Page 1

MRC Ltd

Fume Hood

FH (A) series

USER MANUAL

Thank you very much for purchasing our FH (A) series Fume Hood.

Please read the “Operating Instructions” and “Warranty” before

operating this unit to assure proper operation. After reading these

documents, be sure to store them securely together with the “Warranty”

within touch for future reference.

Warning: Before operating the unit, be sure to read carefully and

fully understand important warnings in the operating instructions.

MRC Ltd

Page 2

MRC Ltd

CONTENT

1. Unpacking, Installation and Debugging .............................................................................................

1.1 Unpacking of Main Body ..................................................................................................................

1.2 Unpacking of Base Cabinet .............................................................................................................6

1.3 Accessories Checking .......................................................................................................................

1.4 Installation Conditions and Operating Environment ........................................................................

1.5 Installation........................................................................................................................................9

1.6 Inspection after Installation................................................................................................................

2. User Instructions ..................................................................................................................................

2.1 Functions............................................................................................................................................

2.2 Product Structure ...........................................................................................................................16

2.3 Control Panel .....................................................................................................................................

2.4 Instructions of Operation ...................................................................................................................

2.5 Regular Maintenance .........................................................................................................................

2.6 Replacement Parts List..................................................................................................................26

2.7 Wiring Diagram.............................................................................................................................28

3. Trouble Shooting and Labels...........................................................................................................29

3.1 Common Failures and Solutions....................................................................................................29

3.2 Label Description...............................................................................................................................

4. Warranty ..........................................................................................................................................34

2 http://www.mrclab.com/

Page 3

MRC Ltd

1. Unpacking, Installation and Debugging

Please firstly check whether the packing box is in good condition. If the packing box is damaged,

please take photos and contact the freight carrier. MRC and its dealers are not responsible for

shipping damages

1.1. Unpacking of Main Body

Choose a proper unpacking method according to the actual situation.

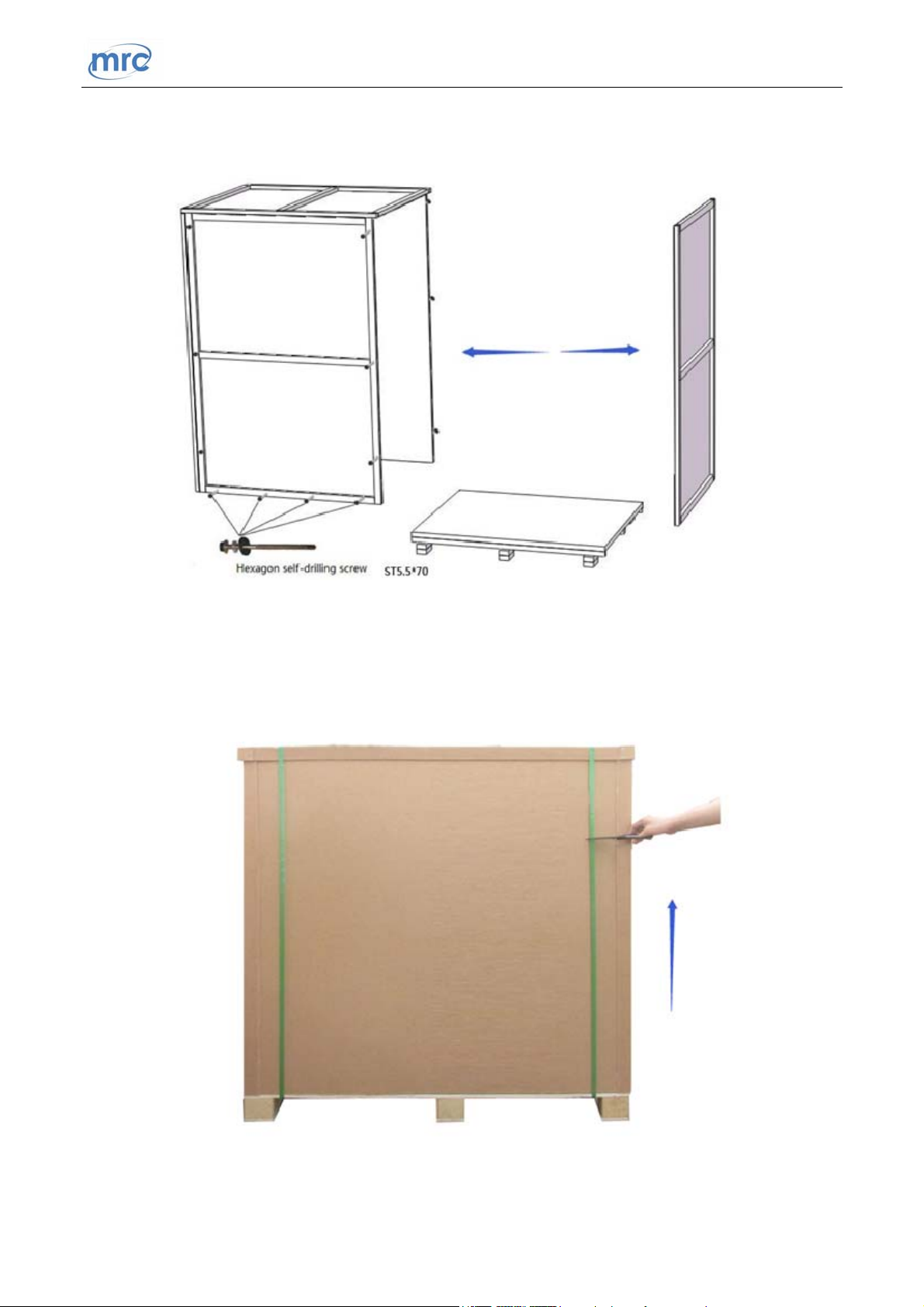

1.1.1. For wooden box

a) Method 1 Necessary tools for unpacking: Electric drill with hexagon dead M8

Picture 1

3 http://www.mrclab.com/

Page 4

MRC Ltd

b) Method 2 Use M8 wrench to unpack

Picture 2

The following diagram demonstrates quick unpacking procedures (Picture 3).

Remove the screws shown in the diagram below, then move the wooden pieces

to right and left.

