Page 1

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Owner & Installation

Manual

Signature Series

MPC*1M414A & MPH*1M414A

Residential Packaged Units

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Page 2

THIS MANUAL MUST BE LEFT WITH THE

HOMEOWNER FOR FUTURE REFERENCE

WARNING

Installation and servicing of air conditioning equipment

can be hazardous due to internal refrigerant pressure

and live electrical components. Only trained and

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

MPC*1M414A

& MPH*1M414A

Air Conditioners and Heat Pumps

C

Table of Contents

Installation ...................................................................2

Electrical Wiring...........................................................3

Duct System ................................................................4

Filters...........................................................................5

Condensate Drain........................................................5

Sequence of Operation................................................

Maintenance................................................................

Wiring Diagrams........................................................11

this equipment. Installation and service performed by

WARNING

other appliance. Such actions could result in property

WARNING

If this unit is to be installed in a mobile or manufactured

guidelines. All other installation guidelines must also

the unit.

Manufactured By

MRCOOL LLC

*F507296-C*

C

CAUTION

The installation of this appliance must conform to the requirements of the National Fire Protection Association; the

jurisdiction should be consulted before installation is made. Such applicable regulations or requirements take precedence

over the general instructions in this manual.

Save these instructions for future reference

507296-02C Page 1 of 12mrcool.com

Page 3

Location

WARNING

or maintenance can cause injury or property damage.

Refer to this manual. For assistance or additional

agency.

Installation

These instructions explain the recommended method of

installation of the packaged heat pump and air conditioner

system.

clearance for free entrance to the air inlet and discharge

service access.

not settle or shift. Adequate structural support must be

provided. Install the unit in level position. Isolate the base

from the building structure to avoid possible transmission

of sound or vibration into the conditioned space.

The heat pump unit foundation should be raised to a

In areas that have

prevent ice accumulation. The unit should not be located

defrost condensate.

Avoid placing the unit near quiet areas, such as

sleeping quarters or study rooms. Normal operating

sound levels may be objectionable if the unit is placed near

certain rooms.

read prior to beginning installation. Note particularly any

CAUTIONS or WARNINGS in these instructions and all

labels on the units.

equipment should be determined prior to installation.

Inspection of Shipment

the unit inside the carton if the carton is damaged. File a

as claim may be denied.

are as ordered.

Limitations

For improved start-up performance, the indoor coil

should be washed with suitable detergent to remove

any residue from manufacturing processes.

Roof Curb Installation

Instructions and be sure that all required clearances are

observed.

