Page 1

Troubleshooting &

Solutions Guide

4th Generation

®

DIY

Due to updates and constantly improving performance, the information and instructions

within this manual are subject to change without notice. Please visit

www.mrcool.com/documentation to ensure you have the latest version of this manual.

E Star™

Version Date: 10-22-21

Series

Page 2

Troubleshooting

Contents

1. Safety Caution .......................................................................................................3

2. General Troubleshooting ......................................................................................4

3. Complain Record Form ..........................................................................................6

4. Information Inquiry ...............................................................................................8

5. Error Diagnosis and Troubleshooting Without Error Code ...............................11

5.1 Remote maintenance ...................................................................................11

5.2 Field maintenance .......................................................................................12

6. Quick Maintenance by Error Code ......................................................................17

7. Troubleshooting by Error Code ...........................................................................18

7.1 EH 00 / EC 51 (EEPROM parameter error diagnosis and solution) ...........18

7.2 EL 01 (Indoor and outdoor unit communication error diag. and solution).. 19

7.3 EH 02 (Zero-crossing detection error diagnosis and solution) . ................... 21

7.4 EH 03 / EC 07 (Fan speed is operating outside of the normal range

diagnosis and solution) .............................................................................. 22

7.5 EH 60/EH 61/EC 53/EC 52/EC 54/EC 56 (Open circuit or short circuit of

temperature sensor diagnosis and solution) ............................................... 25

7.6 EH 0b (Indoor PCB / Display board communication error diagnosis and

solution) ..................................................................................................... 26

7.7 EL 0C (Refrigerant Leakage Detection diagnosis and solution) ................ 27

Page 3

Troubleshooting

7.8 PC 08 (Overload current protection diagnosis and solution) .................... 28

7.9 PC 00 (IPM malfunction or IGBT over-strong current protection diagnosis

and solution) ............................................................................................. 29

7.10 PC 01 (Over voltage or too low voltage protection diag. and solution)...... 30

7.11 PC 02 (High temperature protection of IPM module or high pressure

protection diagnosis and solution) ............................................................ 31

7.12 PC 04 (Inverter compressor drive error diagnosis and solution) ............... 33

Contents

7.13 PC 03 (Low pressure protection diagnosis and solution) .......................... 34

8. Check Procedures .. ............................................................................................. 36

Page 4

1. Safety Caution

WARNING

Be sure to turn off all power supplies or disconnect all wires to avoid electric shock.

While checking indoor/outdoor PCB, please equip oneself with anti-static gloves or wrist

strap to avoid damage to the board.

WARNING

Electricity remains in capacitors even when the power supply is off.

Ensure the capacitors are fully discharged before troubleshooting.

Test the voltage between P and N on back of the main PCB with multimeter. If the voltage is lower than 36V, the

capacitors are fully discharged.

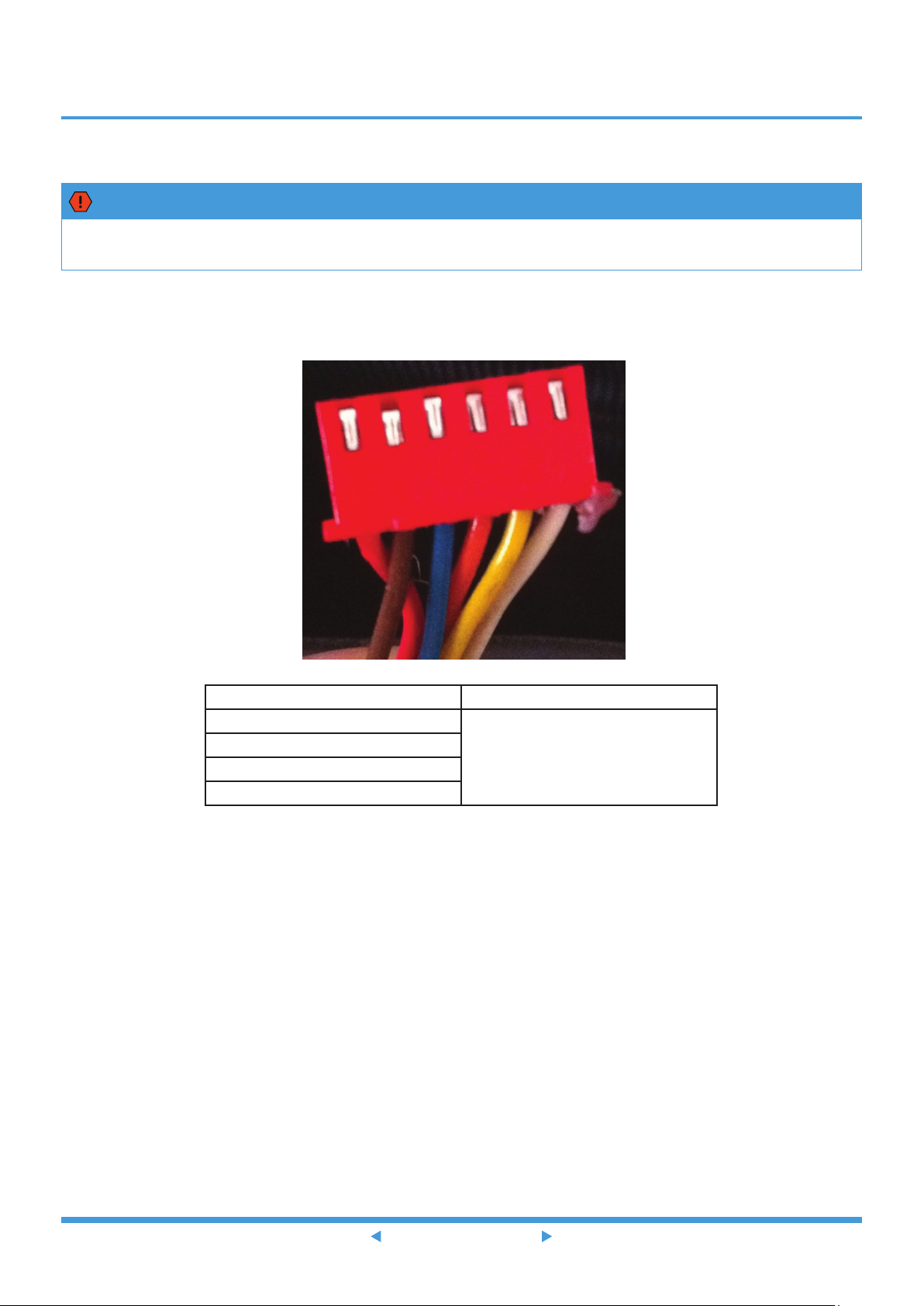

Note: This picture is for reference only. Actual appearance may vary.

Troubleshooting 3

Page 5

2. General Troubleshooting

2.1 Error Display (Indoor Unit)

When the indoor unit encounters a recognized error, the operation lamp will flash in a corresponding series, the timer

lamp may turn on or begin flashing, and an error code will be displayed. These error codes are described in the following

table:

Operation

Lamp

1 time OFF

2 times OFF

3 times OFF

4 times OFF

5 times OFF

5 times OFF

5 times OFF

5 times OFF

5 times OFF

6 times OFF

6 times OFF

12 times OFF

Timer

Lamp

LED

Display

EH 00

EL 01

EH 02

EH 03

EC 51

EC 52

EC 53

EC 54

EC 56

EH 60

EH 61

EC 07

Error Information Solution

Indoor unit EEPROM parameter error TS18

Indoor / outdoor unit communication error TS19

Zero-crossing signal detection error (for some models) TS21

The indoor fan speed is operating outside of the normal range TS22

Outdoor unit EEPROM parameter error (for some models) TS18

Condenser coil temperature sensor T3 is in open circuit or has short

circuited

Outdoor room temperature sensor T4 is in open circuit or has short

circuited

Compressor discharge temperature sensor TP is in open circuit or

has short circuited

Evaporator coil outlet temperature sensor T2B is in open circuit or

has short circuited (for free-match indoor units)

Indoor room temperature sensor T1 is in open circuit or has short

circuited

Evaporator coil temperature sensor T2 is in open circuit or has short

circuited

The outdoor fan speed is operating outside of the normal range

for some models)

TS25

TS25

TS25

TS25

TS25

TS25

TS22

9 times OFF

8 times OFF

7 times FLASH

2 times

3 times FLASH

5 times FLASH

1 time FLASH

7 times FLASH

1 times ON

FLASH PC 01

EH 0b

EL 0C

PC 00

PC 02

PC 04

PC 08

PC 03

--

Indoor PCB / Display board communication error TS26

Refrigerant leak detected TS27

IPM malfunction or IGBT over-strong current protection TS29

Over voltage or over low voltage protection TS30

High temperature protection of IPM module or High pressure

protection (for some models)

Inverter compressor drive error TS33

Current overload protection (for some models) TS28

Low pressure protection (for some models) TS34

Indoor units mode conflict (match with multi outdoor unit)

TS31

--

Troubleshooting 4

Page 6

For other errors:

The display board may show a garbled code or a code undefined by the service manual. Ensure that this code is not a

temperature reading.

Troubleshooting:

Test the unit using the remote control. If the unit does not respond to the remote, the indoor PCB requires replacement.

If the unit responds, the display board requires replacement.

