Page 1

FEATURES

Normal and soft power control to resolve the cleaning blind spot.

Stainless steel housing, tank and lid, nice looking.

Stamp tank without welding gap for better waterproof.

Cooling fan.

Moisture-proofed PCB.

Industrial grade IC & ultrasonic transducer.

Thank you for purchasing ultrasonic cleaner. Please take the time to read these

operating instructions before using and retain them for future reference.

Failure to follow these instructions may lead to serious personal injury

and damage to property.

Blinking LED light bar display for timer and temperature.

AC-SERIES ULTRASONIC CLEANER

USER MANUAL

Page 2

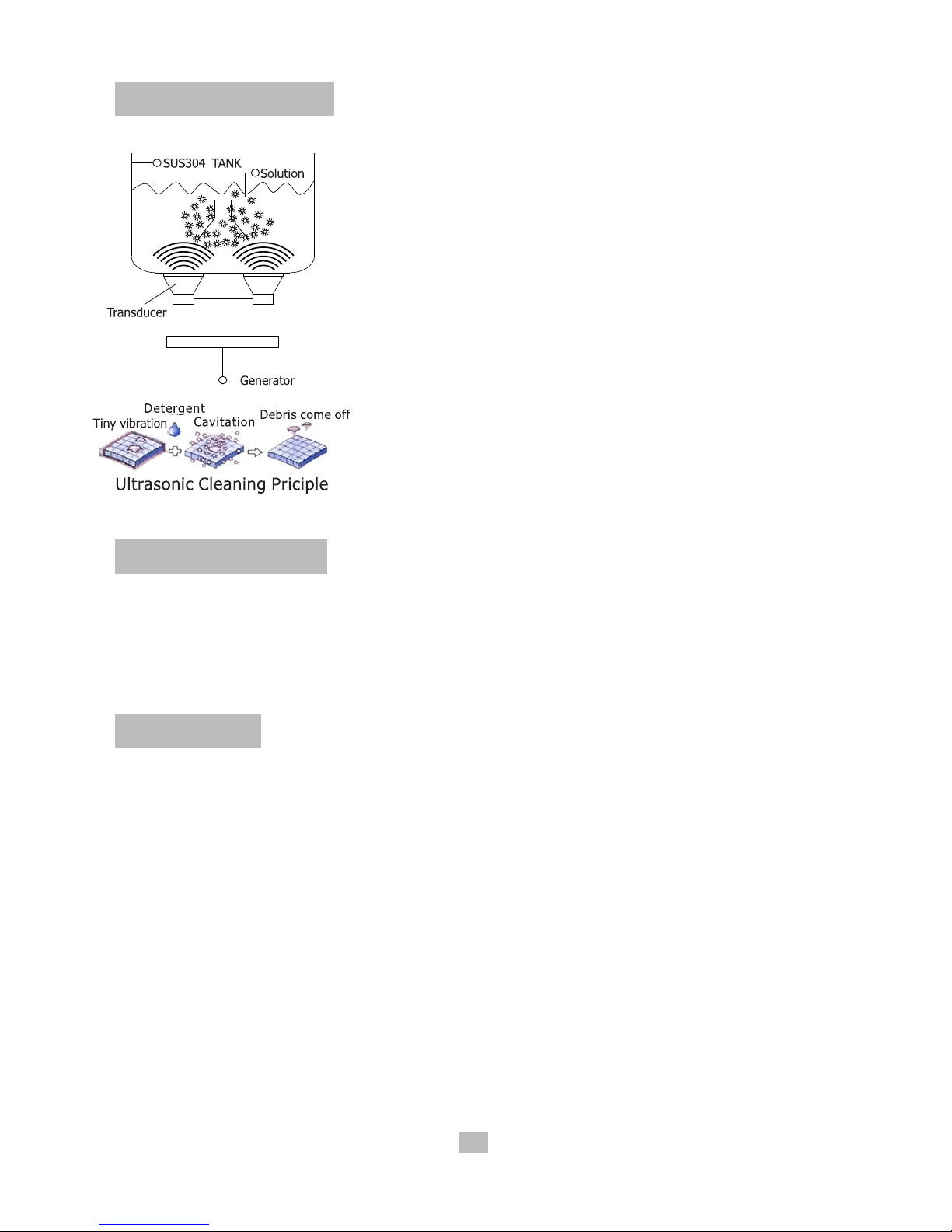

INTRODUCTION

Ultrasonic cleaning is based on the cavitation effect

caused by high frequency ultrasonic wave vibration

signal in the fluid. Microscopic bubbles are formed,

and they implode violently causing the cavitation

which create an intense scrubbing action on the

small enough to penetrate microscopic crevices,cleaning

them thoroughly and consistently.Ultrasonic cleaning is

extremely effective at removing dirt and grime which

would normally require tedious manual cleaning by hand.

It has been used to clean a wide variety of instruments and

mechanical parts such as carburetors,returning them

to almost “like new” condition without damage to delicate parts.

surface of the item being cleaned. The bubbles are

PREPARATION:

1、Carefully unpack the cleaner and remove all traces of packing materials

from it. Visually inspect the cleaner for any parts that may have become loose

or damaged during transit.

Contents:

a: Main machine b: Lid c: Power cord

d: Outlet filter e: User manual f: Mesh basket

2、Place the cleaner on a flat, clean surface where the cooling fans will receive

adequate ventilation and ensure all controls are set to off. Also ensure the

drain tap is in the closed position.

3、 Ensure the power lead is securely plugged into the cleaner and that no part

part of the lead is likely to come into contact with moisture.

4、Carefully fill at least 1/2 of the tank with a solvent solution. For demanding

cleaning we recommend a small amount of washing up liquid, this will help

increase the cleaning performance. The cleaner is now ready for use.

1

Page 3

Attention

While the machine is working normally, ultrasonic and tank syntony

gives a well-proportioned sound, and no shudder on the surface of the

