MRC BPS-210-C1-V2, BPS-360-C1-V2, BPS-750-C1-V2, BPS-1000-C1-V2, BPS-1200-C1-V2 Operation Manual

...Page 1

PLEASE READ THIS MANUAL

CAREFULLY BEFORE OPERATION

3, Hagavish st. Israel 58817

Tel: 972 3 5595252, Fax: 972 3 5594529 mrc@mrclab.com

MRC.VER.01-12.13

O

Oppeerraattiioonn

M

Maannuuaall

B

B

P

P

S

S--

C

C

1

1--

V

V

2

2

S

S

e

e

r

rii

e

ess

LCD BALANCES

Page 2

- 3 -

1. TECHNICAL DATA .................................................................................7

1.1. Connection ports....................................................................................... 10

2. BASIC INFORMATION ........................................................................ 11

2.1. Intended use ............................................................................................. 11

2.2. Inappropriate use ...................................................................................... 11

2.3. Warranty ................................................................................................... 11

2.4. Monitoring the metrological parameters of the instrument ........................ 12

2.5. Data included in this user manual ............................................................. 12

2.6. Staff training ............................................................................................. 12

3. TRANSPORT AND STORAGE ........................................................... 12

3.1. Delivery check .......................................................................................... 12

3.2. Packaging ................................................................................................. 12

4. UNPACKING, ASSEMBLING AND START-UP .................................. 13

4.1. Assembling and place of use .................................................................... 13

4.2. Unpacking ................................................................................................. 14

4.3. Levelling ................................................................................................... 17

4.4. Cleaning ................................................................................................... 17

4.5. Plugging to mains ..................................................................................... 19

4.6. Connecting additional equipment.............................................................. 20

5. BASIC FUNCTIONS ............................................................................ 20

6. KEYBOARD ......................................................................................... 22

7. START-UP ........................................................................................... 23

7.1. Connecting peripheral devices ................................................................. 23

7.2. Balance temperature stabilisation period .................................................. 23

8. USER MENU ....................................................................................... 24

8.1. Moving through user menu ....................................................................... 24

9. LOGGING IN ....................................................................................... 27

10. WEIGHING .......................................................................................... 29

10.1. Required weighing procedures ................................................................. 29

10.2. Zeroing ..................................................................................................... 31

10.3. Taring ....................................................................................................... 31

10.4. Settings for mode <WEIGHING> .............................................................. 33

1.1.1 Setting level of filtering .................................................................... 33

1.1.2 Value release .................................................................................. 34

1.1.3 Autozero function ............................................................................ 35

1.1.4 Displaying the last digit ................................................................... 35

1.1.5 Balance ambient conditions ............................................................ 36

10.5. Printing mode ........................................................................................... 36

10.6. Temporary measuring unit ........................................................................ 38

10.7. Start-up measuring unit ............................................................................ 38

10.8. Availability of measuring units .................................................................. 39

10.9. User unit ................................................................................................... 40

10.10. Information ............................................................................................. 41

10.11. Non-standard information ....................................................................... 42

10.12. F button shortcuts .................................................................................. 43

10.13. Dual range balance (BPS-200/2000-C2) ................................................ 44

Page 3

- 4 -

11. OTHER PARAMETERS ....................................................................... 45

11.1. Available menu languages ........................................................................ 45

11.2. Access levels ............................................................................................ 45

11.3. ‘Beep’ sound – reaction on pressing function button ................................ 45

11.4. Backlight and adjusting display brightness ............................................... 46

11.5. Date .......................................................................................................... 46

11.6. Time .......................................................................................................... 46

11.7. Date format ............................................................................................... 46

11.8. Time format ............................................................................................... 47

11.9. GLP autotest ............................................................................................. 47

12. INFORMATION ABOUT THE BALANCE ............................................. 49

13. BALANCE ADJUSTMENT ................................................................... 50

13.1. Internal adjustment ................................................................................... 51

13.2. Menu adjustment settings ......................................................................... 53

13.3. Manual adjustment ................................................................................... 55

13.3.1. Internal adjustments ................................................................... 55

13.3.2. External adjustment .................................................................... 56

13.3.3. User adjustment ......................................................................... 56

13.4. Adjustment report printout......................................................................... 57

14. DETERMINING CONTENT OF A PRINOUT ....................................... 58

14.1. Adjustment report ..................................................................................... 58

14.2. Header printout ......................................................................................... 60

14.3. Measurement result printout – GLP PRINTOUT ....................................... 62

14.4. Footer printout .......................................................................................... 64

14.5. Non-standard printouts ............................................................................. 66

14.5.1. Inserting texts ............................................................................. 66

14.6. Variables ................................................................................................... 69

15. DATABASE .......................................................................................... 70

15.1. Users ........................................................................................................ 70

15.2. Products.................................................................................................... 73

15.3. Tares ........................................................................................................ 74

15.4. Weighments .............................................................................................. 75

15.5. ALIBI ......................................................................................................... 78

16. EXPORT AND IMPORT OF DATABASE ............................................. 80

16.1. Export database ........................................................................................ 81

16.2. Import database ........................................................................................ 82

16.3. Measurement data print-out ...................................................................... 82

17. BALANCE WORKING MODES ............................................................ 84

17.1. Setup for availability of working modes ..................................................... 85

17.2. Counting parts of the same mass ............................................................. 86

17.2.1. Setup for mode COUNTING PIECES ......................................... 87

17.2.2. Setting the reference mass by determining from the sample of

known quantity............................................................................ 88

17.2.3. Setting the reference mass by entering its mass ........................ 90

17.2.4. Returning to the weighing mode ................................................. 91

17.3. Checkweighing ......................................................................................... 92

17.3.1. Declaration of mass thresholds .................................................. 93

17.4. Dosing....................................................................................................... 95

Page 4

- 5 -

17.4.1. Setting a target weight by entering values .................................. 96

17.4.2. Returning to the weighing mode ................................................. 98

17.5. Deviations % against the mass of the standard ........................................ 98

17.5.1. Setup for reference mass determined by weighing .................... 99

17.5.2. Setup for reference mass by typing its mass ............................ 100

17.5.3. Returning to the weighing mode ............................................... 101

17.6. Animal weighing...................................................................................... 101

17.6.1. Additional setting for animal weighing mode ............................ 101

17.6.2. Method of operation to manually start the process ................... 103

17.6.3. Method of operation to automatically start the process ............ 105

17.7. Density of solids...................................................................................... 106

17.7.1. Density determination of solids ................................................. 108

17.8. Density of liquid ...................................................................................... 112

17.8.1. Density of liquids determination ................................................ 112

17.9. Statistics ................................................................................................. 115

17.9.1. Means of operation ................................................................... 116

17.9.2. Deleting statistics ..................................................................... 119

17.9.3. Returning to the weighing mode ............................................... 120

17.10. Totalising .............................................................................................. 121

17.10.1. Means of operation ................................................................... 122

17.10.2. Returning to the weighing mode ............................................... 124

17.11. Peak hold ............................................................................................. 125

17.11.1. Means of operation ................................................................... 126

17.11.2. Returning to the weighing mode ............................................... 127

18. COMMUNICATION ............................................................................ 128

18.1. RS 232 ports settings ............................................................................. 128

18.2. WIFI port settings.................................................................................... 129

19. PERIPHERALS .................................................................................. 131

19.1. Computer ................................................................................................ 131

19.2. Printer ..................................................................................................... 132

19.3. Bar code reader ...................................................................................... 132

19.4. Additional display .................................................................................... 133

19.5. External buttons ...................................................................................... 133

20. WORKING WITH EXTERNAL DEVICES SUCH AS PRINTER OR

COMPUTER ................................................................................ 135

20.1. Cable pinout diagram .............................................................................. 136

20.2. Format of data setting ............................................................................. 137

20.3. Format of data sent on pressing of PRINT button................................... 137

20.3.1. Format of data sent as response for commands generated from a

computer .................................................................................. 137