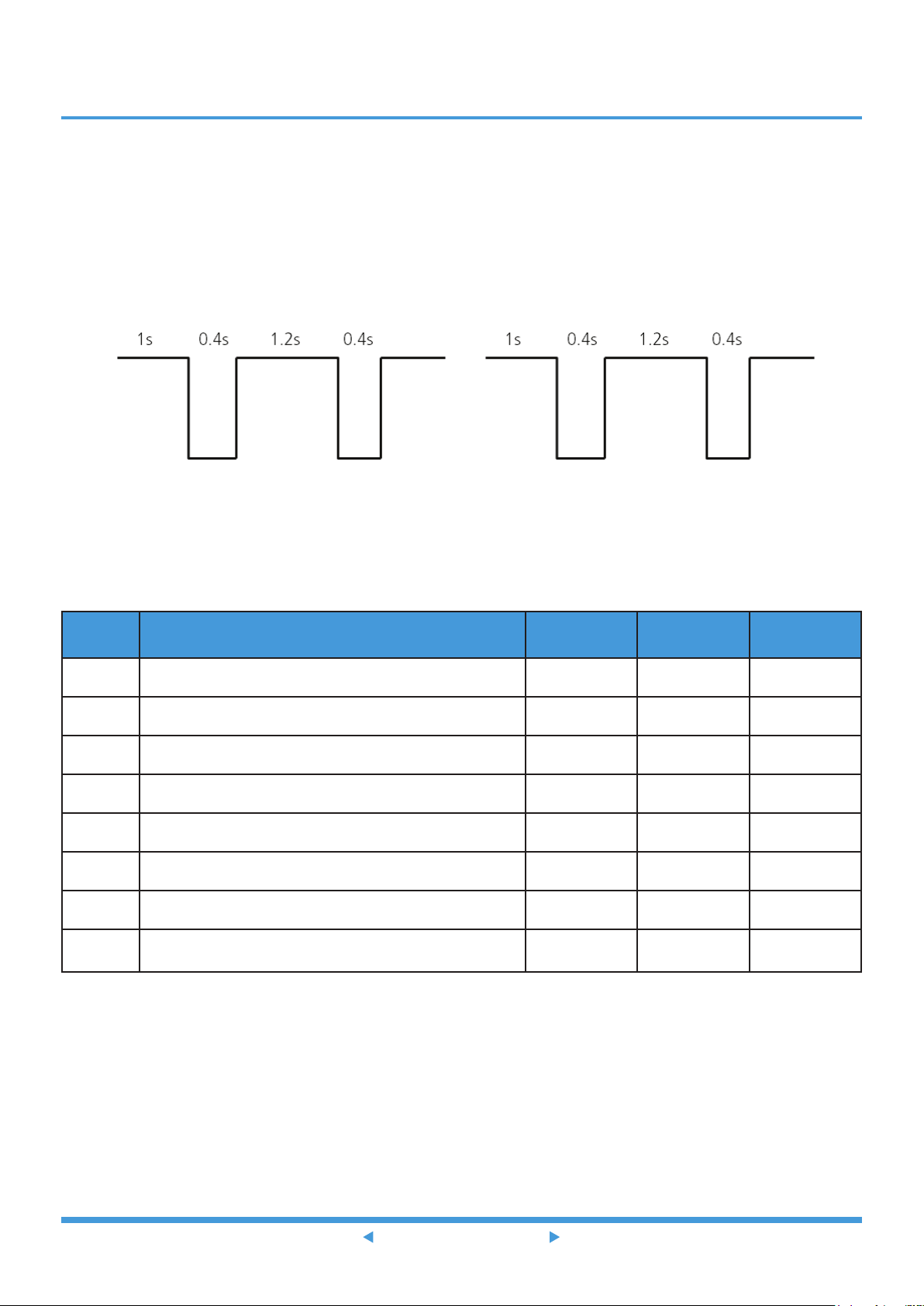

LED flash frequency:

... ...

2.2 Error Display (For Some Outdoor Units)

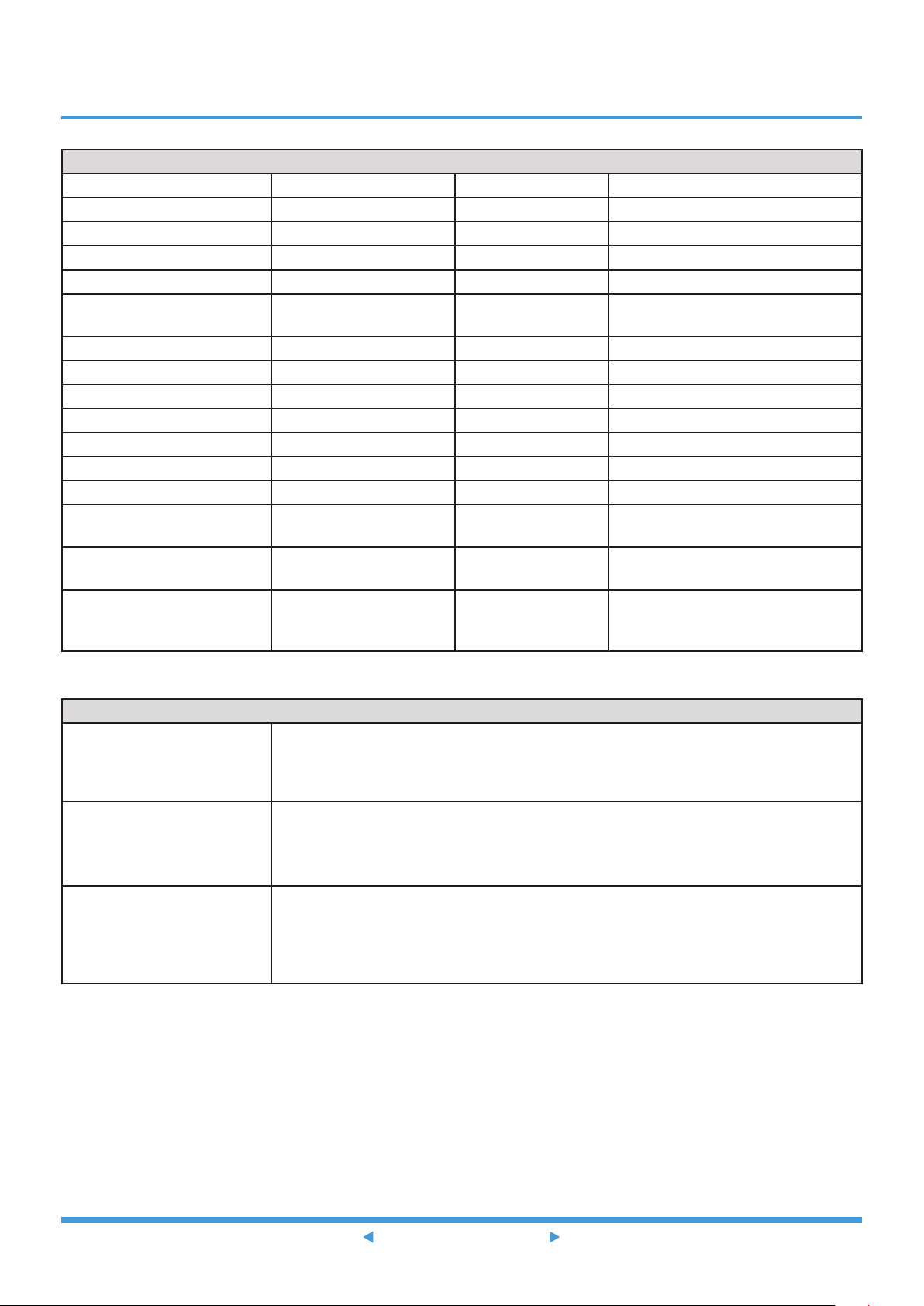

There are 2 LED lights (RED color and GREEN color) welded in outdoor main board. After power on, LED show different

actions when encounter different problems.

No. Problem LED(GREEN) LED(RED) Solution

1 Standby normally

2 Operate normally

3 Compressor driven chip EEPROM parameter error

4 IPM malfunction or IGBT over-strong current protection

5 Over voltage or too low voltage protection

6 Inverter compressor drive error

7 Inverter compressor drive error

8

Communication error between outdoor main chip and

compressor driven chip

ON OFF -

OFF ON -

ON FLASH

Flash OFF

ON ON

OFF FLASH

Flash LIGHT

flash FLASH

TS19

TS30

TS31

TS34

TS34

TS19

Troubleshooting 5

Page 7

3. Complain Record Form

Complain Record Form

Request No.: Date:

Installation Date: Service Date:

Customer Information

Name Telephone No.

Home Address

Email

Product Information

Indoor Unit Model Outdoor Unit Model

Serial No. of indoor unit

Serial No. of outdoor unit

Working Mode □Cooling □Heating □Fan only □Dry

Setting temperature °C / °F Fan speed

Temperature of air inlet °C / °F

Temperature of air

outlet

□Turbo □High □Medium □Low

□Auto

°C / °F

Installation / Condition Information

Indoor temperature °C / °F Indoor humidity %RH

Outdoor temperature °C / °F Outdoor humidity %RH

Length of Connecting pipe Pipe diameter Gas pipe: Liquid pipe:

Length of Wiring wire diameter

System Running Pressure MPa or Bar or PSI

Room size (L*W*H)

Photo of Installation of Indoor unit

(Photo #1)

Failure Description

Error Code of Indoor unit

Unit does not start

Remote control does not work

Indoor display shows nothing

No cooling or heating at all

Less cooling or heating

Unit starts but stops shortly

High noise

High vibration

Photo of Installation

of Outdoor unit

(Photo #2)

Code of Outdoor

PCB

Troubleshooting 6

Page 8

Parameter Checking information by Remote controller

Displaying code Displaying code meaning Display value Display value meaning

T1 Room temperature

T2 Indoor coil temperature

T3 Outdoor coil temperature

T4 Ambient temperature

Tb

TP Discharge temperature

TH Sunction temperature

FT Targeted Frequency

Fr Actual Frequency

IF Indoor fan speed

OF Outdoor fan speed

LA EXV opening steps

CT

ST

A0, A1, b0, b1, b2, b3, b4,

b5, b6, dL, Ac, Uo, Td, dA,

dS, dT

Outlet temperature of

indoor coil

Compressor continuous

running time

Causes of compressor

stop.

Reserved

□Approved

□More Proof needed

□Rejected

Approval from Manufacturer

Troubleshooting 7

Page 9

4. Information Inquiry

• To enter information inquiry status, complete the following procedure within ten seconds:

• Press LED (or DO NOT DISTURB) 3 times.

• Press SWING (or AIR DIRECTION) 3 times.

• Finish 1 and 2 within 10 seconds, you will hear beeps for two seconds, which means the unit goes into parameter

checking mode.

• Use the LED (or DO NOT DISTURB) and SWING (or AIR DIRECTION) buttons to cycle through information displayed.

• Pressing LED (or DO NOT DISTURB) will display the next code in the sequence. Pressing SWING (or AIR

DIRECTION) will show the previous.

• The following table shows information codes. The screen will display this code for two seconds, then the information

for 25 seconds.

Troubleshooting 8

Page 10

Displayed code Explanation

Displayed

value

Meaning Additional Notes

T1

T2

T3

T4

Tb

TP

TH

FT

Fr

IF

OF

Room temperature

Indoor coil

temperature

Outdoor coil

temperature

Ambient

temperature

Outlet temperature

of indoor coil

Discharge

temperature

Suction temperature

Targeted frequency

Actual frequency

Indoor fan speed

Outdoor fan speed

-1F,-1E,-1d,-1c,1b,-1A

-19—99

A0,A1,…A9

b0,b1,…b9

c0,c1,…c9

d0,d1,…d9

E0,E1,…E9

F0,F1,…F9

0

1,2,3,4

14-FF

-25,-24,-23,-22,

-21,-20

-19—99

100,101,…109

110,111,…119

120,121,…129

130,131,…139

140,141,…149

150,151,…159

OFF

Low speed, Medium

speed, High speed,

Turbo.

Actual fan speed is

equal to the display

value converted to

decimal value and

multiplied by 10. This

is measured in RPM.

1. All displayed temperatures

use actual values.

