Page 1

Please read this manual carefully before installation and keep it for future reference.

Installation Manual

Advantage Series

Page 2

Contents

0

Safety Precautions ............................ 3

Accessories

1

2

Installation Summary - Indoor Unit

3

Parts

.....................................................

.........................................

4

5

.......

7

9

Indoor Unit Installation

1. Installation location ............................. 10

2. Attach mounting plate to wall .............. 11

3. Drill wall hole for connective piping ...... 11

4.

refrigerant piping ..................... 13

5. Connect drain hose............................... 14

6. Connect signal cable............................. 16

7. Wrap piping and cables ........................ 17

8. Connect indoor power wire .................. 17

9. Mount indoor unit ............................... 17

.........

10

5

Outdoor Unit Installation

1. Installation location ...................... 19

2. Install drain joint .......................... 20

3. Anchor outdoor unit.................... 21

4. Connect signal and power cables 22

Page 1

.. 19

Page 3

Contents

6

Refrigerant Piping Connection

A. Note on Pipe Length............................................... 24

B.

Connection Instructions – Refrigerant Piping........... 24

1. Cut pipe ............................................................ 24

2. Remove burrs..................................................... 25

3. Flare pipe ends................................................... 25

4. Connect pipes..................................................... 26

MC MC

.......

Air Evacuation

7

1. Evacuation Instructions ..................... 28

2. Note on Adding Refrigerant.............. 29

24

...................

28

8

Electrical and Gas Leak Checks

9

Test Run

10

EU Disposal Guidelines ................... 33

.............................................

.......

30

31

Page 2

Page 4

Safety Precautions

Read Before Installation

Incorrect installation may cause serious damage or injury.

The seriousness of potential damage or injuries is classified as either a WARNING or CAUTION.

This symbol indicates ignoring instructions may cause death or serious injury.

WARNING

This symbol indicates that ignoring instructions may cause moderate injury to

your person, damage to your unit, or other property.

CAUTION

This symbol indicates that you should never perform the indicated action.

WARNING

Do not modify the length of the power supply cord or use an extension cord to power the unit.

Do not share the electrical outlet with other appliances. Improper or insufficient power supply

can cause fire or electrical shock.

When connecting refrigerant piping, do not let substances or gases other than the refrigerant

enter the unit. The presence of other gases or substances will lower the unit’s capacity, and may

cause abnormally high pressure in the operation cycle. This may cause explosion and injury.

Do not allow children to play with the air conditioner. Children should be supervised around

the unit at all times.

1. Installation must be performed by an authorized technician. Improper installation may cause water

leakage, electrical shock, or fire.

2. Installation must be performed according to installation instructions. Improper installation may

cause water leakage, electrical shock, or fire.

(In North America, installation must be performed in accordance with the requirement of NEC and

CEC by authorized personnel only.)

Contact an authorized service technician for repair or maintenance of the unit.

3.

Only use the included accessories and specified parts for installation. Using non-standard

4.

parts can cause water leakage, elctrical shock, or fire and may cause the unit to fail.

5.

Install the unit in a firm location that can support the unit’s weight. If the installation location

cannot support the weight, or the installation is performed improperly, the unit may fall and cause

serious injury and/or damage.

Page 3

Page 5

Safety Precautions

WARNING

For all electrical work, follow all appropriate wiring standards, regulations, and the Installation

6.

Manual. You must use an independent circuit and single outlet to supply power. Do not connect

other appliances to the same outlet. Insuficient electrical capacity or defects in electrical work can

cause electrical shock or fire.

7.

For all electrical work, fuse the specified cables. Connect cables tightly, and clamp them securely

to prevent external forces from damaging the terminal. Improper electrical connections may

overheat, causing fire and/or electrical shock.

8.

All wiring must be properly arranged to ensure that the control board cover can close properly. If

the control board cover is not closed properly, it can lead to corosion and cause the connection

points on the terminal to overheat , causing fire and/or electrical shock.

In certain functional environments, such as kitchens, server rooms, etc., the use of specially

9.

designed air-conditioning units is highly recommended.

10.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard

11.

This appliance can be used by children aged from 8 years and above and persons with reduced

Physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children should not play with the appliance. Cleaning and user

maintenance should not be made by children without supervision.

CAUTION

For units that have an auxiliary electric heater, do not install the unit within 3 feet (1 meter)

of combustible materials.

Do not install the unit in a location that may be exposed to combustible gases. If combustible

gas accumulates around the unit, it may cause fire.

Do not operate your air conditioner in a wet room such as a bathroom or laundry room. Too

much exposure to water may cause electrical components to short circuit.

1. The product must be properly grounded during installation, or electrical shock may occur.

2. Install drainage piping according to the instructions in this manual. Improper drainage may

cause water damage to your home and property.

Note about Flourinated Gasses

1. This air-conditioning unit contains flourinated gases. For specific information on the type of gas

and the amount, please refer to the relevant label on the unit itself.

2. Installation, service, maintenance and repair of this unit must be performed by a certified

technician.

Product uninstallation and recycling must be performed by a certified technician.

3.

4. If the system has a leak-detection system installed, it should be checked for leaks at least every

12 months.

