Page 1

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

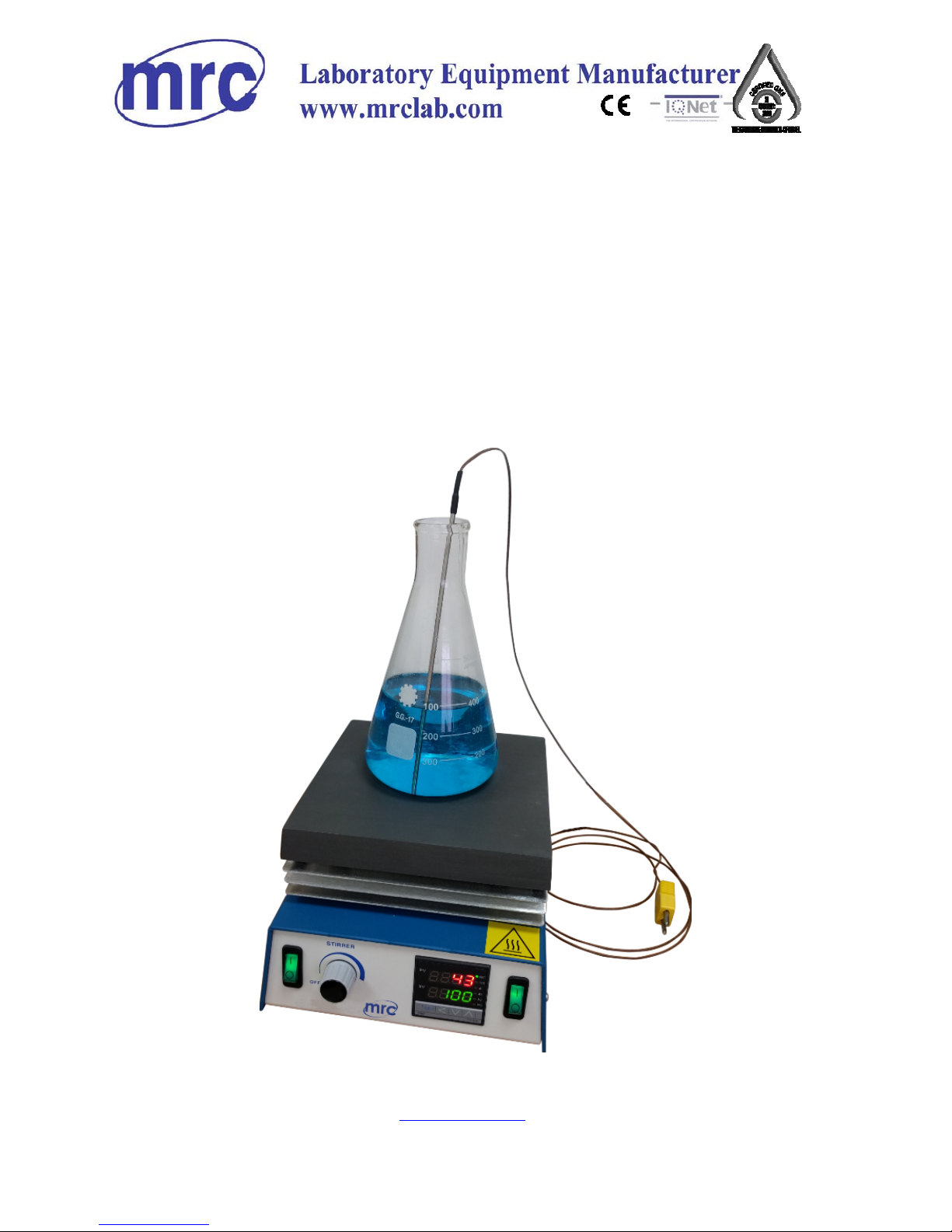

Digital Hotplate

With Stirrer

MH-4D

Operation Manual

Page 2

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Important Before using this product, read this

entire operation manual carefully. Users should

follow all of the operational guidelines contained in

this manual and take all necessary safety

precautions while using this product. Failure to

follow these guidelines could result in potentially

irreparable bodily harm and/or property damage.

Caution All internal adjustments and maintenance must be

performed by qualified service personnel.

Material in this manual is for information purposes only. MRC is

committed to a continuing program of product development and

improvement, and reserves the right to change information, such as

specifications, appearance, and dimensions, described in this

document without notice. MRC makes no representations or

warranties with respect to this manual. In no event shall MRC be held

liable for any damages, direct or incidental, arising out of or related

to the use of this manual.

This manual contains important safety and operation information.

