Page 1

DATALOGGING AC/DC CLAMP POWER METER

TES - 3060/3063

INSTRUCTION MANUAL

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATION

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529 mrc@mrclab.com

MRC.7.14

Page 2

CONTENTS

I. SAFETY INFORMATION

.........................................................1

II. TECHNICAL SPECIFICATIONS

...............................................3

2-1 Environment Conditions

...................................................3

2-2 Maintenance .....................................................................3

2-3 Features............................................................................3

2-4 General Specifications......................................................4

2-5 Measurement Specifications ............................................5

III. PARTS & CONTROLS

.............................................................7

3

-1 Description of Parts & Control .......................................... 7

IV. AC+DC POWER MEASUREMENT

........................................11

4-

1 AC+DC 1φ2W Power(W) and Power Factor (PF)

Measurement ..................................................................11

4-2 3φ3W AC+DC Power Measurement...............................13

4-3 3φ4W AC+DC Power Measurement...............................17

4-4 1φ3W Power Measurement ............................................20

V. OPERATING INSTRUCTION...............................................24

5-1 AC+DC Voltage Measuremen ........................................24

5-2 AC+DC Current Measurement .......................................25

5-3 To Improve Power Factor of a 3φ4W Power System ...26

5-4 To Improve Power Factor of a 3φ3W Power System ....26

5-5 To Improve Power Factor of a 1φ2W Power System ....27

5-6 Resistance & Continuity Measurement ..........................27

5-7 Diode Test & Continuity Measurement...........................28

5-8 Peak Detection Measurement ........................................28

5-9 Operation Of Data Record And Read.............................29

VI. BATTERY REPLACEMENT ................................................

30

Page 3

1

I.

SAFETY INFORMATION

Read the following safety information carefully before

attempting to operate or service the meter.

To avoid damages to the instrument do not exceed the maximum

limits of the input values shown in the technical specification

tables.

Do not use the meter or test leads if they look damaged. Use

extreme caution when working around bare conductors or bus

bars.

Accidental contact with the conductor could result in electric shock.

Use the meter only as specified in this manual; otherwise, the

protection provided by the meter may be impaired.

Read the operating instructions before use and follow all safety

information.

Caution when working with voltages above 60VDC or 30VAC

RMS. Such voltages pose a shock hazard.

Before taking resistance measurements or testing acoustic

continuity, disconnect circuit from main power supply and all

loads from circuit.

Safety symbols

Caution refer to this manual before using the meter.

Dangerous volt

ages.

Meter is protected throughout by double insulation or

reinforced insulation.

When servicing, use only specified replacement

parts.

Comply with EN-61010-1, IEC 1010-2-32

Page 4

3

II.

TECHNICAL SPECIFICATIONS

2-1 Environment Conditions:

Installation categories III

Pollution degree 2

Altitude up to 2000 meters

Indoor use only

Relatively humidity 80% max.

Operation ambient 0 〜50℃

2-2 Maintenance

Repairs or servicing not covered in this manual should

only be performed by qualified personnel.

Periodically wipe the case with a dry cloth. Do not use

abrasives or solvents on this instruments.

2-3 Features•

RS-232 interface to talk with PC

4000 continuity point data logger , 25 point manual

data logger

True Power / Apparent Power / Power Factor

measurement

True RMS. V, A, W, lead, Iag, PF indicator

4 digits with dual display LCD

MIN / MAX Measurement

Amp / Voltage frequency measurement

PEAK HOLD detector

Dual display KW + PF , KVA + PF , V+A

Dual display A + Hz , V + Hz

Page 5

4

2-4 General Specifications

Maximum voltage between any terminal and earth ground

:

600Vrms.

Numerical dual display :4 digit liquid crystal display

(LCD) maximum reading 9999.

Bargraph display

:

40 segments.

Battery life

:

30hr approx. (Alkaline).

Low battery indication

:

The

is displayed when the

battery voltage drops below the

operating voltage.

Auto power off time

:

30 minutes approx.

Sampling rate

:

5 times / sec ( Barograph ),

5 times / sec ( Digital display )

1 times /3sec ( on kw function )

Jaw opening diameter :Cables φ 46mm.

Operating temperature

:0℃

to 50℃ (32℉ to 122℉)

and humidity R.H. < 80% non-condensing.

Storage temperature

:

-10℃to 60℃ (14℉to 140℉)

and humidity R.H. < 70% non-condensing.

Dimensions

:

260(L) x 93(W) x 45mm(H).