5. Keep a record of all leak checks for the lifetime of the unit.

Page 4

Page 6

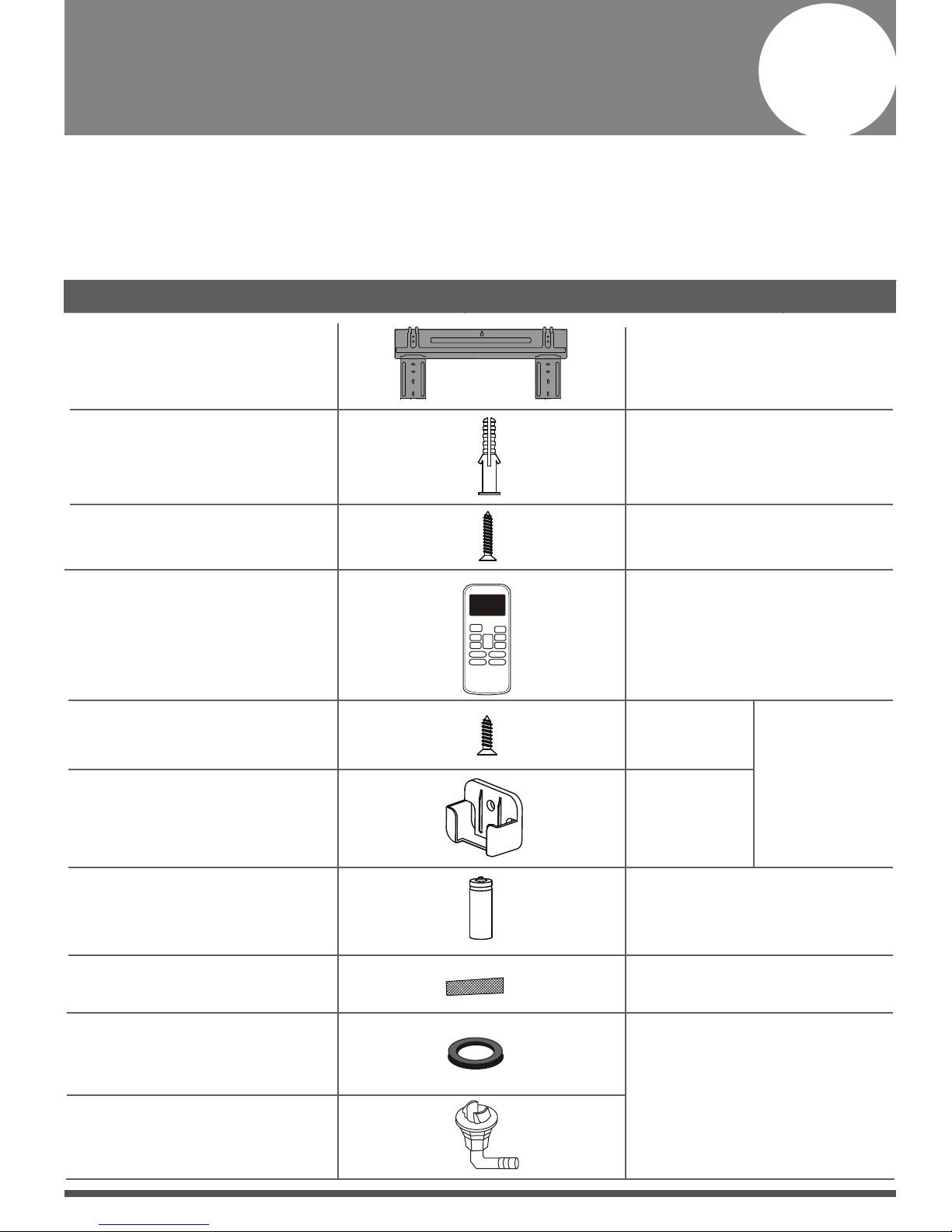

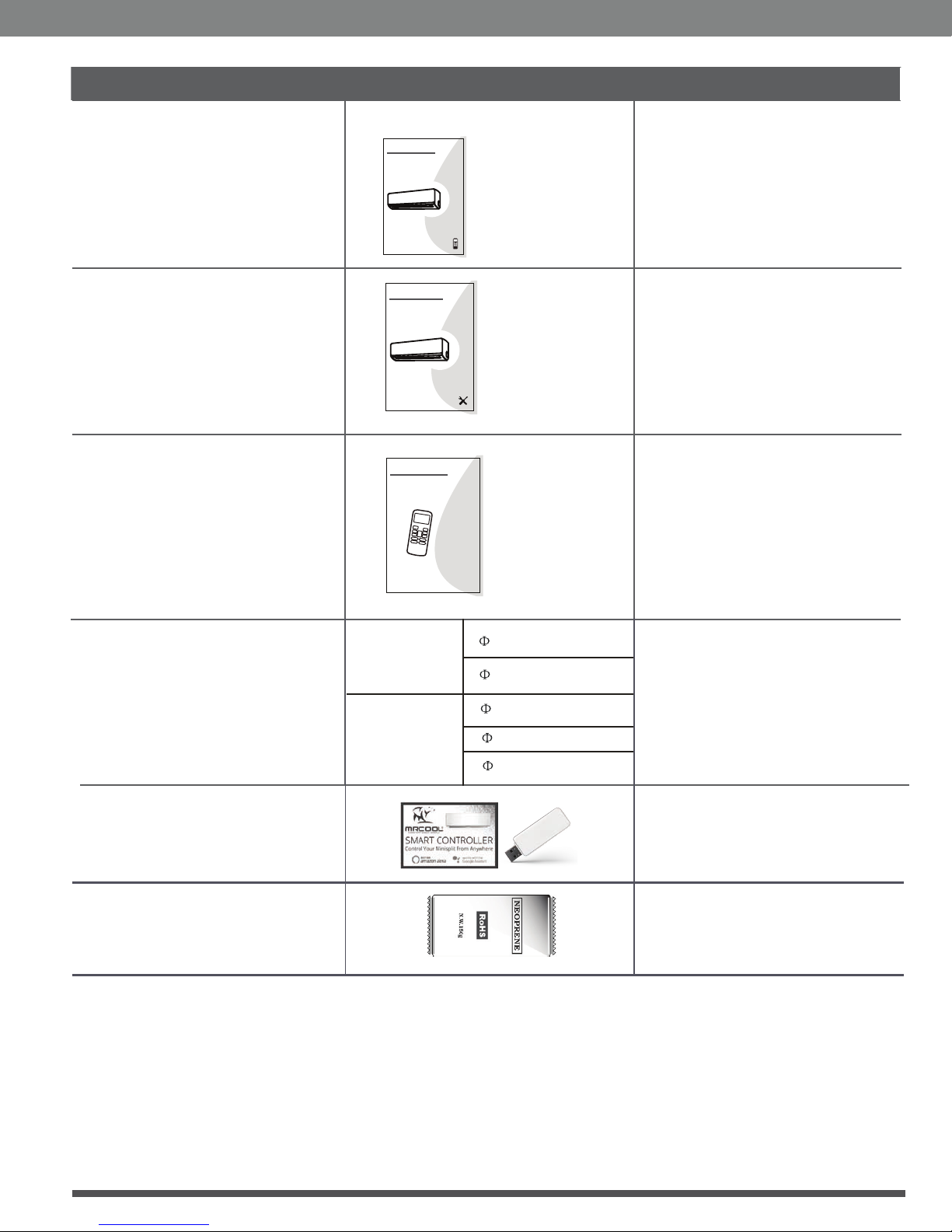

Accessories

1

The air conditioning system includes the following accessories. Use all of the installation parts and

accessories to install the air conditioner. Improper installation may result in water leakage, electrical

shock, fire, or equipment failure.

Name

Mounting plate

Clip anchor

Mounting plate fixing

screw ST3.9 X 25

Remote control

Fixing screw for remote

controller holder ST2.9 x 10

Shape Quantity

1

5

5

1

2

Optional

Parts

Remote control holder

Dry battery AAA.LR03

Air freshening filter

Seal

Drain joint

Page 5

1

2

1

1

(for cooling & heating

models only)

Page 7

Accessories

Name

Owner’s Manual

Installation Manual

Remote Control Manual

INVERTER SPLIT-TYPE ROOMAIR CONDITIONER

Owner’s Manual

All Model Numbers

IMPORTANT NOTE:

Read this manual carefully before installing

or operating your new air conditioning

unit. Make sure to save this manual for

future reference.

INVERTER SPLIT-TYPE ROOMAIR CONDITIONER

Installation Manual

IMPORTANT NOTE:

Read this manual carefully before installing

or operating your new air conditioning

unit. Make sure to save this manual for

future reference.

INVERTER SPLIT-TYPE ROOMAIR CONDITIONER

Remote controller

illustration

Shape Quantity

1

CS78421-548-754

1

CS78421-548-754

1

Connecting pipe assembly

Smart Controller Kit

Neoprene

IMPORTANT NOTE:

Read this manual carefully before installing

or operating your new air conditioning

unit. Make sure to save this manual for

future reference.

Liquid side

Gas side

CS78421-548-754

6.35( 1/4i n)

9.52( 3/8in)

9.52( 3/8in)

12.7( 1/2in)

16( 5/8in)

Parts you must purchase.

Consult the dealer about

the pipe size.

1

(w/ Manual in Controller Box)

1

(Sealant for Wall Sleeve)

Page 6

Page 8

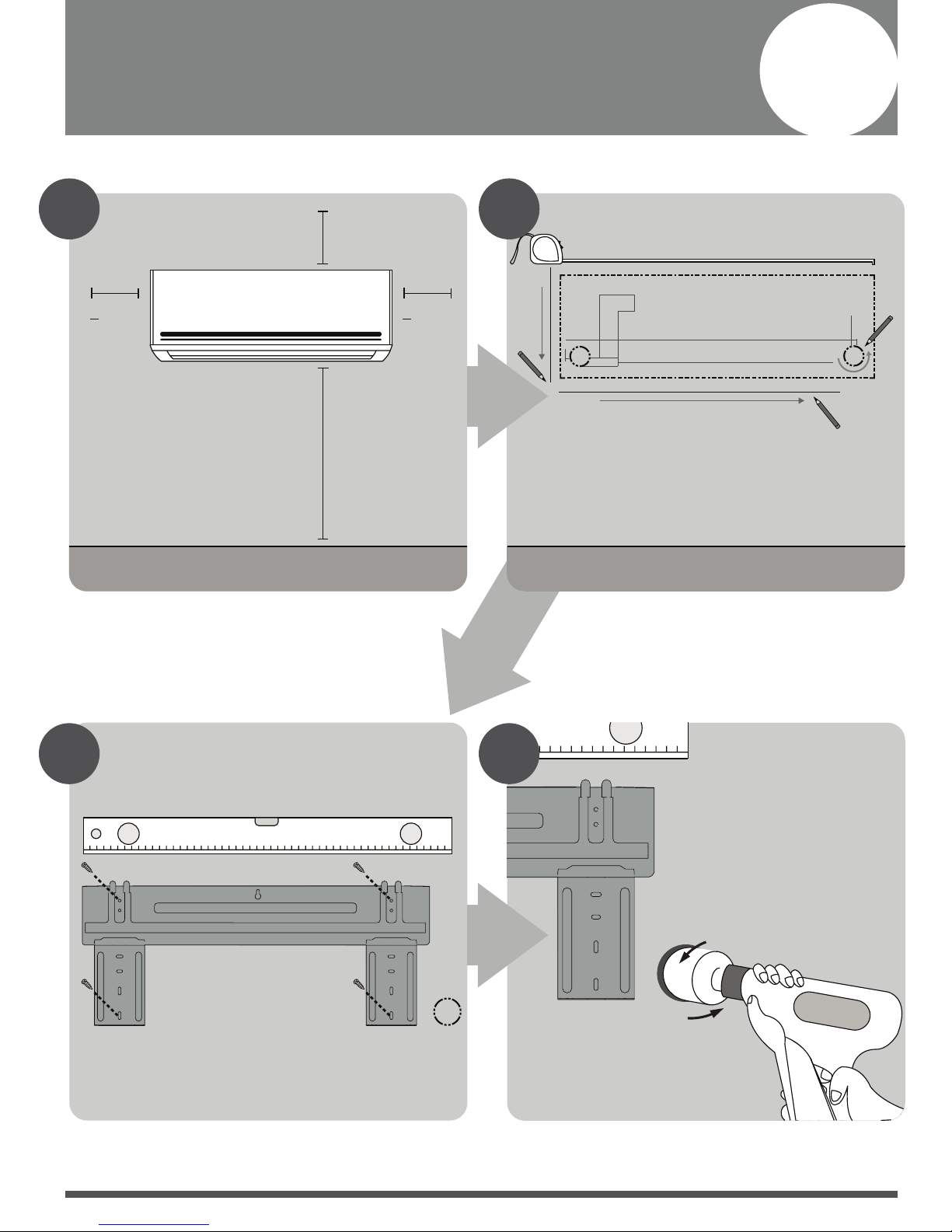

Installation Summary - Indoor Unit

2

1 2

>12cm

(4.75in)

