Page 1

1

Mobile-type PTC Steam Humidifier for office or commercial space

HU-24

INSTALLATION AND OPERATION MANUAL

PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATION

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529 mrc@mrclab.com

MRC.12.16

Page 2

2

Safety Caution

Be sure to read before use. Keep this manual handy for the users to consult at

any time necessary.

The cautions shown here are to ensure the safety in use of the humidifier and to

preclude any danger and damage to the users and others. What could

conceivably result from wrong handling is identified in the form of either

“Warning" or “Caution". They should both be observed strictly as important

points that pertain to safety.

WARNING

CAUTION

Matter that could cause death or

serious injury to human

Matter that could cause injury to

human or damage to property

WARNING

●Do not insert and remove AC plug with wet hands, it may cause electrical shock.

● The nominal current of AC plug having more than 5A must be used singly, not

combination use.

● Do not touch any electric circuit during power on especially by wet hands. It will get electric

shock.

● All of electric cable/wire should not be damaged, processed, pulled or forcibly bended. It will

cause electric leakage and make fire or electric shock.

● All of electric cables/wires should not bind or tie not to cause electric leakage or firing.

● When you have noted smoking or abnormal smell, shut off electric power source

immediately and also off the power switch of the unit. If you keep running the unit it may

cause fire or electric shock. Then please report it to the supplier immediately.

● Do not disassemble the unit except cleaning purpose and also do not modify the unit. It

may cause fire or electric shock.

●Do not splash any water on the unit. It may cause short circuit or electric shock.

Page 3

3

CAUTION

●Be sure not put hands, face close to the steam outlet port, it may cause getting burned.

●Do not move or shake the unit during the operation. It may cause electric shock or

leakage.

●Do not install or locate the unit where such as unstable or vibrating places. The units

may fall down and hurt the people around there.

●Do not install or locate the unit where dusty place , sun shine light exposing directly,

high temperature, close to fire. All are very risky for the fire of the unit.

●Keep open through around the electric plug to shut down the power easily at any

emergency cases.

●Use only specified electric power source and no other voltage required.

●Connect Ground without fail otherwise earth leakage breaker will not work.

●Before carrying out the cleaning works, cut off the power source, otherwise it may cause

electric shock.

●Before carrying out the cleaning works, cut off the power source, and wait till the

temperature get down in the water reservoir, otherwise, it may cause getting burned.

●Do not use extension cables, it may cause electric shock or fire.

●Drain off all water from the water tank and water reservoir if you stop the running for a

while. Otherwise, it cause the offensive odor created by some bacteria and it may affect

health.

●Use only clean water (R.O or Pure water) for the unit. Other liquid may cause trouble of

the unit and make fire or electric shock.

Page 4

4

2

0

0

0

White line

Black line

Green line

Back

Power cable(VCTF-22 3core×2SQ)

