Page 1

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Owner & Installation

Manual

Signature Series

MAHM*CTA AIR Handler

The Signature Series is NOT designed for amateur installation. Installation SHOULD be performed by an authorized technician.

Please read this manual carefully before installation and keep it for future reference.

Page 2

INSTALLATION INSTRUCTIONS

MAHM*CTA Series Air Handler

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury or death.

Table of Contents

Shipping and Packing List ...........................................3

General........................................................................3

Requirements ..............................................................3

Installation Clearances ................................................4

Installation ...................................................................4

Condensate Drain........................................................7

Duct System and Filters ..............................................8

Brazing Refrigerant Lines............................................9

Sealing the Unit .........................................................12

Electrical Connections...............................................12

..............................16

Check-Out Procedures..............................................18

Operation...................................................................18

..........................................19

Repairing or Replacing Cabinet Insulation ................19

Professional Maintenance .........................................20

Use of Air Handler During Construction.....................20

......2

IMPORTANT INFORMATION FOR INSTALLER

This unit has a delay relay that delays the supply blower “ON” for 1 second and keeps the blower “ON” for 45

seconds on all fan and cooling demands. For more details, refer to page 18 for unit sequence of operation.

3 4

100%

2

1

1

SECOND

DELAY

Manufactured By

MRCOOL LLC

Hickory, KY 42051

Save these instructions for future reference

507787-01C mrcool.com Page 1 of 22

CFM

COOLING

DEMAND

100%

CFM

45

SECS

OFF

*P507787-C*1

(P) 507787-01C

Page 3

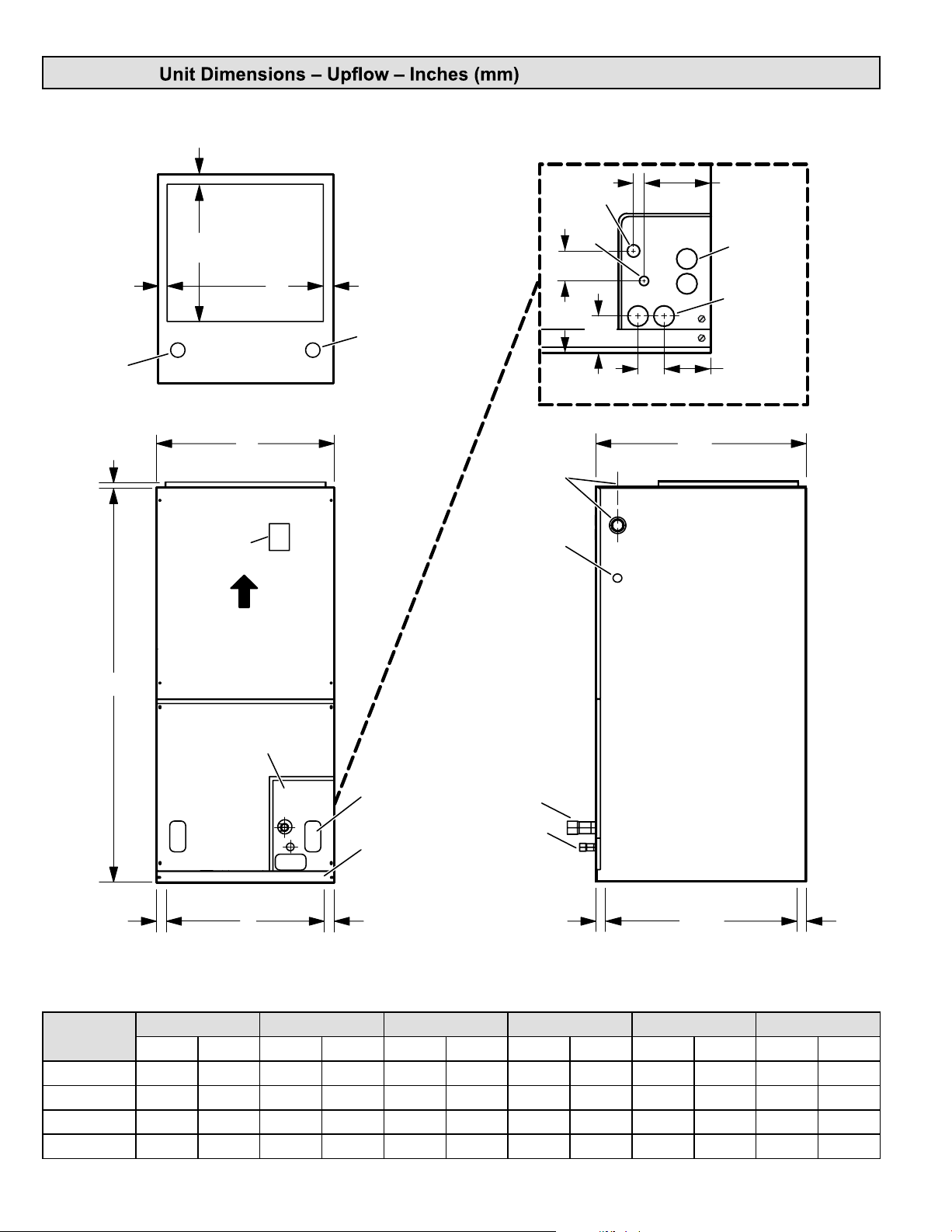

MAHM*CTA

1 (25)

LINE VOLTAGE

INLETS

(Top and Left Side)

3/4

(19)

1 (25)

14-1/2

(368)

TOP VIEW

CIRCUIT

BREAKER

COVER

SUPPLY AIR

OPENING

C

B

1 (25)

LOW VOLTAGE

INLETS

(Top and Right Side)

2-3/8

(60)

4-3/8

(111)

LINE VOLTAGE

INLETS

(Top and Right Side)

LOW VOLTAGE

INLETS

(Either Side)

DETAIL OF PIPING PLATE

3/4 (19)

SUCTION

LINE

LIQUID

LINE

2-3/4

(70)

1-3/4

(44)

4-3/4

(121)

CONDENSATE

CONDENSATE

3-1/2

(89)

22

(559)

DRAINS (2)

(Horizontal)

DRAINS (2)

(Upflow and

Downflow)

AIR FLOW

A

PIPING

PLATE

1-1/8

(29)

D

OPENING

CONDENSATE DRAIN

PIPING PLATE (3)

(2-1/4 x 3-3/4)

FILTER

ACCESS

1-1/8

(29)

