Page 1

Distance Laser Sensor

MRL3 15

MRL3 30

MRL3H 15

MRL3H 30

Technical Reference Manual

V3.0

Please check www.metrologyresource.com

for the latest version

Page 2

Table of Contents

1 Introduction ...................................................................................................................................................... 3

1.1 Product identification .................................................................................................................................... 4

1.2 Components ................................................................................................................................................. 4

1.3 Validity .......................................................................................................................................................... 4

1.4 Measurement range ..................................................................................................................................... 5

1.5 Prevention of erroneous measurements ...................................................................................................... 6

2 Device setup .................................................................................................................................................... 7

2.1 Connection ................................................................................................................................................... 8

2.2 Controlled mode ........................................................................................................................................... 9

2.3 Automatic mode ......................................................................................................................................... 10

2.3 Display mode .............................................................................................................................................. 11

2.3 External Trigger .......................................................................................................................................... 11

3 Installation ..................................................................................................................................................... 13

3.1 Mounting ..................................................................................................................................................... 13

3.2 Device wiring .............................................................................................................................................. 13

3.3 Alignment of the laser beam....................................................................................................................... 15

4 Technical data ............................................................................................................................................... 16

4.1 Measuring accuracy ................................................................................................................................... 16

4.2 Specifications ............................................................................................................................................. 16

5 Electrical components ................................................................................................................................... 18

5.1 ID switch ..................................................................................................................................................... 18

5.2 Reset switch ............................................................................................................................................... 18

5.3 Digital output............................................................................................................................................... 18

5.3 Digital input ................................................................................................................................................. 18

5.5 Analog output ............................................................................................................................................. 19

5.6 Connector ................................................................................................................................................... 20

6 Physical dimensions ...................................................................................................................................... 22

7 Factory settings ............................................................................................................................................. 23

7.1 Operation .................................................................................................................................................... 23

7.2 Communication parameters ....................................................................................................................... 23

7.3 Analog outputs ........................................................................................................................................... 23

7.4 Module ID ................................................................................................................................................... 23

7.5 Digital output 1 (DOUT1) ............................................................................................................................ 23

7.6 Digital output 2 (DOUT2) ............................................................................................................................ 23

7.7 Digital Input 1 (DI1) .................................................................................................................................... 23

7.8 User Distance Offset .................................................................................................................................. 23

8 Command set ................................................................................................................................................ 24

8.1 General ....................................................................................................................................................... 24

8.2 Operation commands ................................................................................................................................. 25

8.3 Configuration commands ........................................................................................................................... 28

8.4 Digital Input................................................................................................................................................. 34

8.5 Special User Commands ............................................................................................................................ 35

8.6 Error Codes ................................................................................................................................................ 38

9 Accessories ................................................................................................................................................... 39

9.1 Viewfinder ................................................................................................................................................... 39

9.2 Target plates............................................................................................................................................... 39

9.3 Laser Glasses ............................................................................................................................................ 39

9.4 Cables ........................................................................................................................................................ 40

9.5 Connector cover for IP65 ........................................................................................................................... 40

Page 3

9.6 Connector cover with 90° cable exit IP65 .................................................................................................. 40

10 Safety instructions ....................................................................................................................................... 41

10.1 Use of the instrument ............................................................................................................................... 41

10.2 Limits to use ............................................................................................................................................. 41

10.3 Areas of responsibility .............................................................................................................................. 42

10.4 Hazards in use ......................................................................................................................................... 42

10.5 Laser classification ................................................................................................................................... 44

10.6 Electromagnetic compatibility (EMC) ....................................................................................................... 45

10.7 Producer Standards ................................................................................................................................. 45

10.8 Disposal .................................................................................................................................................... 45

10.9 Labeling .................................................................................................................................................... 46

10.10 Maintenance ........................................................................................................................................... 47

10.11 Service.................................................................................................................................................... 47

Page 4

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 4/43

1 Introduction

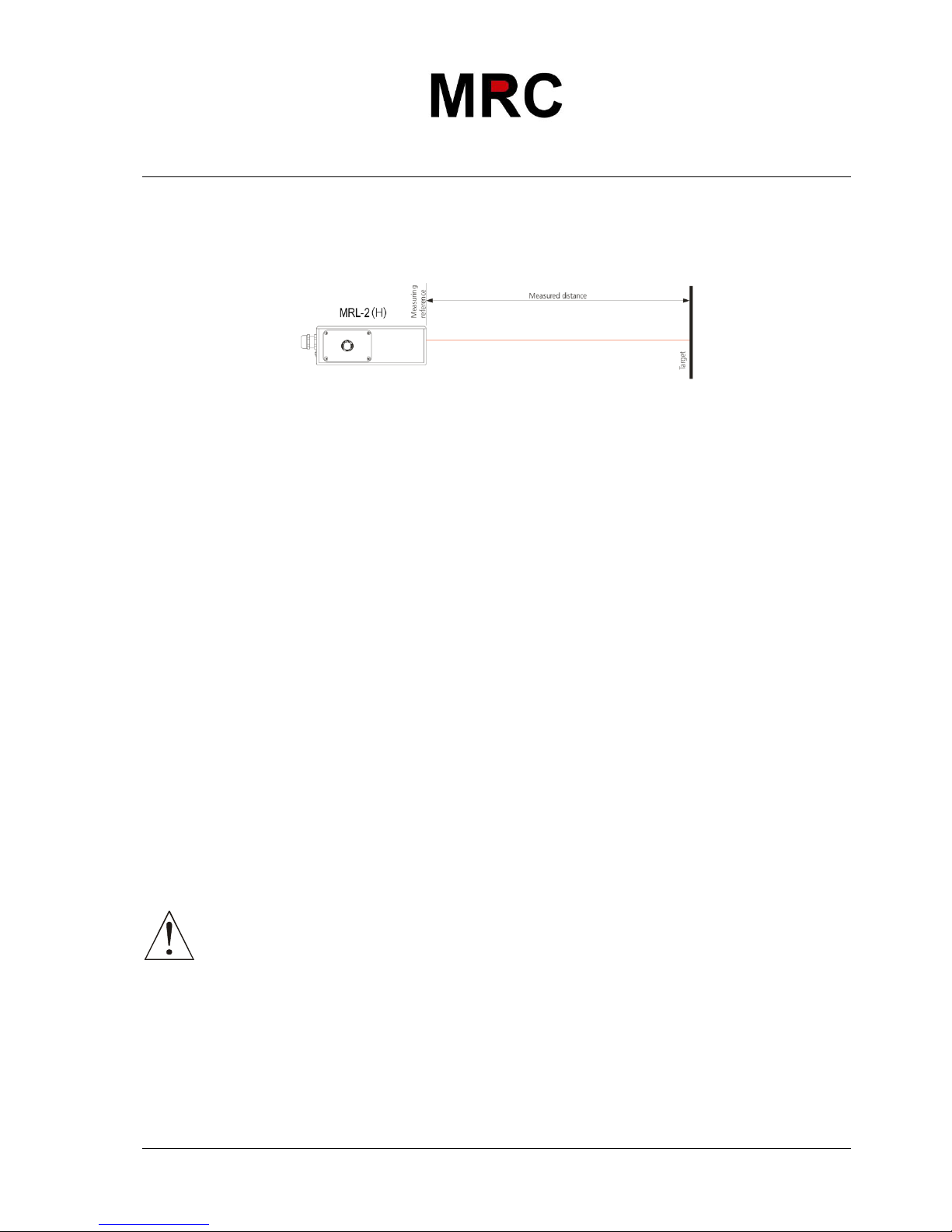

The MRL-3 (H) is a powerful distance measuring instrument for integration into industrial applications. It

allows accurate and contact-less distance measurement over a wide range using the reflection of a laser

beam:

Figure 1: Standard Application

Key features

Measurement range 0.2 to 150 m

Compatible with MRL-2 (H)

Serial interface (RS232 and RS422)

Connection of up to 10 modules on a single RS422 line

Wide range power supply (9...30VDC)

Programmable analog output (0/4...20mA)

Two programmable digital outputs (DO1 and DO2)

Digital output for error signalization (DOE)

D-Sub connector and screw terminal joint for easy connection

One programmable digital input (DI 1)

ASCII protocol to control external display

IP65 (protected against ingress of dust and water)

4 LEDs for status signaling

Complementary configuration software available at MRC web site (www.metrologyresource.com)

Optional: Internal heater for module operation down to -40°C

Laser class II (<0.95mW)