4 http://www.mrclab.com/

Page 5

MRC Ltd

Picture 3

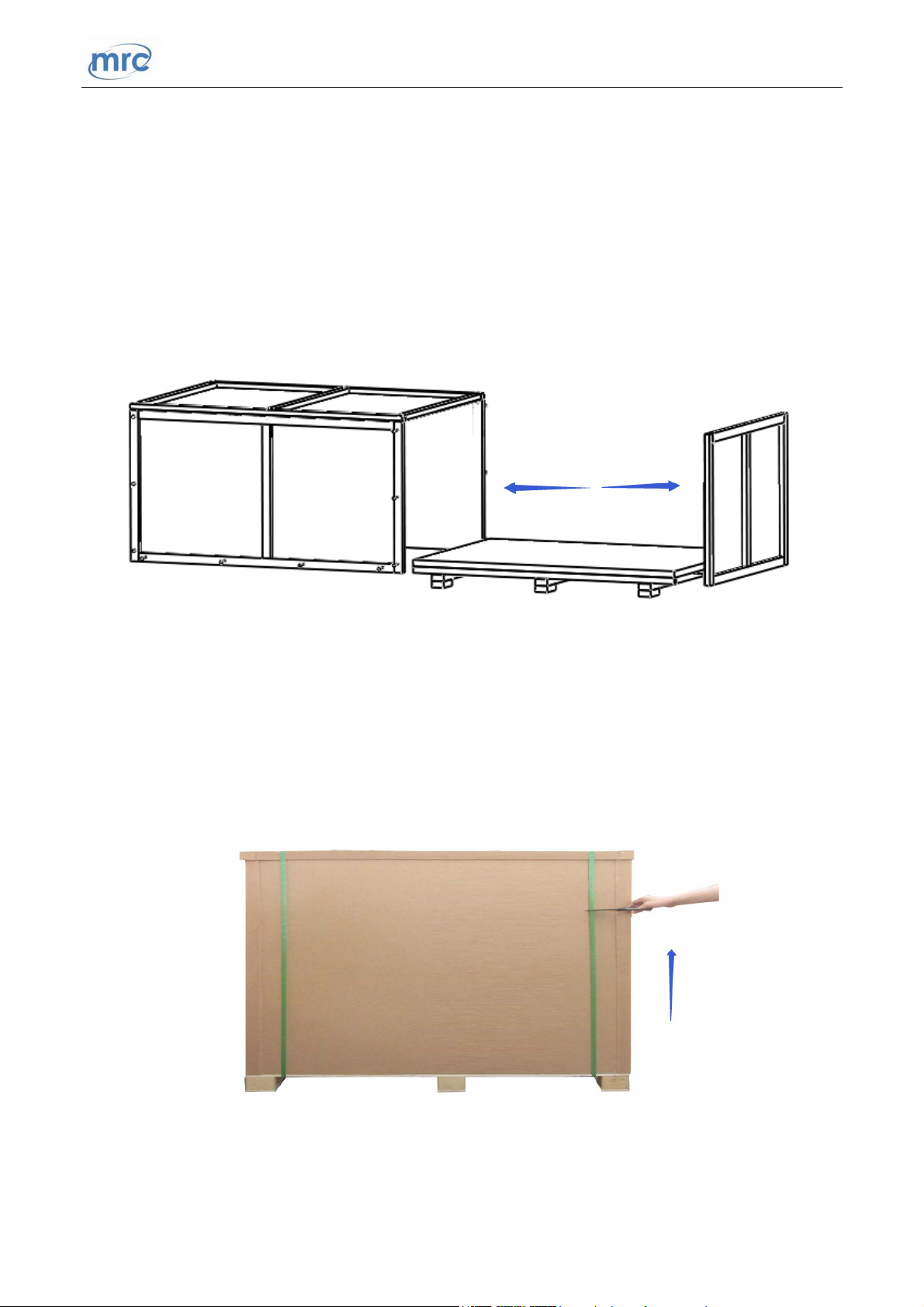

1.1.2. For cartoon box

Use scissor to cut the packing tape, take off the package cover, then move up the box

body.

Picture 4

5 http://www.mrclab.com/

Page 6

MRC Ltd

1.2. Unpacking of Base Cabinet

Choose a proper unpacking method according to the actual situation.

1.2.1. For wooden box

Please refer to the main body unpacking method (of wooden box) in the previous pages,

use M8 electric drill or M8 wrench to remove the screws and unpack the box.

Picture 5

1.2.2. For cartoon box

Please refer to the main body unpacking method (of carton box) in the previous pages,

use scissor to cut the packing tape, take off the package cover and move up the box

body.

Picture 6

6 http://www.mrclab.com/

Page 7

MRC Ltd

1.3. Accessories Checking

Accessories are placed inside the working area and base cabinet. Please refer to 1.5.6. to take

out all accessories and check the completeness referring to this packing list.

Packing list (FH (A) Fume Hood)

Main body box:

No. Items Quantity

1 Main body 1 unit

2 User manual 1 pc

3 Certification of quality 1 pc

4 Inspection report 1 pc

5 UV lamp 1 pc

6 Fuse (5A) 1 pc

7 Fuse (10A) 1 pc

Stainless steel hexagon socket head cap screw M10×20

8

Stainless steel hexagon nut M10

Stainless steel flat washer 10 and spring washer 10

9 PP water sink with accessories 1 set

10 Power cord 1 pc

11 Motor control rod 1 pc

12 Allen wrench 1 pc

Base cabinet box:

4 sets

No. Items Quantity

1 Base stand 1 unit

2 Exhaust duct 1 pc

3 Duct clamp 1 pc

7 http://www.mrclab.com/

Page 8

MRC Ltd

1.4. Installation Conditions and Operating Environment

1.4.1. Location requirements

To avoid disturbances to the Fume Hood and its operator, please follow the guideline

below, while determining a suitable location for the equipment

a) Fume Hood should not be installed in positions where they are likely to be

affected by other items or equipment. Windows, doorways, fans, room air supply

diffuser or ventilation outlet should be away from the Fume Hood.

b) The distance from the front window to any circulation space or air-handling

equipment should be at least 1000 mm, so as to preserve a zone undisturbed by

anyone other than the operator

c) The position of a Fume Hood should satisfy the spatial requirements (e.g. vision,

lighting and convenience of access) of the operator and personnel working

nearby.

d) When a Fume Hood is installed on a bench top, the leading edge should be flush

with or slightly overhanging the edge of the bench top.

