Page 1

Voltage Regulator

TAPCON® 260

Operating Instructions

2374092/04 EN . Bank Parallel Operation with IEC 61850

Page 2

© All rights reserved by Maschinenfabrik Reinhausen

Dissemination and reproduction of this document and use and disclosure of its content are strictly prohibited

unless expressly permitted.

Infringements will result in liability for compensation. All rights reserved in the event of the granting of patents,

utility models or designs.

The product may have been altered since this document was published.

We reserve the right to change the technical data, design and scope of supply.

Generally the information provided and agreements made when processing the individual quotations and orders

are binding.

The original operating instructions were written in German.

Page 3

Table of contents

Table of contents

1 Introduction ......................................................................................................................... 9

1.1 Manufacturer ....................................................................................................................................... 9

1.2 Subject to change without notice......................................................................................................... 9

1.3 Completeness...................................................................................................................................... 9

1.4 Supporting documents......................................................................................................................... 9

1.5 Safekeeping....................................................................................................................................... 10

1.6 Notation conventions ......................................................................................................................... 10

1.6.1 Hazard communication system ........................................................................................................................... 10

1.6.2 Information system .............................................................................................................................................. 11

1.6.3 Typographic conventions .................................................................................................................................... 11

2 Safety ................................................................................................................................. 12

2.1 General safety information ................................................................................................................ 12

2.2 Appropriate use ................................................................................................................................. 12

2.3 Inappropriate use............................................................................................................................... 12

2.4 Personnel qualification ...................................................................................................................... 13

2.5 Operator's duty of care ...................................................................................................................... 13

3 Product description .......................................................................................................... 14

3.1 Scope of delivery ............................................................................................................................... 14

3.2 Function description of the voltage regulation ................................................................................... 14

3.3 Performance features ........................................................................................................................ 15

3.4 Operating modes ............................................................................................................................... 15

3.5 Hardware ........................................................................................................................................... 16

3.5.1 Name plate .......................................................................................................................................................... 17

3.5.2 Operating controls ............................................................................................................................................... 17

3.5.3 Display elements ................................................................................................................................................. 18

3.5.4 Serial interface .................................................................................................................................................... 21

3.5.5 Assemblies .......................................................................................................................................................... 21

4 Mounting ............................................................................................................................ 30

4.1 Preparation ........................................................................................................................................ 30

4.2 Mounting device ................................................................................................................................ 30

4.3 Connecting device ............................................................................................................................. 31

4.3.1 Cable recommendation ....................................................................................................................................... 31

Maschinenfabrik Reinhausen 2014 32374092/04 EN TAPCON® 260

Page 4

Table of contents

4.3.2 Information about laying fiber-optic cable............................................................................................................ 33

4.3.3 Electromagnetic compatibility.............................................................................................................................. 33

4.3.4 Connecting cables to the system periphery ........................................................................................................ 37

4.3.5 Wiring device....................................................................................................................................................... 37

4.3.6 Checking functional reliability .............................................................................................................................. 38

5 Commissioning ................................................................................................................. 39

5.1 Setting the display contrast ............................................................................................................... 39

5.2 Setting parameters ............................................................................................................................ 39

5.2.1 Setting the language ........................................................................................................................................... 40

5.2.2 Setting date and time .......................................................................................................................................... 40

5.2.3 Setting further parameters................................................................................................................................... 41

5.3 Function tests .................................................................................................................................... 42

5.3.1 Checking control functions .................................................................................................................................. 43

5.3.2 Checking additional functions.............................................................................................................................. 44

5.3.3 Checking parallel operation of several banks of transformers ............................................................................ 47

6 Functions and settings..................................................................................................... 52

6.1 Key lock ............................................................................................................................................. 52

6.2 Carrying out tap-change operation manually..................................................................................... 52

6.3 General.............................................................................................................................................. 52

6.3.1 Setting device ID ................................................................................................................................................. 53

6.3.2 Setting the baud rate ........................................................................................................................................... 53

6.3.3 Setting the voltage display kV/V.......................................................................................................................... 54

6.3.4 Setting current display unit .................................................................................................................................. 54

6.3.5 Setting the switching pulse time .......................................................................................................................... 54

6.3.6 Configuring control inputs IO1-X1:33/31 ............................................................................................................. 56

6.3.7 Configuring output relays IO1-X1:25/26 and IO1-X1:23/24 ................................................................................ 57

6.3.8 Dimming display .................................................................................................................................................. 58

6.3.9 Setting motor runtime monitoring ........................................................................................................................ 59

6.3.10 Swapping tapping direction ................................................................................................................................. 61

6.4 NORMset........................................................................................................................................... 61

6.5 Control parameters............................................................................................................................ 63

6.5.1 Setting desired value 1...3................................................................................................................................... 65

6.5.2 Bandwidth............................................................................................................................................................ 66

6.5.3 Setting delay time T1........................................................................................................................................... 66

6.5.4 Setting control response T1 ................................................................................................................................ 67

Maschinenfabrik Reinhausen 20144 2374092/04 ENTAPCON® 260

Page 5

Table of contents

6.5.5 Setting delay time T2........................................................................................................................................... 68

6.6 Limit values........................................................................................................................................ 68

6.6.1 Activating/deactivating absolute or relative limit values ...................................................................................... 69

6.6.2 Setting undervoltage monitoring V< .................................................................................................................... 69

6.6.3 Setting overvoltage monitoring V> ...................................................................................................................... 72

6.6.4 Setting overcurrent monitoring I> ........................................................................................................................ 74

6.6.5 Activating/deactivating function monitoring ......................................................................................................... 75

6.7 Compensation ................................................................................................................................... 75

6.7.1 R&X compensation.............................................................................................................................................. 75

6.7.2 Z compensation................................................................................................................................................... 78

6.8 Cross-monitoring ............................................................................................................................... 79

6.8.1 Setting desired value for regulator 2 ................................................................................................................... 80

6.8.2 Setting undervoltage limit value V< for regulator 2.............................................................................................. 81

6.8.3 Setting overvoltage limit value V> for regulator 2................................................................................................ 82

6.8.4 Setting delay time for error message .................................................................................................................. 83

6.8.5 Setting transformer for regulator 2 ...................................................................................................................... 83

6.9 Transformer data ............................................................................................................................... 84

6.9.1 Setting the primary transformer voltage .............................................................................................................. 85

6.9.2 Setting the secondary transformer voltage.......................................................................................................... 85

6.9.3 Setting primary transformer current..................................................................................................................... 86

6.9.4 Setting the current transformer connection ......................................................................................................... 87

6.9.5 Setting the phase difference for the current transformer/voltage transformer..................................................... 87

6.10 Parallel operation of several banks of transformers .......................................................................... 91

6.10.1 Assigning CAN bus address................................................................................................................................ 91

6.10.2 Selecting parallel operation method .................................................................................................................... 92

6.10.3 Selecting parallel operation control ..................................................................................................................... 95

6.10.4 Setting delay time for parallel operation error messages .................................................................................... 95

6.10.5 Deactivating parallel operation ............................................................................................................................ 96

6.11 Analog tap position capture (optional) ............................................................................................... 96

6.11.1 Setting lower limit value....................................................................................................................................... 96

6.11.2 Setting upper limit value ...................................................................................................................................... 97

6.12 LED selection .................................................................................................................................... 98

6.13 Measuring transducer function ........................................................................................................ 100

6.13.1 Linking measured value with output .................................................................................................................. 100

6.13.2 Assigning minimum physical parameter............................................................................................................ 100

6.13.3 Assigning maximum physical parameter........................................................................................................... 101

Maschinenfabrik Reinhausen 2014 52374092/04 EN TAPCON® 260

Page 6

Table of contents

6.13.4 Assigning minimum absolute value ................................................................................................................... 101

6.13.5 Assigning maximum absolute value .................................................................................................................. 102

6.14 Memory (optional)............................................................................................................................ 102

6.14.1 Setting undervoltage threshold.......................................................................................................................... 103

6.14.2 Setting overvoltage threshold............................................................................................................................ 104

6.14.3 Setting time difference of average value interval .............................................................................................. 105

6.14.4 Setting event memory size ................................................................................................................................ 106

6.14.5 Time plotter ....................................................................................................................................................... 109

6.15 Communication interface SID .......................................................................................................... 115

6.15.1 Assigning a network mask................................................................................................................................. 115

6.15.2 Assigning network address ............................................................................................................................... 115

6.15.3 Entering the time server address ...................................................................................................................... 116

6.15.4 Entering gateway............................................................................................................................................... 116

6.15.5 Entering IED name ............................................................................................................................................ 117

6.16 Communication interface CIC2 (optional)........................................................................................ 117

6.16.1 Selecting the communication port ..................................................................................................................... 117

6.16.2 Selecting communication baud rate .................................................................................................................. 118

6.16.3 Assigning network address ............................................................................................................................... 118

6.16.4 Assigning the TCP port ..................................................................................................................................... 119

6.16.5 Setting the transmission delay time for the RS485 interface............................................................................. 119

6.17 Displaying information about device ................................................................................................ 120

6.17.1 Displaying the info screen ................................................................................................................................. 120

6.17.2 Displaying measured values ............................................................................................................................. 120

6.17.3 Carrying out LED test ........................................................................................................................................ 121

6.17.4 Displaying input/output status ........................................................................................................................... 121

6.17.5 Displaying UC card status ................................................................................................................................. 122

6.17.6 Resetting parameters ........................................................................................................................................ 123

6.17.7 Displaying real-time clock.................................................................................................................................. 123

6.17.8 Displaying parallel operation ............................................................................................................................. 123

6.17.9 Displaying data on CAN bus ............................................................................................................................. 123

6.17.10 Displaying measured value memory ................................................................................................................. 125

6.17.11 Displaying peak memory ................................................................................................................................... 125

6.17.12 Displaying CIC card SCADA information .......................................................................................................... 126

6.17.13 Displaying upcoming messages........................................................................................................................ 126

7 Control system protocol................................................................................................. 127

7.1 Protocol specification....................................................................................................................... 127

Maschinenfabrik Reinhausen 20146 2374092/04 ENTAPCON® 260

Page 7

Table of contents

7.1.1 Downloading ICD file......................................................................................................................................... 127

7.2 Data points ...................................................................................................................................... 128

7.2.1 LPHD - Physical device..................................................................................................................................... 128

7.2.2 LLN0 - Logical node .......................................................................................................................................... 129

7.2.3 ATCC1 - Automatic tap changer controller........................................................................................................ 129

7.2.4 YLTC1 ............................................................................................................................................................... 131

7.2.5 YLTC2 ............................................................................................................................................................... 132

7.2.6 YLTC3 ............................................................................................................................................................... 132

7.2.7 GGIO1 - Generic process I/O............................................................................................................................ 133

7.2.8 GGIO2 - Generic process I/O............................................................................................................................ 134

7.2.9 GGIO3 - Generic process I/O............................................................................................................................ 135

7.2.10 GGIO4 - Generic process I/O............................................................................................................................ 135

7.2.11 GGIO7 - Generic process I/O............................................................................................................................ 136

8 Maintenance and care..................................................................................................... 138

9 Fault elimination.............................................................................................................. 139

9.1 General faults .................................................................................................................................. 139

9.2 No regulation in AUTO mode .......................................................................................................... 139

9.3 Man-machine interface .................................................................................................................... 140

9.4 Incorrect measured values .............................................................................................................. 140

9.5 Parallel operation faults ................................................................................................................... 141

9.6 Tap position capture incorrect ......................................................................................................... 142

9.7 Other faults ...................................................................................................................................... 142

10 Messages......................................................................................................................... 144

10.1 Signal inputs .................................................................................................................................... 144

10.2 Signal outputs .................................................................................................................................. 144

10.3 Event messages .............................................................................................................................. 145

11 Disposal ........................................................................................................................... 147

12 Overview of parameters ................................................................................................. 148

13 Technical data ................................................................................................................. 152

13.1 Indicator elements ........................................................................................................................... 152

13.2 Power supply ................................................................................................................................... 152

13.3 Voltage measurement and current measurement ........................................................................... 154

13.4 Digital inputs and outputs ................................................................................................................ 155

Maschinenfabrik Reinhausen 2014 72374092/04 EN TAPCON® 260

Page 8

Table of contents

13.5 Analog inputs and outputs ............................................................................................................... 156

13.6 Control voltage supply (optional) ..................................................................................................... 156

13.7 Central processing unit .................................................................................................................... 158

13.8 System networking .......................................................................................................................... 158

13.9 Dimensions and weight ................................................................................................................... 159

13.10 Ambient conditions .......................................................................................................................... 161

13.11 Tests................................................................................................................................................ 161

13.11.1 Electrical safety ................................................................................................................................................. 161

13.11.2 EMC tests.......................................................................................................................................................... 161

13.11.3 Environmental durability tests ........................................................................................................................... 161

Glossary........................................................................................................................... 163

List of key words............................................................................................................. 164

Maschinenfabrik Reinhausen 20148 2374092/04 ENTAPCON® 260

Page 9

1 Introduction

Introduction

1

This technical file contains detailed descriptions on the safe and proper installation, connection, commissioning and monitoring of the product.

