Page 1

Please read this manual carefully before installation and keep it for future reference.

Owner’s Manual

®

Universal

DC Inverter / Condenser

MDUO18024036

Thank you for choosing MRCOOL Please read this manual carefully before installation and keep it for future reference.

Copyright © 2020 MRCOOL, LLC | v5.06.2020

Series

Page 2

Contents

!

Safety Precautions ................................... 2

1

Appliance Overview ................................. 5

1. Introduction .................................................................. 5

2. Accessories .................................................................. 6

3. Operating Range .......................................................... 7

4. Unit Dimensions .......................................................... 7

2

Unit Installation ........................... 8

MC MC

3

Post Installation Checks ........... 31

Maintenance

4

1. Troubleshooting ....................................... 34

...............................

1. Installation Location.................................... 8

2. Outdoor Installation ................................. 13

3. Conventional Line Set Installation.......... 14

®

4. No-Vac

5. Installation of Drain Pipe........................... 24

6. Condenser Field Conversion.................... 25

7. Electrical Connection................................. 26

Quick Connect® Installation ... 23

33

2. Error Codes ............................................... 35

3. Unit Maintenance .................................... 36

4. Notice on Maintenance .......................... 38

5. After Sales Services ................................. 41

5

EU Disposal Guidelines ...... 42

Page 1 mrcool.com

Page 3

Safety Precautions

Safety Precautions

!

Read Before Installation

Incorrect installation may cause serious damage or injury.

The seriousness of potential damage or injuries is classified as either a WARNING or CAUTION.

This symbol indicates ignoring instructions may cause death or serious injury.

WARNING

This symbol indicates that ignoring instructions may cause moderate injury

to your person, damage to your unit, or other property.

CAUTION

This symbol indicates that you should never perform the indicated action.

WARNING

Please read the manual in its entirety before installing, operating or repairing.

DO NOT share the electrical circuit with other appliances. Improper or insufficient power supply

can cause fire or electrical shock.

When connecting refrigerant piping,

enter the unit. The presence of other gases or substances will lower the unit’s capacity, and may

cause abnormally high pressure in the operation cycle. This may cause explosion and injury.

DO NOT connect the ground wire to a gas pipe, water pipe, lightning arrester or telephone wire.

DO NOT allow children to play with the air conditioner. Children should be supervised around the

unit at all times.

DO NOT alter the settings of the pressure sensor or other protective devices; if short-circuited or

modified, fire or even an explosion could occur.

Installation must be performed by an authorized technician. Improper installation may cause

1.

water leakage, electrical shock, or fire.

Installation must be performed according to installation instructions. Improper installation may

2.

cause water leakage, electrical shock, or fire.

DO NOT let substances or gases other than the refrigerant

In North America, installation must be performed in accordance with the requirement of NEC and

3.

CEC (by authorized personnel only.) Contact an authorized service technician for repair or

maintenance of the unit.

Only use the included accessories and specified parts for installation. Using non-standard parts

4.

can cause water leakage, elctrical shock, or fire and may cause the unit to fail.

mrcool.com

Page 2

Page 4

Safety Precautions

Install the unit in a firm location that can support the unit’s weight. If the installation location cannot

5.

support the weight, or the installation is performed improperly, the unit may fall and cause serious

injury and/or damage.

For all electrical work, follow all appropriate wiring standards, regulations, and the Installation Manual.

6.

You must use an independent circuit to supply power. Do not connect other appliances to the same

7.

circuit. Insuficient electrical capacity or defects in electrical work can cause electrical shock or fire.

For all electrical work, fuse the specified cables. Connect cables tightly, and clamp them securely to

8.

prevent external forces from damaging the terminal. Improper electrical connections may overheat,

causing fire and/or electrical shock.

All wiring must be properly arranged to ensure that the control board cover can close properly. If the

9.

control board cover is not closed properly, it can lead to corosion and cause the connection points on

the terminal to overheat , causing fire and/or electrical shock.

In certain functional environments, such as kitchens, server rooms, etc., the use of specially designed

10.

air-conditioning units is highly recommended. If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in order to avoid a hazard.

This appliance can be used by children aged 8 years and above and persons with reduced physical,

11.

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and understand the hazards involved.

Children should not play with the appliance. Cleaning and user maintenance should not be made by

children without supervision.

The air conditioner unit can only be cleaned after it has been turned off and disconnected from power,

12.

otherwise electric shock may occur.

13.

If installed in a compact space, ensure that there is adequate ventilation in case of leakage.

Concentration of refrigerant gas can lead to explosion and other hazards.

14.

The fixed wires connecting to this appliance must be configured with an all-pole disconnect under

voltage class III.

Note about Flourinated Gasses:

This air-conditioning unit contains R410A flourinated gases.

1.

The refigerant gas may not have an odor, thus this should not be considered a means of leak detection.

2.

3.

4.

5.

6.

Page 3

Installation, service, maintenance and repair of this unit must be performed by a certified technician.

Product uninstallation and recycling must be performed by a certified technician.

If the system has a leak-detection system installed, it should be checked for leaks at least every 12

months.

Keep a record of all leak checks for the lifetime of the unit.

mrcool.com

Page 5

Safety Precautions

For units that have an auxiliary electric heater, DO NOT install the unit within 3 feet (1 meter) of

combustible materials.

DO NOT install the unit in a location that may be exposed to combustible gases. If combustible gas

accumulates around the unit, it may cause fire.

DO NOT operate your air conditioner in a wet room such as a bathroom or laundry room. Too

much exposure to water may cause electrical components to short circuit.

DO NOT put appendages or other objects into the air inlet or return grills.

1.

DO NOT stop the appliance by directly cutting off the power. Turn off the unit first.

2.

DO NOT install the appliance in areas with -

oil smoke or volatile liquid, as plastic parts may deteriorate, adversely affecting the integrity and

functionality of the appliance.

or corrosive gas; as this may corrode copper piping and welds, adversely affecting the integrity

and functionality of the appliance.

DO NOT force-dry the filter using open flame or blowers, as this could damage it.

This appliance must be properly grounded during installation, or electrical shock may occur.

1.

Install drainage piping according to the instructions in this manual. Improper drainage may cause

2.

water damage to your home and property.

This appliance must be stored in a well ventilated area equal in size to the area specified for

3.

operation.

4.

Use proper measures to protect the outdoor unit from rodents and other small animals that may

damage electrical components, causing the unit to malfunction.

If wired control (i.e. a wall-mount thermostat) is to be used, it should be connected first before

5.

powering up the unit, otherwise it may not funciton properly.

Only use a soft dry cloth or, as necessary, a slightly wet cloth with neutral detergent to clean the

6.

casing of this appliance.

7.

Before operating the unit under low temperature, connect it to power for 8 hours. If it is

deactivated for a short time, for example, one night, do not cut off the power (this is to protect the

compressor).

mrcool.com

Page 4

Page 6

Safety Precautions

Appliance Overview

1

To Our Customers;

Thank you for choosing a MRCOOL home HVAC product. Please read this manual carefully before installation

and operation of the Univeral™ Series Central HVAC System to ensure corect use and handling. In addition to

the safety precautions in the previous section, please adhere to the following guidelines and note our

exceptions to liability.

1. This appliance can be used by children aged 8 years and above and persons with reduced physical, sensory

or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards involved. Children should not play

with the appliance. Cleaning and user maintenance should not be made by children without supervision.

2. To ensure product reliability, the unit may consume power under stand-by status to maintain normal

communication, and for preheating refrigerant and lubricant. If the unit will not be used for an extended

period, disconnect the power supply. Reconnect the power supply and preheat the unit prior to use.

3. Ensure you have selected the proper model for the operating environment. Improper selection may impact

operating performance.

4. This product has undergone strict inspection and operational testing before leaving the factory. To avoid

damage due to improper disassembly, which may impact the normal operation, please do not disassemble the

unit without proper training and equipment.

5. For technical assistance, please contact MRCOOL technical support at (270) 366-0457.

6. When the product is malfunctioning and/or is inoperable, please contact MRCOOL technical support at the

fore mentioned number, as soon as possible and provide the following information:

a. Product Nameplate Contents (model number, cooling / heating capacity, product serial number, factory

date)

b. Nature of Malfunction (specify the circumstances before and after the error occurred)

7. All illustrations and information in the instruction manual are for reference only. In order to improve the

product , we will continuously assess and innovate. We retain the right to make necessary revisions to the

product from time to time. We reserve the right to revise the contents of this manual without notice.

8. If the supply cord is damaged, it must be replaced by MRCOOL, a professional service agent or similarly

qualified person in order to avoid damage to the product.

9. MRCOOL, LLC assumes no responsibility for personal injury, property loss or equipment damage caused by

improper installation and commissioning, unecessary maintenance, or failure to follow relevant federal and

state regulations, industrial standards, and the requirements of this instuction manual.

10. MRCOOL, LLC will bear no responsibilities for personal injury or property damage caused by the following:

a. Improper use of the appliance

b. Altering, maintaining, or operating the product with non-approved equipment.

c. Altering, maintaining, or operating the product outside of the guidelines of this manual.

d. Defects caused by corrosive gas.