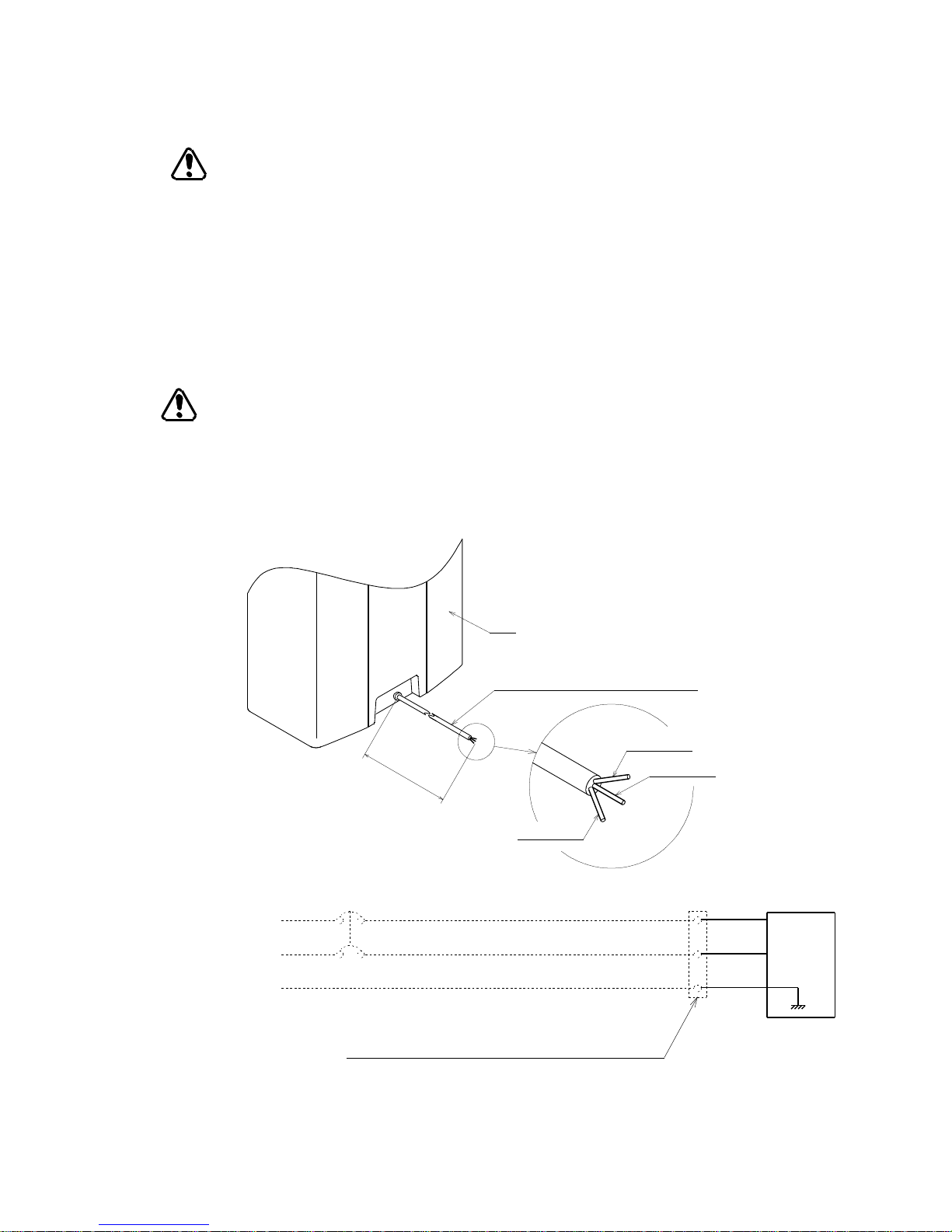

CAUTION for Installation Location

1. Do not install or locate the unit where such as unstable or vibrating places and the unit

should be horizontally-supported.

2. Put the unit away to keep certain distance from surrounding area.

3.Steam comes out from the steam outlet port, it may invite errors in control mechanisms

installed near by the unit, and also may change the color of the furniture or wall.

4. Do not install or locate the unit where dusty place, sun shine light exposing directly,

high temperature, close to fire. All are very risky for the fire of the unit.

CAUTION for Electrical Work

1. Use only dedicated line for the humidifier to supply power and install ground fault

interrupter. (switch panel )

Power supply : AC230V, Rated power : 2.1kW.

2. Power source should be connected to white and black line of power cable and green line

should be connected to earth.

Electrical working drawing

Dotted line parts should be arranged by customer.

Electrical leakage breaker(AC230V-20A induced current 30mA)