Weight

:

Approx. 450 g.

Accessories

:

Carrying case, Test leads,

Battery (one 006p 9V) &

Instruction manual.

Optional Accessory : RS-232 interface & computer

P.C. software.

Page 6

5

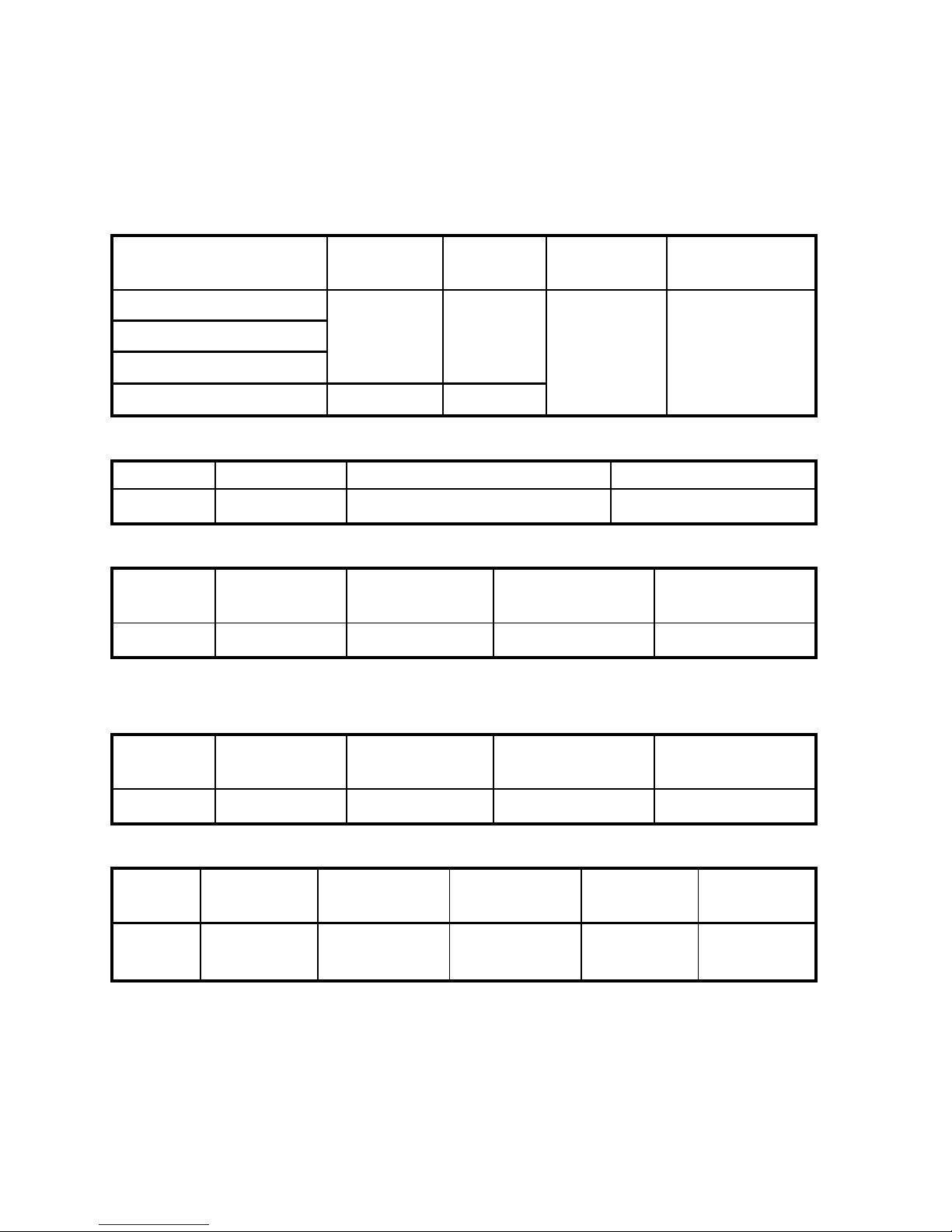

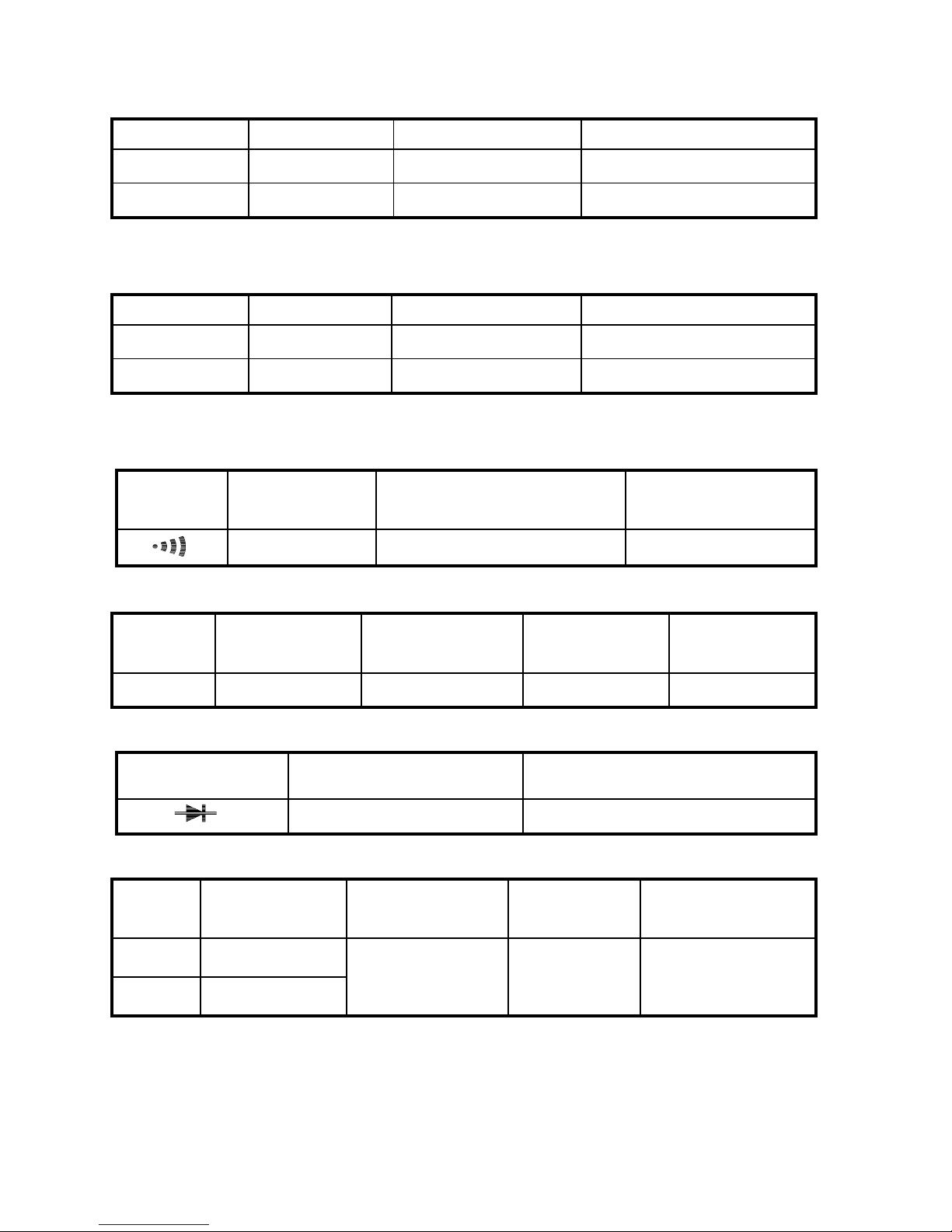

2-5 Measurement Specifications

Accuracy are•±(• of reading • number of digits) at 18• to

28• ( 64• to 82•) with relative humidity to 80•.

TRUE power & Apparent power measurement

Input Resolution Accuracy

Frequency

range

Overload

protection

V<130V , A<150A

V>130V , A<150A

V<130V , A>150A

0.01

±

(2%+5)

V>130V , A>150A 0.1

±

(2%+1)

45Hz〜

500Hz

600V/1100A

DCA

Range Resolution Accuracy Overload protection

1000A 0.1A

±

( 1.5% + 5)

1100A

ACA

Range Resolution Accuracy

Frequency

range

Overload

protection

1000A 0.1A

±

( 1.5% + 5)

45Hz〜500Hz

1100A

※

Crest factor : < 3 for stated accuracy

DCV

Range Resolution Accuracy

Input

impedance

Overload

protection

600V 0.1V

±

(0.5% + 5)

1MΩ

600V

ACV

Range Resolution Accuracy

Input

impedance

Frequency

range

Overload

protection

600V 0.1V

±

( 0.5%+5)

