 1180 990 900 810 750 690 650 620

6300 3520 3000 2650 2250 2050 1950 1850

100

(30.480)

NOTE

23000 15800 12800 10900 9700 9700 8100 7500 7200 6700

Table 8.

507276-05Cmrcool.com

Page 42

Electrical

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

NOTE:

Figure 63.

Figure 64.

507276-05C mrcool.com

NOTE:

Accessory Terminals

Page 43

Indoor Blower Speeds

Figure 65.

•

•

•

•

Figure 66. Typical Field Wiring Diagram

507276-05Cmrcool.com

Page 44

E045B3

E070B3

E090C4

E110C5

E135D5

Figure 67. Typical Wiring Diagram

507276-05C mrcool.com

Page 45

LINE

CIRC

EAC

COOL

FAN

NEUTRALS

FS

Figure 68. Integrated Control

(Automatic Hot Surface Ignition System)

Terminal Designations

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING

WARNING

CAUTION

BEFORE LIGHTING

Placing the Furnace into Operation

507276-05Cmrcool.com

Page 46

Priming Condensate Trap

WARNING

Figure 69.

NOTE:

Gas Valve Operation

See Figure 69

STOP!

STOP!

Turning Off Gas to Unit

Failure To Operate

507276-05C mrcool.com

Heating Sequence Of Operation

Page 47

Gas Pressure Adjustment

Gas Flow (Approximate)

Gas Meter Clocking Chart

Seconds for One Revolution

Capacity

-70 55 110 136 272

-90

-110 33 66 82

-135 27 68 136

Natural LP

1 cu ft

Dial

80 160 200

2 cu ft

Dial

82 102

1 cu ft

Dial

Supply Pressure Measurement

Manifold Pressure Measurement

2 cu ft

Dial

NOTE:

Table 9. Gas Meter Clocking Chart

NOTE:

Capacity Gas

Propane

NOTE

Proper Combustion

Capacity CO2% for Nat CO2% for L.P.

Manifold Pressure in. w.g.

Table 10.

Supply Line Pressure

in. w.g.

Table 11.

507276-05Cmrcool.com

Page 48

High Altitude Information

NOTE:

Capacity

070

090

110

135

Capacity

High Altitude

Propane Natural

73W80* 51W01

Pressure Switch Requirements at Varying Altitudes

070 10U93

Natural Burner

Propane Burner

090 11U70 10U93

110 10U93

135 11U70 10U93

Table 12.

507276-05C mrcool.com

Page 49

WARNING

CARBON MONOXIDE POISONING HAZARD

Do not operate

a summer exhaust fan

507276-05Cmrcool.com

Page 50

Other Unit Adjustments

Primary Limit

Flame Rollout Switches (Two)

Pressure Switch

Temperature Rise

Fan Control

Figure 70.

Electrical

Blower Speeds

NOTE:

Constant Torque Motor

Thermostat Heat Anticipation

507276-05C mrcool.com

Electronic Ignition

Page 51

Blower Performance

MGM95SE045B3XA Performance (Less Filter)

External

Static

Pressure

in. w.c.

MGM95SE070B3XA Performance (Less Filter)

External

Static

Pressure

in. w.c.

High Medium Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

1255 1150 185 895 105 95

1305 1225 250 1105 200 855 110 810 95

1290 360 1190 260 1080 205 825 120 780 105

1275 370 1150 270 215 785 125 720 110

1220 385 1120 280 1015 220 735 135 690 120

1215 390 1090 290 980 230 705 635 125

1190 395 1060 300 950 650 150 600 135

1015 300 900 250 620 155 555

1000 310 870 260 580 160 520

High Medium Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

1380 315 1305 250 1190 200 965 105 920 100

1360 325 1270 255 1180 205 915 115 865 100

1310 335 1250 265 1130 215 880 120 815 110

1275 1205 275 1100 225 835 125 775 115

1250 355 1175 280 1065 230 795 135 730 125

1215 370 295 670 130

1200 380 1100 310 995 705 150

380 1070 310 960 255 670 160 585

1035 320 925 265 610 165 550 155

MGM95SE090C4XA Performance (Less Filter)

External

Static

Pressure

in. w.c.

High Medium Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

370 1505 250 1370 195 1285 160 1135 125

1695 390 265 1325 205 170 1090 135

1660 280 1290 220 1195 185

1615 1390 295 235 200 995 160

1590 1350 305 1200 1110 210 165

1560 1310 320 1155 260 1055 225 895 175

1525 1255 335 1105 270 1005 230 855 190

1220 1065 285 960 805 200

1170 355 1010 295 920 255 760 210

NOTE

507276-05CPage 50 of 57 mrcool.com

Page 52

MGM95SE110C5XA Performance (Less Filter)

External

Static

Pressure

in. w.c.