2. All temperatures are

displayed in °C regardless

of remote used.

3. T1, T2, T3, T4, and T2B

display ranges from -25 to

70 °C. TP display ranges

from -20 to 130 °C.

4. The frequency display

ranges from 0 to 159HZ.

5. If the actual values exceed

or fall short of the defined

range, the values closest

to the maximum and

minimum values will be

displayed.

N/A

Used for some large capacity

motors.

Used for some small capacity

motors.

The display value is 14-FF

(hexadecimal). The

corresponding fan speed

ranges from 200 to 2550 RPM.

LA

CT

ST

EXV opening angle 0-FF

Compressor

continuous running

time

Causes of

compressor stop

0-FF 0-255 minutes

0-99

Actual EXV opening

value is equal to

the display value

converted to decimal

value and then

multiplied by 2.

For a detailed

explanation, contact

technical support.

Troubleshooting 9

-

If the actual value exceeds

or falls short of the defined

range, the value closest to the

maximum and minimum will

be displayed.

-

Page 11

Displayed code Explanation

A0

A1

0

1

2

3

4

5

Reserved

6

Displayed

value

0-FF

2-28

5-20

Meaning Additional Notes

- -

L

A

U

T

A

5

T

5-25

Troubleshooting 10

Page 12

5. Error Diagnosis and Troubleshooting Without Error Code

WARNING

Be sure to turn off unit before any maintenance to prevent damage or injury.

5.1 Remote maintenance

SUGGESTION: When troubles occur, please check the following points with customers before field maintenance.

No. Problem Solution

1 Unit will not start TS13 - TS14

2 The power switch is on but fans will not start TS13 - TS14

3 The temperature on the display board cannot be set TS13 - TS14

4 Unit is on but the wind is not cold (hot) TS13 - TS14

5 Unit runs, but shortly stops TS13 - TS14

6 The unit starts up and stops frequently TS13 - TS14

7 Unit runs continuously but insufficient cooling (heating) TS13 - TS14

8 Cool can not change to heat TS13 - TS14

9 Unit is noisy TS13 - TS14

Troubleshooting 11

Page 13

5.2 Field maintenance

1 Unit will not start TS15 - TS16

2 Compressor will not start but fans run TS15 - TS16

3 Compressor and condenser (outdoor) fan will not start TS15 - TS16

4 Evaporator (indoor) fan will not start TS15 - TS16

5 Condenser (Outdoor) fan will not start TS15 - TS16

6 Unit runs, but shortly stops TS15 - TS16

7 Compressor short-cycles due to overload TS15 - TS16

8 High discharge pressure TS15 - TS16

9 Low discharge pressure TS15 - TS16

10 High suction pressure TS15 - TS16

Problem Solution

11 Low suction pressure TS15 - TS16

12 Unit runs continuously but insufficient cooling TS15 - TS16

13 Too cool TS15 - TS16

14 Compressor is noisy TS15 - TS16

15 Horizontal louver cannot revolve TS15 - TS16

Troubleshooting 12

Page 14

1. Remote Maintenance

Possible causes of trouble

Unit will not start

The power switch is on but fans will not start

The temperature on the display board cannot be set

Unit i s on but the wind i s not col d (hot)

Unit runs , but shortly stops

The unit sta rts up and stops frequently

Unit runs connuousl y but insu ci ent cooling (hea ng)

Cool can not change to heat

Unit i s noi s y

Refrigerant Circuit

Electrical Circuit

nd defrosng frequently

Fan mode

Broken remote control

The main power tripped

Power failure

Loose connecons

Faulty transformer

The remote control is powered o

The voltage is too high or too low

Dirty condenser ns

Dirty air ter

The ambient temperature is too high/low when the mode is cooling/heang

The seng temperature is higher/lower than the room's(cooling/heang)

SILENCE funcon is acvated (oponal funcon)

Frosng a

Test method / remedy

Inspect connecons - ghten

Close the power switch

Test voltage

Change the transformer

Replace the baery of the remote control

Test voltage

Troubleshooting 13

Adjust the seng temperature

Turn the AC later

Clean

Clean or replace

Replace the remote control

Adjust to cool mode

Turn o SILENCE funcon.

Turn the AC later

Page 15

1. Remote Maintenance

Possible causes of trouble

Unit will not start

The power switch is on but fans will not start

The temperature on the display boar d cannot be set

Unit i s on but the wind i s not col d (hot)

Unit runs , but shortly stops

The unit sta rts up and stops frequently

Unit runs connuousl y but insu ci ent cooling (heang)

Cool can not change to heat

Unit i s noi s y

Others

Heavy load condion

Loosen hold down bolts and / or screws

Bad airproof

The air inlet or outlet of either unit is blocked

Shipping plates remain aached

Interference from cell phone towers and remote boosters

Test method / remedy

Check heat load

Tighten bolts or screws

Close all the windows and doors

Remove the obstacles

Reconnect the power or press ON/OFF buon on remote control to restart operaon

Remove them

Troubleshooting 14

Page 16

2. Field Maintenance

Possible causes of trouble

Electrical Circuit

Unit will not start

Compressor will not start but fans run

Compressor and condens er (outdoor) fa n will not start

Evaporator (indoor ) fan will not start

Condenser (Outdoor) fan will not sta rt

Unit runs , but shortly stops

Compressor s hort-cycl es due to overl oad

High dis charge pressure

Low dis cha rge pressure

High s ucon pr essure

Low suc on pressure

Unit runs connuous ly but insu cient cooling

Too cool

Compress or is noi sy

Hori zontal louver ca n not revolve

Blown fuse or varistor

Power failure

Loose connecons

Shorted or broken wires

Safety device opens

Faulty transformer

Faulty thermostat / room temperature sensor

Wrong seng place of temperature sensor

Shorted or open capacitor

Faulty magnec contactor for compressor

Faulty magnec contactor for fan

Low voltage

Faulty stepping motor

Shorted or grounded compressor

Shorted or grounded fan motor

Test method / remedy

Test voltage

Inspect fuse type & size

Inspect connecons - ghten

Test connuity of safety device

Test circuits with tester

Test connuity of thermostat / sensor & wiring

Place the temperature sensor at the central of the air inlet grille

Troubleshooting 15

r

Check resistance with mulmeter

Check control circuit with tester

Check capacitor with tester

Test connuity of coil & c ontacts

Test connuity of coil & c ontacts

Test voltage

Check resistance with mulmeter

Replace the stepping moto

Page 17

2.Field Maintenance

Possible causes of trouble

Compressor and condens er (outdoor) fa n will not

start

Recfy piping so as not to contact each other or with external

plate

Refrigerant Circuit

Others

Unit will not start

Compressor will not start but fans run

Evaporator (i ndoor) fan will not s tart

Condenser (Outdoor) fan will not sta rt

Unit runs , but shortly stops

Compressor s hort-cycl es due to overl oad

High dis charge pressure

Low dis cha rge pressure

High s ucon pr essure

Low suc on pressure

Unit runs connuous ly but insu cient cooling

Too cool

Compress or is noi sy

Hori zontal louver ca n not revolve

ansion valve obstructed

Short cyc ling of condensing air

High temperature condensing medium

Air or incompressible gas in refrigerant cycle

Dirty or parally blocked condenser

Insucient air through evaporator c oil

Overcharge of refrigerant

Dirty evaporator coil

Restricted liquid line

Dirty air ter

Shortage of refrigerant

Compressor stuck

Insucient condensing medium

Exp

Inecient compressor

Broken compressor internal parts

Expansion valve or capillary tube closed completely

Leaking power element on expansion valve

Poor installaon of feeler bulb

Heavy load condion

Loosen hold down bolts and / or screws

Shipping plates remain aached

Poor choices of capacity

Contact of piping with other piping or external plate

Test method / remedy

Clean or replace

Clean coil

Check fan

Replace restricted part

Leak test

Replace the compressor

Change charged refrigerant volume

Troubleshooting 16

ve

Replace val

Remove obstruc on to air ow

Remove obstruc on in air or water ow

Clean condenser or remove obstacle

Purge, evacuate and recharge

Remove obstruc on in air or water ow

Replace valve

Test compressor eciency

Replace compressor

Fix feeler bulb

Check heat load

Replace valve

Choose AC of lager capacity or add the number of AC

Tighten bolts or screws

Remove them

Page 18

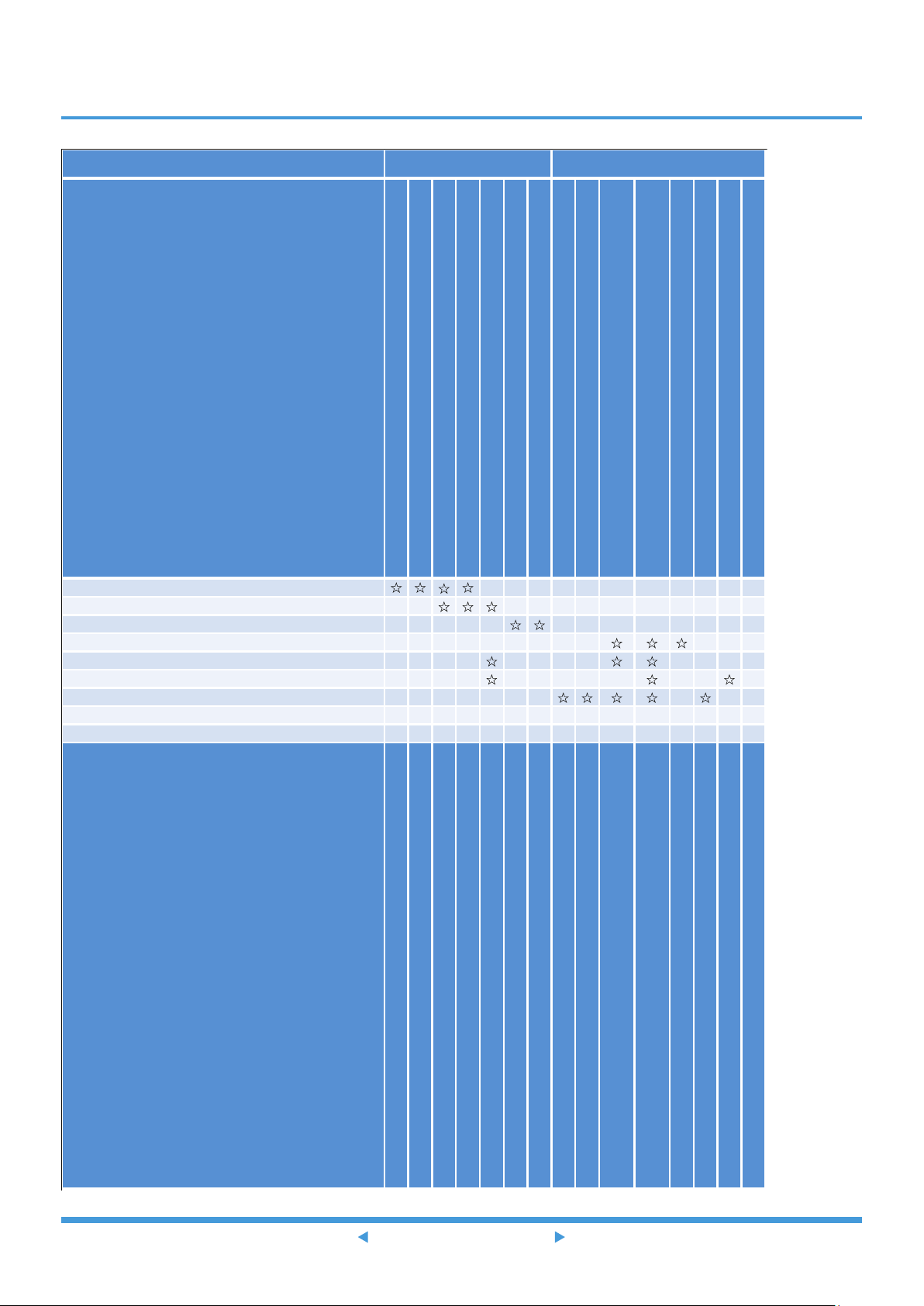

6. Quick Maintenance by Error Code

If you do not have the time to test which specific parts are faulty, you can directly change the required parts according

the error code.