1.4.2. Environment requirements

a) Only applicable to indoor operation

b) Ambient temperature: 15℃~35℃

c) Relative humidity: ≤75%

d) Atmospheric pressure range: 70 kPa~106 kPa

1.4.3. Electrical requirements

a) Electrical parameters: consistent with the rated voltage of the Fume Hood (See

2.1.4 Technical parameters and 2.1.5 Performance index)

8 http://www.mrclab.com/

Page 9

MRC Ltd

b) Power supply need to be grounded (Judging method: test the live wire and the

neutral wire of the main socket with multimeter. The voltage between live and

ground should equal to the voltage of local electrical grid, and the voltage

between neutral and ground should equal to 0. Otherwise, the power supply is

not grounded correctly.)

c) Test the voltage stability before using. If the voltage is unstable, use a voltage

regulator to adjust. Otherwise, the control panel and transformer may be easily

damaged

1.5. Installation

1.5.1. Remove all the package materials

1.5.2. Check the surface of the base cabinet and the main body to make sure there is no

scratch, deformation or foreign bodies

1.5.3. Move the whole equipment

as close as possible to the final installation place

NOTE: Do NOT turnover, disassemble or slant the cabinet during

transportation.

1.5.4. Position the base cabinet to the final location where an appropriate power supply is

nearby; and brake the caster to stabilize the base cabinet

1.5.5. Make sure the voltage and frequency of power supply is same as the required value

which is shown on the label. Take out the power cord from the packaging box and

connect it with the female power cord connector on the main body. Plug in the other end

to connect a power supply

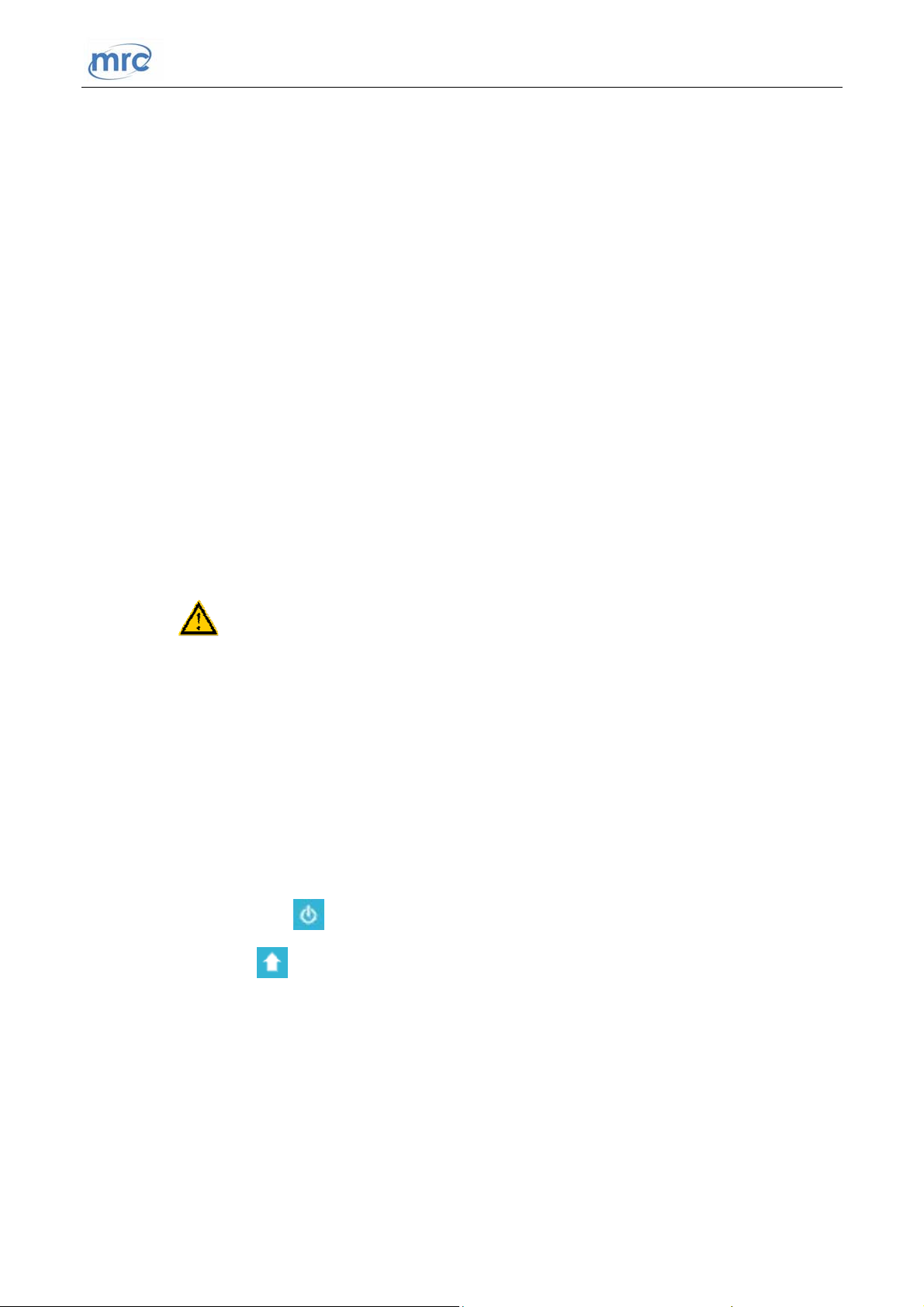

1.5.6. Press the “ ” button on the control panel to power on the equipment. Afterwards,

press the “ ” button to raise the front window, take out the accessories from the

operating area and remove the work table as shown in the picture below. Lastly, power

off the equipment and prepare for installation.

9 http://www.mrclab.com/

Page 10

MRC Ltd

Picture 7

1.5.7. Connect base cabinet with main body

a) Lift the main body and place it on the base cabinet. Make sure each side is in

alignment. Besides, please also make sure the mounting holes of bolt (as shown

in Picture 9) at the bottom of the main body are in alignment with the holes on

the top plate of the base cabinet

b) Make sure the main body and base cabinet are stable enough to prevent side-slip.