Bottom Return Air, Side Return Air with Optional Return Air Base, Return Air from

Both Sides or Return Air from Bottom and One Side.

High Medium Low High Medium Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

2220 1765 335 1635 280 200 2185 655 1915 1620 275 195

2170 660 1920 1715 350 1595 290 1380 205 2160 660 1880 1705 1570 285 1380 205

2130 680 1865 1670 370 1560 305 220 2115 680 1835 1670 365 1535 305 1325 220

2095 700 1835 390 1525 325 1285 230 2060 705 1795 1630 380 1505 320 1285 230

2065 720 1785 510 1600 335 1250 2050 720 1760 510 1570 330 1235

2030 1755 525 1560 355 1215 260 2000 1720 530 1535 1195 260

1995 760 1705 550 1525 1380 370 1150 270 1950 760 1685 550 1505 1380 365 275

1955 770 1660 560 1350 375 1100 290 1935 775 1650 555 1325 375 1100 285

1930 790 1635 575 1300 395 1050 305 1890 790 1610 575 1285 390 1050 295

MGM95SE135D5XA Performance (Less Filter)

External

Static

Pressure

in. w.c.

Bottom Return Air, Side Return Air with Optional Return Air Base, Return Air from

Both Sides or Return Air from Bottom and One Side.

High Medium Low High Medium Low

cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts cfm Watts

2235 735 2070 1830 390 1620 280 2395 925 2235 710 2020 550 1800 380 1610 275

2365 960 2210 2020 565 1770 1585 295 2360 935 2175 735 2005 555 1760 395 1550 295

2330 975 2180 770 1950 580 1535 315 2350 955 2160 760 1955 565 1725 1510 300

2295 1000 2120 785 1925 595 1690 325 2290 990 2195 775 1890 590 1700 325

2275 1015 2075 805 1885 615 2255 995 2060 795 1850 615 1635 1390

2225 1025 2035 815 630 1605 1395 360 2230 1010 815 625 1590 1375 360

2185 1010 2020 835 1815 1565 1330 365 2170 1025 2000 820 1795 1580 1335 370

850 1736 665 1520 500 1310 385 1935 1725 660 1520 500 1295 385

1890 860 1715 680 510 1285 1880 855 1705 680 510 1260

NOTE

507276-05C Page 51 of 57mrcool.com

Page 53

Allowable Heating Speeds

Model Red Yellow Blue Brown Black

070

090

110

135

Table 13.

Allowable Circulation Speeds

Model Red Yellow Blue Brown Black

Table 14.

Service

Exhaust and Air Intake Pipes

WARNING

ELECTRICAL SHOCK, FIRE, OR EXPLOSION

HAZARD.

Blower

WARNING

NOTE:

Electrical

Winterizing and Condensate Trap Care

Cleaning Heat Exchanger

Filters

507276-05CPage 52 of 57 mrcool.com

Page 54

507276-05C Page 53 of 57mrcool.com

Page 55

Cleaning the Burner Assembly

507276-05Cmrcool.com

Page 56

Planned Service

Fresh air grilles and louvers

Burners

Vent pipe

Unit appearance

Blower access door

Return air duct

Operating performance

Combustion gases

Instruct the homeowners to pay attention to their

furnace.

Red LED Flash Code

1

1

NOTE

Table 15.

507276-05C Page 55 of 57mrcool.com

Page 57

Red LED Flash Code

1

1

2

NOTE

2

Repair Parts List

Cabinet Parts

•

•

• Top Cap

Control Panel Parts

• Transformer

•

•

Blower Parts

•

•

•

•

•

Table 16.

Heating Parts

•

•

•

•

•

•

•

•

•

•

•

507276-05CPage 56 of 57 mrcool.com

Page 58

Requirements for Commonwealth of Massachusetts

requirements:

INSTALLATION OF CARBON MONOXIDE

DETECTORS

INSPECTION

EXEMPTIONS: The following equipment is exempt

from 24 CMR 5.08(2)(a) 1 through 4:

VENTING SYSTEM PROVIDED.

APPROVED CARBON MONOXIDE DETECTORS.

SIGNAGE

GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.

VENTING SYSTEM NOT PROVIDED.

A copy of all installation instructions for all Product

equipment, all venting instructions, all parts lists

instructions shall remain with the appliance or

equipment at the completion of the installation.

507276-05C Page 57 of 57mrcool.com

Page 59

Signature Series

MGM*95SE*XA Gas Furnace

ELECTRICIAN and /or HVAC TECHNICIAN:

LICENSE #:

INSTAL LATI ON DAT E:

INSTALLATION LOCATION:

SERIAL NUMBER:

The design and specifications of this product and/or manual are subject to change without prior notice.

Consult with the sales agency or manufacturer for details.

Loading...

Loading...