You can find the parts to replace by error code in the following table.

Error Code

Part requiring replacement

EH 00 EL 01 EH 02 EH 03 EH 60 EH 61 EH 0b EL 0C PC 08

Indoor PCB

Outdoor PCB x x x x x x x

Display board x x x x x x x x

Indoor fan motor x x x x x x x x

T1 sensor x x x x x x x x

T2 Sensor x x x x x x x

Reactor x x x x x x x x

Compressor x x x x x x x x

Additional refrigerant x x x x x x x x

Part requiring

replacement

Indoor PCB

Outdoor PCB

Indoor fan motor x x x x x x x x x x x

Outdoor fan motor x x x x x x x

EC 53 EC 52

x x x x x x x x x x x

EC 54 EC 56 EC 51 EC 07 PC 00 PC 01 PC 02 PC 03 PC 04

x

T3 Sensor x x x x x x x x x x

T4 Sensor x x x x x x x x x x

TP Sensor x x x x x x x x x x

T2B Sensor x x x x x x x x x x

Reactor x x x x x x x x x x

Compressor x x x x x x x x x

IPM module board x x x x x x x

High pressure protector x x x x x x x x x x

Low pressure protector x x x x x x x x x x

Additional refrigerant x x x x x x x x x x

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 17

Page 19

7. Troubleshooting by Error Code

7.1 EH 00 / EC 51 (EEPROM parameter error diagnosis and solution)

Description: Indoor or outdoor PCB main chip does not receive feedback from EEPROM chip.

Recommended parts to prepare:

• Indoor PCB

• Outdoor PCB

Troubleshooting and repair:

Shut off the power supply and

turn it on 2 minutes later.

Is it still displaying

the error code?

YES

Replace the indoor main

PCB(EH 00) /outdoor main

PCB(EC 51).

Remarks:

EEPROM: A read-only memory whose contents can be erased and reprogrammed using a pulsed voltage.

The location of the EEPROM chip on the indoor and outdoor PCB is shown in the following two images:

The unit is operating normally. NO

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole. This pictures are only for reference, actual appearance may vary.

Troubleshooting and repair of compressor driven chip EEPROM parameter error and communication error

between outdoor main chip and compressor driven chip are same as EC 51.

Troubleshooting 18

Page 20

7.2 EL 01 (Indoor and outdoor unit communication error diagnosis and solution)

Description: Indoor unit can not communicate with outdoor unit

Recommended parts to prepare:

• Indoor PCB

• Outdoor PCB

• Short-circuited component

Troubleshooting and repair:

Power off, then restart the unit after 2

minutes.

Does the error code

disappear ?

Yes

Check the wiring connection

between indoor and outdoor

unit, are they good?

Yes

Measure the DC voltage between N/L2

and S (Black pin to N/LN, Red pin to S).

For units with main PCB and IPM board

Check the AC voltage of L, N

output to IPM board, is it same

Unplug all the high voltage

components connected to main

PCB such as 4 way valve, heater,

AC fan one by one to check their

resistance.

Unplug electronic expansion valve.

Check if the DC 5V, 12V to main

both

as power input?

Yes

Is there any component

short circuit?

No

Check the DC 5V, 12V

from IPM board to main

PCB, are they normal?

No

PCB are OK

No

No

No

For units without W

Solved

Correct the connection or

change wires

The value is alternative

from negative to positive

The value is fixed and close

to 0

The value is always positive

wire

Check the wiring connection

from outdoor terminal to

outdoor PCB and wiring

between PCBs if there is

more than 1 PCB

Replace main PCBNo

Yes

Yes

Replace short- circuited

component and outdoor

Yes

For units

with W wire

For units with only one

Replace outdoor PCB

Replace short-circuited

component and main

PCB

PCB

Replace coil of electronic

expansion valve

Check the wiring connection

from indoor terminal to indoor

PCB, are they good?

Turn on the unit, check if W

and 1(L) is connected?

Yes

PCB

Yes

Yes

No

Yes

Check if the power LED is

Unplug all the high voltage

components connected to main

PCB such as 4 way valve, heater,

AC fan one by one to check their

resistance. Is there any component

Unplug electronic expansion valve.

Check if power LED is on ?

Replace indoor PCB

No

on?

No

short circuit?

No

Replace IPM board

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 19

Page 21

Remarks:

• Use a multimeter to test the DC voltage between 2 port (or S or L2 port) and 3 port (or N or S port) of outdoor unit.

The red pin of multimeter connects with 2 port (or S or L2 port) while the black pin is for 3 port (or N or S port) .

• When AC is normal running, the voltage is moving alternately as positive values and negative values

• If the outdoor unit has malfunction, the voltage has always been the positive value.

• While if the indoor unit has malfunction, the voltage has always been a certain value.

S and N

or

L2 and S

or

2 and 3

• Use a multimeter to test the resistance of the reactor which does not connect with capacitor.

• The normal value should be around zero ohm. Otherwise, the reactor must have malfunction.

Note: The picture and the value are only for reference, actual condition and specific value may vary.

Troubleshooting 20

Page 22

7.3 EH 02 (Zero crossing detection error diagnosis and solution)

Description: When PCB does not receive zero crossing signal feedback for 4 minutes or the zero crossing signal time

interval is abnormal.

Recommended parts to prepare:

• Connection wires

• PCB

Troubleshooting and repair:

Check the connections and

power supply.

Is it normal?

YES

Indoor main PCB is defective. Replace

indoor main PCB.

NO

Correct the connections. Turn on the

unit when the power supply is good.

Note: EH 02 zero crossing detection error is only valid for the unit with AC fan motor, for other models, this

error is invalid.

Troubleshooting 21

Page 23

7.4 EH 03 / EC 07 (Fan speed is operating outside of normal range diagnosis and solution)

Description: When indoor / outdoor fan speed keeps too low or too high for a certain time, the LED displays the failure

code and the AC turns off.

Recommended parts to prepare:

• Connection wires

• Fan assembly

• Fan motor

• PCB

Troubleshooting and repair:

Power off, then restart the unit after 2 minutes.

Does a problem remain? The unit is operating normallyNO

YES

Shut off the power supply, Rotate

the fan by hand.

Does it turn easily? Find the cause of the problem and resolve itNO

YES

Check the wiring of fan motor.

Is it improperly wired?

YES

Measure the voltage for

the fan motor from the PCB.

Is it within normal parameters?

YES

Replace the fan motor

Ensure proper connections

Replace the PCBNO

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 22

Page 24

Index:

1. Indoor or Outdoor DC Fan Motor(control chip is in fan motor)

Power on and when the unit is in standby, measure the voltage of pin1-pin3, pin4-pin3 in fan motor connector. If the

value of the voltage is not in the range showing in below table, the PCB must has problems and need to be replaced.

• DC motor voltage input and output (voltage: 220-240V~):

No. Color Signal Voltage

1 Red Vs/Vm 280V~380V

2 --- --- ---

3 Black GND 0V

4 White Vcc 14-17.5V

5 Yellow Vsp 0~5.6V

6 Blue FG 14-17.5V

• DC motor voltage input and output (voltage: 115V~):

No. Color Signal Voltage

1 Red Vs/Vm 140V~190V

2 --- --- ---

3 Black GND 0V

4 White Vcc 14-17.5V

5 Yellow Vsp 0~5.6V

6 Blue FG 14-17.5V

2. Outdoor DC Fan Motor (control chip is in outdoor PCB)

Release the UVW connector. Measure the resistance of U-V, U-W, V-W. If the resistance is not equal to each other, the

fan motor must has problems and need to be replaced. otherwise the PCB must has problems and need to be replaced.

Troubleshooting 23

Page 25

3. Indoor AC Fan Motor

Power on and set the unit running in fan mode at high fan speed. After running for 15 seconds, measure the voltage of

pin1 and pin2. If the value of the voltage is less than 100V(208~240V power supply) or 50V (115V power supply), the

PCB must has problems and need to be replaced.

Troubleshooting 24

Page 26

7.5 EH 60/EH 61/EC 53/EC 52/EC 54/EC 56 (Open circuit or short circuit of temperature

sensor diagnosis and solution)

Description: If the sampling voltage is lower than 0.06V or higher than 4.94V, the LED displays the failure code.

Recommended parts to prepare:

• Connection wires

• Sensors

• PCB

Troubleshooting and repair:

Check the connection between

temperature sensor and PCB.

Is it properly wired? Ensure proper connections.NO

YES

Measure the resistance value

of the sensor.

Is it within acceptable

parameters?

YES

Replace indoor PCB (EH 60/EH 61) or

outdoor PCB (EC 53/EC 52/EC 54/EC 56)

Replace the sensor .NO

Troubleshooting 25

Page 27

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole. This picture and the value are only for reference, actual appearance

and value may vary

7.6 EH 0b (Indoor PCB / Display board communication error diagnosis and solution)

Description: Indoor PCB does not receive feedback from the display board.

Recommended parts to prepare:

• Communication wire

• Indoor PCB

• Display board

Troubleshooting and repair:

Power off, then restart the unit 2 minutes

Check the wirings and connections

Are all the connections

Replace the indoor main PCB

later

Is it still displaying

the error code?

YES

?

good

YES

NO

NO

The unit functions normally

Ensure a proper connection

Does the error still exist?