Page 5

e. Defects caused by shipping damage.

f. Failure to abide by this instruction manual or government regulations.

g. Products made by other manufacturers

h. Natural disasters, improper installation environment, or force majeure.

mrcool.com

Page 7

Appliance Overview

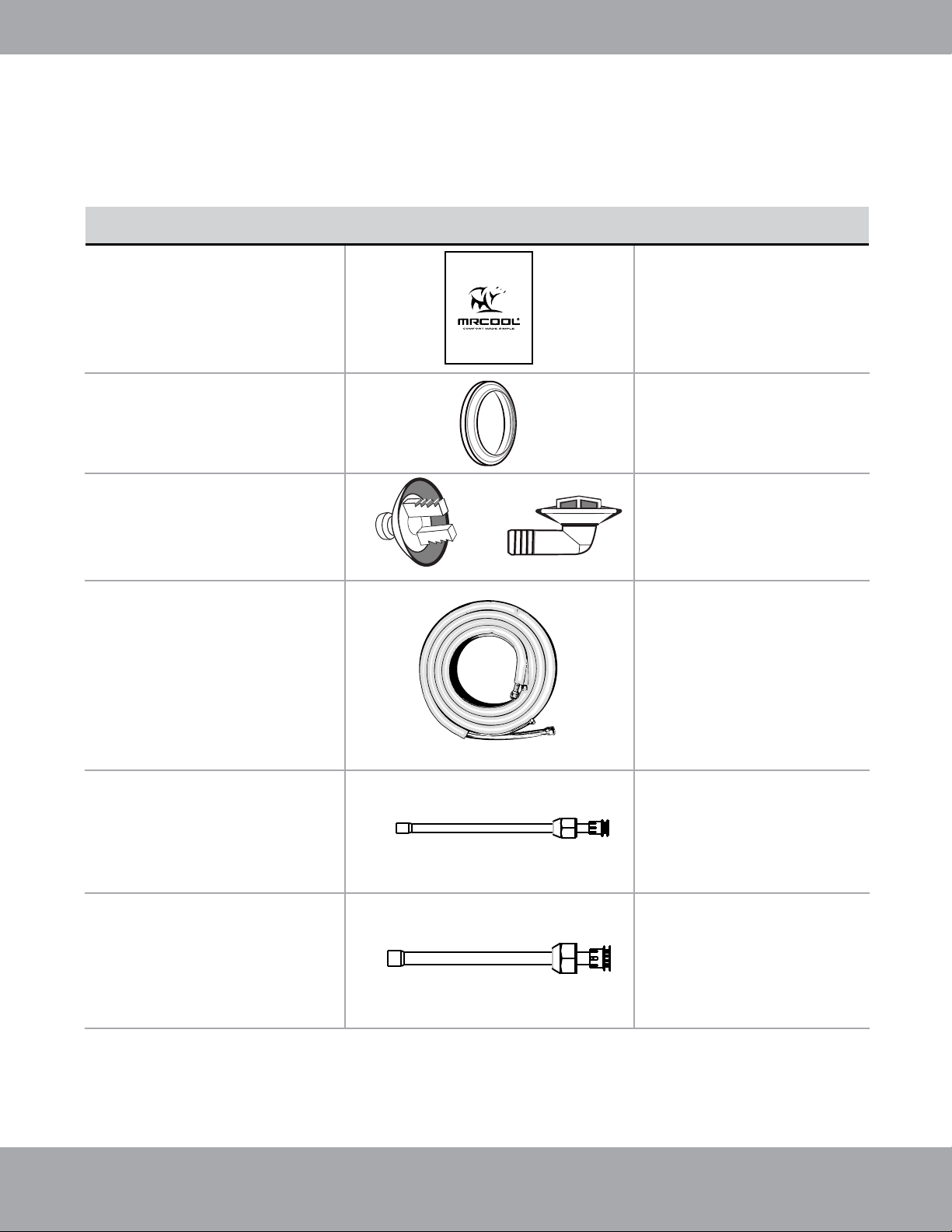

Unless otherwise stated (as “OPTIONAL”) the air conditioning system includes the following

accessories. Use all of the installation parts and accessories to install the air conditioner.

Improper installation may result in water leakage, electrical shock, fire, or equipment failure.

PART LOOKS LIKE... QUANTITY

Owner’s Manual

Owner’s Manual

Universal®™ Series

Central Heating & Air Conditioning

1

3

Drain Plug

Drainage Connector

OPTIONAL

No-Vac

Quick Connect

®

®

Lineset

Gas / Liquid

Pipe Assembly

Liquid Side Stub Kit

or

To plug the unused

drain hole

1

To connect with the

PVC drain pipe

1

1

To connect the unit

with the liquid pipe

Gas Side Stub Kit

1

To connect the unit

with the gas pipe

Fig . 1.1

Page 6mrcool.com

Page 8

Appliance Overview

Operating Range

Outdoor Temperature

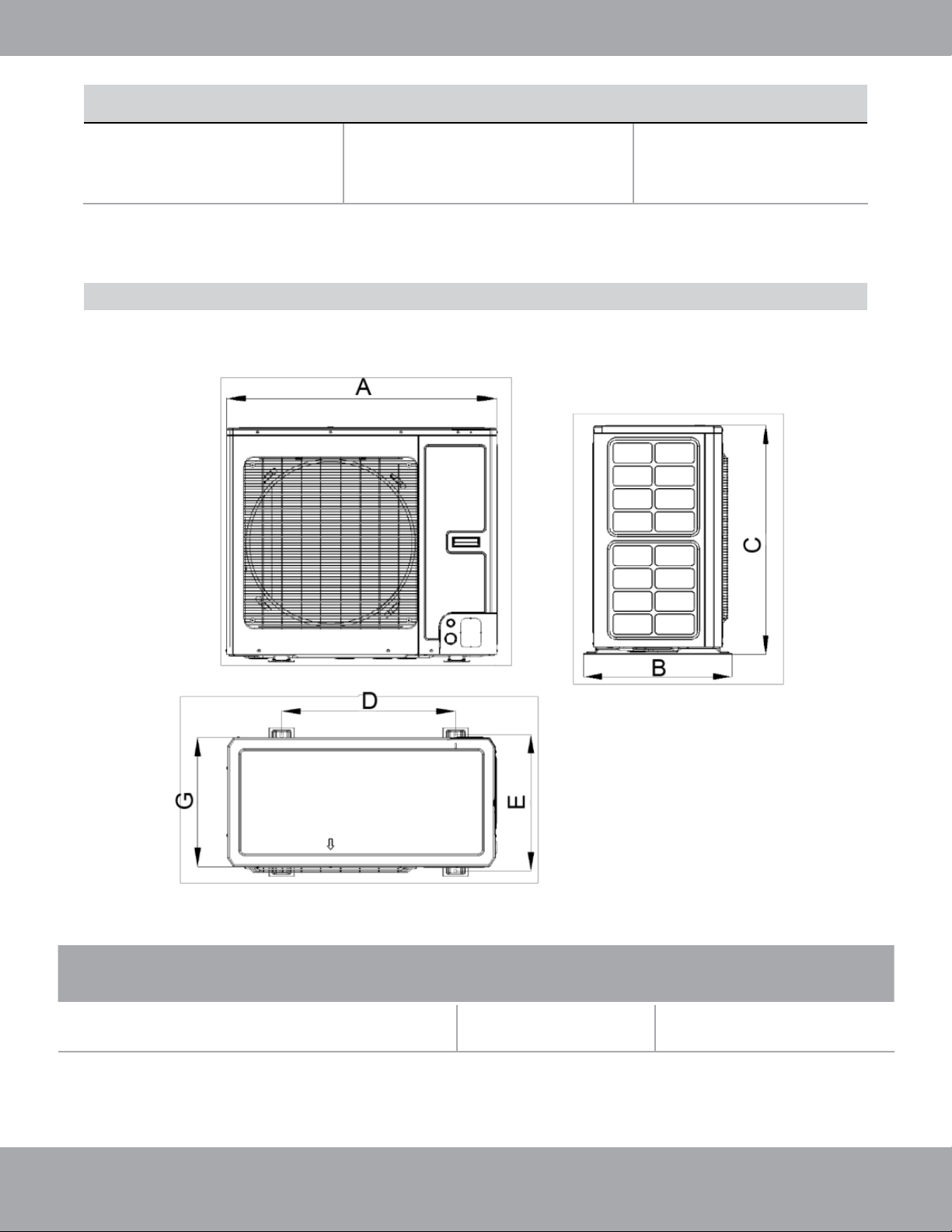

Unit Dimensions

MDUO18024036

COOLING HEATING

5°F(-15°C) ~ 130°F (54°C) -22°F(-30°C) ~ 75°F (24°C)

Outdoor Unit Dimensions

Width (A) x Height (C) x Depth (G)

MDUO18024036

37 x 32.25 x 18.125 in.

940 x 820 x 460 mm

Width (A / D) Depth (B / E)

37 / 24 in.

940 / 610 mm

Page 7 mrcool.com

Fig. 1.2

Mounting Dimensions

20.875 / 19.125 in.

530 / 486 mm

Page 9

Unit Installation

The Universal™ Series has 2 installation methods

1.

The Conventional Weld Line Set Installation

Instructions can be found on pages 14 through 22

OR

View complete install video by scanning this QR code

®

2.

No-Vac® Quick Connect® Line Set

Instructions can be found on page 23

OR

View complete install video by scanning this QR code

MRCOOL

Preferred Method

Installation Location

Installation

2

WARNING

The unit must be installed in a location strong enough to support the weight of the unit and fixed

1.

securely, to avoid toppling.

2.

Install the appliance in a location where the inclination is less than 5°.

3.

Do not install the unit in a location with direct sunlight.

4.

Do not install the unit where combustible gas leakage may occur.

Selection of Installation Location for Outdoor Unit

1.

Select a location pursuant to the following conditions:

2.

Noise and air flow produced by the outdoor unit will not disturb neighbors.

3.

The location is away from animals and plants. If not, please add safety fences to protect the unit.

4.

5.

The area is well-ventilated with no nearby obstacles that could obstruct air flow.

6.

The location is able to support the weight and withstand the operating vibration of the unit.

7.

Installation is able to be performed safely.

8.

The location area is free of combustible or corrosive gas, and oil smoke.

9.

Unit is able to be shielded from strong wind. Strong wind may affect the outdoor fan and lead to

insufficient air flow volume, thus affecting performance.

Unit is away from objects which can generate or amplify noise during operation.

10.

Condensate can be safely drained from the unit.

11.

