Page 1

Page 2

TABLE OF CONTENTS

1. FEATURES..................................................................1

2. SPECIFICATIONS........................................................

.

2

2-1 General Specifications............................................2

2-2 Electrical Specifications......................................... 5

3. FRONT PANEL DESCRIPTION.......................................7

4 SENSOR TYPE SELECTION........................................... 9

5 MEASURING PROCEDURE............................................

.

10

6. OTHER FUNCTION......................................................11

6-1 Data Hold.............................................................

.

11

6-2 Record ( Max./ Min. reading ).................................11

6-3 LCD Backlight ON/OFF...........................................

.

12

7. DATALOGGER.............................................................12

7-1 Preparation before execute datalogger function....................12

7-2 Auto Datalogger ( Set sampling time 1 second )..............≧ 13

7-3 Manual Datalogger ( Set sampling time = 0 second )...........

.

14

7-4 Check time information.......................................................15

7-5 Check sampling time information.........................................15

7-6 SD Card Data structure.......................................................16

8. Saving data from the SD card to the computer..............17

9. ADVANCED SETTING...................................................19

10. POWER SUPPLY from DC ADAPTER............................25

11. BATTERY REPLACEMENT...........................................25

12. SYSTEM RESET.........................................................26

13. RS232 PC SERIAL INTERFACE....................................26

14. OPTIONAL PRESSURE SENSOR..................................

.

28

15. OTHER OPTIONAL ACCESSORIES...............................29

16. PATENT....................................................................30

Page 3

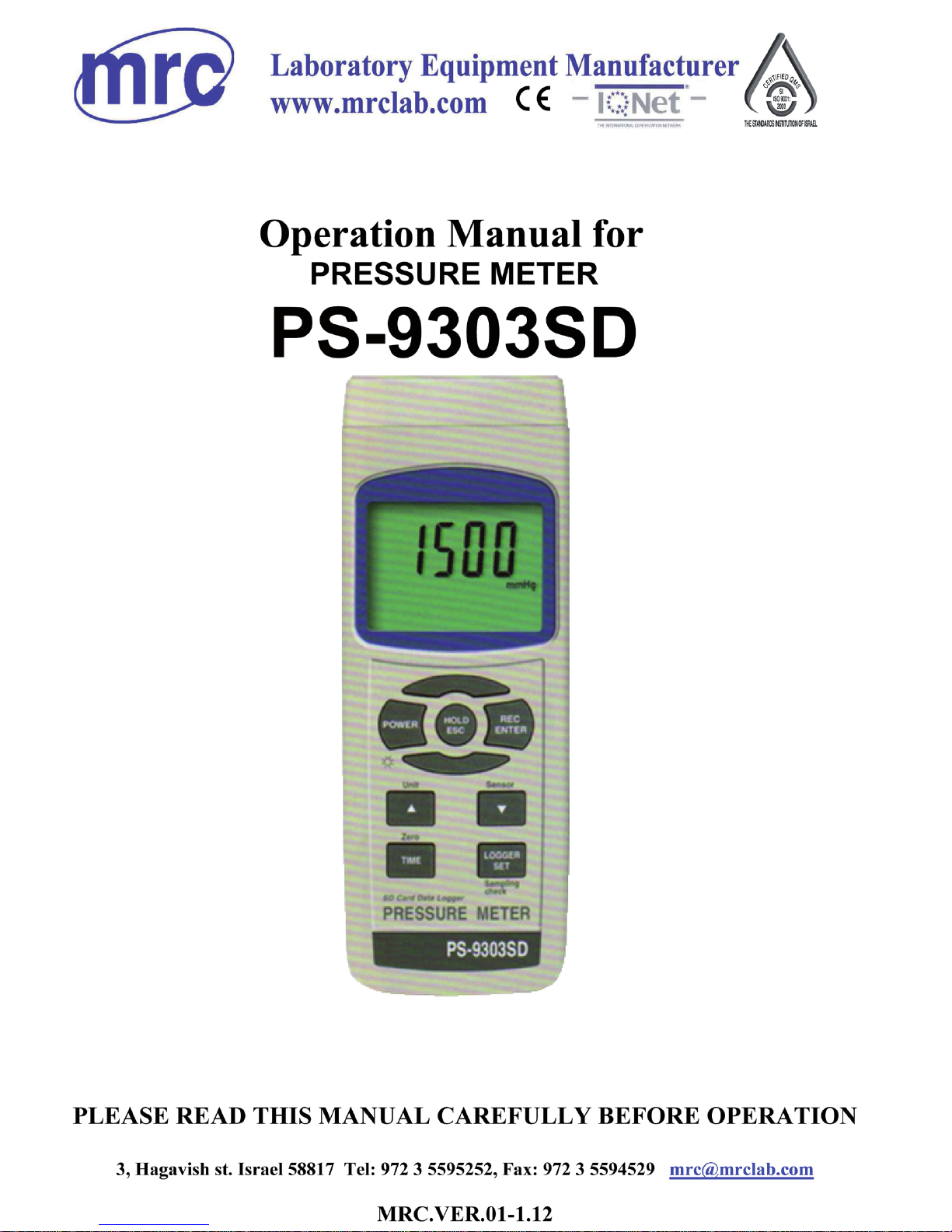

1. FEATURES

* Meter can cooperate optional pressure sensor with 2,

5, 10, 20, 50, 100, 200, 400 Bar, new calibration

procedures are not necessary when change the new

sensor .

* When change the new pressure sensor, just select

pressure type ( 2, 5, 10, 20, 50, 100, 200, 400 bar )

on the front panel button. The sensor type will

memorize into the circuit permanently.

* 10 kinds pressure units ( Bar, Psi, Kg/cm^2, mm Hg,

inch Hg, meter H20, inch H20, Atmosphere, hPA, kPA )

, unit select by push button on the front panel.

* Full line optional pressure sensors are available.

* Cooperate the external pressure sensor that its output

signal is 100 mV for full scale.

* Zero button on the front panel, easy adjust the zero

value of pressure sensor.

* Separate pressure sensor, easy for remote measurement.

* Microprocessor circuit assures maximum possible accuracy,

provides special functions and features,

* Real time SD memory card Datalogger, built-in Clock

and Calendar, sampling time can set from 1 sec to 8

hour 59 min. 59 sec.

* Manual datalogger is available, during execute the

manual datalogger function, it can set the different

location no. ( position 1 to position 99 ).

* Innovation and easy operation, computer is not need to

setup extra software, after execute datalogger, just take

away the SD card from the meter and plug in the SD card

into the computer, it can down load the all the measured

value with the time information ( year/month/date/

hour/minute/second ) to the Excel directly, the user can

make the further data or graphic analysis by themselves.