Pull out this work

table to reveal the

bolt holes

Open the doors of the base cabinet and take out the components from the

accessory bag

Stainless steel hexagon socket head cap screw M10×20

Stainless steel hexagon nut M10

Stainless steel flat washer 10 and spring washer 10

Insert the hexagon socket head cap screws (M10×20) into the holes at the bottom

of the main body (refer to the Picture 8). These screws should pass through the

main body and the base cabinet. Use flat washer 10, spring washer 10 and nut

10 http://www.mrclab.com/

Page 11

MRC Ltd

M10 to fasten the screws and nuts. Make sure the base cabinet is well connected

with the main body.

Four screws to secure

the base cabinet to the

main body

Picture 8

1.5.8. Installation of water tap and gas tap

Insert the work table and mount the water sink on the reserved sink hole.

Connect the laboratory water pipe and gas pipe (inflow) with the lower end of the taps.

Pass the drainpipe (provided) through the reserved hole at the side of the base cabinet

(refer to Picture 10) and connect it with the sewer pipe in the laboratory room (water

sink and drainpipe have been connected in factory)

Water tap

Water sink

Picture 9

11 http://www.mrclab.com/

Page 12

MRC Ltd

Water inlet

Drain hose

Gas inlet

Picture 10

1.5.9. Installation of exhaust duct

Take out the duct clamp and the exhaust duct. Put the clamp on the exhaust duct and

then connect the exhaust duct with the air exhaust outlet on top of the Fume Hood.

Afterwards, use Slotted screwdriver to fasten the duct clamp firmly. The other end of

the exhaust duct should be fixed outside the laboratory room and in the open air.

Exhaust duct

Duct clamp

Slotted screwdriver

Air exhaust outlet

Picture 11

12 http://www.mrclab.com/

Page 13

MRC Ltd

1.6. Inspection after Installation

Refer to this table and follow the instruction in 2.4.2, check the following items after

powering on the Fume Hood.

Checking Items Normal working status

Power status

Fan

Front window

Fluorescent lamp Lamp lights up after pressing button

UV Lamp Lamp lights up after pressing button

Socket

Equipment could be powered on/switched off when press the

power button

Runs normally after pressing the Fan button; speed could be

adjusted by pressing the adjusting button

Front window could be moved smoothly by pressing the UP

and DOWN buttons

Use multimeter to test voltage output after pressing the

socket button

NOTE: Please contact MRC technical department or agent for inspection or

trouble shooting when problems could not be solved. Methodology of trouble

shooting is stated in the After-sale Service Manual.

13 http://www.mrclab.com/

Page 14

MRC Ltd

2. User Instructions

2.1. Functions

2.1.1. Product concept

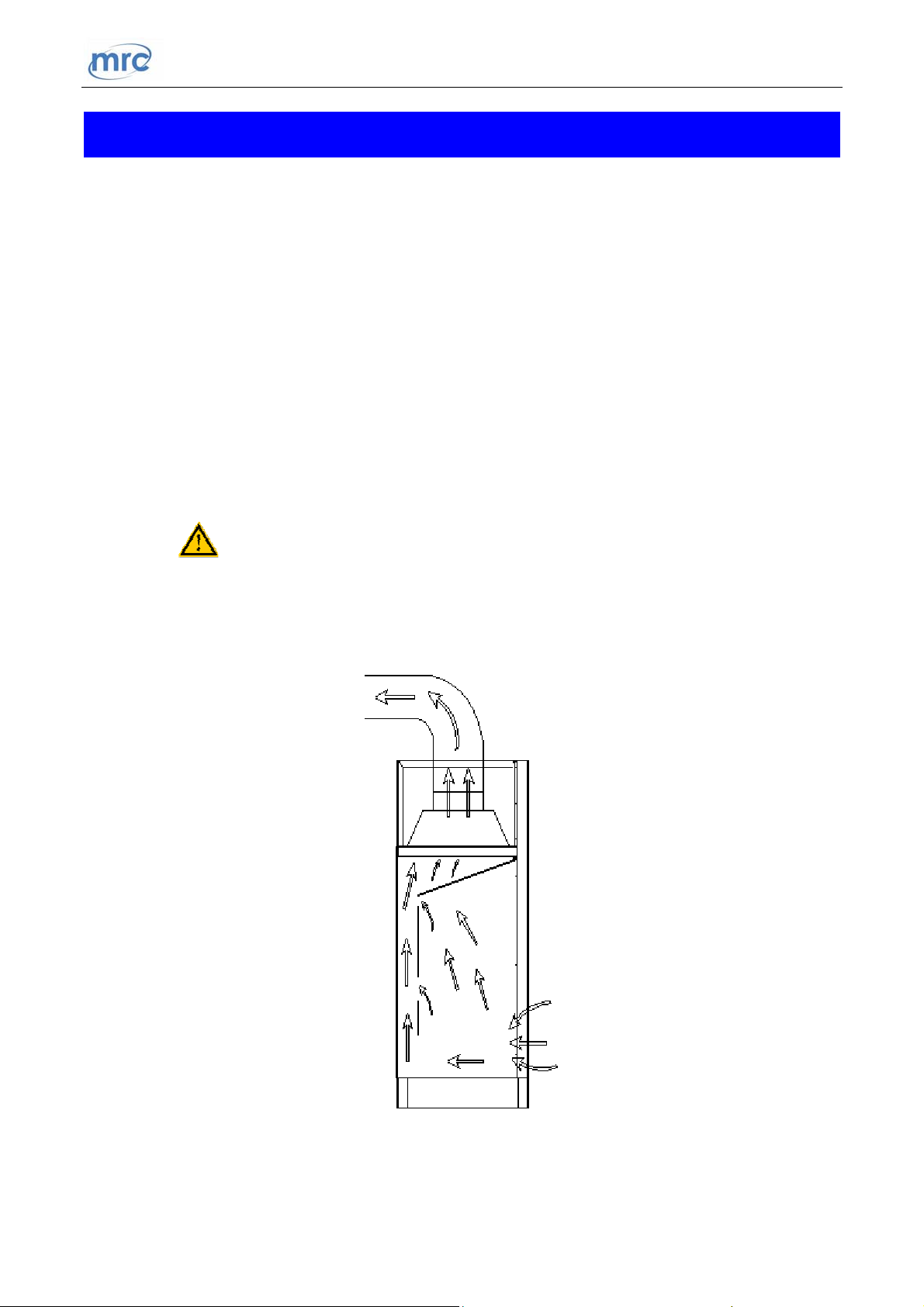

This product belongs to FH (A) series Fume Hood. Fume Hood is a kind of negative

pressure ventilation system for protecting operator and laboratory environment. Room

air flows inward from the front opening of the Fume Hood and is consistently ventilated

by the extract blower. Therefore, contaminated fumes, vapors, toxic gasses, aerosol and

corrosive substance which are probably generated during experiments could be

prevented from spreading to the operator or into the laboratory room. In addition, the

polluted air could be purified by the active carbon filter (optional) before exhausting

through the duct. Thus, the outdoor environment could also be protected.