Page 8mrcool.com

Page 10

Unit Installation

Installation Location

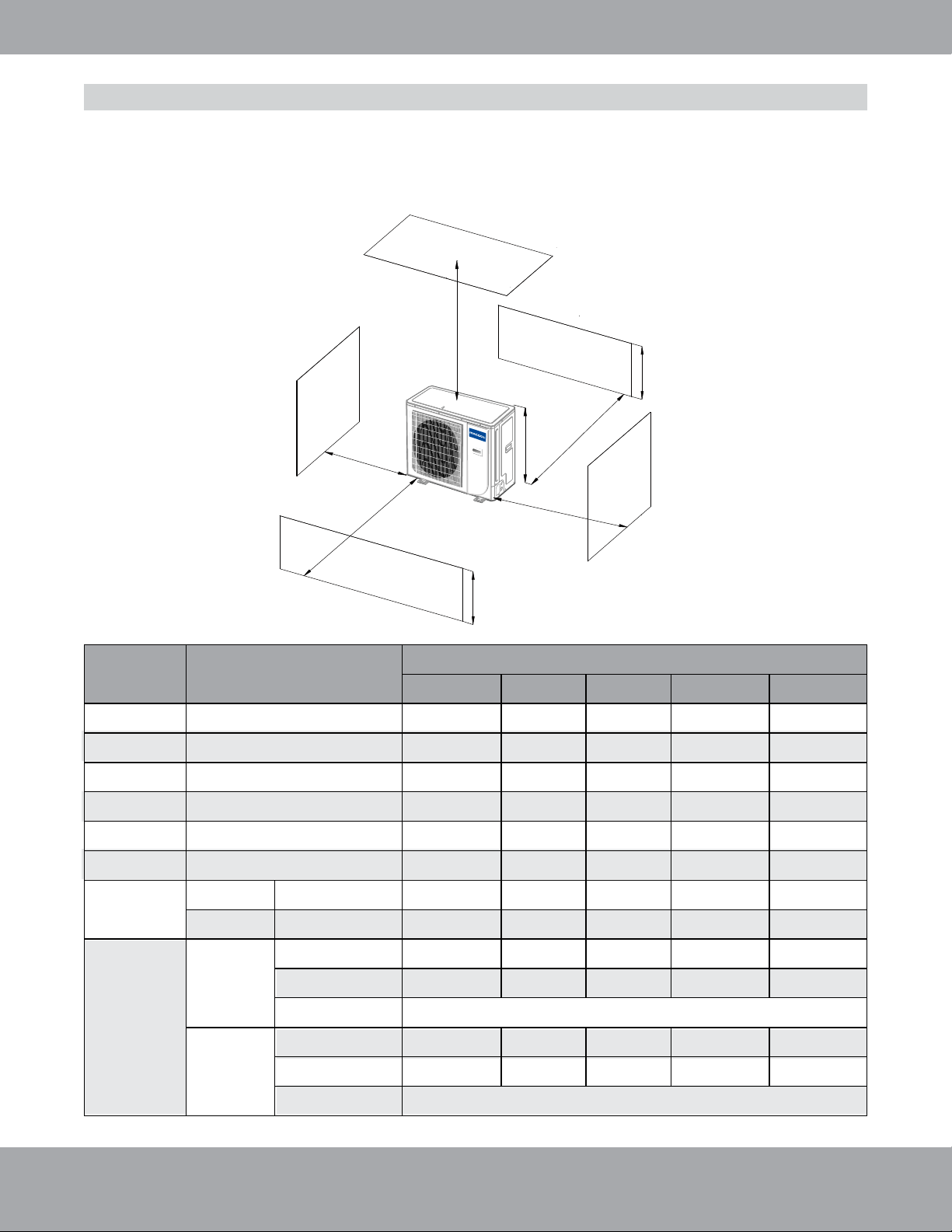

For best performance of the outdoor unit, make sure its installation space conforms to the following

installation dimensions...

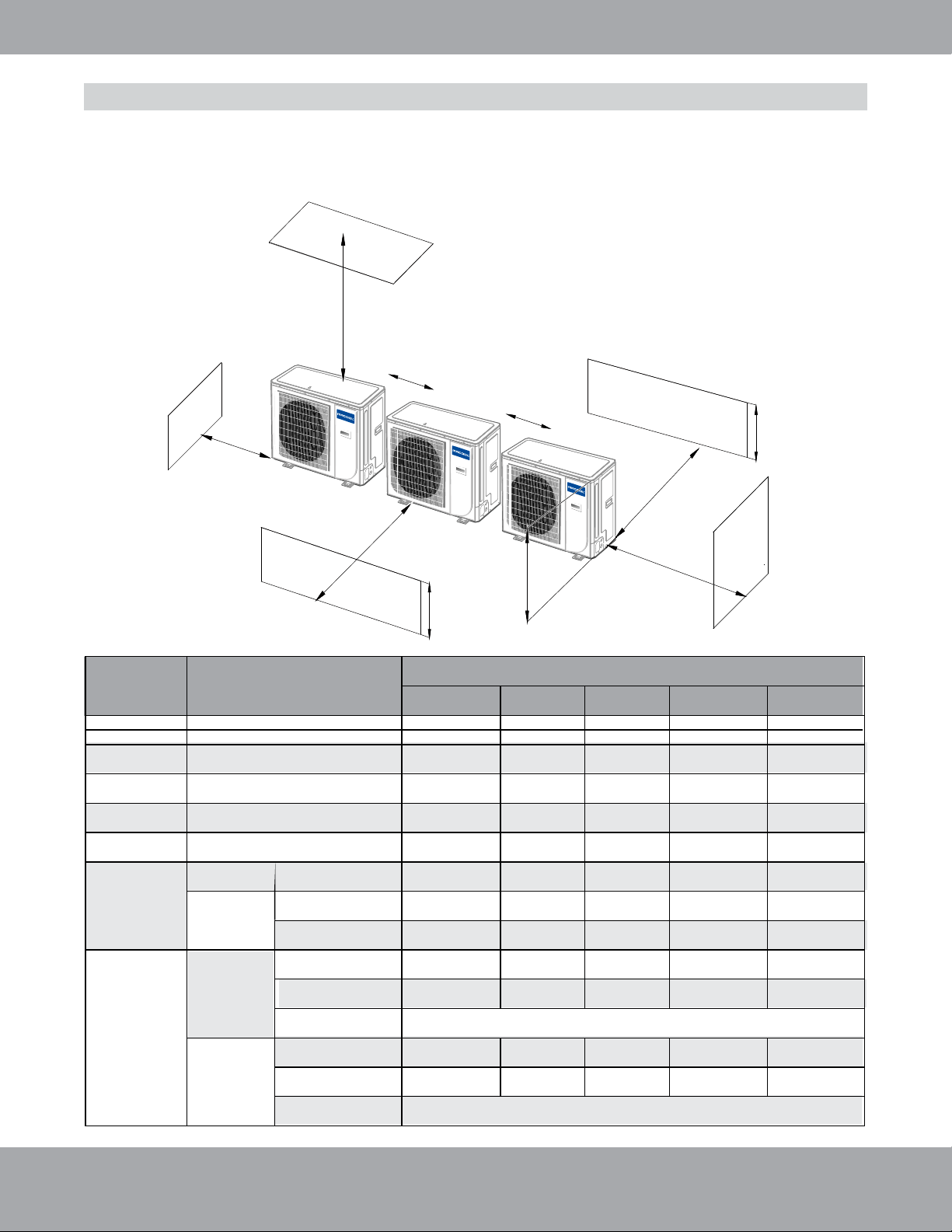

For installation of a single condenser refer to fig 2.1 below:

E

e

B

H

b

C

A ~ E

Hb Hd H

B —

A,B,C, —

B,E —

A,B,C,E —

D —

D,E —

Hb < Hd

B,D

Hb >Hd

Hb < Hd

1/2H < Hb ≤ H

B,D,E

Hb > Hd

1/2H < Hd ≤ H

c

D

Hd > H

H

d < H

Hb ≤ 1/2H

Hb > H

H

d ≤ 1/2H

Hd > H

d

H

b

A

a

H

d

inches (”) millimeters (mm)

a b c d e

≥ 3.94”

≥ 11.81”

300mm

≥ 11.81”

300mm

100mm

≥ 3.94”

100mm

≥ 3.94”

100mm

≥ 5.9”

150mm

≥ 3.94”

100mm

≥ 3.94”

100mm

≥ 9.84”

250mm

≥ 9.84”

250mm

≥ 3.94”

100mm

≥ 5.9”

150mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 78.74”

2000mm

≥ 78.74”

2000mm

Prohibited

≥ 3.94”

100mm

≥ 7.87”

200mm

≥ 78.74”

2000mm

≥ 78.74”