It also includes safety instructions and general information about the product.

This technical file is intended solely for specially trained and authorized personnel.

Manufacturer

1.1

The product is manufactured by:

Maschinenfabrik Reinhausen GmbH

Falkensteinstraße 8

93059 Regensburg, Germany

Tel.: (+49) 9 41/40 90-0

Fax: (+49) 9 41/40 90-7001

E-mail: sales@reinhausen.com

Further information on the product and copies of this technical file are available from this address if required.

Subject to change without notice

1.2

The information contained in this technical file comprises the technical specifications approved at the time of printing. Significant modifications will be included in a new edition of the technical file.

The document number and version number of this technical file are shown in

the footer.

Completeness

1.3

This technical file is incomplete without the supporting documentation.

Supporting documents

1.4

The following documents apply to this product:

▪ Operating instructions

▪ Connection diagrams

Also observe generally valid legislation, standards, guidelines and specifications on accident prevention and environmental protection in the respective

country of use.

Maschinenfabrik Reinhausen 2014 92374092/04 EN TAPCON® 260

Page 10

1 Introduction

Safekeeping

1.5

This technical file and all supporting documents must be kept ready at hand

and accessible for future use at all times.

Notation conventions

1.6

This section contains an overview of the symbols and textual emphasis

used.

WARNING

1.6.1

1.6.1.1

1.6.1.2

Hazard communication system

Warnings in this technical file are displayed as follows.

Warning relating to section

Warnings relating to sections refer to entire chapters or sections, sub-sections or several paragraphs within this technical file. Warnings relating to

sections use the following format:

Type and source of danger

Consequences

► Action

► Action

Embedded warning information

Embedded warnings refer to a particular part within a section. These warnings apply to smaller units of information than the warnings relating to sections. Embedded warnings use the following format:

DANGER! Instruction for avoiding a dangerous situation.

1.6.1.3

Signal words and pictograms

The following signal words are used:

Signal

word

DANGER Indicates a hazardous situation which, if not avoided, will

WARNING Indicates a hazardous situation which, if not avoided, could

CAUTION Indicates a hazardous situation which, if not avoided, could

NOTICE Indicates measures to be taken to prevent damage to

Table 1: Signal words in warning notices

Meaning

result in death or serious injury.

result in death or serious injury.

result in injury.

property.

Maschinenfabrik Reinhausen 201410 2374092/04 ENTAPCON® 260

Page 11

1 Introduction

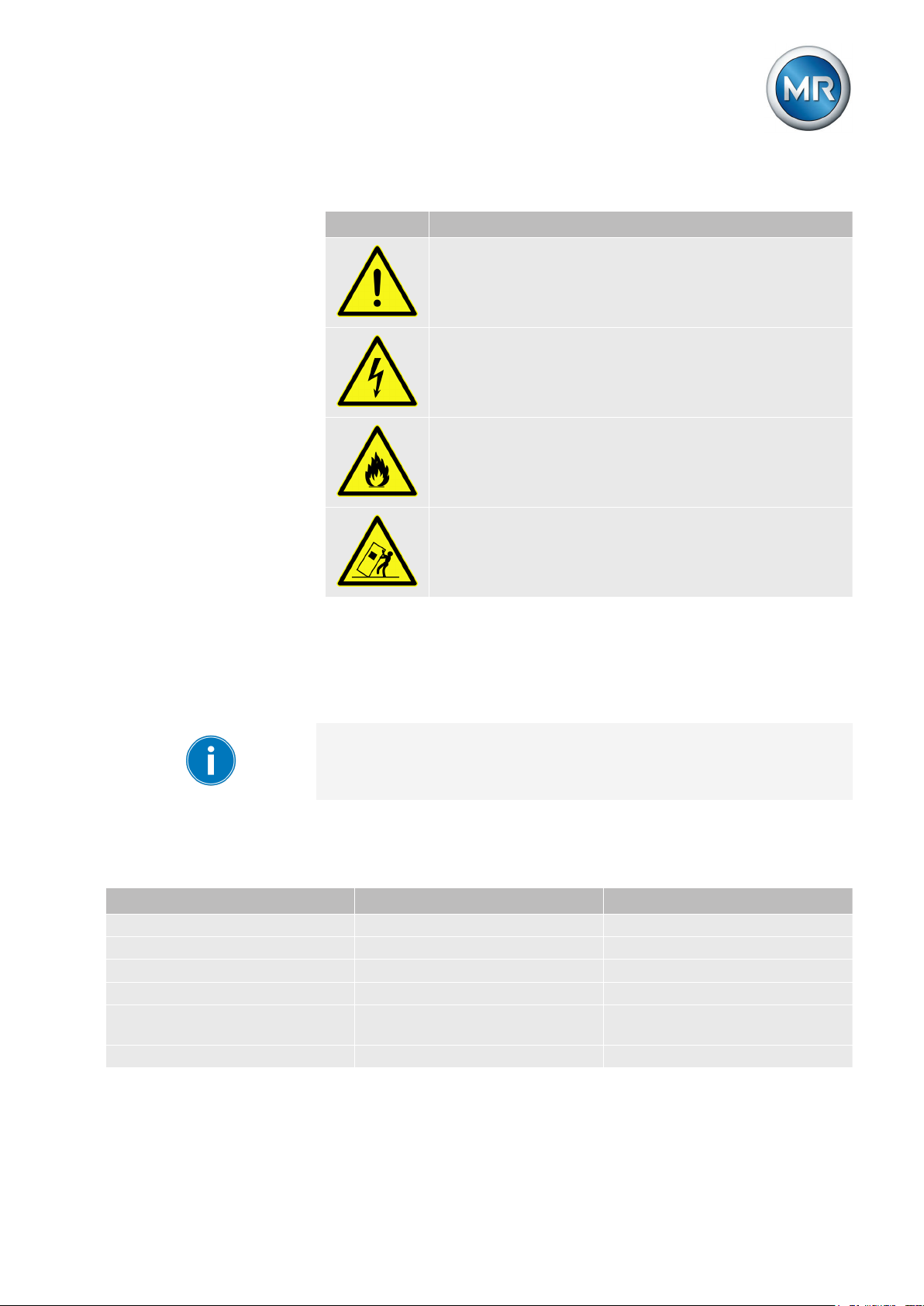

Pictograms warn of dangers:

Pictogram Meaning

Warning of a danger point

Warning of dangerous electrical voltage

Warning of combustible substances

Warning of danger of tipping

Table 2: Pictograms used in warning notices

1.6.2

1.6.3

Typographic convention Purpose Example

UPPERCASE Operating controls, switches ON/OFF

[Brackets] PC keyboard [Ctrl] + [Alt]

Bold Software operating controls Press Continue button

…>…>… Menu paths Parameter > Control parameter

Italics System messages, error mes-

[► Number of pages]. Cross reference [► 41].

Table 3: Typographic conventions

Information system

Information is designed to simplify and improve understanding of particular

procedures. In this technical file it is laid out as follows:

Important information.

Typographic conventions

The following typographic conventions are used in this technical file:

Function monitoring alarm trig-

sages, signals

gered

Maschinenfabrik Reinhausen 2014 112374092/04 EN TAPCON® 260

Page 12

Safety

2

General safety information

2.1

The technical file contains detailed descriptions on the safe and proper installation, connection, commissioning and monitoring of the product.

▪ Read this technical file through carefully to familiarize yourself with the

product.

▪ Particular attention should be paid to the information given in this chap-

ter.

Appropriate use

2.2

The product and associated equipment and special tools supplied with it

comply with the relevant legislation, regulations and standards, particularly

health and safety requirements, applicable at the time of delivery.

If used as intended and in compliance with the specified requirements and

conditions in this technical file as well as the warning notices in this technical

file and attached to the product, then the product does not present any hazards to people, property or the environment. This applies throughout the

product's entire life, from delivery through installation and operation to disassembly and disposal.

2 Safety

The operational quality assurance system ensures a consistently high quality

standard, particularly in regard to the observance of health and safety requirements.

The following is considered appropriate use

▪ The product must be operated in accordance with this technical file and

the agreed delivery conditions and technical data

▪ The equipment and special tools supplied must be used solely for the in-

tended purpose and in accordance with the specifications of this technical file

Inappropriate use

2.3

Use is considered to be inappropriate if the product is used other than as described in the Appropriate use section. Please also note the following:

▪ Risk of explosion and fire from highly flammable or explosive gases, va-

pors, or dusts. Do not operate product in areas at risk of explosion.

▪ Unauthorized or inappropriate changes to the product may lead to per-

sonal injury, material damage, and operational faults. Only modify product following discussion with Maschinenfabrik Reinhausen GmbH.

Maschinenfabrik Reinhausen 201412 2374092/04 ENTAPCON® 260

Page 13

2 Safety

Personnel qualification

2.4

The product is designed solely for use in electrical energy systems and facilities operated by appropriately trained staff. This staff comprises people who

are familiar with the installation, assembly, commissioning and operation of

such products.

Operator's duty of care

2.5

To prevent accidents, disruptions and damage as well as unacceptable adverse effects on the environment, those responsible for transport, installation, operation, maintenance and disposal of the product or parts of the product must ensure the following:

▪ All warning and hazard notices are complied with.

▪ Personnel are instructed regularly in all relevant aspects of operational

safety, the operating instructions and particularly the safety instructions

contained therein.

▪ Regulations and operating instructions for safe working as well as the

relevant instructions for staff procedures in the case of accidents and

fires are kept on hand at all times and are displayed in the workplace

where applicable.

▪ The product is only used when in a sound operational condition and

safety equipment in particular is checked regularly for operational reliability.

▪ Only replacement parts, lubricants and auxiliary materials which are au-

thorized by the manufacturer are used.

▪ The specified operating conditions and requirements of the installation

location are complied with.

▪ All necessary devices and personal protective equipment for the specific

activity are made available.

▪ The prescribed maintenance intervals and the relevant regulations are

complied with.

▪ Installation, electrical connection and commissioning of the product may

only be carried out by qualified and trained personnel in accordance

with this technical file.

▪ The operator must ensure appropriate use of the product.

Maschinenfabrik Reinhausen 2014 132374092/04 EN TAPCON® 260

Page 14

3 Product description

Product description

3

This chapter contains an overview of the design and function of the product.

Scope of delivery

3.1

The following items are included in the delivery:

▪ TAPCON® 260

▪ CD MR-Suite (contains the TAPCON®-trol program)

▪ Technical files

▪ Serial cable RS232

▪ USB adapter with installation CD (optional)

Please note the following:

▪ Check the shipment for completeness on the basis of the shipping docu-

ments.

▪ Store the parts in a dry place until installation.