1MΩ

45Hz

〜

500Hz

600Vrms

※

Crest factor : < 3 for stated accuracy

Page 7

6

Peak indication

Range Resolution Accuracy Overload protection

20A~80A 0.1A

±

(10% + 10)

1100A

80A~1000A 0.1A

±

( 6% + 10)

1100A

※

Peak detect acquisitions time ≦1ms

Peak indication

Range Resolution Accuracy Overload protection

20V~80V 0.1V

±

(10% + 10)

600Vrms

80V~600V 0.1V

±

( 6% + 10)

600Vrms

※

Peak detect acquisitions time ≦1ms

Audible continuity

Range

Continuity

beeper

Open circuit voltage

Overload

protection

< 0.050

≦

3.2V

600Vrms

Resistance ( Ω )

Range Resolution Accuracy

Open circuit

voltage

Overload

protection

10KΩ 1Ω

±

( 1 ﹪ + 5)

≦

3.2 V

600Vrms

Diode test

Range Resolution Overload protection

0.001V 600Vrms

Frequency ( Hz )

Range Resolution Accuracy

Voltage

sensitivity

Overload

protection

1KHz 0.1Hz

5KHz 1Hz

±

(0.5% + 5)

10V or 10A 600V / 1100A

Optional accessories:

RS-232 interface adaptor / software

Page 8

7

III.

PARTS & CONTROLS

3-1 Description of Parts & Control

KW

K

KVA

P P-

3 3W

ME M

PF lead lag

WL123 READ

3 4W Hz

KVA

MINMA X HOLD -

REC ORD

HOLD

Hz

1000A

OFF

V

3 4W

3 3W

KW

600V CATMAX

(Figure-1)

Press and hold the button until the beeper

sounds that means the function activating.

Page 9

8

(1). Transformer jaws

Pick up the AC and DC current flowing through the conductor.

(2). Jaw opening trigger.

(3). Data Hold button

Press it once to hold the measured value and store the

value in memory. Press again to release hold function.

(4). Function selector

For selection of desired function, and awakening from autopower-off mode.

(5). Yellow button (P+ or P- selection)

a. Press “Yellow” button once, LCD will display “P+P

-”

symbo

l, then press “PEAK” button to measure peak

value of a transient signal.

b. Press “Yellow” button until the RE

AD symbol is shown on

LCD and then P

ress “

•

” button to read the previous data.

Press “

•

” button to read the next data. Press “Yellow”

button again to exit.

c. When the rotary switch is set to KW function, press this

button to select KW/PF, A/V or KVA/PF dual displayed.

d. When the rotary switch is set to the 3

•

3W or 3•4W

func

tion, press on the yellow button to select the phase

to be measured.

(6). MIN/MAX/PEAK function button

a. Press it once to select MIN or MAX. Keep pressing it

for

2 seconds to exit MIN/MAX mode.

b.

Press “Yellow” button once

then press this button to

measure peak value P+ or P

- of a transient signal, keep

pressing it for 2 seconds to exit peak mode. It can be

used in ACV and ACA. One of the most common

applications is the measurement of the current value

when starting electrical motors. When measuring

alternating signals, LCD shows the peak value.

(7). DC A/W ZERO button

Page 10

9

Press the button once to zero the A or KW reading.

(8). RECORD button

•

Single Data Record

The clamp meter can store 25 data record in memory.

Once the button is pressed, the data number and

RECORD symbol will be shown on LCD. If the memory is

full, the FULL signal will be shown on LCD when the

record button is pressed.

•

Continue Data Record

The memory size is of 4000 records. To start recording

data, press the RE

CORD button until 2 “beep” sounds

heard and “RECORD” symbol will be shown on LCD. To

stop recording data, press the RECORD button again until

the RECORD symbol disappears.

•

Clear data logger

To clear the memory of the meter, turn the instrument off.

Press on the RECORD button and power on the

instrument. The LCD will show CLr.

(9). LCD display

4 digital LCD with indications for measurement values, unit

symbols, decimal point, polarity, over range, and low

battery ; etc.

(10). RS-232 PC Interface Jack

To connect the RS-232 interface to the PC and meter.

(11). COM Jack

Connect black test lead for voltage, frequency, resistance,

continuity and diode measurement as a negative terminal.

(12). " V

•

Hz " Jack

Connect red test lead for voltage, frequency, resistance,

continuity and diode measurement as a positive terminal.