1

Page 4

* SD card capacity : 1 GB to 16 GB.

* LCD with green light backlight, easy reading.

* It can default auto power off or manual power off.

* Data hold, record max. and min. reading.

* Microcomputer circuit, high accuracy.

* Power by UM3/AA ( 1.5 V ) x 6 batteries or DC 9V adapter.

* RS232/USB PC computer interface.

* Wide applications : Measure pneumatic pressures,

measure automobile engine pressures, pressure for

super heat measurements, hydraulic servo controls,

refrigeration, air conditioning, food processing.

2. SPECIFICATIONS

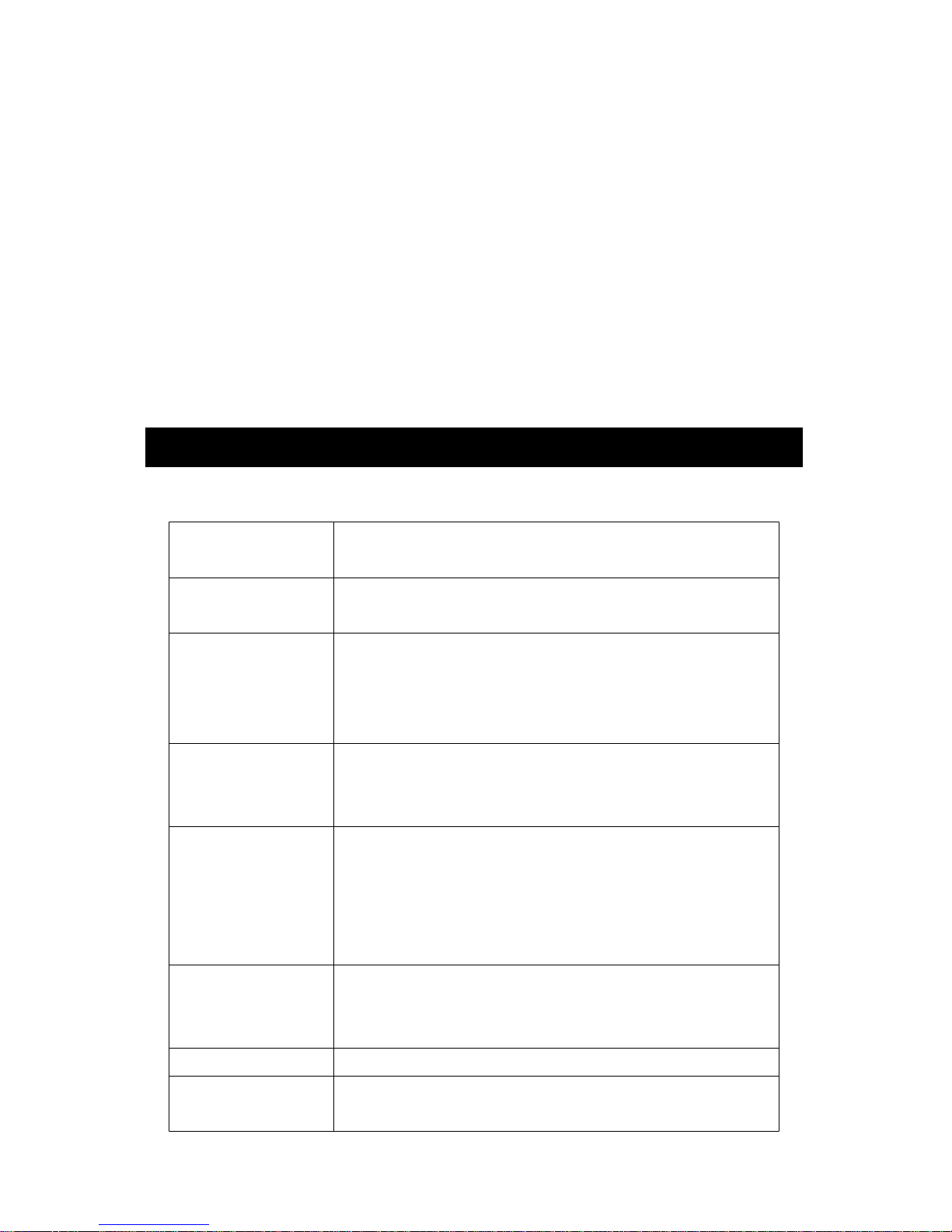

2-1 General Specifications

Circuit Custom one-chip of microprocessor LSI

circuit.

Display LCD size : 52 mm x 38 mm

LCD with green backlight ( ON/OFF ).

Sensor type Can cooperate with optional 2, 5, 10, 20,

50, 100, 200, 400 bar sensor, new

calibration are not necessary when

change the new sensor .

Display units Bar, Psi, Kg/cm^2, mm Hg, inch Hg,

meter H20, inch H20, Atmosphere,

hPA, KPA.

Accuracy ± ( 0.5% + 1 d )

* Under the signal from the sensor is at

full scale ( 100 mV ).

* Meter only.

* Within 23± 5 .℃

Pressure Cooperate the optional external pressure

sensor sensor that its output signal is 100 mV

for full scale. ref. page 28.

Zero adjust Push button on the front panel.

Span adjust Push button gain adjustment, usage for

calibration precisely if necessary.

2

Page 5

Input signal DC 100 mV for full Scale.

from sensor

Datalogger Auto 1 sec to 8 hour 59 min. 59 sec.

Sampling Time

@ Sampling time can set to 1 second,

Setting range

but memory data may loss.

Manual Push the data logger button

once will save data one time.

@ Set the sampling time to

0 second.

@ Manual mode, can also select the

1 to 99 position ( Location ) no.

Data error no. 0.1% of total saved data max.

Memory Card SD memory card. 1 GB to 16 GB.

Advanced * SD memory card Format

setting * Set clock time ( Year/Month/Date,

Hour/Minute/Second )

* Set sampling time

* Auto power OFF management

* Set beep Sound ON/OFF

* Decimal point of SD card setting

* Select sensor type.

Data Hold Freeze the display reading.

Memory Recall Maximum & Minimum value.

Sampling Time Approx. 1 second.

of Display

Data Output RS 232/USB PC computer interface.

* Connect the optional RS232 cable

UPCB-02 will get the RS232 plug.

* Connect the optional USB cable

USB-01 will get the USB plug.

Operating 0 to 50 . ( 32 to 122 ).℃℉

Temperature

Operating Less than 80% R.H.

Humidity

3

Page 6

Power Supply

*

A

Alkaline or heavy duty DC 1.5 V battery

( UM3, AA ) x 6 PCs, or equivalent.

*

A

DC 9V adapter input. ( AC/DC power

adapter is optional ).

Power Current Normal operation ( w/o SD card save

data and LCD Backlight is OFF) :

Approx. DC 5 mA.