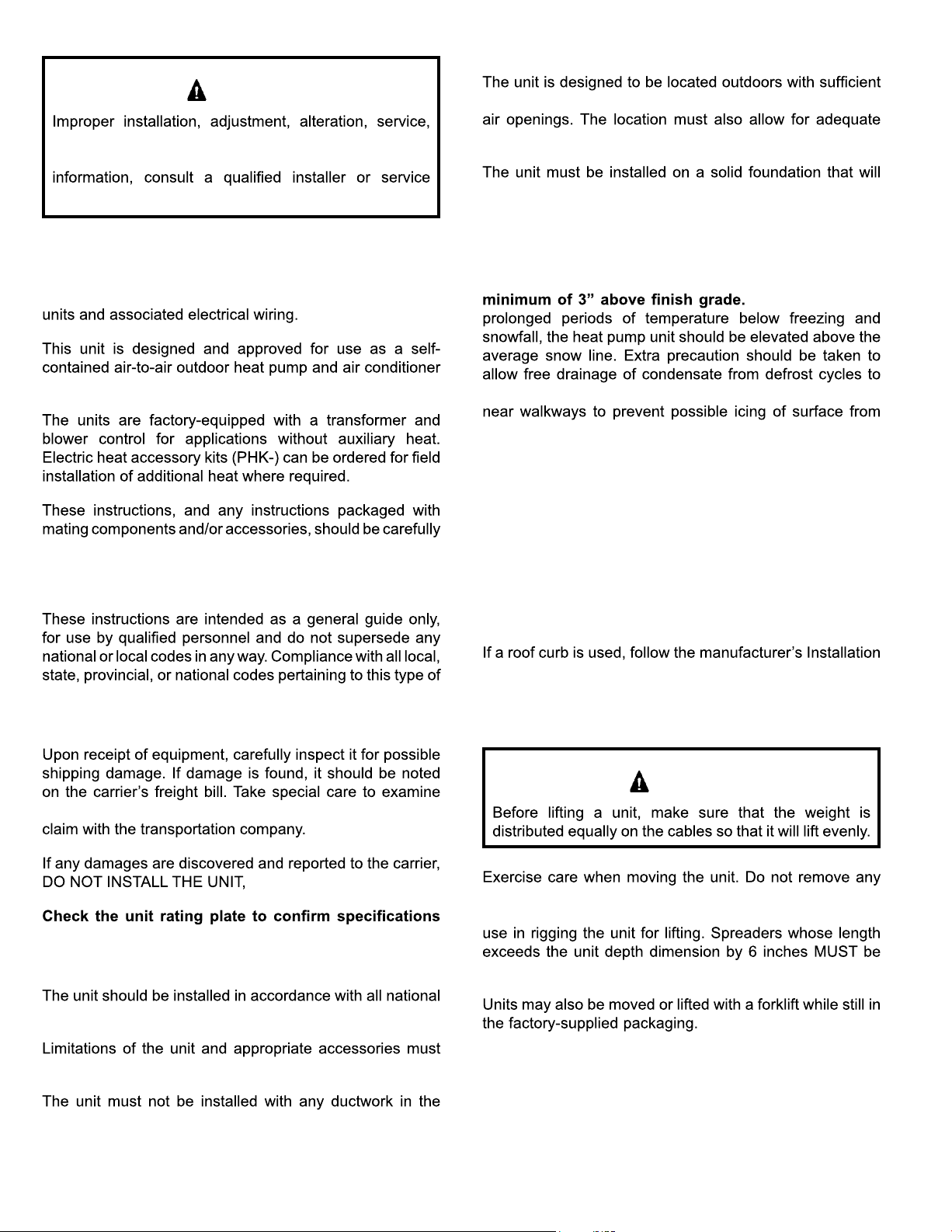

Rigging and Handling

CAUTION

packaging until the unit is near the place of installation.

An optional lifting lug kit may be purchased separately for

used across the top of the unit.

and local safety codes.

of the forklift must be a minimum of 42”.

also be observed.

outdoor air stream. The outdoor fan is not designed to

operate against any additional static pressure.

Page 2 of 12 507296-02Cmrcool.com

The lengths of the forks

Page 4

REDUCE

TO

6.00

REDUCE

TO

W1

C

L

R

O

Y1

FAN

O-OUT

LO-PS

DF

HI-PS

COMMON

Y1 OUT

2

2

24 V

Y

W2

RED

YEL

BLU

WHT

GRN

ORN

W1 & W2 CAN BE USED TO STAGE

ELECTRIC HEAT ACCESSORY ON

15 & 20KW MODELS

5, 7.5 & 10KW HEATER ACCESSORIES

FUNCTION OFF W1 ONLY.

WHT

DEFROST

CONTROL

P-6

P-5

G

W1

C R O

THERMOSTAT

537663-01

NOTE:

IF ANY OF THE ORIGINAL

WIRE IS REPLACED THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

USE COPPER CONDUCTOR

ONLY, MIN 75 C WIRE

CONNECTION MUST BE JUMPERED

WHEN PRESSURE SWITCH IS NOT USED.

LINE VOLTAGE FIELD INSTALLED

WARNING-

ELECTRIC SHOCK HAZARD. UNIT

MUST BE GROUNDED IN ACCORDANCE

WITH NATIONAL AND LOCAL CODES.

REV. VALVE

Service Access

Access to all serviceable components is provided by four

WARNING

Figure 1. Rigging Unit

Figure 2. Typical Field Wiring

Clearances

All units require certain clearances for proper operation

and service. Refer to Table 1 for the minimum clearances

proper unit operation.

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet.

Clearance to

Combustibles

Front of unit

Back of unit

Right side

Base of unit

Top of unit 48 in.

Clearance for

Service Access

24 in.