SUCTION

LINE

LIQUID

LINE

1/2

(13)

20-3/8

(518)

OPENING

FRONT VIEW SIDE VIEW

Dimensions

018 024 030 036 / 042 048 060

in. mm in. mm in. mm in. mm in. mm in. mm

A 43-1/2 1105 45-1/2 1156 47 1194 53-5/8 1362 55 1397 59-3/4 1518

B 18-1/2 470 18-1/2 470 18-1/2 470 21-1/2 546 21-1/2 546 21-1/2 546

C 16-1/2 419 16-1/2 419 16-1/2 419 19-1/2 495 19-1/2 495 19-1/2 495

D 16-1/4 413 16-1/4 413 16-1/4 413 19-1/4 489 19-1/4 489 19-1/4 489

1-1/8

(29)

507787-01Cmrcool.comPage 2 of 22

Page 4

Shipping and Packing List

Package 1 of 1 contains:

Requirements

Check the air handler for shipping damage; if found,

immediately contact the last carrier. Check the unit rating

NOTE: Special procedures are required for cleaning

the all-aluminum coil in this unit. See Page 20 in this

instruction for information.

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer or

equivalent, service agency, or the gas supplier.

The Clean Air Act of 1990 bans the intentional venting

of refrigerant (CFCs, HCFCs and HFCs) as of July

1, 1992. Approved methods of recovery, recycling or

may be levied for noncompliance.

can result in back or other type of injury.

MAHM*CTA units include a factory-installed check/

capacities. These units must be installed as a part of

a matched system as outlined in the MAHM*CTA Product

These instructions are intended as a general guide and do

authorities having jurisdiction before installation.

pertaining to this type of equipment should be determined

as the instructions supplied in separate equipment, before

starting the installation.

In addition to conforming to manufacturer’s installation

instructions and local municipal building codes, installation

The

MAHM*CTA series air handler with all-aluminum coil is

designed for indoor installation only. As shipped, the unit

hand or right-hand air discharge applications. Electric

accessories are available and listed in the Product

This instruction is intended as a general guide and does

authorities having jurisdiction before installation.

sheet metal edges can result in personal injury. Take

and protective clothing.

(NFPA) standards: “Standard for Installation of Air

Conditioning and Ventilation Systems” (NFPA No. 90A)

and “Standard for Installation of Residence Type Warm Air

Heating and Air Conditioning Systems” (NFPA No. 90B).

All models are designed for indoor installation only. The

must conform to the requirements of the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United

Local authorities having jurisdiction should be consulted

before installation is made. Such applicable regulations

or requirements take precedence over the general

instructions in this manual.

the Installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

The air handler is shipped from the factory completely

connection of the duct system.

507787-01C mrcool.com Page 3 of 22

Page 5

Do not remove the cabinet knockouts until it has been

the installation.

conditions. Consider required clearances, space, routing

requirements for refrigerant line, condensate disposal,

information.

materials and vapors, such as gasoline,

that heating elements are at least 18 inches

instructions can result in death, explosion,

•

they exit the conduit opening. Sealant is required to

prevent air leakage into, and condensate from forming

inside of, the air handler, the control box, and on the

electrical controls.

• This unit is approved for installation clearance to

combustible material as stated on the unit rating

plate. Accessibility and service clearances must take

precedence over combustible material clearances.

• The air handler must be installed so that free access

control compartment.

bottom to form a return air plenum. It may also be installed

single-story buildings.

Excessive condensation may occur if the unit is installed

unconditioned space, apply sealant around electrical

Apply sealant on the inside of the cabinet at the

electrical controls.

This unit is approved for installation clearance to

combustible material as stated on the unit rating

plate. Accessibility and service clearances must take

precedence over combustible material clearances.

The air handler must be installed so that free access is

compartment.

When a MAHM*CTA

be:

• 320 square inches for -018 and -024 models;

• 360 square inches for -030 and -036 models;

• 450 square inches for -042 thru -060 models

determine if the open area meets the minimum open area

listed above.

If a return air plenum is used, the return air grille should be

the opening, there must be adequate clearance around the

and controls in an insulated galvanized steel factory-

•

humid space.

• If installed in an unconditioned space, sealant should

cabinet.

For ease in installation, it is best to make any necessary

place.

Refrigerant Metering Device

MAHM*CTA

expansion valve or an RFC device.