When SD card save the data and LCD

Backlight is OFF) :

Approx. DC 25 mA.

* AIf LCD backlight on, the power

consumption will increase approx.

12 mA.

Weight 350 g/0.77 LB.

Dimension 177 x 68 x 45 mm

(7.0 x 2.7x 1.9 inch)

* Meter only

Accessories Instruction manual...........................1 PC

Included

Optional Pressure sensor, PS100-xxBAR,

Accessories

* Refer to page

Hard carrying case, CA-06.

Soft carrying case, CA-05A.

SD memory card ( 1 GB )

SD memory card ( 2 GB )

AC to DC 9V adapter.

USB cable, USB-01.

RS232 cable, UPCB-02.

Data Acquisition software, SW-U801-WIN.

4

Page 7

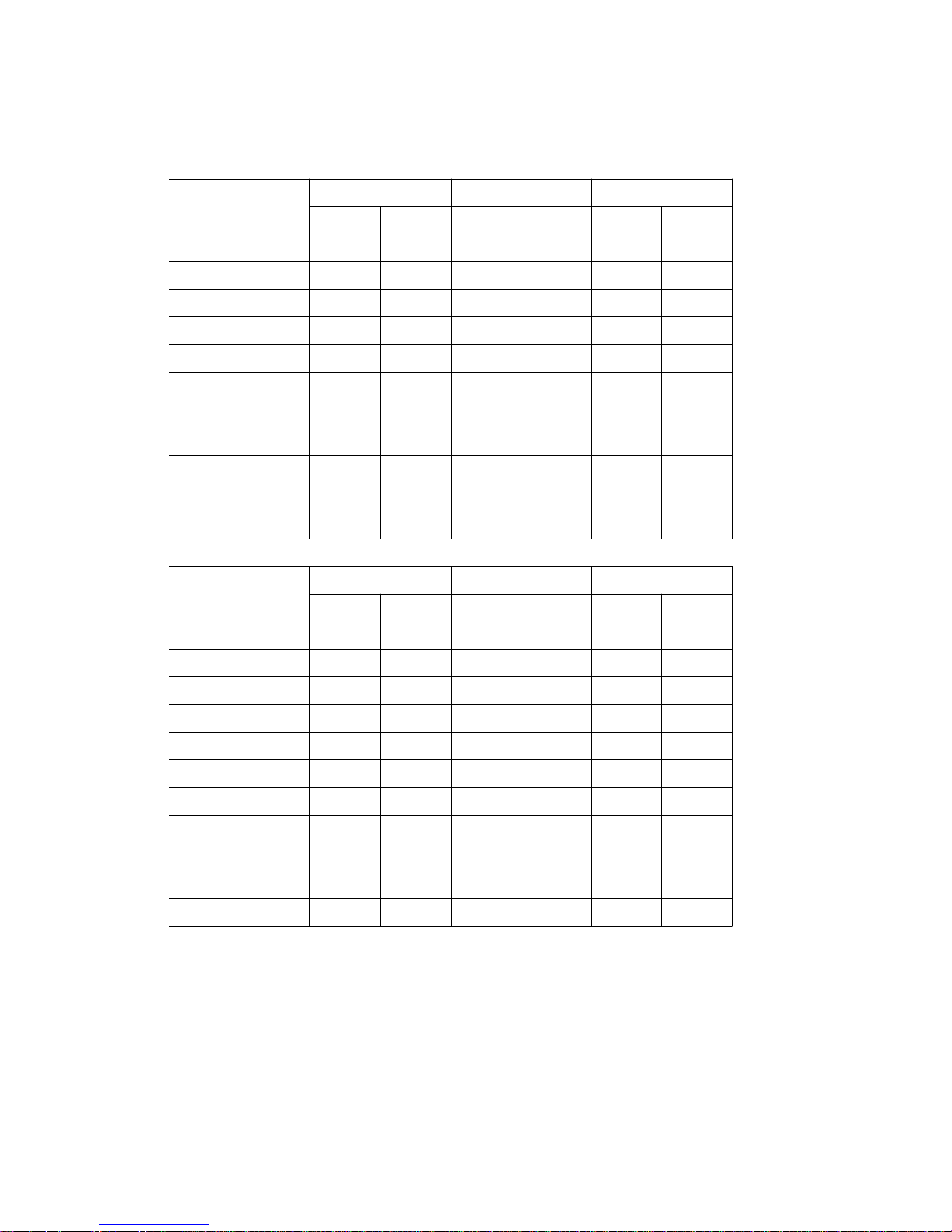

2-2 Electrical Specifications (23±5 )℃

Sensor type 2 bar 5 bar 10 bar

Max. Reso- Max. Reso- Max. Reso-

range lution range lution range lution

bar 2 0.002 5 0.005 10 0.01

Psi 29 0.02 72.5 0.1 145 0.2

Kg/cm^2 2.040 0.002 5.095 0.005 10.19 0.01

mm Hg 1500 2 3750 5 7500 10

inch Hg 59.05 0.05 147.6 0.1 295.2 0.2

meter H20 20.40 0.02 50.95 0.05 101.9 0.1

inch H20 802 1 2006 2 4010 5

Atmosphere 1.974 0.002 4.935 0.002 9.87 0.01

hPA 2000 2 5000 5 10000 10

kPA 200.0 0.2 500.0 0.5 1000 1

Sensor type 20 bar 50 bar 100 bar

Max. Reso- Max. Reso- Max. Reso-

range lution range lution range lution

bar 20 0.02 50 0.05 100 0.1

Psi 290 0.2 725 1 1450 2

Kg/cm^2 20.40 0.02 50.95 0.05 101.9 0.1

mm Hg 15000 20 37500 50 75000 100