21. COMMUNICATION PROTOCOL ...................................................... 139

21.1. List of commands.................................................................................... 139

21.2. Responses format for commands sent from computer level ................... 140

21.3. Commands description ........................................................................... 140

22. ERROR MESSAGES ......................................................................... 145

23. UNDER HOOK WEIGHING ............................................................... 146

24. ADDITIONAL EQUIPMENT ............................................................... 147

24.1. Anti-vibration table .................................................................................. 147

Page 5

- 6 -

24.2. Rack for under hook weighing ................................................................ 147

24.3. Density determination kit (for solids and liquids) ..................................... 147

24.4. Additional display .................................................................................... 147

Page 6

- 7 -

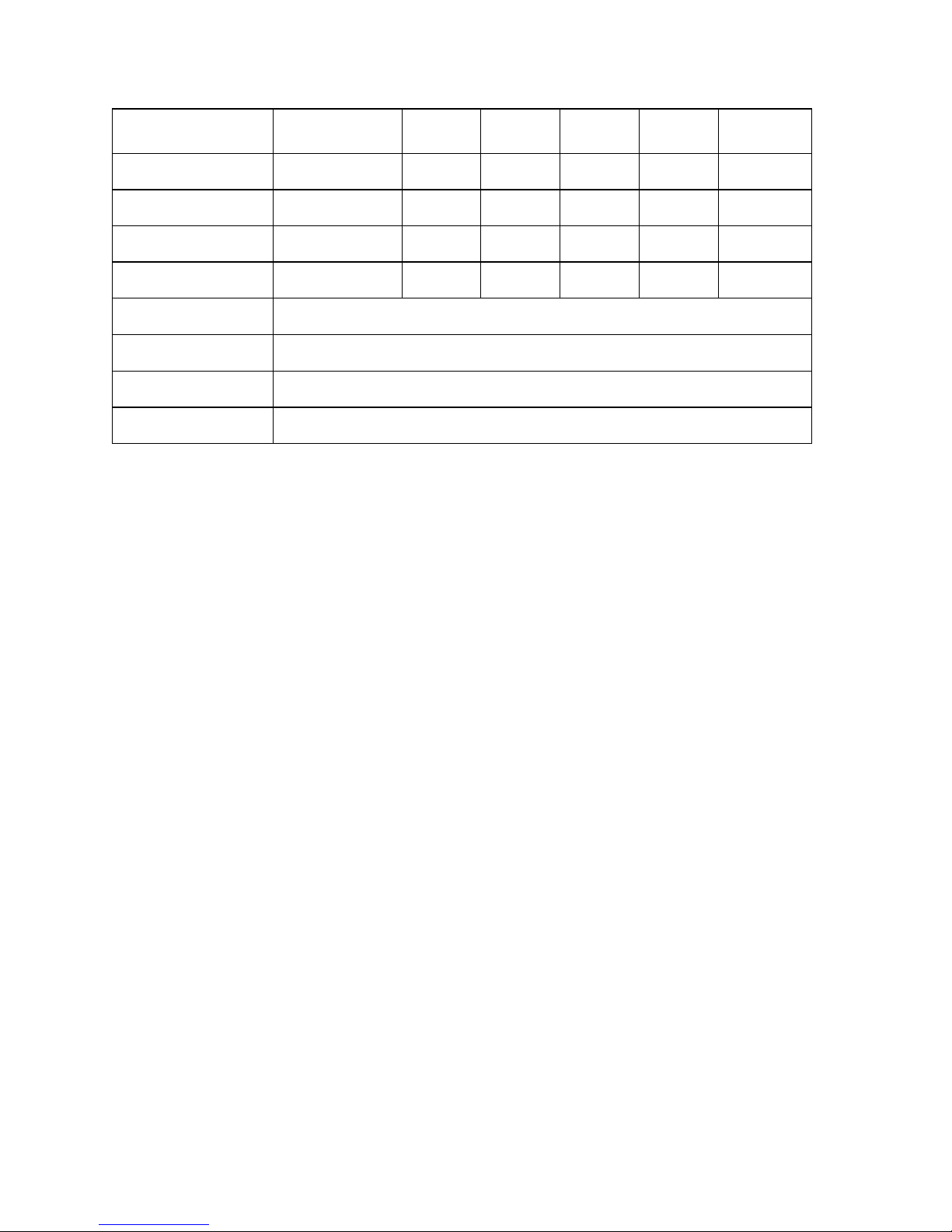

1. TECHNICAL DATA

Balance ASB-C2-V2 series:

ASB-

60/220-C

2-V2

ASB-

160

-C2-V2

ASB-

220-C2-V2

ASB-

310-C2-V2

Max capacity 60/220g 160g 220g 310g

Min capacity 1mg 10 mg 10 mg 10 mg

Readability 0.01/0.1mg 0.1mg 0.1mg 0.1mg

Tare range -220g -160 g -220 g -310 g

Pan size Φ 85 mm

Sensitivity drift 1 ppm/°C in temperature +10 ° - +40 °C

Working

temperature

+10 ° - +40 °C

Power supply 12 ÷ 16 V DC / 2.1 A

Dimensions:

Page 7

- 8 -

Balance BPS-C2-V2 series with weighing pan 128 x 128 mm:

Dimensions:

Type balance

BPS-

200/2000-C1-V2

BPS-

210-C1-V2

BPS-

360-C1-V2

BPS-

600-C1-V2

BPS-

750-C1-V2

BPS-

1000-C1-V2

Max capacity

200/2000g 210g 360g 600g 750g 1000g

Tare range

-2000g -210g -360g -600g -750g -1000g

Min capacity

20mg 20mg 20mg 20mg 20mg 20mg

Readability

1/10mg 1mg 1mg 1mg 1mg 1mg

Working

temperature

+10°C - +40°C

Power supply

12 ÷ 16 V DC / 2,1 A

Sensitivity drift

2 ppm/°C in temperature +10°C -+ 40°C

Pan size

128x128 mm

Page 8

- 9 -

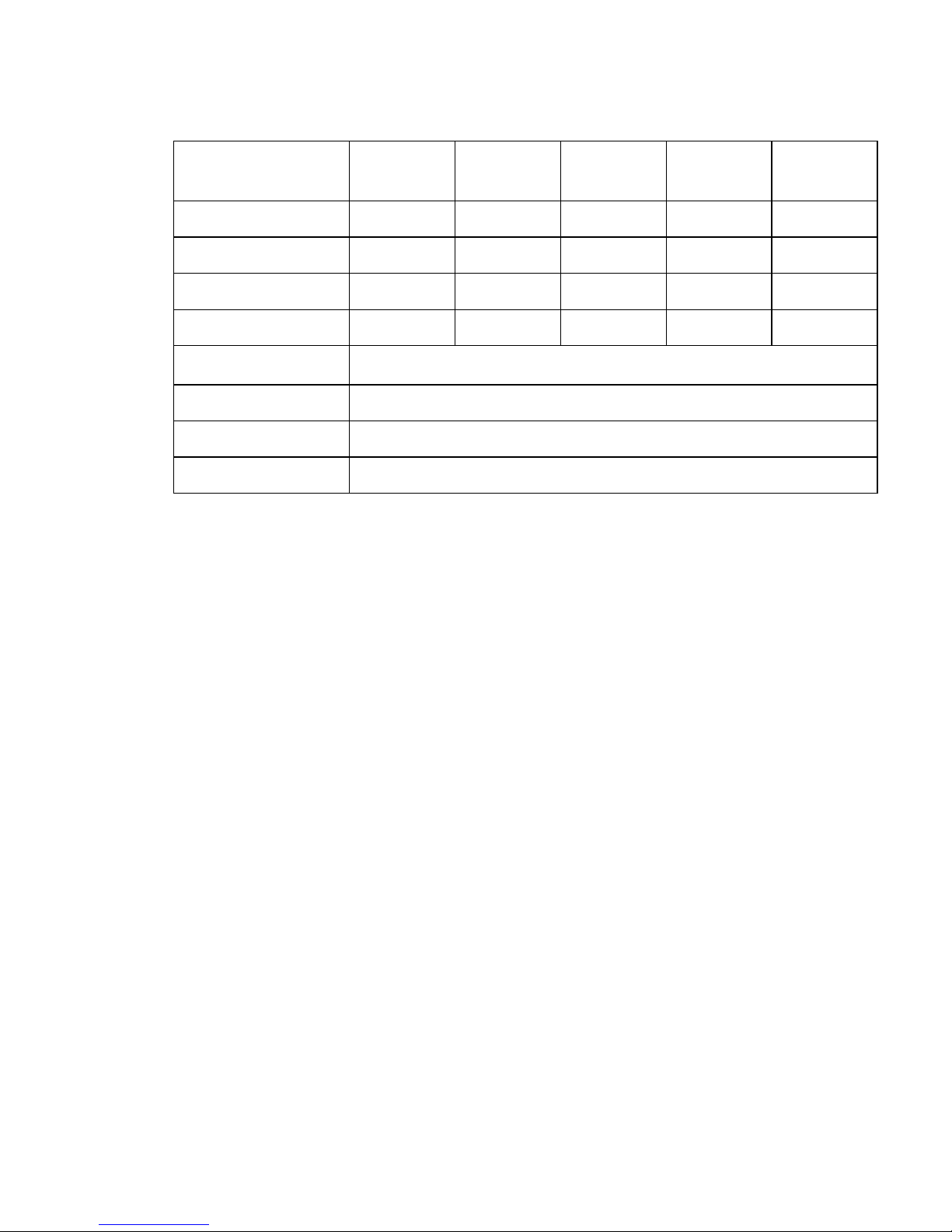

Balance BPS-C2-V2 series with weighing pan 195 x 195 mm:

Type balance

BPS-

1200-C1-V2

BPS-

2100-C1-V2

BPS-

3500-C1-V2

BPS-

4500-C1-V2

BPS-

6000-C1-V2

Max capacity 1200g 2100g 3500g 4500g 6000g

Tare range -1200g -2100g -3500g -4500g -6000g

Min capacity 500mg 500mg 500mg 500mg 500mg

Readability 10mg 10mg 10mg 10mg 10mg

Working

temperature

+10°C - +40°C

Power supply 12 ÷ 16 V DC / 2,1 A

Sensitivity drift 2 ppm/°C in temperature +10°C - +40°C

Pan size 195x195mm

Dimensions:

Page 9

- 10 -

Balance BPP-C2-V2 series:

BPP-

10-C2

-V2

BPP-

35-C2-V2

Max capacity 10 kg 35 kg

Tare range -10 kg -35 kg

Min capacity 2 g 2 g

Readability 0.01 g 0.1 g

Working temperature

+10 °C - +40 °C

Power supply 12 ÷ 16 V DC / 2,1 A

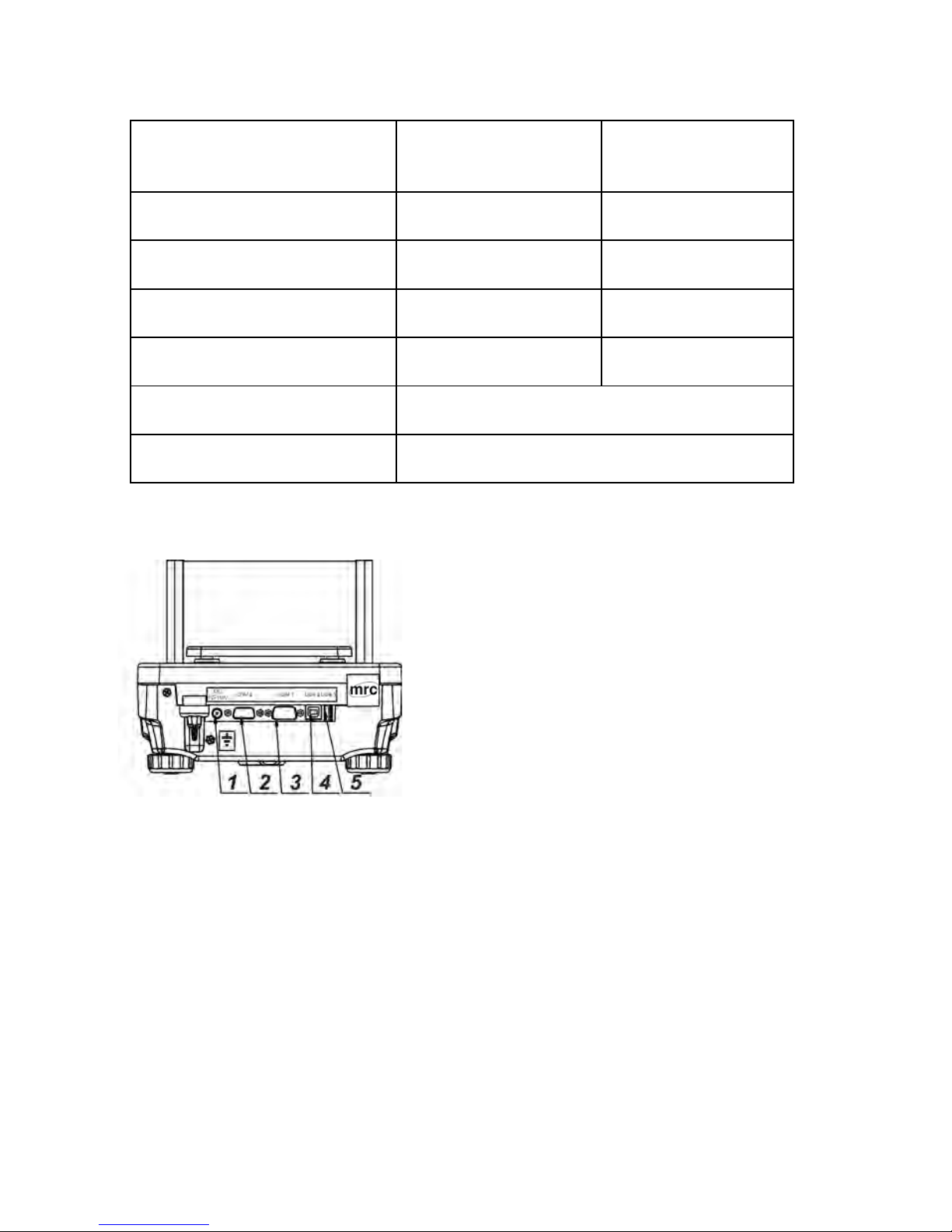

1.1. Connection ports

1

- power port

2

- COM 2 port (e.g. additional display)

3

- COM 1 port (e.g. printer)

4

- USB 2 port (e.g. computer)

5

- USB 1 port (e.g. computer keyboard)

Page 10

- 11 -

2. BASIC INFORMATION

2.1. Intended use

The purchased balanced serves to determine the weighing value of loads in

laboratory environment. It is intended for application as a non-automatic

weighing instrument only, i.e. the material to be weighed is manually and

carefully placed in the centre of the weighing pan. Weighing result should be

read only after stable reading has been obtained.

2.2. Inappropriate use

Do not use the balance as a dynamic weighing instrument. Even if small

quantities of weighed material are added or removed from the weighing pan of

the instrument, the reading should be taken only after stabilisation of the

measurement results. Do not place any magnetic materials on the weighing

pan, as this can cause damage to the measuring system of the instrument.

Be sure to avoid impact shock and overloading the balance in excess of the

prescribed maximum measuring range (max capacity), minus any possible tare

weight that has been applied.

Never use the balance in an environment where explosion is possible. This

balance has not been adjusted for operation in explosive areas.

There must not be any modification made to the balance.

2.3. Warranty

Warranty is invalid for the following:

• non- observation of the guidelines of this user manual,

• use of the balance other than specified in this manual,

• alteration to or opening of the device,

• mechanical damage and damage caused by media, water, wear and

tear,

• inappropriate assembling or defects of electric installation,

• overloading of the measuring instrument.

Page 11

- 12 -

2.4. Monitoring the metrological parameters of the instrument

Metrological characteristics of the balance require periodical inspection to be

carried out by its user. Inspection frequency is dependent on ambient

conditions in which the balance is used, types of performed processes and

accepted quality management system in organisation.

2.5. Data included in this user manual

Please read the user manual carefully before assembling and start-up, even if

the user is experienced with this type of weighing instruments.

2.6. Staff training

This balance should only be operated and maintained by personnel who is

trained and experienced in using this type of balances.

3. TRANSPORT AND STORAGE

3.1. Delivery check

Please check the packaging immediately upon delivery and the device during

unpacking for any visible signs of external damage.

3.2. Packaging

Please retain all parts of the original packaging should the balance be

transported in the future. Only the original packaging should be used for

shipping the balance. Before packing, disconnect all attached cables and

remove any loose/movable parts (weighing pan, anti-draft shield, etc.). Please

place balance and its components in their original packaging, and protect them

against damage during transport.

Page 12

- 13 -

4. UNPACKING, ASSEMBLING AND START-UP

4.1. Assembling and place of use

• The balance should be stored and used in locations free of vibrations and

shakes, free of air movement and dust,

• ambient air temperature should not exceed the range of: +10 °C ÷ +40 °C,

• ambient relative humidity should not exceed 80%,

• during balance operation, ambient temperature in the weighing room should

not change more than 3°C within one hour,

• the balance should be located on a stable wall console desk or a stable

working table which is not affected by vibrations and distant from heat

sources,

• take special precaution when weighing magnetic objects, as part of the

balance is a strong magnet. Should such loads be weighed, use under hook

weighing option, which removes the weighed load from area influenced by

the balance’s magnet. For assembling the hook for under hook weighing

option see the bottom section of balance’s housing,

• in order to avoid the influence of static electricity on the measurement

process, ground the balance’s housing. The grounding bolt is located at the

back of the balance’s housing.

Page 13

- 14 -

4.2. Unpacking

Balance ASB with weighing pan Φ 85 mm:

• open side doors of the weighing

chamber,

• inside the weighing chamber place lower

shield of the weighing chamber (1),

• put centering ring [framing facing

downwards] (2),

• in the centre of centering ring assembly

the weighing pan (3),

• put anti-draft shield in the chamber (4),

• close side doors of the weighing

chamber,

• plug the balance to mains,

pin of power adaptor should be

connected to socket in the back of

balance housing.

Page 14

- 15 -

Balance BPS

Remove the adhesive tape. Carefully remove the balance from its packaging.

Remove all the elements necessary for correct operation from the accessory

box. Carefully remove the plastic and foil transport protective elements and

gently place the balance in its intended place of use.

Assemble the weighing pan, and other elements according to below schema:

Assembling a balance with reading interval 10mg:

- remove the adhesive tape

protecting the mass spring on one

of the rubber bumpers (1),

- assemble the weighing pan (2) on

the rubber bumpers (1),

- after assembling the balance

components, check whether the

weighing pan is firmly placed on the

rubber bumpers.

Assembling a balance with reading interval 1mg:

- remove the adhesive tape protecting the

mass spring on on

e of the rubber bumpers

(1),

- assemble the weighing pan (2) on the

rubber bumpers (1),

- assemble the glass anti-draft shield (3)

- after assembling the balance components,

check whether the weighing pan is firmly

placed on the rubber bumpers.

Page 15

- 16 -

Balance BPP

• Remove the weighing pan and remove transport protective elements as

shown in the picture above (if these elements are attached).

• After the unpacking of the balance unscrew the bolt (1) which blocks the

calibration mechanism.

• Assemble the weighing pan.

• Make sure the weighing pan is placed properly on the shock absorbers:

the weighing pan cannot touch the housing and should be stable.

• After removing the protective elements and placing the weighing pan, plug

the indicator into the port which is on the back of the housing. Next, plug in

all the additional devices. Only then can the scales be connected to mains

(the power port is located at the back of the balance’s housing).

Page 16

- 17 -

• Place the balance at the workplace.

• Using the wrench (3), after adjusting the balance level (see below); tighten

the bolt (2) on the foot (1) to the balance’s footing until the point of

resistance.

4.3. Levelling

Before plugging to mains, level the balance by turning the

adjustable feet in a way that the air bubble of the level is in

its central ring. The balance should be placed at the

workplace firmly on all of its feet.

4.4. Cleaning

Balance should be cleaned with damp cloth by gentle wiping smudges of dirt.

Cleaning of the weighing pan when assembled may cause damage of the

measuring system of the balance. Hence, it is crucial to remove it from the

balance before cleaning.

Page 17

- 18 -

In order to clean the glass walls of the draft shield of the ASB-C2-V2 series balance,

it is acceptable to remove the walls of the draft shield following the below

instruction.

1. Twist off and remove the top glass wall safety frame, and slide the top

glass wall out of the slideway.

2. Remove the back glass wall.

3. Remove the side glass walls. The side glass walls are not replaceable, so

it is important to remember which one is left and right, and after cleaning

install them back properly in the draft shield.

Page 18

- 19 -

4. CAUTION: do not remove the front glass wall.

5. Remove the weighing pan, the weighing pan safety rings and the bottom

metal plates, so as not to damage the balance mechanism durin the

cleaning.

Thus prepared draft shield and glass walls can be properly cleaned. All the

operations should be done carefully. Pay special CAUTION to the place

where the weighing pan was installed: dirt and other small elements might

enter the balance construction through this openiing, which might

negatively influence the balance parametres.

4.5. Plugging to mains

Balance can be connected to mains only with a power adapter that

comes standard with the balance. Nominal power supply of the power

Page 19

- 20 -

adapter (specified on the data plate of the power adapter) should be

compatible to the power from mains.

Plug the balance to mains – the plugging socket is located at the back of

balance housing.

The test of the display unit takes place after connecting to the power (all the

elements and pictograms are backlit for a short time). Next, the name and the

program number appears consequently, the indication will reach ZERO level

(with reading unit depending on the balance). During the process of starting

the balance, the test of the internal mass adjustment mechanism occurs

(single location and elevation of the internal mass adjustment).

If the indication is different from zero, please press

button.

NOTE: If the balance is “verified”, automatic adjustment/calibration occurs right

after it has been switched on.

4.6. Connecting additional equipment

It is inevitable to plug the computer out of the main before connecting additional

equipment or changing it (printer, PC computer, additional display, computer

keypad, etc.).

Connect only the equipment recommended by the balance manufacturer.

When the devices are connected, plug the balance to the main.

5. BASIC FUNCTIONS

• functions related to measuring units

- weighing in grams [g],

- weighing in milligrams [mg] (in balances with d≤0.001g),

- weighing in kilograms [kg] (in balances with d≥0.01g,

- weighing in carats [ct],

- weighing in units from beyond SI (available only in non-verified

instruments):

[lb], [oz], [ozt], [dwt], [tlh], [tls], [tlt], [tlc], [mom], [gr], [ti], [N], [baht], [tola]

• functions related to working modes

- counting pieces,

- checkweighing (control +/-),

- dosing,

- percent setup,

- density determination of solids,

- density determination of liquids,

Page 20

- 21 -

- animal weighing,

- statistics

- totalising

- peak hold

• functions related to setting a balance to ambient conditions at a

workstation

- enabling and disabling autozero system,

- setting parameter of measurement result averaging,

- value release,

- display backlight,

- beep signal,

• functions related to use of communication ports (RS232, USB, WIFI)

- setting communication port,

- setting bound rate,

- continuous data transmission in basic measuring unit,

- continuous data transmission in current measuring unit,

- automatic operation mode.