507787-01Cmrcool.comPage 4 of 22

Page 6

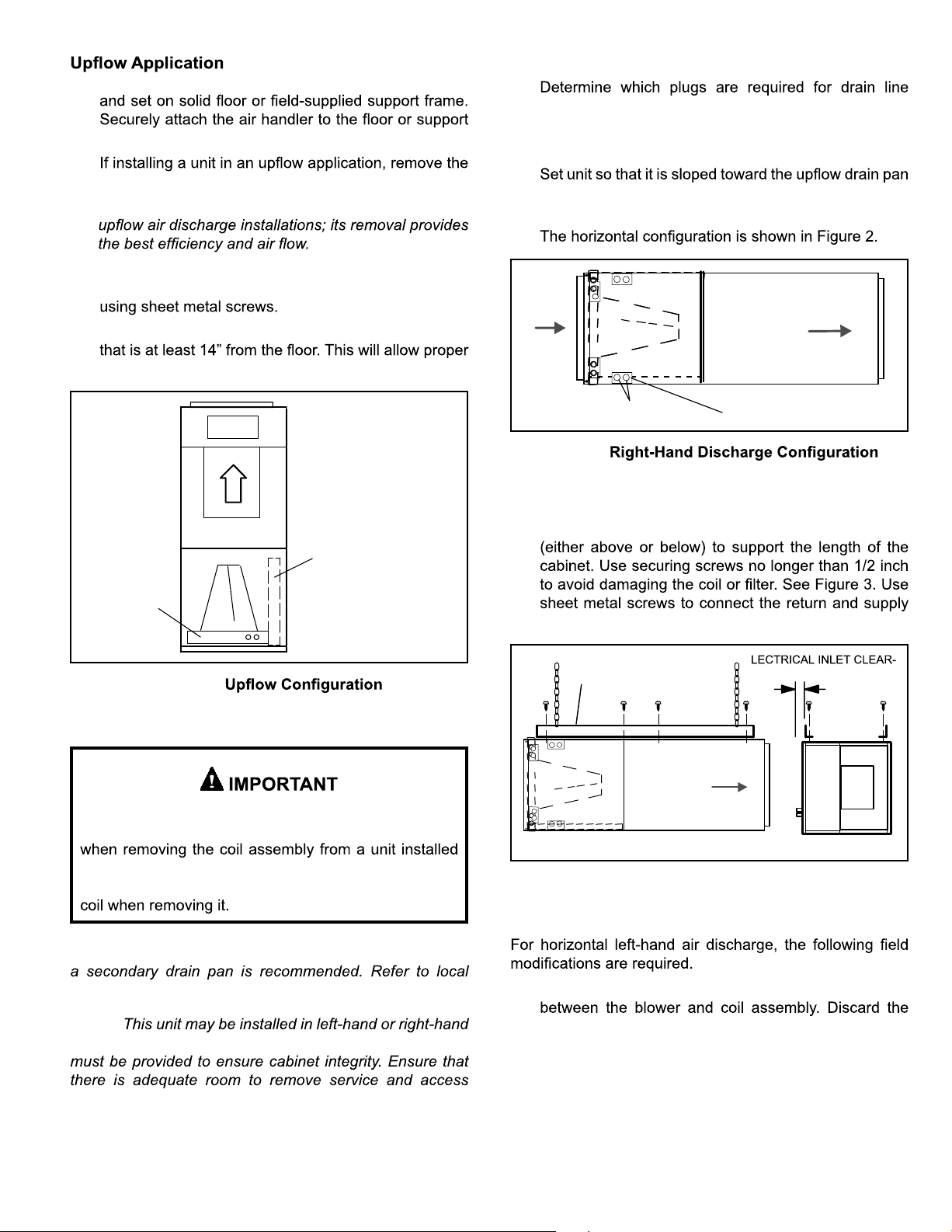

1. The air handler must be supported on the bottom only

frame.

2.

horizontal drain pan.

NOTE: The horizontal drain pan is not required in

3. Place the unit in the desired location and slope unit.

Connect return and supply air plenums as required

Right-Hand Discharge

1.

connections.

2. With access door removed, remove drain line plugs to

install drain lines.

3.

end of the unit and level from front to back of unit (see

Figure 6).

4.

4. Install units that have no return air plenum on a stand

air return.

HORIZONTAL DRAIN PAN

(MUST BE REMOVED)

UP-FLOW /

DOWN-FLOW

DRAIN PAN

Figure 1.

Horizontal Applications

AIR FLOW

Drains

RIGHT‐HAND DRAINS

PLUGS

Figure 2.

5. If the unit is suspended, the entire length of the cabinet

must be supported. If you use a chain or strap, use a

piece of angle iron or sheet metal attached to the unit

air plenums as required.

ANGLE IRON OR SHEET

METAL

MAXIMUM 1/2"

LONG SCREW

E

ANCE 4 IN. (102 MM)

AIR FLOW

When removing the coil, there is a possibility of danger

of equipment damage and personal injury. Be careful

FRONT WEIVDNEWEIV

in right- or left-hand applications. The coil may tip into

the drain pan once it is clear of the cabinet. Support the

Figure 3. Suspending Horizontal Unit

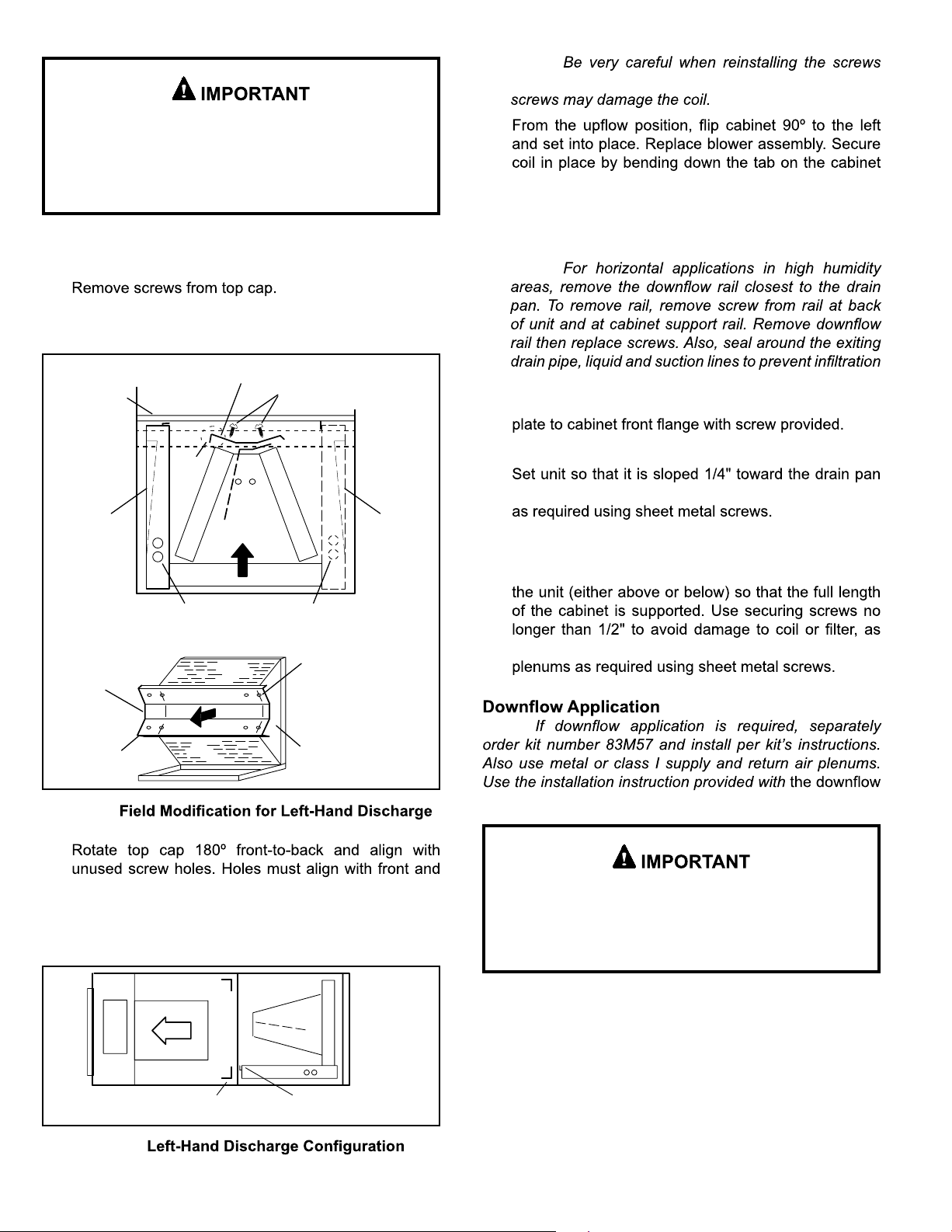

Left-Hand Air Discharge

NOTE: When the unit is installed in horizontal applications,

codes.