NOTE: Experiments with the use of flammable, explosive substances and

strong acids or bases should NOT be conducted by this FH (A) series Fume Hood.

2.1.2. Operating principle/air flow pattern

Picture 12

14 http://www.mrclab.com/

Page 15

Parameter

MRC Ltd

2.1.3. Protected object

The primary goal of the Fume Hood is to protect operators and laboratory environment

from exposure to infectious aerosol and toxic fumes which may be generated from the

reaction during experiments.

2.1.4. Technical parameters

Model

FH-10A

FH-12A FH-15A FH-18A

Rated Voltage AC

Rated Frequency

External Dimension

1040*800*2200 mm 1240*800*2200 mm 1540*800*2200 mm 1840*800*2200 mm

(W*D*H)

Working Zone

820*670*730 mm 1020*670*730 mm 1320*670*730 mm 1620*670*730 mm

Dimension (W*D*H)

Power Supply

400 W 400 W 500 W 500 W

Consumption

Inflow Velocity 0.3~0.8m/s

Maximum Opening 500mm 500mm 500mm 500mm

220V±10%

50 Hz

110V±10%

60Hz

UV Lamp Consumption 20W 20W 30W 30W

Fluorescent Lamp

T5 8W T5 12W T5 16W T5 16W

Consumption

Noise ≤70dB(A)

NOTE: a) Power supply consumption includes the consumption loaded at

working zone, which should not exceed 500W.

b) MRC reserves the right to make changes in future product design,

without reservation and without notification to its users.

15 http://www.mrclab.com/

Page 16

2.1.5. Performance index

a) Vibration amplitude

The net vibration amplitude, at a range of frequency from 10 Hz to 10 KHz,

would not exceed 5 μm (rms)