AC230V 50/60Hz

Earth

White

Black

Green

unit

Humidifier

Earth

Intermediary terminal or high capacity socket

Page 5

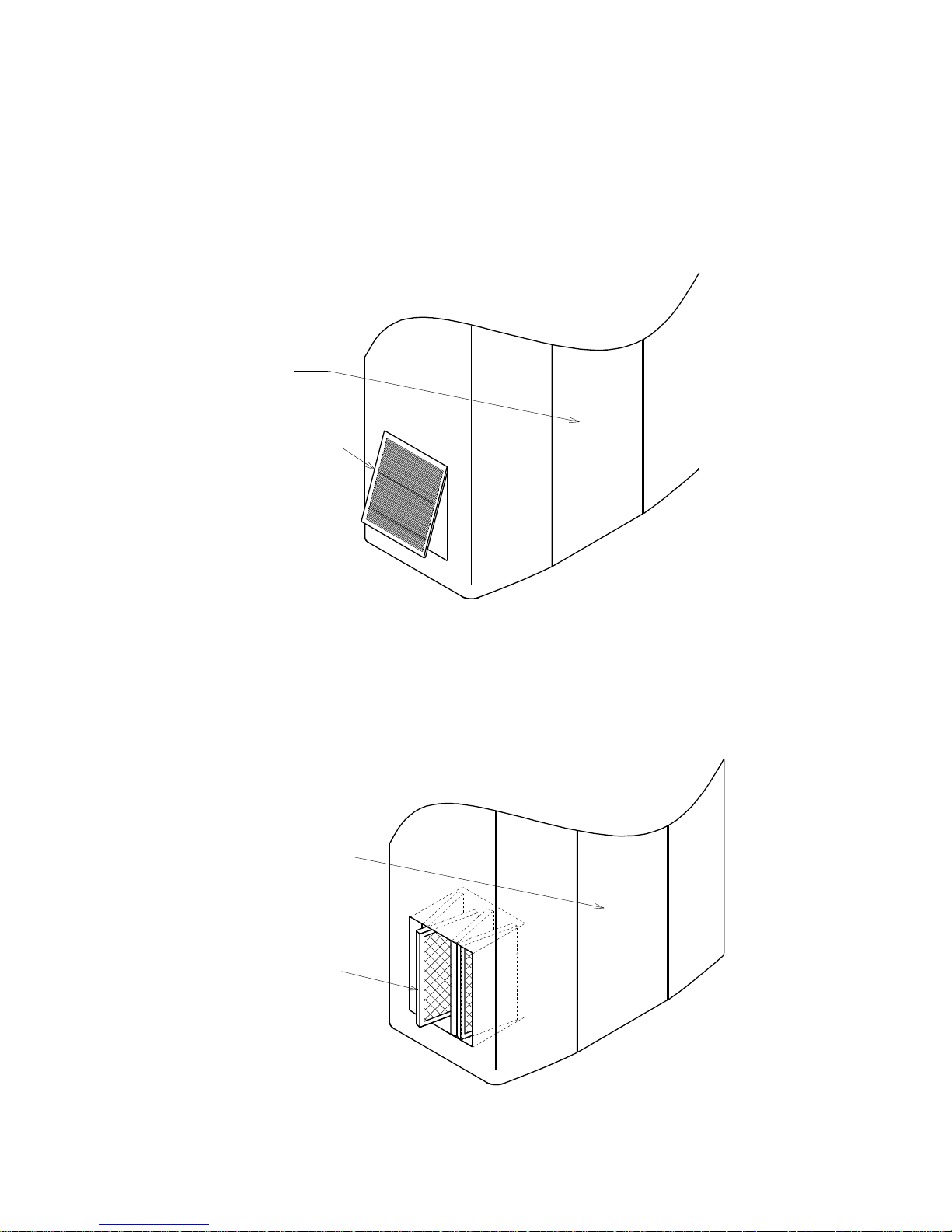

5

Front

Air inlet port

Front

Titanium dioxide filter

Note on operation

Various kinds of the filters

1. Pre-Filter

The filters are installed at the back side of each air inlet ports on both sides of the unit to

protect the suction of dust. (Please refer to P14 for cleaning.)

2. Titanium dioxide filter

3 sheets of the titanium dioxide filter are installed inside the air inlet port on the left side

of the unit to give hygienical, odorless air and sterilize the bacteria and the virus. (Please

refer to P15 for cleaning.)

