Page 1

If you have a second decoder, you can use CV program mode to

program its main address CV513 to #5. So the second decoder’s

sub-address will be 5, 6, 7, and 8.

If you have a third decoder, you can program its main address

CV513 to #9. So the third decoder’s sub-address will be 9,10,11,

and 12.

Always program the main address to 1, 5, 9, 13, 17, 21...

Programming output mode CV515, CV516, CV517 and CV518:

Each pair of the outputs can be set to 3 different types of output

mode as following:

1.Steady ON, or Steady OFF, (Latching) for slo-motion, switch

machines or building lights.

2.Momentary ON/OFF for twin-coil type switch machines.

3. Alternating flashing (with variable flash rates), such as for

grade crossing lights.

Example 1:

To set pair A outputs to control a slo-motion switch machine

(latching) or to turn building lights ON or OFF, program CV515 to a

value of either 0 or 128. CV515 is for pair A.

Example 2:

To set pair B output to control a twin coil switch machine momentarily, program CV516 a value from 1 to 127, with 1 as the minimum

turn-on time (0.1 second), and 127 as the maximum turn-on time

(12.7 seconds). Here CV516 is for pair B. The amount of time the

Output is ON is equal to 0.1 times the number you program into the

CV, but it will work for the other 3 outputs as well.

Caution: Balky or difficult to activate turnouts with twin-coil

switch machines (larger scales) you may have to adjust the

input value to a higher number to get the turnout points to

activate properly. Starting at a minimum value of 1, go up one

value at a time until the turnout activates properly. Starting or

going up with too high a value may cause the twin-coil switch

machine to burn out.

Example 3:

To set pair C outputs to alternating flash for a pair of grade crossing lights, program CV517 to a value between 129 to 255. The flash

rate is equal to 0.1 x (N -128), where N is the value programmed

into CV517. For example, when N=129, the flash rate is 0.1 second

[0.1x(129-128)]. When N=133, the flash rate is 0.5 second

[0.1x(133-128)].

Programming on the Main (OPS mode programming)

To program this decoder on the mainline, you need to know its main

address. Treat the accessory decoder as loco decoder and perform

CV program on main. You can only program CV515, CV516, CV517

and CV518 on the main.

Operation

Read your DCC manual to learn how to operate accessory decoders.

Enter your DCC System’s “Accessory Function.” Enter the accessory’s

output sub-address then use function buttons 1 or 2 to turn on or turn off

the accessory.

Operation with MRC Prodigy Advance

Press Accy button. “Accy” will display. Enter the decoder sub-address

and then press Enter. “1 or 2” will display. To turn on the output, press 1.

To turn off the output, press 2.

Routes

To set routes, a grouping of accessories or turnouts that operate at the

same time with one touch of a button, please refer to your DCC System’s

operation manual to utilize this setting. For Prodigy Advance DCC users,

you can visit our website, www.modelrectifier.com, for more information

on routes.

When setting a route into motion by turning it on, make sure the power

supply that is powering your accessories can handle the load generated by the number of accessories being activated at the same time. If

you use DCC to power the twin coil switch machine, the DCC system

may experience short circuit protection due high current surge.

FCC Compliance

This device complies with the part 15 of FCC rules. Operation is subject

to the following two conditions. (1) This device may not cause harmful

interference, and (2) This device must accept any interference received,

including interference that cause undesired operation.

Return Procedure

If it should become necessary to return your decoder, unplug the decoder

and return the decoder only. Please include a clearly printed letter

including your name, address, daytime telephone number, and detailed

description of the problem you are experiencing. Please also include a

$15.00 check for handling and shipping fee. Be certain to return the

decoder only.

Send the decoder to:

Model Rectifier Corporation

Attn: Parts & Service

80 Newfield Avenue

Edison, NJ 08837-3817 U.S.A.

2005 MODEL RECTIFIER CORPORA TION

80 NEWFIELD A VENUE

EDISON NJ 08837-3817

Tel. 732-225-6360

PRINTED IN USA

MRC Stationary

Accessory Decoder

(T otal 3.0 AMP)

Item #0001628

Thank you for purchasing our highly advanced

DCC stationary accessory decoder.

This Decoder is an NMRA compatible accessory decoder.