2000mm

Prohibited

Fig . 2 .1

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

Page 9 mrcool.com

Page 11

Unit Installation

Installation Location

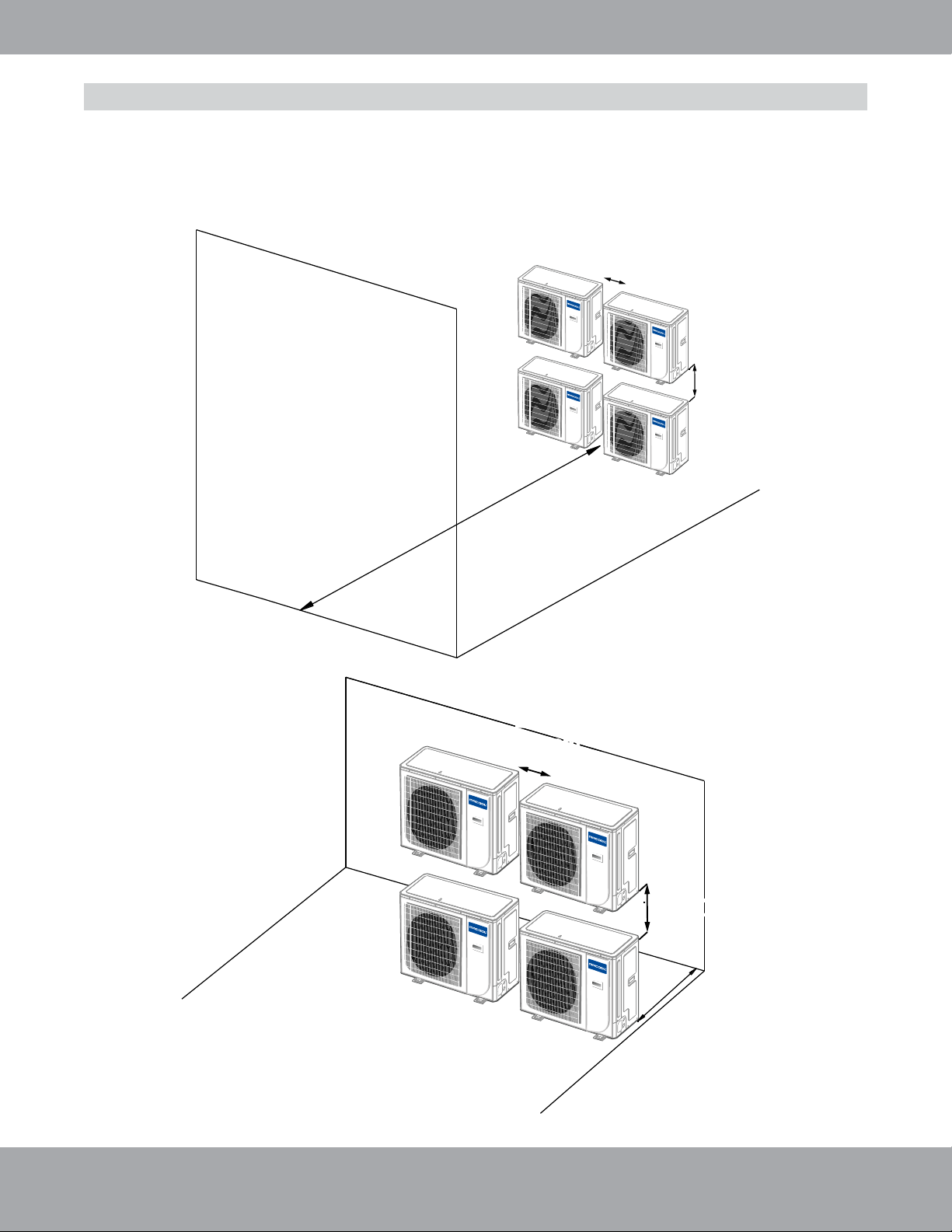

For best performance of the outdoor unit, make sure its installation space conforms to the following

installation dimensions...

For installation of multiple condensers side by side refer to fig 2.2 below:

E

e

≥ 15.75”

400mm

C

c

≥ 15.75”

400mm

B

H

b

D

A ~ E

A,B,C, —

A,B,C,E

D

D,E

B,D

B,D,E

Hb Hd H

Hb < Hd

Hb >Hd

Hb < Hd

Hb > Hd

—

—

—

Hd > H

Hd ≤ 1/2H

H

d < H

Hb ≤ 1/2H

1/2H < Hb ≤ H

Hb > H

H

d ≤ 1/2H

1/2H < Hd ≤ H

Hd > H

d

b

A

H

d

H

inches (”) millimeters (mm)

a b c d e

≥ 11.81”

300mm

≥ 11.81”

300mm

≥ 11.81”

300mm

≥ 11.81”

300mm

≥ 11.81”

300mm

≥ 9.84”

250mm

≥ 11.81”

300mm

≥ 11.81”

300mm

≥ 11.81”

300mm

≥ 9.84”

250mm

≥ 11.81”

300mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

Prohibited

Prohibited

a

≥ 78.74”

2000mm

≥ 78.74”

2000mm

≥ 78.74”

2000mm

≥ 78.74”

2000mm

≥ 98.43”

2500mm

≥ 78.74”

2000mm

≥ 98.43”

2500mm

≥ 98.43”

2500mm

≥ 98.43”

2500mm

Fig. 2.2

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

≥ 39.37”

1000mm

Page 10mrcool.com

Page 12

Unit Installation

Installation Location

For best performance of the outdoor unit, make sure its installation space conforms to the following

installation dimensions...

For installation of multiple condensers in rows refer to fig 2.3 below:

≥ 7.87”

≥ 7.87”

200mm

200mm

≥ 157.5”

4000mm

≥ 7.87”

≥ 7.87”

200mm

200mm

≥ 7.874”

2000mm

H

≥ 7.874”

2000mm

≥ 15.75”

400mm

≥ 15.75”

400mm

Hb

B

≥ 177.17”

4500mm

≥ 23.62”

600mm

Fig. 2.3

Hb H

Hb ≤ 1/2H

1/2H < Hb ≤ H

Hb > H

inches (”) millimeters (mm)

B ≥ 9.84” 250mm

B ≥ 11.81” 300mm

Prohibited

Page 11 mrcool.com

Page 13

Unit Installation

Installation Location

For best performance of the outdoor unit, make sure its installation space conforms to the following

installation dimensions...

For installation of multiple condensers on a vertical face refer to fig 2.4 below:

≥ 15.75”

400mm

≥ 19.69”

500mm

WALL

≥ 7.874”

2000mm

≥ 15.75”

≥ 15.75”

400mm

400mm

≥ 19.69”

≥ 19.69”

500mm

500mm

Fig. 2.4

≥ 11.81”

300mm

Page 12mrcool.com

Page 14

Unit Installation

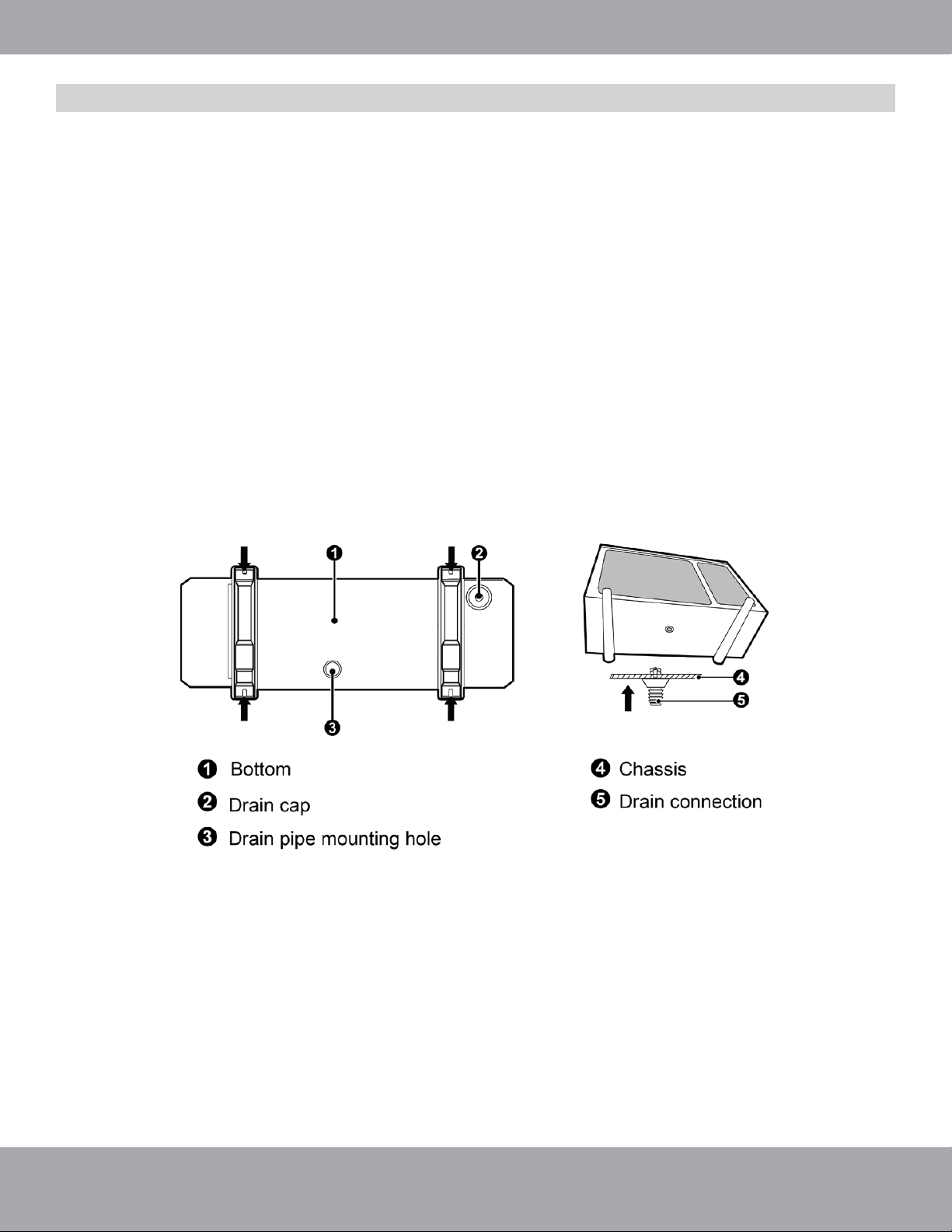

Outdoor Unit Installation

If the outdoor unit is installed on a solid surface such as concrete, use M10 screw bolts and nuts to

1.

secure the unit. Make sure the unit stands erect and level.

Do not install it on top of a building.

2.

If the unit vibrates and generates noise, add rubber cushions between the unit’s feet and the

3.

installation surface.

When the outdoor unit is in heating or defrosting mode, it must drain water. When installing the

4.

drain pipe, plug the accompanied drainage connector to the drainage hole on the chassis of the

outdoor unit. Then, connect the drain hose to the drainage connector. If the drainage connector is

used, the outdoor unit should be at least 10cm from the ground.

Plugs and drainage connector are not recommended if there is an electrical heater of the chassis.

5.

Refer to Fig. 2.5 for details.

Fig. 2.5

Page 13 mrcool.com

Page 15

Unit Installation

Conventional Line Set Installation

INSTALLATION METHOD

Connect the refrigerant lines to the unit first. When bending a refrigerant pipe, be careful not to

kink or crimp the pipe. Do not over-tighten the screw nut, otherwise leakage may occur. The

outside of the refrigerant pipe should have a layer of insulating cotton to protect it from

mechanical damage during installation, maintenance and transportation.