Replace the display board

Troubleshooting 26

Page 28

7.7 EL 0C (Refrigerant Leakage Detection diagnosis and solution)

Description: Define the evaporator coil temperature T2 of the compressor just starts running as Tcool.

In the beginning 5 minutes after the compressor starts up, if T2< Tcool-1°C(1.8°F) does not keep continuous 4 seconds

and compressor running frequency higher than 50Hz does not keep for 3 minutes, and this situation happens 3 times,

the LED displays the failure code and AC turns off.

Recommended parts to prepare:

• T2 sensor

• Indoor PCB

• Additional refrigerant

Troubleshooting and repair:

Power off, then restart the unit 2 minutes later.

Does a problem remain?

YES

Put your hands in front of the

indoor air outlet.

Is there cool

air blowing out from

indoor air outlet?

NO

Check system for leakages.

NO

Are any leakages

present?

NO

Check System for blockages and

clear blockages if present.

YES

YES

Check the T2 sensor.

Is it securely

attached?

Repair the leakage and

recharge the refrigerant.

YES

Replace the

indoor PCB

Troubleshooting 27

Page 29

7.8 PC 08 (Overload current protection diagnosis and solution)

Description: An abnormal current rise is detected by checking the specified current detection circuit.

Recommended parts to prepare:

• Outdoor PCB

• Connection wires

• Compressor

Troubleshooting and repair:

Check the power supply.

Is it in working order?

YES

Check system for blockages.

Do any exist?

No

Check the compressor resistance values.

Are they within acceptable

parameters?

YES

Check the connections and wires.

Are they properly connected ?

YES

Yes

NO

Stop the unit.NO

Clear the blockage.

Replace the compressor.NO

Ensure proper connections or

replace the wires.

Check the reactor.

Is it in working order?

YES

Replace the outdoor unit.

Replace outdoor PCB.NO

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 28

Page 30

7.9 PC 00(IPM malfunction or IGBT over-strong current protection diagnosis and solution)

Description: When the voltage signal the IPM sends to the compressor drive chip is abnormal, the LED displays the

failure code and the AC turns off.

Recommended parts to prepare:

• Connection wires

• IPM module board

• Outdoor fan assembly

• Compressor

• Outdoor PCB

Troubleshooting and repair:

Check the wiring between

PCB and compressor.

Does an error exist?

NO

Check the IPM.

Is it in working order?

YES

Check the outdoor fan and the

outdoor unit ventilation.

Is it in working order?

YES

Check the compressor

resistance values.

YES

NO

NO

Ensure proper connections or

replace the wires and connectors.

Replace the IPM board or

replace the outdoor PCB.

Please refer to the solution of the “Fan

Speed is out of control” malfunction.

Are they within

acceptable parameters?

YES

Replace the outdoor PCB.

NO

Replace the compressor.

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 29

Page 31

7.10 PC 01(Over voltage or too low voltage protection diagnosis and solution)

Description: Abnormal increases or decreases in voltage are detected by checking the specified voltage detection circuit.

Recommended parts to prepare:

• Power supply wires

• IPM module board

• PCB

• Reactor

Troubleshooting and repair:

Check the power supply.

Is it in working order? Turn off the unit.NO

YES

Check the connections and wires.

Are they in working order?

YES

Power on and measure the

voltage between P and N.

While the unit is in standby,

is the voltage between P and N is around

DC 310V, 340V or 380V? When start up

the unit, is it in 220V~400V?

YES

Check the reactor.

Is it in working order? Replace outdoor PCB.

NO

NO

Ensure proper connections or

replace the wires.

Replace the IPM boardNO

YES

Replace the reactor.

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 30

Page 32

7.11 PC 02(High temperature protection of IPM module or High pressure protection

diagnosis and solution)

Description: If the temperature of IPM module is higher than a certain value, the LED displays the failure code.

For some models with high pressure switch, outdoor pressure switch cut off the system because high pressure is higher

than 4.4 MPa, the LED displays the failure code.

Recommended parts to prepare:

• Connection wires

• Outdoor PCB

• IPM module board

• High pressure protector

• System blockages

Troubleshooting and repair:

Check the fastening screws on the

PCB and IPM radiator.

Are they

fixed tightly?

NO

Tighten the screws and apply

silicon grease.

YES

Replace the outdoor

control PCB.

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 31

Page 33

Are the high pressure switch

and main control boar wired

correctly

? Are the high pressure switch

and main control boar wired

correctly

?

Method

:

Disconnect the plug

.

Measure the resistance of the

high pressure protector

,

if the

protector is normal the value is

o, Does a problem still exist

?

No

Is the high pressure

protector broken

?

Is the high pressure

protector broken

?

Is the outdoor ambient

temperature is higher than

50

?

Yes

Check if the outdoor unit

ventilation is good

Yes

Is the heat exchanger dirty

?

Yes

Replace outdoor main board

.

Is

the problem resolved

?

No

High pressure protection

High pressure protection

Is the outdoor fan running

properly

?

NO

Connect high pressure switch and

mian control board

Connect high pressure switch and

main control board

Replace high pressure protector

Replace high pressure protector

Stop the unit

Stop the unit

Ensure that the outdoor unit

Ensure that the outdoor unit

the

“Fan

Speed is

range

”

.

the

“Fan

Speed is

range

”

.

Clean the heat exchanger

Clean the heat exchanger

Check whether the refrigerant

Yes

Method: Disconnect the plug.

Measure the resistance of the

high pressure protector, if the

protector is normal the value is

o, Does a problem still exist?

Yes

Is the outdoor ambient

temperature is higher than

50

?

No

No

Check if the outdoor unit

ventilation is good

Is the outdoor fan running

properly?

Yes

Is the heat exchanger dirty?

No

Replace outdoor main board. Is

the problem resolved?

Check whether the refrigerant

No

Troubleshooting 32

Page 34

7.12 PC 04(Inverter compressor drive error diagnosis and solution)

Description: An abnormal inverter compressor drive is detected by a special detection circuit, including communication

signal detection, voltage detection, compressor rotation speed signal detection and so on.

Recommended parts to prepare:

• Connection wires

• IPM module board

• Outdoor fan assembly

• Compressor

• Outdoor PCB

Troubleshooting and repair:

Check the wiring between the

PCB and compressor.

Is it improperly wired?

NO

Check the IPM.

Is it functioning

properly?

YES

Check the outdoor fan and

the outdoor unit ventilation.

Is it functioning

properly?

YES

Check the compressor

resistance values.

NO

NO

YES

Ensure proper connections or replace

the wires and connectors.

Replace the IPM board or

replace the outdoor PCB.

Please refer to “Fan

Speed Malfunction”

Are they within

acceptable parameters?

YES

Replace the outdoor PCB.

Replace the compressor.NO

Note: For certain models, outdoor PCB could not be removed separately. In this case, the outdoor electric

control box should be replaced as a whole.

Troubleshooting 33

Page 35

7.13 PC 03(Low pressure protection diagnosis and solution)

Description: Outdoor pressure switch cut off the system because low pressure is lower than 0.13 MPa, the LED displays

the failure code.

Recommended parts to prepare:

• Connection wires

• Outdoor PCB

• Low pressure protector

• Refrigerant

Troubleshooting and repair:

Troubleshooting 34

Page 36

Low pressure protection

Low pressure protection

Are the low pressure protector

and main control board wired

properly

?

Are the low pressure protector

and main control board wired

properly

?

Method

:

Disconnect the plug

.

Measure the resistance of the

low pressure protecto

r. I

f the

protector is normal the value is

o. Does a problem still exist

?

Yes

Yes

Replace outdoor main board

.

Does a

problem still exist

?

No

Is the low pressure

protector broken

?

Is the low pressure

protector broken

?

Is the outdoor ambient

temperature

too low

?

No

Is the

valve core of

the

high

p

ressure

valve

fully o

pened

?

Is the

valve core of

the

high

p

ressure

valve

fully o

pened

?

Is the indoor fan running

properly in cooling mode

?

No

Check whether the refrigerant

system is functioning properly

.

Check whether the refrigerant

system is functioning properly

.

When the lvel of refrigerant is not

sufficient

,

doe the system function

properly after more refrigerant is added

No

Reconnect the low pressure protector and main

control board

Reconnect the low pressure protector and main

control board

R

eplace low pressure protector

R

eplace low pressure protector

Open the valve core of the high

pressure valve

Open the valve core of the high

pressure valve

Stop the unit

Stop the unit

Please refer to the solution of

the

“Fan

Speed is

operating outside of normal

range

”

malfunction

.

Method: Disconnect the plug.

Measure the resistance of the

low pressure protector. If the

protector is normal the value is

o. Does a problem still exist?

No

Is the outdoor ambient

temperature too low ?

No

Yes

Is the indoor fan running

properly in cooling mode?

Yes

Replace outdoor main board.. Does a

problem still exist?

When the level of refrigerant is not

sufficient, does the system function

properly after more refrigerant is added?

Yes

No

Please refer to the solution of the “Fan

Speed is operating outside of normal

range

”

malfunction.

Troubleshooting 35

Page 37

8. Check Procedures

8.1 Temperature Sensor Check

WARNING

Be sure to turn off all power supplies or disconnect all wires to avoid electric shock.

Operate after compressor and coil have returned to normal temperature in case of injury.

1. Disconnect the temperature sensor from PCB (Refer to Chapter 5 & 6. Indoor & Outdoor Unit Disassembly).

2. Measure the resistance value of the sensor using a multi-meter.

3. Check corresponding temperature sensor resistance value table (Refer to Chapter 8. Appendix).

Note: The picture and the value are only for reference, actual condition and specific value may vary.

