Page 1

Silent Oil Free Air Compressors

O

O

p

peerraattiioo

n

n

M

Maa

n

n

u

uaall

C

C

O

O

M

MPP--6611//8811//6611

X

X//8811

X

X//6611

X

X

Y

Y//8811

X

X

Y

Y

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529

mrc@mrclab.com

Page 2

Warning: to ensure your safety, before operation or maintenance, please be

sure to read this manual carefully!

Notice:

1, Our air compressor is oil free design, please do not add any lubricating oil.

2, To ensure the compressor working performance and long service life, it is better to

drain it every 3 days, for up to 7 days, please be sure to drain it!

Thank you for purchasing our Silent Oil Free Air Compressor, it can be used for all

industries, which need clean and silent air supply, and please contact with your local

distributor for the most suitable model for you.

Operational Safety:

When using our Silent Oil Free Air Compressors, please take a note for all the following

information:

1, Keep clean for the workplace. Cluttered areas invite injuries.

2, Do not run the compressor in damp condition. The compressor should never be used in an

area where it could be exposed to water or excessively damp conditions.

3, Guard against electric shock. During operation, please do not let the compressor connect to

other grounding items.

4, Do not let children or pets come into workplace, do not allow them touch the motor,

highpressure hose, air tools, main cable or some other parts.

5, Keep the compressors well. After use, please don't forget drainage, and please release the

pressure of tank, keep the compressor in a dry and ventilated place.

6, Do not use the compressor with force. Before operation, please do referto the rated voltage

and frequency of the compressor, and do not use it overload .(Do not let the compressor work for

more than 1hour continually, it is not good to keep long service life for the compressor)

7, Do not abuse the hose/cable.Never pull the compressor by the air hose or electrical

cable. Keep hose/cableaway from heat and sharp edges. And do not touch the metal

plug pins when connecting or removing the electrical plug.

8, The compressors only can be used to press air, can not be used for any other gas

under any situation.

9, Disconnect the compressor from power supply after operation. Before carrying out any

maintenance on the compressor, always switch off and unplug the compressor from the power

supply.

10, Do not use the compressor overpressure. The fixed max pressure is 8 Bar, and safety valve

would release pressure at 8.5Bar.

11, For maintenance, please use the original spare parts, or it may cause air compressor

damage, even personal injury.

12, Do not use the compressor where with flammable and explosive gas.