24 in.

24 in.

CAUTION

Compressor

adjusted and ready for operation. Do not loosen

compressor mounting bolts.

Unpacking

Carefully remove outer packaging material and discard.

corner and seal the shipping openings in the base from

prevent air leakage during unit operation.

the installer. Refer to the unit rating plate for maximum

507296-02C Page 3 of 12mrcool.com

Table 1. Minimum Clearances

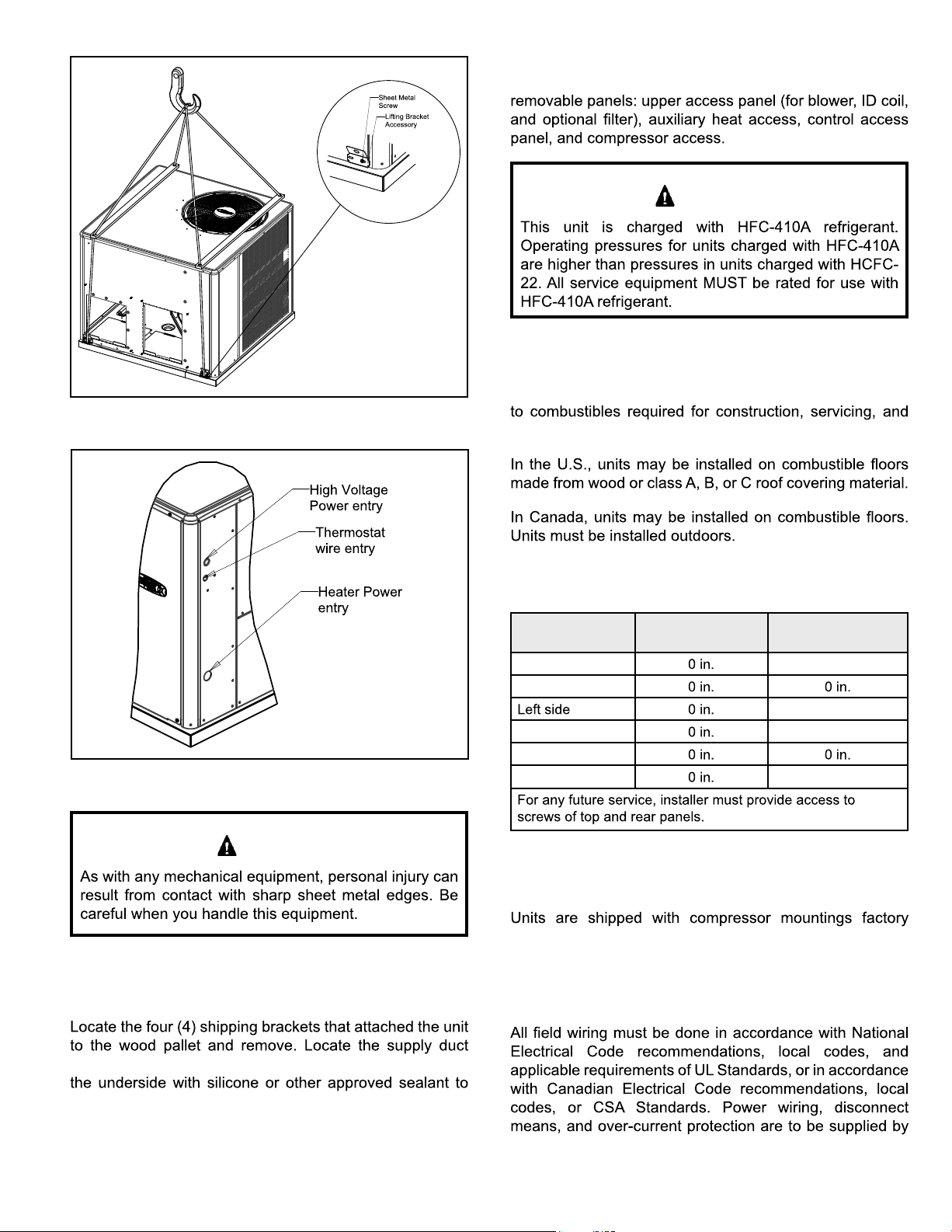

Electrical Wiring

Page 5

or pigtail leads located on the main control box and are

CAUTION

during normal operation.