NOTE:

air discharge horizontal applications. Adequate support

1. Remove access panels and the corrugated padding

corrugated padding.

2. Pull the coil assembly from unit. Pull off the horizontal

drain pan.

panels if installing in the horizontal position.

3. Remove the drain plugs from back drain holes on

horizontal drain pan and reinstall them on front holes.

507787-01C mrcool.com Page 5 of 22

Page 7

NOTE:

into the coil end plate engaging holes. Misaligned

After removal of drain pan plug(s), check drain hole(s)

to verify that drain opening is fully open and free of any

debris. Also check to make sure that no debris has

fallen into the drain pan during installation that may plug

up the drain opening.

4. Rotate drain pan 180º front-to-back and install it on the

opposite side of the coil.

5.

6. Remove plastic plug from left hole on coil front end

seal and reinstall plug in back hole.

TOP CAP ROTATED TO

CORRECT POSITION

CABINET

SUPPORT

DRAIN PAN

REINSTALLED

HERE

90º

BEND

TOP CAP SCREWS

DRAIN PAN

SHIPPING

LOCATION

8.

support rail as illustrated.

9. Install the horizontal shield (-060 model) on the front

edge of the horizontal drain pan as illustrated in Figure

5.

NOTE:

of humid air.

10. Knock out drain seal plate from access door. Secure

11. Flip access door and replace it on the unit.

12.

end of the unit. Connect return and supply air plenums

13. If suspending the unit, it must be supported along the

entire length of the cabinet. If using chain or strap,

use a piece of angle iron or sheet metal attached to

REINSTALLED HERE REMOVED FROM HERE

COIL SHOWN IN UPLOAD POSITION FOR EASY CONVERSION

TOP

CAP

90º

BEND

———— DRAIN PLUGS ————

ALIGN HOLES WITH

HOLES IN COIL END

PLATE. STARTING WITH

THE ROUND HOLES ON

THIS END.

BACK COIL END SEAL

Figure 4.

7.

back coil end plates. The top cap has a 45º bend on

one side and a 90º bend on the other. The 90º bend

must be on the same side as the horizontal drain

pan as illustrated in Figure 4.

illustrated in Figure 3. Connect return and supply air

NOTE:

kit.

If electric heat section with circuit breakers (ECBA25) is

installed in a MAHM*CTA unit in a downflow application, the

circuit breakers must be rotated 180° to the UP position.

See ECBA25 installation instructions for more details.

DOWN-FLOW RAIL FRONT EDGE OF HORIZONTAL

Figure 5.

DRAIN PAN

507787-01Cmrcool.comPage 6 of 22

Page 8

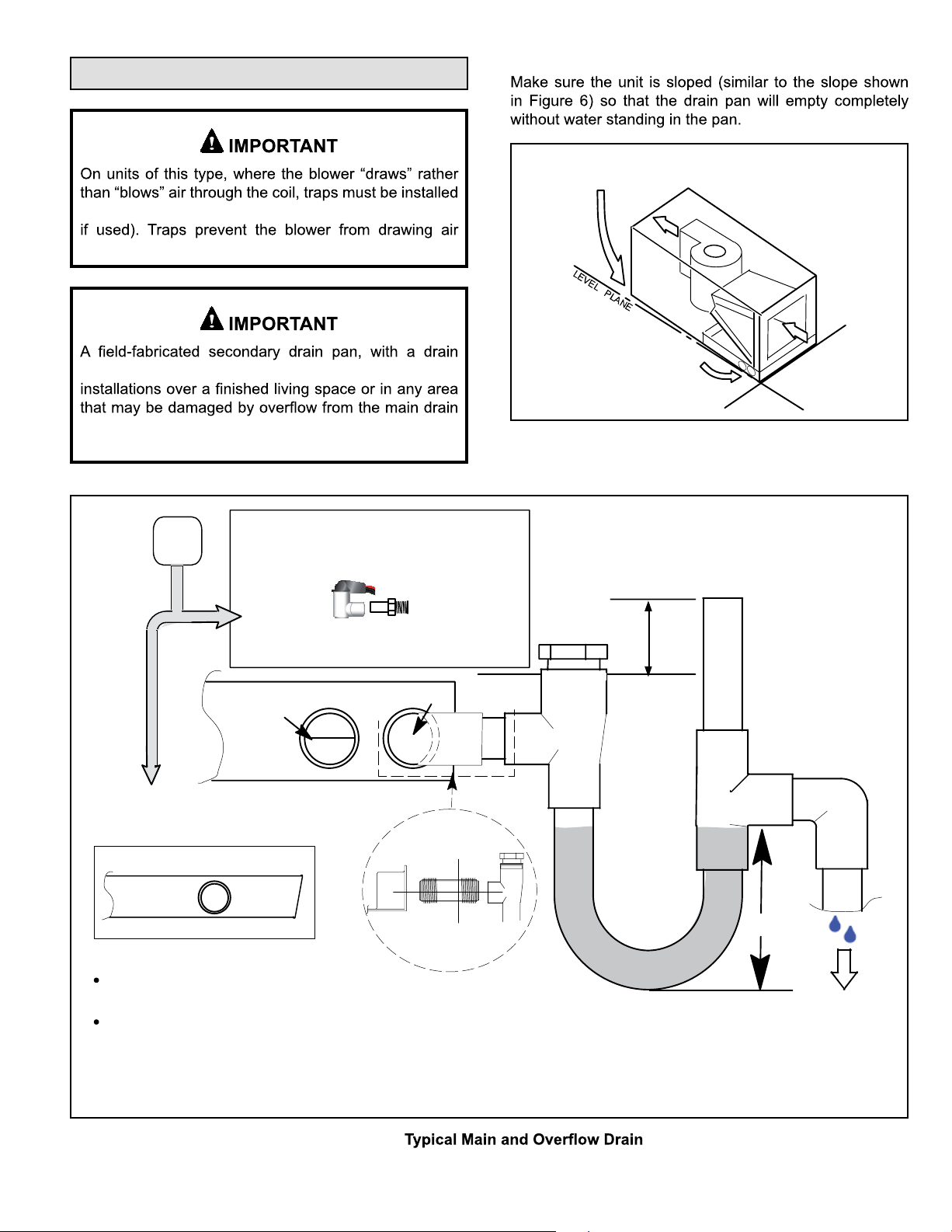

Condensate Drain

in the condensate drain lines (primary and auxiliary,

through the drain lines into the air supply.