inch Hg 590.5 0.5 1476 1 2952 2

meter H20 204.0 0.2 509.5 0.5 1019 1

inch H20 8020 10 20050 20 40100 50

Atmosphere 19.74 0.02 49.35 0.05 98.7 0.1

hPA 20000 20 50000 50 10000 100

kPA 2000 2 5000 5 1000 10

5

Page 8

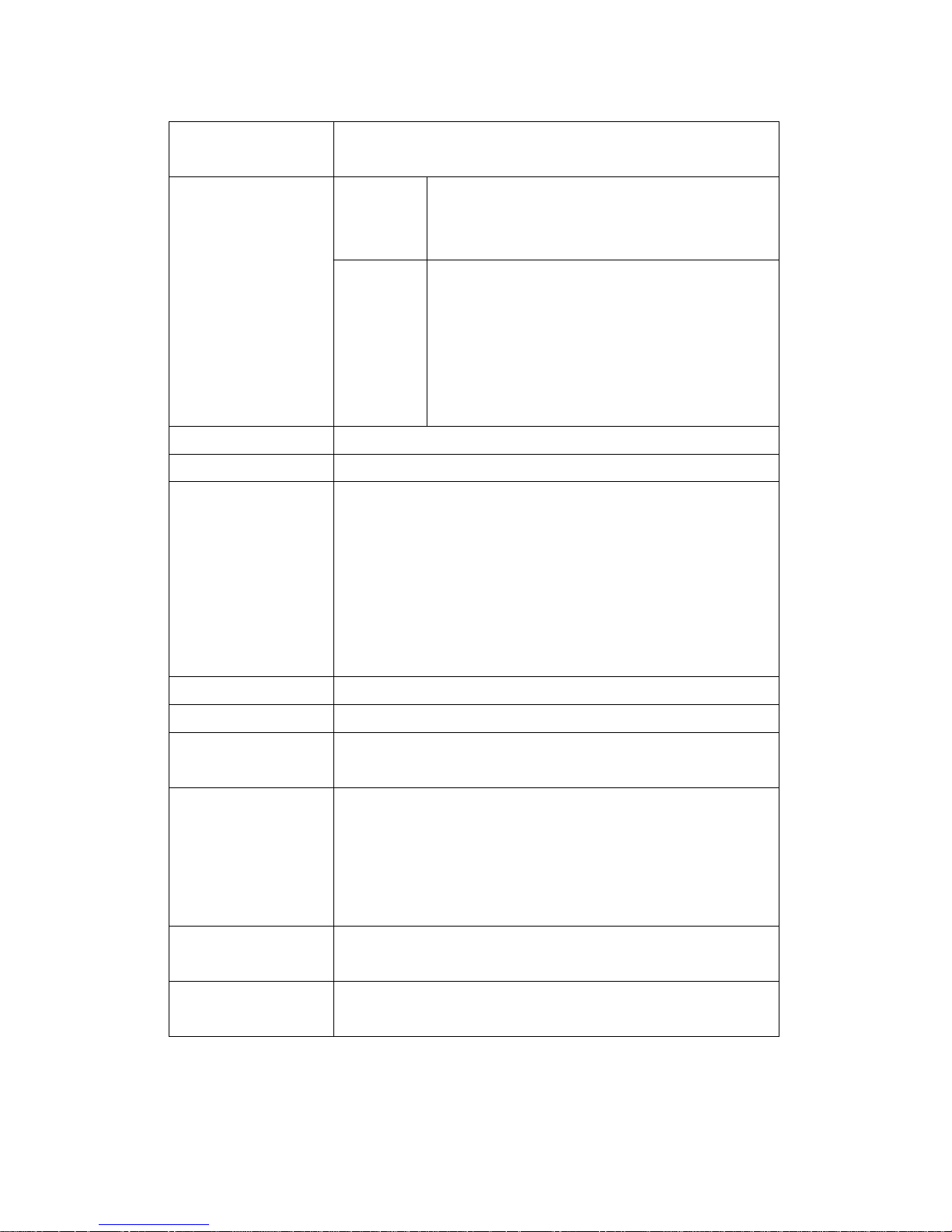

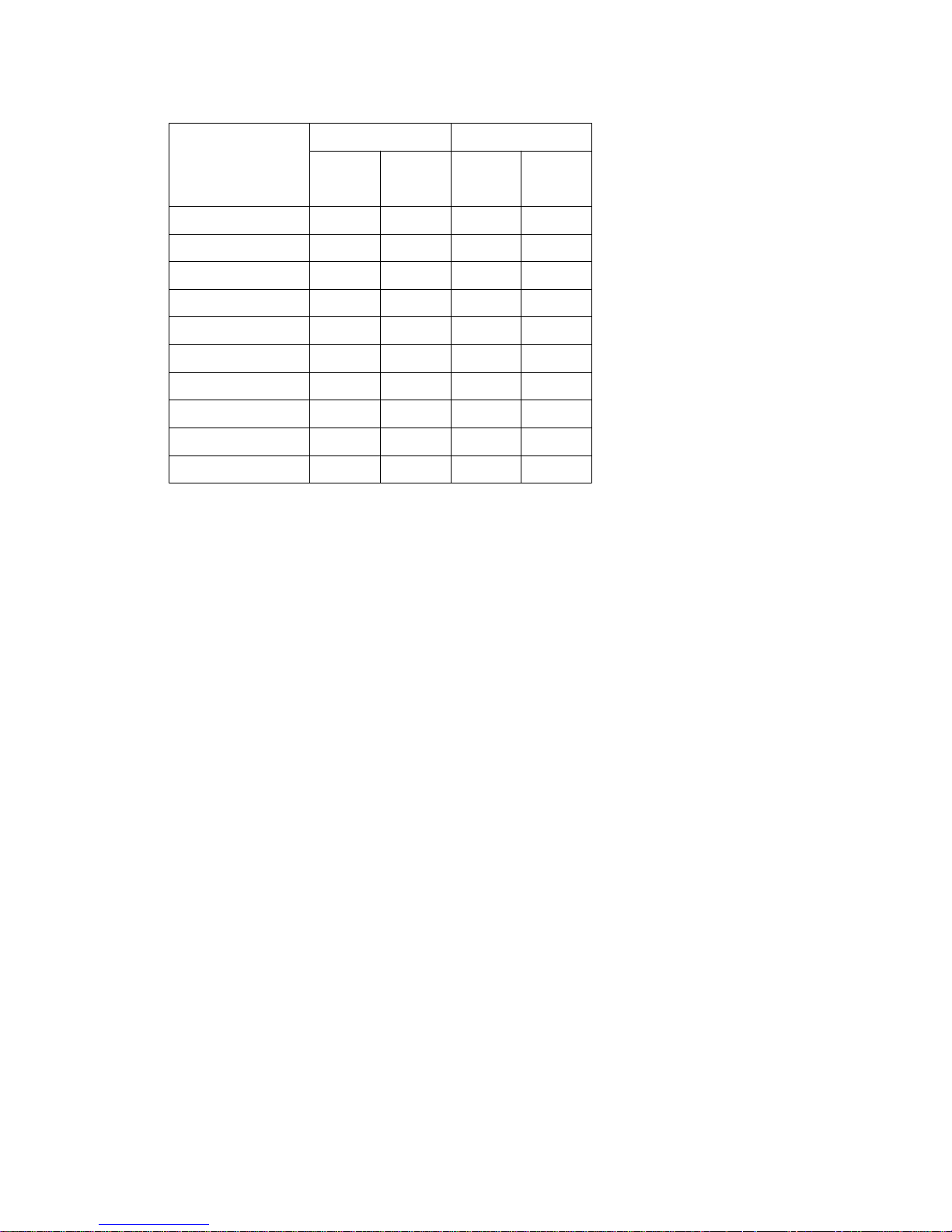

Sensor type 200 bar 400 bar

Max. Reso- Max. Reso-

range lution range lution

bar 200 0.2 400 0.5

Psi 2900 2 5800 5

Kg/cm^2 204.0 0.2 408.0 0.5

mm Hg 150000 200 300000 500

inch Hg 5905 5 11810 10

meter H20 2040 2 4075 5

inch H20 80200 100 160600 200

Atmosphere 197.4 0.2 394.5 0.5

hPA 200000 200 400000 500

kPA 20000 20 40000 50

6

Page 9

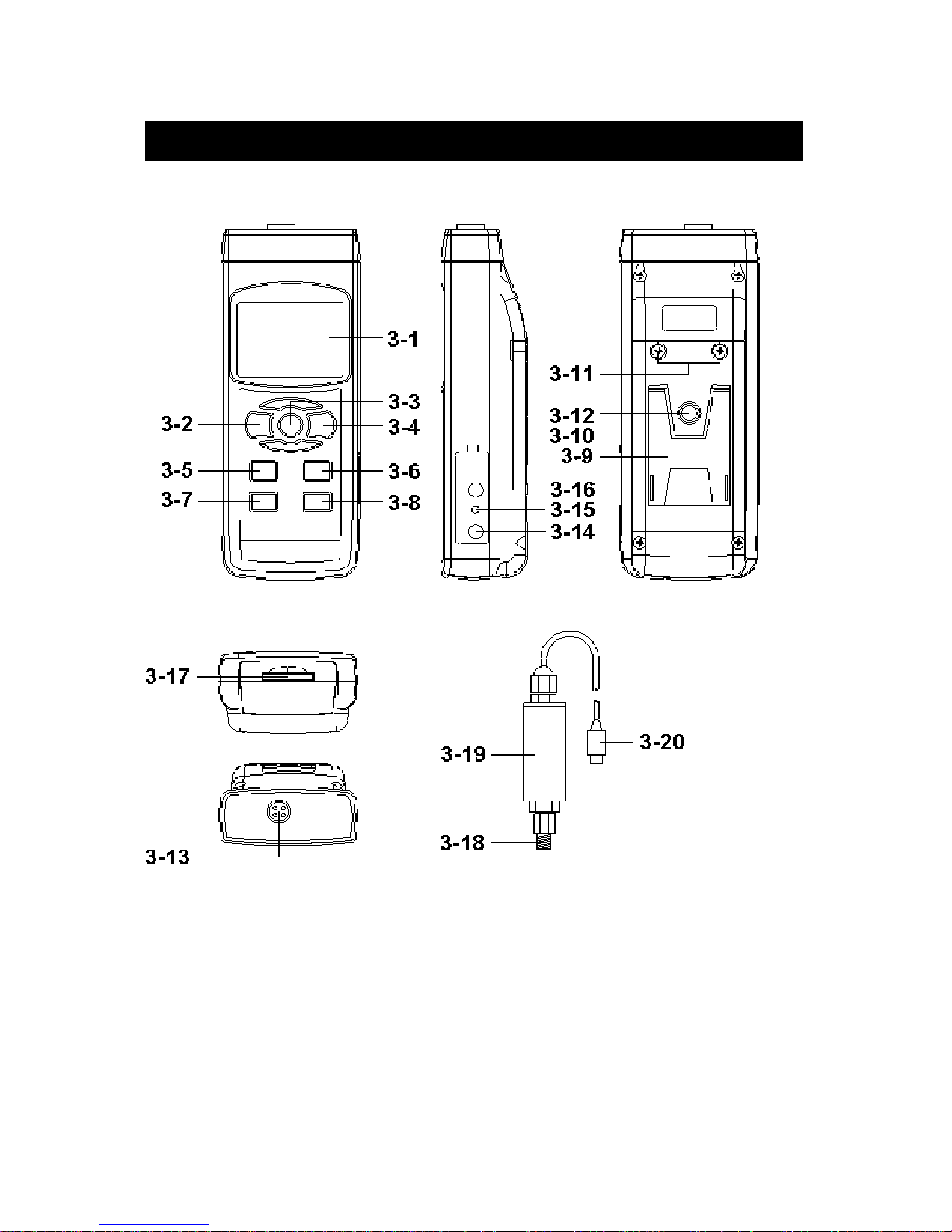

3. FRONT PANEL DESCRIPTION

Fig. 1

7

Page 10

3-1 Display

3-2 Power Button ( Backlight Button )

3-3 Hold Button ( ESC Button )

3-4 REC Button ( Enter Button )

3-5 Unit Button ( Button )▲

3-6 Sensor type Button ( Button )▼

3-7 Zero Button ( Time Button )

3-8 Logger Button ( SET Button, Sampling check )

3-9 Stand

3-10 Battery Compartment/Cover

3-11 Battery Cover Screw

3-12 Tripod Fix Nut

3-13 Probe Socket

3-14 DC 9V Power Adapter Input Socket

3-15 Reset Button

3-16 RS-232 Output Terminal

3-17 SD card socket

3-18 Port Connector of Pressure Sensor

3-19 Pressure Sensor Main body

3-20 Plug of Pressure Sensor

8

Page 11

4. SENSOR TYPE SELECTION