Minimum Ceiling

Clearance is

15cm (5.9in)

>12cm

(4.75in)

For Ceilings Greater

Than 9 Foot Suggested

Floor Clearance is

230cm(90.55in)

For Ceilings Less

Than 9 Foot Suggested

Floor Clearance is

200cm(78.55in)

Select Installation Location

(Page 10)

Determine Wall Hole Position

(Page 11)

3

Attach Mounting Plate

(Page 11)

4

Drill Wall Hole

(Page 11)

Page 7

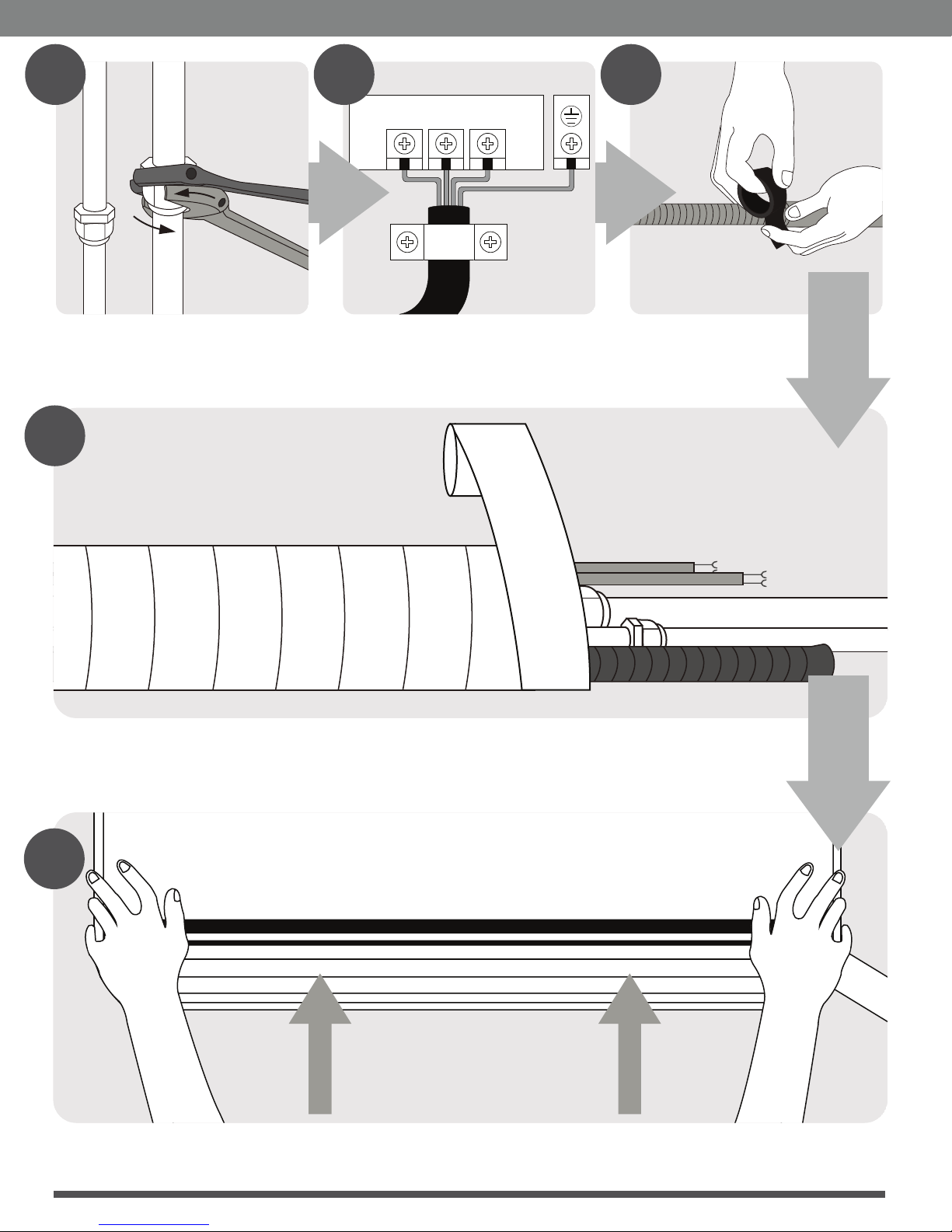

Page 9

Installation Summary - Indoor Unit

5 6 7

L N S

8

Connect Piping

(Page 24)

Connect Wiring

(Page 16)

Wrap Piping and Cable

(Page 17)

Prepare Drain Hose

(Page 13)

9

STEP

Mount Indoor Unit

8

(Page 17)

Page 8

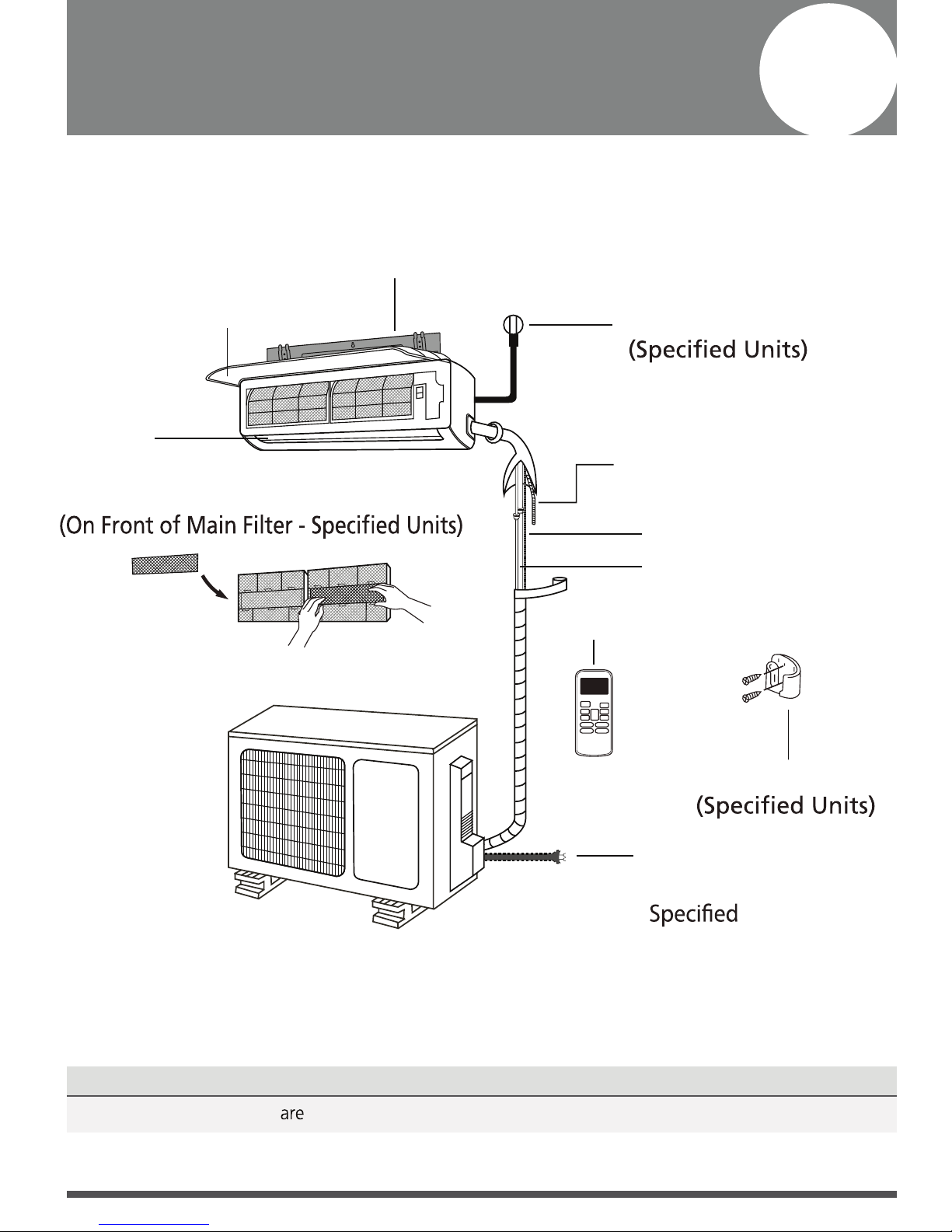

Page 10

Parts

3

Wall Mounting Plate

Louver

Front Panel

Functional Filter

Power Cable

Drainage Pipe

Signal Cable

Refrigerant Piping

Remote Control

NOTE ON ILLUSTRATIONS

Illustrations in this manual for explanatory purposes. The actual shape of your indoor unit may vary.

Page 9

Remote Holder

Outdoor Unit

Power Cable

( Units)

Fig. 2.1

Page 11

Indoor Unit Installation

4

Installation Instructions – Indoor

Unit

PRIOR TO INSTALLATION

Before installing the indoor unit, refer to the

label on the product box to make sure that the

model number of the indoor unit matches the

model number of the outdoor unit.

Step 1: Select installation location

Before installing the indoor unit, you must

choose an appropriate location. The following

are standards will help you choose an

appropriate location.