Refrigerant lines should adopt water-proof insulating material. The pipe wall thickness should be

0.5-1.0mm and able to withstand 6.0MPa. Excessive length of the refrigerant lines will negatively

affect cooling and heating performance. Attempt to minimize refrigerant line length when

possible.

When the drop between indoor and outdoor units is larger than 32 feet (10 meters), an oil return

bend should be added every 19.69 feet (6 meters).

DO NOT CRIMP SERVICE VALVE

LINE SET SIZE

MUST MATCH

CONNECTOR IF PIPE IS

SMALLER THAN CONNECTION

SERVICE VALVE

CONNECTION

Outdoor Unit Model

MDUO18024036

Be extremely careful not to dent or damage the piping while bending them away from the unit. Any

dents in the piping will affect the unit’s performance.

Size of Fitting Pipe

Liquid Pipe Gase Pipe

3 / 8 inch 3 / 4 inch

Maximum

Pipe Length

98.4 feet

30 m

Maximum Drop

between indoor and

outdoor units

49.2 feet

15 m

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

Page 14mrcool.com

Page 16

Unit Installation

OIL RETURN BENDS

Add an oil return bend as described below:

IF Outdoor unit is beneath the indoor unit, there is no need to add a non-return bend at the lowest or

highest position of the vertical pipe, as shown below in Fig. 2.6:

IF Outdoor unit is above the indoor unit, it is necessary to add an oil return bend and a non-return

bend at the lowest and highest position of the vertical pipe, as shown below in Fig. 2.7:

Fig. 2.6

System gas pipe

Oil return bend

Outdoor unit

Indoor unit

Install an oil

return bend

every 6m

Outdoor unit

Install an oil

return bend

every 6m

Non-return bend

System gas pipe

Oil return bend

Fig. 2.7

Indoor unit

Use the following dimensions in Fig. 2.8 to form the oil return bend(s):

B

C

A

A B C

mmInches mmInches mmInches

Ф12 Ф1/2

Ф16 Ф5/8 ≥33 ≤150

Ф19 Ф3/4 ≥34

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

≥1

≥1.3

≥1.34

≥26

Page 15 mrcool.com

≥5.91

≥5.91

≥5.91

Fig. 2.8

≤150

≤150

Page 17

Unit Installation

Conventional Line Set Installation

Pipe Cutting

Step 1: Cut Pipe

1. When preparing refrigerant pipes, take extra care to cut

and flare them properly. This will ensure efficient operation

and minimize the need for future maintenance.

2. Measure the distance between the indoor and outdoor

units.

3. Using a pipe cutter, cut the pipe a little longer than

the measured distance.

4. Make sure that the pipe is cut at a perfect 90° angle.

Refer to Fig. 2.9 for cut examples.

90°

Oblique Rough Warped

Fig. 2.9

DO NOT DEFORM PIPE WHILE CUTTING

Be extra careful not to damage, dent, or deform the

pipe while cutting. This will drastically reduce the

heating efficiency of the unit.

Step 2: Remove burrs

Burrs can affect the air-tight seal of refrigerant piping

connection. They must be completely removed.

1. Hold the pipe at a downward angle to prevent burrs

from falling into the pipe.

2. Using a reamer or deburring tool, remove all burrs from

the cut section of the pipe. Refer to Fi g. 2 .10

3. After removing burrs from cut pipe, seal the ends with

PVC tape to prevent foreign materials from entering the

pipe.

Pipe

Reamer

Point down

Fig. 2.10

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

Page 16mrcool.com

Page 18

Unit Installation

Conventional Line Set Installation

Pipe Flaring

Step 3: Flare pipe ends

Proper flaring is essential to achieve an airtight seal.

1. After removing burrs from cut pipe, seal the ends with

PVC tape to prevent foreign materials from entering the pipe.

2. Sheath the pipe with insulating material as necessary

3. Remove the cut-off valve of outdoor unit and take out the

flare nut from the bag of indoor unit accessories. Fit the flare

nut on the pipe - see Fig 2.11.

4. Make sure it is facing in the right direction, because you

can not remove the nut or change its direction after flaring.

See Fig. 2.12.

5. Remove PVC tape from ends of pipe when ready to

perform flaring work.

6. Clamp flare form on the end of the pipe. The end of the

pipe should extend ~ 1/16” (1.6mm) beyond the edge of the

flare form as shown in Fig. 2.13

7. Place flaring tool onto the form.as shown in Fig. 2.14

Flare nut

Copper pipe

Fig. 2.11

Fig. 2.12

. Turn the handle of the flaring tool clockwise until the pipe

8

is fully flared.

9. Remove the flaring tool and flare form, then inspect the

end of the pipe for cracks and even flaring.

PIPING EXTENSION BEYOND FLARE FORM

Flare form

A = ~1/16” (1.6mm)

Fig. 2.14

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

Pipe

Fig. 2.13

A

Page 17 mrcool.com

Page 19

Unit Installation

Conventional Line Set Installation

Replacement Condenser Only

Fig. 2.15

MRCOOL Universal Series DC Inverter

Must install lter drier bi ow

with this installation type

Accessory copper

90 pipe Q+y*2

Purge with

Nitrogen

Weld joint

Existing Air Handler

Existing Air Handler

in house

must be

410 air handler

and 410 TXV

Bioow valve

must have 410

TXV Bioow valve

WELD Type Complete Unit Replacement

Fig. 2.16

DC Inverter

Open stop valves with allen wrench only

after nishing lineset connections and

before powering on the unit

Must install lter drier bi ow

with this installation type

MRCOOL Universal Series

Must open stop

valves after pulling

vacuum and before

powering on

Weld joint

Must Purge with Nitrogen

before brazing joints

Purge with

Nitrogen

Air Handler

Weld joint

Must Purge with Nitrogen

before brazing joints

mrcool.com Page 18

Page 20

Unit Installation

Conventional Line Set Installation

Pipe Bending

1. Use your hands to bend the pipes. Work carefully to collapse them.

2. Do not bend the pipes in at an angle greater than 90°.

3. If the pipe is repeatedly bent or extended, it will become hard and difficult to manipulate. Avoid bending

or extending the pipe for more than 3 times.

MINIMUM BEND RADIUS

4. Do not bend the pipe excessively, otherwise it will break.

Refer to

Fig. 2.17

Radius

≥4in (10cm)

When bending connective refrigerant

piping, the minimum bending radius is

a10cm. Refer to Fi g. 2 .17

Extend the pipe by unwinding it

Fig. 2.17

Pipe

Pipe

5. As shown in Fig. 2.18 , use a sharp cutter to cut the

pipe insulation and bend the pipe after it is exposed. After

bending, place the insulation back on the pipe and secure

it with adhesive tape.

Insulation

Cutter

Cut line

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

Fig. 2.18

Page 19 mrcool.com

Page 21

Unit Installation

Conventional Line Set Installation

Pipe Connection

WARNING

Connect the pipe to the unit. Follow all instructions below. Use both spanner and torque wrench.

1.

When connecting the tapered screw nut, first apply chilled machine oil on its inner and outer

2.

surface and then screw it on 3 or 4 threads.

Confirm the tightening torque by referring to the following table. If the screw nut is over-twisted,

3.

it may be damaged and cause leakage.

Check whether gas leakage is occuring and then apply thermal insulation.

4.

Wind sponge around the joint of gas pipe and heat insulation sheath of gas collecting pipe.

5.

Be sure to connect gas pipe after liquid pipe is connected.

6.

Keep pipe connection joint exposed to perform the leak test (refer to Post Installation Checks

7.

section of this manual).

1. Screw on the flare nut of the flared connecting pipe onto the outdoor unit valve. Refer to Fig. 2.19 & Fig.

2.20,

using the torque values in the table below.

Cut Off Valve

Refrigerant Line Set

Connection Pipes

Knockout Holes

Fig. 2.19A

Pipe diameter (in. | mm) Tightening torque (N·m)

Ф1/4” | Ф6.4

Ф3/8 | Ф8.3

Ф1/2” | Ф12.7

Ф5/8” | Ф15.9

Ф3/4” | Ф19

Ф7/8” | Ф22.2

2. On Model MDUO18024036 plug the knockout holes shown in Fig. 2.19A

with material such as neoprene to prevent small animals and debris from

entering the unit.

15-30

35-40

45-50

60-65

70-75

80-85

DO NOT USE EXCESSIVE TORQUE

Excessive force can break the nut or damage

the refrigerant piping. You must not exceed

torque requirements shown in the table.

Fig. 2.19B

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

Page 20mrcool.com

Page 22

Unit Installation

Conventional Line Set Installation

Vacuum Lines

WARNING

Make sure the outlet of the vaccuum pump is away from any potential source of fire and is

well-ventilated.

1. Remove the caps on the liquid valve, gas valve and also the service port.

2. Connect the hose at the low pressure side of the manifold valve assembly to the service port of the unit’s

gas valve. Meanwhile, the gas and liquid valves should be kept closed to avoid refrigerant leak.

3. Connect the hose used for evacuation hose to the vacuum pump.

4. Open the switch on the lower pressure side of the manifold valve assembly and start the vacuum pump.

The switch at the high pressure side of the manifold valve assembly should be kept closed. If not, evacuation

would fail.

5. The evacuation duration typically depends on unit capacity. for Model MDUO18024036 time is

generally 30 minutes. Verify if that the pressure gauge on the low pressure side of the manifold valve

assembly reads -0.1Mp (-75cmHg). If it does not, there is leak somewhere. Close the switch fully and stop the

vacuum pump.

6. Wait for 10min to see if the system pressure remains unchanged. During this time, the reading of the

pressure gauge at the low pressure side should not be larger than 0.005Mp (0.38cmHg).