Accessories for easy use of the sensor

CAUTION

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Page 5

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 5/43

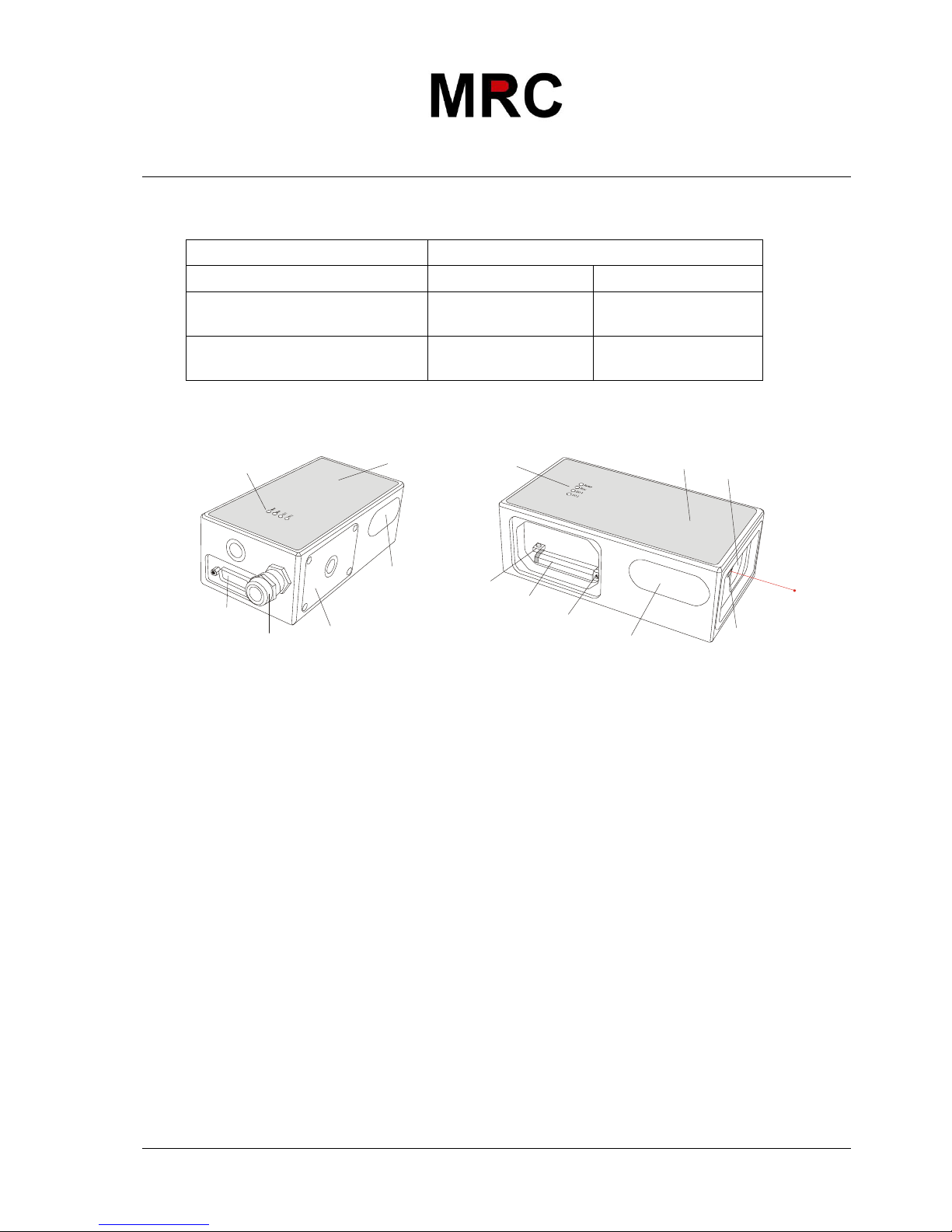

1.1 Product identification

The product is identified by the serial label on the top of the enclosure:

Version

Typical Accuracy

1.5mm

3.0mm

Standard version

MRL3 15

Part No.: 500602

MRL3 30

Part No.: 500601

Extended temperature range MRL3H 15

Part No.: 500612

MRL3H 30

Part No.: 500611

1.2 Components

1 Status LEDs

status signaling

2 15-Pin D-Sub connector

RS422, RS232, analog, digital output

3 Cable gland (M16 x 1.5mm)

for connection cable insertion

4 Caver

provides access to electrical components

5 N/A

6 Reset Switch

Resets the MRL3 (H) to default settings

7 Screw terminal

RS422, RS232, analog, digital output

8 ID switch

defines the module ID for RS422 operation

9 Laser beam outlet

10 Receiver optics

11 Product label

see 10.9 Labeling on page 42

1.3 Validity

This manual is valid for MRL3H devices with the following software version:

Interface software version: 0100 or later

Board software version: 0100 or later

To get the software version of the MRL3 use the command described in 8.3.9 Get software version (sNsv) on

page 29.

5

8

7

6

10

1

9

11

1

5

4

2

3

1

11

Page 6

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 6/43

1.4 Measurement range

The MRL3 (H) is an optical instrument, whose operation is influenced by environmental conditions. Therefore, the

measurement range achieved in the application can vary. The following conditions may influence the measurement

range:

Key

Factors increasing range

Factors reducing range

Target surface

Bright and reflecting surfaces such as the target

plates (See 9 Accessories on page 35)

Matt and dark surfaces

Green and blue surfaces

Airborne particles

Clean air

Dust, fog, heavy rainfall, heavy snowfall

Sunshine

Darkness

Bright sunshine at target

The MRL3 (H) does not compensate the influence of atmospheric environment, which may be relevant when measuring

long distances (e.g. > 150m). These effects are described in:

B.Edlen: “ The Refractive Index of Air, Metrologia 2”, 71 -80 (1966

)

1.5 Prevention of erroneous measurements

1.5.1 Rough surfaces

On a rough surface (e.g. coarse plaster), measure against the center of the illuminated area. To avoid

measuring to the bottom of plaster joints use a target plate (see access

ories) or board.

1.5.2 Transparent surfaces

To avoid measuring errors, do not measure towards transparent surfaces such as colorless liquids (such as water) or

(dust free) glass. For unfamiliar materials and liquids, always take a trial measurement.

Erroneous measurements can occur when aiming through panes of glass,

or if there are several objects in the line of sight.

1.5.3 Wet, smooth, or high-gloss surfaces

1 Aiming at an “acute“ angle deflects the laser beam. The MRL3 (H) may receive a signal that is

too weak (error message 255) or it may measure the distance targeted by the deflected laser beam.

2 If aiming at a right angle, the MRL3 (H) may receive a signal that is too strong (error message 256).

1.5.4 Inclined, round surfaces

Measurement is possible as long as there is enough target surface area for the laser spot.

1.5.5 Multiple reflections

Erroneous measurements can occur in the case that the laser beam is reflected from other objects than the

target. Avoid any reflecting object along the measurement path.

2 Device setup

We recommend performing the configuration steps in an office before mounting the device, especially if you

are not familiar with the MRL3 (H).

Page 7

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 7/43

The MRL3 (H) supports two types of operation modes:

Controlled mode

Automatic mode

The first decision to be taken is the type of operation mode that will be used to transmit the distance

measurement data. While the controlled mode provides maximum flexibility and accuracy, it is often not

suitable for integration into existing PLCs or analog environments. In such cases the automatic mode might

be preferred.

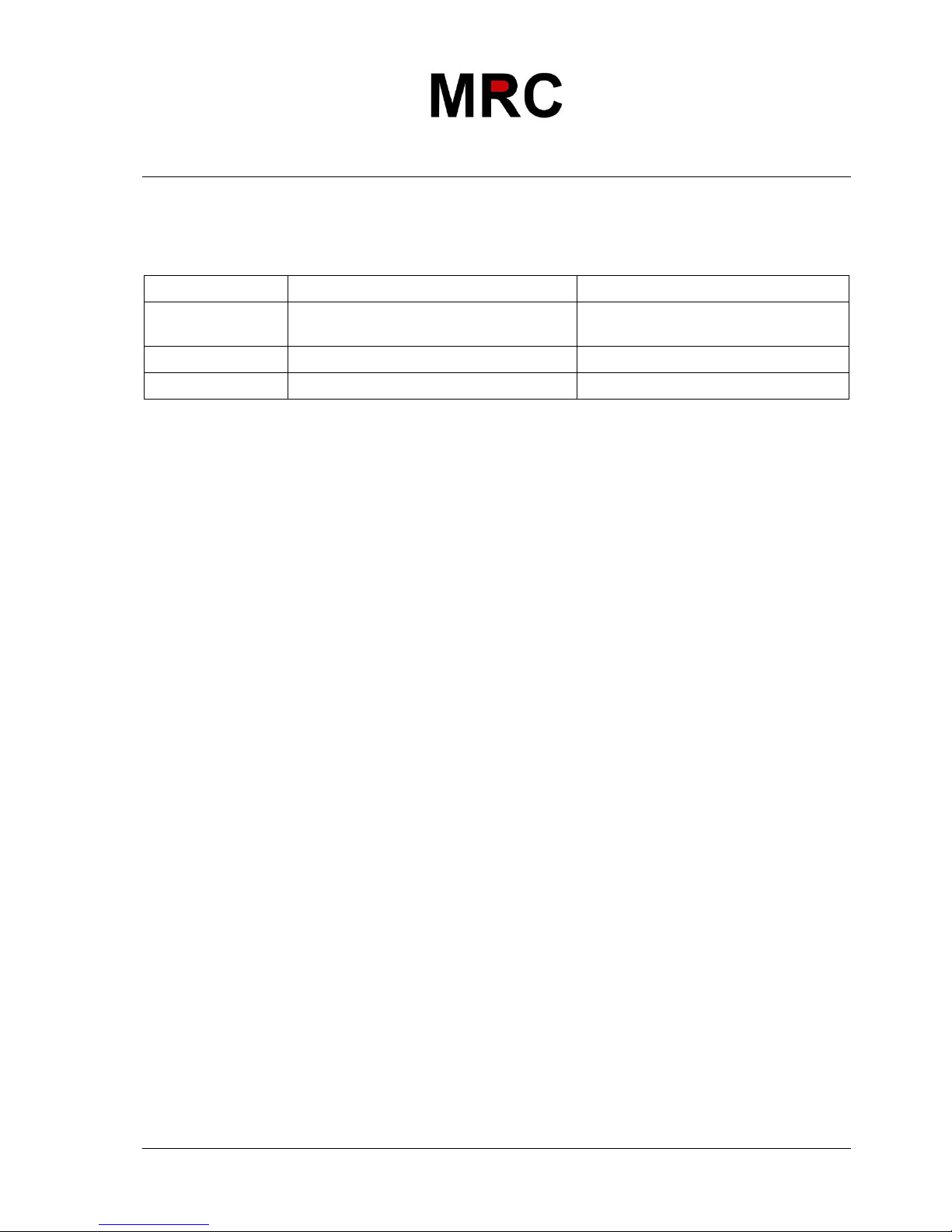

Key

controlled mode

automatic mode

(with analog output and digital outputs)

Accuracy

Maximum measurement accuracy

Accuracy depends on signal scaling

(see 8.3.5 on page 26)

Flexibility

Access to full command set

Limited

Integration

Requires protocol implementation

Wiring of AO and DO signals

Connection

Connection of up to 10 MRL3 (H)s to

a single RS-422 line.