water, yet there is spray made by the tiny bubbles. If there are discontinuous

surges, please add or release a little of washing solution in the tank,

stopping the surges is better for the objects cleaning.

Please read the following very carefully as failure to comply may

invalidate your guarantee.

1) DO NOT run the cleaner continuously for more than 30 minutes at a time, as

doing so can damage the internal components.

2) DO NOT operate the unit without fluid in the tank. Always ensure the fluid is no

higher than the max mark, Always ensure there is a minimum depth of 7cm.

3) DO NOT drop any item into the tank as this may cause damage to the

transducer. Always place the items gently into the tank and use the basket.

4) The more items that you place in your cleaning bath the less efficient it

will clean.It is not advised to overlap items. Always allow plenty of clear

space between the items.

5) Do keep the lid on during use. This will prevent splashes and reduce

evaporation of the fluid.

2

SAFETY PRECAUTIONS

Keep it away from children!

This device is not intended to use by individuals with restricted physical

sensory or metal capacities or those with lack of experience or knowledge,

include children, unless they are supervised by an individual who is responsible

for their safety or have received training in operating the device.

Page 4

6) Never immerse the machine or power cord in water or other liquid.

7) DO NOT touch the power plug with wet hands, especially when inserting

or removing the plug.

8)DO NOT touch the unit if the machine has fallen into water during operation.

Remove the power plug from the socket first.

9) DO NOT disassemble the machine, except by professionals.

10) UNPLUG the power source while filling or emptying the tank.

11) DO NOT spray water or liquid over the device and the control panel

12) DO NOT operate the cleaner without proper grounding.

13) DO NOT place the device on a soft surface, where the vents could be blocked.

14)Upon completion of the cleaning cycle, turn the heater knob off and isolate

the machine from the electrical supply.

15)Take care when adding or removing items from the cleaning tank as the

fluid is likely to be hot and displaced fluid can damage the internal components.

Any displaced fluid must be dried up immediately.

16)In the event of failure/emergency, disconnect the mains supply by removing

the plug from the mains socket.