Balance can be used to weigh loads under the weighing platform – i.e. under hook

weighing option. Balance software enables generating a report from adjustment

process in a form of a printout containing modifiable data (see CAL REPORT)

Page 21

- 22 -

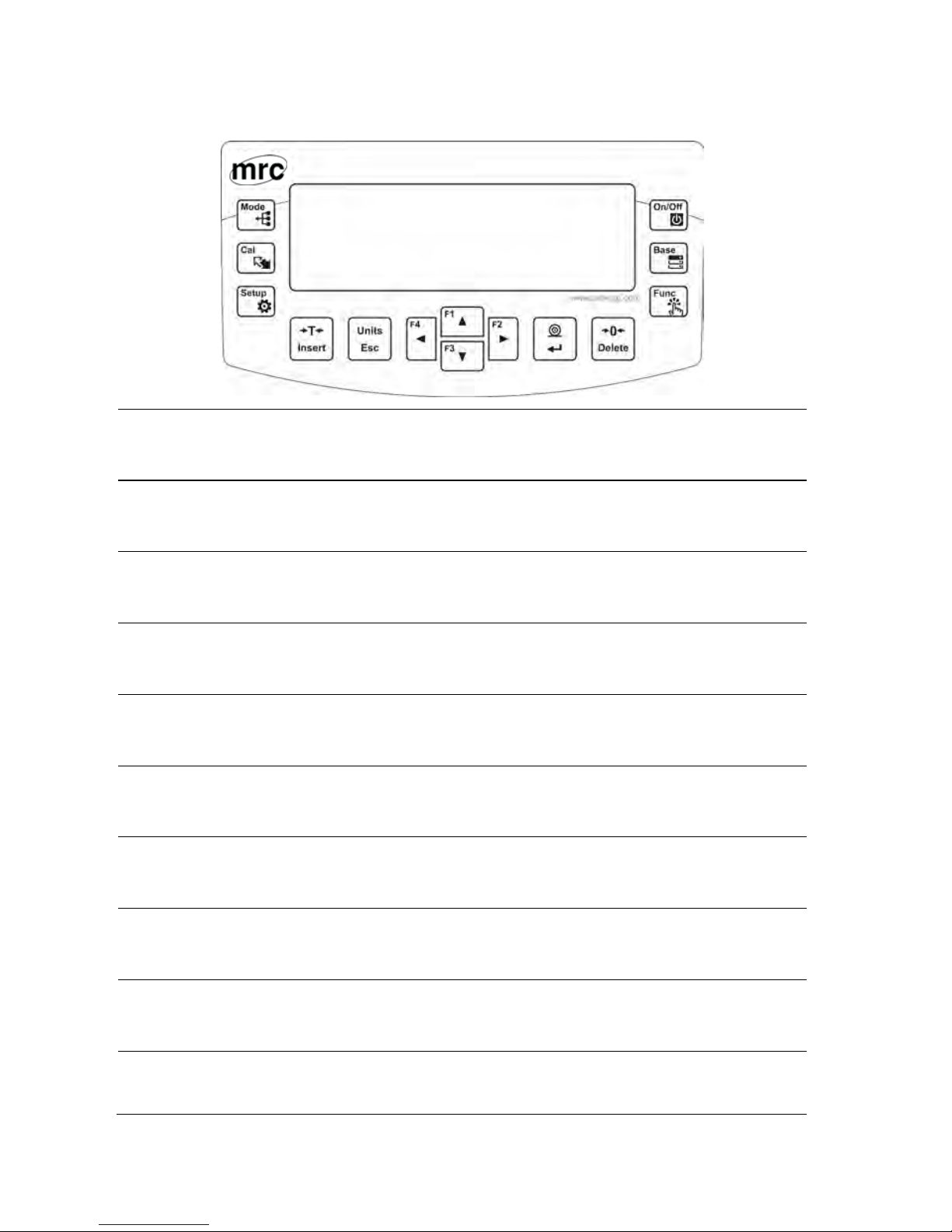

6. KEYBOARD

ON/OFF button enables switching on and of

f balance’s

display. If switched off balance components other than the

display are powered, and balance is in stand-by mode.

F button. Function button

, which enables quick entering

the settings of an active working mode.

MODE button for selecting balance’s working mode.

UNITS button changes measuring units.

PRINT/ENTER button-

sends current display status to a

peripheral device (PRINT) or accepts selected value of a

parameter or function (ENTER).

ZERO button– zeroing of balance’s indication.

TARE –taring of balance’s indication.

Adjustment –

function button of immediate initiating the

adjustment / calibration process.

Function button for entering the main menu of a balance.

Navigating arrows for moving in balance’s menu or

changing parameter value.

Page 22

- 23 -

7. START-UP

When plugged to mains, the balance displays name and number of software, and

afterwards proceeds to weighing mode.

7.1. Connecting peripheral devices

The balance must be unplugged from the mains before connecting or

disconnecting peripheral devices (printer or computer). Use only peripheral

devices recommended by the manufacturer with your balance. These have

been matched to your balance. After connecting a peripheral device, plug the

balance to mains.

7.2. Balance temperature stabilisation period

Before start of measuring processes, it is necessary to wait until the balance is

thermally stabilised.

For balances that were stored in much lower temperatures before plugging to

mains (e.g. during winter period) thermal stabilisation should last

approximately 4 hours for BPS balances, and 8 hours for ASB-C2 & BPP-C2

balances. During the thermal stabilization, the indications on the display panel

can change. Correct operation of a balance is possible within temperature

range specified in technical parameters, see point 1.

It is recommended that ambient temperature changes at balance’s place of

use are very small (slow to change).

Page 23

- 24 -

8. USER MENU

Balance menu is divided into 6 basic function groups. Each group has individual

name starting with capital letter P.

8.1. Moving through user menu

A user moves through balance menu using buttons on overlay’s keyboard:

Setup button. Entering balance’s main menu.

Selecting group of parameter one by one downwards or

changing parameter value by one value downwards.

Selecting group of parameters one by one upwards or changing

parameter value by one value upwards.

Selecting group of parameters for activating. On pressing the

button, the display indicates the first parameter in a selected

group

Exit to previous menu level, e.g. to main menu.

Abandon parameter changes.

Accept / confirm introduced changes.

Deleting a character while editing the text values of the menu,

e.g. user name.

Inserting a character while editing the text values of the menu,

e.g. user name

Page 24

- 25 -

Name of function groups and their content:

P1 ADJUSTMENT

P1.1 INT. CALIB. | [internal adjustment]

P1.2 EXT. CALIB. | [external adjustment]

P1.3 USER CALIBRATION | [user adjustment]

P1.4 CALIBRATION TEST | [adjustment test]

P1.5 AUTO. CALIB. |NONE [automatic adjustment]

P1.6 AUTO. CALIB. C. |1 [time of automatic adjustment]

P2 OPERATION MODE

P2.1 ACCESSIBILITY | [settings for the accessibility of individual

modes while working with the balance]

P2.2 WEIGHING | [setting for the function weighing]

P2.3 COUNTING PCS | [settings for the function counting pieces]

P2.4 CHECKWEIGHING | [settings for the function checkweighing]

P2.5 DOSING | [settings for the function dosing]

P2.6 DEVIATIONS | [settings for the function deviations % against

the mass of the standard]

P2.7 DENS. OF SOLIDS | [settings for determining density of solids]

P2.8 DENS OF LIQUIDS | [settings for determining density of liquids]

P2.9 ANIMAL WEIGHING | [settings for the function animal weighing]

P2.10 STATISTICS | [settings for the function statistics]

P2.11 TOTALISING | [settings for the function totalising]

P2.12 PEAK HOLD |[settings for the function peak hold]

P3 COMMUNICATION

P3.1 COM 1 | [transmission parameters port COM 1]

P3.2 COM 2 | [transmission parameters port COM 2]

P3.3 WIFI | [transmission parameters port WIFI]

Page 25

- 26 -

P4 DEVICES

P4.1 COMPUTER |COM 1/COM 2/USB/WIFI/NONE [PC connection port]

P4.2 PRINTER |COM 1/COM 2/USB/WIFI/PENDRIVE/USB PC/NONE

[printer connection port]

P4.3 BARCODE READER |COM 1/COM 2/NONE [barcode reader port]

P4.4 ADD. DISPLAY |COM 1/COM 2/NONE [additional display port]

P4.5 EXT. BUTTONS |TARE / PRINT

P5 PRINTOUT

P5.1 CAL. REPORT | [contents of the adjustment report]

P5.2 HEADER | [contents of the header print-out]

P5.3 GLP PRNT. | [contents of the weighment result prnt.]

P5.4 FOOTER | [contents of the footer print-out]

P5.5 NSD.PRN.1 | [project of non-standard print-out 1]

P5.6 NSD.PRN. 2 | [project of non-standard print-out 2]

P5.7 NSD.PRN. 3 | [project of non-standard print-out 3]

P5.8 NSD.PRN. 4 | [project of non-standard print-out 4]

P5.9 VARIABLE 1 | [project of variable 1]

P5.10 VARIABLE 2 | [project of variable 2]

P6 OTHER

P6.1 LANGUAGE |ENGLISH [menu language]

P6.2 ACCESS LEV. |ADMIN [access levels for editing menu]

P6.3 KEY SOUND |YES/NO [key sound]

P6.4 BACKLIGHT |70 [display backlight level]

P6.5 DATE |2013.05.27 [data settings]

P6.6 TIME |8:53:00 A [time settings]

P6.7 DATE FORM.|YYYY.MM.DD/YYYY.DD.MM/DD.MM.YYYY/MM.DD.YYYY

[date format]

P6.8 TIME FORM. |12H/24H [time format]

P6.9 GLP AUTOTEST | [carrying out autotest for the balance]

P7 INFO

P7.1 BALANCE ID |

P7.2 SCALETYPE. |

P7.3 PROG. VER. |

P7.4 TEMP. |

P7.5

SETUP PRNT. |

CAUTION

Changes introduced in balance memory will be saved, when

abandoning the menu (on return to weighing).

Press ESC button several times.