Page 11

10

KW

K

KVA

P P-

3 3W

ME M

PF lead lag

WL123 READ

3 4W Hz

KVA

MINMA X HOLD -

REC ORD

READ

3 4W

PF lead lag

WL123

REC ORD

3 3W

ME M

KVA

KW

Hz

KVA

K

MA X

P P-HOLD MIN-

(Figure-2)

(13). Low Battery:

A

s battery power is not sufficient .

Will be displayed

as a symbol of low battery.

(14). Analog Display Scale.

(15). Analog Display.

(16). Units Symbols.

Page 12

11

IV.

AC+DC POWER MEASUREMENT

WARNING

Wait until “- - - -” symbol is shown on LCD before clamping

on to any conductor and pressing on the ZERO button to

zero any residual magnetic field in the jaws.

4-1 AC+DC 1φ2W Power(W) and Power Factor (PF) Measurement

KW

PF lag

HOLD

Hz

1000A

OFF

V

3 4W

3 3W

KW

600V CATMAX

600V MAX CAT

PF lag

KW

(Figure-3)

Turn the clamp on with the jaws clamped on to no conductor.

Set the rotary switch to KW (refer to figure 3).

Insert the test leads into the input terminals.

Page 13

12

Connect the test probe of COM (black) terminal to the

neutral line.

Connect the test probe of V (red) terminal to the power line.

Clamp the conductor where V (red) terminal is connected.

The power clamp will automatically select the appropriate range.

Read the Watt and PF values displayed on the LCD.

Press YELLOW button to select KW/PF, A/V, or KVA/PF.

KVAR is a calculated value, and its accuracy greatly

depends on the accuracy of V, A and KW especially when

PF is very close to 1. To get a more accurate value when

PF is greater than 0.91 (φ < 25°), users can obtain KVAR by

themselves from the following equation for pure sine wave

input :

PF

KW

KVA

=

KVA (Apparent Power) :

KVA =

VA*

1000

KVAR (Reactive Power) : KVAR=

(KVA) (KW)

22

−

NOTE

The "+" sign printed on jaw must face the power source for

accurate measurement.

Page 14

13

4-2 3φ3W AC+DC Power Measurement

KW

600V MAX CAT

WL12

3 3W

3 3W

PF lag

WL12

KW

MAX600V CAT

WL12

PF lag

3 3W

3 4W

KW

3 3W

V

1000A

Hz

HOLD

OFF

(Figure-4)

Page 15

14

600V CATMAX

WL 23

PF lag

3 3W

KW

MAX CAT600V

WL 23

PF lag

3 3W

KW

3 4W

V

KW

3 3W

1000A

Hz

OFF

HOLD

WL 23

3 3W

(Figure-5)

600V

PF la g

3 3W

WL123

KW

MAX CAT

HOLD

(Figure-6)

Page 16

15

First, measure W

RS(L1L2)

(refer to figure 4).

a. Turn the power on without clamping to any wire.

b. Set the rot

ary switch at 3φ3W, and W

L12

symbol will

appear to instruct users to take measurement of W

RS(L2L1)

.

c. Insert the test leads into the input ja

ck.

d.

Select one phase (eg. S or L2) as COM and connect

the

test probe of the COM (black) terminal to that phase (eg.

S or L2).

e. Connect the t

est probe of V (red) terminal to

the second

phase (eg. R or L1).

f. Clam

p the same phase as

step e. (eg. R or L1).

g. The power clamp will automatically select proper range.

h.

Wait until the reading is

stable (about 3~6 seconds),

press the YELLOW button and W

L23

symbol will appear

to instruct users to take measurement of W

TS

(W

L3L2

).

Second, measure W

TS(L3L2)

(refer to figure 5).

a. Disconnect the test probe from the phase where jaws

is

clamp on in previous m

easurement.

b. Connect the test probe to t

he third phase (eg. T or L3).

c.

Camp the third phase where te

st probe is connected to

(eg. T or L3)

d. The power clamp will automat

ically select proper range.

e. Wait

until the reading is stable (about 3~6 seconds),

press the YELLOW button.

Page 17

16

The power clamp will process those two sets of data (W

L12

,

W

L23

), and show the result on the LCD. W

L123

symbol will

be shown to indicate the watt of 3φ3W power.

At this moment, the watt of 3φ3W power is stored into the

memory.

If willing to read the details of that singly data record,

please refer to 5-9.

W

3φ3W

= W

RS(L1L2)

+ W

TS(L3L2)

KVA K

W

KVAR

WW W33

2

33

2

33

φφ φ

=+

PF

KW

KVA

W

W

W

33

33

33

φ

φ

φ

=

If willing to record data (W

L12

or W

L23

), press “RECORD”

button to complete.