b) Illumination

The average illumination would not less than 400 lux. Tested real illumination

would not less than 350 lux

c) Electrical performance

Dielectric Withstand Test: the Fume Hood would not breakdown in 5s when the

voltage increases by 1390V (AC) within 5s

Ground resistance ≤0.1Ω

MRC Ltd

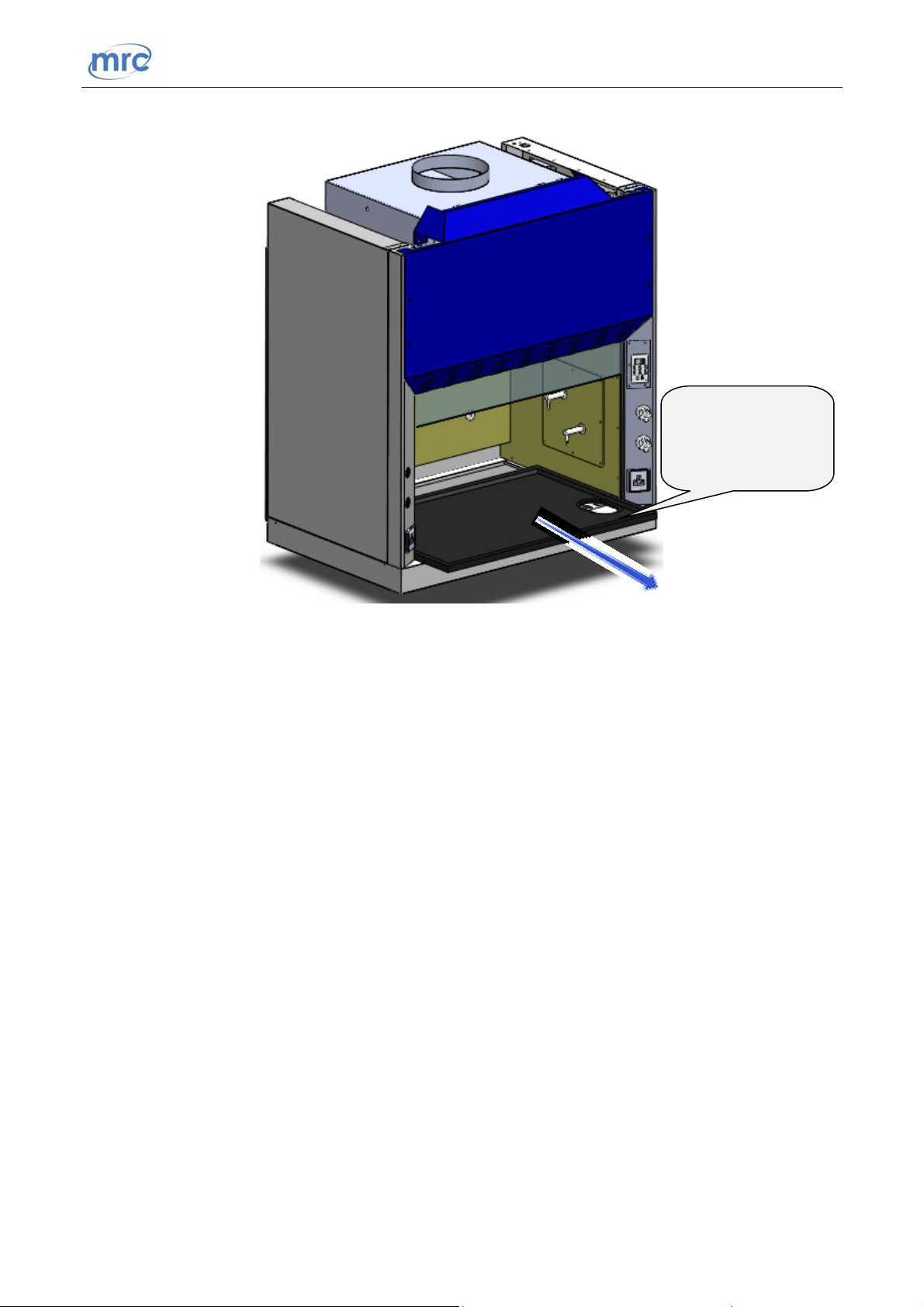

2.2. Product Structure

2.2.1. Structural composition of FH(A) Series Fume Hood

Picture 13

16 http://www.mrclab.com/

Page 17

MRC Ltd

1. Caster

2. Base cabinet

3. Water sink

4. Water tap

5. Water tap control knob

6. Gas tap control knob

7. Access panel

8. Control panel

9. Gas tap

10. Power socket

11. Fuse holder

12. Exhaust outlet

13. Front window

14. Phenolic compact laminate

15. Work table

16. Socket

17. Gas inlet

18. Water inlet

19. Drain hose

2.2.2. Structure introduction

a) Driving system of front window

Driving system consists of tubular motor, front window and hauling mechanism

(hauling sash)

b) UV lamp

The entire work zone could be sterilized effectively by the UV lamp located at

the top of work zone. Emission of 253.7 nanometers could ensure the most

efficient decontamination.

c) Fluorescent light

The Fume Hood is equipped with LED lamp tube, which ensures the standard

requirement of average illumination (400 lux) is met. The measured value at any

point inside the working zone should be greater than 350 lux.

Page 18

MRC Ltd

d) Socket

Socket, located at the two sides beside the front opening, could supply electricity

power for devices used in experiments and could be controlled by the

button.

NOTE: Please make sure the total load of sockets should be ≤ 500W.

e) Fuse protector

Fuse holders are installed on the top right of the equipment (refer to Figure 13).

Fuse of live wire is inside the female power cord connector. Socket (working

zone) fuse holder and neutral wire (power source) fuse holder is beside the

female connector . The specification of each fuse tube complies with the label

right below the fuse holder. Please refer to the label when replace the fuse tube.

f) Structure

i. External case body adopted 1.0 mm cold-rolled steel in double layer

structure with electrostatic coating and rust-proof treatment. The

structural strength and stability are enhanced.

ii. Inner wall of work area is fully made of Phenolic Compact Laminate

which provides corrosion resistance as well as attractive appearance;

work table is made of solid chemical resistant laminate which is easy to

clean and wash.

iii. Fume hood front window adopted 5 mm toughened glass.

iv. Control panel adopted soft-touch buttons and microprocessor control

system that make the operation easily to be controlled

v. The electronic control system could prevent overload of the circuit and

electric shock, stabilize the performance, protect the equipment and

extend the use life of the Fume Hood.

vi. The sockets (at working zone) adopted non-flammable PC material that is

specialized for laboratory use

18 http://www.mrclab.com/

Page 19

2.3. Control Panel

2.3.1. Soft touch buttons

Main functions could all be executed by pressing the relevant button. There are totally 8

common buttons on the control panel (refer to Picture 14). The indicator light above

each button shows the working status of the relevant function. The small LED display

shows the speed level of the blower.

MRC Ltd

Picture 14

Power button, the main switch of the Fume Hood

Fluorescent lamp, press to turn on the light, interlocked with UV lamp

UV lamp, only works when both the blower and the fluorescent lamp are turned off

Front window up, press and hold to continuously raise the window

Blower (Fan), press to turn on the blower, interlocked with UV lamp

19 http://www.mrclab.com/

Page 20

MRC Ltd

Front window down, press and hold to continuously lower the window

Socket power, press to activate the sockets in the working zone

Adjust fan speed, press to adjust the speed of the blower (fan) from F1 to F9

2.3.2. Control of the front window

The height of the front window could be adjusted by pressing the and

buttons. The window will be moved continuously when pressing the button and it will

stop moving immediately when the button is released

Please make sure the height of the front window is within the safety height range (520

mm).

2.3.3. Control of the fan speed

The blower (fan) could be turned on by pressing button (only when the UV lamp

is turned off). The speed of the fan could be adjusted by pressing button. 9 speed

levels could be selected. The relevant speed level would be displayed on the LED

screen.

When turn off the blower or power off the Fume Hood, the level of fan speed is

memorized by the equipment and would be resumed when turn on the blower again.

2.3.4. UV sterilization

UV light could be turned on by pressing the UV button. Please make sure the window is

fully closed before starting UV sterilization. Interlock function was adopted between

UV light and the blower/fluorescent light. UV light could be automatically turned off

when either the blower or fluorescent light is turned on. During sterilization, people

should leave the room for safety of eyes and skin.

2.4. Instructions of Operation

2.4.1. Normal Operation Notice

a) Make

sure input voltage is correct and stable. The rated load of main power

socket should be higher than cabinet consumption. Plug must be well grounded.

20 http://www.mrclab.com/

Page 21

MRC Ltd

b) The equipment should be powered off and unplugged before doing any

replacement of parts, such as UV lamp and fluorescent lamp.

c) The front window is made of explosion-proof toughened glass. In order to keep

the front window clean and clear, please wipe it by wet soft cloth and keep it

away from hydrofluoric acid

d) The air deflector and other internal accessories should be cleaned according to

the use of the Fume Hood

e) The air duct and the blower of the Fume Hood should be cleaned and maintained

regularly in a proper way

f) Fume Hood should be placed in a position where there should be no other

equipment or machine within 150mm of the front window

g) Do NOT place any soft or tiny materials (such as soft tissue) on the work table

during the operation to prevent breakdown of the blower causing by sucking

those materials

h) The packed Fume Hood should be stored in a warehouse with relative humidity

no more than 75% and temperature lower than 40℃. The warehouse should have

good ventilation performance without acid, alkali or other corrosive gases

i) The maximum storage period is one year. A performance inspection should be

done if the storage period exceeds one year

NOTE: MRC WILL NOT BE LIABLE FOR ANY RISK OR

DAMAGE ARISING FROM YOUR FAILURE TO APPROPRIATELY

OPERATION THE FUME HOOD!