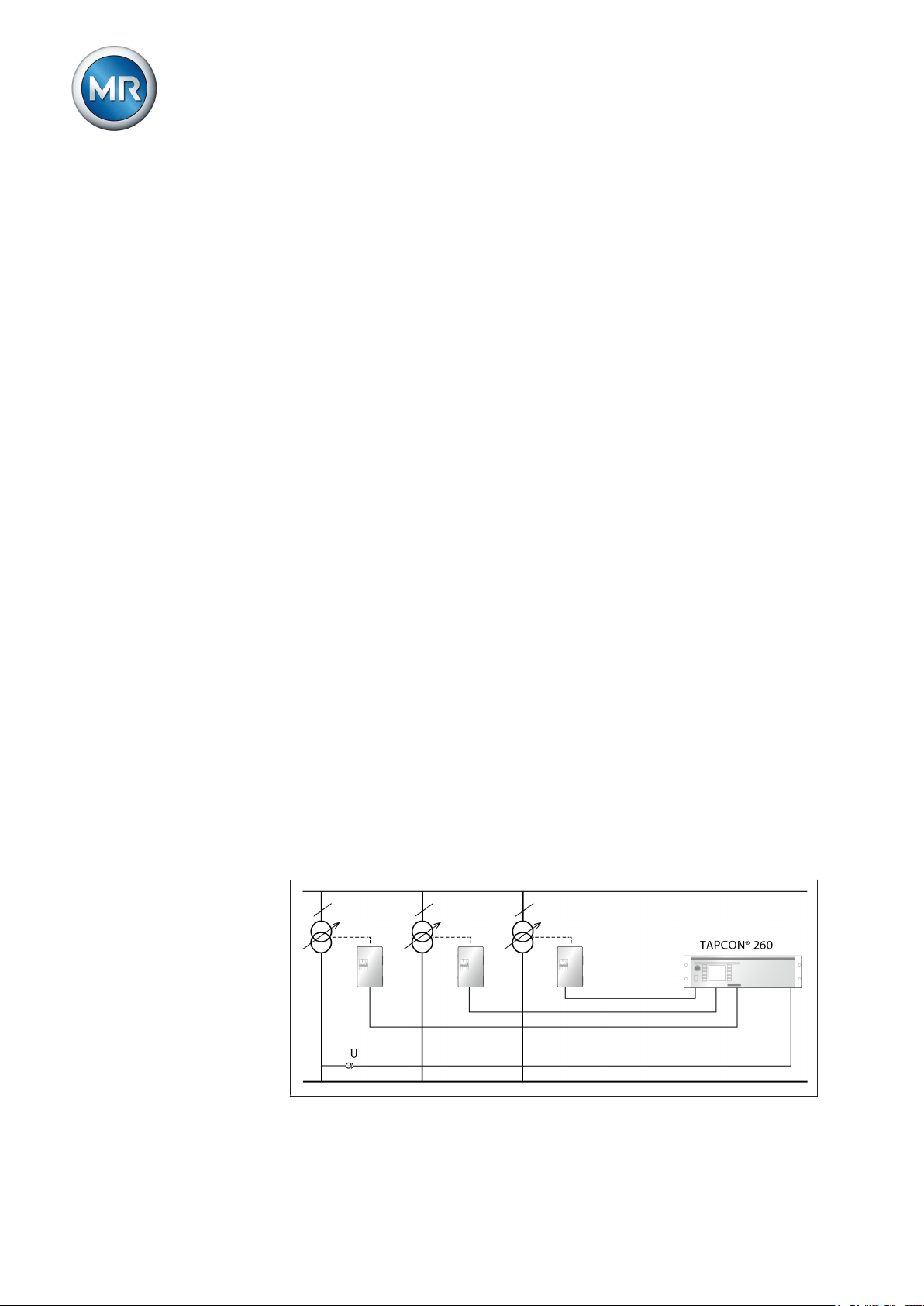

Function description of the voltage regulation

3.2

The TAPCON® 260 serves to keep constant the output voltage of a bank of

transformers with on-load tap-changers. The bank of transformers consists

of 3 single-phase transformers, each with an on-load tap-changer and motor-drive unit.

The TAPCON® 260 compares the measured voltage of the bank of transformers (U

tween U

) with a defined reference voltage (U

actual

actual

and U

is the control deviation (dU).

desired

). The difference be-

desired

The TAPCON® 260 parameters can be optimally adjusted to the line voltage

response to achieve a balanced control response with a small number of

tap-change operations by the on-load tap-changer.

The following diagram shows an overview of voltage regulation.

Figure 1: Overview of voltage regulation of a bank of transformers

Maschinenfabrik Reinhausen 201414 2374092/04 ENTAPCON® 260

Page 15

3 Product description

Performance features

3.3

The TAPCON® 260 is responsible for controlling tapped transformers in a

bank of transformers.

Apart from control tasks, the TAPCON® 260 provides additional functions

such as:

▪ Integrated protective functions:

– Undervoltage blocking and overvoltage blocking

– Overvoltage detection with high-speed return

▪ Compensation for voltage drops on the line (line drop compensation)

▪ Compensation for voltage fluctuations in the meshed grid (Z compensa-

tion)

▪ Digital inputs and outputs can be individually programmed on-site by the

user

▪ Additional indicators using LEDs outside the display

▪ Display of all measured values such as voltage, current, active power,

apparent power or reactive power, power factor (cos φ)

▪ Selection of 3 different desired values

▪ When ordering you can choose between tap position capture:

– using analog signal 4…20 mA

– using analog signal via resistor contact series

– using digital signal via BCD code

▪ Parallel operation of up to 16 banks of transformers in 2 groups using

the following methods:

– Master/Follower

– Circulating reactive current minimization

Operating modes

3.4

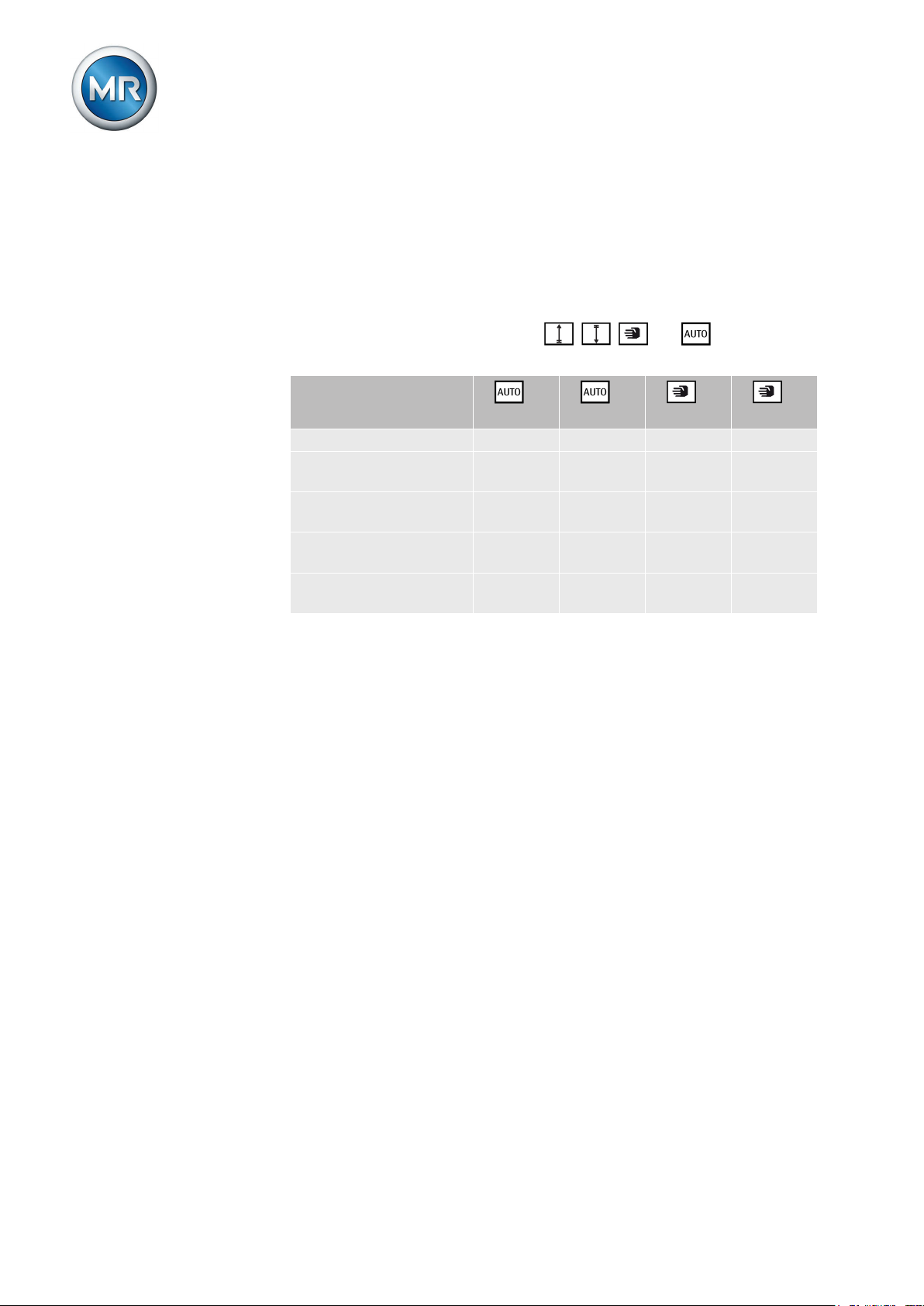

The device can be operated in the following operating modes:

Auto mode (AUTO)

In auto mode, the voltage is automatically controlled in accordance with the

set parameters. You cannot change further device settings in auto mode.

There is no active management by a higher level control system in this operating mode.

Manual mode (MANUAL)

In manual mode, there is no automatic control. The motor-drive unit can be

controlled via the device's operating panel. You can change the device settings.

Maschinenfabrik Reinhausen 2014 152374092/04 EN TAPCON® 260

Page 16

3 Product description

Local mode (LOCAL)

There is no active management by a superordinate control system in this operating mode.

Remote mode (REMOTE)

In remote mode, you can perform commands using an external control level.

In this case, manual operation of the , , and keys is disa-

bled.

Automatic regulation Yes Yes No No

Tap-change operation

using operating controls

Tap-change operation

using inputs

Tap-change operation

using SCADA*

Value adjustment using

SCADA*

Table 4: Overview of operating modes

*) Optional when connecting TAPCON® to a control system (SCADA)

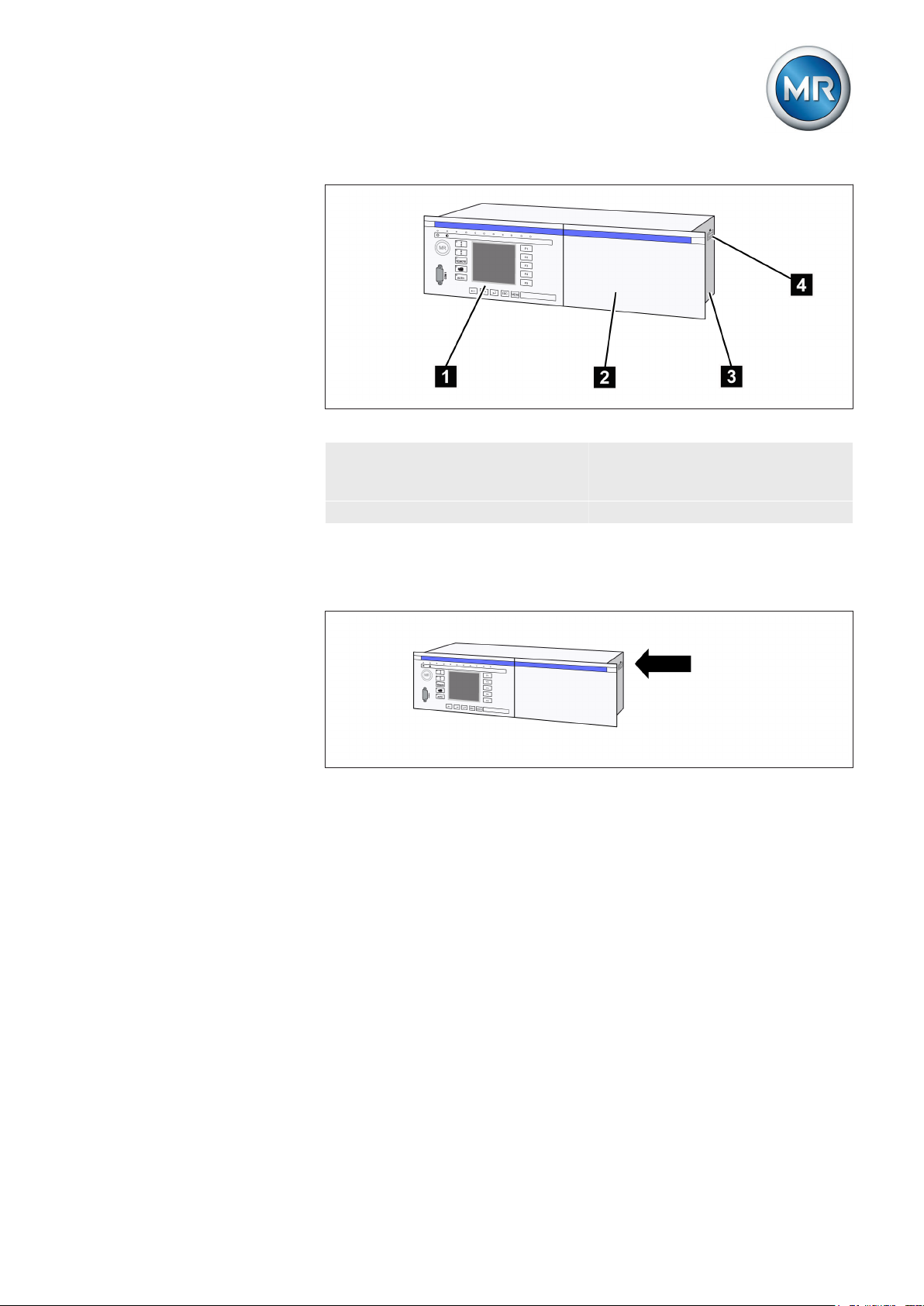

Hardware

3.5

The individual assemblies are fitted in a standardized 19-inch plug-in housing. The front panels of the assemblies are secured to the plug-in housing at

the top and bottom. An IEC 60603-2 plug connector provides the electrical

connection.