Personal Safety

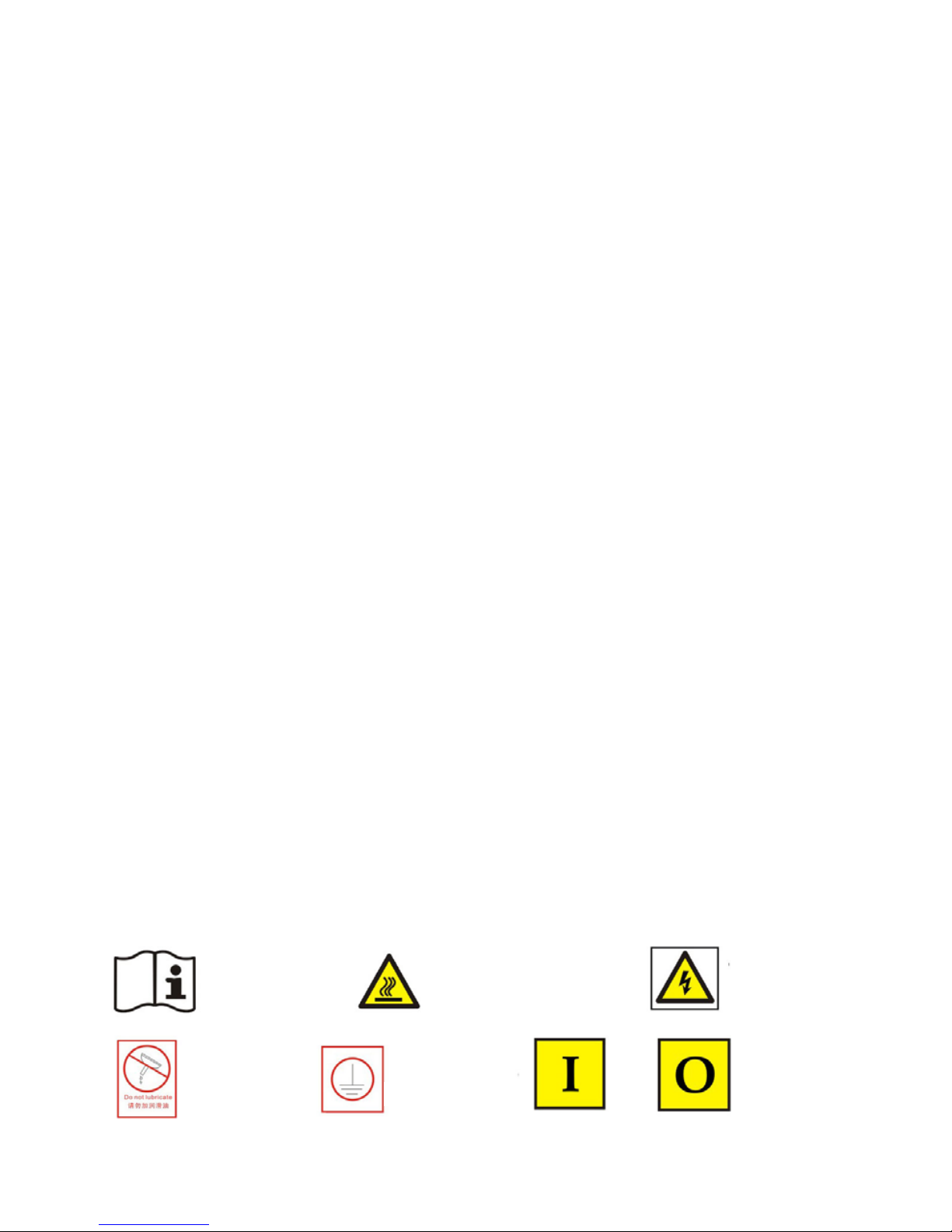

Symbols used on the air compressor.

Warning shock

hazard

OFF

Do not lubricate

Ground protect°

ON

1

Read the

operator manual

Warning high

temperature parts

Page 3

Principle description: Motor

Working Principle:

Oilless air motor is belong to miniature reciprocating piston type compressor, its mechanical structure is

with motor single shaft drive symmetric distribution crank rocker, the principal motion is piston ring,

and assistant motion is cylinder jacket. The piston ring lubricates itself automatically and no need

add any lubricating oil. The reciprocating motion of crank rocker makes periodic change of the

cylinder jacket capacity, the motor works a cycle, the cylinder jacket capacity has two oppositedirection changes. When the positive direction is the expanding direction of cylinder jacket, it is

vacuum, the atmosphere pressure is higher than air pressure inside the cylinder jacket, air enter

into cylinder jacket through intake valve, and it's the intaking operation. When the negative

direction is the reducing direction of cylinder jacket, air inside of cylinder jacket will be pressed,

and pressure grows rapidly. When the pressure is higher than atmosphere pressure, the air outlet

valve will open, it is exhausting operation. Structure as single-axis and double -cylinder makes

air flow is twice than singlecylinder at rated speed, vibrating noise of single- cylinder air

compressor is solved perfectly, and the integral structure is more compact.

Air Compressor Working Principle:

A motor drives directly the eccentric wheel-connecting bar system making the piston move

reciprocally. The piston is made from high temperature- resistant and abrasion-resistant

nonmetal material and is able to work without lubrication for a long time.

Compressed air discharge enters in the air tank; a pressure gauge displays the pressure in

the tank. When the pressure inside rises to 8 bar, power is automatically cut off by a pressure

switch, the compressor is shut off. When the pressure inside decreases to 5 bar, power is turned

on by the pressure switch and the compressor starts again and the pressure in the tank gradually

rises again.This happens repeatedly.

Spare Parts:

Air Filter & Regulator: with two functions. One function as filter, before pressed air enter into

the connected equipment, the filter would filter the moisture from air flow, and keep it in the

transparent cup. For all the water collected in the transparent cup, you may drain it out with a

tube at the bottom of cup; another function is to adjust the outlet pressure, pull out the lock

handle, turn it, the pressure gauge may show you the pressure you can get (0.1-0.8Mpa). And

please take a note that clockwise rotation can bring you higher pressure, or it is lower pressure.

Press down the lock handle, the pressure will be fixed.

Pressure Switch: it is with reaction of tank pressure to control the motor starts and stops. Our

compressor was set as 0.8Mpa stop, 0.5Mpa restart. Nob located as "-", it is connecting; located

as "0", it means disconnect.

Safety Valve: if here will be something wrong with pressure switch or some other reasons, the

motor can not stop working after 0.8Mpa, and more than 0.8Mpa, the safety valve will open to

release air pressure.

Overload Fuse: if here will be something wrong cause high current, the overload fuse will be

blown automatically to protect motor from damage; after you checked all the parts well, you

should replace a new fuse, then the compressor can start work again.

Drain Valve: drain out the water from tank.

Operation and Maintenance Instruction:

1, Operating requirement.

The compressor should be operated in the room with temperature of 3-42°Cand relative

humidity not greater than 85%. Surrounding area of the machine should be clean, dry, free of

corrosive gas, well ventilated and indirect sunlight.

The compressor should be placed on a flat and solid ground, to prevent movement during

working.

Page 4

Electric power supply of our air compressor is single phase, and with overload fuse to protect

the compressors during working. (if you will need the compressor as 3-phase power supply, we

can do the special)

Power supply of our air compressors is 198V-242V, abnormal voltage may cause overheat or

difficult to start for compressor. To ensure normal performance, if working area of the

compressor can not supply normal voltage, please equip with a single phase power regulator,

and power of the regulator should be more than 4000VA.

After unpacking, check the compressor for any missing parts and damages, check accessories

and spare parts and technical documents supplied together with the compressor according to the

packing list.