Proper installation locations meet the

following standards:

Good air circulation

Convenient drainage

Noise from the unit will not disturb other

people

Firm and solid—the location will not vibrate

DO NOT install unit in the following locations:

Near any source of heat, steam, or

combustible gas

Near flammable items such as curtains or

clothing

Near any obstacle that might block air

circulation

Near a doorway

In a location subject to direct sunlight

NOTE ABOUT WALL HOLE:

If there is no fixed refrigerant piping:

While choosing a location, be aware that you

should leave ample room for a wall hole (see

Drill wall hole for connective piping step)

for the signal cable and refrigerant piping that

connect the indoor and outdoor units. The

default position for all piping is the right side

of the indoor unit (while facing the unit).

However, the unit can accommodate piping

to left or right.

Strong enough to support the weight of the

unit

A location at least one meter from all other

electrical devices (e.g., TV, radio, computer)

Page 10

Page 12

Indoor Unit Installation

Refer to the following diagram to ensure proper distance from walls and ceiling:

Minimum Ceiling

Clearance is

15cm (5.9in)

>12cm

(4.75in)

For Ceilings Greater

Than 9 Foot Suggested

Floor Clearance is

230cm(90.55in)

For Ceilings Less

Than 9 Foot Suggested

Floor Clearance is

200cm(78.55in)

Step 2: Attach mounting plate to wall

The mounting plate is the device on which you

will mount the indoor unit.

Remove the screw that attaches the mounting

plate to the back of the indoor unit.

Place the mounting plate against the wall in a

location that meets the standards in the

Select Installation Location step. (See

Mounting Plate Dimensions for detailed

information on mounting plate sizes.)

Drill holes for mounting screws in places that:

• have studs and can support the weight of

the unit

• correspond to screw holes in the mounting

plate

Secure the mounting plate to the wall with

the screws provided.

5. Make sure that mounting plate is flat against

the wall.

the wall.

r

>12cm

(4.75in)

Fig. 3.1

Step 3: Drill wall hole for connective piping

You must drill a hole in the wall for refrigerant

piping, the drainage pipe, and the signal cable

that will connect the indoor and outdoor units.

1. Determine the location of the wall hole based

on the position of the mounting plate. Refer

to Mounting Plate Dimensions on the

next page to help you determine the optimal

position. The wall hole should have a 2.5in

(65mm) diameter at least, and at a slightly

lower angle to facilitate drainage.

2. Using a 2.5in (65-mm) core drill, drill a hole in

the wall. Make sure that the hole is drilled at

a slight downward angle, so that the outdoor

end of the hole is lower than the indoor end

by about 0.2 to 0.275in (5mm-7mm). This will

ensure proper water drainage. (See

Fig. 3.2

)

3. Place the protective wall cuff in the hole. This

protects the edges of the hole and will help

seal it when you finish the installation process.

NOTE FOR CONCRETE OR BRICK WALLS:

If the wall is made of brick, concrete, or similar

material, drill 0.2in-diameter (5mm-diameter)

holes in the wall and insert the sleeve anchors

provided. Secure the mounting plate to the

wall by tightening the screws directly into the

clip anchors.

Page 11

CAUTION

When drilling the wall hole, make to

avoid wires, plumbing, and other sensitive

components.

Page 13

Indoor Unit Installation

Wall

Indoor Outdoor

)

5-7mm

0.2- 0.3in

(

Fig.3.2

MOUNTING PLATE DIMENSIONS

Different models have different mounting

plates. In order to ensure that you have ample

room to mount the indoor unit, the diagrams to

the right show different types of mounting

plates along with the following dimensions:

• Width of mounting plate

• Height of mounting plate

• W etalp ot evitaler tinu roodni fo htdi

etalp ot evitaler tinu roodni fo thgieH•

• Recommended position of wall hole (both

to the left and right of mounting plate)

Left rear wall

hole 2.5in (65mm)

Left rear wall

hole 2.5in (65mm)

Left rear wall

hole 2.5in (65mm)

4in (101mm)

11.4in (290mm)

1.95in (49mm)

7.55in (192mm)

1.7in (43mm)

11.7in (297mm)

5.45in (138mm)

2.25in (57mm)

12.55in (319mm)

1.35in (34mm)

13.7in (348.4mm)

7.05in (179mm)

5.35in (136mm)

28.45in (722mm)

Series 9K Models

16.8in (426mm)

31.6in (802mm)

Series 12K Models

20.37in (517.4mm)

5.65in (144mm)

38in (965mm)

Series 18K Models

9.15in (232mm)

5.05in (128mm)

1.45in (37mm)

Indoor unit outline

Right rear wall

1.95in (49mm)

hole 2.5in (65mm)

1.7in (43mm)

Indoor unit outline

Right rear wall

1.7in (43mm)

hole 2.5in (65mm)

2.3in (58mm)

Indoor unit outline

Right rear wall

hole 2.5in (65mm)

1.55in (40mm)

• Relative distances between screw holes

Correct orientation of Mounting Plate

2.1in

(53.5mm)

Left rear wall

hole 2.5in (65mm)

8.6in (219mm)

1.85in (47mm)

13.2in (335mm)

6.85in (174.3mm)

3in (76mm)

42.5in (1080mm)

Series 24K Models

Fig. 3.3

21.77in (553mm)

11.8in (300mm)

5.95in (151mm)

5.85in

(148.7mm)

1.85in (47mm)

Right rear wall

hole 2.5in (65mm)

2.1in (53.5mm)

Indoor unit outline

Page 12

Page 14

Indoor Unit Installation

Step 4: Prepare refrigerant piping

The refrigerant piping is inside an insulating

sleeve attached to the back of the unit. You

must prepare the piping before passing it

through the hole in the wall. Refer to the

Refrigerant Piping Connection section of

this manual for detailed instructions on pipe

1. Based on the position of the wall hole

relative to the mounting plate, choose the

side from which the piping will exit the unit.

2. If the wall hole is behind the unit, keep the

knock-out panel in place. If the wall hole is

to the side of the indoor unit, remove the

plastic knock-out panel from that side of

the unit. (See Fig. 3.3 ). This will create a

slot through which your piping can exit the

unit. Use needle nose pliers if the plastic

panel is too difficult remove by hand.

Use scissors to cut down the length of the

insulating sleeve to reveal about 6in (15cm) of

the refrigerant piping. This serves two

purposes:

• To facilitate the Refrigerant Piping

Connection process

• To facilitate Gas Leak Checks and enable

you to check for dents

If existing connective piping is already

embedded in the wall, proceed directly to the

Connect Drain Hose step. If there is no

embedded piping, connect the indoor unit’s

refrigerant piping to the connective piping that

will join the indoor and outdoor units. Refer to

the Refrigerant Piping Connection section

of this manual for detailed instructions.

Based on the position of the wall hole relative

to the mounting plate, determine the

necessary angle of your piping.

Grip the refrigerant piping at the base of the

bend.

Fig. 3.3

Knock-out Panel

Slowly, with even pressure, bend the piping

towards the hole. Do not dent or damage the

piping during the process.

NOTE ON PIPING ANGLE

Refrigerant piping can exit the indoor unit from

four different angles:

• Left-hand side

• Left rear

• Right-hand side

• Right rear

Refer to Fig. 3.4 for details.

CAUTION

Be extremely careful not to dent or damage the piping while bending them away from the unit.

Any dents in the piping will affect the unit’s performance.

Page 13

Fig. 3.4

Page 15

Indoor Unit Installation

Step 5:Connect drain hose

By default, the drain hose is attached to the

left-hand side of unit (when you’re facing

the back of the unit). However, it can also

be attached to the right-hand side.

1. To ensure proper drainage, attach the

drain hose on the same side that your

refrigerant piping exits the unit.

2. Attach drain hose extension (purchased

separately) to the end of drain hose.

3. Wrap the connection point firmly with

Teflon tape to ensure a good seal and

to prevent leaks.

Fig. 3.5

Make there are no

kinks or dent

in the

hose to ensure

proper drainage.

4. For the portion of the drain hose that

will remain indoors, wrap it with foam

pipe insulation to prevent condensation.

5. Remove the air filter and pour a small

amount of water into the drain pan to

make sure that water flows from the unit

hsmoothly.

NOTE ON DRAIN HOSE

PLACEMENT

Make sure to arrange the drain

hose according to Fig. 3.5.

DO NOT kink the drain hose.

DO NOT create a water trap.

DO NOT put the end of drain hose in

water or a container that will collect

water.

NOT CORRECT

Kinks in the drain hose

will c eate water traps.r

Fig. 3.6

NOT CORRECT

Dents in the drain hose

will create water traps.

Fig. 3.7

PLUG THE UNUSED DRAIN HOLE

To prevent unwanted leaks you must plug

the unused drain hole with the rubber plug

provided.

NOT CORRECT

Do not place the end

of the drain hose in

water or in containers

that collect water. This

will prevent proper

drainage.