You must carefully read, understand, and follow all the instructions in

this manual prior to operating this instrument. Keep this manual in a

safe place nearby for reference and make it easily available to all

users.

1) This manual highlight DANGER/WARNING/CAUTION/NOTICE

alerts to prevent injury or property damage and also to achieve

optimum performance of your instrument.

2) These alerts are classified into four types in this manual

depending on the importance and the risk levels as described

below

3) The claim which is out of the quality guarantee published by

the Manufacturer is out of Manufacturer’s responsibility.

4) The damage which is from unexpected fault or damage of user

by Acts of God is out of Manufacturer’s responsibility.

Page 3

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Table of content

Section 1 Warning and Cautions………….…..……………………………1-1

Section 2 General Description ………….………………..…………………2-1

Features

Safety

Convenience

Construction

Section 3 Unpacking and installation…………………….……….………3-1

Installation environment

Connecting to Power Supply

Location Condition

Connecting to the main power

Section 4 Operation……………………………………….…………………….4-1

Power On

Change the Set Value (SV)

Change the Alarm Value

Autotuning (AT)

Temperature Offsetting (OFFSET)

Stir Control Knob

External Temperature Probe Input (optional)

Section 5 Maintenance………………………..…………….……….….………5-1

Cleaning Product

Relocation

Keeping Product

Section 6 Troubleshooting …………….……………………………….….…6-1

Section 8 Warranty Information………….…………………………..….….7-1

Page 4

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Section 1 Warnings and Cautions

DANGER

Ignoring the following warnings could cause serious injuries or

even fatal accidents.

Understand all alert labels prior to operating this equipment.

Never remove or damage the alert labels.

Never move this equipment while under operation.

Never install or use this equipment in explosive or flammable

atmospheres.

Never use or store flammable or hazardous substances near to

this equipment.

Never use the equipment to heat flammable or hazardous

substances.

Always wear proper protective gear (such as goggles, gloves,

masks or an apron) when using this equipment.

Never allow water, organic solvents, dust, or corrosive gases to

get inside the equipment.

Never immerse this equipment in water or operate it under

water.

Never reach for this equipment if it has fallen into water.

Check electrical requirements described in this operation

manual or on the ID plate of this equipment before use.

Connect this equipment to a dedicated power outlet nearby.

Connect this equipment only to properly grounded power

outlets to protect you and your instrument. Do not ground to

gas pipes or water pipes.

Never install this equipment closer than 30 cm (12 inches) to a

wall of combustible material. Observe minimum distances (in

general, 30 cm) from other devices.

If you observe strange smoke, odor or noise from the

instrument, unplug the power cord immediately and turn off

the main power switch. After the smoke or odor disappears,

contact your dealer or MRC if any repair is required.

Page 5

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Never disassemble, repair, or modify this equipment on your

own. Doing so will void your warranty and may result in injuries

or product damages.

Do not heat any substances above temperature which will

cause hazards of explosion, implosion or release of toxic or

flammable gases from the material being heated.

Do not use in the presence of pressurized or sealed containers.

Fire or explosion may result causing injury or death

Do not operate the plate with external temperature probe

in the air or out of the liquid.

The external probe must be properly placed into a liquid

on the top surface during the whole process, to prevent

damage to the plate

The plate might be covered with aluminum foil to protect

it, DO NOT cover any other parts of the device and make

sure the radiation sheets underneath are not covered.

The Aluminum topped plates are not designed to be used with

metal containers. For heating of such containers it's advisable

to use a ceramic top hot plate.

To avoid electric shock, always use a property grounded

electrical outlet of correct voltage, and correct handling

capacity equipment

CAUTION

Ignoring the following cautions could cause injuries or property

damages.

Keep away the power cord from the hot plate, to prevent

melting and damages.

Do not touch the top plate or any object near it even when the

heater is turned off. You may get burned due to residual heat.

After using this equipment, make sure to turn off the main

power switch and also to disconnect the power cord from the

power outlet for the safety of other users.

Page 6

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Do not place heavy objects, including this equipment, on top

of the power cord and do not strip, scratch, bend, twist, pull, or

heat the power cord. A damaged power cord is a fire and

electrical shock hazard.

Make sure to set up this equipment on a flat, stable, clean,

non-slip, dry, and fireproof surface inside a lab with proper

safety measures.

Do not touch the power outlet, power socket, or power cord

with wet hands. And make sure to connect the power cord

directly and firmly to the power outlet and power socket.

Do not put or insert any objects (especially if conductive or

flammable) inside this equipment.

Do not expose this equipment to any heat sources including

direct sunlight.

Mechanical shock or vibration can damage this equipment. Pay

extra attention while moving it. Damages caused by

mechanical shock or vibration may result in injury or fire.