Units are factory wired for a 230-volt power supply.

If power supply is 208 volts, it will be necessary to

change a wire connection on the unit transformer from

240V terminal to 208V terminal as shown on the wiring

diagram.

Use only copper conductors.

*

“O” connection used only on heat pump models

*

Thermostat

The room thermostat should be located on an inside

installation.

Contactor

changed

Figure 3. 208/230 Line Voltage Wiring

or Circuit Breaker

Disconnect

Single Phase

off W1 only.

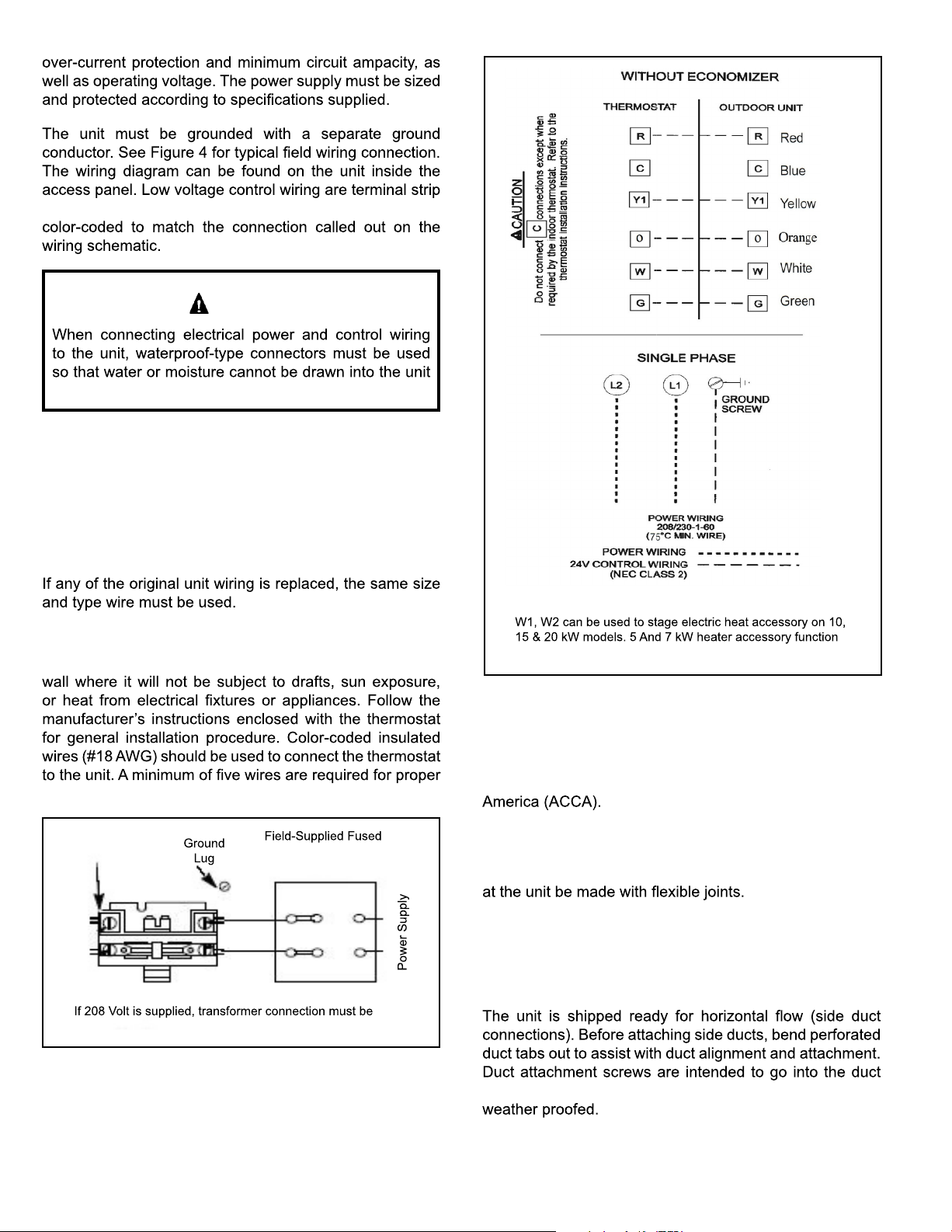

Figure 4. Typical Wiring Connections

Duct System

Duct system should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors of

A closed return duct system shall be used. This shall not

preclude use of economizers or outdoor fresh air intake. It

is recommended that supply and return duct connections

The supply and return air duct systems should be designed

for the CFM and static requirements of the job. They

should not be sized to match the dimensions of the

duct connections on the unit.