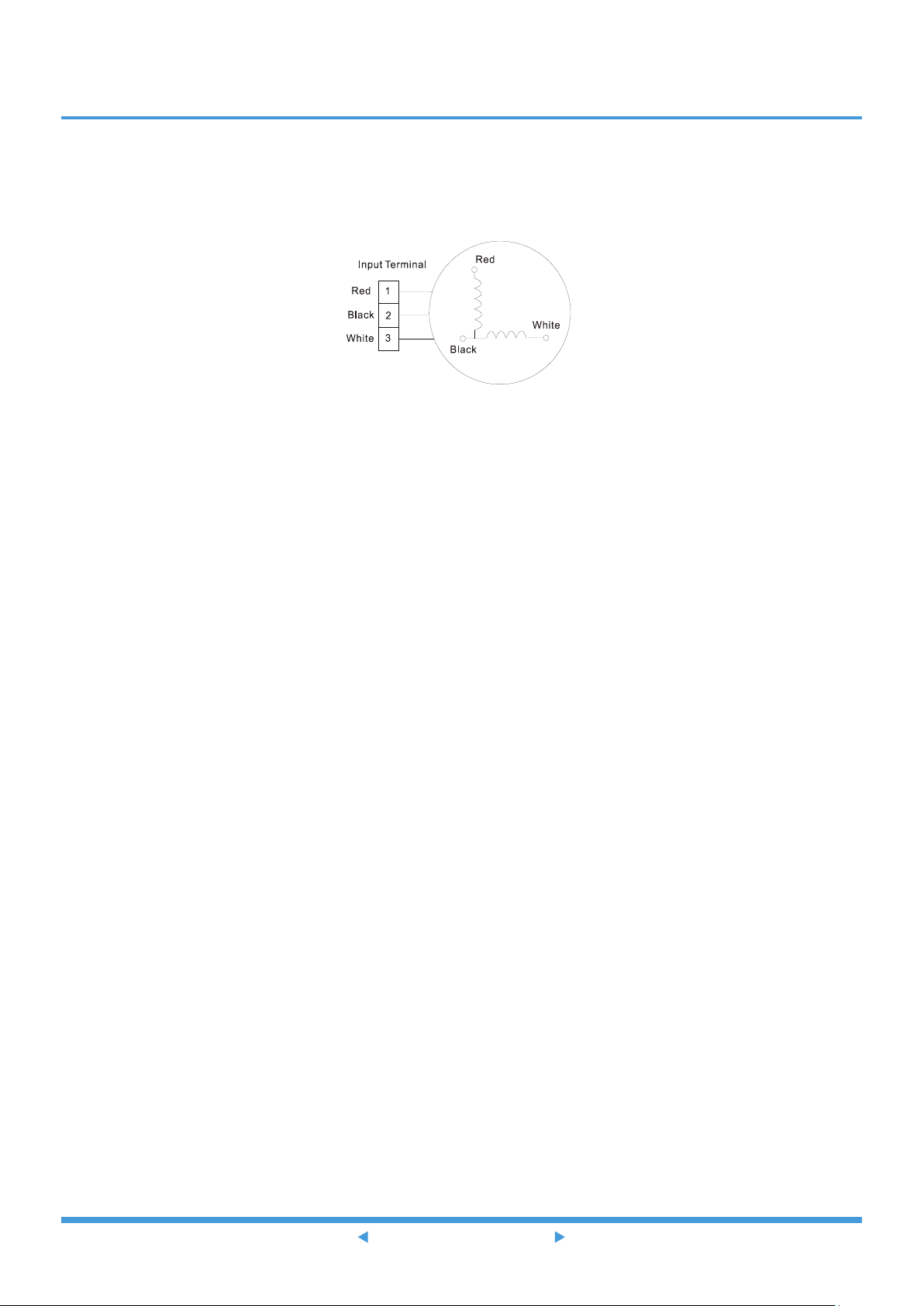

8.2 Compressor Check

1. Disconnect the compressor power cord from outdoor PCB (Refer to Chapter 6. Outdoor Unit Disassembly).

2. Measure the resistance value of each winding using a multi-meter.

3. Check the resistance value of each winding in the following table.

Troubleshooting

Page 38

Resistance Value

Blue-Red

Red-Black

ASM135D23UFZ ATQ420D1UMU ASN98D22UFZ ATF235D22UMT ATQ360D1UMU

1.75Ω 0.37Ω 1.57Ω 0.75Ω 0.37ΩBlue-Black

Resistance Value

Blue-Red

Red-Black

Resistance Value

Blue-Red

Red-Black

Resistance Value

ATM115D43UFZ2 ATF250D22UMT ATF310D43UMT KSK103D33UEZ3(YJ)

ASM98D32UFZ

1.87Ω 0.75Ω 0.65Ω 2.13Ω 2.2ΩBlue-Black

ASN140D21UFZ ASK89D29UEZD KSN140D21UFZ KTM240D57UMT KSK103D33UEZ3

1.28Ω 1.99Ω 1.28Ω 0.62Ω 2.13ΩBlue-Black

KTF310D43UMT KTQ420D1UMU ATN150D30UFZA KTM240D43UKT KTN110D42UFZ

Blue-Red

Red-Black

Resistance Value

Blue-Red

Red-Black

0.65Ω 0.37Ω 1.03Ω 1.03Ω 1.82ΩBlue-Black

KTF250D22UMT KSN140D58UFZ

0.75Ω 1.86ΩBlue-Black

Troubleshooting

Page 39

Note: The picture and the value are only for reference, actual condition and specific value may vary.

8.3 IPM Continuity Check

WARNING

Electricity remains in capacitors even when the power supply is off.

Ensure the capacitors are fully discharged before troubleshooting.

1. Turn off outdoor unit and disconnect power supply.

2. Discharge electrolytic capacitors and ensure all energy-storage unit has been discharged.

3. Disassemble outdoor PCB or disassemble IPM board.

4. Measure the resistance value between P and U (V, W, N); U (V, W) and N.

Digital tester Resistance value Digital tester Resistance value

(+)Red (-)Black

N U

U V

P

V W

W -

∞

(Several MΩ)

Troubleshooting

(+)Red (-)Black

N

∞

(Several MΩ)

Page 40

Note: The picture and the value are only for reference, actual condition and specific value may vary.

Troubleshooting

Page 41

8.4 4-way Valve Check

1. Power on, use a digital tester to measure the voltage, when the unit operates in cooling, it is 0V. When the unit

operates in heating, it is about 230VAC.

If the value of the voltage is not in the range, the PCB must have problems and need to be replaced.

2 Turn off the power, use a digital tester to measure the resistance. The value should be 1.8~2.5 KΩ.

Troubleshooting

Page 42

8.5 EXV Check

WARNING

Electricity remains in capacitors even when the power supply is off.

Ensure the capacitors are fully discharged before troubleshooting.

1. Disconnect the connector from outdoor PCB.

2. Measure the resistance value of each winding using a multi-meter.

3. Check the resistance value of each winding in the following table.

6 5 4 3 2 1

Red Brown Blue Orange Yellow White

Color of lead winding Normal Value

Red- Blue

Red - Yellow

Brown-Orange

Brown-White

About 50Ω

Troubleshooting

Page 43

Appendix

Contents

i) Temperature Sensor Resistance Value Table for T1, T2, T3, and T4 (°C – K) ......2

ii) Temperature Sensor Resistance Value Table for TP (for some units) (°C --K) ....3

iii) Pressure On Service Port .......................................................................................4

Page 44

i) Temperature Sensor Resistance Value Table for T1,T2,T3 and T4 (°C – K)

°C °F K Ohm °C °F K Ohm °C °F K Ohm °C °F K Ohm

-20 -4 115.266 20 68 12.6431 60 140 2.35774 100 212 0.62973

-19 -2 108.146 21 70 12.0561 61 142 2.27249 101 214 0.61148

-18 0 101.517 22 72 11.5 62 144 2.19073 102 216 0.59386

-17 1 96.3423 23 73 10.9731 63 145 2.11241 103 217 0.57683

-16 3 89.5865 24 75 10.4736 64 147 2.03732 104 219 0.56038

-15 5 84.219 25 77 10 65 149 1.96532 105 221 0.54448

-14 7 79.311 26 79 9.55074 66 151 1.89627 106 223 0.52912

-13 9 74.536 27 81 9.12445 67 153 1.83003 107 225 0.51426

-12 10 70.1698 28 82 8.71983 68 154 1.76647 108 226 0.49989

-11 12 66.0898 29 84 8.33566 69 156 1.70547 109 228 0.486

-10 14 62.2756 30 86 7.97078 70 158 1.64691 110 230 0.47256

-9 16 58.7079 31 88 7.62411 71 160 1.59068 111 232 0.45957

-8 18 56.3694 32 90 7.29464 72 162 1.53668 112 234 0.44699

-7 19 52.2438 33 91 6.98142 73 163 1.48481 113 235 0.43482

-6 21 49.3161 34 93 6.68355 74 165 1.43498 114 237 0.42304

-5 23 46.5725 35 95 6.40021 75 167 1.38703 115 239 0.41164

-4 25 44 36 97 6.13059 76 169 1.34105 116 241 0.4006

-3 27 41.5878 37 99 5.87359 77 171 1.29078 117 243 0.38991

-2 28 39.8239 38 100 5.62961 78 172 1.25423 118 244 0.37956

-1 30 37.1988 39 102 5.39689 79 174 1.2133 119 246 0.36954

0 32 35.2024 40 104 5.17519 80 176 1.17393 120 248 0.35982

1 34 33.3269 41 106 4.96392 81 178 1.13604 121 250 0.35042

2 36 31.5635 42 108 4.76253 82 180 1.09958 122 252 0.3413

3 37 29.9058 43 109 4.5705 83 181 1.06448 123 253 0.33246

4 39 28.3459 44 111 4.38736 84 183 1.03069 124 255 0.3239

5 41 26.8778 45 113 4.21263 85 185 0.99815 125 257 0.31559

6 43 25.4954 46 115 4.04589 86 187 0.96681 126 259 0.30754

7 45 24.1932 47 117 3.88673 87 189 0.93662 127 261 0.29974

8 46 22.5662 48 118 3.73476 88 190 0.90753 128 262 0.29216

9 48 21.8094 49 120 3.58962 89 192 0.8795 129 264 0.28482

10 50 20.7184 50 122 3.45097 90 194 0.85248 130 266 0.2777

11 52 19.6891 51 124 3.31847 91 196 0.82643 131 268 0.27078

12 54 18.7177 52

13 55 17.8005 53 127 3.07075 93 199 0.77709 133 271 0.25757

14 57 16.9341 54 129 2.95896 94 201 0.75373 134 273 0.25125

15 59 16.1156 55 131 2.84421 95 203 0.73119 135 275 0.24512

16 61 15.3418 56 133 2.73823 96 205 0.70944 136 277 0.23916

17 63 14.6181 57 135 2.63682 97 207 0.68844 137 279 0.23338

18 64 13.918 58 136 2.53973 98 208 0.66818 138 280 0.22776

19 66 13.2631 59 138 2.44677 99 210 0.64862 139 282 0.22231

126 3.19183 92 198 0.80132 132 270 0.26408

Appendix 2

Page 45

ii) Temperature Sensor Resistance Value Table for TP (for some units) (°C --K)