Page 26

- 27 -

9. LOGGING IN

In order to have full access to the user’s parameters and editing of database, the

person operating the balance, should log in as <ADMINISTRATOR> each time

they turn it on. The software enables the entry of 10 users with varying degrees of

authority.

The first login procedure

• While in the main window select <LOG IN>,available by pressing ,

or by pressing one of the function buttons to which the shortcut <LOG

IN> is assigned, or after pressing the button

, enter the users’

database and select the user <ADMIN>

• After selecting the < ADMIN> button and confirming the choice by

pressing

, the program asks you to enter the user’s password,

• You must enter „1111” and confirm by pressing ,

• The program returns to the main window,

• After the first login, you should first enter the users and assign the

appropriate access levels to them (procedures are described later in this

manual, see section 14).

The next time you log in, select a user from the list and enter the password.

After that the program starts working with the permissions for the selected

user.

If any user is logged in, the pictogram

is displayed.

Logout procedure

• In order to log out, select <NONE> from the list of available users

• The program returns to the main window, and the display shows no

logged-in user. (no logged-in user, no pictogram on the display).

Page 27

- 28 -

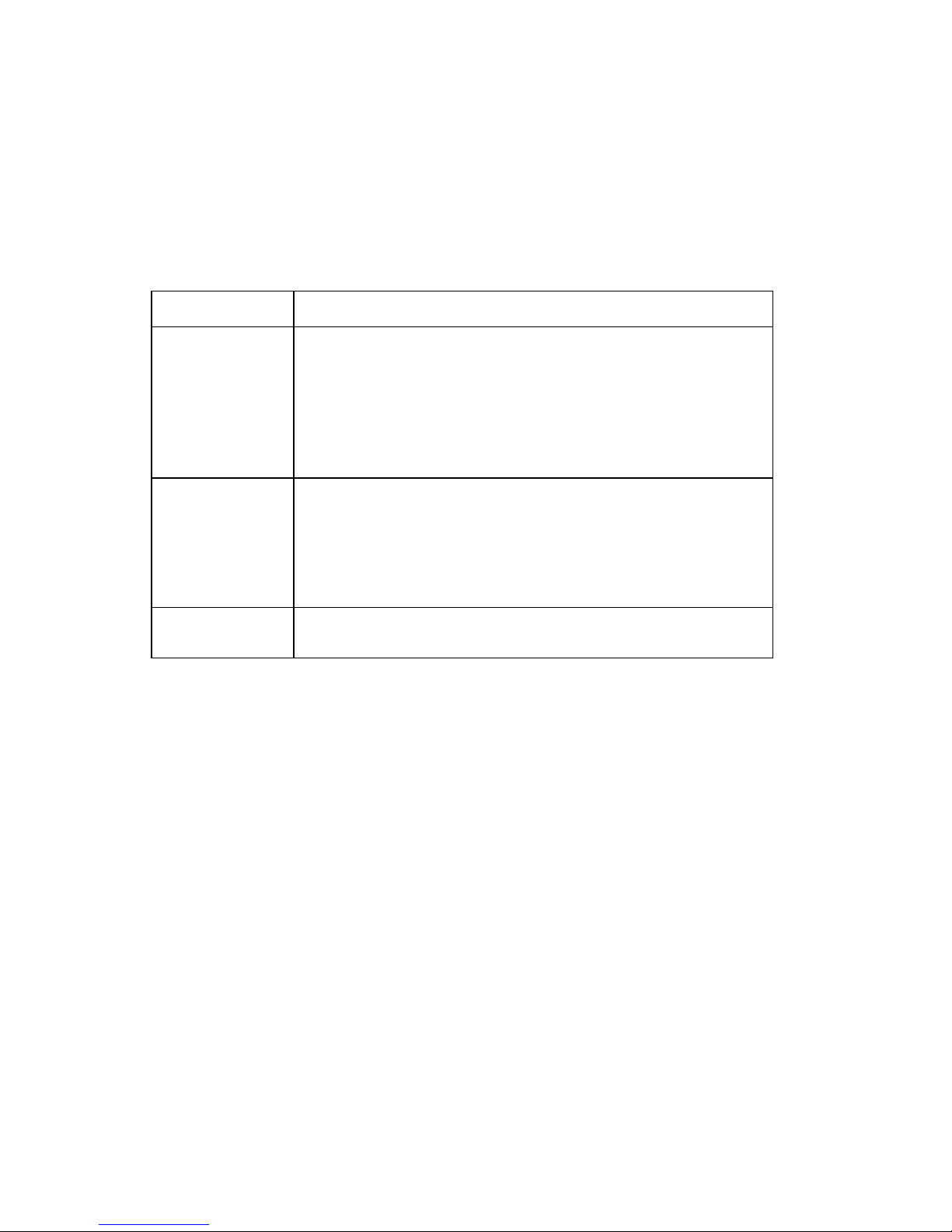

Access levels

The balance software features three access levels: ADMINISTRATOR,

ADVANCED, USER.

When you turn the balance on, the display is active all the time, which enables

carrying out mass measuring processes.

The table below shows the access to the edition of user parameters,

databases and software functions depending on the access level.

Access Access levels

USER

Access to parameters in the submenu: <Reading> and

setting in parameter group <Others> except for <Date

and Time>. All the weighing processes can be started

and carried out at this time. The user has the access to

the information preview in <Databases>, and can also

define universal variables.

ADV

Access to editing of parameters in the submenu:

<Reading>; <Working modes>; <Communication>;

<Devices>; <Others> except for <Date and Time>. All

the weighing processes can be started and carried out

at this time.

ADMIN

Access to all the user parameters, functions and

editing databases.

Page 28

- 29 -

10. WEIGHING

10.1. Required weighing procedures

In order to ensure long lasting use of a balance and reliable

measurement of weighed loads, follow below procedures:

Start the balance with no load on the weighing pan

(permissible value of load on the weighing pan on balance

start is ±10% of its maximal capacity).

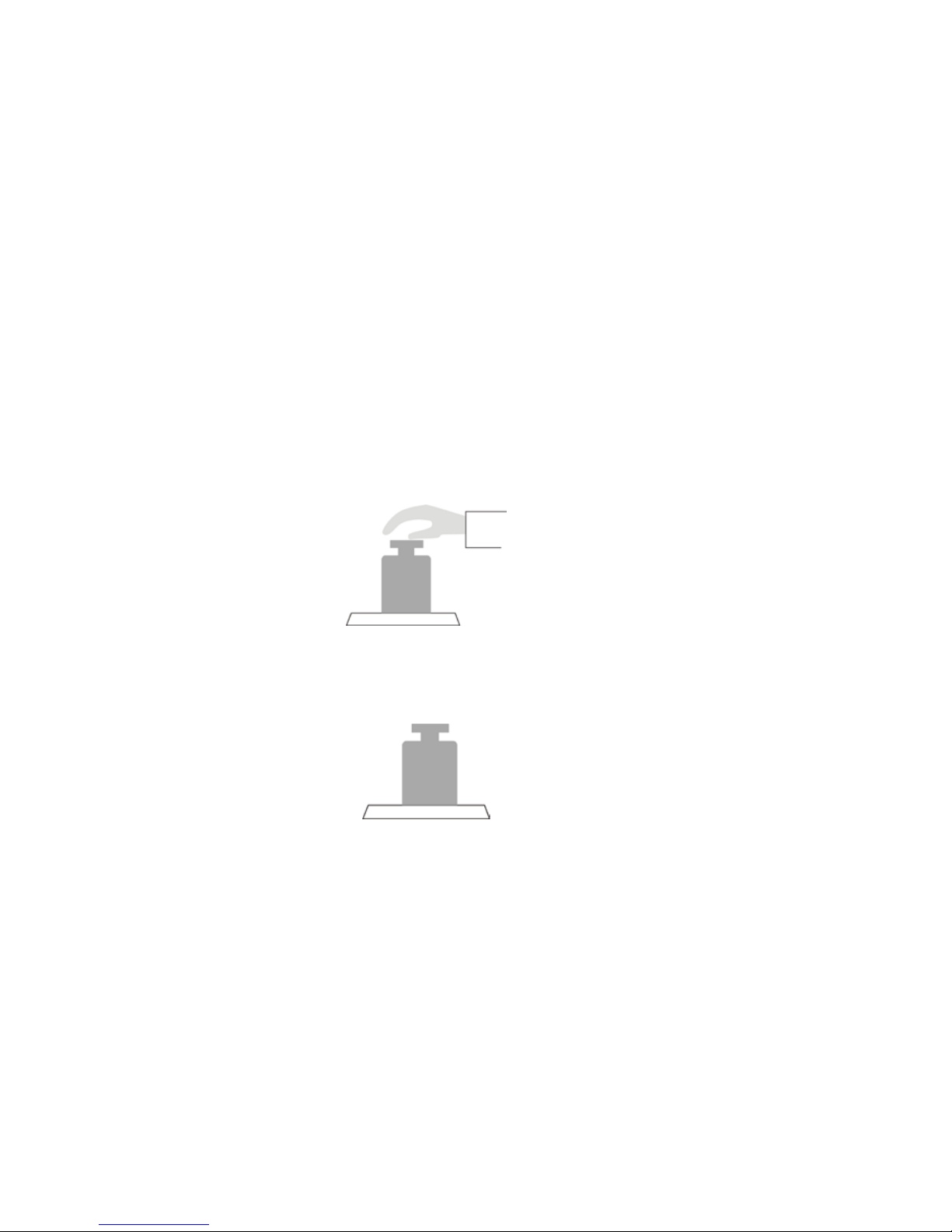

Load balance’s weighing pan steadily with no shocks:

YES

NO

Place weighed loads centrally on the weighing pan:

YES

NO

Avoid side loading, in particular side shocks:

NO

NO

Page 29

- 30 -

Before the start of weighing process or in case of drastic change of ambient

conditions at a workstation (e.g. ambient temperature change at a workstation more

than 3°C) the balance requires adjusting. The procedure of balance adjustment is

described further in this user manual.

• Before the start of weighing procedure, it is recommended to load the

balance’s weighing pan a few times with mass close to balance max

capacity,

• Check if unloaded balance indicates “precise zero”

and whether

measurement is stable

, if not, press /Delete button,

• Press UNITS button, to set a measuring unit:

[g], [mg], [ct], and also if enabled in factory menu (non-verified balances)

[kg], [lb], [oz], [ozt], [dwt], [tlh], [tls], [tlt], [tlc] [mom], [gr], [ti], [N], [baht], [tola]

• Place weighed object on balance’s weighing pan and read result only on

stabilisation of measurement result,

• Mass indication of a load placed on balance’s weighing pan can be tarred

for multiple Times by pressing →T

←

/Insert (pay CAUTION not to exceed

maximal capacity of a balance by applying multiple tare function).