APPLICATION

3

17)Never plugged in the machine unattended .

Provided product is non-porous and can normally be immersed in water

almost anything can be thoroughly cleaned. Here are some examples:

Page 5

4

Hospital

Beauty and Chiropody Institutes: scissors, scalpels, comedo

removers, pincers, nippers, forceps and razors with the removal

of organic tissue before sterilization treatments.

Tattoo Studios: grips, tips and needles.

Dental Practices and Dental Technician Laboratories:

dental instruments, removing organic and blood residues,

cleaning hand pieces, drills, heads for ultrasonic ablators,

glass objects and mirrors; the removal o f cement from

spatulas and plaster from prostheses.

Hospital Wards :endoscopic probes, surgical instruments.

Veterinary hospital:veterinary instruments.

Analysis Laboratories:glass containers in analysis laboratories

with removal of proteins, blood and organic tissue.

Laboratories

Gold smithery and

Silver smithery

Necklaces, bracelets, rings, precious stones, watch casings

and straps, precision mechanical movements.

Manufacturing

Aerospace,Pharmaceutical,Defence,Automotive,Marine,

Filtration,Moulding,Food and Beverage, Plating & Surface

Finishing,Semi-Conductors.

Optical

During edging and polishing, debris and abrasives can scratch

lenses. Ultrasonic cleaning can effectively protect the lenses.

Military Reusable brass, gun parts, bullets etc.

Regeneration For cleaning dot matrix printers and photocopier ink cartridges.

Maintenance Mobile phones, bicycle gears, air purifiers. It cleans out debris

in tiny holes and crevices effectively.

Items Not Suitable For Ultrasonic Cleaning

Soft Jewelry: Pearls, emerald, ivory, coral. Agate, sea turtle shells, etc.

Welded, Plated and Glued Items: Welded or plated metal items, glued items.

Watches: Except diver’s watches with depth rating over 50m(150ft).

Others: Ceramic, camera filters with preexisting cracks.

Page 6

MECHANICAL ULTRASONIC CLEANER STRUCTURE

Unit front view/side view

A: Stainless steel housing B: Lid C: SUS304 tank

D: Max line E: Plastic carrying handles F: Drain tap G:Rubber feet

5

A

C D

E

F

G

B

Page 7

6

Unit back view

A:L ouver

B:S ock et

C:P ower s witch

D:Q C PA SSED s ticke r

E:R ati ng lab el

A

B

C

D

E

Front panel

E

C

A B

F

I

D

G

H

A: Heating knob:Turn rightwards to set the temperature from 20-80℃,turn

leftwards to reduce the temperature.

(Note:1:It’s useless to turn rightwards when temperature reach to 80℃ and

turn leftwards when temperature reach to 20℃)

B:Timer knob : Turn rightwards to set the timer from 0-30mins,turn leftwards

(Note :1:I t’s useless to t urn rightwards when timer reach to 3 0min s and

turn leftwards when timer reach to 0)

to reduce the timer.

Page 8

C:Heating indicator:When turn on power switch and setting temperature

reached ,the heating indicator will light up.

D:Timer indicator:When turn on power switch and setting timer reached ,

the timer indicator will light up.

E:Heating LED light bar:Temperature display

F:Timer LED light bar:Timer display

G:Normal power :100% power to the tank for normal applications .

H:Soft power:Half power for delicate applications .

I: Warning marking

OPERATION

Step

Action

1

2

Select your cleaning solution; fill at least ½ of solution into the tank.

Do not exceed the filling line.

Note: Do not ever use alcohol, gasoline or flammable solutions.

Doing so could cause a fire or explosion. Use only water-based solutions.

Place the items into a basket, Slowly lower the basket into

tank, do not allow items to contact the tank bottom (solution

should cover the items)

Power switch a: Plug the machine into grounded outlet.

b: Turn on the power switch on back side of the machine.

The timer and heating indicator light up.

Ultrasonic

power choose

Choose normal soft ultrasonic power you need .