Sloping The Unit

THIS CORNER SHOULD BE 5/8" (+/- 1/8") HIGHER

THAN DRAIN CORNER

pipe to the outside of the building, is required in all

DRAIN CORNER

pan. In some localities, local codes may require a

secondary drain pan for any horizontal installation.

ABOVE

FINISHED

SPACE?

YES

NOTE — WHEN A AIR HANDLER IS LOCATED

ABOVE A FINISHED SPACE THE SECONDARY

DRAIN PAN MUST HAVE A LARGER FOOTPRINT

THAN THE AIR HANDLER.

SECONDARY

DRAIN PAN

WHEN A COIL IS LOCATED ABOVE A FINISHED SPACE, A

3/4” (19.1MM) SECONDARY DRAIN LINE MUST BE:

CONNECTED TO SECONDARY DRAIN PAN

OR

CONNECTED TO THE OVERFLOW DRAIN OUTLET OF

THE AIR HANDLER DRAIN PAN.

TRAPS MUST BE DEEP ENOUGH TO OFFSET MAXIMUM STATIC DIFFERENCES —

GENERALLY, TWO INCHES (51MM).

1

P-TRAP 49P66 REQUIRES A LARGER INSTALLATION SPACE THAN THE J-TRAP 91P90.

2

PIPE NIPPLE PROVIDED IN BAG ASSEMBLY - SCH 80, 3/4” I. D. X 5” - 34K7401 (1): CUT THE PIPE IN HALF AND USE IT TO ROUTE THE MAIN DRAIN.

ALWAYS RUN AN OVERFLOW DRAIN LINE. IF NOT POSSIBLE TO

ROUTE OVERFLOW DRAIN LINE, INSTALL LOW VOLTAGE

OVERFLOW SWITCH KIT. WIRE KIT TO SHUT DOWN

COMPRESSOR PER INSTRUCTIONS.

COMPACT OVERFLOW SWITCH WITH 3/4” FEMALE SLIP INLET

NO

AND MALE ADAPTER, TWO PART DESIGN FOR USE WHERE

OBSTRUCTIONS PREVENT DIRECT THREADING

AIR HANDLER DRAIN PAN

OVERFLOW

DRAIN

OVERFLOW DRAIN LINE

PART #

X3169

MAIN

DRAIN

MAIN

DRAIN

CUT TO

REQUIRED

LENGTH

PROVIDED

PIPE NIPPLE

SIDE VIEW

2

Figure 6. Sloping the Unit for Proper Drainage

VENT MUST EXTEND

ABOVE HEIGHT OF

COIL DRAIN PAN BY

TWO INCHES (51MM)

CLEAN OUT

PRESS IN

(DO NOT GLUE)

1” X 3/4” X 3/4”

REDUCING

TEE WITH

PLUG

1

P-TRAP

49P66, J-TRAP #

91P90 OR ANY

PVC SCH 40 P- OR

J-TRAP 3/4”

FOR NEGATIVE PRESSURE COILS (BLOWER

AFTER COIL) TRAPS ARE REQUIRED ON ALL

DRAIN LINES CONNECTED TO COIL.

VENT

TRAP DEPTH

LEVEL PLANE

2”

(51MM)

DRAIN LINE SHOULD

SLOPE A MINIMUM OF

ONE INCH PER 10

FEET (25MM PER 3

METERS)

TO APPROVED

DRAIN

Figure 7.

507787-01C mrcool.com Page 7 of 22

Page 9

connections.

On some pans, the primary and secondary drain holes

have knockouts.

1. MAHM*CTA

includes green (main drain) and red (secondary drain)

UNSCREW PLUGS

AND CONNECT

PROPERLY SIZED

FIELD-PROVIDED

FITTINGS AND

DRAIN LINES.

DRAIN PAN

GREEN MAIN

DRAIN PLUG

RED SECONDARY

DRAIN PLUG

Figure 8. Drain Line Connections

NOTE:

7. Route the drain line to the outside or to an appropriate

drain. Drain lines must be installed so they do not block

service access to the front of the air handler. A 24”

and service access.

NOTE:

Test Condensate Drain

Test the drain pan and drain line after installation:

1.

2. Check the installed drain pan. Drain pan must be

leaking. Water must be draining from the end of the

primary drain line.

3. Correct any leaks found.

2.

and connect primary drain line to the main drain pan

connection.

NOTE:

connections on the drain pan.

3. If the secondary drain line is to be used, remove the

plug or the knockout and route the drain line so that

requirements on the secondary drain line.

4. Check again to ensure drain ports and drain pan are

free of all debris.

5. Plug and check any unused drain pan openings for

leaks or seepage from the drain pan.

6. Install a 2” trap in the main (primary) drain lines as

close to the unit as practical (see Figure 7). Make sure

NOTE:

Duct System and Filters

Duct System

of the supply plenum.

Supply and return duct system must be adequately sized

to meet the system’s air requirements and static pressure

conditioned areas or 2” minimum in unconditioned areas.

extend at least 3 ft. from the air handler before turning or

branching off plenum into duct runs. The plenum forms

Filters

Model Filter Size – in.

-018, -024, -030 15" x 20" x 1"

-036, -042, -048, -060 18" x 20" x 1"

Table 1. Unit Air Filter Size Chart

507787-01Cmrcool.comPage 8 of 22

Page 10

Brazing Refrigerant Lines

and performance may be reduced. The pressure drop

may also cause the limit to trip more frequently during

resulting in an increase in the number of service

against the data given in the appropriate Product

Service and Application Note ACC002 (August 2000).

handler. If an isolation connector is used, it must be

Field-Fabricated Return Air Duct Flange for

Horizontal Applications

A return air duct system is recommended, but not factory-

closet, run a full-size return connection to a location outside

the closet.