The meter can cooperate with optional 2, 5, 10, 20, 50,

100, 200, 400 bar sensor, new calibration are not necessary

when change the new sensor .

Those different optional pressure sensor are :

* 2 bar pressure sensor, Model : PS100-2BAR

* 5 bar pressure sensor, Model : PS100-5BAR

* 10 bar pressure sensor, Model : PS100-10BAR

* 20 bar pressure sensor, Model : PS100-20BAR

* 50 bar pressure sensor, Model : PS100-50BAR

* 100 bar pressure sensor, Model : PS100-100BAR

* 200 bar pressure sensor, Model : PS100-200BAR

* 400 bar pressure sensor, Model : PS100-400BAR

When change the different sensor ( 2 Bar, 5

Bar, 10 Bar, 20 Bar, 50 Bar, 100 Bar, 200 Bar,

400 Bar ), it should accordin

g

the procedures

that mentioned in Section 9-7, pa

g

e 23 to

select the convenient pressure sensor at first.

After already select the convenient pressure sensor type,

press Sensor type Button ( 3-6, Fig. 1 ) once, the Display

will show the sensor type to confirm.

For example, if the pressure type already select 2 bar

pressure sensor ( Model : PS100-2BAR ), then if press

Sensor type Button ( 3-6, Fig. 1 ) once, the Display will

show :

2

bAr

9

Page 12

5. MEASURING PROCEDURE

1)Plug in the " Plug of Pressure Sensor " ( 3-20, Fig. 1 )

to meter's " Probe Input Socket " ( 3-13, Fig. 1 )

2)Power on the meter by pushing the " Power Button "

( 3-2, Fig. 1 ) once.