The assemblies are connected to one another via a data bus and direct current (DC) supply. This allows for an upgrade with additional plug-in modules

and extension cards at a later date.

+

LOCAL +REMOTE +LOCAL +REMOTE

No No Yes No

No No No Yes

No No No Yes

No Yes No Yes

Maschinenfabrik Reinhausen 201416 2374092/04 ENTAPCON® 260

Page 17

3 Product description

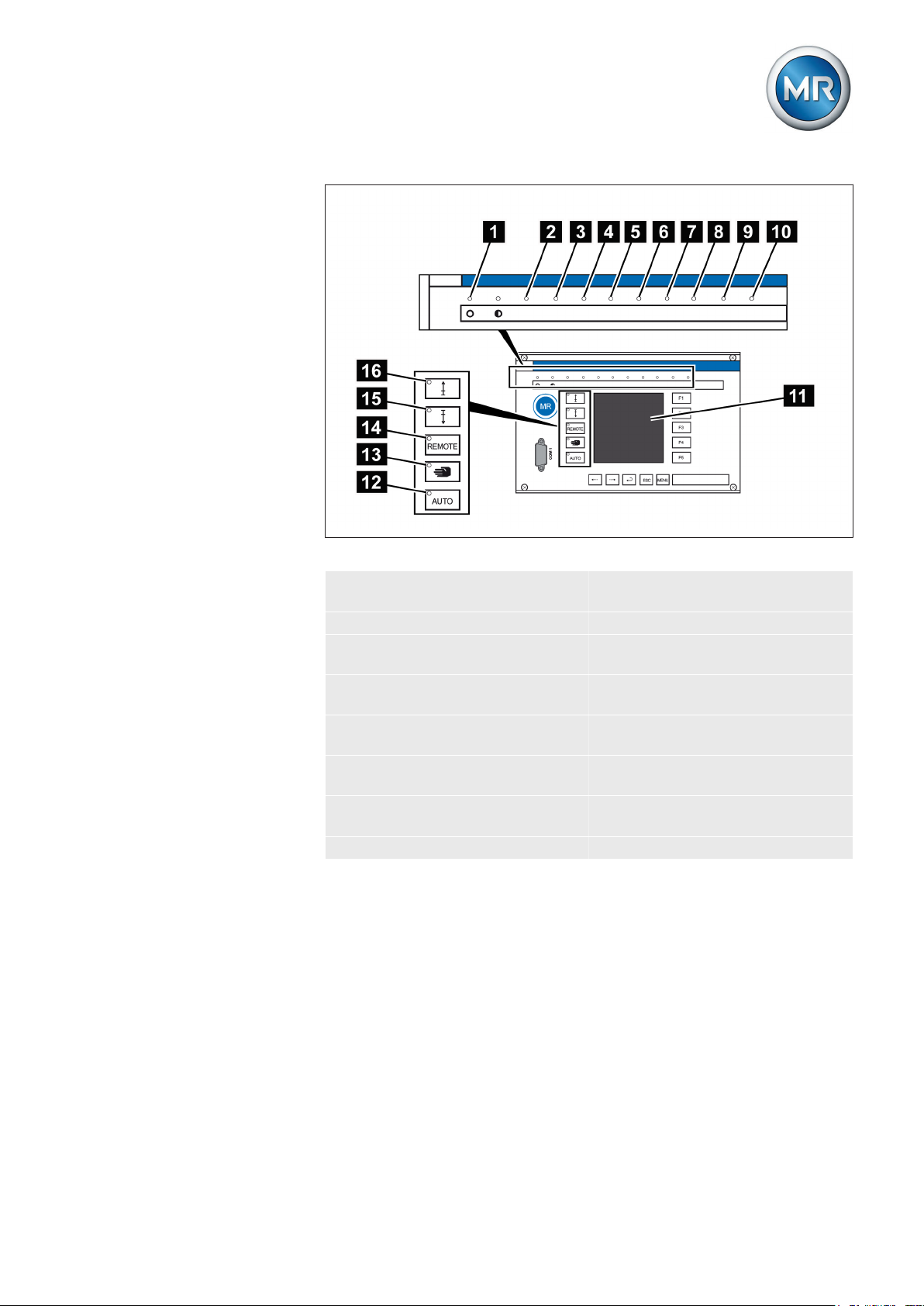

Figure 2: Front view

3.5.1

3.5.2

1 Operating panel with display

and LEDs

2 Rack for optional expansions 4 Name plate

3 19-inch plug-in housing (in ac-

cordance with DIN 41494 Part

5)

Name plate

The name plate is on the outside of the device:

Figure 3: Name plate

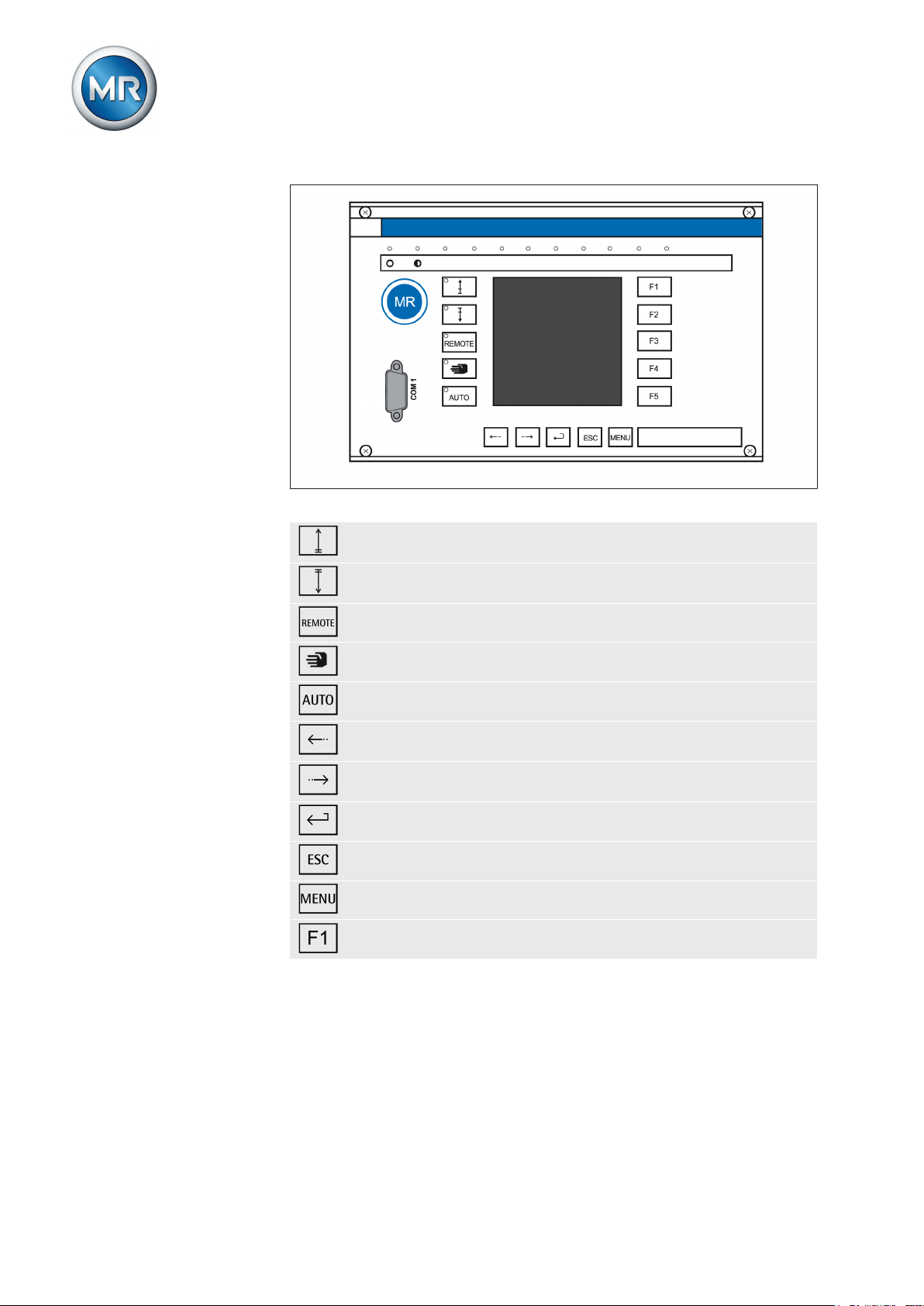

Operating controls

The device has 15 pushbuttons. The illustration below is an overview of all

the device's operating controls .

Maschinenfabrik Reinhausen 2014 172374092/04 EN TAPCON® 260

Page 18

Figure 4: Operating controls

RAISE key: Sends control command for raise tap-change to the

motor-drive unit in manual mode. See also [► 52].

LOWER key: Sends control command for lower tap-change to the

motor-drive unit in manual mode. See also [► 52].

REMOTE key: Activate/deactivate "Remote" operating mode.

3 Product description

3.5.3

MANUAL key: Activate "Manual" operating mode.

AUTO key: Activate "Auto mode" operating mode.

PREV key: Change measured value display and switch to previ-

ous parameters.

NEXT key: Change measured value display and switch to next

parameters.

ENTER key: Confirm selection and save modified parameters.

ESC key: Escape current menu and select previous menu levels.

MENU key: Select main menu.

F1 to F5 function keys: Select functions displayed on the screen.

Display elements

The device has a graphics display and 15 LEDs, which indicate the various

operating statuses or events.