Point-to-point connection

The following two sections describe the configuration of the MRL3 (H) for the controlled and automatic

modes.

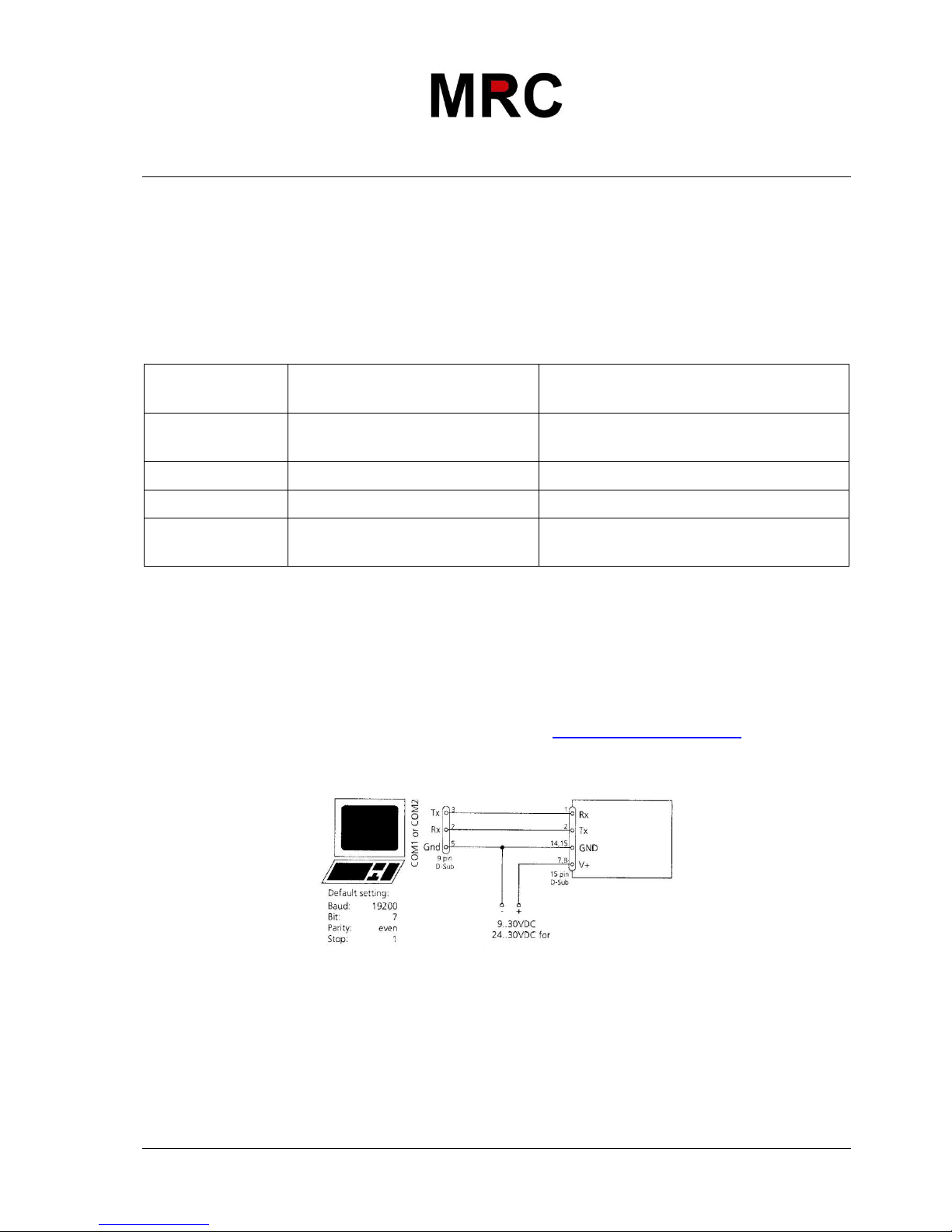

2.1 Connection

To be able to configure the MRL3 (H), it must be powered and connected to a PC. Figure 2 shows the

necessary connections. On the PC, any terminal program can be used to communicate with the module.

Additionally, a configuration utility is available on the web page www.metrologyresource.com.

Figure 2: Connection for MRL3(H) Configuration

Page 8

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 8/43

2.2 Controlled mode

In controlled mode, each operation of a MRL3 (H) is triggered by a command sent from a host system over a

serial line. While a single device can be connected to the host system using the RS232 interface, up to 10

devices can be connected to a single serial RS422 line. The related command set is described in Chapter 8

on page 21.

2.2.1 Configuration

After connecting the module, the steps below are necessary to configure the MRL3 (H) for the controlled

interface mode.

No.

Action

Comment

Command

1

Set ID switch

Changes of the module ID are

activated after a power cycle.

Example for module 0:

Change the ID Switch to position 0

Set ID switch to position 0

Power OFF; Wait 10s; Power ON

2

Set controlled mode

Set the MRL3 (H) to the controlled

mode, if not already in controlled

mode.

Example for module 0:

Set to controlled mode by the stop

command.

s0c<trm>

1)

3

Set communication

parameters

If necessary, change the settings for

the serial interface.

Example for module 0:

Set serial interface to 19200 Baud, 8

Bit, no Parity

s0br+2<trm>

1)

Power OFF; Wait 10s; Change

settings on the host; Power ON

1) Commands are described in 8 Command set on page 22

Remark: If the communication parameters of the module are lost, please reset the configuration to the

factory settings (7

Factory settings on page 21) using the reset button (5.2 Reset switch

on page 17). Please note that the ID switch must be reset manually.

2.2.2 Host software

Host software is required for operation of the MRL3 (H) in controlled mode. When connecting multiple

devices to a single serial li

ne (RS422), strict Master-Slave communication must be implemented (MRL3 (H)

operates as slave). Please consult the MRC Web page for application notes.

Careful testing of the host software together with the devices prior to installation is strongly recommended.

Page 9

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 9/43

2.3 Automatic mode

The automatic mode is provided for host-less operation of the MRL3 (H). The analog and digitals outputs are

updated according the configuration described below as soon as the unit is powered up.

Analog Output

The analog output is configurable and works with two ranges:

– 0..20mA

– 4..20mA

Digital Outputs

Three digital outputs are included in the MRL3 (H). Two are programmable, while the third is used to

signal an error state of the device.

2.3.1 Configuration

After connecting the module, the following steps are necessary to configure the MRL3 (H) for the automatic

mode.

No.

Action

Comment

Command

1

Set current output

range

Defines if the current output range

from 0 to 20mA respectively from 4

to 20mA.

Example for module 0:

Set current output range from 4mA

to 20mA.

s0vm+1<trm>

1)

2

Set distance range Defines minimum distance (D

min

)

and the maximum distance (D

max

)

for the distance range of the analog

output.

Example for module 0:

Set distance range from 0m to 10m

s0v+00000000+00100000<trm>

1

)

3

Set analog output in

error case

Sets the current that should be

applied in case of an error.

Example for module 0:

Set current to 0mA in case of an

error.

s0ve+000<trm>

1)

4

Configure digital

output

Set the ON and OFF level for the

digital outputs.

Example for module 0:

DO 1: off=2000mm on=2005mm

DO 2: off=4000mm on=4005mm

s01+00020000+00020050<trm>

1

s02+00040000+00040050<trm>

1

5

Save settings The changed configuration must be

Page 10

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 10/43

No.

Action

Comment

Command

saved to make it permanent.

Example for module 0:

Save settings for module 0

s0s<trm>

1)

6

Set automatic mode

Set the MRL3 (H) to the automatic

mode with the desired update rate.

Example for module 0:

Set measurement rate to fastest

possible speed.

s0A+0<trm>

1)

1) Commands are described in 8 Command set on page 21

Note: If the serial line settings of the module have been lost, please reset the configuration to the factory

settings (7

Factory settings on page 20) using the reset button (5.2 Reset switch on page 17).

Please note that the ID switch must be reset manually.

2.4 Display Mode

If the Display Mode the MRL3 formats the measured distance as an ASCII string which is understood with an

External Display with a serial interface. Since the MRL3 outputs this formatted string automatically on the

serial interface after completing the measurement, the results can be displayed on an external display

without the use of an additional controller. For a detailed description of this mode please contact MRC.

2.5 External Trigger

Page 11

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 11/43

The MRL-3(H) includes the option of triggering measurements with an external switch or push button on

Digital Input 1 (DI 1). Using the Digital Input DI 1 disables the Digital Output DO 1.

The command to activate the external trigger option is described in 8.4 Digital Input on page 30.

2.5.1 Configuration

After connecting the MRL-3(H), the following steps are necessary to activate the external trigger. The

example shows the configuration for triggering a single distance measurement.

No. Action Com

ment Command

No. Action Comment

Command

1

Activate Digital Input

DI1

Defines the action fro a trigger on DI1

Example for module 0:

Configure DI1 to trigger a single distance

measurement

s0D1I+<trm>

1)

5

Save settings

The changed configuration must be

saved to make it permanent

Example for module 0:

Save setting for module 0

s0s<trm>

1)

1) Commands are described in 8 Command set on page 20 Distance Laser Sensor V1.01 Page 10/43

Page 12

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 12/43

3 Installation

3.1 Mounting

Three M4 threaded holes in the bottom of the MRL-2 (H) make it easy to mount the device.