Cabinet and Duct Flange

CABINET

DOOR FLANGE

1−1/2

(38)

DUCT

FLANGE

3/4

(19)

1−1/2(38)

3/4

(19)

”A”

BRAKE DOWN 90 DEGREES

1/2

(13)

UNIT SIZE

-018, -024,

-030

-036, -042,

-048, -060

3/4

(19)

1/4 (6) DIA.

2−HOLES

"A"

18-3/8"

21-1/2"

BOTTOM OF

CABINET

DUCT

ADAPTER

3/4

(19)

1−1/2

(38)

Refrigerant lines must be clean, dry, refrigerant-grade

copper lines. Air handler coils should be installed

combinations.

Handle the refrigerant lines gently during the installation

restriction.

Do not remove the caps from the lines or system

connection points until connections are ready to be

completed.

absorb moisture very quickly. It is very important that the

refrigerant system be kept closed as much as possible.

DO NOT remove line set caps or service valve stub

caps until you are ready to make connections.

charge from only the high side may result in

suction tubing. Application of a brazing torch

to a pressurized system may result in

ignition of the refrigerant and oil mixture.

applying heat.

When using a high pressure gas such as

nitrogen to pressurize a refrigeration or air

conditioning system, use a regulator that

(6.9 to 13.8 kPa).

Figure 9. Cabinet and Duct Flange

507787-01C mrcool.com Page 9 of 22

Page 11

hazardous to your health.

Avoid breathing vapors or fumes from brazing

areas.

Wear gloves and protective goggles or face shield to

protect against burns.

prevent oxidation and the introduction of moisture into

the system.

NOTE:

.

1.

the lines in a direct path, avoiding unnecessary turns

and bends.

2. Make sure that the suction line is insulated over the

entire exposed length and that neither suction nor

3. To avoid damaging the rubber grommets in the cabinet

source.

NOTE:

suction line connections.

4. Connect the suction and liquid lines to the evaporator

coil. Take care to protect the cabinet and internal

components as detailed in Figure 10.

5. Braze using an alloy of silver or copper and phosphorus

NOTE: Do not use soft solder.

6.

NOTE:

7. Reinstall the rubber grommets into the refrigerant

piping panel.

NOTE:

not touching metal edges or copper tubing.

8. Make sure outdoor unit has been placed according

to the Installation Instructions and is connected to the

refrigerant lines

507787-01Cmrcool.comPage 10 of 22

Page 12

PLEASE READ IMPORTANT ISSUES CONCERNING BRAZING

p

OPERATIONS IN THE BRAZING REFRIGERANT LINES SECTION

BEFORE PROCEEDING.

NOTE - REFER TO OUTDOOR UNIT INSTALLATION

INSTRUCTIONS FOR REFRIGERANT PIPING SIZE

REQUIREMENTS.

NOTE - Use silver alloy brazing rods with five or six percent

minimum silver alloy for copper-to-copper brazing, 45

ercent alloy for copper-to-brass and copper-to-steel

brazing.

REMOVE ACCESS PANEL

A

REMOVE RUBBER PLUG FROM BOTH LIQUID

B

AND SUCTION LINES

NOTE - MAHM*CTA SERI ES UNITS USE NITROGEN OR DRY AIR

AS A HOLDIN G CHARGE. IF THERE IS NO PRESSURE WHEN

THE RUBBER PLUGS ARE REMOVED, CHECK THE COI L FOR

LEAKS BEFOR E INSTALLING.

EITHER REMOVE OR PUSH PIPE WRAPPING BACK

C

THROUGH HOLE IN PIPING PLATE BEFORE LINE

SET CONNECTION AND BRAZING.

LOW

HIGH

PIPING

PLATE

CONNECT PIPES

D

NOTE - REFRIGERANT LINE SETS

SHOULD BE ROUTED TO ALLOW

FILTER ACCESSIBILITY.

PLACE A WET RAG AGAINST PIPING

F

PLATE AND AROUND THE SUCTION

LINE CONNECTION.

BRAZE CONNECTION. ALLOW PIPE TO

G

COOL BEFORE REMOVING WET RAG

FROM CTXV SENSING BULB AND PIPING

PANEL AREA.

REPEAT PREVIOUS PROCEDURE FOR LIQUID

H

LINE.

CONNECT GAUGES AND

E

START NITROGEN FLOW

FLOW REGULATED NITROGEN (

THROUGH THE REFRIGERATION GAUGE SET INTO THE

VALVE STEM PORT CONNECTION ON THE OUTDOOR

UNIT LIQUID LINE SERVICE VALVE AND OUT OF THE

VALVE STEM PORT CONNECTION ON THE SUCTION

SERVICE VALVE.

REFER TO INSTRUCTIONS PROVIDED WITH OUTDOOR

UNIT FOR LEAK TESTING, EVACUATING AND CHARGING

PROCEDURES

AT 1 TO 2 PSIG)

NITROGEN

Figure 10. Brazing Connections

507787-01C mrcool.com Page 11 of 22

Page 13

Sealing the Unit

installed in an unconditioned area.

Electric Shock Hazard. Can cause injury or

death. Unit must be properly grounded in

If installed in an unconditioned space, sealant should be

sealing strips, caulking, or equivalent sealing method

Use duct tape and/ or Permagum to seal closed any

any gaps or holes in the cabinet.

pole contactors. Disconnect all remote electric

Electric Shock Hazard.

Can cause injury or death.

Foil-faced insulation has conductive

characteristics similar to metal. Be sure there

insulation. If the foil-faced insulation comes in

provide a path for current to pass through

to the outer metal cabinet. While the current

produced may not be enough to trip existing

electrical safety devices (e.g., fuses or circuit

breakers), the current can be enough to cause

an electrical shock hazard that could cause

personal injury or death.

Electrical Connections

supplies before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical

shock.

in one opening.

• Wiring must conform to the current National Electric

Code ANSI/NFPA No. 70, or Canadian Electric Code

Part I, CSA Standard C22.1, and local building codes.

for minimum circuit ampacity and maximum overcurrent protection size.

•

protection are to be supplied by the installer. Refer

to the air handler rating plate for maximum over-

as operating voltage. Select the proper supply circuit

17 in the National Electric Code, ANSI/NFPA No. 70 or

tables 1 through 4 in the Canadian Electric Code, Part

I, CSA Standard C22.1.

•

•

single phase, 60 cycles. For 208-volt applications, see

“208 Volt Conversion” later in this section.

507787-01Cmrcool.comPage 12 of 22

Page 14

•

voltage and line voltage. Refer to the dimension

•

provided caps to seal holes not used.