Page 6

6

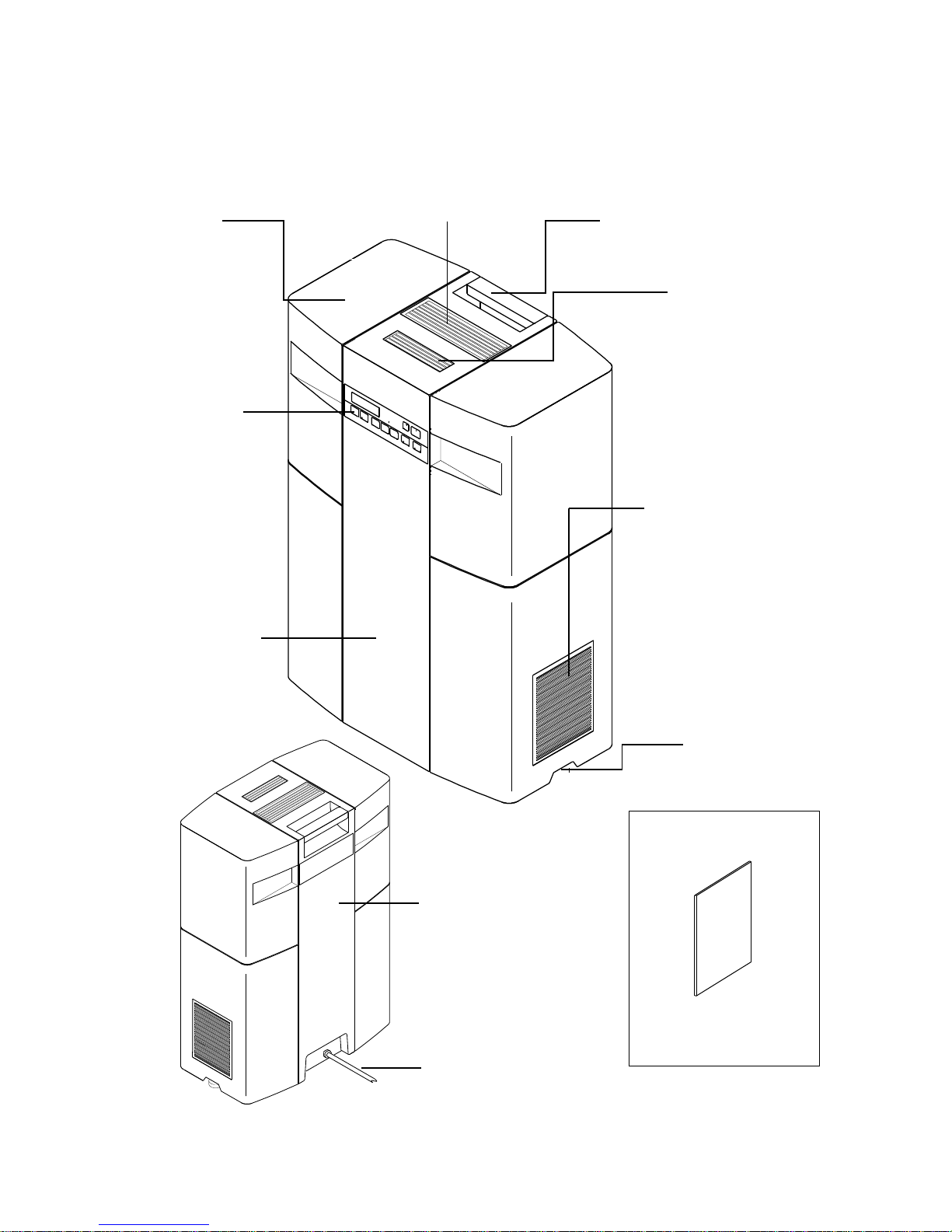

1. Product overview

Front view

Water tank cover (on either side) Steam outlet port Handle

Clean air outlet port

Operation

buttons

Air inlet port

(on either side)

Front panel

Back view Adjuster

Accessory

Back side panel

Installation and

operation manual

Power cable

On the right side: built in humidity sensor

On the left side: built in air cleaning unit

Page 7

7

8

6

4

2

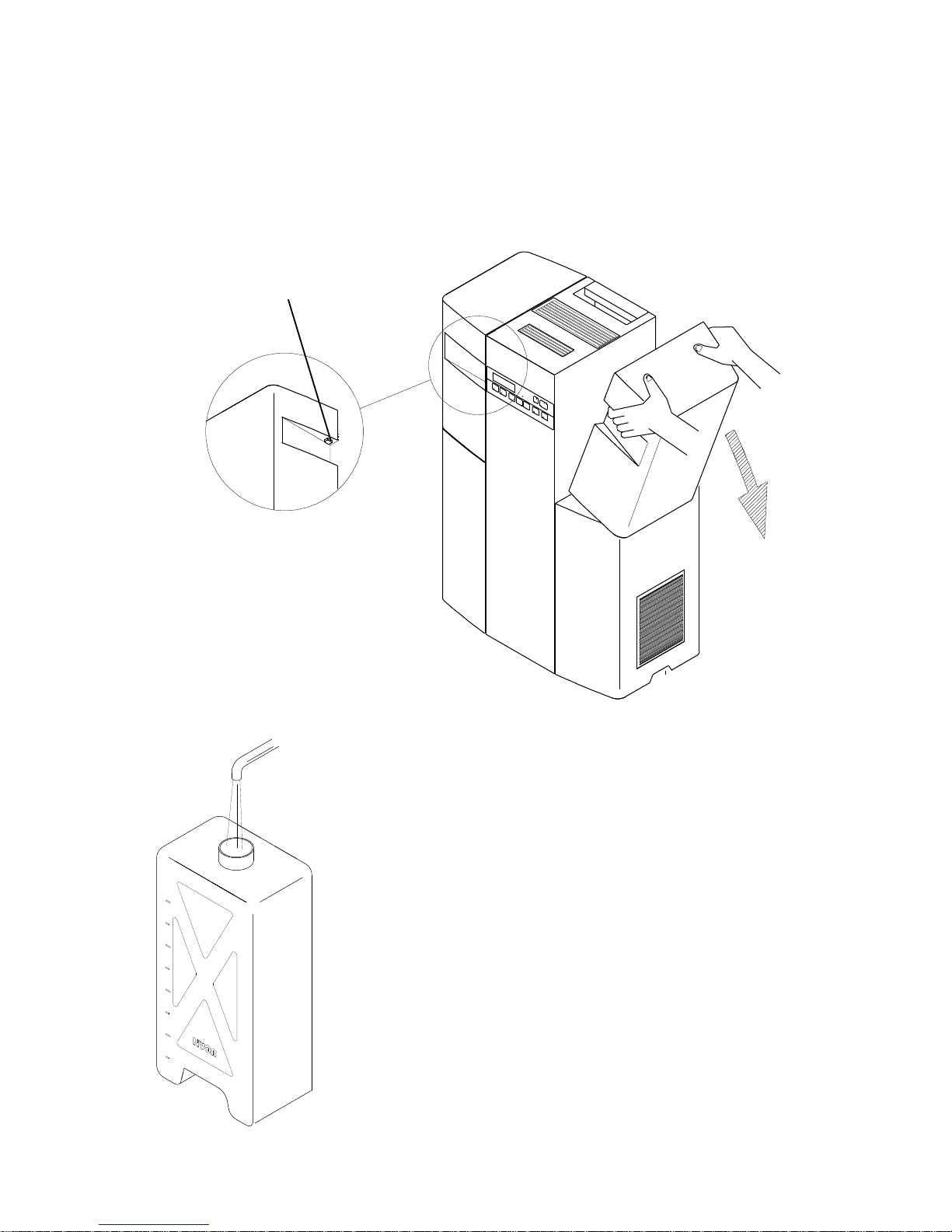

2. How to remove the water tank cover

Push the unlock button situated on upper parts of both front and rear sides at the

hollow parts of the cover and remove it to the arrowed line showing in the below.