panel. Duct to unit connections must be sealed and

Page 4 of 12 507296-02Cmrcool.com

Page 6

1.

the unit base insulation to access bottom metal covers

underneath the insulation.

2.

3.

bottom duct connections or roof curb seals.

4.

5.

NOTE: Install drain lines and trap so they do not block

service access to the unit.

See Figure 5 for proper drain arrangement. The drain line

must pitch to an open drain or pump to prevent clogging

material to prevent air leakage into the return air system.

CAUTION

Filters

NOTE:

is limited.

Unit Model Filter 1 Filter 2

Table 2. Unit Air Filter Sizes - inches

Minimum Pitch:

Open

Mounting

Frame

Trap must be deep enough to offset maximum static difference

Figure 5. Typical Condensate Drain Connection

Condensate Drain

Crankcase Heater (if used)

to prevent excessive migration of liquid refrigerant into the

for condensate line connection. Plumbing must conform

to the unit to keep this feature active.

threads.

Do not

the system disconnect switch.

Heater Kit Accessory (if used)

The condensate drain line must be properly trapped,

routed to a suitable drain and primed prior to unit

commissioning.

507296-02C Page 5 of 12mrcool.com

auxiliary heat. A heater kit accessory may also be used. To

1.

do not open

access.

Page 7

2.

and discard.

3. Remove the heater blockoff by removing the four

4. Insert the heater into the control panel and fasten in

the same mounting holes.

5.

connections on the heater kit.

Sequence of Operation

Cooling

Heating - Heat Pump Stage

and outdoor fan. The reversing valve is not energized in

the heating mode. The thermostat again automatically

stops unit operation.

Heating - Auxiliary Electric Heat

continues to operate until all heating elements have turned

off.

Defrost System

compressor and outdoor fan. The thermostat automatically

thermostat and the defrost control.

Defrost Thermostat

The defrost thermostat is located on the outdoor coil.

thermostat contacts close and send a signal to the defrost

control board to start the defrost timing. It also terminates

Figure 6. Heater Kit Accessory Installation

507296-02Cmrcool.com

Page 8

Defrost Control

The defrost control board includes the combined functions

heating operation to defrost mode and back. During the

relay is energized and the defrost begins.

1.

°F in heating

NOTE: 15°F is an approximate temperature,

depending upon model and installation location.

2.

The maximum defrost period is 14 minutes and cannot be

adjusted.

NOTE:

A test option is provided for troubleshooting. The test mode

may be started any time the unit is in the heating mode and

the defrost thermostat is closed or jumpered. If the jumper

the test pins. When the jumper is placed across the TEST

in defrost mode until the defrost thermostat opens or 14

minutes have passed. If the jumper is not removed until

and the defrost time interval must not have expired.

3.

conditions.

DEFROST TIMING

PINS (P1)

TEST

PINS

DIAGNOSTIC

COMPRESSOR

DELAY PINS

REVERSING

VALVE

S87

LOW PRESSURE

SWITCH

DEFROST

THERMOSTAT (S6)

S4

HIGH PRESSURE

SWITCH

LEDS

24V TERMINAL

STRIP

CONNECTIONS

SERVICE LIGHT

CONNECTIONS

Figure 7. Defrost Control Board

Defrost Control Timing Pins

Each timing pin selection provides a different accumulated

compressor run time period during one thermostat run

cycle. This time period must occur before a defrost cycle

again until the jumper is removed and reapplied.

Compressor Delay (Quiet Shift)

NOTE: The 30-second “off” cycle is not functional when

jumpering the TEST pins.