However, MRC’s Command 2000 and the MRC Prodigy do

not support NMRA accessory decoder protocol. You must use

MRC Prodigy Advance or other DCC systems that support CV

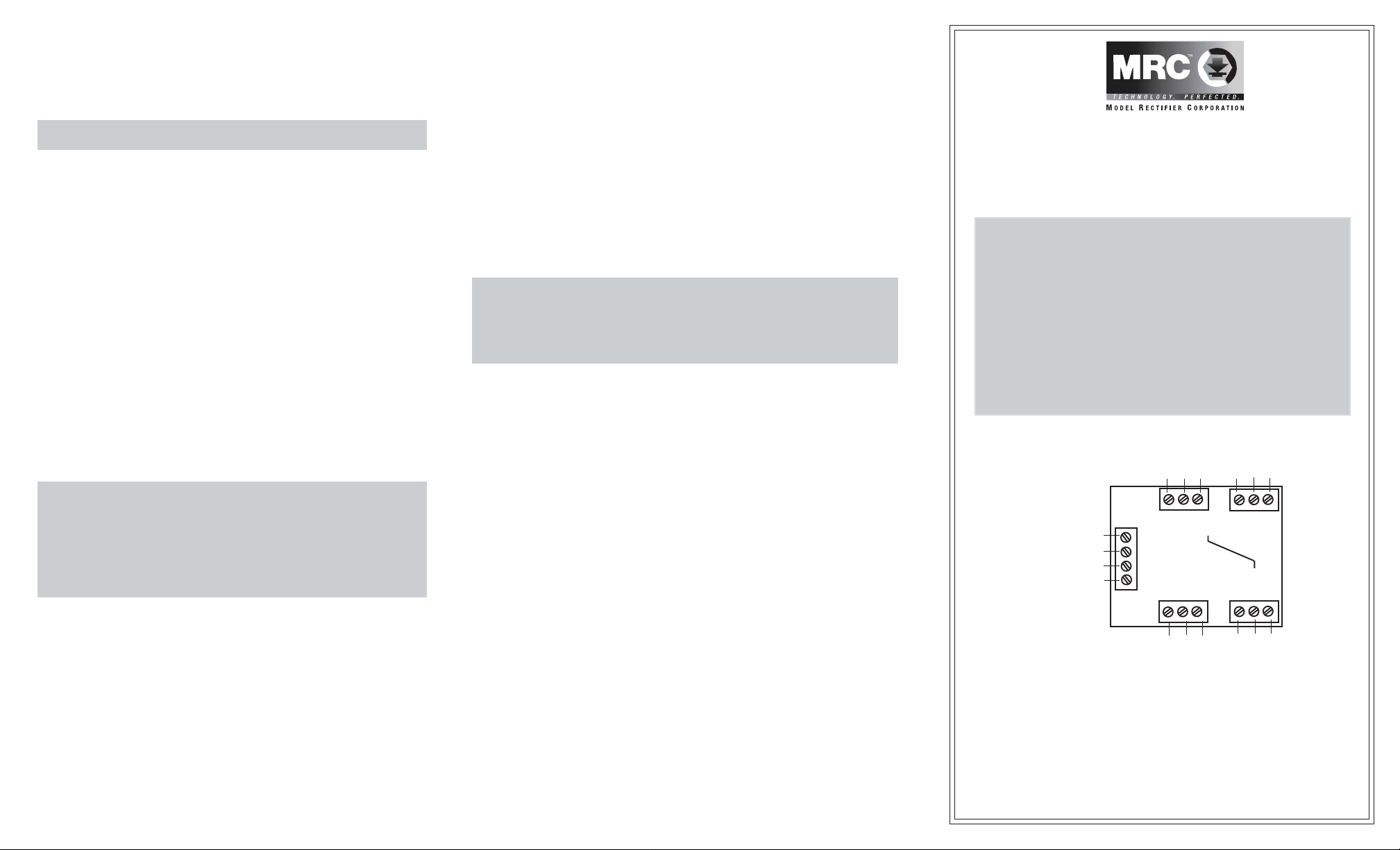

programming and have accessory decoder function capability. The MRC stationary accessory decoder comes with 4 pairs

of outputs. Think of it as 4 decoders in 1, each having its own

sub-address. The pairs are labeled as A, B, C and D (see

Diagram 1A).