Maschinenfabrik Reinhausen 201418 2374092/04 ENTAPCON® 260

Page 19

3 Product description

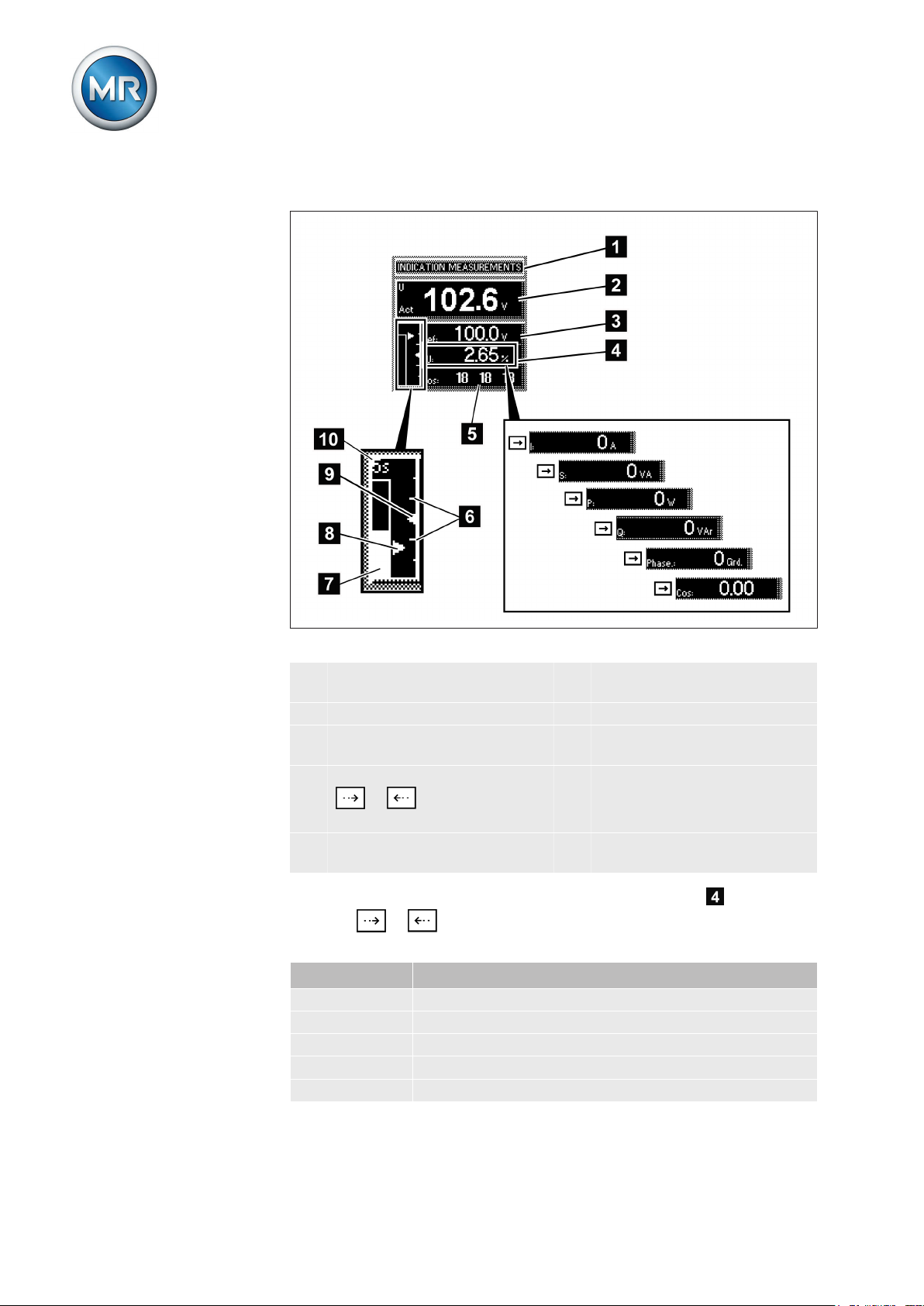

Figure 5: Display elements

1 Operating status LED, green 9 Motor protective switch LED,

yellow

2 Overcurrent blocking LED, red 10 Master LED, green/yellow/red

3 Undervoltage blocking LED,

11 Graphics display

red

4 Overvoltage blocking LED,

12 Auto mode active LED

red

5 Parallel operation active LED,

13 Manual mode active LED

green

6 NORMset active LED , green 14 Remote operating mode ac-

tive LED

7 Parallel operation fault LED,

15 Lower tap-change active LED

yellow

8 Tap difference LED, yellow 16 Raise tap-change active LED

Maschinenfabrik Reinhausen 2014 192374092/04 EN TAPCON® 260

Page 20

Display

3 Product description

Other measured values

Figure 6: Display

1 Status line 6 Bandwidth (upper and lower

limit)

2 Measured voltage U

3 Reference voltage U

Act

Ref

4 Other measured values (use

or to switch between

7 Time bar for delay time T1

8 Highlighting for measured

voltage U

Act

9 Highlighting for reference volt-

age U

Ref

them)

5 Current tap position ED1,

10 Remaining delay time T1

ED2, ED3

In auto mode and manual mode the measured value display can be set

using the or keys. The following measured values can be dis-

played:

Unit Measured value

dU Control deviation

I Current

S Apparent power

P Active power

Q Reactive power

Maschinenfabrik Reinhausen 201420 2374092/04 ENTAPCON® 260

Page 21

3 Product description

Unit Measured value

Phase Phase angle

Cos Active factor: Cosine φ [phi] (output factor)

Table 5: Measured value display

Status line

3.5.4

Current messages and events are displayed in the status line . You can

find more information about messages and events in the Messages [► 144]

chapter.

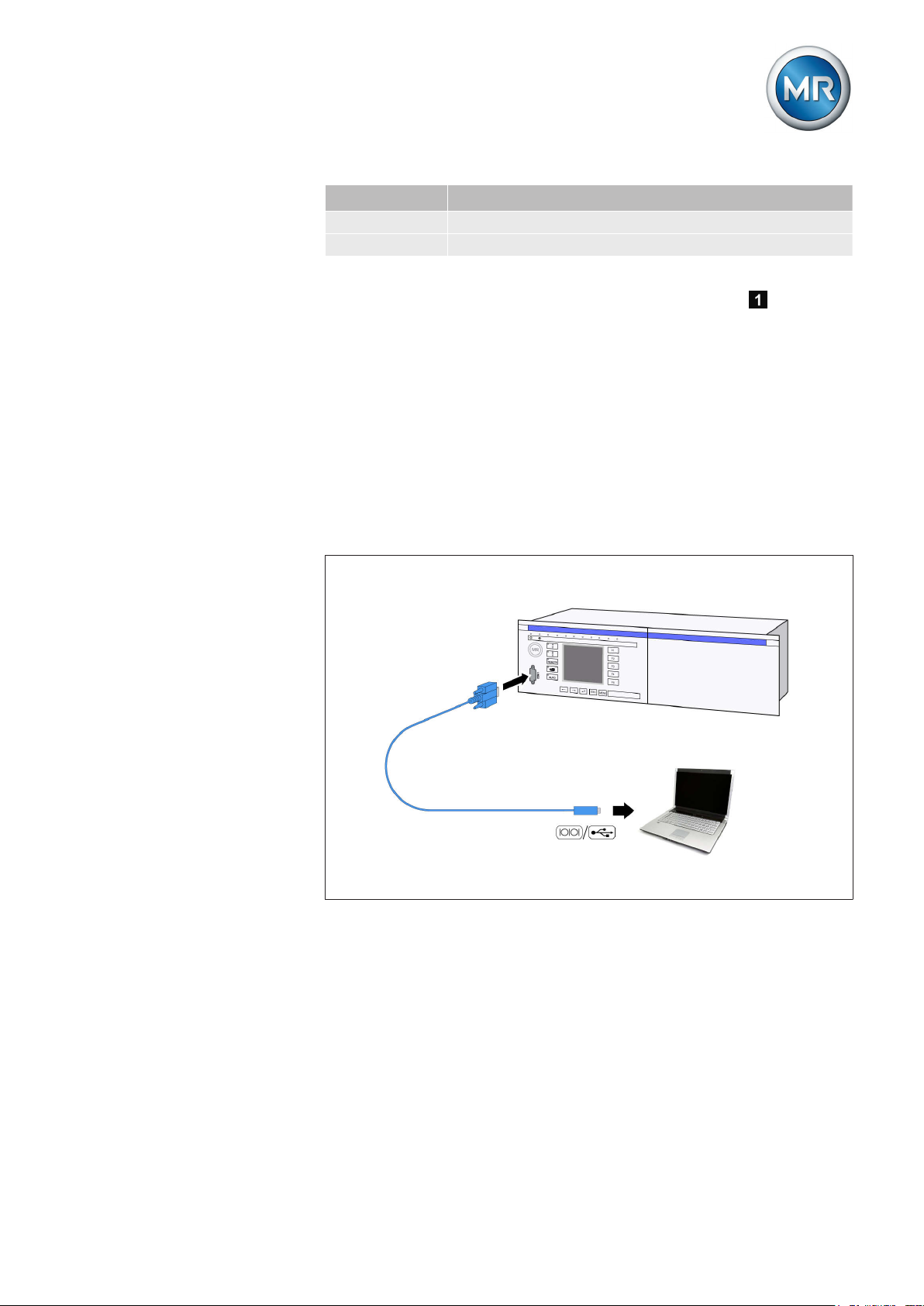

Serial interface

The parameters for the device can be set using a PC. The COM 1 (RS232)

serial interface on the front panel is provided for this purpose. You can use

the connection cable supplied to establish a connection to your PC via the

RS232 or USB port (using the optional USB adapter).

TAPCON®-trol software is needed for parameterization via the serial interface. The software and the related operating instructions are contained on

the CD provided.

Figure 7: Device connection to a PC

3.5.5

Maschinenfabrik Reinhausen 2014 212374092/04 EN TAPCON® 260

Assemblies

Depending on configuration, the device may have various assemblies which

perform the functions required. Depending on configuration, the device may

be equipped with the following assemblies:

Page 22

3 Product description

Card Default/option Max. number

AN Option 1

AC Option 1

AD Option 1, optional with extension

module

CIC Option 2

CPU Standard 1

IO Standard 1

MI Standard 1

SU Standard 1

UC Standard 3, 4 (for SID)

Table 6: Assemblies

The functions of the assemblies are described in the following sections. You

can find more information about the assemblies in the Technical data

[► 152] section.