NOTE

Once a phase is selected as COM, users can not change this

selection in the subsequent measurement. For example, if S (or

L2) phase is selected, S (or L2) phase is always connected to the

COM during measurement of W

RS

(or W

L1L2

) and W

TS

(or W

L3L2

)

in 3φ 3W unbalanced power.

NOTE

The "+" sign print

ed on jaw must face the power source, and

make sure all the connections and clamping are correct for correct

measurement.

NOTE

In the 3φ3W unbalanced power measurement

, one of W

RS

or

W

TS

could be negative. Users must make sure all the

connections and clamping are correct to obtain correct power.

Page 18

17

4-3 3φ4W AC+DC Power Measurement

KW

600V MAX CAT

PF lag

WL1

3 4W

MAX600V CAT

WL1

3 4W

PF lag

KW

3 4W

3 3W

V

1000A

KW

Hz

HOLD

OFF

WL1

3 4W

(Figure-7)

HOLD

CAT600V MAX

WL 2

PF lag

KW

3 4W

600V CATMAX

PF lag

WL 2

3 4W

KW

KW

3 3W

3 4W

1000A

OFF

Hz

V

WL 2

3 4W

(Figure-8)

Page 19

18

600V CATMAX

PF lag

KW

WL 3

3 4W

MAX600V CAT

3 4W

WL 3

3 4W

PF lag

KW

OFF

Hz

V

KW

3 3W

1000A

HOLD

W L 3

3 4W

(Figure-9)

600V

PF lag

WL123

KW

MAX CAT

HOLD

3 4W

(Figure-10)

Page 20

19

a. Turn the power on without clamping on to any wire.

b. Set

the rotary switch at 3

φ

4W

.

c.

Insert the test leads into the input ja

ck.

d. Connect the neutral line to the COM (black) terminal.

e. Connect the test probe

of the V (red) terminal to the first

phase (eg. R or L1).

f. Clamp on to the same phase (eg.

R or L1).

g.

The power clamp meter will

automatically select proper

range.

h. Wait unt

il the reading is

stable (about 3~6 seconds),

press the YELLOW button,

and W

L1

symbol will disappear.

and W

L2

symbol appears to instruct users to take

measurement of W

S(L2)

/PF

S(L2)

.

Second, measure W

S(L2)

/PF

S(L2)

(refer to figure 8)

a. Disconnect the test probe from the phase where jaws

is

clamp on in previous measurem

ent.

b. Connect the test probe of t

he V (red) terminal to the

second phase (eg. S or L2).

c.

Clamp the phase where test probe is connected to

(eg. S

or L2 phase)

d. The power clamp will automat

ically select proper range.

e. Wait

until the reading is stable (about

3~6 seconds),

press t

he YELLOW button, and W

L2

symbol will disappear.

W

L3

symbol will appear to instruct users to take

measurement of W

T(L3)

/PF

T(L3)

.

Third, measure W

T(L3)

/PF

T(L3)

(refer to figure 9)

a. Disconnect the test probe from the phase where ja

ws

clamped in previous measurem

ent.

b. Connect the test probe of the V (red) terminal to th

e third

phase (eg. T or L3 phase).

c.

Clamp the phase where test

probe is connected to (eg.

T or L3).

First, measure W

R(L1)

/PF

R(L1)

(refer to figure 7).

Page 21

20

d. The power clamp will automatically select proper range.

e. Wait unt

il the reading is st

able (about 3~6 seconds), press

the YELLOW but

ton, and W

L3

symbol will disappear.

The power clamp will process these three sets of data (W

L1, WL2

W

L3

) and show the result on the LCD. WL

123

symbol will be

shown to indicate the watt of 3

φ

4W power (refer to figure 10).

At this moment, the of 3φ4W power are stored in the

memory.

If willing to read the details of that singly data record,

please refer to 5-9.

W

3φ4W

= W

R(L1)

+ W

S(L2) WT(L3)

KVA K

W

KVAR

WW W34

2

34

2

34

φφ φ

=+

PF

KW

KVA

W

W

W

34

34

34

φ

φ

φ

=

If willing to record data (W

L1,

W

L2 or WL3

), press “RECORD”

button to complete.

NOTE

The "+" sign printed on jaw must face the power source. Make

sure all the connections and clamping are correct for correct

measurement.