3)Press the " Sensor Type Button " ( 3-6, Fig 1 ) once to

check if the meter's sensor type is same as the

external pressure sensor.

4)Press the " Unit Button " ( 3-5, Fig. 1 ) once in sequence

to select the measuring unit as : Bar, Psi, Kg/cm^2,

mm Hg, inch Hg, meter H20, inch H20, Atmosphere, hPA,

kPA.

Unit Display indicator

Psi PSI

inch Hg In Hg

inch H20 In H2O

hPA hPA

KPA _PA

Bar bAr

Kg/cm^2 _g C2

mm Hg -- Hg

meter H2O -t H20

Atmosphere AtP

Remark

:

After select the desired unit, power off th

e

meter then power on again, the meter circui

t

memory will save the selected unit wit

h

default.

10

Page 13

5)Zero adjustment :

If the Display is not show zero value, push the " Zero

Button " ( 3-7, Fig. 1 ), > 10 seconds continuously, the

Display value will change to zero value.

6)Connect the " Port Connector of Pressure Sensor "

( 3-18, Fig. 1 ) to the installation that intend to measure

the pressure value.

7)Apply the pressure, meter will show the pressure value.

6. OTHER FUNCTION

6-1 Data Hold

During the measurement, press the " Hold Button " ( 3-3,

Fig. 1 ) once will hold the measured value & the LCD will

display a " HOLD " symbol.

Press the " Hold Button " once again will release the data

hold function.

6-2 Data Record ( Max., Min. reading )

1)The data record function records the maximum and

minimum readings. Press the " REC Button " ( 3-4, Fig.

1 ) once to start the Data Record function and there

will be a " REC " symbol on the display.

2)With the " REC " symbol on the display :

a)Press the " REC Button " ( 3-4, Fig. 1 ) once, the

" REC MAX " symbol along with the maximum value

will appear on the display.

If intend to delete the maximum value, just press

the " Hold Button " ( 3-3, Fig. 1 ) once, then the

display will show the " REC " symbol only & execute

the memory function continuously.

11

Page 14

b)Press the " REC Button " ( 3-4, Fig. 1 ) again, the

" REC MIN " symbol along with the minimum value

will appear on the display.

If intend to delete the minimum value, just press

the " Hold Button " ( 3-3, Fig. 1 ) once, then

the display will show the " REC " symbol only &

execute the memory function continuously.

c)To exit the memory record function, just press the

" REC Button " for 2 seconds at least. The display will

revert to the current reading.

6-3 LCD Backlight ON/OFF

After power ON, the " LCD Backlight " will light

automatically. During the measurement, press the

" Backlight Button " ( 3-2, Fig. 1 ) once will turn OFF the

" LCD Backlight ".

Press the " Backlight Button " once again will turn ON the

" LCD Backlight " again.

7. DATALOGGER

7-1 Preparation before execute datalogger function

a. Insert the SD card

* It recommend use memory card 4 GB.≦

Prepare a " SD memory card " ( 1 GB to 16 GB, optional ),

insert the SD card into the " SD card socket " ( 3-17, Fig. 1 ).

The front panel of the SD card should face against the

down case.

b. SD card Format

If SD card just the first time use into the meter, it

recommend to make the " SD card Format " at first. ,

please refer chapter 9-1, page 20.

*It recommend strongly, do not use memory cards that

have been formatted by other meter or by a computer.

Reformat the memory card with your meter.

12

Page 15

c. Time setting

If the meter is used at first time, it should to adjust the

clock time exactly, please refer chapter 9-2, page 20.

d. Decimal format setting

The numerical data structure of SD card is

default used the " . " as the decimal, for

example "20.6" "1000.53" . But in certain

countries ( Europe ...) is used the " , " as the

decimal point, for example " 20, 6 "

"1000,53". Under such situation, it should

change the Decimal character at first, details

of setting the Decimal point, refer to Chapter

9-6, page 23.

7-2 Auto Datalogger ( Set sampling time 1 second )≧

a. Start the datalogger

Press the " REC Button ( 3-4, Fig. 1 ) once , the LCD will

show the text " REC ", then press the " Logger Button "

( 3-8, Fig. 1 ), the bottom text " DATALOGGER " will

flashing, at the same time the measuring data along the

time information will be saved into the memory circuit.

Remark :

*

How to set the sampling time, refer to Chapter 9-3

page 21.

*

How to set the beeper sound is enable, refer to

Chapter 9-5, page 22.

13

Page 16

b. Pause the datalogger

During execute the Datalogger function , if press the

" Logger Button " ( 3-8, Fig. 1 ) once will pause the

Datalogger function ( stop to save the measuring data

into the memory circuit temporally ). In the same time

the text of " DATALOGGER " will be no flashing.

Remark :

If press the " Logger Button " ( 3-8, Fig. 1 ) once again

will execute the Datalogger again, the bottom text of "

DATALOGGER " will flashing .

c. Finish the Datalogger

During pause the Datalogger, press the " REC Button "

( 3-4, Fig. 1) continuously at least two seconds, the " REC "

indication will be disappeared and finish the Datalogger.

7-3 Manual Datalogger ( Set sampling time = 0

second )

a. Set sampling time is to 0 second

Press the " REC Button ( 3-4, Fig. 1 ) once , the LCD will

show the text " REC ", then press the " Logger Button " (

3-8, Fig. 1 ) once, the bottom text " DATALOGGER " will

flashing once and Beeper will sound once, at the same

time the measuring data along the time information will be

saved into the memory circuit. The lower Display will show

the Position ( Location ) no. and saved into the SD card too.

14

Page 17

Remark :

During execute the Manual Datalogger, press the " ▲

Button " ( 3-5, Fig, 1 ) the lower no. ( position no. ) will

flashing. It can use the " Button " ( 3-5, Fig. 1) or " ▲

Button " ( 3-6, Fig. 1 ) to set the measuring Location▼

no. ( 1 to 99, for example room 1 to room 99 ) to

identify the measurement location , the lower Display will

show P x ( x = 1 to 99 ).

b. Finish the Datalogger

Press the " REC Button " ( 3-4, Fig. 1) continuously at

least two seconds, the " REC " indication will be

disappeared and finish the Datalogger.

7-4 To check the time information

During the normal measurement screen ( not execute

the Datalogger ),

1)If press " Time Button " ( 3-7, Fig. 1 ) once , the lower

LCD display will present the time information of

Hour/Minute/Second ( h.m.s ) in the lower Display.