Fig. 3.8

Page 14

Page 16

Indoor Unit Installation

BEFORE PERFORMING ELECTRICAL WORK, READ THESE REGULATIONS

1. All wiring must comply with local and national electrical codes, and must be installed by a

licensed electrician.

2. All electrical connections must be made according to the Electrical Connection Diagram

located on the panels of the indoor and outdoor units.

3. If there is a serious safety issue with the power supply, stop work immediately. Explain your

reasoning to the client, and refuse to install the unit until the safety issue is properly resolved.

4. Power voltage should be within 90-100% of rated voltage. Insufficient power supply can

cause malfunction, electrical sock, or fire.

5. If connecting power to fixed wiring install a surge protector and main power switch with a

capacity 1.5 times the maximum unit current.

If connecting power to fixed wiring, a switch or circuit breaker that disconnects all poles and

6.

has a contact separation of at least 1/8in (3mm) must be incorporated in the fixed wiring, The

qualified technician must use an approved circuit breaker or switch.

7. Only connect the unit to an individual branch circuit outlet. Do not connect another appliance

to that outlet.

8. Make sure to properly ground the air conditioner.

9. Every wirre must be firmly connected. Loose wiring can cause the terminal to overheat,

resulting in malfunction and possible fire.

10. Do not let wires touch or rest against refrigerant tubing, the compressor, or any moving parts

within the unit.

11. If the unit has an auxiliary electric heater, it must be installed at least 40in (1 meter) away

from combustible materials.

WARNING

BEFORE PERFORMING ANY ELECTRICAL OR WIRING WORK, TURN OFF THE MAIN POWER

TO THE SYSTEM.

Page 15

Page 17

Indoor Unit Installation

Step 6: Connect signal cable

The signal cable enables communication

between the indoor and outdoor units and

provides power to the indoor unit. A 16

gauge AWG signal cable (H07RN-F) is

provided for the unit. The tables below are

for reference.

NOTE: the rated amp (A) draw will be at the

condenser (outdoor unit) and a table is

provided in that section, showing the

required power cable gauge specific to each.

Minimum Cross-Sectional Area of

Power and Signal Cables

North America

Appliance Amps (A)

10 18

AWG

TAKE NOTE OF FUSE SPECIFICATIONS

The air conditioner’s circuit board (PCB) is

designed with a fuse to provide overcurrent

protection. The specifications of the fuse are

printed on the circuit board, such as:

T3.15A/250VAC, T5A/250VAC, etc.

1. Prepare the cable for connection:

a. Usingwirestrippers,strip therubberjacket

from both ends of signal cable to reveal

about 1.57in (40mm) of the wires inside.

b. Strip the insulation from the ends of the

wires.

c. Using wire crimper, crimp u-type lugs on

the ends of the wires.

PAY ATTENTION TO LIVE WIRE

While crimping wires, make sure you clearly

distinguish the Live (“L”) Wire from other wires.

13 16

18 14

25 12

30 10

Other Regions

Rated Current of

Appliance (A)

> 3 and 6 0.75

> 6 and

> 10 and

> 16 and

> 25 and

> 32 and

10 1

16 1.5

25 2.5

32 4

40 6

Nominal Cross-Sectional

Area (mm²)

CHOOSE THE APPROPRIATE CABLE SIZE

The size of the power supply cable, signal

cable, fuse, and switch needed is determined

by the maximum unit current. The maximum

unit current is indicated on the nameplate

located on the side panel of the unit. Refer to

this nameplate to choose the right cable, fuse,

or switch.

2. Open front panel of the indoor unit.

3. Using a screwdriver, open the wire box cover

on the right side of the unit. This will reveal

the terminal block.

Terminal block

Wire cover

Screw

Cable clamp

Fig. 3.9

The Wiring Diagram is located

on the inside of the indoor unit’s

wire cover.

WARNING

ALL WIRING MUST PERFORMED IN

ACCORDANCE WITH THE WIRING DIAGRAM

LOCATED ON THE INSIDE OF THE INDOOR

UNIT’S WIRE COVER.

4. Unscrew the cable clamp below the terminal

block and place it to the side.

5. Facing the back of the unit, remove the plastic

panel on the bottom left-hand side.

Page 16

Page 18

Indoor Unit Installation

6. Feed the signal wire through this slot, from

the back of the unit to the front.

7. Facing the front of the unit, match the wire

colors with the labels on the terminal block,

connect the u-lug and firmly screw each wire

to its corresponding terminal.

CAUTION

DO NOT MIX UP LIVE AND NULL WIRES

This is dangerous, and can cause the air

conditioning unit to malfunction.

8. After checking to make sure every connection

is secure, use the cable clamp to fasten the

signal cable to the unit. Screw the cable clamp

down tightly.

9. Replace the wire cover on the front of the

unit, and the plastic panel on the back.

DO NOT INTERTWINE SIGNAL CABLE WITH

OTHER WIRES

While bundling these items together, do not

intertwine or cross the signal cable with any

other wiring.

2. Using adhesive vinyl tape, attach the drain

hose to the underside of the refrigerant pipes.

3. Using insulation tape, wrap the signal wire,

refrigerant pipes, and drain hose tightly

together. Double-check that all items are

bundled in accordance with Fig. 3.12

DO NOT WRAP ENDS OF PIPING

When wrapping the bundle, keep the ends

of the piping unwrapped. You need to access

them to test for leaks at the end of the

installation process (refer to Electrical Checks

and Leak Checks section of this manual).

Step 8: Mount indoor unit

NOTE ABOUT WIRING

THE WIRING CONNECTION PROCESS MAY

DIFFER SLIGHTLY BETWEEN UNITS.

Step 7: Wrap piping and cables

Before passing the piping, drain hose, and the

signal cable through the wall hole, you must

bundle them together to protect them, insulate

them, and save space.

1. Bundle the drain hose, refrigerant pipes, and

signal cable according to Fig. 3.12.

Indoor Unit

Space behind unit

Refrigerant piping

Insulation tape

Signal wire

DRAIN HOSE MUST BE ON BOTTOM

Make sure that the drain hose is at the bottom

of the bundle. Putting the drain hose at the

top of the bundle can cause the drain pan

to overflow, which may lead to fire or water

damage.

Drain hose

Fig. 3.12

If you installed new connective piping to the

outdoor unit, do the following:

1. If you have already passed the refrigerant

piping through the hole in the wall, proceed

to Step 4.

2. Otherwise, double-check that the ends of the

refrigerant pipes are sealed to prevent dirt or

foreign material from entering the pipes.

3. Slowly pass the wrapped bundle of refrigerant

pipes, drain hose, and signal wire through the

hole in the wall.

4. Hook the top of the indoor unit on the upper

hook of the mounting plate.

5. Check that unit is hooked firmly on mounting

plate by applying slight pressure to the left and

right-hand sides of the unit. The unit should

not jiggle or shift.

6. Using even pressure, push down on the

bottom half of the unit. Keep pushing down

until the unit snaps onto the hooks along the

bottom of the mounting plate.

7. Again, check that the unit is firmly mounted

by applying slight pressure to the left and the

right-hand sides of the unit.

Page 17

Page 19

Indoor Unit Installation

If refrigerant piping is already embedded in

the wall, do the following:

1. Hook the top of the indoor unit on the upper

hook of the mounting plate.

2. Use a bracket or wedge to prop up the unit,

giving you enough room to connect the

refrigerant piping, signal cable, and drain

hose. Refer to Fig. 3.13 for an example.

Connect drain hose and refrigerant piping

(refer to Refrigerant Piping Connection

section of this manual for instructions).

Keep pipe connection point exposed to

perform the leak test (refer to Electrical

Checks and Leak Checks section of this

manual).

After the leak test, wrap the connection point

with insulation tape.

Remove the bracket or wedge that is propping

up the unit.

Using even pressure, push down on the

bottom half of the unit. Keep pushing down

until the unit snaps onto the hooks along the

bottom of the mounting plate.

Fig. 3.13

UNIT IS ADJUSTABLE

Keep in mind that the hooks on the mounting plate are smaller than the holes on the back of the

unit. If you find that you don’t have ample room to connect embedded pipes to the indoor unit,

the unit can be adjusted left or right by about 1.25-1.95in (30-50mm), depending on the model.

(See Fig. 3.14.)

1.2-1.95in

(30-50mm)

1.2-1.95in

(30-50mm)

Move to left or right

Fig. 3.14

Page 18

Page 20

Outdoor Unit Installation

5

Installation Instructions – Outdoor

Unit

Step 1: Select installation location

Before installing the outdoor unit, you must

choose an appropriate location. The following

standards will help you choose an appropriate

location.

Proper installation locations meet the

following standards:

Meets all spatial requirements shown in

Installation Space Requirements (Fig. 4.1)

Good air circulation and ventilation

Firm and solid location that can support the

unit and will cause vibration.