°C °F K Ohm °C °F K Ohm °C °F K Ohm °C °F K Ohm

°C °F K Ohm °C °F K Ohm °C °F K Ohm °C °F K Ohm

-20 -4 542.7 20 68 68.66 60 140 13.59 100 212 3.702

-19 -2 511.9 21 70 65.62 61 142 13.11 101 214 3.595

-18 0 483 22 72 62.73 62 144 12.65 102 216 3.492

-17 1 455.9 23 73 59.98 63 145 12.21 103 217 3.392

-16 3 430.5 24 75 57.37 64 147 11.79 104 219 3.296

-15 5 406.7 25 77 54.89 65 149 11.38 105 221 3.203

-14 7 384.3 26 79 52.53 66 151 10.99 106 223 3.113

-13 9 363.3 27 81 50.28 67 153 10.61 107 225 3.025

-12 10 343.6 28 82 48.14 68 154 10.25 108 226 2.941

-11 12 325.1 29 84 46.11 69 156 9.902 109 228 2.86

-10 14 307.7 30 86 44.17 70 158 9.569 110 230 2.781

-9 16 291.3 31 88 42.33 71 160 9.248 111 232 2.704

-8 18 275.9 32 90 40.57 72 162 8.94 112 234 2.63

-7 19 261.4 33 91 38.89 73 163 8.643 113 235 2.559

-6 21 247.8 34 93 37.3 74 165 8.358 114 237 2.489

-5 23 234.9 35 95 35.78 75 167 8.084 115 239 2.422

-4 25 222.8 36 97 34.32 76 169 7.82 116 241 2.357

-3 27 211.4 37 99 32.94 77 171 7.566 117 243 2.294

-2 28 200.7 38 100 31.62 78 172 7.321 118 244 2.233

-1 30 190.5 39 102 30.36 79 174 7.086 119 246 2.174

0 32 180.9 40 104 29.15 80 176 6.859 120 248 2.117

1 34 171.9 41 106 28 81 178 6.641 121 250 2.061

2 36 163.3 42 108 26.9 82 180 6.43 122 252 2.007

3 37 155.2 43 109 25.86 83 181 6.228 123 253 1.955

4 39 147.6 44 111 24.85 84 183 6.033 124 255 1.905

5 41 140.4 45 113 23.89 85 185 5.844 125 257 1.856

6 43 133.5 46 115 22.89 86 187 5.663 126 259 1.808

7 45 127.1 47 117 22.1 87 189 5.488 127 261 1.762

8 46 121 48 118 21.26 88 190 5.32 128 262 1.717

9 48 115.2 49 120 20.46 89 192 5.157 129 264 1.674

10 50 109.8 50 122 19.69 90 194 5 130 266 1.632

11 52 104.6 51

12 54 99.69 52 126 18.26 92 198 4.703

13 55 95.05 53 127 17.58 93 199 4.562

14 57 90.66 54 129 16.94 94 201 4.426

15 59 86.49 55 131 16.32 95 203 4.294

16 61 82.54 56 133 15.73 96 205 4.167

17 63 78.79 57 135 15.16 97 207 4.045

18 64 75.24 58 136 14.62 98 208 3.927

19 66 71.86 59 138 14.09 99 210 3.812

124 18.96 91 196 4.849

Appendix 3

Page 46

iii) Pressure On Service Port

Cooling chart (R410A):

°F(°C)

BAR

PSI

MPa

ODU(DB)

0(-17) 5(-15)

IDU(DB/WB)

70/59 (21.11/15) 6.4 6.5 7.3 8.0 8.2 7.8 8.1 8.6 10.1 10.6

75/63 (23.89/17.22) 6.7 6.8 7.9 8.6 8.6 8.3 8.7 9.1 10.7 11.2

80/67 (26.67/19.44) 7.1 7.2 8.5 9.5 9.3 8.9 9.1 9.6 11.2 11.9

90/73 (32.22/22.78) 7.7 7.8 9.6 10.5 10.3 9.5 10.0 10.6 12.4 13.0

70/59 (21.11/15) 93 94 106 116 119 113 117 125 147 154

75/63 (23.89/17.22) 97 99 115 125 124 120 126 132 155 162

80/67 (26.67/19.44) 103 104 123 138 135 129 132 140 162 173

90/73 (32.22/22.78) 112 113 139 152 149 138 145 154 180 189

70/59 (21.11/15) 0.64 0.65 0.73 0.8 0.82 0.78 0.81 0.86 1.01 1.06

75/63 (23.89/17.22) 0.67 0.68 0.79 0.86 0.86 0.83 0.87 0.91 1.07 1.12

80/67 (26.67/19.44) 0.71 0.72 0.85 0.95 0.93 0.89 0.91 0.96 1.12 1.19

90/73 (32.22/22.78) 0.77 0.78 0.96 1.05 1.03 0.95 1 1.06 1.24 1.3

15

(-9.44)

45

(7.22)

75

(23.89)

85

(29.44)

95 (35)

105

(40.56)

115

(46.11)

120

(48.89)

1.4

1.2

0.8

0.6

0.4

0.2

1

70/59

75/63

80/67

90/73

0

Appendix 4

Page 47

Heating chart (R410A):

°F(°C)

BAR

PSI

MPa

ODU(DB/WB)

IDU(DB)

55(12.78) 30.3 28.5 25.3 22.8 20.8 18.5 16.5

65(18.33) 32.5 30.0 26.6 25.4 23.3 20.5 19.0

75(23.89) 33.8 31.5 27.8 26.3 24.9 21.5 20.0

55(12.78) 439 413 367 330 302 268 239

65(18.33) 471 435 386 368 339 297 276

75(23.89) 489 457 403 381 362 312 290

55(12.78) 3.03 2.85 2.53 2.28 2.08 1.85 1.65

65(18.33) 3.25 3.00 2.66 2.54 2.33 2.05 1.90

75(23.89) 3.38 3.15 2.78 2.63 2.49 2.15 2.00

57/53

(13.89/11.67)

47/43

(8.33/6.11)

37/33

(2.78/0.56)

27/23

(-2.78/-5)

17/13 (-8.33/-

10.56)

0/-2

(-17/-19)

4

3.5

3

2.5

2

-17/-18

(-27/-28)

1.5

0.5

55

1

65

75

0

Appendix 5

Page 48

Cooling chart (R22):

°F(°C)

BAR

PSI

MPa

ODU(DB)

0(-17) 5(-15)

IDU(DB/WB)

70/59 (21.11/15) 4.0 4.1 4.6 5.0 5.1 4.9 5.1 5.4 6.3 6.6

75/63 (23.89/17.22) 4.2 4.3 4.9 5.4 5.4 5.2 5.4 5.7 6.7 7.0

80/67 (26.67/19.44) 4.4 4.5 5.3 5.9 5.8 5.6 5.7 6.0 7.0 7.4

90/73 (32.22/22.78) 4.8 4.9 6.0 6.6 6.4 5.9 6.3 6.6 7.8 8.1

70/59 (21.11/15) 58 59 67 73 74 71 74 78 91 96

75/63 (23.89/17.22) 61 62 71 78 78 75 78 83 97 102

80/67 (26.67/19.44) 64 65 77 86 84 81 83 87 102 107

90/73 (32.22/22.78) 70 71 87 96 93 86 91 96 113 117

70/59 (21.11/15) 0.40 0.41 0.46 0.50 0.51 0.49 0.51 0.54 0.63 0.66

75/63 (23.89/17.22) 0.42 0.43 0.49 0.54 0.54 0.52 0.54 0.57 0.67 0.70

80/67 (26.67/19.44) 0.44 0.45 0.53 0.59 0.58 0.56 0.57 0.60 0.70 0.74

90/73 (32.22/22.78) 0.48 0.49 0.60 0.66 0.64 0.59 0.63 0.66 0.78 0.81

15

(-9.44)

45

(7.22)

75

(23.89)

85

(29.44)

95 (35)

105

(40.56)

115

(46.11)

120

(48.89)

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

70/59

75/63

80/67

90/73

0

Appendix 6

Page 49

Heating chart (R22):

°F(°C)

BAR

PSI

MPa

ODU(DB/WB)

IDU(DB)

55(12.78) 18.9 17.8 15.8 14.3 13.0 11.6 10.3

65(18.33) 20.3 18.8 16.6 15.9 14.6 12.8 11.9

75(23.89) 21.1 19.7 17.3 16.4 15.6 13.4 12.5

55(12.78) 274 258 229 207 189 168 149

65(18.33) 294 273 241 231 212 186 172.6

75(23.89) 306 286 251 238 226 194 181

55(12.78) 1.89 1.78 1.58 1.43 1.30 1.16 1.03

65(18.33) 2.03 1.88 1.66 1.59 1.46 1.28 1.19

75(23.89) 2.11 1.97 1.73 1.64 1.56 1.34 1.25

57/53

(13.89/11.67)

47/43

(8.33/6.11)

37/33

(2.78/0.56)

27/23

(-2.78/-5)

17/13 (-8.33/-

10.56)

0/-2

(-17/-19)

2.5

2

1.5

-17/-18

(-27/-28)

0.5

1

55

65

75

0

Appendix 7

Page 50

Cooling chart (R32):

°F(°C)

BAR

PSI

MPa

ODU(DB)

0(-17) 5(-15)

IDU(DB/WB)

70/59 (21.11/15) 6.5 6.6 7.4 8.2 8.4 8.0 8.3 8.8 10.3 10.8

75/63 (23.89/17.22) 6.8 6.9 8.1 8.8 8.8 8.5 8.9 9.3 10.9 11.4

80/67 (26.67/19.44) 7.2 7.3 8.7 9.7 9.5 9.1 9.3 9.8 11.4 12.1

90/73 (32.22/22.78) 7.9 8.0 9.8 10.7 10.5 9.7 10.2 10.8 12.6 13.3

70/59 (21.11/15) 95 96 108 118 121 115 119 128 150 157

75/63 (23.89/17.22) 99 101 117 128 126 122 129 135 158 165

80/67 (26.67/19.44) 105 106 125 141 138 132 135 143 165 176

90/73 (32.22/22.78) 114 115 142 155 152 141 148 157 184 193

70/59 (21.11/15) 0.65 0.66 0.74 0.82 0.84 0.80 0.83 0.88 1.03 1.08

75/63 (23.89/17.22) 0.68 0.69 0.81 0.88 0.88 0.85 0.89 0.93 1.09 1.14

80/67 (26.67/19.44) 0.72 0.73 0.87 0.97 0.95 0.91 0.93 0.98 1.14 1.21

90/73 (32.22/22.78) 0.79 0.80 0.98 1.07 1.05 0.97 1.02 1.08 1.26 1.33

15

(-9.44)

45

(7.22)

75

(23.89)

85

(29.44)

95 (35)

105

(40.56)

115

(46.11)

1.4

1.2

120

(48.89)

0.8

0.6

0.4

0.2

1

70/59

75/63

80/67

90/73

0

Appendix 8

Page 51

Heating chart (R32):

°F(°C)

BAR

PSI

MPa

ODU(DB/WB)

IDU(DB)