Unlock button

3. Supplying water

Pure or R.O water should be used.

1. Open the water tank cover, and pull out the water tank.

2. Remove the cap for the water tank, and fill up the pure or

R.O water in the tank.

3. Fasten the cap tightly and set back the water tank to the unit

and close the tank cover.

Page 8

8

4. Function of the display and operating elements

①. ON/OFF key (Power Switch) : Switch the unit On or Off.

②. Operating display : Shows current humidity and functions.

③. Set switch for setting humidity level : Set humidity level with switch ④

④. Setting humidity level : Set the humidity level up and down with pushing SET

switch ③ at same time.

⑤. Ventilation switch : Switch the ventilation On and Off .

⑥. Heater output : Change for high power (2kW) or low power (1kW) with pushing

SET switch ③.

⑦. Sterilization switch : Switch the sterilization function On or Off .

⑧. Air cleaning switch : Switch the air cleaning function On or Off.

⑨. Lock switch : Child lock for all function by pressing the button for 3 seconds.

⑩. LED for water supply : When the water tank gets empty, LED lights with alarm.

Page 9

9

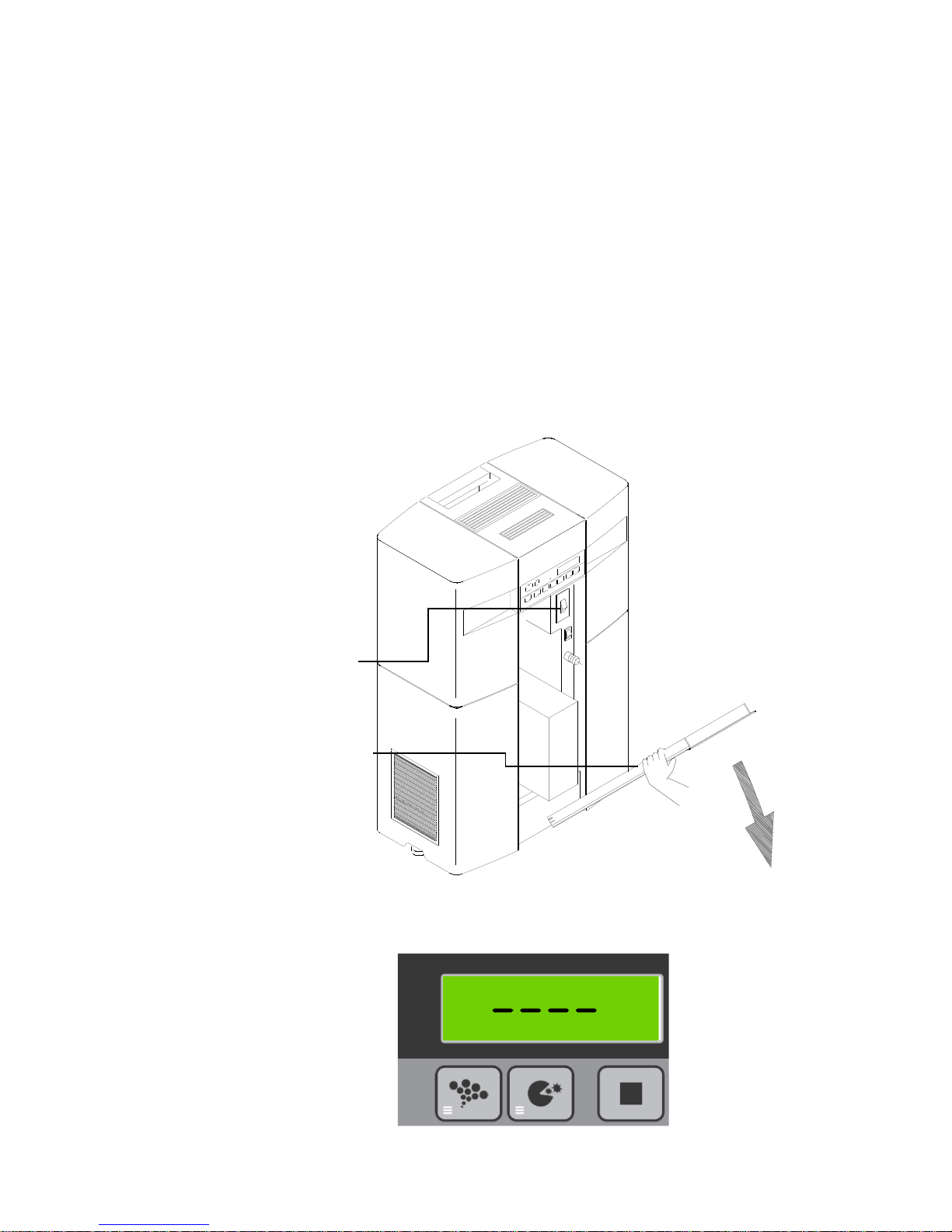

5. Operation

Notes on operation :

1. Fill the pure or R.O water in the water tank.

Open the tank cover and remove the water tank then fill the pure or R.O water into

tank, and set back it to the unit to according to P.6.