Always obey all applicable safety regulations and never use the device outside the specifications stated

under 4 Technical data on page 15

3.2 Device wiring

3.2.1 Power Supply

For trouble free operation use a separate power supply for the MRL-3 (H)

MRL-3 9…30V, 0.5A DC

MRL-3 (H) 24…30V DC, 2.5A DC

3.2.2 Cable connection

A ferrite must be mounted to the connecting cable. Use a ferrite with an impedance of 150 to 260 at

25MHz and 640 to 730

at 100MHz. As example you can use SFC10 from KE Kitagawa.

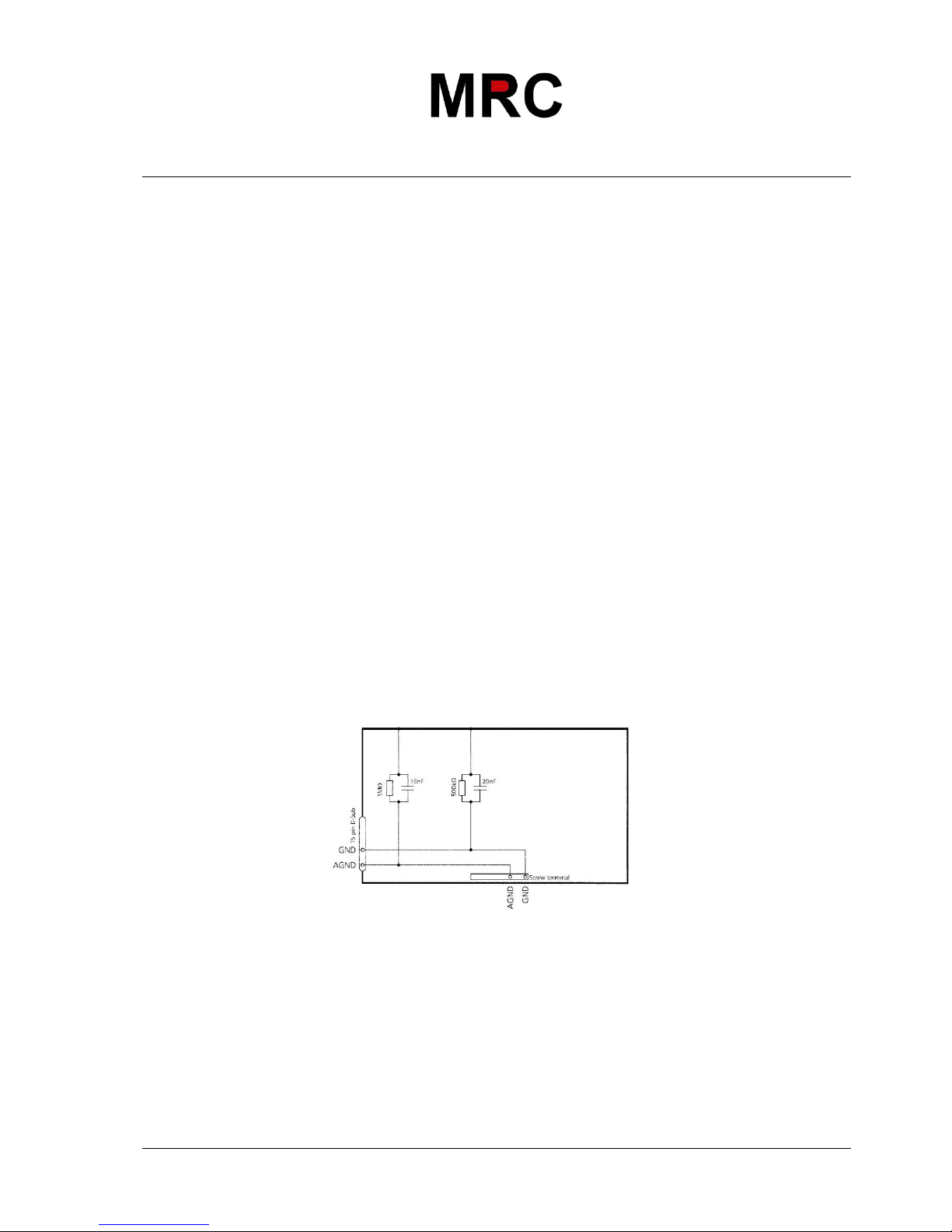

3.2.3 Shield and Ground

The MRL3 (H) contains two electrical isolated grounds, the general ground (GND) and the analog ground

(AGND). GND and AGND are connected to the housing by a RC element. Please see figure 3

Figure 3: Connection between shield and ground

Page 13

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 13/43

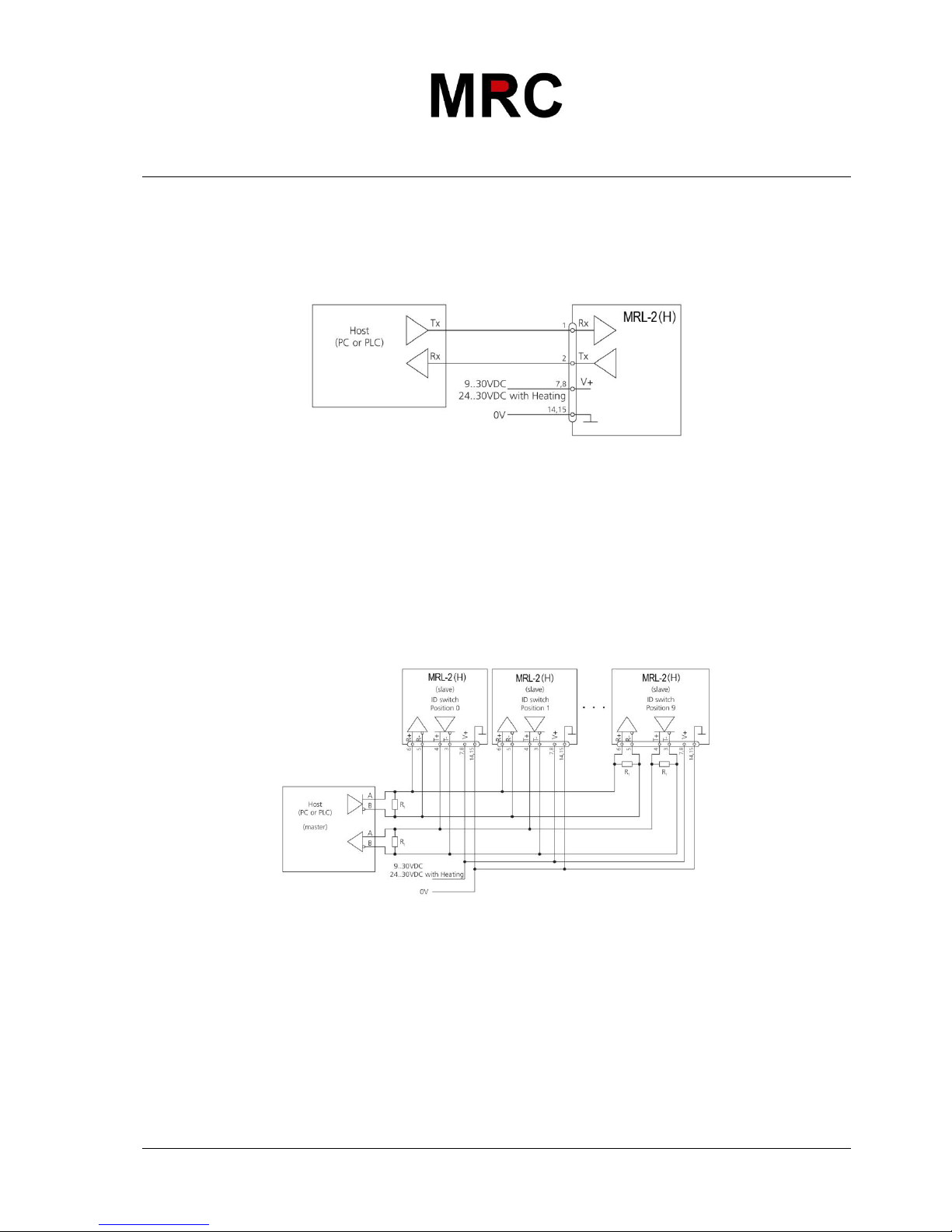

3.2.4 Controlled mode

RS232

When using the RS232 interface only point-to-point communication is possible.

Never connect multiple MRL3 (H)s on a RS232 serial line

Figure 4: Point-to-point connection with RS232

RS422

It is possible to connect multiple devices on a single RS422 line. To ensure proper operation, strict MasterSlave communication must be used. It is important, that the Master has full control of the communication and

never initiates a new communication be

fore termination of the previous communication (answer from the

MRL3 (H) or timeout).