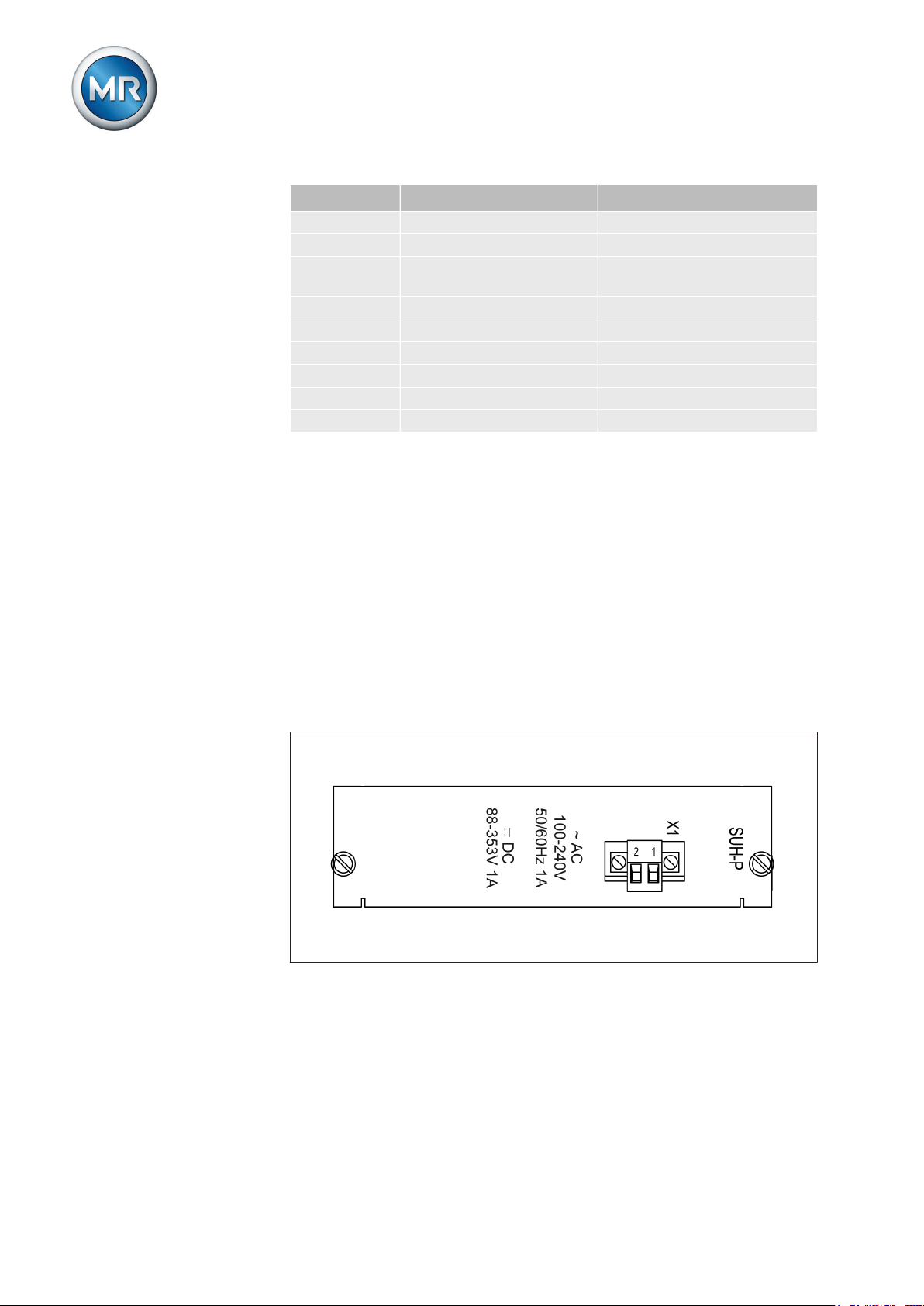

3.5.5.1

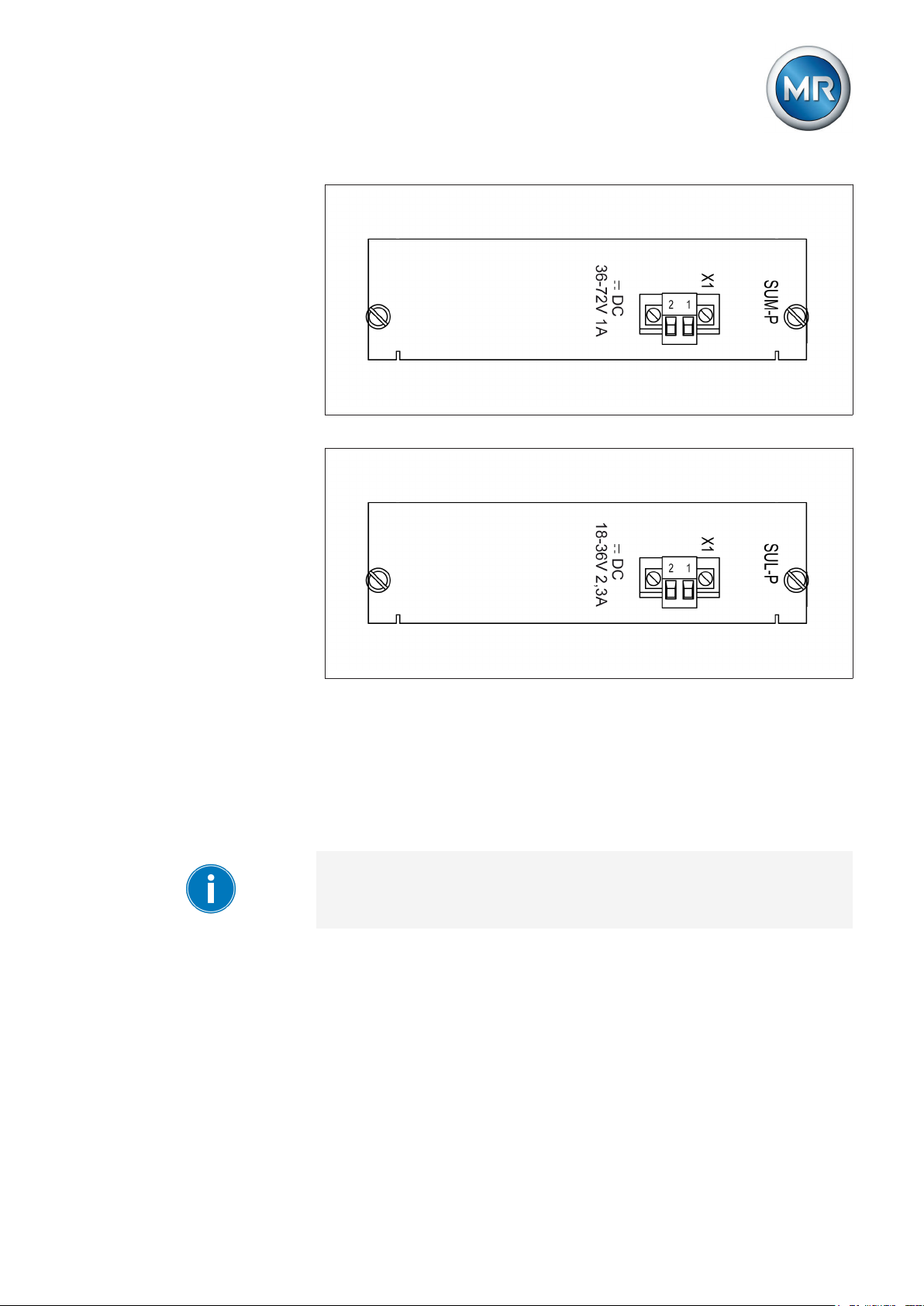

Power supply

The wide range power supply (SU card) supplies the device with power. Depending on configuration, the device is equipped with one of the following

variants:

▪ SUH-P: Rated input voltage 100...240 V AC or 88...353 V DC (input volt-

age range 88...264 V AC, 88...353 V DC)

▪ SUM-P: Input voltage 36...72 V DC

▪ SUL-P: Input voltage 18...36 V DC

Figure 8: SUH-P card

Maschinenfabrik Reinhausen 201422 2374092/04 ENTAPCON® 260

Page 23

3 Product description

Figure 9: SUM-P card

3.5.5.2

Figure 10: SUL-P card

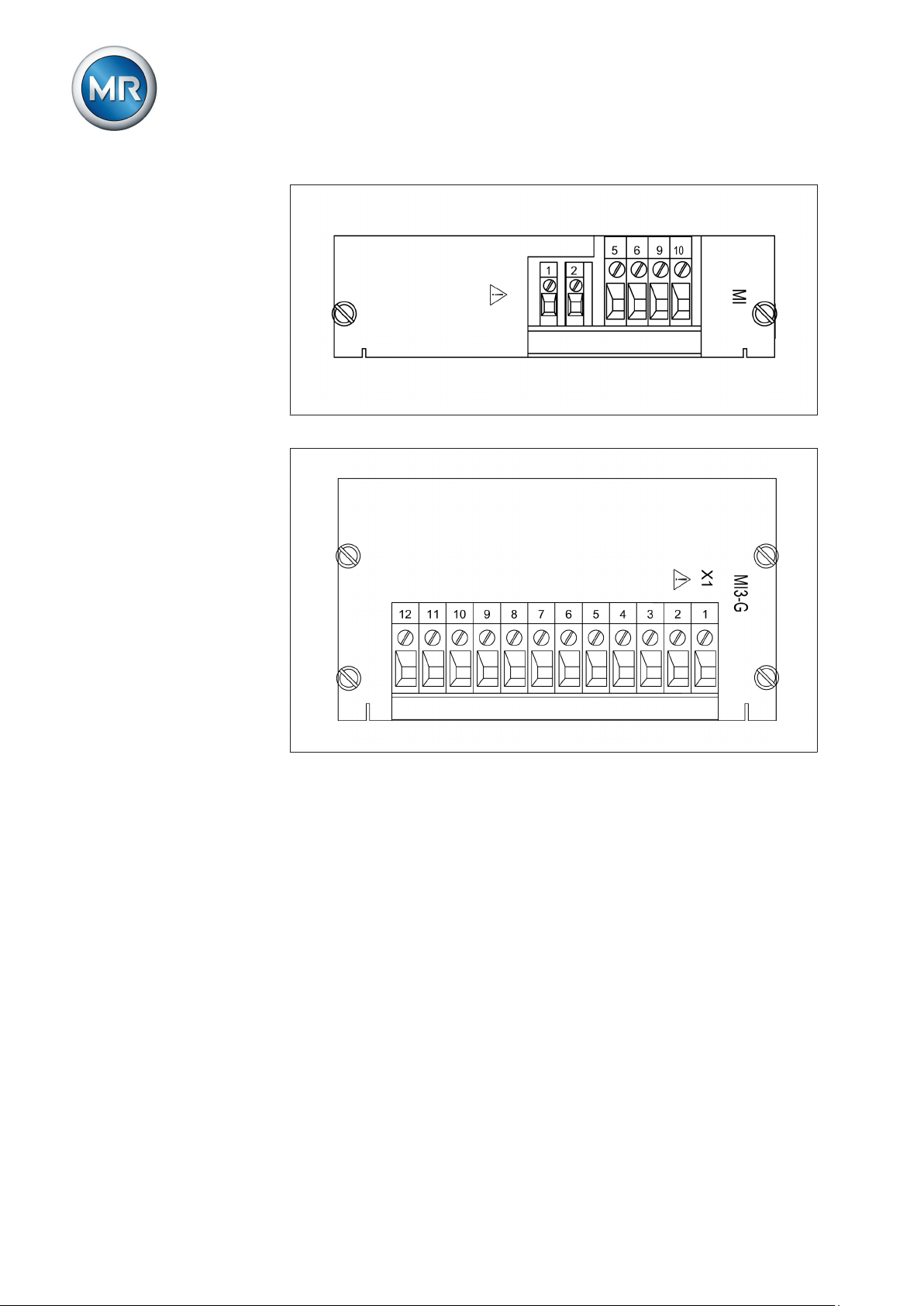

Voltage measurement and current measurement

To measure voltage and current, the device can be equipped with the assembly MI or MI3-G:

▪ MI: 1-phase measurement of voltage and current

▪ MI3-G: 3-phase measurement of voltage and current

Only connect the MI card to one current transformer, otherwise the current

measurement will not work.

Maschinenfabrik Reinhausen 2014 232374092/04 EN TAPCON® 260

Page 24

3 Product description

Figure 11: MI-1 card

3.5.5.3

Figure 12: MI3G card

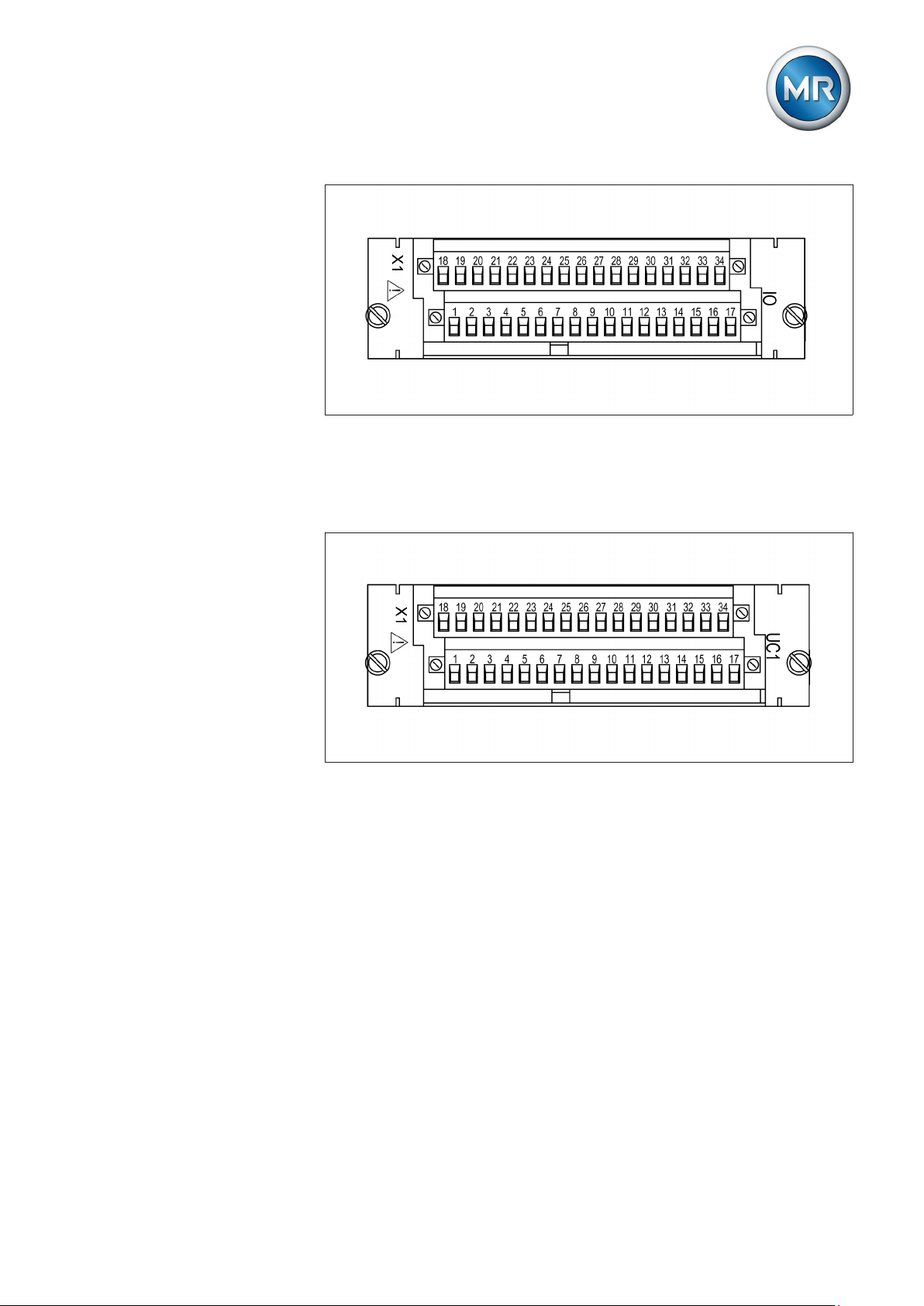

Digital inputs and outputs

To record and output digital signals, the device may be equipped with the

following assemblies:

▪ IO card

▪ UC card

IO card

The IO card contains 9 digital inputs and 8 digital potential-free outputs. 5

outputs take the form of change-over contacts.

Maschinenfabrik Reinhausen 201424 2374092/04 ENTAPCON® 260

Page 25

3 Product description

Figure 13: IO card

UC card

The UC card contains 10 digital inputs and 10 digital potential-free outputs.

The device can be equipped with several UC cards (UC1, UC2...).