2. Power Supply

2-1 After finishing electric work according to P.3, open the tank cover and pull the back

side panel to the direction of arrow as shown below.

2-2 Push the electrical leakage breaker ‘’On’’.

Close the back side panel.

2-3 Switch on the power switch on the display panel.

Electrical

leakage

breaker

Back side panel

2-4. An alarm will sound when the power is supplied, then the display shows the

standby operation status as shown below.

Page 10

10

Operating the control unit.

1. Press the On/Off key.

An alarm will sound and show the current humidity on the display panel.

2. Set the required humidity level in %.

- Push the SET switch on the panel, it shows the humidity level setting by last time.

- If you require other humidity level, push UP or DOWN switch with pushing SET

switch.

Factory setting: 50%

Setting range : 0-99%

- If you disengage a finger from SET switch, then the display shows current humidity.

3. Start of steam generation

When the current humidity is lower than the setting humidity, the unit is activated and

starts generating the steam after about 10 minutes.

4. Shutdown the unit

By pushing the’’ On/Off ‘’switch, an alarm will sound and indicate ‘’-----‘’ in the display

then the unit will shutdown in about 10 minutes after run of the ventilation.

Page 11

11

Other functions

1. Ventilation switch

By the ventilation switch, it can spread the steam from the outlet port.

Please set the switch ‘’On’’ under the normal operation.

Note : Be sure not to put hands, face close to the steam outlet port, it may cause

getting burned. If you operate the unit with ventilation switch ‘’OFF’’ the hot

steam comes out from steam outlet.

2. HIGH / LOW switch for heating power.

Switch to change the humidifying heater to high or low.

Can change the humidifying heater high or low by pushing this switch with pushing

SET switch at the same time. LED display shows high in the left and low in the right

sides.

High setting Low setting

Page 12

12

3. Air Cleaning switch

To clean air.

Clean air will be supplied in the room from air sanitization outlet port.

4. Switch for sterilization

To sterilize air.

Sterilized ozone is emitted inside the room from the air sanitization outlet port.

5. Switch for Rock

Child lock for all function by pressing the button for 3 seconds.

The lock is released by pressing another 3 seconds.

Page 13

13

Fault indication

1. Warning for water supply.

1-1 When the water tank gets empty, ‘’FEED WATER’’ is shown in the display with

alarm and stop the unit automatically.

1-2 Fill water in the tank, and set back to the unit, then Error LED in the display and

alarm are disappeared then the unit restarts.

Note : Warning alarm can be switched off by pushing lock switch.

2. Exchange the UV lamp for air cleaning.

2-1 When UV lamps built in the air cleaning unit has exceeded the life time and no

lighting up the UV lamp, LED lights and showing the error message in the

display with alarm.

2-2 Replace the UV lamps, error message is disappeared after replace the UV

lamps, and restart the air cleaning operation. ( please refer P16 for

replacement of UV lamp )

* Warning alarm can be switch off by pushing the lock switch.

Page 14

14

6. Cleaning the unit

CAUTION

Drain off all water from the water tank and water

reservoir if you stop the running for a while.

It cause the offensive odor created by some bacteria and it may affect

health.

Before carrying out the cleaning works, cut off

the power source.

It may cause electric shock.

Before carrying out the cleaning works, cut off

the power source, and wait till the temperature

get down in the water reservoir.

It may cause burn injury.

WARNING

Do not splash any water on the unit.

It may cause short circuit or electric shock.

Do not maintain the unit while in use or shortly

after operating.

It may cause burn injury.

Page 15

15

2

4

6

8

1 Cleaning the water tank.

When the inside of the tank gets dirty, put some water in the tank and close the cap

firmly, and wash by shaking.

2 Cleaning the pre-filter

2-1 Pull out the handle under the air inlet ports as shown below sketch and take out air

inlet ports.

Air inlet port

2-2 The pre-filter is inserted at the back side of the air inlet port.

Pull out the pre-heater, and take up dust by vacuum.

Page 16

16

Air inlet port

Pre-filter

Page 17

17

Front

Titanium dioxide filter

3 Cleaning the Oxidized Titanium Filter

3-1 3 sheets of oxidized titanium filters are installed inside the air inlet port at the left

side of the unit. Take out the air inlet port and pull out the filters.

3-2 Wash oxidized titanium filters lightly in water and dry in the sun, then back them to

the unit.

Note: There is no opposite sides to the same oxidized titanium filter.