Time Delay

ensures the compressor is off for a minimum amount of

to protect the compressor from short cycling in case the

The delay is bypassed by placing the timer select jumper

Pressure Switch Circuit

defrost control board on heat pump models. Air conditioning

During a single demand cycle, the defrost control will

It is intended that this

product should be set at the 60-minute time interval at

initial installation. If the timing selector jumper is not in

507296-02C mrcool.com

interrupted by any pressure switch wired to the control

board. In addition, the diagnostic LEDs will indicate a

of an open pressure switch (see Table 3).

Page 9

The unit will remain locked out until power to the board

is interrupted, then re-established, or until the jumper

is applied to the TEST pins for 0.5 seconds.

NOTE: The defrost control board ignores input from the

low pressure switch terminals as follows:

If the measured performance value varies from table value

refrigerant to nameplate charge. It is critical that the exact

• During the TEST mode

• During the defrost cycle

•

•

If the TEST pins are jumpered and the 5-minute delay

is being bypassed, the LO PS terminal signal is not

ignored during the 90-second start-up period.

Diagnostic LEDs

Defrost Board Diagnostic LEDs

Green LED

(DS2)

OFF OFF

Red LED

(DS1)

Condition

system performance.

components.

Model

2 Ton 13

2.5 Ton

3 Ton 14

3.5 Ton 14

4 Ton

5 Ton

Suction

Superheat +/- 3°

Subcooling +/- 2°

Table 4. Air Conditioner Unit Cooling System

Performance Values

Model

Suction

Superheat +/- 3°

Liquid Subcooling

Liquid

+/- 2°

ON

Fault & Lockout Codes

OFF

OFF ON

OFF

ON OFF

Table 3. Defrost Control (CMC1) Diagnostic LEDs

System Performance

the suction superheat value to judge performance. When

checking performance of a unit that uses an expansion

system performance.

2 Ton 18

2.5 Ton

3 Ton

3.5 Ton 22

4 Ton 22

5 Ton 5

Table 5. Heat Pump Cooling System Performance

Values

Model Liquid Subcooling +/- 2°

2 Ton

2.5 Ton

3 Ton

3.5 Ton

4 Ton

5 Ton

25

15

28

35

28

Table 6. Heat Pump Heating System Performance

Values

Page 8 of 12 507296-02Cmrcool.com

Page 10

Maintenance

WARNING

Motors

Indoor and outdoor fan and vent motors are permanently

lubricated and require no maintenance.

Before performing maintenance operations on the

shock could cause personal injury or death.

constant torque motor. These motors remain energized and

use Tap 3 for cooling speed and Tap 5 for heating speed.

Outdoor Coil

Periodic inspection and maintenance normally consists of

the outdoor coil surface or other parts in the air circuit.

Cleaning should be as often as necessary to keep the coil

cleaning.

Filters

Replace disposable or clean permanent type as necessary.

Table 7. Cooling Performance - AC Models

80 DB / 67 WB Deg.

Return Air

Cooling

Input

(1000 BTU)

24

42

48 132 143 144 145 151 152 154

24

42 248 325 385 411

48 338 352 455 482

Pressure 65° 70° 75° 80° 82° 85° 90° 95° 100° 105° 110° 115°

135

135 142 143 145 152 154 155

Suction

135 142 143 144 151 152 154 155

132 135 141 143 145 148

131 133 134 135 141 144 152

282 318 388 413 438

Air Temperature Entering Outdoor Coil, Degree F

314 323 358 432 483

damaged.

141 143 148 152 154

351 423

324 415 438

507296-02C mrcool.com

Page 11

Table 9. Cooling Performance - HP Models

80 DB / 67 WB Deg.

Return Air

Cooling

Input

(1000 BTU)

24

42

48 132 135 138 142 143 144

24 255 388 414

42 238 324 348 421 445

48 248 412 438

Pressure 65° 70° 75° 80° 82° 85° 90° 95° 100° 105° 110° 115°

134 138 141 143 145 148 151 152 154 155

133 141 143 145 151 153

Suction

133 134 135 138 142

254 314 322 383

245 312 415 438

138 142 143 144 145 151 152 154

131 134 138 141 144 148 148 148

285 322 343 443

Air Temperature Entering Outdoor Coil, Degree F

151 152 154 155

Table 8. Heating Performance - HP Models

70 Deg. F Return Air Air Temperature Entering Outdoor Coil, Degree F

Cooling

Input

(1000 BTU)