Noise from the unit will not disturb others

Protected from prolonged periods of direct

sunlight or rain

24in (60cm) above

12in (30cm)

12in (30cm)

on left

79in (200cm)

in front

DO NOT install unit in the following locations:

Near an obstacle that will block air inlets

and outlets

Near a public street, crowded areas, or where

noise from the unit will disturb others

Near animals or plants that will be harmed

by hot air discharge

from back wall

24in (60cm)

on right

Fig. 4.1

Page 19

Near any source of combustible gas

In a location that is exposed to large

amounts of dust

In a location exposed to a excessive amounts

of salty air

Page 21

Outdoor Unit Installation

SPECIAL CONSIDERATIONS FOR EXTREME

WEATHER

If the unit is exposed to heavy wind: Install

unit so that air outlet fan is at a 90° angle to

the direction of the wind. If needed, build a

barrier in front of the unit to protect it from

extremely heavy winds. Ensure the wind barrier

does not block necessary air flow.

See Fig. 4.2 and Fig. 4.3 below.

Strong wind

Strong wind

Fig. 4.2

If the drain joint comes with a rubber seal

(see Fig. 4.4 - A), do the following:

1. Fit the rubber seal on the end of the drain joint

that will connect to the outdoor unit.

2. Insert the drain joint into the hole in the base

pan of the unit.

3. Rotate the drain joint 90° until it clicks in place

facing the front of the unit.

4. Connect a drain hose extension (not included)

to the drain joint to redirect water from the

unit during heating mode.

If the drain joint doesn’t come with a rubber

seal (see Fig. 4.4 - B), do the following:

1. Insert the drain joint into the hole in the base

pan of the unit. The drain joint will click in

place.

2. Connect a drain hose extension (not included)

to the drain joint to redirect water from the

unit during heating mode.

Wind Baffle

Strong wind

Fig. 4.3

If the unit is frequently exposed to heavy

rain or snow:

Build a shelter above the unit it to protect it

from the rain or snow. Be careful not to

obstruct air flow around the unit.

Step 2: Install drain joint

Heat pump units require a drain joint. Before

bolting the outdoor unit in place, you must install

the drain joint at the bottom of the unit. Note

that there are two different types of drain joints

depending on the type of outdoor unit.

Base pan hole of

outdoor unit

Seal

Seal

Drain joint

(A) (B)

Fig. 4.4

IN COLD CLIMATES

In cold climates, make sure that the drain hose

is as vertical as possible to ensure swift water

drainage. If water drains too slowly, it can

freeze in the house and flood the unit.

Page 20

Page 22

Outdoor Unit Installation

Step 3: Anchor outdoor unit

The outdoor unit can be anchored to the ground

or to a wall-mounted bracket.

UNIT MOUNTING DIMENSIONS

H

sizes and the distance between their mounting

feet. Prepare the installation base of the unit

according to the dimensions below.

W

Air Inlet

D

Outdoor Unit Dimensions (inches)

Width (W) x Height (H) x Depth (D)

A-09-HP-C-230A

A-12-HP-C-230A

A-18-HP-C-230A

A-24-HP-C-230A

30.31 x 21.85 x 11.81 (inches) 19.2” (487) 11.73” (298).

30.31 x 21.85 x 11.81 (inches) 19.2” (487) 11.73” (298)

30.31 x 21.85 x 11.81 (inches) 19.2” (487) 11.73” (298)

33.27 x 27.64 x 14.29 (inches) 21.26” (540) 13.8” (350)

A

Air Inlet

B

Fig. 4.5

Air Outlet

Mounting Dimensions (inches)

Width (A) Depth (B)

If you will install the unit on the ground or

on a concrete mounting platform, do the

following:

1. Mark the positions for four expansion bolts

based on dimensions in the Unit Mounting

Dimensions chart.

2. Pre-drill holes for expansion bolts.

3. Clean concrete dust away from holes.

4. Place a nut on the end of each expansion bolt.

5. Hammer expansion bolts into the pre-drilled

holes.

Page 21

6. Remove the nuts from expansion bolts, and

place outdoor unit on bolts.

7. Put washer on each expansion bolt, then

replace the nuts.

8. Using a wrench, tighten each nut until snug.

WARNING

WHEN DRILLING INTO CONCRETE, EYE

PROTECTION IS RECOMMENDED AT ALL

TIMES.

Page 23

Outdoor Unit Installation

If you will install the unit on a wall-mounted

bracket, do the following:

CAUTION

Before installing a wall-mounted unit, make

sure that the wall is made of solid brick,

concrete, or of similarly strong material. The

wall must be able to support at least four

times the weight of the unit.

1. Mark the position of bracket holes based on

dimensions in the Unit Mounting Dimensions

chart.

2. Pre-drill the holes for the expansion bolts.

3. Clean dust and debris away from holes.

4. Place a washer and nut on the end of each

expansion bolt.

5. Thread expansion bolts through holes in

mounting brackets, put mounting brackets

in position, and hammer expansion bolts

into the wall.

6. Check that the mounting brackets are level.

7. Carefully lift unit and place its mounting feet

on brackets.

8.

Bolt the unit firmly to the brackets.

TO REDUCE VIBRATIONS OF WALLMOUNTED UNIT

If allowed, you can install the wall-mounted

unit with rubber gaskets to reduce vibrations

and noise.

BEFORE PERFORMING

ELECTRICAL WORK, READ

THESE REGULATIONS

1. All wiring must comply with local and

national electrical codes, and must be

installed by a licensed electrician.

2. All electrical connections must be made

according to the Electrical Connection

Diagram located on the side panels of the

indoor and outdoor units.

3. If there is a serious safety issue with the

power supply, stop work immediately.

Explain your reasoning to the client, and

refuse to install the unit until the safety

issue is properly resolved.

4. Power voltage should be within 90-100%

of rated voltage. Insufficient power supply

can cause electrical shock or fire.

5. If connecting power to fixed wiring, install a

surge protector and main power switch with

a capacity of 1.5 times the maximum current

of the unit.

6. If connecting power to fixed wiring, a switch

or circuit breaker that disconnects all poles

and has a contact separation of at least 1/8in

(3mm) must be incorporated in the fixed

wiring. The qualified technician must use an

approved circuit breaker or switch.

7. Only connect the unit to an individual branch

circuit outlet. Do not connect another

appliance to that outlet.

8. Make sure to properly ground the air

conditioner.

Step 4: Connect signal and power cables

The outside unit’s terminal block is protected by

an electrical wiring cover on the side of the unit.

A comprehensive wiring diagram is printed on

the inside of the wiring cover.

9. Every wire must be firmly connected. Loose

wiring can cause the terminal to overheat,

resulting in product malfunction and possible

fire.

10. Do not let wires touch or rest against

refrigerant tubing, the compressor, or any

moving parts within the unit.

11. If the unit has an auxiliary electric heater, it

must be installed at least 40in (1 meter)

away from any combustible materials.

Page 22

Page 24

Outdoor Unit Installation

WARNING

BEFORE PERFORMING ANY ELECTRICAL

OR WIRING WORK, TURN OFF THE MAIN

POWER TO THE SYSTEM.

1. Prepare the cable for connection:

USE THE RIGHT CABLE

• Outdoor power cable is not provided

• Indoor power / signal cable from outdoor

unit is provided (see Indoor Unit installation)

• See table below for gauge requirements

Minimum Cross-Sectional Area of

Power and Signal Cables

North America

Model Series

9K & 12K

18K

24K

Appliance

Amps (A)

15 14

20

25

Other Regions

AWG

12

10

PAY ATTENTION TO LIVE WIRE

While crimping wires, make sure you clearly

distinguish the Live (“L”) Wire from other wires.

WARNING

ALL WIRING MUST PERFORMED STRICTLY

IN ACCORDANCE WITH THE WIRING

DIAGRAM LOCATED INSIDE THE

OUTDOOR UNIT’S WIRE COVER.

2. Unscrew the electrical wiring cover and

remove it.

3. Unscrew the cable clamp below the terminal

block and place it to the side.

4. Match the wire colors / labels with the labels on

the terminal block, and firmly screw the u-lug

of each wire to its corresponding terminal.

5. After checking to make sure every connection

is secure, loop the wires around to prevent

rain water from flowing into the terminal.

6. Using the cable clamp, fasten the cable to the

unit. Screw the cable clamp down tightly.

7. Insulate unused wires with PVC electrical tape.

Arrange them so that they do not touch any

electrical or metal parts.

Rated Current of

Appliance (A)

> 3 and 6 0.75

> 6 and

> 10 and

> 16 and

> 25 and

> 32 and

10 1

16 1.5

25 2.5

32 4

40 6

Nominal Cross-

Sectional Area (mm²)

a. Using wire strippers, strip the rubber jacket

from both ends of cable to reveal about

1.57in (40mm) of the wires inside.

b. Strip the insulation from the ends of the

wires.

c. Using a wire crimper, crimp u-lugs on the

ends of the wires.

8. Replace the wire cover on the side of the unit,

and screw it in place.

Cover

Outdoor Unit Wiring Diagram

is located on the inside of the

wire cover on the outdoor unit.

Page 23

Fig. 4.6

Page 25

Refrigerant Piping Connection

6

Note on Pipe Length

The length of refrigerant piping will affect the performance and energy efficiency of the unit. Nominal

efficiency is tested on units with a pipe length of 16.5ft (5 meters).

Refer to the table below for specifications on the maximum length and drop height of piping.