①Wash in the water.

②Dry in the sun.

Page 18

18

Front

Titanium dioxide filter

4 Replace UV lamp

4-1 3 sheets of oxidized titanium filters are installed inside the air inlet port at the left

side of the unit. Take out the air inlet port and pull out the filters.

4-2 UV lamps are plugged in the sockets, so pull out the lamps as shown the below, and

replace them with new lamps.

Note : There is no polarization setting for the UV lamps.

Be sure to plug the lamps firmly into the sockets.

4-3 After replace the UV lamps, set the oxidized titanium filters on the position and fix

the air inlet port.

Note : There is no opposite sides to the same oxidized titanium filter.

UV lamp

Socket

Page 19

19

5 Replacing the lamp for sterilization

5-1 Open the water tank cover on the left side of the unit, and pull out the tank as

shown the below.

5-2 Loosen 2 screws on the side cover, and remove the side cover as shown the below

sketch.

Side cover

Page 20

20

5-3 Pull out lamp unit for sterilization from ventilation duct inside the unit, and

disconnect the lead from connector.

Connector

Ventilation duct

Lamp unit

5-4 Replace the lamp unit for sterilization with new one as set.

5-5 Installation of the unit follows the reverse sequence.

Page 21

21

6 Drainage water from the unit

CAUTION

Drain off all water from the water tank and water reservoir if

you stop the running for a while.

It cause the offensive odor created by some bacteria and it may affect health.

Before carrying out the cleaning works, cut off the power

source.

It may cause electric shock.

Before carrying out the cleaning works, cut off the power

source, and wait till the temperature get down in the water

reservoir.

It may cause burn injury.

6-1 Open the tank cover, then open the front panel to the direction A as showing the

below sketch. .

Remove the panel by pulling out to the direction B as showing below sketch.

A

B

Page 22

22

6-2 Remove 2 water tanks.

6-3 Supply the main power to the unit, and setting Stand-by operation.

Display showing when stand-by operation.

Part Names

Drainage switch

Drain port

Drain hose

Bucket (arranged by customer)

Page 23

23

6-4 The drain hose plugged into the drain port is jointed with bucket.

Drain hose

Bucket

(arranged by customer)

6-5 Drain starts when setting ‘’On’’ the drainage switch.

When the water is completely drained, setting‘’ Off’’ the drainage switch.

ELB

Drainage switch

6-6 Setting ‘’Off’’ the power supply switch after drainage.

6-7 Put back the front panel to the original position.

Page 24

24

7 Cleaning the water reservoir

Water reservoir must be maintained on a periodic basis and in the off-season by

following procedure.

7-1 Finishing drainage of the water in the unit. Clean the water reservoir.

7-2 Remove the back panel of the unit

Water reservoir

7-3 After confirming switching off the switch panel and earth leakage breaker on the unit,

remove the heating cables from terminal block.

Heating cable

黒

赤

白

Page 25

25

7-4 Unfasten the hose band and pull out the steam hose from the top cover of the water

reservoir.

Steam hose

Hose band

7-5 Unfasten 2 screws fixing the water reservoir.

Fixed bracket

Fixing screw

Top cover of the

water reservoir

Page 26

26

Plastic brush

7-6 Push up on the water reservoir as shown the below and remove water reservoir from

the unit.

Water reservoir

Water supply tube

Note: There is some water left in the water reservoir, so tilt the reservoir direction to the water

supply hose when detaching the reservoir from the unit.

7-7 Remove the top cover of the reservoir, and remove any limescale by a brush ( do not use

a wire brush ) inside the water reservoir and top cover, then wash them up with clean

water.

Page 27

27

7-8 After cleaning the water reservoir, water supply tube fixed in the bottom of the water

reservoir must be screwed firmly with water supply port of the unit.

Water supply tube

Water supply port

Note: O- ring is installed in the water supply tube.

Degradation and deformation of O-ring cause the leakage of the water, so

need to check O-ring when mounting the water reservoir, and replace with

new O-ring if needed.

O-ring

7-9 Installation of the water reservoir follows the reverse sequence.

Note: In order to avoid mishandling the unit, please set ‘’Off’’ for both switch panel

and earth leakage breaker.

Page 28

28

s

o

u

n

d

B

o

i

l

i

n

g

B

u

b

b

l

i

n

g

B

u

b

b

l

i

n

g

7. Daily Maintenance

1 Cleaning each filter

- When the filters get dirty at air inlet port.

- Periodic basis.

Pre- filter at air inlet port : every 3~4 months

Oxidized Titanium Filters (3 sheets) : every 3~4 months

2 Drainage the water reservoir

Produce the sounds of water boiling coming from the unit during on operation is the

sign that the water in the reservoir get dirty.

Please drain water from reservoir or cleaning the reservoir.

3 Wiping the body of the unit.

The places like steam output port and air inlet ports get dirty easily, so wiping by wet

clothes when they get dirty.