7. Open the liquid valve slightly, and let some refrigerant go to the connection pipe to balance the pressure

inside and outside of the connection pipe, so that air will not come into the connection pipe when removing

the hose. Note that the gas and liquid valve can be opened fully only after the manifold valve assembly is

removed.

8. Return the caps to the liquid valve, gas valve and service port.

9. For large-size units, there are maintenance ports for liquid valve and gas valve. During evacuation, you

may connect the two hoses of the branch valve assembly to the maintenance ports to speed up the

evacuation.

Refer to Fig. 2.20

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

Page 21 mrcool.com

Page 23

Unit Installation

Conventional Line Set Installation

Vacuum Lines

Pressure gauge (Low-Pressure)

Switch (Low-Pressure)

Refrigerant Lines

(to indoor unit)

Liquid Valve

Gas Valve

Service Port

Cap

Vacuum Pump

Gauge Manifold

Hose

Pressure Gauge (Hi-Pressure)

Switch (Hi-Pressure)

Connection Pipe

Cap

Service Pipe

Cap

Hose with the Valve Pin

Fig. 2.20

Adding Refrigerant

Outdoor Unit Model Standard Pipe Length

MDUO18024036

For installation with a No-Vac® Quick Connect® Line Set, refer to the next section starting on page 23

24.6 feet | 7.5m ≤31.2 feet | ≤9.5m 0.32 oz/ft 30 g/m

Max Pipe Length

Requiring No Added Charge

Additional Refrigerant

per Line Length

Page 22mrcool.com

Page 24

No-Vac® Quick Connect® Line Set Installation

INSTRUCTIONS FOR USE WITH

NO-VAC™ QUICK CONNECT® LINE SET

SOLD SEPARATELY

KINK RESISTANT, PRECHARGED, SIMPLE SECURE QUICK CONNECT, 100% CONNECTION GUARANTEE

Please read and follow the instrucons and diagram below� :

Connecons must be made exactly as specified to avoid system leaks and /or damage

Take ou t matching male connectors M1 and M2.

1.

Remove protecve cap with the copper gasket at each stop valve on the DC INVERTER and ensure the threads are clean and complete.

2.

Tighten the M1 connector to the cutoff valve *1 with a ghtening force of 50N.

3.

Tighten the M2 connector to the cutoff valve *2 with a ghtening force of 70N.

Repeat step 3 for AIR HANDLER at the other end of the LINE SET.

4.

Unroll and route the LINE SET between the AIR HANDLER and the DC INVERTER.

5.

Remove the protecve caps of the valves at both ends of the LIN E SE T. Verify that all threads are clean and complete.

6.

Tighten the LINE SET F1 valve to the M1 Connector (aached in step 3) with a force of 45N. Tighten the LINE SET F2 valve to the

7.

M2 Connector (aached in step 3) with a ghtening force of 65N.

8. Repeat this process for the AIR HANDLER at the other end of the LINE SET.

At the OUTDOOR UNIT remove the protecve cap at the cutoff valve switch and open the cutoff valve with a hex wrench to

9.

run the refrigeraon circuit. If there is any fizz, grease or other leakage, close the valve immediately and check that steps

3 and 7 were done properly. Otherwise, immediately apply soapy water for micro-leakage detecon. Soak the joints using

a sponge or spray bole. If any bubbles form, close the valve immediately and check that steps 3 and 7 were done properly.

10. Aer the correct connecon, re-ghten the

cutoff

valve’s protecon cap and cover the M1, M2 and F1, F2 connecons

with the grey insulang sleeve to help prevent condensaon.

Complete unit replacement

using the No-Vac® Quick Connect® lines

50 N

M1

F1

*1

3/8”

70 N

*2

3/4”

M2

F2

*1

*2

70 N

50 N

M1 F1

3/8”

M2 F2

3/4”

Air Handler

MRCOOL Universal Series

DC Inverter

Connect using precharged

line set with quick connect

ttings in length 15, 25, 35, 50 feet

ⱡFailur e to follow the instrucons provided co uld result in severe ha rm to you, this produc t, or other property.

The manufacturer, distributor, and sel ler are not responsible for any h arm resul ng from the failure to follow

instruc ons and the failure to follow th ese instrucons will void any and all warranes express or implied.

Open the stop valve

only after connecting

the refrigerate lines

Page 23 mrcool.com

www.mrcool.com

A-coil Precharged

with 410 Refrigerate

v05-30-2019

Page 25

Unit Installation

Installation of Drain Pipe

If the outdoor unit is located on a level lower

than the indoor unit, arrange the condensate drain

according Fig. 2.21.

1. Drain hose should be placed on the ground

and its end should not be immersed into water.

2. The entire lineset, including drain pipe should

be wound with insulating tape. Wind the insulating

tape from bottom to top.

3. The entire lineset, including drain pipe should

be supported and fixed onto the wall with saddles.

1

Sealed

Saddle

2

3

Drain Pipe

If the outdoor unit is located on a level higher

than the indoor unit, arrange the condensate drain

according Fig. 2.22.

1. Drain hose should be placed on the ground

utilizing a trap

2. The entire lineset, including drain pipe should

be wound with insulating tape to avoid water

returning to the interior. Wind the insulating tape

from bottom to top.

3. The entire lineset, including drain pipe should

be supported and fixed onto the wall with saddles.

Fig. 2.21

Fig. 2.22

Page 24mrcool.com

Page 26

Unit Installation

Condenser Field Conversion

Converting Unit From 3 Ton to 2 Ton

Follow these instructions during unit installation in order to enable a Universal Series 3 ton condenser

and air handler split system to operate at 2 ton capacity.

1. DO NOT attempt this conversion while the unit is powered on.

2. Locate the capacity dip switch on the condenser main board. The capacity dip switch is circled on

the photo below.

3. The default position of the capacity dip switch is 1 & 2 ‘Up’ and 3 &4 ‘Down’. Up being a switch

pushed toward the letters (ON DIP). Down being a switch pushed toward the numbers (1 2 3 4).

4. The default position of the capacity dip switch is 36k.

5. To activate the 24k capacity, flip capacity dip switch 1 from the Up position to the Down position.

Fig. 2.23

Location of

Dip Switch on

Condenser

Main Board

DEFAULT 3 TON

2 TON SETTING

NOTE

Refer to the Universal Air Handler Installation Manual for Dip Swith Instructions and

settings to convert the Universal Air Handler from 3 ton to 2 ton.

Fig. 2.24

Fig. 2.25

mrcool.comPage 25

Page 27

Unit Installation

Electrical Connection

Electrical Regulations

WARNING Before performing electrical work, read the following regulations

1. Electrical installation must be conducted only by professionals in compliance with local laws,

regulations and this installation manual. Never artificially extend the length of power cord. The

electric circuit must be equipped with a circuit breaker and air switch. Both must have sufficient

capacity.

2. Unit operating power must be within the nominal range stated in the instruction manual. Use a

specialized power circuit for the air conditioner. Do not draw power from another power circuit.

3. The air conditioner circuit should be at least 1.5m away from any flammable surface.

4. The external power cord and the communication wire must be effectively fixed.

5. The external power cord and the communication wire must NOT directly contact any hot objects.

For example: they must not come into contact with chimney pipes, warm gas pipes or other hot

objects.

6. The external power cord and the communication wire must NOT be squeezed. Never pull, stretch

or bend the wires.

7. The external power cord and the communication wire must NOT collide with any metal beam or

edge on the ceiling, or touch any metal burrs or sharp metal edge.

8. Connect wires correspondingly by referring to the circuit diagram labeled on the unit or electric

box. Screws must be tightened up. Slipped screws must be replaced by specialized flat-head screws.

9. Please use the power cables that are packaged with the appliance. Do not change the power

cables arbitrarily. Do not change the length and terminals of the power cables. If you want to change

the power cables, please contact MRCOOL’s local service center.

10. Wiring terminals should be connected firmly to the terminal board. Loose connection is

forbidden.

11. After the electrical installation is finished, please use wire clamps to secure the power cord,

connection wire of temperature controller and outdoor unit and the communication cords. Make

sure the wires are not clamped too tight.

12. The wire gauge of power cord should be sufficiently large. Damaged power cord or other wires

must be replaced by specialized wires. Wiring work must be done according to national wiring rules

and regulations.

13. This outdoor unit has a heating four-way valve.

mrcool.com

Page 26

Page 28

Electrical Connection

Electrical Parameters

Unit Installation

Outdoor Unit Model Power Supply Max. Fuse Size

MDUO18024036

208/230V

1Ph - 60Hz

Min. Circuit

Ampacity

24 amps (3 Ton)

18 amps (2 Ton)

35 amps (3 Ton)

20 amps (2 Ton)

Connecting the Power Cord & Communication Wire

For solid wires (Refer to Fig. 2.26 A):

1. Use wire cutters to cut off the wire end and then peel away about 25mm of the insulation layer.

2. Use a screwdriver to unscrew the terminal screw on the terminal board.

3. Use nippers to bend the solid wire into a ring that fits the terminal screw.

4. Form a proper ring and then put it on the terminal board. Use a screwdriver to tighten up the terminal

screw

For braided wires (Refer to Fig. 2.26 B & Fig. 2.27):

1. Use wire cutters to cut off the wire end and then peel away about 10mm of the insulation layer.

2. Use a screwdriver to unscrew the terminal screw on the terminal board.

3. Use a round terminal fastener or clamp to fix the round terminal firmly on the peeled wire end.

4. Locate the round terminal conduit. Use a screwdriver to replace it and tighten up the terminal screw (as

shown in Fig. 2.27).

A. Solid Wire

1” (25mm)

3/8” (10mm)

Insulation Layer

B. Braided Wire

Solderless

Terminal

Fig. 2.26

Page 27 mrcool.com

Page 29

Unit Installation

Electrical Connection

Connecting the Power Cord & Communication Wire

WARNING

1. Before work begins, please check to ensure the unit is powered OFF.

2. Improper wire connection may cause electrical components to burn.

3. Connect the wires firmly to the wiring box. Incomplete installation may create a fire hazard.

4. Use wire clamps to secure the external covers of connecting wires. Insulators must be clamped

securely; otherwise, electrical leakage may occur.