3.5.5.4

Figure 14: UC1 card

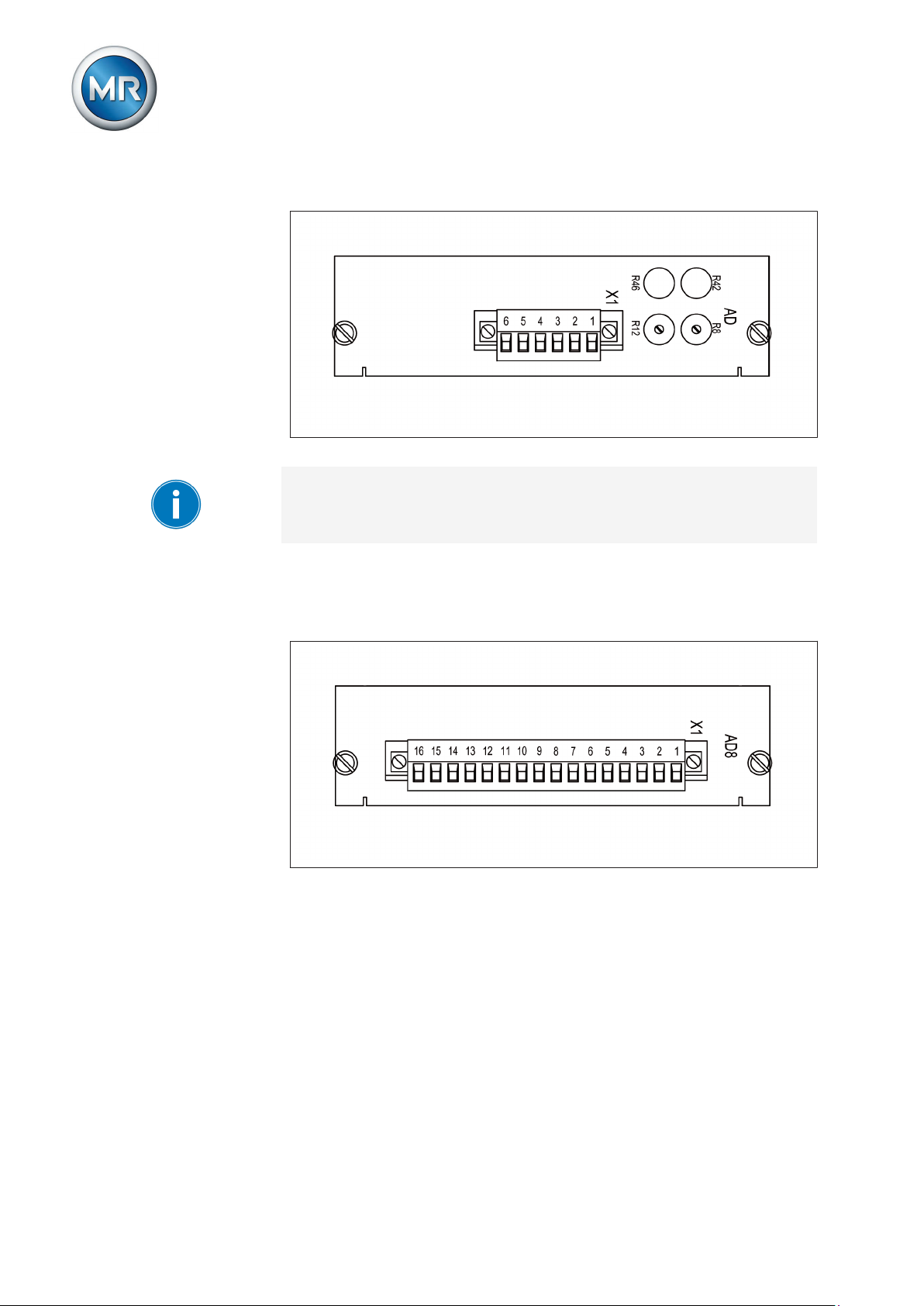

Analog inputs and outputs

To record and output analog signals, the device may be equipped with the

following assemblies:

▪ AD card

▪ AD8 card

▪ AN card

AD card

The analog input card has 1 input or with an extension card 2 inputs that can

record the following analog signals:

▪ 0...±10 V

▪ 0...±10 mA

▪ 0...±20 mA

Maschinenfabrik Reinhausen 2014 252374092/04 EN TAPCON® 260

Page 26

3 Product description

▪ Resistance measurement (50...2 000 Ω)

Figure 15: AD card

Only use the R8/R12 and R42/R46 rotary potentiometers to calibrate the resistance measurement.

AD8 card

The analog input card has 8 inputs that can record the analog signals

(4...20mA).

Figure 16: AD8 card

AN card

Depending on configuration, the AN card provides 2 analog outputs or with

an extension module AN1 a total of 4 analog outputs. The following signal

types are supported:

▪ 0...±20mA

▪ 0...±10mA

▪ 0...±1mA

▪ 0...±10V

Maschinenfabrik Reinhausen 201426 2374092/04 ENTAPCON® 260

Page 27

3 Product description

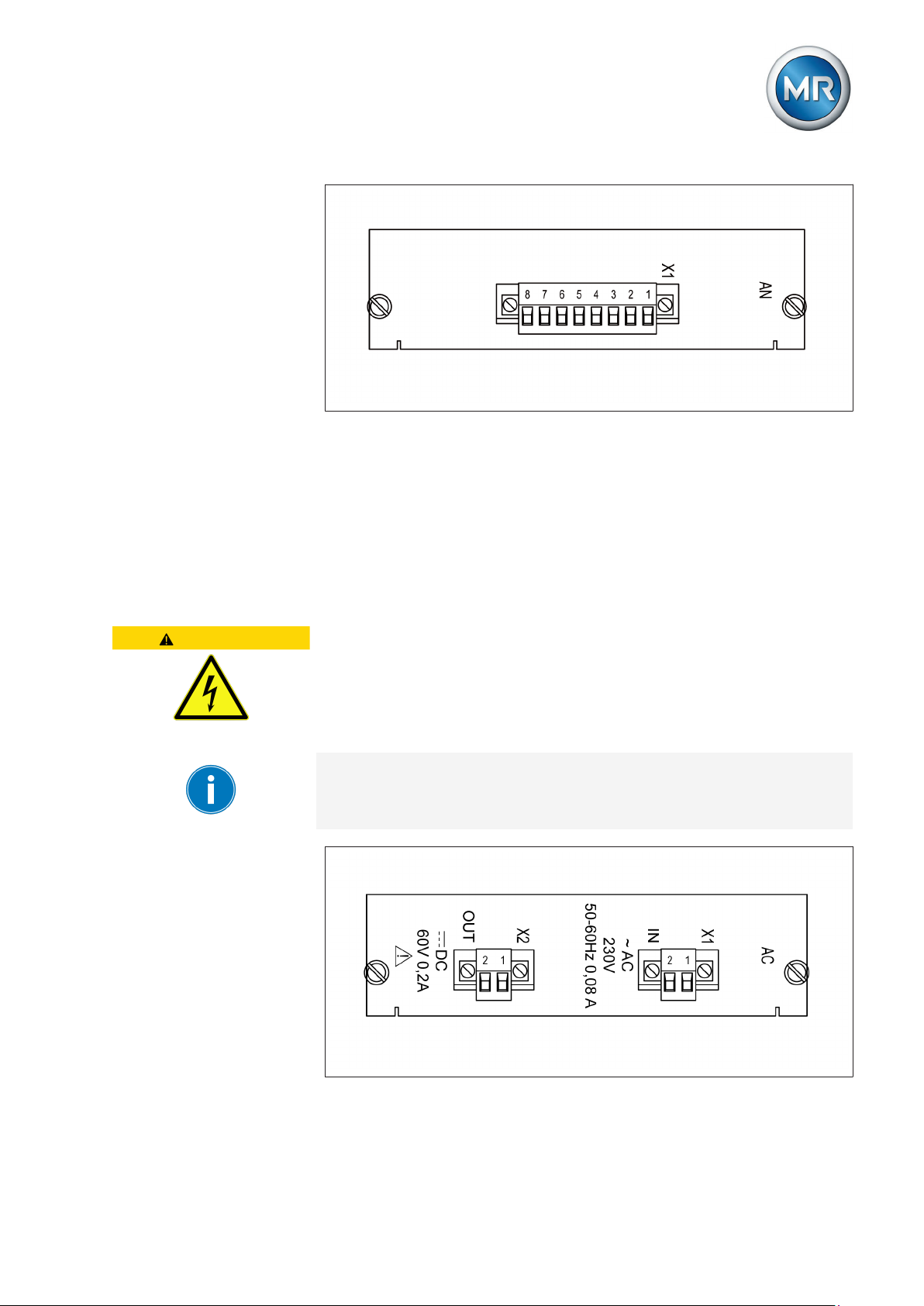

Figure 17: AN card

3.5.5.5

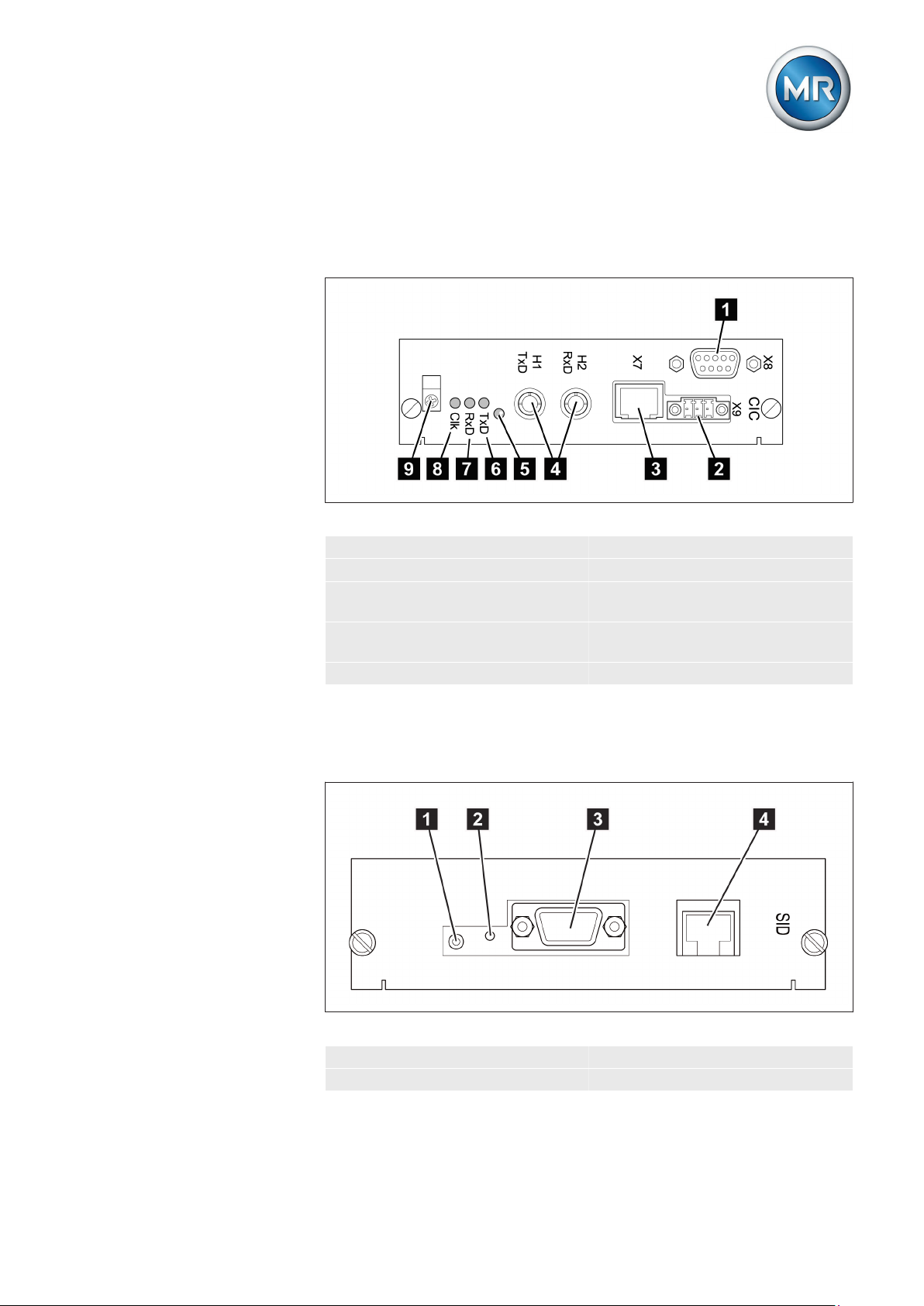

Control voltage supply

An additional non-regulated control voltage of 60 V DC can be created with

the AC card if your system does not have external DC voltage as the signal

voltage for the device's digital inputs. Depending on device configuration,

one of the following two variants can be fitted:

▪ AC230: 230 V AC input voltage

▪ AC115: 115 V AC input voltage

CAUTION

Risk of injury from increased output voltage

Slight loading of the AC card may result in the output voltage increasing to

up to 85 V DC.