55(12.78) 30.9 29.1 25.8 23.3 21.2 18.9 16.8

65(18.33) 33.2 30.6 27.1 25.9 23.8 20.9 19.4

75(23.89) 34.5 32.1 28.4 26.8 25.4 21.9 20.4

55(12.78) 448 421 374 337 308 273 244

65(18.33) 480 444 394 375 346 303 282

75(23.89) 499 466 411 389 369 318 296

55(12.78) 3.09 2.91 2.58 2.33 2.12 1.89 1.68

65(18.33) 3.32 3.06 2.71 2.59 2.38 2.09 1.94

75(23.89) 3.45 3.21 2.84 2.68 2.54 2.19 2.04

57/53

(13.89/11.67)

47/43

(8.33/6.11)

37/33

(2.78/0.56)

27/23

(-2.78/-5)

17/13 (-8.33/-

10.56)

0/-2

(-17/-19)

4

3.5

3

2.5

2

-17/-18

(-27/-28)

1.5

0.5

55

1

65

75

0

Appendix 9

Page 52

System Pressure Table-R22

Pressure Temperature Pressure Temperature

Kpa bar PSI °C °F Kpa bar PSI °C °F

100 1 14.5 -41.091 -41.964 1600 16 232 41.748 107.146

150 1.5 21.75 -32.077 -25.739 1650 16.5 239.25 43.029 109.452

200 2 29 -25.177 -13.319 1700 17 246.5 44.281 111.706

250 2.5 36.25 -19.508 -3.114 1750 17.5 253.75 45.506 113.911

300 3 43.5 -14.654 5.623 1800 18 261 46.706 116.071

350 3.5 50.75 -10.384 13.309 1850 18.5 268.25 47.882 118.188

400 4 58 -6.556 20.199 1900 19 275.5 49.034 120.261

450 4.5 65.25 -3.075 26.464 1950 19.5 282.75 50.164 122.295

500 5 72.5 0.124 32.223 2000 20 290 51.273 124.291

550 5.5 79.75 3.091 37.563 2050 20.5 297.25 52.361 126.250

600 6 87 5.861 42.550 2100 21 304.5 53.43 128.174

650 6.5 94.25 8.464 47.234 2150 21.5 311.75 54.48 130.064

700 7 101.5 10.92 51.656 2200 22 319 55.512 131.922

750 7.5 108.75 13.249 55.848 2250 22.5 326.25 56.527 133.749

800 8 116 15.465 59.837 2300 23 333.5 57.526 135.547

850 8.5 123.25 17.58 63.644 2350 23.5 340.75 58.508 137.314

900 9 130.5 19.604 67.287 2400 24 348 59.475 139.055

950 9.5 137.75 21.547 70.785 2450 24.5 355.25 60.427 140.769

1000 10 145 23.415 74.147 2500 25 362.5 61.364 142.455

1050 10.5 152.25 25.216 77.389 2550 25.5 369.75 62.288 144.118

1100 11 159.5 26.953 80.515 2600 26 377 63.198 145.756

1150 11.5 166.75 28.634 83.541 2650 26.5 384.25 64.095 147.371

1200 12 174 30.261 86.470 2700 27 391.5 64.98 148.964

1250 12.5 181.25 31.839 89.310 2750 27.5 398.75 65.852 150.534

1300 13 188.5 33.371 92.068 2800 28 406 66.712 152.082

1350 13.5 195.75 34.86 94.748 2850 28.5 413.25 67.561 153.610

1400 14 203 36.308 97.354 2900 29 420.5 68.399 155.118

1450 14.5 210.25 37.719 99.894 2950 29.5 427.75 69.226 156.607

1500 15 217.5 39.095 102.371 3000 30 435 70.042 158.076

1550 15.5 224.75 40.437 104.787

Appendix 10

Page 53

System Pressure Table-R410A

Pressure Temperature Pressure Temperature

Kpa bar PSI °C °F Kpa bar PSI °C °F

100 1 14.5 -51.623 -60.921 2350 23.5 340.75 38.817 101.871

150 1.5 21.75 -43.327 -45.989 2400 24 348 39.68 103.424

200 2 29 -36.992 -34.586 2450 24.5 355.25 40.531 104.956

250 2.5 36.25 -31.795 -25.231 2500 25 362.5 41.368 106.462

300 3 43.5 -27.351 -17.232 2550 25.5 369.75 42.192 107.946

350 3.5 50.75 -23.448 -10.206 2600 26 377 43.004 109.407

400 4 58 -19.953 -3.915 2650 26.5 384.25 43.804 110.847

450 4.5 65.25 -16.779 1.798 2700 27 391.5 44.592 112.266

500 5 72.5 -13.863 7.047 2750 27.5 398.75 45.37 113.666

550 5.5 79.75 -11.162 11.908 2800 28 406 46.136 115.045

600 6 87 -8.643 16.444 2850 28.5 413.25 46.892 116.406

650 6.5 94.25 -6.277 20.701 2900 29 420.5 47.638 117.748

700 7 101.5 -4.046 24.716 2950 29.5 427.75 48.374 119.073

750 7.5 108.75 -1.933 28.521 3000 30 435 49.101 120.382

800 8 116 0.076 32.137 3050 30.5 442.25 49.818 121.672

850 8.5 123.25 1.993 35.587 3100 31 449.5 50.525 122.945

900 9 130.5 3.826 38.888 3150 31.5 456.75 51.224 124.203

950 9.5 137.75 5.584 42.052 3200 32 464 51.914 125.445

1000 10 145 7.274 45.093 3250 32.5 471.25 52.596 126.673

1050 10.5 152.25 8.901 48.022 3300 33 478.5 53.27 127.886

1100 11 159.5 10.471 50.848 3350 33.5 485.75 53.935 129.083

1150 11.5 166.75 11.988 53.578 3400 34 493 54.593 130.267

1200 12 174 13.457 56.223 3450 34.5 500.25 55.243 131.437

1250 12.5 181.25 14.879 58.782 3500 35 507.5 55.885 132.593

1300 13 188.5 16.26 61.268 3550 35.5 514.75 56.52 133.736

1350 13.5 195.75 17.602 63.684 3600 36 522 57.148 134.866

1400 14 203 18.906 66.031 3650 36.5 529.25 57.769 135.984

1450 14.5 210.25 20.176 68.317 3700 37 536.5 58.383 137.089

1500 15 217.5 21.414 70.545 3750 37.5 543.75 58.99 138.182

1550 15.5 224.75 22.621 72.718 3800 38 551 59.591 139.264

1600 16 232 23.799 74.838 3850 38.5 558.25 60.185 140.333

1650 16.5 239.25 24.949 76.908 3900 39 565.5 60.773 141.391

1700 17 246.5 26.074 78.933 3950 39.5 572.75 61.355 142.439

1750 17.5 253.75 27.174 80.913 4000 40 580 61.93 143.474

1800 18 261 28.251 82.852 4050 40.5 587.25 62.499 144.498

1850 18.5 268.25 29.305 84.749 4100 41 594.5 63.063 145.513

1900 19 275.5 30.338 86.608 4150 41.5 601.75 63.62 146.516

1950 19.5 282.75 31.351 88.432 4200 42 609 64.172 147.510

2000 20 290 32.344 90.219 4250 42.5 616.25 64.719 148.494

2050 20.5 297.25 33.319 91.974 4300 43 623.5 65.259 149.466

2100 21 304.5 34.276 93.697 4350 43.5 630.75 65.795 150.431

2150 21.5 311.75 35.215 95.387 4400 44 638 66.324 151.383

2200 22 319 36.139 97.050 4450 44.5 645.25 66.849 152.328

2250 22.5 326.25 37.047 98.685 4500 45 652.5 67.368 153.262

2300 23 333.5 37.939 100.290

Appendix 11

Page 54

System Pressure Table-R32

Pressure Temperature Pressure Temperature

Kpa bar PSI °C °F Kpa bar PSI °C °F

100 1 14.5 -51.909 -61.436 1850 18.5 268.25 28.425 83.165

150 1.5 21.75 -43.635 -46.543 1900 19 275.5 29.447 85.005

200 2 29 -37.323 -35.181 1950 19.5 282.75 30.448 86.806

250 2.5 36.25 -32.15 -25.87 2000 20 290 31.431 88.576

300 3 43.5 -27.731 -17.916 2050 20.5 297.25 32.395 90.311

350 3.5 50.75 -23.85 -10.93 2100 21 304.5 33.341 92.014

400 4 58 -20.378 -4.680 2150 21.5 311.75 34.271 93.688

450 4.5 65.25 -17.225 0.995 2200 22 319 35.184 95.331

500 5 72.5 -14.331 6.204 2250 22.5 326.25 36.082 96.948

550 5.5 79.75 -11.65 11.03 2300 23 333.5 36.965 98.537

600 6 87 -9.150 15.529 2350 23.5 340.75 37.834 100.101

650 6.5 94.25 -6.805 19.752 2400 24 348 38.688 101.638

700 7 101.5 -4.593 23.734 2450 24.5 355.25 39.529 103.152

750 7.5 108.75 -2.498 27.505 2500 25 362.5 40.358 104.644

800 8 116 -0.506 31.089 2550 25.5 369.75 41.173 106.111

850 8.5 123.25 1.393 34.507 2600 26 377 41.977 107.559

900 9 130.5 3.209 37.777 2650 26.5 384.25 42.769 108.984

950 9.5 137.75 4.951 40.911 2700 27 391.5 43.55 110.39

1000 10 145 6.624 43.923 2750 27.5 398.75 44.32 111.776

1050 10.5 152.25 8.235 46.823 2800 28 406 45.079 113.142

1100 11 159.5 9.790 49.621 2850 28.5 413.25 45.828 114.490

1150 11.5 166.75 11.291 52.324 2900 29 420.5 46.567 115.821

1200 12 174 12.745 54.941 2950 29.5 427.75 47.296 117.133

1250 12.5 181.25 14.153 57.475 3000 30 435 48.015 118.427

1300 13 188.5 15.52 59.936 3050 30.5 442.25 48.726 119.707

1350 13.5 195.75 16.847 62.325 3100 31 449.5 49.428 120.970

1400 14 203 18.138 64.648 3150 31.5 456.75 50.121 122.218

1450 14.5 210.25 19.395 66.911 3200 32 464 50.806 123.451

1500 15 217.5 20.619 69.114 3250 32.5 471.25 51.482 124.668

1550 15.5 224.75 21.813 71.263 3300 33 478.5 52.15 125.87

1600 16 232 22.978 73.360 3350 33.5 485.75 52.811 127.060

1650 16.5 239.25 24.116 75.409 3400 34 493 53.464 128.235

1700 17 246.5 25.229 77.412 3450 34.5 500.25 54.11 129.398

1750 17.5 253.75 26.317 79.371 3500 35 507.5 54.748 130.546

1800 18 261 27.382 81.288

Appendix 12

Page 55

4th Generation

®

DIY

E Star™

Series

Loading...

Loading...