Ensure, that all MRL3 (H)s are set to different ID number Automatic mode

Figure 5: Connecting multiple devices with RS422

Page 14

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 14/43

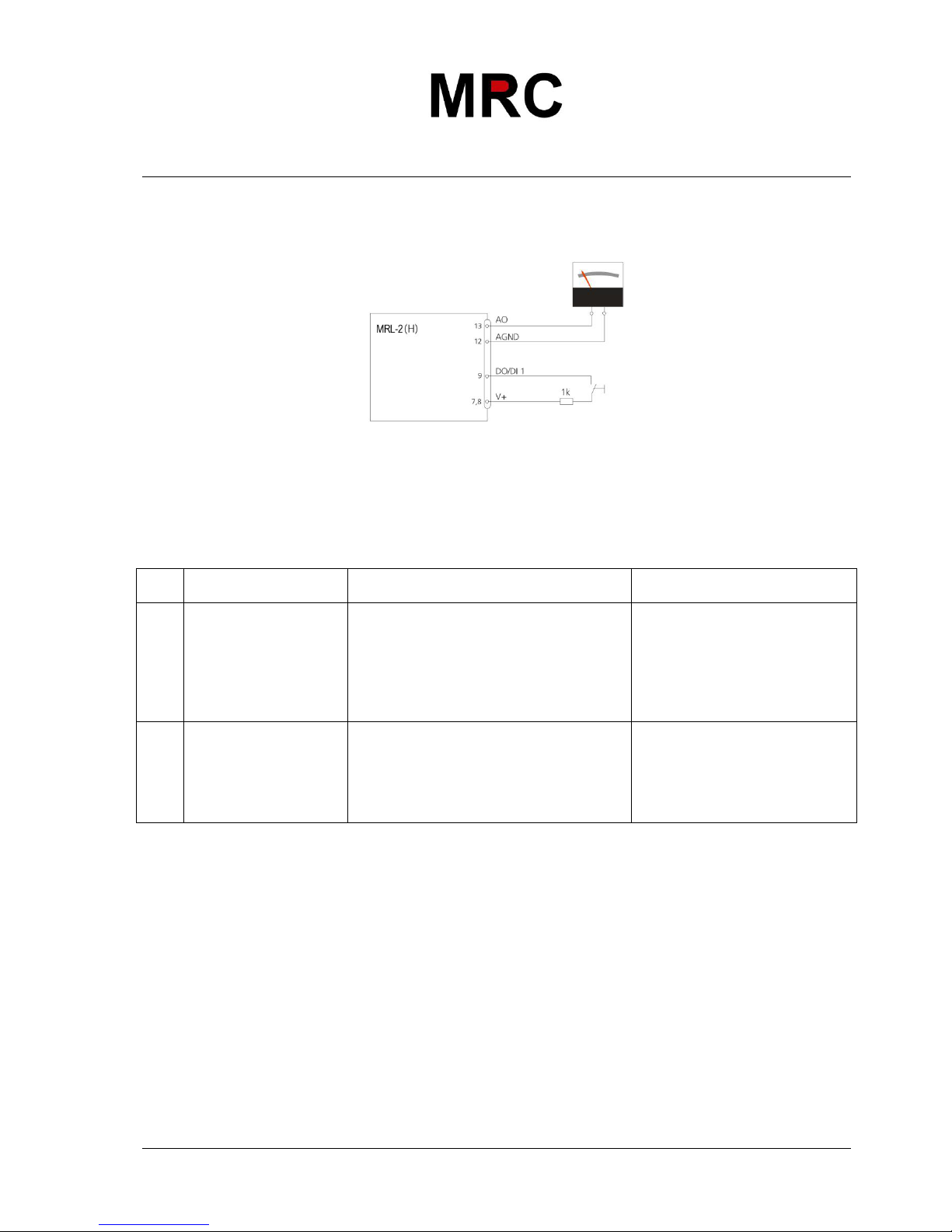

3.2.5 Automatic mode

The analog interface of the MRL3 (H) is isolated from the rest of the device. When using the analog

interface, connect the analog ground (AGND).

Make sure, that the total resistance in the analog path is smaller than 500

3.3 Alignment of the laser beam

Alignment of the laser beam is often difficult when the target is far away, as the laser spot is not visible. The

MRL3 (H) has an adapter for mounting a telescopic viewfinder that simplifi

es alignment significantly. Please

refer to chapter 9 Accessories on page 35 for a description of the viewfinder.

Figure 6: Connection of an instrument and a PLC

Page 15

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 15/43

4 Technical data

4.1 Measuring accuracy

The measuring accuracy corresponds to the ISO-recommendation

ISO/R 1938-1971 with a statistical confidence level of 95.4% (i.e. ±

twice the standard deviation

, refer to diagram on the right). The

typical measuring accuracy relates to average conditions for

measuring. It is ±1.5mm for the MRL3 (H) 15 and ± 3.0mm for the

MRL3 (H) 30 valid in the tracking mode

The maximum measuring error relates to unfavorable conditions such

a

s:

- Highly reflecting surfaces (e.g. reflector tapes)

- Operation at the limits of the permitted temperature range,

adaptation to ambient temperature interrupted

- Very bright ambient conditions, strong

heat shimmer

and can be up to ± 2 mm for MRL3 (H) 15 and ± 5 mm for MRL3 (H)

30. The MRL3 (H) does not compensate changes of atmospheric environment. This changes can influence

the accuracy if measuring long distances (>150m) at conditions very different to 20°C, 6

0% relative humidity

and 953 mbar air pressure. The influences of the atmospheric environment is described in

B.Edlen: “ The Refractive Index of Air, Metrologia 2”, 71 -80 (1966)

99.7%

95.4%

Page 16

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 16/43

4.2 Specifications

Typical measuring accuracy for

MRL3 15 / MRL3 (H) 15 1)

MRL3 30 / MRL3 (H) 30

1)

± 1.5 mm @ 2σ

± 3.0 mm @ 2σ

Smallest unit displayed

0.1 mm

Measuring range on natural surfaces

0.05 to approx 65 m

Measuring range on orange (reflecting) target plate

See Chapter 9 Target plates on page 36

ca. 0.05 to 150 m, future 500 m

Measuring reference from front edge (See 6 Physical dimensions)

Diameter of laser spot at target at a distance of 4mm @ 5 m

8mm @ 10 m

Approx 28mm x 14mm @ 50m

Approx 40mm x 25mm @ 100m

Time for a measurement

Single measurement

Tracking

004 to approx. 3 sec

0.04 to approx. 3 sec

Light source

Laser diode 620-690 nm (red)

IEC 60825-1:2001; Class 2

FDA 21CFR 1040.10 and 1040.11

Beam divergence:0.16 x 0.6 mrad

Pulse duration: 0.45x10

-9

s

Maximum radiant power: 0.95 mW

Laser Life Time

3)

>25,000h @ 25°C

ESD

IEC 61000-4-2 : 1995

EMC

EN 61000-6-4

EN 61000-6-2

Power supply

9 ... 30V DC 0.5A for MRL3

24 ... 30V DC 2.5A for MRL3 (H) (Heating option)

Dimensions

150 x 80 x 55 mm

Temperature range during operation 2)

MRL3 15 / MRL3 30

MRL3 (H) 15 / MRL3 (H) 30

-10 °C to +50 °C

-40 °C to +50 °C

Temperature range during storage

-40 °C to +70 °C

Degree of Protection IP65; IEC60529 (protected against ingress of dust and water)

Weight

MRL3: 630 g

MRL3 (H): 680 g

Interface

1 serial asynchronous interface (RS232/RS422)

1 programmable analog output 0/4 .. 20mA

2 programmable digital outputs

1 programmable digital input

1 digital output for error status

1

) See 4.1

Measuring accuracy on page 15.

2

) In case of permanent measurement (tracking mode) the max. temperature is reduced to 45°C

3

) 500 – 1000h at 50°C.

Page 17

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 17/43

5 Electrical components

5.1 ID switch

This switch is used to set the module ID and can be set from 0 to 9.

5.2 Reset switch

To reset the module to factory settings do the following:

Switch OFF the power for the module

Press the reset button and keep it pressed

Switch on the power for the module

Keep the reset button pressed until all LEDs on the module are illuminated

Release the reset button

Switch the power off and wait 5 seconds

Switch the power on and wait until the green power LED is on

5.3 Digital output

The MRL3 (H) contains two digital outputs for level monitoring (DO 1 and DO

2) and one digital output for error signalization (DO E). These outputs are

open drain outputs as shown in figure 7 and can drive up to 200mA. In the

ON state, the FET transistor is electro-conductive.

5.4 Digital Input

The Digital Output (DO 1) can be configured as a Digital Input (DI 1). This is useful for triggering

measurements by means of an external s

witch or push button. Please refer to Chapter 8, Digital Input on

page 31.

5.5 Analog output

The analog output of the MRL-3(H) is a current source (0..20mA or 4..20mA). It is capable of driving loads up

to 500Ω. The analog output has an accuracy of +/- 1% Full scale.

uMax= Range = ( Conf MaxDist – ConfMinDist) uMax=max. uncertainty

100 100 Conf MaxDist =DDistance programmed for the maximum output current

Conf MinDist=DDistance programmed for the minimum output current

Figure 7 Open Drain Output

DOUT

On

Page 18

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 18/43

No.1

1

9

15

8

e.g. The configured measurement range is 0...20m and the actual measured distance is 14m. This results in

a measurement uncertainty of ± 0.2m (1% of 20m), which includes all parameters (temperature drift,

sensor accuracy, linearity, target color etc.). The uncertainty decreases, if the ambient temperature is

stable.

5.6 Connector

5.6.1 D-Sub connector

Pin Designator Description

1 Rx RS232 receive line

2 Tx RS232 send line

3 T- RS422 send line negative

4 T+ RS422 send line positive

5 R- RS422 receive line negative

6 R+ RS422 receive line positive

7

PWR

DC Power

+ 9V…+30V for MRL3

+24V…+30V for MRL3 (H) (Heating option)

8 PWR

9 DO 1 Digital output 1 (Open Drain)

10 DO 2 Digital output 2 (Open Drain)

11 DO E Digital output for error signalization (Open Drain)

12 AGND Analog ground

13 AO Analog output (0/4..20mA)

14 GND Ground line

15 GND Ground line

5.6.2 Screw terminal

Pin Designator Description

1 R+ RS422 Receive line positive

2 R- RS422 Receive line negative

3 T+ RS422 Send line positive

4 T- RS422 Send line negative

5 Tx RS232 Transmit line

6 Rx RS232 Receive line

7 AGND Analog ground

Page 19

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 19/43

8 AO Analog output (0/4..20mA)

9 DO E Digital output for error signalization (Open Drain)

10 DO 2 Digital output 2 (Open Drain)

11 DO 1 Digital output 1 (Open Drain)

12 GND Ground line

13 PWR Power DC

+9V...+30V MRL3

+24...+30V MRL3 (H) (Heating option)

6 Physical dimensions

All dimensions in mm

Page 20

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 20/43

7 Factory settings

7.1 Operation

Mode: Controlled

7.2 Communication parameters

Baud: 19200

Data bit: 7

Parity: Even

Stop bit: 1

7.3 Analog outputs

Min output: 4mA

Range min: 0m

Range max: 10m

Error output: 0mA

7.4 Module ID

ID Number: 0

7.5 Digital output 1 (DOUT1)

ON: 2m + 5mm = 2005mm

OFF: 2m - 5mm = 1995mm

7.6 Digital output 2 (DOUT2)

ON: 1m – 5mm = 995mm

OFF: 1m + 5mm = 1005mm

7.7 Digital input 1 (DI 1)

Inactive, configured as output

7.8 User distance offset

User distance offset = 0mm

Page 21

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 21/43

8 Command set

8.1 General

8.1.1 Command termination <trm>

All commands for the MRL-2 (H) are ASCII based and terminated <trm> with <cr><lf>.