(to accessory) (to accessory)

Diagram 1A

Com

output1

output2

(from power supply)

12VAC input

DCC input

(from DCC track)

Each subdecoder has three terminal hookups labeled OUTPUT 1,

COMMON, and OUTPUT 2 (see Diagram 1A). These terminal hookups go to the accessory or switch machine. Do not apply any power

to these terminals. It will damage the decoder.

This decoder gets its power and DCC signal from your DCC command

base or through the track rails. It can also power your accessories from

DCC track power or any external 12-vac power supply.

A

Red wire

C

Com

output1

(to accessory) (to accessory)

output2

Com

output1

B

D

Com

output1

output2

output2

Page 2

It is always better to power your accessories with an external power

supply so your DCC system utilizes its full power to run your trains.

This decoder also rectifies the AC power, so accessories requiring DC

current, such as slo-motion DC switch machines or LEDs, do not need a

separate DC power supply.

Hookup from your DCC system to decoder

There are 4 input terminals on the decoder board (see Diagram 1A).

1.If you do not want the DCC signal to power any accessories, run 2 wires

between your DCC unit or your track rails closest to the decoder, and the

lower 2 input terminals marked “DCC Track” (see Diagram 1A). Then

using an external 12-vac power supply, connect its 2 output wires to the

upper 2 input terminals marked “12-vac.”

The quantity and type of accessories will determine the requirements

of your 12-volt power supply.

2.If you want the DCC signal to power your accessories, run 2 wires

between your DCC unit or your track rails closest to the decoder, and

the lower 2 input terminals, and then jump them from the two lower

input terminals to the upper two input terminals (see Diagram 1B).