Before operation:

§ Take off the air inlet nut, install the air intaker and keep the pipe facing down.together with

the compressor according to the packing list.Before operation:

§ Take off the air inlet nut, install the air intaker and keep the pipe facing down.

§ Check the compressor, make sure the drain valve is closed, pressure switch is located at "0",

air outlet ball valve is closed, and power supply is normal

§ Connect air supply pipe with the quick coupling.

§ Connect to power supply, then installation is completed..

2, Test before operation:

Turn the handle of pressure switch to "on", the motor would start work immediately, and here

will be air leakage from air filter and regulator to protect restart of motor, simultaneously, here

is air flow come into air tank. The reading of pressure gauge will slowly rise with increasing

pressure inside of air tank, after the pressure shown as 0.1Mpa, air filter and regulator would

stop releasing, and when the reading of pressure gauge reaches 08Mpa,pressure switch

activates, the power supply is cut off, machine stops running. (now, you may adjust air filter

and regulator to get the pressure as youneed)After tank pressure down to 0.5Mpa, pressure

switch activates, motor would start running again. After testing, if the compressor can autom atically stop and start, it is work in normal.

3, Maintenance-drainage

During operation, moisture from air will be pressed and collected in air tank, too much moisture

will influence the quality of air supply, and affects normal work of the appliance, thus you

should drain the water timely. The frequency for draining is depended on environment condition

and operation time, but usually every 3 days one time. The way to drain off the condensated water

is as follows:

Put the drain pipe which connects with the drain valve quick coupling in a container, with

compressed air in the air tank slowly turns counterclockwise the knob on the drain valve to

drain off the water in the air tank until all accumulated water comes out from the pipe. After

that turn tightly clockwisethe knob to ensure no leakage.

4, Change of air filter core

An air filter is installed on air inlet of the motor to prevent the dust in the air from entering the air

compressor and reduce noise. After being used for a period, the filter core in the air filter will

get clogged. In a result sucking capacity of the air compressor will be reduced, therefore the

filter core must be replaced regularly. The way of replace is as follows: open the lid on the air

filter, take out the old filter core, put in a new one, and then close the lid.

Notice: it is better to check and replace the air filter core regularly, we suggest as working

every 300 hours to have a check.

Split-up drawing of motor and maintenance

1 CastAlu shell units 12 Gasket of cylinder Head

2 Eccentric wheel units 13 Screw of plate valve

3 Fan 14 Fix plate

4 Screw of connecting rod 15 Air outlet valve

5 Connecting rod 16 Air inlet valve

6 Piston ring 17 Valve gasket

7 Plate 18 Screw of valve

8 Screw of plate 19 Cylinder head

9 Cylinder Jacket 20 Screw of cylinder head

10 Gasket of cylinder jacket 21 Connecting pipe

11 Plate valve 22 Holder of aluminium alloy

Page 5

Matenance procedures:

1, Make note and stick label for the direction of air inlet and outlet in order to rebuild in the

cylinder head.

2, Take off the screw of the cylinder head and cylinder head.

3, Take off the gasket of cylinder jacket from cylinder head.

4, Take off the cylinder plate valve.

5, Take off the cylinder jacket, plate, piston ring.

6, Check the quality of gasket of cylinder head, piston ring, cylinder jacket, gasket of cylinder

jacket, air outlet valve and air inlet valve, find out the broken parts, and replace them.

7, Clear the scrap on the plate with the water-solubility impregnant.

8, Put the plate on the connecting rod, and then cover the plate.

9, Refix the piston ring, glue the screw of the plate and turn tightly.

10, Cover piston ring with cylinder jacket carefully, you need incline the cylinder jacket to avoid

damaging the piston ring.

11, Fix air inlet, outlet valve, and fix plate in the original place.

12, Glue the screw of valve and turn tightly.

13, Install the gasket of cylinder jacket to the bottom of the plate valve and place the plate valve

on the cylinder jacket. Make sure the cylinder jacket is correctly equipped in the gasket of cylinder

jacket.

14, Check the air direction of inlet and outlet, make sure they are correct.

15, Put the gasket of cylinder head on the flute of cylinder head.

16, Cover the plate with cylinder head, and keep the correct direction of air inlet and outlet

again.

17, Tie up the screw of cylinder head.

Quality Inspection List

Reason

Problem

Pressure

low

Pressure

high

High noise

level

The motor

overheated

The motor

can't restart

Air leak

Pressure switch broken

√ √

Starting capacitor broken

√

Safty valve broken.

√

√ √

The drain valve is leaking

√

√

A

ir outlet valve broken

√

√

√

Piston ring broken

√

√

Overload protector cut off (push the

button for re-start)

√

The holder of luminium alloy

cracked

√

Solenoid valve broken

√

√

Check valve broken

√

√

√

Voltage less than 200V

√

Outside temperature is too low

√

The air intaker is blocked

√

The air intaker is loose

√

Screw loose

√

The compressor isn't on flat ground

√

The air inlet & outlet valve is

damaged

√

√

The surrounding area of the

machine isn't well ventilated

√

We reserves the right to make any improvement on our products and without advanced notice!

4

Loading...

Loading...