During times between carrying out the following measurement series do not unplug

the balance from mains. It is recommended to switch off the balance’s display by

pressing ON/OFF button. On repeated pressing of the ON/OFF button the balance

is ready for operation and carrying out the following measurements.

Page 30

- 31 -

10.2. Zeroing

In order to zero mass indication press button.

The mass indication on the display should equal zero, and precise zero

and stability marker

should appear.

Zeroing process is tantamount to determining new zero point

recognised by the balance as precise zero. Zeroing is possible only in

stable status of display indication.

Caution:

Zeroing the display indication is possible only within the ±2% range of

instrument’s maximal capacity If the zeroed value is above the ±2% of the

maximal capacity, then th e softw are ind ic ates an error mes sage Err2.

10.3. Taring

In order to determine the net weight of a weighed object, place object’s

container (packaging) on balance’s weighing pan, and on stabilisation of

measurement result press

button. The display should indicate mass

equal to zero and symbols: Net and

.

On taking off the weighed load and its packaging from instrument’s

weighing pan, the display indicates sum of total tarred mass with minus

sign.

The software also enables assigning tare value to a product from a

database. Then, on product selection from a database, the software

automatically uploads data on tare value for the specific product.

Caution:

Taring negative values is impossible. On tarring negative values the

balance responds with an error message Err3. In such c as e zero balance’s

indication and repeat tarring procedure.

Page 31

- 32 -

Manual tare determination

Procedure:

• While in optional mode press quick access button F, to which the

option <ENTER TARE> is assigned in <SHORTCUTS> settings

(description of the setting further in this user manual, point <F button

shortcuts>),

• which opens a window,

• use the arrow buttons to enter tare value and press

button,

• the balance returns to weighing mode, and the display indicates

entered tare value with minus „–" sign.

Selection of tare from TARE DATABASE

Procedure:

• while in any working mode, press F – quick access button, to which

option <SELECT TARE> is assigned in <SHORTCUTS>

(description of the setting further in this user manual, point <F button

shortcuts), or choose option <SELECT TARE> after pressing

button,

• which displays the first mass value of the mass packages that was

saved in tare database,

• use the arrow buttons to select the tare which is to be recalled and

press

button,

• the balance returns to the weighing mode, and the display indicates

entered tare value with minus „–" sign.

Or

• While in any working mode press

button,

• Enter b3 option <TARE>

• Which displays the first mass value of the mass packages that was

saved in tare database,

• Use the arrow buttons to select the tare which is to be recalled and

press

button,

• The balance returns to the weighing mode, and the display indicates

entered tare value with minus „–" sign.

Page 32

- 33 -

Deleting tare

Entered tare value can be deleted by pressing

button on the

balance’s overlay or by entering tare value of 0.000g (see description

above).

10.4. Settings for mode <WEIGHING>

The software allows the set-up of operating parameters (filters, value release

and autozero option, deleting the last digit and other settings) separately for

each working mode.

It enables customising the instrument and utilising properties depending on the

user’s needs and expectations or specific requirements for selected working

mode (e.g. DOSING); as a result the work is quick and easy.

Available settings

P2.2.1 – READOUT

P2.2.1.1 – FILTER [V.FAST/ FAST / NORMAL / SLOW / V. SLOW]

P2.2.1.2 – RESULT CONF. [REL. / FAST / FAST+REL.]

P2.2.1.3 – AUTOZERO [YES / NO]

P2.2.1.4 – LAST DIGIT [ALWAYS / NEVER / WHEN STAB.]

P2.2.1.5 – AMBIENT CONDITIONS (STABLE/UNSTABLE)

P2.2.2 – PRINT MODE

P2.2.2.1 – MODE [EACH / WHEN STAB. / AUTO]

P2.2.2.2 –AUTO. PROG

P2.2.3 – UNITS

P2.2.3.1 – AVAILABILITY

P2.2.3.2 –START UNIT [G]

P2.2.3.3 – USER UNIT1

P2.2.3.4 – USER UNIT2

P2.2.4 – INFORMATION [TARE / NETTO / GROSS / USER / PRODUCT /

/NSTD. INF. / NONE]

P2.2.5 – INF. NSTD. (non-standard information – any text, max 19 characters)

P2.2.6 – SHORTCUTS (available options depending on the working mode)

P2.2.6 1 – F1 [NONE / ENTER TARE/ …]

P2.2.6.2 – F2 [NONE / ENTER TARE / …]

P2.2.6.3 – F3 [NONE / ENTER TARE/ …]

P2.2.6.4 – F4 [NONE / ENTER TARE / …]

1.1.1 Setting level of filtering

Depending on the balance working conditions you should set the filter. In ideal

conditions you can set the filter to be very fast (parameter value P.2.2.1.1 Filter to

be V.FAST); however, if the working conditions are bad (shakes, drafts), the filter

Page 33

- 34 -

should be set to slow or very slow (parameter value P.2.2.1.1 to SLOW or V.

SLOW). The effectiveness of the filter is different for the weighing range. The filter

works slower when “approaching” the weighed mass, it works more intensively

when the weighed mass is placed within the set range of the filter (parameter filter

range is accessible only from the service menu – the user does not have an access

to it).

Depending on the adjusted filter, the weighing time will be shorter (V.FAST and

FAST) or longer (SLOW and V. SLOW)

CAUTION

The higher level of filtering, the longer the weighing time.

1.1.2 Value release

Due to various ambient conditions at workplaces, and in order to set balance to

present conditions, it is necessary to determine the value release parameter

as: FAST.+REL., FAST or RELIABLE. Depending on selected option,

weighing time is either shorter or longer.

Page 34

- 35 -

1.1.3 Autozero function

In order to ensure balance’s precise mass indication, autozero (Auto) software

parameter has been introduced. The application of this function is automatic

control and correction of zero indication. When the function is enabled, it

compares balance indications at declared time interval e.g. 1s, on condition

that weighing pan is unloaded and display indication is close to zero. If results

vary less than declared AUTOZERO range e.g. one division, balance will zero

automatically, marker of stable measurement result–

and precise zero

marker –

will be displayed.

If AUTOZERO function is enabled, then each weighing process starts from

precise zero point. There are, however, some case when this function can be a

disturbing factor in the measuring process; for instance very slow placing of

load on the weighing pan (e.g. load pouring) in such case zero indication

correction can also correct actual indication of loaded mass.

1.1.4 Displaying the last digit

Function enables displaying the last digit on the balance display.

Page 35

- 36 -

1.1.5 Balance ambient conditions

This parametre has two settings: STABLE and UNSTABLE. Setting on STABLE

mode makes the balance work much faster than on UNSBABLE mode. This

parametre relates to the ambient conditions in which the balance operates. If the

ambient conditions are unstable it is recommended to use UNSTABLE mode.

Normally the parametre is set on: STABLE.

10.5. Printing mode

This function enables setting the printing mode, i.e. button activity

.

A user has the possibility of selecting the following settings:

• <WHEN STAB> the stable measurement result, along with the settings

for parameter < GLP PRINTOUT> are sent to the printer port. Pressing

the button

, when the result is not stable (no sign on

display), the balance software will send the measurement result to the

port after reaching the stable condition of the measurement.

• <ANYONE> every single pressing of

button results in sending

the measurement result to the printer port along with the settings for

parameter <GLP PRINTOUT>. Every measurement result is sent

(stable and unstable). The <?> sign appears at the beginning of the

printing frame when the result is unstable.

This function applies only to non-verified balances.

• <AUTO> - select this option to enable automatic printing of

measurements. If this option has been selected, remember to select

<AUTO PROG > parameter to suit your needs.

Automatic operation proceeds as follows:

Press

button to zero the balance (marker of stable

measurement

and zero marker are shown on display)

Place the load, the balance sends the first stable measurement to

the printer port,

Remove the load from the balance,

Next measurement is possible when the reading on the display is

lower than the set value of < AUTO PROG. > parameter (next

measurement does not require zero value).

Page 36

- 37 -

This procedure applies to changing settings:

For automatic working mode adjust the threshold value.

Page 37

- 38 -

10.6. Temporary measuring unit

This function is only available in <WEIGHING> mode. In other modes

measurements are only possible in basic unit [g].

Function enables selecting a measuring unit which will be indicated next to

mass reading during the weighing process. Set measuring unit will be in use

from the moment of its activation until its change or switching off and on the

balance.

Each press of the

button causes change of the measuring unit.

Available settings:

• For verified balances, a user can select from the following: [g], [mg] or

[kg], [ct]

• For non-verified balances, a user can select from the following measuring

units: [g], [mg], [kg], [ct], [lb], [oz], [ozt], [dwt], [tlh], [tls], [tlt], [tlc], [mom],

[gr], [ti], [N]

10.7. Start-up measuring unit

This function is only available in <WEIGHING> mode. In other modes

measurements are only possible in basic unit [g].

After selecting the start-up unit, when switched on, the balance will work in

<WEIGHING> mode with this very unit.

The units which can be selected are determined by the balance’s status, i.e.

whether the balance is verified or non-verified.

Procedure:

Page 38

- 39 -

10.8. Availability of measuring units

This function is only available in <WEIGHING> mode. In other modes

measurements are only possible in basic unit [g].

The user can declare the weighing units which will be available when selecting

temporary unit by pressing

button. For these units the parameter

availability is set to <YES>. These parameters can be selected by the user.

Procedure:

Page 39

- 40 -

10.9. User unit

A user can declare two weighing units. User unit is the result of balance indication

multiplied by the factor that was introduced for user unit.

User units are marked as [u1] – user 1 unit and [u2] – user 2 unit.

The way of declaring factor for an individual user is shown below

User units are available only for non-verified balances.

Page 40

- 41 -

10.10. Information

Function enables displaying additional information in the bottom line.

Depending on the needs, a user can choose the following options, which are

shown while working in mode <WEIGHING>:

Page 41

- 42 -

10.11. Non-standard information

Function enables declaring non-standard information, which is to be displayed

in the bottom line of the display. A user can insert any text consisting of

maximum 19 characters.