8.1.2 Module identification N

Since the module can be addressed with the ID switch, the ID is represented in the commands by N. On the

location of the N insert the Module ID.

8.1.3 Parameter separator

The command syntax uses the '+' sign as parameter separator. The '+' sign can be replaced by the minus '-'

sign if applicable by the command.

8.1.4 Module identification N

All configuration commands that are used to set configuration values can also be used to read the currently

set value by omitting the parameter. The command syntax is described as follows:

Set Command

Get Command

Command

sNuof+xxxxxxxx<trm>

sNuof<trm>

Return Successful

gNof?<trm>

gNuof+xxxxxxxx<trm>

Return Error

gN@Ezzz

gN@Ezzz

Parameters

N Module ID

xxxxxxxx Offset in 1/10 mm; + positive / - negative

zzz Error code

8.1.5 Startup sequence

After power on the MRL-2 does all the initializations and sends a start sequence gN?. On this sequence, the

N stands for the Module ID. After sending this start sequence, the MRL-2 is ready to measure.

Page 22

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 22/43

8.2 Operation commands

8.2.1 STOP/CLEAR command (sNc)

Stops the current execution and resets the status LEDs as well as the digital outputs.

Command

Command

sNc<trm>

Return Successful

gN?<trm>

Return Error

gN@Ezzz

Parameter

N Module ID

zzz Error Code

8.2.2 Distance measurement (sNg)

Triggers simple measurement of distance. Each new command cancels an active measurement.

Command

Command

sNg<trm>

Return Successful

gNg<trm>

Return Error

gNg+xxxxxxxx<trm>

Parameter

N Module number (0..9)

xxxxxxxx Distance in mm

zzz Error Code

8.2.3 Signal measurement (sNm)

Signal measurement can be done continuously or with a single measurement. The signal strength is

returned as a relative number in the range of 0 to 25 million.

Command

Command

sNm+c<trm>

Return Successful

gNm+xxxxxxxx<trm>

Return Error

gN@Ezzz

Parameter

N Module number (0..9)

C 0: single measurement

1: repetitive measurements !use only with one sensor

zzzzzzz Signal strength (range 0…25 million)

zzz:Error code

8.2.4 Temperature measurement (sNt)

Triggers measurement of temperature.

Command

Page 23

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 23/43

Command

sNt<trm>

Return Successful

gNt+xxxxxxxx<trm>

Return Error

gN@Ezzz<trm>

Parameter

N Module number (0..9)

xxxxxxxxx Temperature in 1/10°C

zzz:Error code

8.2.5 Laser ON (sNo)

Switches laser ON.

Command

Command

sNo<trm>

Return Successful

gN?<trm>

Return Error

gN@Ezzz

Parameter

N:Module number (0..9)

zzz:Error code

8.2.6 Laser OFF (sNp)

Switches laser OFF.

Command

Command

sNp<trm>

Return Successful

gN?<trm>

Return Error

gN@Ezzz

Parameter

N:Module number (0..9)

zzz:Error code

8.2.7 Single sensor Tracking (sNh)

Never use this command if more than one module is connected to the

RS232/RS422 line

Triggers continuous measurement of the distance. This command is not to be used with more then one

MRL-2(H) on a RS-232/RS-422 line. The measurements are continued until the STOP/CLEAR command is

issued. The status LEDs and the digital outputs are updated corresponding to the new measured distance.

Command

Command

sNh<trm>

Return Successful

gNh+xxxxxx<trm>

Return Error

gN@Ezzz

Page 24

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 24/43

Parameter

N Module ID

xxxxxxxxxxx Distance in 0.1mm

zzz Error Code

8.2.8 Tracking with buffering – Start (sNf)

Triggers continuous measurement of the distance with internal buffering in the module (buffer for one

measurement). The rate of measurements is defined with the sampling time. If the sampling time is set to

zero, the measurements are executed as fast as possible. The last measurement can be read out from the

module with the command sNq. The measurements are continued until the 'sNc' command is issued.

Set Command

Get Command

Command

sNf+xxxxxxxx<trm>

sNf<trm>

Return Successful

gNf?<trm>

gNf+xxxxxxxx<trm>

Return Error

gN@Ezzz<trm>

gN@Ezzz<trm>

Parameter

N Module ID

xxxxxxxx:Samplling time in 10 ms (if 0 -> max possible rate)

zzz Error Code

8.2.9 Read out - Tracking with buffering - Read out (sNq)

After starting “tracking with buffering” with the command sNf, the last measurement can be read out from

the module with the command sNq.

Command

Command

sNq<trm>

Return Successful

gNq+xxxxxxxx+c<trm>

Return Error

gN@Ezzz+c<trm>

Parameter

N Module ID

Xxxxxxxx Distance in 1/10 mm

c: 0 = no new measurement since last sNq command

1 = new measurement since last sNq command, not overwritten

2 = new measurement since last sNq command, overwritten

zzz: Error code

8.3 Configuration commands

Page 25

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 25/43

8.3.1 Set communication parameter (sNbr)

Sets the communication parameters for the serial interface.

This command saves all configurations Flash Memory.

The changed baud rate is and activated after the next ower ON.

Bold = default parameters (first use or after reset)

Command

Command input: s Nbr+ y <trm>

Return s uccessful: gN?<trm>

Return error: gN@Ezzz <trm>

Parameters: N: Module ID

y : Defines the new settings

% Baud rate Data bit Parity % Baud Rate Data bit Parity

0 1200 8 N 5 4800 7 E

1 9600 8 N 6 9600 7 E

2 19200 8 N

7 19200 7 E

3 1200 7 E 8 38400 8 N

4 2400 7 E 9 38400 7 E

8.3.2 Set automatic mode (sNA)

This command activates the automatic mode of the MRL3 (H). It triggers continuous measurement of the distance and

sets the analog and digital outputs according to the measured distance values. The ra te of measurements is defined with

the sampling time. If the sampling time is set to zero, the measurements are executed as fast as possible.

The automatic mode is active until the 'sNc' command is issued.

The operation mode is stored in the MRL3 (H) and activated immediately. This mode is also activated after

next power ON.

Internally “tracking with buering” is started (command s Nf

). Therefore the last measurement can also be

read out from the module with the command s Nq.

Command

Command

s NA+xxxxxxxx <trm>

Return Successful

gNA?<trm>

Return Error

gN@Ezzz <trm>

Page 26

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 26/43

Parameter

N Module ID

xxxxxxxx: Sampling time in 10 ms (if 0 -> max possible rate)

zzz: Error code

8.3.3 Set/Get analog output min level (sNvm)

This command sets the minimum analog output current level (0 or 4 mA).

Set Command

Get Command

Command

sNvm+x<trm>

sNvm<trm>

Return Successful

gNvm?<trm>

gNvm+x<trm>

Return Error

gN@Ezzz

gN@Ezzz

Parameter

N Module ID

x: Minimum output for analog out

0: Minimum signal is 0 mA

1: Minimum signal is 4 mA

zzz: Error code

8.3.4 Set analog output value in error case (sNve)

This command sets the analog output current level in mA in case of an error. This level can be lower as the min level set

in 8.3.3 Set/Get analog output min level (sNvm).

Set Command

Get Command

Command

sNve+xxx<trm>

sNve<trm>

Return Successful

gNve?<trm>

gNve+xxx<trm>

Return Error

gN@Ezzz

gN@Ezzz

Parameter

N Module ID

xxx: Value in case of an error in 0.1mA

zzz: Error code

8.3.5 Set/Get distance range (sNv)

Sets the minimum and maximum distances corresponding to the minimum and maximum analog output current levels.

0...20mA 4...20mA

Aout Analog current output

DIST Actual measured distance

D

min

Distance programmed for the minimum output current

D

max

Distance programmed for the maximum output current

Page 27

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 27/43

Set Command

Get Command

Command

sNv+xxxxxxxx+yyyyyyyy<trm>

Return Successful

gNv?<trm>

Return Error

gN@Ezzz

Parameter

N Module ID

xxxxxxxx:Minimum distance in 1/10 mm corresponding to 0mA / 4mA

yyyyyyyy:Maximum distance in 1/10 mm corresponding to 20mA

zzz: Error code

8.3.6 Set digital output levels (sNn)

Sets the distance levels at which the digital outputs are switched ON and OFF with a hysteresis.

Two different situations are possible:

ON level > OFF level

The ON level of the hysteresis is larger than the OFF level.

With an increasing distance, the digital output is switched on

(open drain output is closed) when the distance exceeds the

ON level. With a decreasing distance, the digital output is

switched off (open drain output is open) when the distance falls

below the OFF level.

ON level < OFF level

The ON level of the hysteresis is smaller than the OFF level. With a decreasing distance, the digital output is

switched on (open drain output is closed) when the distance

falls below the ON level. With an increasing distance, the digital

output is switched off (open drain output is open) when the

distance exceeds the OFF level.