Maximum Length and Drop Height of Refrigerant Piping per Unit Model

Model Capacity (BTU/h) Max. Length (ft/m) Max. Drop Height (ft/m)

< 15,000 82ft (25) 33ft (10)

R410A Inverter Split Air

Conditioner

Connection Instructions –

Refrigerant Piping

Step 1: Cut pipes

When preparing refrigerant pipes, take extra care

to cut and flare them properly. This will ensure

efficient operation and minimize the need for

future maintenance.

15,000 and < 24,000 98.5ft (30) 66ft (20)

24,000 and < 36,000 164ft (50) 82ft (25)

36,000 and 60,000 213ft (65) 98.5ft (30)

2. Using a pipe cutter, cut the pipe a little longer

than the measured distance.

3. Make sure that the pipe is cut at a perfect 90°

angle. Refer to Fig. 5.1 for bad cut examples.

90°

Oblique Rough Warped

1. Measure the distance between the indoor and

outdoor units.

Fig. 5.1

Page 24

Page 26

Refrigerant Piping Connection

DO NOT DEFORM PIPE

WHILE CUTTING

Be extra careful not to damage, dent, or

deform the pipe while cutting. This will

drastically reduce the heating efficiency of

the unit.

Step 2: Remove burrs

Burrs can a

piping connection. They must be completely

removed.

1. Hold the pipe at a downward angle to prevent

burrs from falling into the pipe.

2. Using a reamer or deburring tool, remove all

burrs from the cut section of the pipe.

ffect the air-tight seal of refrigerant

Pipe

Reamer

Flare nut

Copper pipe

Fig. 5.3

4. Remove PVC tape from ends of pipe when

ready to perform flaring work.

5. Clamp flare form on the end of the pipe.

The end of the pipe must extend beyond the

edge of the flare form in accordance with the

dimensions shown in the table below.

Point down

Fig. 5.2

Step 3: Flare pipe ends

roper flaring is essential to achieve an airtight

P

seal.

1. After

removing burrs from cut pipe, seal

the ends with PVC tape to prevent foreign

materials from entering the pipe.

2. Sheath the pipe with insulating material.

3. Place flar

e nuts on both ends of pipe. Make

sure they are facing in the right direction,

because you can’t put them on or change

their direction after flaring. See Fig. 5.3.

Fig. 5.4

PIPING EXTENSION BEYOND FLARE FORM

Outer Diameter of

Pipe (in/mm)

Ø 0.25” (Ø 6.35) 0.0275” (0.7) 0.05” (1.3)

Ø 0.375” (Ø 9.52) 0.04” (1.0) 0.063” (1.6)

Ø 0.5” (Ø 12.7) 0.04” (1.0) 0.07” (1.8)

Ø 0.63” (Ø 16) 0.078” (2.0) 0.086” (2.2)

Flare form

A (in/mm)

Min. Max.

A

Page 25

Fig. 5.5

Pipe

Page 27

Refrigerant Piping Connection

6.

Place flaring tool onto the form.

7. Turn the handle of the flaring toool clockwise

until the pipe is fully flared.

8. Remove the flaring tool and flare form, then

inspect the end of the pipe for cracks and

even flaring.

Step 4: Connect pipes

When connecting refrigerant pipes, be careful

not to use excessive torque or to deform the

piping in any way. You should first connect the

low-pressure pipe, then the high-pressure pipe.

Instructions for Connecting Piping

to Indoor Unit

1. Align the center of the two pipes that you will

connect. See Fig. 5.7.

Indoor unit tubing Flare nut Pipe

Fig. 5.7

MINIMUM BEND RADIUS

When bending connective refrigerant piping,

the minimum bending radius is 10cm. See Fig

5.6.

≥4in (10cm)Radius

Fig. 5.6

TORQUE REQUIREMENTS

Tighten the flare nut as tightly as possible by

hand.

Using an adjustable wrench, grip the nut on

the unit tubing.

While firmly gripping the nut on the unit

tubing, use a torque wrench to tighten the

flare nut according to the torque values in the

Torque Requirements table below. Loosen

the flaring nut slightly, then tighten again.

Fig. 5.8

Outer Diameter of Pipe (in/mm) Tightening Torque ( • ) Add. Tightening Torque ( • )

Ø 0.25” (Ø 6.35) 1,500 (11lb•ft) 1,600 (11.8lb•ft)

Ø 0.375” (Ø 9.52) 2,500 (18.4lb•ft) 2,600 (19.18lb•ft)

Ø 0.5” (Ø 12.7) 3,500 (25.8lb•ft) 3,600 (26.55lb•ft)

Ø 0.63” (Ø 16) 4,500 (33.19lb•ft) 4,700 (34.67lb•ft)

DO NOT USE EXCESSIVE TORQUE

Excessive force can break the nut or damage the refrigerant piping. You must not exceed torque

requirements shown in the table above.

Page 26

Page 28

Refrigerant Piping Connection

Instructions for Connecting Piping

to Outdoor Unit

1. Unscrew the cover from the packed valve on

the side of the outdoor unit. (See Fig. 5.9)

Valve cover

Fig. 5.9

2. Remove protective caps from ends of valves.

3. Align flared pipe end with each valve, and

tighten the flare nut as tightly as possible by

hand.

4. Using an adjustable wrench, grip the body

of the valve. Do not grip the nut that seals

the service valve. (See Fig. 5.10)

USE ADJUSTABLE WRENCH TO

GRIP MAIN BODY OF VALVE

Torque from tightening the flare nut can snap

off other parts of valve.

Fig. 5.10

While firmly gripping the body of the valve,

5.

use a torque wrench to tighten the flare nut

according to the correct torque values.

6. Loosen the flaring nut slightly, then tighten

again.

7. Repeat Steps 3 to 6 for the remaining pipe.

Page 27

Page 29

Air Evacuation

MC MC

7

Preparations and Precautions

Air and foreign matter in the refrigerant circuit

can cause abnormal rises in pressure, which can

damage the air conditioner, reduce its efficiency,

and cause injury. Use a vacuum pump and

manifold gauge to evacuate the refrigerant

circuit, removing any non-condensable gas and

moisture from the system.

Evacuation should be performed upon initial

installation and when unit is relocated.

BEFORE PERFORMING EVACUATION

Check to make sure that both highpressure and low-pressure pipes between

the indoor and outdoor units are

connected properly in accordance with the

Refrigerant Piping Connection section of

this manual.

Check to make sure all wiring is connected

properly.

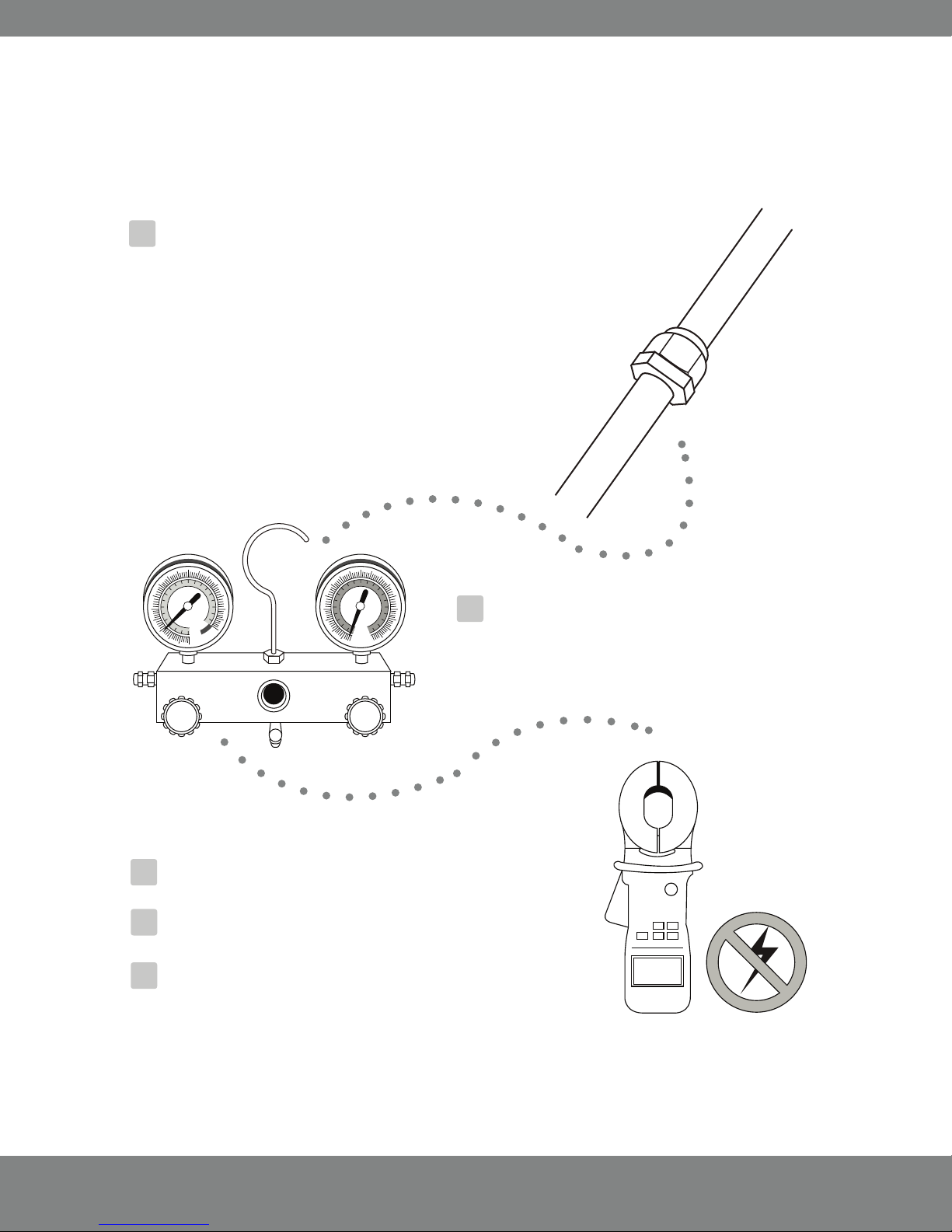

Evacuation Instructions

Before using the manifold gauge and vacuum

pump,read their operation manuals to familiarize

yourself with how to use them properly.