2.4.2. Operation Process

a) Connect to a suitable power supply

b) Power on the Fume Hood by pressing the power switch under the working zone,

the LED screen would be lighted as “

”

c) Press the POWER button on the control panel to enable all functions

(fluorescent lamp, UV lamp, blower, socket, front window). The LED screen

21 http://www.mrclab.com/

Page 22

MRC Ltd

would display the accumulated operating time of the blower (if the optional

active carbon filter is ordered and equipped, the LED screen would display the

accumulated operating time of the filter).

NOTE: The displayed figure needs to multiply by 10 to get the actual

operating time. The unit is hour.

d) Press the UP button to raise the front window to a proper height. Please

refer to 2.1.4 for the maximum opening of the front window

e) Press the FAN button to turn on the blower. The LED screen would

display the speed level of the fan memorized from the last time of operation. The

indicator light above the FAN button would be turned on to show the working

status of the blower. Make sure the blower runs at least FIVE minutes before

starting any experiment.

NOTE: The blower would be turned off automatically when the UV

lamp is turned on.

f) Press the LAMP button to turn on the fluorescent light. The indicator light

above the button would be turned on to show the working status of the

fluorescent light. Please refer to the actual condition of illumination in the

laboratory room to decide whether the fluorescent light is needed.

g) After finishing the experiment, turn off the blower and the fluorescent light and

press the DOWN button to close the front window

h) Press the UV button to turn on the UV light. The indicator light above the

button would be turned on to show the working status of the UV lamp. Please

make sure the sterilization is at least 30 minutes. Press the UV button again to

turn off the UV lamp. Please refer to the actual situation to decide whether

sterilization is needed.

NOTE: a) When the UV light is in working status, people should leave

the room in order to protect skin and eyes.

22 http://www.mrclab.com/

Page 23

MRC Ltd

b) UV lamp should be replaced regularly according to the

frequency of use. The service life of UV lamp is about 600 hours.

i) Press the POWER button to power off the Fume Hood after all functions

have been turned off. Press the power switch to disconnect power before

plugging out.

j) If power failure happened during the operation causing by interruption of

electricity supply or dropping off of plug or other abnormal situations, the

equipment could memorized the current operating status automatically and

resume those functions when power on again.

2.5. Regular Maintenance

A detailed daily record of operating time is recommended, as the accumulated using time

will directly affect the plan of maintenance.

NOTE: a) To avoid electric shock, please cut off ALL power before applying

maintenance for the equipment!

b) The blower and the exhaust duct should be inspected and maintained

regularly.

c) The accumulated operating time is a vital factor of deciding when the

maintenance is needed. A comprehensive record of operation is highly recommended to

be taken down after each time of operating.

2.5.1. Overall maintenance period

Comprehensive maintenance is recommended to be carried out for a period of 1000

working hours or one year; weekly and monthly maintenance is also required to

optimize the performance of the Fume Hood.

2.5.2. Preparation before maintenance

Material needed: soap, hot water or warm water, a piece of soft cotton cloth, a piece of

dry cloth or towel, rubbing alcohol or other disinfectants, 1:100 dilution of household

bleach, abrasive household cleaners, sterile water.

2.5.3. Clean the equipment surface

23 http://www.mrclab.com/

Page 24

MRC Ltd

a) Clean the surface of working zone

Wipe the entire surface with a soft cotton cloth which has been soaked with

concentrated liquid soap. Afterwards, wipe off the foam with another cotton

cloth or towel which has been soaked with clean hot/warm water. At the end,

wipe the entire surface with a dry cotton cloth or towel rapidly.

For the contaminated or dirty work surface and sump, use 70% rubbing alcohol

or other disinfectant to wipe.

NOTE: Disinfectants used for wiping should not damage the 304

stainless steel.

b) Clean the external surface and front window

Use a piece of soft cotton cloth or towel with non-abrasive household cleanser to

wipe the surface.

2.5.4. Maintenance methods

a) Weekly and monthly maintenance

i. Clean the external surface and front window (refer to 2.5.3.b)

ii. (Not necessary) Use towel with 70% rubbing alcohol or 1:100 dilution of

household bleach to wipe the working table, the inner face of front

window and the inner wall surface of the working area (exclude the top

wind grid). Use another towel with sterile water to wipe those areas to

erase the remains of chlorine

iii. Check the various functions of the Fume Hood

iv. Record down the maintenance result

b) Annual maintenance

i. Check the two lifting belt (sash) of the front window tubular motor, make

sure both of them are well connected to the motor with same tightness

ii. Check the UV lamp and fluorescent lamp, replace it if needed

24 http://www.mrclab.com/

Page 25

MRC Ltd

iii. Apply for overall performance test of the cabinet annually to ensure that

the safety performance has met the requirements. User is responsible for

testing costs

iv. Record down the maintenance result

2.5.5. Storage

conditions

Fume Hood should be stored in a warehouse with relative humidity no more than 75%

and temperature lower than 40℃. The warehouse should have good ventilation

performance without acid, alkali or other corrosive gases. Storage period shall not

exceed one year. Fume Hood stored for more than one year needs to be unpacked and

checked before selling and using. Only the tested and qualified safety cabinet could be

sold.