It should be remembered though, that the declared non-standard information is

visible. Therefore, option P2.1.2 should be set to < NSTD. INF. >.

Page 42

- 43 -

10.12. F button shortcuts

Function enables assigning quick access option for weighing functions which

are accessible by choosing F1, F2, F3 or F4. A user can choose the following

options in <WEIGHING> mode, which can be assigned to any of the F

buttons< NONE / ENTER TARE / PRINT HEADER / PRINT FOOTER /

VARIABLE 1 / VARIABLE 2>. There are different options available in other

modes (see further on in this manual).

Page 43

- 44 -

10.13. Dual range balance (BPS-200/2000-C2-V2)

Balance BPS-200/2000-C2 series is a dual range weighing instrument. The

accuracy of the I weighing range is d

1

=0.001g, and of the II weighing range is

d

2

=0.01g.

Transfer from weighing with the accuracy of the I weighing range to weighing with

the accuracy of the II weighing range takes place automatically on exceeding

Max

1

200g (with no user activity needed). On switching to weighing with the

accuracy of the II weighing range, the display signals by indicating

symbol

on its left side, and an additional marker of last but one digit of the weighing result.

From now on the balance weighs mass with the accuracy of the II weighing range.

To return to weighing in the accuracy of the I weighing range:

• Take the weighed load off the weighing pan

• As the indication returns to zero and pictograms →0

←

and are lit,

press

button.

The balance returns to weighing with the accuracy of the I weighing range, and II

weighing range

pictogram and marker of the last but one digit are blanked.

Page 44

- 45 -

11. OTHER PARAMETERS

A user can set up parameters which have an influence on working with the balance.

These parameters are included in group P6 OTHER.

Changing settings for particular parameters is the same as described in the

previous paragraph of this user manual.

P6 OTHER

P6.1 LANGUAGE |ENGLISH [menu languages]

P6.2 ACCESS LEV. |ADMIN [access levels for editing menu]

P6.3 KEY SOUND. |YES/NO [key sound]

P6.4 BACKLIGHT |70 [display backlight level]

P6.5 DATE |2013.05.27 [date settings]

P6.6 TIME |8:53:00 A [time settings]

P6.7 DATE FORM. |YYYY.MM.DD / YYYY.DD.MM / DD.MM.YYYY /

MM.DD.YYYY [date format]

P6.8 TIME FORM. |12H / 24H [time format]

P6.9 GLP AUTOTEST | [carrying out autotest for the balance]

P6.10 SETUP PRNT. | [balance parameters print-out]

Enter group P6 OTHER menu.

11.1. Available menu languages

Enables selecting the balance menu descriptions.

Available languages: ENGLISH

11.2. Access levels

Enables choosing access levels when entering the balance menu.

Available access levels: ADMIN. / USER. / ADV.

Depending on the option selected, a user of a specific access level can access and

make changes to the settings in the balance.

11.3. ‘Beep’ sound – reaction on pressing function button

Enables switching on/ switching off the ‘beep’ sound, which informs a user about

pressing any button on balance’s overlay.

NO - ‘beep’ sound switched off

YES - ‘beep’ sound switched on.

Page 45

- 46 -

11.4. Backlight and adjusting display brightness

Enables setting the brightness of the backlight or switching off the display

brightness completely.

100 - maximum brightness of the backlight

10 - minimum brightness of the backlight

NONE - display brightness switched off

11.5. Date

Enables setting the current date.

As follows:

11.6. Time

Enables setting the current time.

As follows:

11.7. Date format

Enables altering the date format on the printout

[YYYY.MM.DD / YYYY.DD.MM / DD.MM.YYYY / MM.DD.YYYY]

Where:

YYYY – year

MM – month

DD - day

Page 46

- 47 -

11.8. Time format

Enables choosing the time format on the printout [12H / 24H].

For the set value [12H], in parameter P6.6 TIME letters <A> or <P> will be

displayed next to the time value.

Where:

A stands for hours before noon, P stands for hours after noon.

Letters AM or PM are printed out next to the time value.

11.9. GLP autotest

AUTOTEST function is designed to aid a user in assessing balance’s operation and

diagnosing the reasons for occurrence of errors in weighing which exceed the

maximum permissible values for a given balance model.

By means of a simple, repeatable and fully documented way the function enables

optimizing balance’s settings to maintain the best possible repeatability and

weighing time at workstation. The main purpose of the function is the possibility of

monitoring the above-mentioned parameters at optional moment and saving

records from the carried out tests in the form of printed reports of the tests that are

automatically generated at the end of examination.

The test controls repeatability of placing the interval weight and determining error of

indication with reference to balance’s maximum capacity.

Testing procedure:

• two times loading of the internal weight, followed by 10 times loading of

the internal weight

• balance internal adjustment

• calculating the value of standard deviation

• report printout

Test results:

*Deviation for Max.

*Value of repeatability of indication expressed as standard deviation

Page 47

- 48 -

Example of a report:

.....................................................

--------- Autotest GLP: Report ---------

Balance type %PS00&2

Balanc

e ID

400010

User Admin

Software rev. v.0.4.9

Date 2013.07.16

Time 09: 17:16

----------------------------------------

Number of measurements 10

Reading unit 0.001/0.01 g

Internal weight mass 1402.094 g

Filter Normal

Value release Fast &Reliable

----------------------------------------

Deviation for Max. -0.118 g

Repeatability 0.0088 g

Signature

........................................

PROCEDURE:

Parameter <P6.9 GLP AUTOTEST > is initiated by pressing

button.

The balance software starts the autotest GLP procedure and it is carried out

automatically from now on to the end.

A user can stop the procedure at any time by pressing

button in the window.

Once the procedure is finished, the value of standard deviation of all

measurements is shown in the main display, and message <RESULT> in the

bottom line, and the final report is printed out automatically (as shown above). It is

possible to print out the report again by pressing

button.

Report is not saved, therefore when abandoning this level, it is deleted from the

balance volatile memory.

To abandon the window press

button and the program returns to the main

menu. To return to weighing press button repeatedly.

Page 48

- 49 -

12. INFORMATION ABOUT THE BALANCE

This menu includes information about the balance and its installed software. The

parameters are strictly informative.

Once the parameter <PRINT. SET>> is chosen, the balance settings are sent to

the printer (all parameters). The parameters are transferred via port that was

chosen for <PRINTERS>.

Page 49

- 50 -

13. BALANCE ADJUSTMENT

In order to ensure the highest weighing accuracy, it is recommended to periodically

introduce to balance memory a corrective factor of indications in relation to a mass

standard – i.e. balance adjustment.

Adjustment should be carried out:

- Before the beginning of weighing procedure,

- If long breaks between following measuring series occur,

- If temperature inside the balance changes more than: 3°C.

Types of adjustment:

- Internal automatic adjustment

* triggered by temperature change

* triggered by elapsing time

- Manual internal adjustment

* initiated by pressing

- Adjustment with external weight

* with declared mass which cannot be modified

* of any weight, but not lower than 30% of maximum range.

CAUTION

In case of verified balances (with internal automatic adjustment system)

only the automatic internal adjustment and manual internal adjustment

system are available for a user. Remember to carry out the adjustm ent

process when there is no load on the pan! In case there is load on the

weighing pan, the display will indicate a command <RANGE EXCEEDED>

. In such a case the load should be removed from the weighing pan and

the process of the adjustment should be finished.

Adjustment process can be aborted if necessary by pressing Esc at any

time during the process.

Page 50

- 51 -

13.1. Internal adjustment

Adjustment process can be initiated automatically and manually.

Manual means of activating adjustment procedure is achieved by pressing

. System of automatic adjustment will carry out the process fully

automatically and will inform the user on successive process stages.

Cycle of automatic adjustment process:

- Balance software detects the necessity of carrying out adjustment and

signals it by displaying a thermometer pictogram and <Cal> at the top of

the display.

- During this time interval of about 2 minutes within which weighing

procedure can be completed

- As the 2 minute time elapses, balance display indicates message CAL_30

and starts counting down from 30..29..28 to 0 (indicated value is the

counter),

- Balance user has 30 seconds to make a decision

In order to start adjustment, do not take any actions

In order to complete weighing procedure, press Esc. When pressed,

balance returns to weighing procedure and displays last weighing

result. In about 5 minutes balance indicates CAL_30 message again.

- The adjustment process can be postponed for multiple times, but it needs

to be pointed out that postponing of adjustment for a long time may lead to

larger errors of weighing process. The errors are the effect of temperature

changes and as a consequence changes of balance sensitivity.

Page 51

- 52 -

Automatic adjustment process takes place in three different areas:

• Adjustment on plugging the balance to mains – verified balances.

• Adjustment triggered by temperature change inside the balance. The

balance is equipped with very precise system for monitoring

temperature. At each adjustment process, the temperature is saved

in the system. The next adjustment is automatically initiated if

temperature changes more than 3°C from the last saved

temperature.

• Adjustment triggered by elapsing time. It is possible to declare time

intervals which are criteria for balance adjustment. Accessible

settings are: adjustment after 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 hours

since last carried out adjustment procedure,

CAUTION

Declaring time intervals for balance adjustment is available only in

non-verified balances. In case of verified balances the time interval

between the following adjustm ents is set for 3 hour s.

Page 52

- 53 -

13.2. Menu adjustment settings

P1 CALIBRATION

P1.1 INT.CALIB. | [internal adjustment]

P1.2 EXT.CALIB. | [external adjustment]

P1.3 USER CALIB. | [user adjustment]

P1.4 CALIB. TEST | [adjustment test]

P1.5 AUTO. CAL. T. | NONE/TIME/TEMP./BOTH [automatic

adjustment]

P1.6 AUTO CAL. C. | [time of automatic adjustment]

• P1.1 INT. CALIB. – Internal adjustment

Start of internal adjustment process. Adjustment is conducted automatically,

and no user assistance is required. If weighing pan of the balance is loaded,

balance will display a command to unload the weighing pan. If weighing pan is

loaded with a relatively small mass (up to 4% of balance max capacity) then

adjustment process will be carried out automatically, but measuring results

may differ by the amount that was present on balance weighing pan.

or

• P1.2 EXT. CALIB. – External adjustment (with an external weight)

Adjustment with external weight, which value is saved in factory menu of

balance, function unavailable in verified balances.

CAUTION

Function unavailable in verified balances.

Page 53

- 54 -

• P1.3 USER CALIB. – User adjustment (with an external weight)

Adjustment with external weight at any mass in the balance range, however,

not lower than 30% of max range.