NOTE

In the 3φ4W power measurement

, all three WR or W

S

and WT

must be positive. If users find one negative power, check the

connection of test leads and clamping of jaw. Make sure all the

connections and clamping are correct to obtain correct power.

4-4 1φ3W Power Measurement

Page 22

21

MAX600V CAT

PF lag

WL12

3 3W

KW

KW

MAX600V CAT

WL12

PF lag

3 3W

3 4W

KW

3 3W

V

1000A

Hz

HOLD

OFF

WL12

3 3W

(Figure-11)

Page 23

22

600V CATMAX

PF lag

3 3W

WL 23

KW

MAX CAT600V

WL 23

PF lag

3 3W

KW

3 4W

V

KW

3 3W

1000A

Hz

OFF

HOLD

WL 23

3 3W

(Figure-12)

600V

PF lag

3 3W

WL123

KW

MAX CAT

HOLD

(Figure-13)

Page 24

23

1φ3W power measurement is similar to 3φ3W unbalanced

power measurement except the nomenclature is different.

Two measurements of W

RS(L1G)

and W

TS(L2G)

are required.

First, measure W

RS(L1G)

(refer to figure 11).

a. Turn the power on without clamping to

any wire.

b. Set

the rotary switch at 3

φ

3W.

c.

Insert the test leads into the input ja

ck.

d. Connect

the test probe of t

he COM (black) terminal to

ground.

e. Connect the t

est probe of V (red) term

inal to the second

phase (eg. L1).

f. Clam

p the same phase

as step e. (eg. L1).

g. The power clamp will automat

ically select proper range.

h.

Wait until the reading is

stable (about 3~6 seconds),

press the YELLOW butt

on, and W

L23

symbol will appear

to instruct users to take measurement of W

TS(L2G)

.

Second, measure W

TS

(or W

L2G

) (refer to figure 12).

a. Disconnect the test probe from t

he phase where jaws

clamped in the previous m

easurement.

b. Connect the test probe to the L2 line.

c. Clamp the L2 line where test probe is connected to.

d. The power clamp will automatically select proper range.

e.

Wait until the reading is st

able (about 3~6 seconds), press

the YELLOW but

ton.

The power clamp will add the two values together and show

the result on the LCD. At this moment the watt of 1φ3W

power is stored in the memory.

W

1φ3W

= W

RST

= W

RS(L1G) + WTS(L2G)

If willing to read the details of that singly data record,

please refer to 5-9.

If willing to record data (W

L1G

or W

L2G

), press “RECORD”

button to complete.

Page 25

24

V.

OPERATING INSTRUCTION

5-1 AC+DC Voltage Measuremen

Hz

HOLD

Hz

1000A

OFF

V

3 4W

3 3W

KW

600V CATMAX

V

(Figure-14)

WARNING:

Maximum input is 600V. Do not attempt to take

any voltage measurement that exceeds these limits.

Exceeding these limits could cause electrical shock and

damage to the clamp meter.

Set the rotary switch to V (refer to figure 14).

Insert the test leads into the input terminal.

Connect the test probes of the test leads in PARALLEL to

the circuit to be measured.

The clamp will automatically select the appropriate range.

Read the voltage and frequency values displayed on the LCD.

NOTE

The sensitivity for voltage frequency measurement is 10V,

and the frequency range is 45 - 500Hz. If the frequency is

less than 45 Hz, the LCD will show -.- Hz.

Page 26

25

5-2 AC+DC Current Measurement

Hz

HOLD

Hz

1000A

OFF

V

3 4W

3 3W

KW

600V CATMAX

A

CAT600V

A

Hz

A

(Figure-15)

Set the rotary switch at A (refer to figure 15).

Press the ZERO button once to zero the reading and LCD

will show “- - - -” sign.

Press the trigger to open the jaw and fully enclose the

conductor to be measured. No air gap is allowed between

the two jaw halves.

The clamp will automatically select the appropriate range.

Read the current and frequency values displayed on the LCD.

NOTE

The sensitivity for current frequency measurement is

10A, and the frequency range is 45 - 500Hz. If the

frequency is less than 45 Hz, the LCD will show -.- Hz.

Page 27

26

5-3 To Improve Power Factor of a 3φ4W Power System

Calculate KVAR

R(L1)

, KVAR

S(L2)

, and KVAR

T(L3)

values of

each phase.

Based upon the calculated values, users can purchase

required 3φ or 1φ capacitor at rated voltage and frequency

to improve power factor.

If value of capacitance is needed, users can obtain the

value by the following equation.