5. Ground wire must be connected.

Screw with

special washer

Round

Terminal

Terminal

Board

Wire

For all terminal wiring (Refer to Fig. 2.28):

Lead the connection wire and power cord through the insulation tube. Then fix

the wires with wire clamps (as shown in Fig. 2.28).

Fig. 2.27

Insulation Tube

Cord Clamp

Fig. 2.28

Page 28mrcool.com

Page 30

Unit Installation

Electrical Connection

Connecting the Power Cord & Communication Wire

WARNING

1. High and low voltage wires should be led through different rubber rings of the electric box cover.

2. Do not bundle up the temperature controller wire or lay them side by side, otherwise errors will

occur.

3. High and low voltage wires should be secured separately. Secure the former ones with large

clamps and the latter ones with small clamps.

.

4. Use screws to tighten the power cord and communication wire of the units on the terminal board.

Improper connection may create a fire hazard.

5. If the power cord and communication wire are not correctly connected, the air conditioner may

suffer damage.

6. Ground the units through connecting the ground wire.

7. The units should comply with applicable local and national rules and regulations on power

consumption.

8. When connecting the power cord, make sure the phase sequence of the power supply matches

with the corresponding terminals, otherwise the compressor will get reversed and operate

abnormally.

Electrical wiring of Single-phase unit: MDUO18024036

Breaker

POWER

208-230V L1

1PH L2

60Hz G

L1

L2

2

Y

1

Outdoor

Unit

Page 29 mrcool.com

B

W1

R

C

Thermostat

Fig. 2.29-A

Page 31

Unit Installation

Electrical Connection

Connecting the Power Cord & Communication Wire

1. Remove the big handle/front panel of the outdoor unit and insert one end of the communication

wire and the power cord to the terminal board.

2. The power cord should be secured along with the right side plate and fixed to the hook with a

wire clamp so as to avoid contacting the pipeline. The temperature controller wire should also be laid

along with the right side plate but away from the power cord.

Electrical wiring of Single-phase unit: MDUO18024036

Y B W1 R C G

Fig. 2.29-B

L2L2

L1L1

The wires should be

bundled with a cable tie

Communication Wire

should enter through

the upper hole

Power Cord should enter

Fig. 2.30

through the lower hole

Page 30mrcool.com

Page 32

Refrigerant Piping Connection

Post Installation Checks

Before Test Run

Only perform test run after you have completed the following steps:

• Electrical Safety Checks – Confirm that the electrical system is safe and operating properly

• Gas Leak Checks – Check all flare nut connections and confirm that the system is not leaking

• Confirm that gas and liquid (high and low pressure) valves are fully open

List of Checks to Perform Possible Malfunctions PASS/FAIL

3

Is the main body installed securely?

Did you conduct a water leakage test?

Is the unit well insulated from heat?

Does water drain properly from drain

hose?

Is the voltage consistent with that

stated on the nameplate?

Are the wires and pipes installed

correctly?

Has the unit been safely grounded?

Do the specifications of wires comply

with the requirement?

The unit may fall down, vibrate or produce

noise.

Cooling capacity may become

unsatisfactory.

Condensate, water drops may occur

Condensate, water drops may occur

The unit may fail or its components may

get burned.

The unit may fail or its components may

ignite.

Risk of electric leakage.

The unit may fail or its components may

ignite.

Outdoor (2):

Indoor (2):

Is there any obstacle blocking the air

inlet and outlet of the units?

Have you recorded the length of

refrigerant pipe and the refrigerant

charging amount?

Cooling capacity may become

unsatisfactory.

The refrigerant charging amount can’t be

controlled.

Page 31 mrcool.com

Page 33

Post Installation Checks

Test Run

DOUBLE-CHECK PIPE CONNECTIONS

During operation, the pressure of the refrigerant circuit will increase. This may reveal leaks that were not present

during your initial leak check. Take time during the Test Run to double-check that all refrigerant pipe connection

points do not have leaks.

Test Run Instructions

Preparation before connecting the power:

1. Power must not be connected if the installation work is not completed.

2. Control circuit is correct and all the wires are firmly connected.

3. Cut-off valves of the gas pipe and liquid pipe are open.

4. The inside of the unit should be clean. Take irrelevant objects out if there is any.

5. After checking, re-install the front side plate.

Operation after connecting the power:

1. If all the above works are finished, power on the unit.

2. If the outside temperature is more than 30°C, heating mode can’t be enabled.

3. Make sure the units can run normally.

4. If there are any loud and/or abnormal sounds contact MRCOOL Tech Support immediately.

NOTICE:

1. If you use remote control to turn off the unit and then immediately turn the unit on again, compressor will

need 3min to restart. Even if you press “ON/OFF” button on the remote control, it won’t be started up right

away.

2. If there’s no display on the wired control Change to: temperature controller, it’s probably because the

connection wire between the units and wired control Change to: temperature controller is not connected.

Please check again.

Page 32mrcool.com

Page 34

Outdoor Unit Installation

Maintenance

Maintenance

4

4

Troubleshooting

(1) If your air conditioner fails to function normally, check the following items before conducting

maintenance:

Problem Cause Corrective Measure

If you turn o the unit and then

immediately turn it on, in order to protect

the compressor and avoid system

overload, compressor will delay running

fo 3 minutes.

Please wait for approx. 3 minutes.

The air conditioner

will not activate.

Inadequate cooling

or heating

performance

Wire connection is wrong.

Fuse or circuit breaker is broken.

Power failure.

Power plug is loose. Re-insert the power plug.

Remote control has low battery. Replace the batteries.

Air inlet and outlet of the units have

been blocked.

Improper temperature setting. Reset to a proper temperature.

Fan speed is too low. Reset to a proper fan speed.

Air ow direction is incorrect. Change the direction of air louvers.

Doors or windows are open. Close them.

Exposed under direct sun light.

Too many heat sources in the room. Remove unnecessary heat sources.

Filter is blocked or dirty. Have a professional clean the lter.

Connect wires according to the wiring

diagram.

Replace the fuse or switch on the circuit

breaker.

Restart after power returns.

Clear the obstacles and keep the area

well ventilated.

Put on curtains or louvers in front of the

windows.

Air inlet and outlet of the units have

been blocked.

Page 33 mrcool.com

Clear the obstacles and keep the area

well ventilated.

Page 35

Maintenance

(2) The following situations are not operation failures.

Problem Time of Occurrence Cause

Mist comes from the

conditioner.

The air conditioner

generates noise.

Dust comes from the

air conditioner.

During operation.

System switches to heating mode after

defrosting.

The air conditioner is buzzing when

operation begins.

When the unit is turned on, it purrs.

About 20 secs after the unit rst enables

heating mode or when defrosting under

heating mode.

There is a hissing sound when the unit

has started or stopped and a slight

hissing sound during and after operation.

There is a crunching sound during and

after operation.

If the unit is running under high

humidity, the wet air in the room will be

quickly cooled down.

Defrosting process will generate some

water, which will turn to vapor.

Temperature control will be buzzing

when it starts working. The noise will

become weak 1 minute later.

When the system has just started, the

refrigerant is not stable. About 30 secs

later, the purr of the unit becomes low.

It’s the sound of the 4-way valve

switching direction. The sound will

disappear after the valve is in position.

It’s the sound of gaseous refrigerant that

stops owing and the sound of the

drainage system.

Because of temperature change, the

front panel and other components may

swell and cause an abrasive sound.

The air conditioner

generates smells.

There is a hissing sound when the unit is

turned on or suddenly stopped during

operation or after defrosting.

The unit starts operation after being

unused for a long time.

During operation.

Because refrigerant suddenly stops

owing or changes the ow direction.

Dust inside the units come out together

with the air.

Smells from the operating environment

may be conducted through the air

handler.

NOTICE

Check the above items and take appropriate corrective measures. If the air conditioner

continues improper function, please turn off the air conditioner immediately and contact

MRCOOL or your installing dealer.

Page 34mrcool.com

Page 36

Maintenance

Error Code

WARNING

1) When abnormalities occur, stop the unit immediately and disconnect power. Contact

MRCOOL. If the unit continues to run abnormally, it may damage the unit and cause an

electric shock or a fire hazard.

2) DO NOT attempt repairs to the appliance yourself. Improper repair and maintenance

can create electric shock and fire hazards. Please contact MRCOOL Tech Support for

further guidance or a qualified professional for repairs.

If the display panel or wired control displays an error code, please refer to the following table:

Number Error Code Error

1 E1 Compressor high pressure protection

2 E4 Compressor air discharge high-temperature protection

3 E3

4 F2 Condenser temperature sensor error

5 F3 Outdoor ambient temperature sensor error

6 F4 Discharge temperature sensor error

7 F6 Outdoor unit tube temperature sensor error

8 C5 Indoor unit jumper cap error

9 EE Outdoor unit memory chip error

10 PF Electric box sensor error

11 H3 Compressor overload protection

12 H4 Overload

13 H5 IPM protection

14 H6 DC fan error

15 H7 Driver out-of-step protection

Compressor low pressure protection, refrigerant lack protection and refrigerant

collecting mode

16 HC Pfc protection

17 Lc Startup failure

18 Ld Compressor phase-sequence protection

19 LF Power protection

20 U7 4-way valve switch-over error

21 P0 Drive reset protection

Page 35 mrcool.com

Page 37

Maintenance

Number Error Code Error

22 P5 Over-current protection

23 P6 Master control and driver communication error

24 P7

25 P8 Driver module high temperature protection

26 P9 Zero-crossing protection

27 PA AC current protection

28 Pc Driver current error

29 Pd Sensor connection protection

30 PE Temperature drift protection

31 PL Bus low-voltage protection

32 PH Bus high-voltage protection

33 PU Charge loop error

34 PP Input voltage error

35 ee Driver memory chip error

36 C4 ODU jumper cap error

Driver module sensor error

NOTICE

When the unit is connected with the wired controller, the error code will show simultaneously

on it.