CAUTION

Function unavailable in verified balances.

• P1.4 CALIB. TEST – Adjustment test

This fuction enables comparing the result of internal automatic adjustment

with the value of internal weight saved in balance’s factory parameters.

The process is conducted automatically and its result is shown on the

display (if the balance is connected via RS 232 port with a computer or

printer, the adjustement result will be printed out). Press ESC to go back to

the previous menu.

• P1.5 AUTO. CALIB. T. – Temperature of automatic adjustment

(balances with internal adjustment)

Determination of factor which signals start of automatic internal adjustment

NONE - no factor will cause start of adjustement

(adjustment automatically turned off)

TEMP. - adjustment triggered by change of temperature

TIME - adjustment triggered by time interval set in P1.6 AUTO CALIB.

C.

BOTH - adjustment triggered by time and temperature.

CAUTION

Function unavailable in non-verified balances.

Page 54

- 55 -

• P1.6 AUTO CALIB. C. - Time of automatic adjustment (balances

with internal adjustment system)

Determination of time interval, after which automatic adjustment process is

initiated.

CAUTION

Function unavailable in verified balances.

13.3. Manual adjustment

13.3.1. Internal adjustments

Press Cal button

or

The balance performs internal adjustment automatically. During

adjustment process do not load the weighing pan with any load. The

message is displayed <DO NOT TURN OFF CALIBRATION> in the

bottom line. Once adjustment process is completed, balance saves its

result in memory and returns to weighing mode.

CAUTION

- Press Esc button to abort adj ustm ent proc es s.

-If, during adjustment process, weighing pan of a balance is loaded, the

display will show an error message. Adjustment will be stopped. As

weighing pan is unloaded, the adjustment process will continue and be

completed.

Page 55

- 56 -

13.3.2. External adjustment

The external adjustment in balances BPS series should be carried out with

external mass standard / weigh class F

1

Start of external adjustment process,

Balance will display a command ordering unloading of weighing pan

<REMOVE MASS> (weighing pan must be empty). When weighing pan is

unloaded, press

button.

The balance determines mass of empty pan and message <CALIBRATION>

is displayed in the bottom line. It is followed by message message <PLACE

MASS> in the bottom bar, and in the main window the mass value to be

placed on the weighing pan e.g. 200.000g (depending on the type of

balance). Place an external adjustment weight with mass determined on

balance’s display and press

button. The balance determines the mass

and message <CALIBRATION> is displayed in the bottom line. On

completing adjustment process the balance returns to submenu P1.2

INT.CALIB.

If a balance is verified, it is not possible for a user to carry out

external adjustment process.

13.3.3. User adjustment

The external adjustment in balances BPS series should be carried out with

external mass standard / weigh class F

1

Start of external adjustment process,

Page 56

- 57 -

The first procedure of the process is to enter the mass of the weight that is to

be used for adjustment. The mass must be ≥ 30% Max capacity.

Once the mass of the weight is entered and confirmed, the message is

displayed which asks you to remove the weight from the pan <REMOVE

MASS> (weighing pan must be empty). After that, press button, the

balance determines the weight of unloaded pan and message

<CALIBRATION> is shown in the bottom line .

Next, message <PLACE MASS>is displayed in the bottom bar, and in the

main window the value of the mass to be placed e.g. 200.000g (depending

on balance type). Place the weight of the indicated mass and press

button. The balance determines the mass and message <CALIBRATION> is

displayed in the bottom line. After the adjustment process, the balance

returns to submenu P1.2 EXT.CALIB.

If a balance is verified, it is not possible for a user to carry out

external adjustment process.

13.4. Adjustment report printout

At the end of each adjustment process or adjustment test, an adjustment

report is generated automatically and sent to communication port COM 1. The

content of the report is declared in menu P5.0 GLP PRINTOUTS.

The description of how to declare the settings for this option is included

further in this manual, in the section on printouts.

The report can be printed out via the printer connected to the balance or it can

be sent to the computer and saved as a file for archiving.

Page 57

- 58 -

14. DETERMINING CONTENT OF A PRINOUT

14.1. Adjustment report

P5.1 CAL. REPORT, is a group of parameters which enable declaring data that is

on an adjustment printout.

P5.1 CAL. REPORT

P5.1.1 PROJECT |

P5.1.2 CALIB. TYPE | YES

P5.1.3 USER | YES

P5.1.4 PROJECT | YES

P5.1.5 DATE | YES

P5.1.6 TIME | YES

P5.1.7 BALANCE ID | YES

P5.1.8 CAL.DIFFER. | YES

P5.1.9 DASHES | YES

P5.1.10 SIGNATURE | YES

• P5.1.1 PROJECT

Option enables entering the name of the project (e.g. associated with a specific

type of weighment). The name can be up to 16 characters.

For instance, a project name entered into the balance in capital letters, looks

like the figure below:

• P5.1.2 CALIB. TYPE.

Enables printing out the type of the adjustment being carried out.

• P5.1.3 USER

Enables printing out the name of logged-in user.

Page 58

- 59 -

P5.1.4 PROJECT

Enables printing out the name of the project. (see parameter P5.0.1)

• P5.1.5 DATE

Enables printing out the date of the carried out adjustment.

• P5.1.6 TIME

Enables printing out the time of the carried out adjustment.

• P5.1.7 BALANCE ID

Enables printing out the balance ID number.

• P5.1.8 CAL. DIFFER.

Enables printing out the difference between the mass of adjustment weight

measured during the last adjustment and the current measured mass of this

weight.

• P5.1.9 DASHES

Enables printing out the dashes that separate the date of printout from the

signature

• P5.1.10 SIGNATURE

Enables printing out the signature of a user performing the adjustment.

Choose one of the options for the above-mentioned parameters.

NO - do not print on the report

YES - print on the report

Example of a report:

Page 59

- 60 -

14.2. Header printout

P5.2 HEADER, is a group of parameters which enable declaring data that is on the

header printout.

P5.3 HEADER

P5.2.1 DASHES | YES

P5.2.2 WORKING MODES | YES

P5.2.3 DATE | YES

P5.2.4 TIME | YES

P5.2.5 SCALE TYPE | YES

P5.2.6 BALANCE ID | YES

P5.2.7 USER | YES

P5.2.8 PRODUCT | YES

P5.2.9 VARIABLE 1 | YES

P5.2.10 VARIABLE 2 | YES

P5.2.11 EMPTY LINE | YES

P5.2.12 CAL.REPORT | YES

P5.2.13 NON-STANDART PRNT. | NONE / NSTD.PRN. 1 /

NSTD. PRN. 2 / NSTD.PRN.3

/ NSTD. PRN.4

• P5.2.1 DASHES

Enables printing out a line of separating dashes.

• P5.2.2 WORKING MODES

Enables printing out the name of balance’s working mode.

• P5.2.3 DATE

Enables printing out the date in the header.

• P5.2.4 TIME

Enables printing out the time in the header.

• P5.2.5 SCALE TYPE

Enables printing out the scale type.

Page 60

- 61 -

• P5.2.6 BALANCE ID

Enables printing out balance ID number.

• P5.2.7 USER

Enables printing out the name of a logged-in user.

• P5.2.8 PRODUCT

Enables printing out the name of a selected product.

• P5.2.9 VARIABLE 1

Enables printing out the value of VARIABLE 1.

• P5.2.10 VARIABLE 2

Enables printing out the value of VARIABLE 2.

• P5.22.11 EMPTY LINE.

Enables printing out an empty separating line.

• P5.2.12 CAL. REPORT

Enables printing out a report from the last adjustment, according to the

settings declared for the adjustment report printout (see sec. 12.1 in this

manual).

• P5.2.13 NSTD. PRINT.

Enables printing out one of the four non-standard printouts on the header

printout.

You can choose one from the following options: NONE / NSTD. PRN 1 /

NSTD.PRN.2/NSTD.PRN. 3 / NSTD. PRN.4

The way of entering non-standard printouts is described further in this manual.

For the parameters described above i.e. P5.2.1 to P5.2.12 you should choose

from:

NO - do not print in the header

YES - print in the header

For the parameter P5.2.13, you should choose one of the following options:

NONE / NSTD.PRN. 1 / NSTD. PRN 2 / NSTD.PRN 3 / NSTD. PRN.4

Page 61

- 62 -

Example of a header printout:

14.3. Measurement result printout – GLP PRINTOUT

P5.3 GLP PRINTOUT, is a group of parameters which enable declaring data that is

on the measurement result printout.

P5.3 GLP PRNT.

P5.3.1 DATE | YES

P5.3.2 TIME | YES

P5.3.3 USER | YES

P5.3.4 PRODUCT | YES

P5.3.5 VARIABLE 1 | YES

P5.3.6 VARIABLE 2 | YES

P5.3.7 TARE | YES

P5.3.8 GROSS | YES

P5.3.9 CURR.RES. | YES

P5.3.10 CAL. REPORT | YES

P5.3.11 NSTD.PRNT. | NONE / NSTD.PRN. 1 /NSTD.PRN. 2 /

NSTD. PRN.3 / NSTD.PRN. 4

• P5.3.1 DATE

Enables printing out the date of measurement.

• P5.3.2 TIME

Enables printing out the time of measurement.

• P5.3.3 USER

Enables printing out the name of a logged-in user.

Page 62

- 63 -

• P5.3.4 PRODUCT

Enables printing out the name of the product that was weighed.

• P5.3.5 VARIABLE 1

Enables printing out the value of VARIABLE 1.

• P5.3.6 VARIABLE 2

Enables printing out the value of VARIABLE 2.

• P5.3.7 TARE

Enables printing out the tare value.

• P5.3.8 GROSS

Enables printing out the gross mass value.

• P5.3.9 CURR. RES.

Enables printing out the current measurement result (NET mass) in the

current unit.

• P5.3.10 CAL. REPORT

Enables printing out a report from the last adjustment, according to the

settings declared for the adjustment report printout (see sec. 12.1 in this

manual).

• P5.3.11 NSTD. PRNT.

Enables printing out one of the four non-standard printouts on the header

printout.

You can choose one from the following options: NONE / NSTD. PRN 1 /

NSTD.PRN.2/NSTD.PRN. 3 / NSTD. PRN.4

The way of entering non-standard printouts is described further in this manual.

Example of a printout:

Page 63

- 64 -

14.4. Footer printout