Manifold Gauge

Compound gauge

-76cmHg

Low pressure valve

Pressure hose /

Charge hose

Low pressure valve

1. Connect the charge hose of the manifold

gauge to service port on the outdoor unit’s

low pressure valve.

Pressure gauge

High pressure

valve

Charge hose

Vacuum

pump

Fig. 6.1

2. Connect another charge hose from the

manifold gauge to the vacuum pump.

Page 28

Page 30

Air Evacuation

3. Open the Low Pressure side of the manifold

gauge. Keep the High Pressure side closed.

4. Turn on the vacuum pump to evacuate the

system.

5. Run the vacuum for at least 15 minutes, or

until the Compound Meter reads 76cmHG (-10

5

Pa).

Flare nut

6. Close the Low Pressure side of the manifold

gauge, and turn off the vacuum pump.

Cap

7. Wait for 5 minutes, then check that there

has been no change in system pressure.

8. If there is a change in system pressure, refer

to Gas Leak Check section for information

on how to check for leaks. If there is no

change in system pressure, unscrew the cap

from the packed valve (high pressure valve).

9. Insert hexagon wrench into the packed valve

(highpressure valve) and open the valve by

turning the wrench in a 1/4 counter clockwise

turn. Listen for gas to exit the system, then

Valve body

Valve stem

Fig. 6.2

11. Remove the charge hose from thes ervice port.

12. Using hexagon wrench, fully open both the

high pressure and low pressure valves.

13. Tighten valve caps on all three valves (service

port, high pressure, low pressure) by hand.

You may tighten it further using a torque

wrench if needed.

close the valve after 5 seconds.

OPEN VALVE STEMS GENTLY

10. Watch the Pressure Gauge for one minute

to make sure that there is no change in

pressure. The Pressure Gauge should read

slightly higher than atmospheric pressure.

When opening valve stems, turn the hexagonal

wrench until it hits against the stopper. Do not

try to force the valve to open further.

Note on Adding Refrigerant

Some systems require additional charging depending on pipe lengths. The standard pipe length varies

according to local regulations. For example, in North America, the standard pipe length is 25ft (7.5m).

In other areas, the standard pipe length is 16ft (5m). The additional refrigerant to be charged can be

calculated using the following formula:

ADDITIONAL REFRIGERANT PER PIPE LENGTH

Connective Pipe

Length (m)

< Standard pipe length Vacuum Pump N/A

> Standard pipe

length

Air Purging

Method

Vacuum Pump

CAUTION

DO NOT mix refrigerant types.

Page 29

Additional Refrigerant

Liquid Side: Ø 0.25” (ø 6.35)

R22:

(Pipe length – standard length) x 30g/m

(Pipe length – standard length) x 0.32oZ/ft

Inverter R410A:

(Pipe length – standard length) x 15g/m

(Pipe length – standard length) x 0.16oZ/ft

Fixed-frequency R410A:

(Pipe length – standard length) x 20g/m

(Pipe length – standard length) x 0.21oZ/ft

Liquid Side: Ø 0.375” (ø 9.52)

R22:

(Pipe length – standard length) x 60g/m

(Pipe length – standard length) x 0.64oZ/ft

Inverter R410A:

(Pipe length – standard length) x 30g/m

(Pipe length – standard length) x 0.32oZ/ft

Fixed-frequency R410A:

(Pipe length – standard length) x 40g/m

(Pipe length – standard length) x 0.42oZ/ft

Page 31

Electrical and Gas Leak Checks

8

Electrical Safety Checks

After installation, confirm that all electrical wiring

is installed in accordance with local and national

regulations, and according to the Installation

Manual.

BEFORE TEST RUN

Check Grounding Work

Measure grounding resistance by visual detection

and with grounding resistance tester. Grounding

resistance must be less than 4.

Note: This may not be required for some

locations in the US.

DURING TEST RUN

Check for Electrical Leakage

During the Test Run, use an electroprobe and

multimeter to perform a comprehensive electrical

leakage test.

WARNING – RISK OF

ELECTRIC SHOCK

ALL WIRING MUST COMPLY WITH LOCAL

AND NATIONAL ELECTRICAL CODES,

AND MUST BE INSTALLED BY A LICENSED

ELECTRICIAN.

Gas Leak Checks

There are two different methods to check for

gaseous leaks.

Soap and Water Method

Using a soft brush, apply soapy water or liquid

detergent to all pipe connection points on the

indoor unit and outdoor unit. The presence of

bubbles indicates a leak.

Leak Detector Method

If using leak detector, refer to the device’s

operation manual for proper usage instructions.

If electrical leakage is detected, turn off the unit

immediately and call a licensed electrician to find

and resolve the cause of the leakage.

Note: This may not be required for some

locations in the US.

AFTER PERFORMING GAS LEAK CHECKS

After confirming that the all pipe connection

points DO NOT leak, replace the valve cover

on the outside unit.

Page 30

Page 32

Test Run

9

Before Test Run

Only perform test run after you have completed

the following steps:

• Electrical Safety Checks – Confirm that

the electrical system is safe and operating

properly

• Gas Leak Checks – Check all flare nut

connections and confirm that the system is

not leaking

• Confirm that gas and liquid (high and low

pressure) valves are fully open

Test Run Instructions

You should perform the Test Run for at least

30 minutes.

1. Connect power to the unit.

2. Press the ON/OFF button on the remote

controller to turn it on.

List of Checks to Perform PASS/FAIL

No electrical leakage

Unit is properly grounded

All electrical terminals

properly covered

Indoor and outdoor units

are solidly installed

All pipe connection

points do not leak

Water drains properly

from drain hose

All piping is properly

insulated

Unit performs COOL

function properly

Outdoor (2): Indoor (2):

3. Press the MODE button to scroll through

the following functions, one at a time:

• COOL – Select lowest possible temperature

• HEAT – Select highest possible temperature

4. Let each function run for 5 minutes, and

perform the following checks:

Unit performs HEAT

function properly

Indoor unit louvers

rotate properly

Indoor unit responds to

remote control

Page 31

Page 33

DOUBLE-CHECK PIPE CONNECTIONS

During operation, the pressure of the refrigerant

circuit will increase. This may reveal leaks that

were not present during your initial leak check.

Take time during the Test Run to double-check

that all refrigerant pipe connection points do

not have leaks. Refer to Gas Leak Check

section for instructions.

5. After the Test Run is successfully complete,

and you confirm all check points in List of

Checks to Perform have PASSED, do the

following:

a. Using remote control, return unit to

normal operating temperature.

b. Using insulation tape, wrap the indoor

refrigerant pipe connections that you

left uncovered during the indoor unit

installation process.

Testing

Manual control button

Fig. 8.1

IF AMBIENT TEMPERATURE IS BELOW

63°F (17°C)

You can’t use the remote controller to turn on

the COOL function when the ambient

temperature is below 63°F. In this instance, you

can use the MANUAL CONTROL button to test

the COOL function.

1. Lift the front panel of the indoor unit, and

raise it until it clicks in place.

2. The MANUAL CONTROL button is located

on the right-hand side of the unit. Press it 2

times to select the COOL function.

See Fig.8.1

3. Perform Test Run as normal.

Page 32

Page 34

EU Disposal Guidelines

10

This appliance contains refrigerant and other potentially hazardous materials. When disposing of this

appliance, the law requires special collection and treatment. Do not dispose of this product as

household waste or unsorted municipal waste.

When disposing of this appliance, you have the following options:

• Dispose of the appliance at a designated municipal electronic waste collection facility.

• When buying a new appliance, the retailer will receive the old appliance free of charge.

• The manufacturer will receive the old appliance free of charge.

• Sell the appliance scrap metal dealers.

Special notice

Disposing of this appliance in the forest or other natural surroundings endangers your health and is

bad for the environment. Hazardous substances may leak into the ground water and enter the food

chain.

Page 33

Page 35

Advantage Series

Consult with the sales agency or manufacturer for details.

r notice.

Loading...

Loading...