24

42 25 33 42 54

48 32 84 114 122

24 283 312 323

42

48

Pressure 0° 5° 10° 17° 20° 25° 35° 40° 47° 50° 55° 60°

Suction

33 41

31 38 45 55 81 88

35 42 58 82 115

85 111

44 54 58

253 281 312 323

251 258 321 328 335

311 315 322 331 333 341

318 323 332 358 384

281 334 343 355

113 121

507296-02Cmrcool.com

Page 12

S4

S79

S173

J1-11

Wiring Diagrams

LINE VOLTAGE FIELD INSTALLED

CONTACTOR

K1-2

L2

YEL W/ STRIPE

J1-2

PUR

FAN

MOTOR

J2-2

J1: PLUG THROUGH CONTROL PANEL (12 PIN)

J2: PLUG FOR ACCESSORY HEAT (6 PIN)

B4

YEL W/ STRIPE

208/230-1-60

POWER SUPPLY WITH MIN.

C COPPER WIRE

75

BLK

COMPRESSOR

B1

T2

RED

GRY

F

J1-1

ORG

OUTDOOR

BLK W/ STRIPE

R

C

C

S

BLACK

G

N

(IF USED)

HR1

H

HEATER

CRANK

CASE

BLK

CAPACITOR

YEL

J1-3

INDOOR

BLOWER

MOTOR

240V

DUAL

B3

C12

L

208V

BLK

T1

CONTACTOR

24V

L1

K1-1

BLK

TRANSFORMER

TI

BLK

BLK

J2-1

A/C (CONSTANT TORQUE BLOWER)

CONNECTION DIAGRAM

SINGLE PHASE

NOTE: TAP1 FOR FAN ONLY

TAP 2 FOR COOLING

TAP3 FOR HIGH STATIC COOLING

TAP4 AND TAP5 FOR ELECTRIC HEAT- REFER TO HEATING LABEL

IF ANY OF THE ORIGINAL

WIRE IS REPLACED THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

USE COPPER CONDUCTOR

ONLY, MIN 75

C WIRE

WARNING-

ELECTRIC SHOCK HAZARD. UNIT

MUST BE GROUNDED IN ACCORDANCE

WITH NATIONAL AND LOCAL CODES.

537663-01

J2-4

THERMAL PROTECTION

SWITCH (IF USED)

NOTE:

SWITCH (IF USED)

LOW PRESSURE

HIGH PRESSURE

SWITCH

CONTROL CIRCUIT

WIRING TO BE 24 VOLT,

N.E.C. CLASS 2

BLU

RED

BLU

J1-12

YEL

YEL

Y

GRN

CONTACTOR

KI

5

YEL

4

3

YEL

YEL

2

1

GRN

WHT

WHT

BLK

FUNCTION OFF W1 ONLY.

J2-6

J2-5

BLU

WHT

THERMOSTAT

W1

G

C

R

INDOOR BLOWER MOTOR

N

G

L

C

B-3

W1 & W2 CAN BE USED TO STAGE

ELECTRIC HEAT ACCESSORY ON

10, 15 & 20KW MODELS

5 & 7.5KW HEATER ACCESSORIES

S1

Figure 8. Connections Diagram - A/C Constant Torque

507296-02C Page 11 of 12mrcool.com

Page 13

C WIRE

DIAGNOSTIC CODES FOR DEFROST CONTROL LEDS

NOTE:

IF ANY OF THE ORIGINAL

WIRE IS REPLACED THE

SAME SIZE AND TYPE WIRE

MUST BE USED.

USE COPPER CONDUCTOR

ONLY, MIN 75

C

L

G

N

FUNCTION OFF W1 ONLY.