Set Command

Get Command

Command

sNn+xxxxxxxx+yyyyyyyy<trm>

sNn<trm>

Return Successful

gNn?<trm>

gNn+xxxxxxxx+yyyyyyyy <trm>

Return Error

gN@Ezzz

gN@Ezzz

DO

Distance

Off On

0

closed

open

DO

Distance

OffOn

0

closed

open

Page 28

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 28/43

Parameter

N: Module number (0..9)

n: Digital output port (1 or 2)

xxxxxxxx : Distance ON level in 1/10 mm for switching digital output ON

yyyyyyyy : Distance OFF level in 1/10 mm for switching digital output OFF

zzz : Error code

8.3.7 Save configuration parameters (sNs)

This command saves all configuration parameters, which are set by the commands above. The parameters

are written to the Flash Memory.

Command

Command

s Ns<trm>

Return Successful

gNs?<trm>

Return Error

gN@Ezzz

Parameter

N: Module number (0..9)

zzz : Error code

8.3.8 Set configuration parameters to factory default (sNd)

This command restores all configuration parameters to their factory default values. The parameters are

written to the Flash Memory.

The communication parameters are also reset to factory settings.

Command

Command

s Nd<trm>

Return Successful

gN?<trm>

Return Error

gN@Ezzz

Parameter

N: Module number (0..9)

zzz : Error code

8.3.9 Get software versions (sNsv)

Retrieves the software version of the MRL3 (H).

Command

Command

s Nsv <trm>

Return Successful

gNsv +xxxxyyyy <trm>

Page 29

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 29/43

Return Error

gN@Ezzz <trm>

Parameter

N: Module number (0..9)

xxxx : Module software version number

yyyy : Interface software version number

zzz : Error code

8.3.10 Get Serial Number (sNsn)

Retrieves the serial number of the MRL3 (H).

Command

Command

s Nsn<trm>

Return Successful

gNsn+ xxxxxxyy <trm>

Return Error

gN@Ezzz

Parameter

N: Module number (0..9)

xxxxxx : Serial number

zzz : Error code

8.3.11 Get device generation and type (dg)

This command returns the device type, generation and current communication settings.

Works only from MRL3 and newer.

Command

Command

s Nsn<trm>

Return Successful

gNsn+ xxxxxxyy <trm>

Return Error

gN@Ezzz

Parameter

N: Module number (0..9)

xxxxxx : Serial number

zzz : Error code

Page 30

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 30/43

8.4 Digital Input

The following commands configure the terminal DO1. This port can also be used as digital input. For safety

reasons, always use a resistor to protect the connection terminal.

8.4.1 Configure digital input (sNDi1)

The digital output 1 of the MRL-2 can also be used as digital input. Its state can be read or trigger a

configurable action. Use the following command to configure the behavior of the digital input.

On active digital input, the digital output function of DO1 is deactivated

Set Command

Get Command

Command

sNDI1+xxxxxxxx<trm>

sNDI1<trm>

Return Successful

gNDI1?<trm>

sNDI1+xxxxxxxx<trm>

Return Error

gN@Ezzz<trm>

gN@Ezzz<trm>

Parameter

N Module number (0..9)

xxxxxxxx 0: Digital input inactive (DO1 active)

1: activate the digital input to read out its state with the

. command 8.4.2 Read digital input (sNRI).

2: Trigger Distance measurement (sNg)

3: Start/Stop Single sensor Tracking (sNh)

4: Start/Stop Tracking with buffering (sNf)

zzz Error code

8.4.2 Read digital input (sNRI)

Displays the state of the digital input, if the input is not inactive.

.

Command

Command

sNRI<trm>

Return Successful

gNRI+x<trm>

Return Error

gN@Ezzz<trm>

Parameter

N Module number (0..9)

X 0: Input Off (Signal Low)

1: Input On (Signal High)

zzz Error code

8.5 Special Users Commands

The special user commands can be configured by the user and are an extension to the standard commands.

Use

Page 31

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 31/43

these commands carefully and only if you really understand what they do.

8.5.1 Get/Set user distance offset (sNuof)

The user can set an individual overall offset correction for all distance measurement commands in this

'Special User Command' section. The standard distances measurement commands are not involved

Set Command

Get Command

Command

sNuof+xxxxxxxx<trm>

sNuof<trm>

Return Successful

gNof?<trm>

gNuof+xxxxxxxx<trm>

Return Error

gN@Ezzz

gN@Ezzz

Parameter

N Module ID

xxxxxxxx Offset in 1/10 mm; + positive / - negative

zzz Error code

8.5.2 User Configured Distance measurement (sNug)

Triggers simple distance measurement, similar to the command 8.2.2 Distance measurement (sNg) on page

21. This command returns the distance corrected with the user offset (and user gain) as set with the

command 8.5.1 Set/Get user distance offset (sNuof). Each new command cancels an active measurement.

This command takes the user distance offset into account

Command

Command

sNug<trm>

Return Successful

gNug+xxxxxxxx<trm>

Return Error

gN@Ezzz<trm>

Parameter

N Module number (0..9)

xxxxxxxx Distance in 0.1mm

zzz Error code

8.5.3 User configured single sensor tracking (sNuh)

Triggers continuous measurement of the distance and outputs the result immediately to the serial interface.

The measured distance is corrected with the user offset (and user gain) as set with the command 8.5.1

Set/Get user distance offset (sNuof). Since the MRL-2(H) returns the result directly after completing a

measurement, never use this command if more than one device is connected to the serial line. The

measurements are continued until the stop/clear command (sNc) is issued. Each measurement updates the

status LED's and the digital outputs.

Page 32

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 32/43

This command takes the user distance offset into account

Never use these commands if more than one module is connected to the

RS232/RS422 line

Command

Command

sNuh<trm>

Return Successful

gNuh+xxxxxxxx<trm>

Return Error

gN@Ezzz<trm>

Parameter

N Module number (0..9)

xxxxxxxx Distance in 0.1mm

zzz Error code

8.5.4 User configured tracking with buffering – Start (sNuf)

Triggers continuous measurement of the distance with internal buffering in the module (buffer for one

measurement). The measured distance is corrected with the user offset (and user gain) as set with the

command 8.5.1 Set/Get user distance offset (sNuof). Define the rate of measurements with the sampling

time. If the sampling time is set to zero, the measurements are executed as fast as possible. The last

measurement can be read out from the module with the command sNuq. The measurements are continued

until the stop/clear command (sNc) command is issued.

This command takes the user distance offset into account

Set Command

Get Command

Command

sNuf+xxxxxxxx<trm>

sNuf<trm>

Return Successful

gNuf<trm>

gNuf+xxxxxxxx<trm>

Return Error

gN@Ezzz<trm>

gN@Ezzz<trm>

Parameter

N Module number (0..9)

xxxxxxxx Sampling time in 10ms (if 0 -> use max. possible .

. sample rate)

zzz Error code

8.5.5 Read out – user configured tracking with buffering (sNuq)

After starting “User-configured fast tracking with buffering” with the command sNuf, the last measurement

can be read out from the MRL-2(H).

This command takes the user distance offset into account

Page 33

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 33/43

Command

Command

sNuq<trm>

Return Successful

gNuq+xxxxxxxx+c<trm>

Return Error

gN@Ezzz+c<trm>

Parameter

N Module number (0..9)

xxxxxxxx Sampling time in 10ms (if 0 -> use max. possible . .

. sample rate)

c 0 = no new measurement since last sNuq command

1 = one new measurement since last sNuq . .

. command, not overwritten

2 = more than one measurement since last sNuq

. command overwritten

Zzz Error code

8.5.6 Set user configured automatic mode (sNuA)

This command activates the user automatic mode of the MRL3. It triggers continuous measurement of the

distance and sets the analog and digital outputs according to the measured distance values. The rate of

measurements is defined with the sampling time. If the sampling time is set to zero, the measurements are

executed as fast as possible.

In difference to the command sNA, this command returns measuring results according to the user parameters.

The automatic mode is active until the „sNc‟ command is issued.

This command works with the MRL3 and newer.

The operating mode is stored in the MRL3 and activated immediately. This mode is

also activated after next power ON.

Internally “tracking with buffering” is started (command sNuf). Therefore the previous

measurement can also be read out from the module with the command sNuq.

Command

Command

sNuA+xxxxxxxx<trm>

Return Successful

gNuA?<trm>

Return Error

gN@Ezzz

Parameter

N: Module number (0..9)

xxxxxx: Serial number

zzz: Error code

Page 34

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 34/43

8.6 Error codes

No.

Format

Meaning

203

@E203

wrong syntax in command, or prohibited command, or prohibited parameter in command

entry, or non-valid result

210

@E210

Not in tracking mode, use command sNf to start tracking mode first.

211

@E211

Sampling too fast, set the sampling time to a larger value using sNf

(also for command sNA)

212

@E212

Command cannot be executed, because in tracking mode, first use command sNc to stop

tracking mode.

220

@E220

Communication error

230

@E230

Distance value overflow caused by wrong user configuration.

Change user offset (and/or user gain)

231

@E232

Wrong mode for digital input status read.

233

@E233

Number cannot be displayed. (Check output format)

234

@E234

Distance out of range

235

@E235

Selected configuration parameters result in too narrow range

236

@E236

Digital output manual mode (DOM) cannot be activated when configured as digital input

252

@E252

Temperature too high

(contact MRC if error occurs at room temperature)

253

@E253

Temperature too low

(contact MRC if error occurs at room temperature)

254

@E254

Bad signal from target

It takes too long to measure according distance

255

@E255

Received signal too weak, distance < 200mm

(Use different target and distances, if the problem persists, please contact MRC)

256

@E256

Received signal too strong

(Use different target and distances, if the problem persists, please contact MRC)

257

@E257

Too much background light

(Use different target and distances, if the problem persists, please contact MRC)

258

@E258

Power supply voltage is too high

260

@E260

Distance cannot be calculated because of ambiguous targets. Use clear defined

targets to measure the distance.