Do not impact the top plate or heat sink. You can damage the

equipment or get injured.

Do not install this equipment near any device that generates

high frequency noise such as high frequency welding

machines, high frequency sewing machines, or SCR power

controllers.

Before cleaning, make sure to unplug the power cord to avoid

electric shock or fire.

Do not use chlorine bleach, ammonia-based cleaners,

abrasives, ammonia, or metal scouring pads. Wipe with a soft

damped cloth or a sponge soaked in water or diluted neutral

detergent.

The user shall be aware that, if the equipment is used in a

manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

The instrument should be placed so, that handy operation of

the ON-OFF Switch is possible.

Service only by a qualified Service engineer.

Page 7

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Always disconnect from power supply prior to maintenance

and servicing.

Connect the instrument to a ground mains outlet, after

ensuring that the Voltage is the same as given on the name

plate

The Instrument must be connected to an earthen (grounded)

supply

Page 8

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Section 2 General Description

Congratulations of your purchase of MRC hotplate which is specially

designed to provide maximum benefit for your investment with

respect to performance, safety, ease of use, and durability.

Item/Model MH-4D

Dimension (W x D x H, mm) 200 X 250 X 130

Top plate dimension (mm) 175 X 175 mm

Maximum heating capacity 800W

Current consumption (110V) 7.3A

Temp. range Up to 300°C

Temp. control Digital

Magnetic stirrer 100 – 1200 rpm

Features Performance

Microprocessor PID Feedback Control

Fast and precise temperature control is provided by the

microprocessor PID controller

Quick Heat Up Time

Ample heating capacity and superb heat transfer rate of the

tightly integrated structure of heater and top plate allow quick

heat up time (up to 300°C).

Page 9

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Auto-tuning (AT)

Automatic tuning of the PID parameters provides more

accurate temperature control.

Temperature Offsetting

In case your own thermometer is to be used for temperature

control for specific applications, there can be some differences

between the temperature of your thermometer and the

displayed temperature of this unit.

Safety

High and Low Temperature Limits

The high temperature limit of the top plate is set to 300°C to

protect you and your media. However, you can set your own

high and low temperature limits to reduce operation time and

also to avoid inadvertent mistakes.

Convenience

Two large digital displays on the control panel clearly show

both set and actual temperatures of the top plate side by side.

You can easily set your own temperature limit at any value

between 0 and 300°C.

Heating rate can be set from 0 to 100% at 1% interval for

delicate temperature control.

One support rod (optional) can be attached to hold various

kinds of devices such as temperature sensors, thermometers,

and so on.

Page 10

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Construction

(1) Top Plat

(2) Radiation Sheets

(3) Main Power Switch

(4) FY-400 Temperature Controller

(5) Stirring Control Knob

(6) Stirring Switch

(7) Stirring motor

(8) Socket for Temperature Probe

(9) Identification Label

(10) Threaded Holes for Support Rod (Optional)

(11) Power Cord

Page 11

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Section 3 Unpacking and Installation

Upon receiving the instrument, check to ensure that no damage has

occurred during shipment. It is important that any damage that

occurred during shipment must be detected before unpacking. If

such damage is found, notify the carrier immediately.

After unpacking, check to ensure that all the following parts and

accessories are included in the package. If not, contact your dealer or

MRC immediately.

Item Quantity

Main Body 1

Operation Manual 1

External Probe 1

Stirring magnet (option) 1

Support Rod (option) 1

RS232 or RS485 Communication (option) 1

Programmer (option) 1

Separate Control box (option) 1

Installation Environment

It should be installed in suitable environment as described below.

Avoid direct sunlight.

Room temperature should be 5°C ~ 40°C

Relative Humidity (RH%) should be less 80%.

Altitude should be less than 2,000m.

Page 12

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Location Conditions

DANGER

Never install or use this equipment in explosive atmospheres.

Never install or use this equipment with or near to hazardous

or flammable substances.

Never expose this equipment to any heat sources including

direct sunlight.

Never install this equipment closer than 20 cm (8 inches) to a

wall of combustible material.

Never install this equipment near any device that generates

high frequency noises.

Set up this equipment on a flat, stable, clean, non-slip, dry, and

fireproof surface inside a lab with proper safety measures.

Observe the minimum distances (in general, 30 cm or 12

inches) from other devices. In addition, any device which can

be affected by the motor vibrations should not be placed near

this equipment.

Connecting to Power Supply

When connecting power, use only the power cord that came with

your instrument. The power connection procedures are as follows:

(1) Before connecting the power cord, make sure that the main

power switch is turned off.