To use HU-24 long term.

We recommend the customer to drain the

water from the reserv oir regularly.

In case of ON-SE ASON, it is desirable to

drain the water once per week.

Page 29

29

8. Trouble Shooting

Trouble function

Possible reason

countermeasure

No operation

No electric power switch on

Supply the power

Switch off earth leakage

breaker

Switch on earth leakage

breaker

Not setting humidity level

Setting humidity level

LED lights for water supply

Supply water

LED lights for water supply

Empty in the water tank

Supply water

Censor for supply water getting

dirty *

Cleaning the censor

No steam output

Soon after the switch on the

unit

Need about 10 minutes to

get steam

Wrong setting of humidity level

or lower setting humidity than

current humidity

To check the setting humidity

level

LED lights for water supply

Supply water

Less output the steam

Mossy surface in the water

reservoir ?

Clean the water reservoir

Empty in the water tank

Supply water in the tank

Dirty at the steam outlet port

Clean the steam outlet port

Have an abnormal noise

Mossy surface in the water

reservoir ?

Clean the water reservoir

Have an unusual odor

Not carried out the drainage in

the water reservoir

Drain the water in the water

reservoir

Triggered by short circuit or

electric leakage

Do service call

Not control the switch

Rocked the rock switch

Release the rock switch

Plastic brush

Water supply sensor

*Position of the water supply censor

The water supply sensor is installed in the water

tank receiver at right side of the unit.

Clean the sensor that looks dirty using nylon brush.

Page 30

30

9. Maintenance list

To maintain operational safety, MRC must be maintained at regular

intervals.

Below you will find a summary of the work to be carried out for each of

maintenance stages take into consideration of annual number of operating hour

as 1,000 hours.

Components

Work to be done

( 1time / year )

Approx. time for

replacement (years)

Pre-filter

Cleaning of dirt

3

Oxidized titanium filter

Wash lightly in water

5

UV lamp for air cleaning

Wipe the lamp with a dry

cloth

10

Lamp set for sterilization

Wipe the lamp set with a

dry cloth

10

Drain pump

----

3

PTC immersion heater

Cleaning of dirt

3

Each hose/pipe

Cleaning of the dirt inside

the hose/pipe

3

Steam hose

-----

5

10. Warranty

Please see P.33 of this manual for the detail.

Page 31

31

11Specification

Power supply

AC230 V 50/60Hz

Rated power

(L)1100w / (H) 2100w

Steam output

(L)1.2kg/h / (H)2.4kg/h

Air volume at steam outlet port(Max)

30 m3/h

Air volume for air cleaning, and

sterilization (Max)

30m3/h

Water tank capacity

10 L x 2

Humidity display range

10_ _ _99%RH

Water quality

Pure or R.O water

Auxiliary function

Output switch ( L ) & (H )

Display for current relative humidity

( %RH)

Function for air cleaning

Function for air sterilization

Fault indications on display

Ambient condition

0…40˚C(No freezing), Max.70%RH

Weight

Dry: 24.5kg Full: 44.5kg

External dimensions(mm)

Page 32

32

Wiring diagram

Page 33

33

WARRANTY

MRC warrants to the original first customer that the products will be free from defects

in material and workmanship for only the period of 12 months from the date of

delivery from the MRC factory.

If any MRC product is proven to be defective in the material or workmanship by MRC

during above applicable warranty period, MRC only will repair or supply replacement

for the defective product at free of charge. And only after having informed by MRC, the

customer can return the defective parts to MRC without any charge, the costs for

transport of the parts to be repaired shall be borne by MRC.

In case of replaced or repaired the goods, the original warranty period shall be

kept. MRC shall not be liable for under any circumstance:

1. If all actions described in MRC’s installation and operation manuals do not carry

out even by well trained and sufficiently qualified personnel authorized by the owner.

2. If the customer do not follow MRC’s installation and operation manuals.

3. If the products have been modified, or altered without written agreement with

MRC.

4. Under circumstances of any direct, indirect, incidental, consequential damages, or

damages for injury occurrence to person or property, loss of business or information,

loss of profit or production interruption in relation to the manufacture or use of the

products.

5. Any damage or malfunction due to act of providence such as earthquakes or fires.

6. Any damage or malfunction during transportation or transfer such as dropping the

product after the purchase.

7. Any damage or malfunction caused by other source not directly caused by MRC

products.

8. Any damages or malfunctions caused by mishandling or unauthorized repairing jobs.

9. The oscillators for the Ultrasonic Humidifiers.

The sheathed heater for Resistive Steam Humidifiers.

PTC (Positive Temperature Coefficient) heater for Steam Humidifiers.

MRC shall not be liable for any cost or expense whatever either direct or indirect costs

for removal, re-installation for any defective product and installation for the

replacement.

By purchasing MRC products, the purchaser understands and agrees the terms and

conditions of this warranty.

Loading...

Loading...