Where

Capacitance (Farad) =

KVARfV*1000

2

2

π

f

: f

requency in Hz, V: phase voltage

It is recommended that the KVAR value of the capacitor

should be a little less than the value measured.

5-4 To Improve Power Factor of a 3φ3W Power System

Calculate KVAR

3

φ

value of a balanced system.

Based upon the calculated value, users can purchase

required 3φ capacitor at rated voltage and frequency to

improve power factor.

If value of capacitance is needed, users can obtain the

value by the following equation.

Capacitance (Farad) =

KVARfV*1000

2

2

π

where

f

: f

requency in Hz, V: line voltage

It is recommended that the KVAR value of the capacitor

should be a little less than the value measured.

Page 28

27

5-5 To Improve Power Factor of a 1φ2W Power System

Calculate KVAR value of a 1φ2W power system.

Based upon the calculated value, users can purchase

required capacitor at rated voltage and frequency to improve

power factor.

If value of capacitance is needed, users can obtain the

value by the following equation.

Capacitance (Farad) =

KVARfV*1000

2

2

π

where

f

: f

requency in Hz, V: line voltage

It is recommended that the KVAR value of the capacitor

should be a little less than the value measured.

5-6 Resistance & Continuity Measurement

WARNING

Before taking any in circuit resistance measurement, remove power

form the circuit being tested and discharge all capacitors.

Before taking resistance measurements, make sure the

circuit is not live and discharge any capacitors present in

the circuit.

Set the function switch to • range.

Connect the black test lead to the COM terminal and the red

test lead to the

•

terminal.

Connect the test leads to the circuit being measured and

read the displayed value.

When the reading is below 50

•

,

it will be indicated by a

continuous beeping.

Page 29

28

K

HOLD

Hz

1000A

OFF

V

3 4W

3 3W

KW

600V CATMAX

(Figure-16)

Note : Continuity test is available to check open/short of the

circuit.

5-7 Diode Test & Continuity Measurement

Connect red test lead to the " • " terminal and black test

lead to the " COM" terminal.

Set range switch to the diode test position " " .

Connect the red test lead to the anode side and black test

lead to the cathode side of the diode being tested.

Read forward voltage ( Vf ) value on LCD.

If the test leads is connected rather than procedure(4), the

digital reading should nearly equal to the reading in the

open circuit condition. This can be used for distinguishing

anode and cathode poles of a diode.

When the reading is below 0.050V, it will be indicated by a

continuous beeping.

5-8 Peak Detection Measurement

Page 30

29

Set Function / Range Switch to desired •A or •V range.

Set the clamp Meter into the " PEAK HOLD " mode by

pushing the "YELLOW" button. The LCD will display " P+ P- ".

Press the “PEAK” button to enter PEAK mode. LCD

will display “P+ MAX” or “P- MIN”. The “PEAK” button

is toggle selector the P+ and P- value.

Press the “PEAK” button for two seconds to exit the PEAK

mode.

Follow this procedure for AC Voltage and current measurement.

The displayed reading is the positive peak value or negative

peak value of a surge in current or a voltage transient pulse.

Because the surge transient pulse is usually asymmetric.

5-9 Oper

ation Of Data Record And Read

Singly Data Record

The clamp meter can store 25 data record in memory.

Once the button is pressed, the data number and

RECORD symbol will be shown on LCD. If the memory is

full, the FULL signal will be shown on LCD when the record

button is pressed.

Singly Data Record

Press “Yellow” button until the READ symbol shown on LCD, then

Press “

•

” button to read previous data. Press “•” button to read

next data. Press “Yellow” button again to exit.

Continue Data Record

The full memory size got 4000 records. To start recording

data, press the RECORD button until 2 “beep” sounds

heard and “RECORD” symbol will be shown on LCD. To

stop recording data, press the RECORD button again until

the RECORD symbol disappears.

Continue Data Record

With the connection of RS-232 interface & computer P.C.

software.

Page 31

30

Clear data logger

To clear the memory of the meter, power off the meter,

then hold RECORD button and then power on it until the

LCD shows CLr.

VI.

BATTERY REPLACEMENT

WARNING

To prevent electrical hazard or shock, turn off clamp meter

and disconnect test leads before removing back cover.

As battery power is not sufficient, LCD will display

.

Replacement with one new battery type 9 V is required.

Set Range switch to OFF position.

Use a screwdriver to unscrew the screw secured on back

cover. Take out the batteries and replace with one new

battery Type 9V.

Place back cover and secure by a screw.

Loading...

Loading...