Temperature

setting

a:Turn the “Heater” knob rightwards to set heating temperature

from 20℃ to 80℃.The light of preset temperature will blinking

3 seconds to start heating ,the LED light bar will display the

ambient temperature and rise up until the temperature reached

to preset temperature,heating will auto stop and the light of

preset temperature will always blinking, the LED light bar

below preset temperature all light off and heating indicator light up.

7

Page 9

8

b:Turn the knob leftwards to reduce the temperature .

c:To stop heating immediately, turn knob leftwards to off

until heating indicator light up again.

Note:

1.Temperature with 13 gear ranges ,from 20,25,30,35,

40,45,50,55,60,65,70,75,80℃

2.Heating will auto start again when actual temperature

lower around 3 than the preset temperature.℃

3.To get the best cleaning result, the solution’s temperature

we suggest is 40℃-60℃. Warm water and dish washing liquid

can soften grease and improve cleaning result.

4.If the preset temperature below environment temperature,

the heating couldn`t start.

Timer setting

a:Turn the “Timer” knob rightwards to set timer from 0-30

minutes. The preset timer light blinking 3 seconds and all

LED light bar below preset timer will light up ,ultrasonic start

working .The LED light bar will be shortened as operation time is

going on .When cleaning is completed,the timer indicator light up.

b:Turn the knob leftwards to reduce the ultrasonic working time .

c:To stop ultrasonic immediately,turn knob leftwards to off

until timer indicator light up again.

Note:

Timer with 9 gear ranges,from 1, 2, 3, 4, 5, 15, 20, 25, 30mins

Start

Ultrasonic

After the timer be set,the ultrasonic start working.

Note:

During ultrasonic working state, you will hear the “sizzling”

voice ,that means the cleaner running properly.

Stop ultrasonic

and heating

1.Turn the “timer” knob to “OFF”, the machine will stop working,

The timer indicator will light up.

2.Turn the “heater” knob to “OFF”, the heating will stop and

the heating indicator will light up.

Page 10

DIFFERENT WAYS OF CLEANING

GENNRAL CLEANING—use only tap water. Use warm temperature about 50 .℃

ENHANCED CLEANING—add few drops of standard washing up liquid liquid soap, ,

or detergent into water, other non-acidic cleaning agents can also be used.

EXTENSIVE CLEANING—removing tarnish, carbon & rust from non-plated metals, it is

recommended to use specialist cleaning solution in associated using ultrasonic cleaner.

When

finished

use

1.When the cleaning is completed, turn off timer and heating.

Then turn off the power switch in back of the machine

2. Unplug the power cord, open the lid and retrieve the basket

and the items.

3. Empty the tank and clean both the outside and inside of

the machine with clean and dry cloth for next use.

4.Keep the drainage valve closed.(for machines above 6L).

WARNING : Strong acid or alkaline cleaning solution will cause

corrosion, ru st and even pu ncture of tank or machine bo dy. To

overcome this problem, dilute to mild PH solution or request for

tank made of specific grade of stainless steel like SUS304.

SPECIFICATIONS

Model

Tank size

Unit size

Volume

Ultrasonic

power

Ul traso nic

frequency

Heating

power

L×W× H(mm) L×W× H(mm)

(L) (W)

(kHz )

AC-80H

AC-120H

AC-150H

AC-200H

AC-250H

AC-300H

AC-400H

150×140×10 0

240×140×10 0

300×155×15 0

300×240×15 0

330×300×15 0

500×300×15 0

500×300×20 0

190×170×22 0

270×170×24 0

330×180×31 0

330×270×31 0

360×330×31 0

550×330×31 0

550×330×36 0

2

3

6

9

13

20

27

50

100

150

200

300

400

500

40

(W)

100

100

300

300

400

500

500

Heating Setting: 20-80℃ can be adjustable.

Timer Setting:0-30minutes can be adjust able.

3, Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529 mrc@mrclab.com

MRC.2.17

Loading...

Loading...