2)If press " Time Button " ( 3-7, Fig. 1 ) once again , the

lower LCD display will present the time information of

Year/Month/Date ( yy.mm.dd ) in the lower Display.

3)If press " Time Button " ( 3-7, Fig. 1 ) once again ,

the LCD will return to normal screen.

7-5 Check sampling time information

During the normal measurement screen ( not execute the

Datalogger ), If press " Sampling Button " ( 3-8, Fig. 1 )

once , the lower LCD display will present the Sampling

time information in second unit.

15

Page 18

7-6 SD Card Data structure

1)When the first time, the SD card is used into the meter,

the SD card will generate a route :

PSA01

2)If the first time to execute the Datalogger,

under the route PSA01\, will generate a new

file name PSA01001.XLS.

After exist the Datalogger, then execute again,

the data will save to the PSA01001.XLS until

Data column reach to 30,000 columns, then

will generate a new file, for example PSA01002.XLS

3)Under the folder PSA01\, if the total files more

than 99 files, will generate anew route, such as

PSA02\ ........

4)The file's route structure :

PSA01\

PSA01001.XLS

PSA01002.XLS

.....................

PSA01099.XLS

PSA02\

PSA02001.XLS

PSA02002.XLS

.....................

PSA02099.XLS

PSAXX\

.....................

.....................

Remark :

XX : Max. value is 10.

16

Page 19

8. Saving data from the SD card

to the computer ( EXCEL software )

1)After execute the Data Logger function, take away the

SD card out from the " SD card socket " ( 3-17, Fig. 1 ).

2)Plug in the SD card into the Computer's SD card slot

( if your computer build in this installation ) or

insert the SD card into the " SD card adapter ". then

connect the " SD card adapter " into the computer.

3)Power ON the computer and run the " EXCEL software ".

Down load the saving data file ( for example the file

name : PSA01001.XLS, PSA01002.XLS ) from the SD

card to the computer. The saving data will present into

the EXCEL software screen ( for example as following

EXCEL data screens ) , then user can use those EXCEL

data to make the further Data or Graphic analysis

usefully.

EXCEL data screen ( for example )

17

Page 20

EXCEL graphic screen ( for example, graphic )

18

Page 21

9. ADVANCED SETTING

Under do not execute the Datalogger function,

press the " SET Button " ( 3-8, Fig. 1 ) continuously at

least two seconds will enter the " Advanced Setting " mode.

then press the " SET Button " ( 3-8, Fig. 1 ) once a while

in sequence to select the eight main function, the

display will show :

Sd F..... SD memory card Format

dAtE.....

.

Set clock time ( Year/Month/Date, Hour/Minute/

Second )

SP-t......Set sampling time ( Hour/Minute/Second )

PoFF.....Auto power OFF management

bEEP....

.

Set beeper sound ON/OFF

dEC......

.

Set SD card Decimal character

tyPE.....

.

Set the external optional sensor type

ESC...... Escape from the advanced setting

Remark :

During execute the " Advanced Setting " function,

if press " ESC Button " ( 3-3, Fig. 1 ) will exit the

" Advanced Setting " function, the LCD will return

to normal screen.

19

Page 22

9-1 SD memory card Format

When the lower display show " Sd F "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " (▲▼

3-6, Fig. 1 ) to select the upper value to " yES " or

" no ".

yES - Intend to format the SD memory card

no - Not execute the SD memory card format

2)If select the upper to " yES ", press the " Enter Button

" ( 3-4, Fig. 1 ) once again, the Display will show text

" yES Enter " to confirm again, if make sure to do the

SD memory card format, then press " Enter Button "

once will format the SD memory clear all the existing

data that already saving into the SD card.

9-2 Set clock time ( Year/Month/Date,

Hour/Minute/ Second )

When the upper display show " dAtE "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-6, Fig. 1 ) to adjust the value ( Setting start from

Year value ). After the desired value is set, press the

" Enter Button " ( 3-4, Fig. 1 ) once will going to

next value adjustment ( for example, first setting

value is Year then next to adjust Month, Date, Hour,

Minute, Second value ).

Remark :

The adjusted value will be flashed.

20

Page 23

2)After set all the time value ( Year, Month, Date, Hour,

Minute, Second ), press the " SET Button " ( 3-8, Fig.

1 ) once will save the time value, then the screen will

jump to Sampling time " setting screen ( Chapter 9-3 ).

Remark :

After the time value is setting, the internal clock will

run precisely even Power off if the battery is under

normal condition ( No low battery power ).

9-3 Set sampling time ( Hour/Minute/Second )

When the upper display show " SP-t "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-6, Fig. 1 ) to adjust the value ( Setting start from

Hour value ). After the desired value is set, press the

" Enter Button " ( 3-4, Fig. 1 ) once will going to next

value adjustment ( for example, first setting value is

Hour then next to adjust Minute, Second value ).

Remark :

The adjusted value will be flashed.

2)After set all the sampling time value ( Hour, Minute,

Second ), press the " SET Button " ( 3-8, Fig. 1 ) once

will save the sampling value with default then the

screen will jump to " Auto power OFF " setting

screen ( Chapter 9-4 ).

21

Page 24

9-4 Auto power OFF management

When the lower display show " PoFF "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-6, Fig. 1 ) to select the upper value to " yES " or

" no ".

yES - Auto Power Off management will enable.

no - Auto Power Off management will disable.

2)After select the upper text to " yES " or " no ", press the

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

function with default.

9-5 Set beeper sound ON/OFF

When the lower display show " bEEP "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-6, Fig. 1 ) to select the upper value to " yES " or

" no ".

yES - Meter's beep sound will be ON with default.

no - Meter's beep sound will be OFF with default.

is power ON.

2)After select the upper text to " yES " or " no ", press the

" Enter Button " ( 3-4, Fig. 1 ) will save the setting

function with default.

22

Page 25

9-6 Decimal point of SD card setting

The numerical data structure of SD card is default used

the " . " as the decimal, for example "20.6" "1000.53" .

But in certain countries ( Europe ...) is used the " , " as

the decimal point, for example " 20,6 " "1000,53".

Under such situation, it should change the Decimal

character at first.

When the lower display show " dEC "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-6, Fig. 1 ) to select the upper text to " bASIC " or

" Euro ".

bASIC - Use " . " as the Decimal point with default.

Euro - Use " , " as the Decimal point with default.

2)After select the upper text to " bASIC " or " Euro ",

press the " Enter Button " ( 3-4, Fig. 1 ) will save the

setting function with default.

9-7 Set the external optional pressure sensor type

When the lower display show " tyPE "

1)Use the " Button " ( 3-5, Fig. 1 ) or " Button " ▲▼

( 3-6, Fig. 1 ) to select the upper Display no. to 2, 5, 10

20. 50, 100, 200 or 400.