360

@E360

Measuring time is too short.

361

@E361

Measuring time is too long.

not

listed

Hardware failure (Contact MRC)

Before contacting MRC, please collect as much information as possible.

Page 35

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 35/43

9 Accessories

9.1 Viewfinder

The telescopic viewfinder can be used for easy alignment of the MRL3 (H) for long distances.

Part Number

Description

500100

Telescopic viewfinder

9.2 Target plates

The target plates provide a defined measuring target. Please use the different

sides for the distances as stated below:

Front color brown, for measuring distances from 20 m to 200 m

Back color white, for measuring distances from 0.2 m to 30 m

Part Number Description

500110

Target plate small, 105 x 147 mm

500111

Target plate large, 210 x 297 mm

9.3 Laser Glasses

The red lens glasses improve visibility of the laser dot at bright environment conditions. It can be use for

distances up to 10-15m.

Part Number

Description

500120

Laser Glass

Page 36

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 36/43

9.4 Cables

Part Number

Description

500200

PC-Connection cable:

MRL3 (H) to - 9 pin D-Sub for PC (RS232)

- 2 wires for power supply

500201

RS422-Connection cable:

MRL3 (H) to - 5 wires for RS422

- 2 wires for power supply

500202

Connection cable for automatic mode:

MRL3 (H) to - 2 wires for current output

- 5 wires for digital outputs and power

supply

9.5 Connector cover IP65

If the MRL-3 is connected via the cable gland and the 15 pin D-Sub connector is not used, this cover

protects the 15 pin D-Sub connector of the MRL-3.

Part Number Description

500251

Connector Cover IP65

9.6 Connector with 90° cable exit IP65

The connector allows the connection of the MRL-3 with IP65 protection.

Part Number

Description

500253 Connector 90° IP65

Page 37

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 37/43

10 Safety instructions

The following directions should enable the person responsible for the MRL3 (H), and the user of the

instrument, to anticipate and avoid operational hazards.

The MRL3 (H) is made to be integrated into technical systems. A basic technical education is therefore

essential. This device may only be operated by trained persons.

The person responsible for the instrument must ensure that all users understand these directions and adhere

to

them.

If the MRL3 (H) is part of a system, the manufacturer of such a system is responsible for all safety-relevant

issues, such as the manual, labeling and instruction.

10.1 Use of the instrument

Permitted use:

The permitted use of the MRL3 (H) is: measuring distances.

Prohibited use:

1) Using the instrument without instruction

2) Using outside the stated limits

3) Deactivation of safety systems and removal of explanatory and hazard labels

4) Openi

ng of the equipment, except to open the cover for access to the screw terminal

5) Carrying out modification or conversion of the product

6) Operation after failure in operation

7) Use of accessories from other manufacturers without the express approval of MRC.

8) Aiming directly into the sun

9) Deliberate dazzling of third parties; also in the dark

10) Inadequate safeguards at the surveying site (e.g. when measuring on roads, etc.)

WARNING

Prohibited use can lead to injury,

malfunction, and material damage. It is the duty of the person responsible

for the instrument to inform the user about hazards and how to counteract them. The MRL3 (H) must not be

operated until the user has been adequately instructed.

10.2 Limits to use

See section ”Technical Data”

Environment:

Suitable for use in an atmosphere appropriate for permanent human habitation. Cannot be used in an

aggressive or explosive environment.

10.3 Areas of responsibility

Responsibilities of the manufacturer of the original equipment MRC

MRC is responsible for supplying the product, including the Technical Reference Manual and original

accessories, in a completely safe condition.

Page 38

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 38/43

Responsibilities of the manufacturer of non-MRC accessories:

The manufacturers of non-MRC accessories for the MRL3 (H) are responsible for developing, implementing

and communicating safety concepts for their products. They are also responsible for the effectiveness of

these safety concepts in combination with the MRC equipment.

Responsibilities of the person in charge of the instrument:

WARNING:

The person responsible for the instrument must ensure that the equipment is us

ed in accordance with the

instructions. This person is also accountable for the deployment of personnel and for their training and for

the safety of the equipment when in use.

The person in charge of the instrument has the following duties:

1) To understand the safety instructions of the product and the instructions

in the Technical Reference Manual.

2) To be familiar with local safety regulations relating to accident prevention.

3) To inform MRC immedi

ately if the equipment becomes unsafe.

10.4 Hazards in use

Important hazards in use

WARNING:

The absence of instruction, or the inadequate imparting of instruction, can lead to incorrect or prohibited use,

and can give rise to accidents with far-reaching human, material and environmental consequences.

Precautions:

All users must follow the safety instructions given by the manufacturer and the directions of the person

responsible for the instrumen

t.

CAUTION:

Watch out for erroneous distance measurements if the instrument is defective or if it has been dropped or

has been misused or modified.

Precautions:

Carry out periodic test measurements, partially after the instrument has been subject to abnormal use, and

before, during and after important measurements. Make sure the MRL3 (H) optics are kept clean.

WARNING:

Hidden labels of the MRL3 (H) when installed could cause a dangerous situation.

Page 39

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 39/43

Precautions:

Always ensure the visibility of MRL3 (H) labels at all times or add labels corresponding to the local safety

regulation.

CAUTION:

When using the instrument for distance measurements or for positioning moving objects (e.g. cranes,

building equipment, platforms, etc.) unforeseen events (e.g. breaking the laser beam) may cause erroneous

measurements.

Precautions:

Only use this product as a measuring sensor, not as a control device. The

system must be configured and

operated in such a way that no damage will occur in case of an erroneous measurement, malfunction of the

device or power failure due to installed safety measures (e.g. safety limit switch).

WARNING:

Operate the equipment appropriately in accordance with the regulations in force. Always prevent access to

the equipment by unauthorized personnel.

CAUTION:

Be careful when pointing a telescope towards the sun, because t

he telescope functions as a magnifying

glass and can injure eyes and/or cause damage inside the MRL3 (H).

Precautions:

Do not point the telescope directly at the sun.

10.5 Laser classification

The MRL3 (H) produces a visible laser beam, which emerges from the front of the instrument.

It is a Class 2 laser product in accordance with:

1) IEC60825-1 (2001) ”Radiation safety of laser products”

2) EN60825-1 (2001) ”Radiation safet y of laser products”

It is a Class II laser product in

accordance with:

1) FDA 21CFR 1040.10 1004.11 (US Department of Health and Human Service, Code of Federal

Regulations)

Laser Class 2/II products:

Do not stare into the laser beam or direct it towards other people unnecessarily. Eye protection is normally

afforded by aversion responses including the blink reflex.

WARNING:

Looking directly into the beam with optical aids (binoculars, telescopes) can be hazardous.

Page 40

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 40/43

Precautions:

Do not look into the laser beam. Make sure the laser is aimed above or below eye level. (particularly with

fixed installations, in machines, etc.).

CAUTION:

Looking into the laser beam may be hazardous to the eyes.

Precautions:

Do not look into the laser beam. Make sure the laser is aimed above or below eye level (particularly with

fixed installations, in machines, etc.).

10.6 Electromagnetic compatibility (EMC)

The term “electromagnetic compatibility” is taken to mean the capability of the MRL3 (H) to function smoothly

in an environment where electromagnetic radiation and electrostatic discharges are present, and without

causing electromagnetic interference to other equipment.

WARNING:

Electromagnetic radiation can cause interference in other equipment. Although the MRL3 (H) meets the strict

regulations and standards that are in force in this respect, MRC cannot comp

letely exclude the possibility

that interference may be caused to other equipment.

10.7 Producer Standards

MRC hereby certifies that the product has been tested and complies with the specifications as stated in this'

Technical Reference Manual'. The test equipment used is in compliance with national and international

standards. This is established by our Quality Management System. Further, the MRL-3(H) devices are

produced incompliance with 2002/95/EG «RoHS»

Page 41

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 41/43

10.8 Disposal

This symbol on the product or on its packaging indicates that this product must not be

disposed of with your other household waste. Instead, it is your responsibility to dispose of the

equipment by handing it over to a designated collection point for the recycling of waste

electrical and electronic equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural resources and ensure that it is

recycled in a manner that protects human health and the environment. For more information

about where you can drop off your waste equipment for recycling, please contact your local

city office, your household waste disposal service or the dealer where you purchased the

product.

In countries in which MRC has no subsidiaries, MRC delegates the duty for the disposal

in compliance with 2002/96/EG«WEEE» to the local dealer or to the customer, if no dealer is

present.

Page 42

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 42/43

10.9 Labeling

Figure 8: The label is applied on the top of the device

Standard applied EN60825-1:2001

IEC60825-1:2001

Emitted wavelength 620-690nm

Beam divergence 0.16 x 0.6 mrad

Pulse duration

0.45x10

-9

s

Max. radiant power* 0.95 mW

10.10 Maintenance

The MRL3 (H) is almost maintenance free. The only thing you have to do is cleaning the optical surfaces.

CAUTION:

Look after the optical surfaces with same care that you would apply to spectacles, cameras and field

glasses.

Page 43

TECHNICAL REFERENCE MANUAL

Distance Laser Sensor Page 43/43

10.11 Service

If you need to service the device, please contact MRC for instructions.

Important Notice

MRC reserves the right to make corrections, modifications, enhancements, improvements and other changes

to its products, documentation and services at any time and to discontinue any product or service without

notice. Customers should obtain the latest relevant information before placing orders and should verify that

such information is up to date and complete. All products are sold subject to MRC terms and conditions of

sale supplied at the time of order acknowledgment.

Metrology Resource Co

3759 S. Baldwin Road. Suite 195

Lake Orion, MI 48359

Tel. 1-248-628-8671

Fax. 1-248-274-3088

Email sales@metrologyresource.com

www.metrologyresource.com

© Copyright by MRC

Loading...

Loading...