•

installed electric heat) is given in Figure 14. Refer to

for proper installation.

USE COPPER CONDUCTORS ONLY

1.

2. Remove the air handler access panel.

3.

connection box.

4.

5. Replace the air handler access panel.

TOP

SIDE

Figure 12. Control Panel Relocated to End Panel

208 Volt Conversion

1.

2. Remove the air handler access panel.

3.

panel as a reference, move the 2 connected black

transformer leads from the 240 volt terminal on the

transformer to the 208 volt terminal on the transformer.

NOTE:

in Figure 12.

SIDE

Figure 11. Electrical Connections

TOP

Electrically ground air handler. Connect

Failure to do so can result in death or electrical

shock.

208 / 240 VOLT TRANSFORMER

PRIMARY SECONDARY

240 Volts

208 Volts

Figure 13. Converting Unit from 240VAC to 208VAC

507787-01C mrcool.com Page 13 of 22

Page 15

Figure 14. Typical Wiring Diagram

MAHM*CTA

507787-01Cmrcool.comPage 14 of 22

Page 16

Figure 15. Typical Wiring Diagram MAHM*CTA

507787-01C mrcool.com Page 15 of 22

Page 17

SEE

NOTE

AIR HANDLERTHERMOSTAT

R

G

BU

Y

AIR

CONDITIONER

UNIT

COOLING‐ONLY APPLICATION

NOTE

THERMOSTAT

SEE

AIR HANDLERTHERMOSTAT

R

G

BU

W

HEAT‐ONLY APPLICATION

AIR HANDLER

R

HEAT PUMP

UNIT

AIR HANDLERTHERMOSTAT

R

G

W

BK

SEE

NOTE

COOLING APPLICATION WITH

BU

Y

AIR CONDITIONER

ELECTRIC HEAT

UNIT

NOTE - Connect common wire only if required (Refer to the appropriate thermostat installation instructions).

Figure 16.

Air Flow – Cooling Blower Speed

CONNECT COMMON

WIRE ONLY IF

REQUIRED

(REFER TO THE

APPROPRIATE

THERMOSTAT

INSTALLATION

INSTRUCTIONS)

G

BU

BK

W

HEAT PUMP APPLICATION WITH

ELECTRIC HEAT

capacity rating of the air handler.

If the outdoor unit is smaller than the maximum cooling

chart in Table 2.

supplies before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical

shock.

Change Blower Speed

1.

2. Remove the air handler access panel.

3.

4.

harness connector.

NOTE:

5. Replace all panels.

6.

507787-01Cmrcool.comPage 16 of 22

Page 18

BLOWER RELAY

NOTE - Refer to wiring diagram located on the

unit

ance (table 2).

All air data measured external to unit with 1

inch non-pleated air filter in place.

All factory settings are medium speed.

5

BLOWER RELAY

HARNESS

BLUE (MED)

2

PLASTIC CAPS

RED (L0)

BLACK (HI)

All data given while air handler is operating

with a dry DX coil.

All downflow applications run on high speed

YELLOW (COM)

when utilizing electric heat.

4-PIN

BLOWER CONNECTOR

Figure 17. Changing Blower Speed

NOTE:

Air Handler Model Blower Speed .10" WC .20" WC .30" WC .40" WC .50" WC

LOW 538 525 503 471 418

-018

-024

-030

-036

-042

-048

-060

MED 688 670 639 603 548

HIGH 919 881 855 788 710

LOW 677 673 657 629 592

MED 1011 979 942 803 742

HIGH 1106 1045 999 917 857

LOW 871 870 853 812 769

MED 1078 1057 1024 987 936

HIGH 1311 1261 1214 1154 1086

LOW 1020 972 956 909 806

MED 1276 1240 1191 1148 1086

HIGH 1559 1521 1446 1395 1327

LOW 1300 1273 1250 1211 1155

MED 1527 1493 1452 1390 1345

HIGH 1816 1756 1693 1605 1528

LOW 1257 1212 1157 1116 1053

MED LOW 1486 1448 1411 1364 1330

MED 1721 1675 1630 1594 1553

MED HIGH 1721 1675 1630 1594 1553

HIGH 1840 1794 1754 1721 1681

LOW 1098 1049 1001 926 831

MED LOW 1624 1594 1565 1520 1492

MED 1815 1783 1758 1730 1685

MED HIGH 1903 1869 1837 1809 1764

HIGH 1981 1957 1923 1893 1861

•

•

•

Table 2. MAHM*CTA

507787-01C mrcool.com Page 17 of 22

Page 19

Check-Out Procedures

3 4

NOTE:

instructions.

Pre-Start-Up Checks

• Is the air handler properly and securely installed?

•

1. Set thermostat to call for auxiliary heat (approximately

minimum of 3 minutes for all sequencers to cycle on.

2. Set the thermostat so that it does not call for heat.

Operation

• Will the unit be accessible for servicing?

• Has an auxiliary pan been provided under the unit

could cause damage?

• Have ALL unused drain pan ports been properly

plugged?

• Has the condensate line been properly sized, run,

trapped, pitched, and tested?

• Is the duct system correctly sized, run, sealed, and

insulated?

•

• Is the indoor coil factory-installed TXV or RFC properly

sized for the outdoor unit being used?

• Have all unused parts and packaging been disposed

of?

•

•

• Is the unit properly grounded and protected (fused)?

•

location?

• Are all access panels in place and secure?

Check Blower Operation

1.

come on.

Time Delay Relay

1. When cooling demand is initiated, there is a 1 second

motor-on delay.

2. After the motor-on delay expires, motor ramps up

3.

seconds.

4.

100%

1

1

SECOND

DELAY

2

CFM

COOLING

DEMAND

Figure 18. Blower Time Delay

When the thermostat calls for cooling, 24 volts is put on

relay energizes. The normally open contacts close, causing

and Y is completed, closing the circuit to the contactor in

the outdoor unit, starting the compressor and outdoor fan

motor.

On heat pumps, circuit R and O energizes the reversing

100%

CFM

45

SECS

OFF

Check Cooling Operation

1. Set thermostat to force a call for cooling (approximately

2. The outdoor unit should come on immediately and the

later.

3.

system is moving cooled air.

4. Set the thermostat 5ºF higher than the indoor

should cycle off.

reversing valve remains energized as long as the

and outdoor unit should cycle off. Air handler should cycle

off 45 seconds after the outdoor unit shuts off.

and W is completed, and the heat sequencer is energized.

on the thermostat sub-base, or they may also be connected

to a second stage on the sub-base.