5 & 7.5 KW HEATER ACCESSORIES

W1 & W2 CAN BE USED TO STAGE

ELECTRIC HEAT ACCESSORY ON

10, 15 & 20KW MODELS

J2-5

J2-6

1

2

3

4

BLK

WHT

WHT

GRN

YEL

DEFROST

5

INDOOR BLOWER MOTOR

NOTE: TAP1 FOR FAN ONLY

TAP 2 FOR COOLING

TAP3 FOR HIGH STATIC COOLING

TAP4 AND TAP5 FOR ELECTRIC HEAT- REFER TO HEATING LABEL

CONNECTION DIAGRAM, HEAT PUMP

BLU

(IF USED)

FLOAT SWITCH

RED

CONSTANT TORQUE BLOWER, SINGLE PHASE

YEL

G

THERMOSTAT

WHT

FAN

CONTROL

REV. VALVE

J1-5

GRY

L1

W1

WHT

BLU

W1

O-OUT

J1-6

J1-8

GRY

BLK

LOW PRESSURE

C

C

LO-PS

J1-9

BLK

S79

SWITCH

RED

L

J1-7

BRN

DEFROST

R

R

DF

J1-10

BRN

T'STAT

ORG

O

24 V

COMMON

S6

O

YEL

Y1

Y1 OUT

Y

S1

CONTROL CIRCUIT WIRING TO

BE 24 VOLT, NEC CLASS-2

CMC1

HI-PS

J1-11

J1-12

S173

SWITCH

(IF USED)

YEL

YEL

THERMAL PROTECTION

YEL

CONTACTOR

BLU

WARNING-

ELECTRIC SHOCK HAZARD. UNIT

MUST BE GROUNDED IN ACCORDANCE

WITH NATIONAL AND LOCAL CODES.

S4

SWITCH

HIGH PRESSURE

J2-4

K1

BLU

GRN

537661-01

T1

BLK

TRANSFORMER

BLK

J2: PLUG FOR ACCESSORY HEAT (6 PIN)

J1: PLUG THROUGH CONTROL PANEL (12 PIN)

Note: Because the Pressure Switches are monitored only when "Y1" (Input) is active, the code

for pressure switch open will not be seen when "Y1" is off. Instead, the "Normal Operation" or

"Anti Short Cycle" code will be seen.

Also, when a pressure switch opens and caused a short cycle lockout, the pressure switch-open

code will be seen until it closes, then the short cycle lockout code will flash unless it has already

expired.

J2-1

FAN

Simultaneous Slow Flash

DS1 (GREEN) DS2 (RED)

BLK

CONTACTOR

K1-1

L1

Control

Description

No Power to Control OFF OFF

Anti-Short Cycle Lockout Alternate Slow Flash

Low Pressure Switch Fault OFF Slow Flash

(See instructions or markings on System Diagnostic

Normal Operation / Power to

Module for codes of System Diagnostic Module)

High Pressure Switch Fault Slow Flash OFF

Low Pressure Switch Lockout OFF ON

High Pressure Switch Lockout ON OFF

BLU

24V

240V

208V

BLU

WHT

J2-2

B4

CONDENSER

FAN MOTOR

GRY

K1-2

CONTACTOR

YEL W/STRIPE

YEL W/STRIPE

T2

L2

L

C

NC

BLK

T1

BLK

INDOOR

BLOWER

B3

BLK

CMC1

DEFROST

CONTROL

BLK

MOTOR

PUR

C12

N

G

J1-3

J1-1

J1-2

ORG

F

C

H

DUAL

YEL

B1

COMPRESSOR

HR1

CAPACITOR

RED

BLK

208/230V-1PH,60HZ

S

C

CASE

CRANK

R

HEATER

(IF USED)

LINE VOLTAGE FIELD INSTALLED

Figure 9. Connections Diagram - Heat Pump Constant Torque

Page 12 of 12 507296-02Cmrcool.com

Page 14

Signature Series

MPC*1M414A & MPH*1M414A

Residential Package

ELECTRICIAN a nd/or HVAC TECHNICIAN:

LICENSE #:

INSTALL AT ION DATE:

INSTALLATION LOCATION:

SERIAL NUMBER:

The design and specifications of this product and/or manual are subject to change without prior notice.

Consult with the sales agency or manufacturer for details.

Loading...

Loading...