23

Page 26

Selecting no. via the optional pressure sensor

type :

If the select no. is " 2 " . The meter will cooperate :

2 bar pressure sensor, Model : PS100-2BAR

If the select no. is " 5 " . The meter will cooperate :

5 bar pressure sensor, Model : PS100-5BAR

If the select no. is " 10 " . The meter will cooperate :

10 bar pressure sensor, Model : PS100-10BAR

If the select no. is " 20 " . The meter will cooperate :

20 bar pressure sensor, Model : PS100-20BAR

If the select no. is " 50 " . The meter will cooperate :

50 bar pressure sensor, Model : PS100-50BAR

If the select no. is " 100 " . The meter will cooperate :

100 bar pressure sensor, Model : PS100-100BAR

If the select no. is " 200 " . The meter will cooperate :

200 bar pressure sensor, Model : PS100-200BAR

If the select no. is " 400 " . The meter will cooperate :

400 bar pressure sensor, Model : PS100-400BAR

2)After Display the convenient pressure sensor type is

selected to , press the " Enter Button " ( 3-4, Fig. 1 )

will save the setting function with default.

9-8 ESC

When the display show " ESC "

When the Display show the text " ESC ", then press the

" SET Button " ( 3-8, Fig. 1 ) or " ESC Button " ( 3-3, Fig. 1 )

will finish the Advanced Setting procedures.

24

Page 27

Remark :

During execute the " Advanced Setting " function,

if press " ESC Button " ( 3-3, Fig. 1 ) will exit the

" Advanced Setting " function, the LCD will return

to normal screen.

10. POWER SUPPLY from DC

ADAPTER

The meter also can supply the power supply from the

DC 9V Power Adapter ( optional ). Insert the plug of

Power Adapter into " DC 9V Power Adapter Input Socket

" ( 3-14, Fig. 1 ). The meter will permanent power ON

when use the DC ADAPTER power supply ( The power

Button function is disable ).

11. BATTERY REPLACEMENT

1)When the left corner of LCD display show " ", it

is necessary to replace the battery. However, in-spec.

measurement may still be made for several hours after

low battery indicator appears before the instrument

become inaccurate.

2)Loose the screws of the " Battery Cover " ( 3-11, Fig. 1 )

and take away the " Battery Cover " from the instrument

and remove the battery.

3)Replace with DC 1.5 V battery ( UM3, AA,

Alkaline/heavy duty ) x 6 PCs, and reinstate the cover.

4)Make sure the battery cover is secured after changing batteries.

25

Page 28

12. SYSTEM RESET

If the meter happen the troubles such as :

CPU system is hold ( for example, the key button can

not be operated... ).

Then make the system RESET will fix the problem.

The system RESET procedures will be either following

method :

During the power on, use a pin to press the " Reset Button "

( 3-15, Fig. 1 ) once a while will reset the circuit system.

13. RS232 PC SERIAL INTERFACE

The instrument has RS232 PC serial interface via a 3.5

mm terminal ( 3-16, Fig. 1 ).

The data output is a 16 digit stream which can be

utilized for user's specific application.

A RS232 lead with the following connection will be

required to link the instrument with the PC serial port.

Meter PC

(9W 'D" Connector)

Center Pin..........................Pin 4

(3.5 mm jack plug)

Ground/shield.......................Pin 2

2.2 K

resister

Pin 5

26

Page 29

The 16 digits data stream will be displayed in the

following format :

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Each digit indicates the following status :

D15 Start Word

D14 4

D13 When send the upper display data = 1

When send the lower display data = 2

D12, D11 Annunciator for Display

Bar = 22 mm Hg = 78 inch H2O = 25

Psi = 23 inch Hg = 80 ATP = 26

Kg/cm^2 = 77 meter H20 = 79

hPA = 91 kPA = 88

D10 Polarity

0 = Positive 1 = Negative

D9 Decimal Point(DP), position from right to the

left

0 = No DP, 1= 1 DP, 2 = 2 DP, 3 = 3 DP

D8 to D1 Display reading, D1 = LSD, D8 = MSD

For example :

If the display reading is 1234, then D8 to

D1 is : 00001234

D0 End Word

RS232 FORMAT : 9600, N, 8, 1

Baud rate 9600

Parity No parity

Data bit no. 8 Data bits

Stop bit 1 Stop bit

27

Page 30

14. OPTIONAL PRESSURE SENSORS

Description * Optional, pressure sensor that cooperate

with PS-9303SD.

* Out put : 100 mV DC for full scale.

* 4 pin DIN plug, 2 pins to accept DC 5 V

exciting voltage(power supply) for

pressure transducer, another two pins for

output signal of 100 mV full scale.

* Size : 30 mm dia. x 85 mm.

* Weight : 160 g.

Model 2 bar sensor........... PS100-2BAR

5 Bar sensor.............. PS100-5BAR

10 Bar sensor.............PS100-10BAR

20 Bar sensor.............PS100-20BAR

50 Bar sensor.............PS100-50BAR

100 Bar sensor...........PS100-100BAR

400 Bar sensor...........PS100-400BAR

Accuracy PS100-2BAR................± ( 2 % + 0.02 bar )

(23 ± 5 )℃

PS100-5BAR................± ( 2 % + 0.05 bar )

PS100-10BAR..............± ( 2 % + 0.1 bar )

PS100-20BAR..............± ( 2 % + 0.2 bar )

PS100-50BAR..............± ( 2 % + 0.5 bar )

PS100-100BAR............± ( 2 % + 1 bar )

PS100-400BAR............± ( 2 % + 4 bar )

28

Page 31

15. OTHER OPTIONAL ACCESSORIES

Memory card SD memory card ( 2 GB )

RS232 cable * Computer interface cable.

UPCB-02 * Used to connect the meter to

the computer ( COM port ).

USB cable * Computer interface cable.

USB-01 * Used to connect the meter to

the computer ( USB port ).

Data

T

he The SW-U801-WIN is a multi

Acquisition displays ( 1/2/4/6/8 displays )

software powerful application software,

SW-U801-WIN provides the functions of data

logging system, text display, angular

display, chart display, data recorder

high/low limit, data query, text

data recorder high/low limit, data

report, chart report.. .xxx.mdb data

file can be retrieved for EXCEL,

ACESS.., wide intelligent applications.

Power adapter AC 110V to DC 9V.

USA plug.

AC 220V/230V to DC 9V.

Germany plug.

29

Page 32

16. PATENT

The meter ( SD card structure ) already

get patent or patent pending in following

countries :

Germany Nr. 20 2008 016 337.4

JAPAN 3151214

TAIWAN M 358970

M 359043

CHINA ZL 2008 2 0189918.5

ZL 2008 2 0189917.0

USA Patent pending

30

Loading...

Loading...