507787-01Cmrcool.comPage 18 of 22

Page 20

When the thermostat calls for heating, 24 volts is applied

the circuit to the contactor in the outdoor unit, starting the

compressor and outdoor fan motor.

If the room temperature continues to decrease, the circuit

room thermostat. Circuit R-W1 energizes a heat sequencer.

REPLACED before the unit is put back into operation.

separated or torn.

Matte- or foil-faced insulation is installed in indoor

thermostat. They may also be connected to a second

heating stage W2 on the thermostat sub-base.

on the thermostat sub-base so that the electric heat control

Homeowner Maintenance

duct by the installer.

conditions (surrounding ambient temperature and humidity)

and the varying conditions inside the unit. If the insulation

inside surface temperature of the cabinet.

and outside of the cabinet can cause condensation on the

corrosion and, subsequently, component failure.

Areas of condensation on the cabinet surface are an

indication that the insulation is in need of repair.

condition, the insulation should be cut in an X pattern,

and placed back against the cabinet surface, being careful

to not overly compress the insulation so the insulation can

retain its original thickness. If such repair is not possible,

replace the insulation. If using foil-faced insulation, any

cut, tear, or separations in the insulation surface must be

•

cause of inadequate heating or cooling performance.

•

GLUE - Make sure there is

full coverage of glue on the

•

sized for it.

•

1. CUT INSULATION IN X PATTERN

2. APPLY GLUE

3. PRESS GLUED TABS AGAINST CABINET

metal or insulation so there

are no areas where air

pockets may form which

can lead to sweating.

Figure 19.

507787-01C mrcool.com Page 19 of 22

Page 21

Professional Maintenance

unit.

(less than 50psi). If the coil cannot be cleaned using

thoroughly after cleaning.

(salt).

Use of Air Handler During Construction

It is not recommended to use this air handler unit during any

Air handler units may be used for heating (heat pumps)

conditions are met:

• A room thermostat must control the air handler. The

•

maintained during construction.

•

completion.

• The air handler evaporator coil, supply fan assembly

•

according to these installation instructions.

507787-01Cmrcool.comPage 20 of 22

Page 22

Installing Contractor’s Name_______________________

_

Installing Contractor’s Phone_______________________

Job Address____________________________________

8

Temperature

1

Duct

System

5

Duct Static

Installing Date_______________________________

Air Handler Model #__________________________

Thermostat

SUPPLY

AIR

9

Disconnect

Switch

2

Line Voltage

3

Integrated Control

Blower Motor Amps

6

Electric Heat Amps

7

RETURN

AIR

DUCT SYSTEM

1

SUPPLY AIR DUCT

Sealed

Insulated (if necessary)

Registers Open and Unobstructed

RETURN AIR DUCT

Sealed

Filter Installed and Clean

Registers Open and Unobstructed

2

INTEGRATED CONTROL

Jumpers Configured Correctly (if applicable)

Appropriate Links in Place (if applicable)

3

VOLTAGE CHECK

Supply Voltage ___________

Low Voltage _____________

Electrial Connections Tight

4

DRAIN LINE

Leak Free

Filter

TOTAL EXTERNAL STATIC (dry coil)

5

Supply External Static ______ ______

Return External Static ______ ______

Total External Static = ______ ______

6

ELECTRIC HEAT AMPS____________

7

INDOOR BLOWER AMPS___________

INDOOR BLOWER CFM____________

TEMPERATURE DROP (Cooling Mode)

8

Return Duct Temperature ___________

Supply Duct Temperature − ___________

8

TEMPERATURE RISE (Heating Mode)

Return Duct Temperature __________

Supply Duct Temperature − __________

9

THERMOSTAT

Adjusted and Programmed

Operation Explained to Owner

4

Drain Line

dry coil wet coil

Temperature Drop = ___________

Temperature Rise = __________

Explained Operation of System to Homeowner

Technician’s Name:_______________________Date Start−Up & Performance Check Completed__________

Figure 20.

507787-01C mrcool.com Page 21 of 22

Page 23

Installing Contractor’s Name_______________________

_

Installing Contractor’s Phone_______________________

Job Address____________________________________

Thermostat

9

1

Duct System

2

Integrated

Control

Filter

RETURN

AIR

4

Drain Line

5

Installing Date_______________________________

Air Handler Model #__________________________

Disconnect

Switch

Line Voltage

3

1

Duct System

SUPPLY

AIR

Electric Heat Amps

6

Blower motor Amps

7

8

DUCT SYSTEM

1

SUPPLY AIR DUCT

Sealed

Insulated (if necessary)

Registers Open and Unobstructed

RETURN AIR DUCT

Sealed

Filter Installed and Clean

Registers Open and Unobstructed

2

INTEGRATED CONTROL

Jumpers Configured Correctly (if applicable)

Appropriate Links in Place (if applicable)

3

VOLTAGE CHECK

Supply Voltage ___________

Low Voltage _____________

Electrial Connections Tight

4

DRAIN LINE

Leak Free

Duct Static

Temperature

TOTAL EXTERNAL STATIC (dry coil)

5

dry coil wet coil

Supply External Static ______ ______

Return External Static ______ ______

Total External Static = ______ ______

6

ELECTRIC HEAT AMPS____________

7

INDOOR BLOWER AMPS___________

INDOOR BLOWER CFM____________

TEMPERATURE DROP (Cooling Mode)

8

Return Duct Temperature ___________

Supply Duct Temperature − ___________

Temperature Drop = ___________

8

TEMPERATURE RISE (Heating Mode)

Return Duct Temperature __________

Supply Duct Temperature − __________

Temperature Rise = __________

9

THERMOSTAT

Adjusted and Programmed

Operation Explained to Owner

Explained Operation of System to Homeowner

Technician’s Name:_______________________Date Start−Up & Performance Check Completed__________

Figure 21.

507787-01Cmrcool.comPage 22 of 22

Page 24

Signature Series

MAHM*CTA Air Handler

ELECTRICIAN and /or HVAC TECHNICIAN:

LICENSE #:

INS TA LLATION DATE:

INSTALLATION LOCATION:

SERIAL NUMBER:

The design and specifications of this product and/or manual are subject to change without prior notice.

Consult with the sales agency or manufacturer for details.

Loading...

Loading...