25 http://www.mrclab.com/

Page 26

MRC Ltd

2.6. Replacement Parts List

FH1000(A) Fume Hood Replacement Part List

NO. Part Name Specification

JAA01 Fuse tube 5A\10A

JAA02 UV lamp holder T8 LG13-01A

JAA03 Fluorescent lamp T5 8W

JAA04 UV lamp T6 20W

JAA05 UV lamp ballast TL8-20W

JAA06 Blower FH320A

JAA07 Main control panel FH(A) series fume hood main control

JAA08 Front window glass 880*700*5

JAA09 Active carbon filter(optional) 660*500*30

FH1200(A) Fume Hood Replacement Part List

NO. Part Name Specification

JZ01 Fuse tube 5A\10A

JZ02 UV lamp holder T8 LG13-01A

JZ04 Fluorescent lamp T5 12W

JZ04 UV lamp T6 20W

JZ05 UV lamp ballast TL8-20W

JZ06 Blower FH320A

JZ07 Main control panel FH(A) series fume hood main control

JZ08 Front window glass 1080*700*5

JZ09 Active carbon filter(optional) 660*500*30

26 http://www.mrclab.com/

Page 27

MRC Ltd

FH1500(A) Fume Hood Replacement Part List

NO. Part Name Specification

JAB01 Fuse tube 5A\10A

JAB02 UV lamp holder T8 LG13-01A

JAB03 Fluorescent lamp T5 16W

JAB04 UV lamp T6 30W

JAB05 UV lamp ballast TL8-30W

JAB06 Blower FH355A

JAB07 Main control panel FH(A) series fume hood main control

JAB08 Front window glass 1380*700*5

JAB09 Active carbon filter(optional) 900*590*30

FH1800(A) Fume Hood Replacement Part List

NO. Part Name

JAC01 Fuse tube

JAC02 UV lamp holder

JAC03 Fluorescent lamp

JAC04 UV lamp

JAC05 UV lamp ballast

JAC06 Blower

JAC07 Main control panel

Specification

5A\10A

T8 LG13-01A

T5 16W

T6 30W

TL8-30W

FH355A

FH(A) series fume hood main control

JAC08 Front window glass

JAC09 Active carbon filter(optional)

1680*700*5

1200*590*30

27 http://www.mrclab.com/

Page 28

2.7. Wiring Diagram

MRC Ltd

28 http://www.mrclab.com/

Page 29

MRC Ltd

Picture 15

29 http://www.mrclab.com/

Page 30

MRC Ltd

3. Trouble Shooting and Labels

3.1. Common Failures and Solutions

3.1.1. Trouble shooting

Please confirm that the power is well connected, the power cord, the circuit and the

fuses are in good condition (without any damage) before trouble shooting the following

problems

Failures Checking Part Suggestion

Fluorescent lamp fail

to work

UV lamp fail to work

Button fail to work Control panel

Fluorescent lamp tube Replace the fluorescent lamp tube

Circuit Check the circuit

Control panel Replace the control panel

Fluorescent lamp and

blower

Lamp holder Connect the tube and lamp holder tightly

Ballast Replace the ballast

Make sure the fluorescent lamp and the blower are

turned off

Checking according the fluorescent lamp failure step,

then confirm.

Make sure the power is well connected and the fuse

is in good condition

Check if the button is broken

Make sure the connecting wire is well connected

Replace the control panel

Blower Replace the blower if it is defective

Blower fail to work

No electricity in

socket

Circuit Check the circuit

Control panel Replace the control panel

Socket fuse Check if the socket fuse is broken

Socket Check if the socket is broken

Circuit Check the circuit

30 http://www.mrclab.com/

Page 31

MRC Ltd

Control panel Replace the control panel

Front window fail to

work

No electricity in

equipment

Display fail to work

Transmission part Check the transmission connection and lead rail

Motor of front window Check the front window motor

Circuit Check the circuit

Control panel Replace the control panel

Power supply Check whether the power supply is well connected

Power cord Check whether the power cord is in good condition

Fuse Check if the fuse is damaged

Potential transformer Check whether the transformer works normally

Control panel Replace the control panel

Signal transmission line

Display screen Check whether the screen is in good condition

Control panel Replace the control panel

Check whether the signal transmission line is well

connected

NOTE: a) The above trouble shooting methods should be done by qualified

electricians under safe conditions (cut off power supply). Other components should

not be removed. Risk caused by failing to follow those instructions would be

responsible by user.

b) Please contact MRC technical department if a failure could not be

traced or solved. Do NOT repair the equipment without a qualified electrician.

c) The trouble shooting and repair of this equipment only could be

undertaken by trained and recognized technicians.

d) Please contact MRC technical department or agent to order

required component or part. The model number and the serial number of

purchased Fume Hood need to be indicated.

3.1.2. Simple accessories replacement

a) Replace the fuse

31 http://www.mrclab.com/

Page 32

MRC Ltd

Fuse of socket and fuse of neutral wire is located on top of the equipment (refer

to picture 13). For replacing the fuse, turn off the power and disconnect the plug.

Use a Phillips screwdriver and rotate it anticlockwise to unscrew the fuse holder.

Replace the fuse inside the fuse holder and then, use a Phillips screwdriver and

rotate it clockwise to screw back the fuse holder. Live wire fuse is also located

on top of the equipment, inside the female connector. For replacing the live wire

fuse, turn off the power and disconnect the plug. Use a Slotted screwdriver to

lever up the fuse holder to open it. Replace the fuse inside the fuse holder and

then, press the fuse holder back.

The parameter of the fuse tubes in the round fuse holders are required to

conform to labels, that are F5A φ5×20 mm and F10A φ5×20 mm.

Picture 16

b) Replace fluorescent light

For replacing the lamp tube, press UP button to rise up the front window to the

highest position, then turn off the power and disconnect the plug. Remove the

power cord of the lamp tube refer to picture 17. Then remove the lamp tube by

pulling the small slice on the tube base as shown in the Picture 17. Install a new

lamp tube by pushing it in and connecting with the power cord.

32 http://www.mrclab.com/

Page 33

MRC Ltd

Picture 17

c) Replace the UV lamp

The UV lamp tube should change regularly, for example every 600 hours. For

replacing the lamp tube, press the UP button to rise up the window to the highest

position, then turn off the power and disconnect the plug. Rotate the tube for 90°

to remove it and then install a new UV lamp tube by rotating in reverse

direction.

Picture 18

33 http://www.mrclab.com/

Page 34

3.2. Label Description

3.2.1. Fuse label

Picture 19

a. Operating area 5A socket fuse label, located under the socket fuse holder

b. 10A power fuse label, located under the female power connector

MRC Ltd

3.2.2. Ground label

Picture 20

3.2.3. Load requirements label

Picture 21

34 http://www.mrclab.com/

Page 35

MRC Ltd

4. Warranty

4.1. Warranty is 12 months from EX-factory date (excluding consumable accessories, UV and

Fluorescent lamp, fuse

4.2. MRC would not be liable for any repair of damage caused by improper operation

4.3. If the warranty has been expired, MRC would still responsible for repair with relative

charges

4.4. Life time of fume hood is 8 years from production date on the label

4.5. MRC would provide equipment drawings and necessary technical data for maintenance

companies or personnel trained by MRC engineers

Warranty Declaration: One-year Warranty, Life-long Maintenance

35 http://www.mrclab.com/

Loading...

Loading...