(2) Plug the other end into a properly grounded and dedicated

power outlet nearby.

Page 13

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Connecting to Main Power

DANGER

Check electrical requirements in the operation manual or on

the ID plate attached to the back of this equipment before use.

Make sure to connect this equipment only to properly

grounded as well as dedicated power outlets to protect you

and your equipment.

In order to prevent fire or power cord damage due to

overloading, do not use power strips or improper extension

cords.

Page 14

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Section 4 Operation

FY-401 Digital controller

SYMBOL NAME FUNCTION

PV 1

Measured value

(PV) display

Displays PV or various parameter symbols

(Red)

SV 2

Set value

(SV) display

Displays SV or various parameter set values

(Green)

3

Set key

Used for parameter calling up and set value

registration

4 Auto/Manual key Switches between Auto (PID) output mode and Manual output mode.

5 Shift key Shift digits when settings are changed

6

Down key

*Program hold

Decrease numbers (-1000, -100, -10, -1)

* Program hold (Programmable controller)

7

Up key

*Program run

Decrease numbers (+1000, +100, +10, +1)

* Program run (Programmable controller)

OUT1 8 OUT1 lamp Lights when OUT1 is activated

OUT2 9 OUT2 lamp Lights when OUT2 is activated

AT 10 Auto tuning lamp Lights when Auto tuning is activated

AL1 11 Alarm 1 lamp Lights when Alarm 1 is activated

AL2 12 Alarm 2 lamp Lights when Alarm 2 is activated

AL3 13 Alarm 3 lamp Lights when Alarm 3 is activated

MAN 14 Manual output lamp Lights when manual output is activated

PRO 15

*Program running

lamp

*Flashes when program is running (Programmable controller)

OUT1% 16

OUT% bar-graph

display

Output% is displayed on 10-dot LED.

AUTO

Page 15

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Operations

Power On

Controller will display as below

Change the Set Value (SV)

Change SV for example from 0 to 100

NOTICE

You can change the temperature setting even during

operation.

Changing the temperature setting is allowed only within the

low and high temperature limits.

Page 16

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Change the Alarm Value

Change AL1 value for example to "5.0" (AL1 active, if PV exceeds SV

over 5.0)

Autotuning (AT)

Temperature control using digital PID controllers have automatic

auto-tune functions. During the auto-tune period the PID controller

controls the power to the process and measures the rate of change,

overshoot and response time of the plant. This is often based on the

Zeigler-Nichols method of calculating controller term values. Once

the auto-tune period is completed the P, I ,D values are stored and

used by the PID controller.

Use AT function to automatically calculate and set the optimize PID

value for your system

DO NOT touch the plate or the temperature controller or

add media during autotuning process.

Page 17

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Temperature Offsetting (OFFSET)

The temperature shown on the Actual Temperature Display is

measured by a temperature sensor inside the unit. However, this

temperature can be different from the temperature of your own

thermometer which you may use as a standard for your specific

applications. If needed, you can offset such temperature differences

at 0.1°C interval

NOTICE

If, for example, the actual temperature of the top plate is 100°C but

the displayed temperature is 98°C, you can match the displayed

temperature with the actual temperature of the unit by selecting the

offset value of +2°C

Stir Control Knob

Turn it clockwise to set desired stirring speed.

Turn it all the way counterclockwise to turn off stirring function.

Stirring Instructions

1. Fill vessel with liquid to be stirred.

2. Place stir bar into vessel.

3. Place vessel in the center of the top surface.

4. Turn Stir Control Knob

5. Stir bar to cease rotation before removing the vessel from the

unit.

NOTICE

Please note that the viscosity of the stirred material will affect the

ability of the stir bar to remain coupled to the rotating ring magnet.

Materials of high viscosity must be stirred at slower speed

settings.

Page 18

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

External Temperature Probe Input

Connect the K type optional External Temperature probe into the

back socket.

To Connect the External Temperature Controller

1. Turn the Stir Control Knob and the main switch to the OFF

position.

2. Disconnect power cord.

3. Connect the External Temperature probe to the socket on the

back of the unit.

4. Fill vessel with liquid to be heated.

5. Place vessel in the center of the top surface.

6. Place stir bar into vessel.

7. Put the temperature external probe in vessel.

8. Reconnect power cord.

9. Turn the main switch and the stirring switch to the ON

position.

10. Product is now ready for use with External Temperature

Controller.

11. Repeat the above process when disconnecting the

temperature controller.

CAUTION

Do not use the plate with external temperature probe in

the air or out of the liquid, this can cause serious damage

to the plate, due to lack of control.