Remember, if you use this method to power your accessories, you

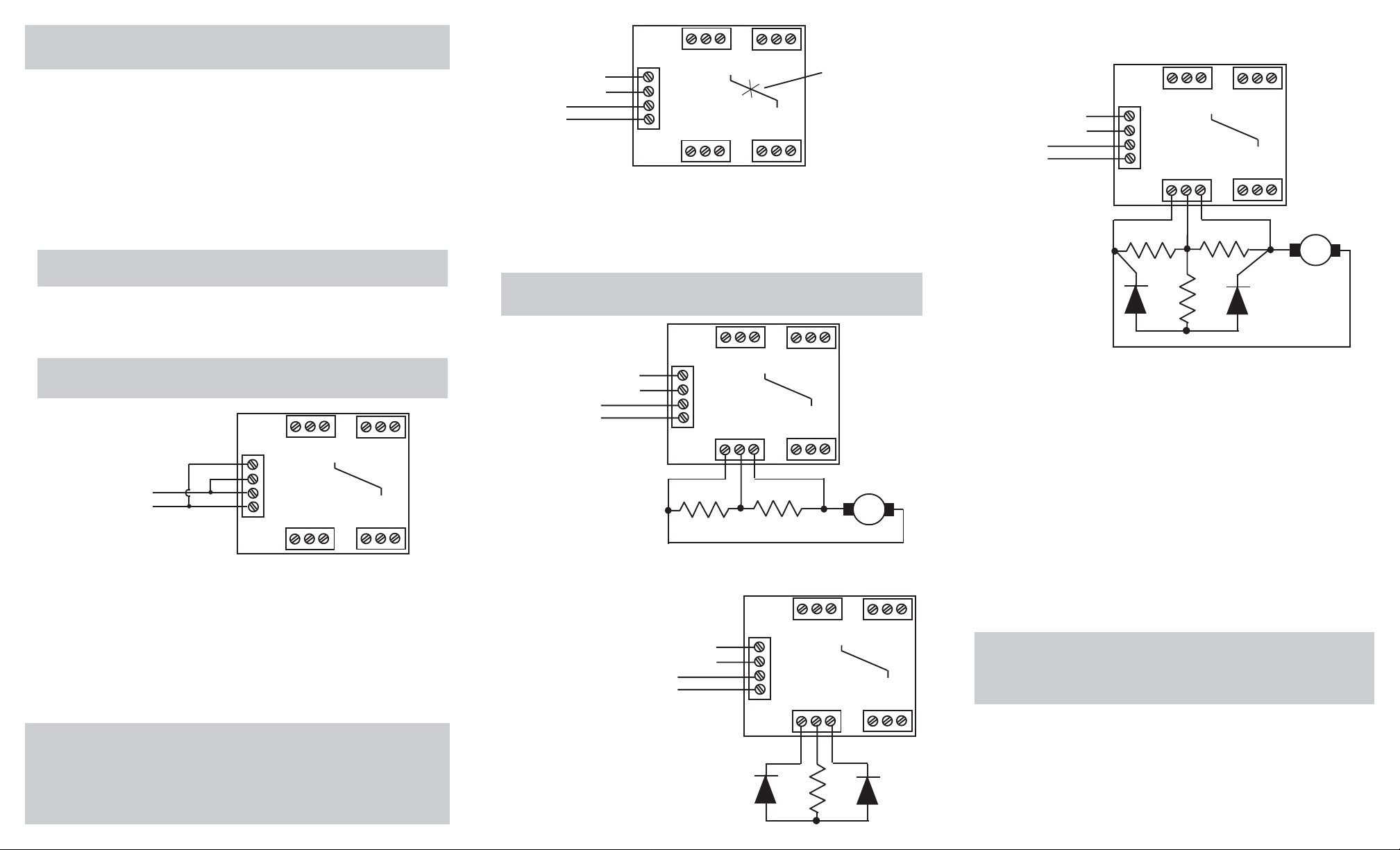

will have less power to operate your trains. (Diagram 1B)

Diagram 1B

B

D

From DCC track

A

Red wire

C

Hooking up your accessory decoder to twin coil (AC) switch

machines

Your accessory decoder comes from the factory pre-programmed to

operate in latching mode, “Constant On.” However, twin coil switch

machines use a momentary pulse to activate them.

If left in the “Constant On” output, the decoder will burn out the switch

machines. Please reprogram the accessory decoder to operate the twincoil switch machines prior to hooking them up to the accessory decoder.

See section on programming the decoder.

If you are going to use the accessory decoder solely for twin-coil switch

machines, cutting the red wire will automatically set the decoder for use

of this type of switch machine. All you need to program is its program

address. See section on programming and Diagram 2. Twin-coil switch

machine has three terminals or wires. Usually the middle one is common. Make sure the common wire is connected to the Com terminal.

Diagram 2

A

C

B

D

Red wire

Cut this red wire if

the decoder is used

only for twin coil

switch machine

B

D

Slo-motion

switch machine

A

Red wire

A

From 12V power supply

From DCC track

Red wire

C

Hooking up your accessory decoder to a slo-motion switch machine

(DC) or signal LEDs (DC)

Your accessory decoder rectifies the AC input so an auxiliary DC power

supply is not needed, just an AC power supply can be used for DC

accessories. Follow Diagram 3 for each pair of the four outputs (A-B-C-D).

The decoder is shipped with four pieces of 300-ohm resistors for use

with slo-motion switch machines or signal LEDs.

Diagram 3

From 12V power supply

From DCC track

Hooking up LEDs only

Diagram 4

From 12V power supply

From DCC track

C

Use the supplied resistors to hook up

signal LEDs to the four pairs of

outputs (A-B-C-D) of your accessory

decoders.

LED1 LED2

M

B

D

Using LEDs and slo-motion switch machine from same decoder

pairs of output (A-B-C-D) (Diagram 5)

Diagram 5

B

D

Slo-motion

switch machine

From 12V power supply

From DCC track

A

Red wire

C

M

LED1

Programming the decoder

This decoder has the following CVs:

CV513 – main address that is a 2 digit (1-127) address

CV515 – The output mode of Pair A (subdecoder A)

CV516 – The output mode of Pair B (subdecoder B)

CV517 – The output mode of Pair C (subdecoder C)

CV518 – The output mode of Pair D (subdecoder D)

If your DCC system cannot program CV513 to CV518, you can use

CV1 to CV6 to program the decoder on the program track. The CV

mapping follows:

CV1 = CV513 = main address

CV3 = CV515 = pair A output mode

CV4 = CV516 = pair B output mode

CV5 = CV517 = pair C output mode

CV6 = CV518 = pair D output mode

Programming

During the programming mode, you cannot program reverse polarity

into the accessory decoder. You can only reverse the polarity of a

specific output when you program a route for your accessory

decoders on your DCC system.

Programming address CV513:

The main address can only be programmed on the program track.

This main address, once programmed, automatically assigns the

four outputs their sub-addresses, so you need only to program one

address to the decoder. Your decoder’s main address is preprogrammed to #1 at the factory. So the sub-addresses are 1, 2, 3

and 4.

LED2

Loading...

Loading...