Unit Maintenance

Warning

1) Only professionals may carry out annual maintenance.

2) Before contacting any wire, make sure power is turned o.

3) Do not allow ammable objects near the unit.

4) Do not use organic solvent to clean the air conditioner.

5) If you need to replace a component, contact a professional to repair the unit with a component supplied

by MRCOOL to ensure the quality.

6) Improper operation may damage the unit, causing electric shock or re.

7) Do not immerse the air conditioner in water or electric shock may occur. Do not use water to rinse the

unit during cleaning.

Page 36mrcool.com

Page 38

Maintenance

Unit Maintenance

Warning

1) Before cleaning, ensure the power is o. Turn o at circuit breaker and remove the power socket, to

avoid electric shock.

2) Do not wash the air conditioner with water, otherwise re or electric shock may occur.

3) When cleaning the lter, be careful. If you need to work above the ground, please exercise caution.

Outdoor Heat Exchanger

Clean the heat exchanger on the outdoor unit periodically — at least once every two months.

Remove the dust and sundries on the surface of the heat exchanger with dust collector and nylon

brush. If there is a compressed air source; use the compressed air to gently blow the dust off the

surface of the heat exchanger. Do not use tap water for cleaning.

Condensate Drain

Periodically check if the condensate drain is blocked to avoid condensate water problems.

Pre-Season Inspection Check List

1) Check for blockages in the air inlet/outlet;

2) Check the ground connection;

3) Check the battery in the remote control;

4) Check that the air filter screen is properly installed and clean;

5) If starting up again after a long period of inactivity, present the power switch of the air conditioner

to “ON” status at least 8 hours prior to operation to preheat the crankcase on the compressor.

6) Check that the outdoor unit is firmly secured;

7) If problems are detected, contact your local service professional or MRCOOL.

Post-Season Maintenance Check List

1) Deactivate the main power to the air conditioner;

2) Remove dust and debris from the outdoor unit;

3) If the outdoor unit is rusty, paint the rusty location to prevent it from growing.

Component Replacement

Components are available from MRCOOL and associated dealers.

Page 37 mrcool.com

Page 39

Maintenance

Notice on Maintenance

Service Information

The manual contains specific information for service personnel who will perform maintenance on

the product.

General Work Area

Inform others working in the immediate vicinity about the nature of work being performed. Avoid

work confined spaces. Section off the area around the workspace. Ensure conditions within the area

are safe by removing potentially flammable material.

Ventilated Area

Ensure the area is adequately ventilated before opening into the system or conducting any

refrigerant work. Maintain adequate ventilation while working. Effective ventilation will safely disperse

any released refrigerant into the atmosphere.

Refrigeration Equipment Checks

Ensure all electrical components are compatible with the product and built to the correct

specifications. Follow manufacturer maintenance and service guidelines at all times. When in doubt,

consult the MRCOOL’s technical department for assistance.

If using flammable refrigerants, conduct the following checks:

1) Ensure ventilation machinery and outlets are operating adequately and are not obstructed;

2) If an indirect refrigerating circuit is being used, check the secondary circuit for the presence of

refrigerant;

3) Check that equipment markings are visible and legible. Replace markings that are illegible.

4) Ensure refrigeration pipe or components are installed in a position where they are unlikely to be

exposed to any substance which may corrode refrigerant containing components unless the

components are constructed of materials which are inherently resistant to being corroded or

are suitably protected against being so corroded.

Electrical Device Checks

Electrical component repair and maintenance should include initial safety checks and component

inspection procedures. If a fault exists that could compromise safety, do not connect the circuit to

an electrical supply until the fault is corrected.

Page 38mrcool.com

Page 40

Maintenance

Electrical Device Checks

Initial safety checks should include:

1) Safe discharge of capacitors to avoid the possibility of sparking;

2) No live electrical components and wiring should be exposed while charging, recovering or purging

the system;

3) The system is safely grounded.

Sealed Component Repairs

ELECTRICAL SAFETY

Ensure that this system is installed using a disconnect box that meets national, state, and local

electrical and HVAC code requirements. The location of the disconnect box(es), number of

disconnect boxes needed, and distance from the unit(s) to the disconnect box(es) should be

handled in accordance with national, state, and local electrical and HVAC code.

ATTENTION

1) Electrical component casings should not be altered in such a way that the level of protection

is affected. This includes damage to cables, excessive number of connections, terminals not

made to original specification, damage to seals, incorrect fitting of glands, etc.

2) Ensure the apparatus is securely mounted.

3) Ensure the seals or sealing materials have not degraded in such a way that they no longer

serve the purpose of preventing the ingress of flammable atmospheres. Replace parts in

accordance with manufacturer specifications.

NOTICE

The use of silicon sealant may inhibit the effectiveness of some types of leak detection

equipment. Intrinsically safe components do not have to be isolated prior to working on them.

Intrinsically Safe Component Repair

1) Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that

this will not exceed the permissable voltage and current permitted for the equipment in use.

2) Intrinsically safe components are the only types that can be worked on while live in the presence

of a flammable atmosphere. The test apparatus must be at the correct rating.

3) Replace components only with parts specified by the manufacturer. Other parts may result in the

ignition of refrigerant in the atmosphere from a leak.

Page 39 mrcool.com

Page 41

Maintenance

Notice on Maintenance

Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges

or any other adverse environmental effects. The check should also take into account the effects of

ageing or continual vibration from sources such as compressors or fans.

Charging Procedures

In addition to conventional charging procedures, the following parameters must be followed:

1) Ensure refrigerant contamination does not occur when charging equipment.

2) Hoses or lines should be as short as possible to minimize the refrigerant contained in them.

3) Cylinders must be kept upright.

4) Take extreme care to avoid refrigerant overfill.

5) Label the system when charging is complete (if not already).

6) Extreme care shall be taken not to overfill the refrigeration system.

7) Prior to recharging the system pressure test with OFN. The system must be leak tested when

charging is complete and prior to commissioning. A follow up leak test must be carried out before

leaving the site.

Decommissioning

Before decommissioning, it is essential that the technician become completely familiar with all of the

equipment in detail. It is a recommended good practice that all refrigerants be recovered safely.

Before decommissioning, an oil and refrigerant sample should be taken in case analysis is required

prior to re-use of reclaimed refrigerant. It is essential that electrical power is available before the

task is commenced.

Before decommissioning procedure ensure that:

1) You are familiar with the equipment and its operation.

2) The system has been isolated electrically.

3) Mechanical handling equipment is available, if required, for handling refrigerant cylinders.

4) All personal protective equipment is available and being used correctly.

5) The recovery process is supervised at all times by a competent person.

6) Recovery equipment and cylinders conform to the appropriate standards.

Decommissioning procedure:

1) Pump down refrigerant system, if possible.

2) If a vacuum is not possible, make a manifold so that refrigerant can be removed from various parts

of the system.

3) Make sure that cylinder is situated on the scales before recovery takes place.

4) Start the recovery machine and operate in accordance with manufacturer's instructions.

5) Do not overfill cylinders. No more than 80% volume liquid charge.

Page 40mrcool.com

Page 42

Maintenance

Notice on Maintenance

Decommissioning (cont.)

6) Do not exceed the maximum working pressure of the cylinder, even temporarily.

7) When the cylinders have been filled correctly and the process completed, ensure the cylinders and the

equipment are removed from site promptly and all isolation valves on the equipment are closed.

8) Recovered refrigerant must not be charged into another refrigeration system until it has been cleaned and

checked.

Labelling

Equipment shouold be labelled to state that it has been de-commissioned and emptied of refrigerant. The

label must be dated and signed.

Recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is a recommended

good practice that all refrigerants are removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery cylinders are

employed. Ensure that the correct number of cylinders for holding the total system charge are available.

Ensure that all cylinders to be used are designated for the recovered refrigerant and labelled for that

refrigerant. Cylinders should be complete with pressure relief valve and associated shut-off valves in good

working order.

In addition, a set of calibrated weighing scales shall be available and in good working order. Hoses shall be

complete with leak-free disconnect couplings and in good condition. Before using the recovery machine,

check that it is in satisfactory working order and has been properly maintained. Consult the manufacturer if

in doubt.

The recovered refrigerant should be returned to the refrigerant supplier in the correct recovery cylinder, and

the relevant Waste Transfer Notice arranged. Do not mix refrigerants in recovery units and especially not in

cylinders.

If compressors or compressor oils are to be removed, ensure that they have been evacuated to an acceptable

level to make certain that flammable refrigerant does not remain within the lubricant. The evacuation process

shall be carried out prior to returning the compressor to the suppliers. Only electric heating to the compressor body shall be employed to accelerate this process. When oil is drained from a system, it shall be carried

out safely.

After-Sales Services

Any quality or other issues encountered in the purchased air conditioner, please contact the local MRCOOL

after-sales service department.

Page 41 mrcool.com

Page 43

Refrigerant Piping Connection

EU Disposal Guidelines

6

This appliance contains refrigerant and other potentially hazardous materials. When disposing of this appliance, the law requires special collection and treatment. DO NOT dispose of this product as household waste

or unsorted municipal waste.

When disposing of this appliance, you have the following options:

• Dispose of the appliance at a designated municipal electronic waste collection facility.

• When buying a new appliance, the retailer will receive the old appliance free of charge.

• The manufacturer will receive the old appliance free of charge.

• Sell the appliance to certified scrap metal dealers.

Special notice

Disposing of this appliance in the forest or other natural surroundings endangers your health and is

bad for the environment. Hazardous substances may leak into the ground water and enter the food

chain.

Page 42mrcool.com

Page 44

Universal™ Series

ELECTRICIAN and /or HVAC TECHNICIAN:

LICENSE #:

INSTALL ATION DATE:

INSTALLATION LOCATION:

SERIAL NUMBER:

The design and specifications of this product and/or manual are subject to change without prior notice.

Consult with the sales agency or manufacturer for details.

Copyright © 2019 MRCOOL, LLC.

Loading...

Loading...