The external probe must be properly placed into a liquid

on the top surface during the whole process, to prevent

damage to the plate

The top surface and the vessel used may be at substantially

higher temperatures than indicated by the setting on the

Heating Temperature Display as the controller regulates

the liquid temperature inside the vessel.

Page 19

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Section 5 Maintenance

Inspection

Interval

Item

Daily Weekly

Connection status of power cord or plug

Damages in power cord or plug

Cleanliness of top plate

Cleanliness of main body and accessories

Damages in plate, switches, buttons, Controller

Heating capability check (up to 300℃)

Stirring capability check (up to 1200 rpm)

Assembly status of all parts or accessories

Cleaning Product

WARNING

Never immerse this unit in water or any other liquid.

Do not allow any liquid or wet material to get inside the unit

when cleaning.

Do not reconnect this unit to power outlets until all cleaned

surfaces have dried.

CAUTION

DO NOT use of caustic soda in cleaning reagent

Page 20

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Cleaning Product (continued)

Always make sure to keep top plate, main body, and accessories

clean. Dirt and other foreign substances can cause fire or electric

shock. Before attempting cleaning,

(1) Disconnect the power cord from the power outlet and ensure

that the equipment is cool enough,

(2) Wipe with a soft dry cloth first to remove any foreign matter

and, if not enough,

(3) Wipe with a soft damp cloth or a sponge soaked in water or

diluted neutral detergent when necessary.

Relocation

If you need to move the equipment to another place,

(1) Disconnect the power cord from the power outlet,

(2) Pack the equipment and its accessories into the original

packaging or any other suitable container before moving.

CAUTION

Pay attention to avoid mechanical shock or vibration while

moving the instrument. Damages caused by mechanical shock

or vibration may result in injury or fire.

Keeping Product

If you know you will not use this equipment for an extended period

of time,

(1) Disconnect the power cord from the power outlet and clean

the equipment with soft cloth.

(2) Pack the equipment properly and make sure to store it in dry

place.

Page 21

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Section 6 Troubleshooting

Power

troubles

Cause Corrective action

Unsuitable power supply

Meet the electrical requirements of this

equipment before use.

Loose power connection

Reconnect the power cord firmly to the

power outlet as well as to the power

socket at the back of the instrument.

Damages in power cords,

Power outlets, plug, controller

Replace the damaged part with a

proper one.

No Power

Internal circuit failure Contact MRC for service

Electrical overload

Disconnect all the appliances connected

to the breaker first and reconnect them

one by one to find the reason for the

overload.

Damages in heating element Contact MRC for service.

Repetitive tripping of

circuit breaker

Internal circuit failure Contact MRC for service.

Main switch failure Contact MRC for service.

Controller failure Contact MRC for service.

No operation with

power on

Internal circuit failure Contact MRC for service.

Operation

troubles

Cause Corrective action

Temperature sensor is

disconnected

Connect the temperature sensor

Too low setting of the

temperature controller

Increase the temperature setpoint

Heating element failure Contact MRC for service.

No heat

Internal circuit failure Contact MRC for service.

Too low setting of the

heating rate

Increase the temperature setpoint

Too much media Reduce the media volume.

No or too slow

temperature

change during heating to

increase the heating rate

Internal circuit failure Contact MRC for service.

Internal circuit failure Contact MRC for service

Switches malfunction

Damaged switches Contact MRC for service.

Page 22

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

com.mrclab@mrc

Stirring knob malfunction Damaged knob Contact MRC for service.

Controller display

malfunction

Damage due to chemical spill

or overheating or technical

problem

Contact MRC for service.

Section 7 Warranty Information

The warranty provided for one year and begins from the date

of the purchase by the user

The warranty protection extends to any subsequent owner

during the first-year warranty period.

This warranty does not apply if the product has been damaged

by accident, abuse, misuse, or misapplication, or from ordinary

wear and tear.

The Technical Services Department must be contacted for

warranty determination and direction prior to performance of

any repairs.

Expendable items, glass, filters and gaskets are excluded from

this warranty. Replacement or repair of components parts or

equipment under this warranty shall not extend the warranty to

either the equipment or to the component part beyond the

original warranty period.

The Technical Services Department must give prior approval

for return of any components or equipment.

Your MRC Sales Office is ready to help with comprehensive site

preparation information before your equipment arrives. Printed

instruction manuals carefully detail equipment installation,

operation and preventive maintenance.

If equipment service is required, please call our Technical

Services Department at +972(0)3-5595252 (office) or +972(0)36227732/1 (Service Laboratory)

We're ready to answer your questions on equipment warranty,

operation, maintenance, service and special application.

Outside the Israel, contact your local distributor for warranty

information.

Loading...

Loading...