► Only wire card when not energized.

The output performance of the AC card is limited. The generated DC voltage can be used only for the control inputs of the device.

Figure 18: AC230 card

Maschinenfabrik Reinhausen 2014 272374092/04 EN TAPCON® 260

Page 28

Figure 19: AC115 card

3 Product description

3.5.5.6

Central processing unit

The CPU card is the device's central computing unit. All internal device functions and the application functions, such as processing measured values,

are controlled and monitored by the CPU card.

The CPU card contains a flash memory (optional measured value memory)

as a non-volatile data storage in which the operating data such as measured

values or events are stored. An EEPROM for storing parameters and a realtime clock (RTC) for recording time are included on the CPU card.

The CPU card contains the following interfaces:

▪ RS232 system interface

▪ CAN bus

3.5.5.7

Figure 20: CPU card

1 CAN bus interface

System networking

The device is equipped with the following assemblies:

Maschinenfabrik Reinhausen 201428 2374092/04 ENTAPCON® 260

Page 29

3 Product description

CIC card

As an option, the device can be equipped with up to 2 CIC cards. The CIC

cards are used to communicate using a control system protocol or

TAPCON®-trol software (CIC2).

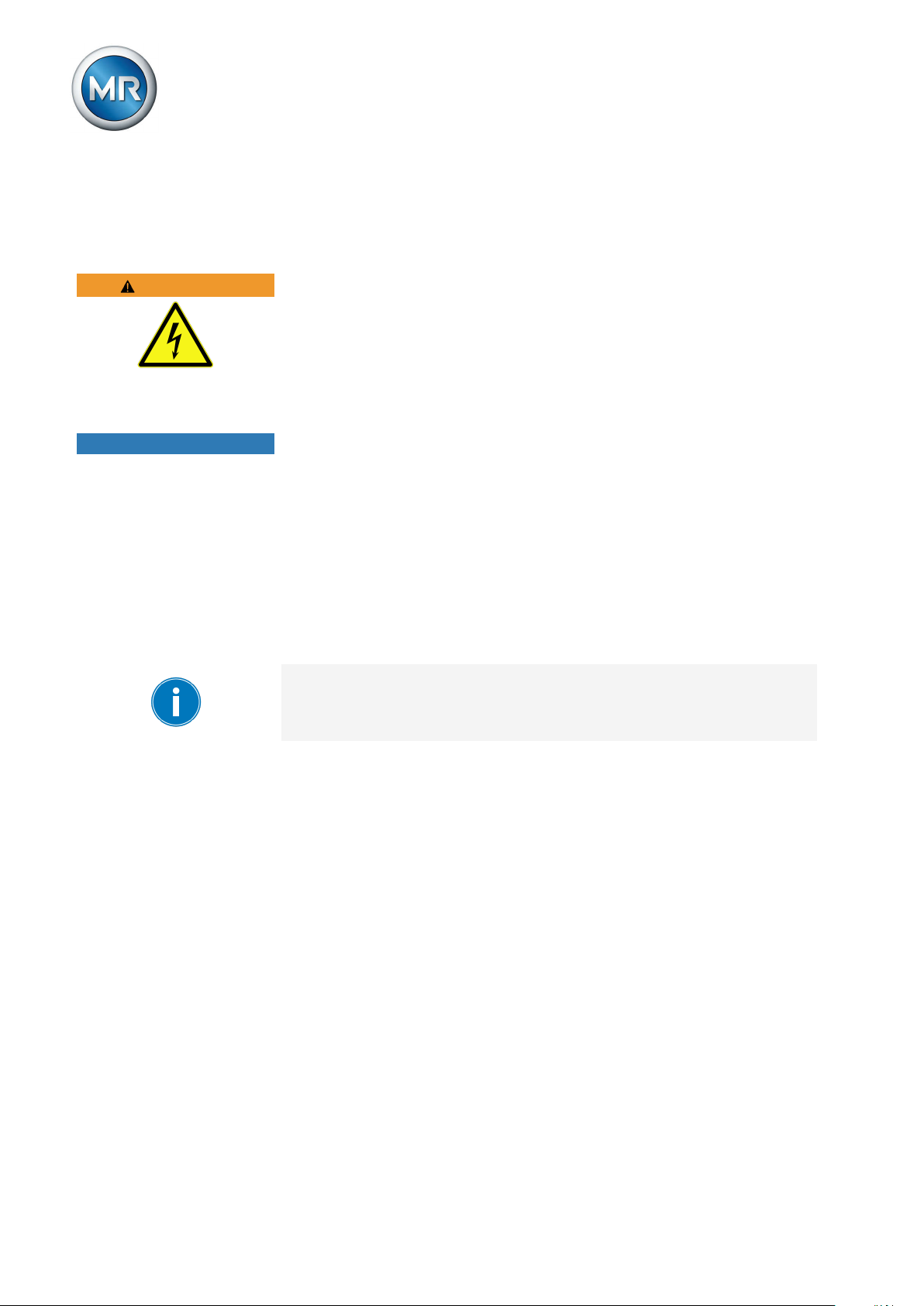

Figure 21: CIC card

1 RS232 6 TxD LED for transmit signal

2 RS485 7 RxD LED for receive signal

3 RJ45 (Ethernet), optional 8 Clk LED for operating mode

(flashes for 2 seconds)

4 Fiber-optic cable, optional 9 Clip for connecting cable

shield

5 Reset key

SID card

The SID interface card is used to connect the device to the control station

system (SCADA). The IEC 61850 protocol transfers the data using Ethernet.

Figure 22: SID card

1 Reset key 3 RS232 system interface

2 LED for operating status 4 RJ45 (Ethernet)

Maschinenfabrik Reinhausen 2014 292374092/04 EN TAPCON® 260

Page 30

4 Mounting

Mounting

4

This chapter describes how to correctly mount and connect the device. Note

the connection diagrams provided.

WARNING

NOTICE

Electric shock

Risk of fatal injury due to electrical voltage.

► De-energize the device and system peripherals and lock them to pre-

vent them from being switched back on.

► Do so by short-circuiting the current transformer; do not idle the current

transformer.

Electrostatic discharge

Damage to the device due to electrostatic discharge.

► Take precautionary measures to prevent the build-up of electrostatic

charges on work surfaces and personnel.

Preparation

4.1

The following tools are needed for mounting:

▪ Screwdriver for the fixing bolts (M6)

▪ Small screwdriver for connecting the signal lines and supply lines

Depending on installation site and mounting variant, you may need additional tools and corresponding attachment material (screws, nuts, washers)

which are not included in the scope of supply.

Mounting device

4.2

Depending on your order, you can mount the device in one of the following

variants:

▪ 19" frame (in accordance with DIN 41494 Part 5)

▪ 19" flush control panel frame

Below you will find a description of how to mount the device in a 19" frame.

For control panel installation or wall mounting, note the technical files supplied.

To mount the device in a 19" frame, proceed as follows:

1. Place cage nuts in the desired locations on the 19" frame, noting the

device dimensions [► 159].

Maschinenfabrik Reinhausen 201430 2374092/04 ENTAPCON® 260

Page 31

4 Mounting

2. Place device in 19" frame and screw down.

Figure 23: Example of device mounting in a 19" frame

WARNING

4.3

4.3.1

Connecting device

The following section describes how to establish the electrical connection to

the device.

Electric shock

Risk of fatal injury due to connection mistakes

► Ground the device with a protective conductor using the grounding

screw on the housing.

► Note the phase difference of the secondary terminals for the current

transformer and voltage transformer.

► Connect the output relays correctly to the motor-drive unit.

Supply the voltage via separators and ensure that current paths can be

short circuited. Fit the separator, clearly labeled, near the device's power

supply so that it is freely accessible. This will allow the device to be replaced with ease in the event of a defect.

Cable recommendation

Please note the following recommendation from Maschinenfabrik Reinhausen when wiring the device.

Excessive line capacitance can prevent the relay contacts from breaking the

contact current. In control circuits operated with alternating current, take into

account the effect of the line capacitance of long control lines on the function of the relay contacts.

Maschinenfabrik Reinhausen 2014 312374092/04 EN TAPCON® 260

Page 32

4 Mounting

Cable Card Terminal Cable type Conductor

Max. length

cross-section

Power supply SU X1:1/2 Unshielded 1.5 mm² Voltage

MI/MI1 1/2 Shielded 1.5 mm² -

measurement

Current

MI/MI1 5/6/9/10 Unshielded 4 mm² -

measurement

Relay* IO X1:1...10

Unshielded 1.5 mm² -

X1:19...26

Relay* UC X1:1...10 Unshielded 1.5 mm² Signal inputs IO X1:11...17

Shielded 1.0 mm² -

X1:27...34

Signal inputs UC X1:11...17

Shielded 1.0 mm² -

X1:27...34

CAN bus CPU 1...5 Shielded 1.0 mm² 2000 m

Table 7: Recommendation for connection cable (standard connections)

Cable Card Terminal Cable type Conductor

*) Observe line capacitance, see note above.

Max. length

cross-section

AC AC X1/2:1/2 Unshielded 1.5 mm² Analog inputs AD8 X1:1...3 Shielded 1.5 mm² 400 m (< 25 Ω/km)

Analog out-

AN/AN1 X1 Shielded 1mm² -

puts

RS-232 CIC X8 Shielded 0.25 mm² 25 m

RS-485 CIC X9 Shielded 0.75 mm² 1000 m (< 50 Ω/km)

Ethernet SID

CIC

Media con-

MC1 - Optical fiber

verter

RJ45

X7

shielded, CAT7- 100 m

- -

with MTRJST duplex

patch cable

Media converter

MC2 - Fiber-optic

cable, con-

- -

nector type:

F-ST; fiber

type: multi

mode/single

mode; wavelength:

1310 nm

Table 8: Recommendation for connection cable (optional connections)

Maschinenfabrik Reinhausen 201432 2374092/04 ENTAPCON® 260

Page 33

4 Mounting

4.3.2

4.3.3

Information about laying fiber-optic cable

To ensure the smooth transfer of data via the fiber-optic cable, you must ensure that mechanical loads are avoided when laying the fiber-optic cable and

later on during operation.

Please note the following:

▪ Radii must not fall below the minimum permissible bend radii (do not

bend fiber-optic cable).

▪ The fiber-optic cables must not be over-stretched or crushed. Observe

the permissible load values.

▪ The fiber-optic cables must not be twisted.

▪ Be aware of sharp edges which could damage the fiber-optic cable's

coating when laying or could place mechanical loading on the coating

later on.

▪ Provide a sufficient cable reserve near distributor cabinets for example.

Lay the reserve such that the fiber-optic cable is neither bent nor twisted

when tightened.

Electromagnetic compatibility

The device has been developed in accordance with applicable EMC standards. The following points must be noted in order to maintain the EMC

standards.

4.3.3.1

4.3.3.2

Wiring requirement of installation site

Note the following when selecting the installation site:

▪ The system's overvoltage protection must be effective.

▪ The system's ground connection must comply with all technical regula-

tions.

▪ Separate system parts must be joined by a potential equalization.

▪ The device and its wiring must be at least 10 m away from circuit-break-

ers, load disconnectors and busbars.

Wiring requirement of operating site

Note the following when wiring the operating site:

▪ The connection cables must be laid in metallic cable ducts with a ground

connection.

▪ Do not route lines which cause interference (for example power lines)

and lines susceptible to interference (for example signal lines) in the

same cable duct.

▪ Maintain a gap of at least 100 mm between lines causing interference

and those susceptible to interference.

Maschinenfabrik Reinhausen 2014 332374092/04 EN TAPCON® 260

Page 34

Figure 24: Recommended wiring

4 Mounting

1 Cable duct for lines causing

interference

2 Interference-causing line (e.g.

power line)

3 Cable duct for lines suscepti-

ble to interference

4 Line susceptible to interfer-

ence (e.g. signal line)

▪ Short-circuit and ground reserve lines.

▪ The device must never be connected using multi-pin collective cables.

▪ Signal lines must be routed in a shielded cable.

▪ The individual conductors (outgoing conductors/return conductors) in

the cable core must be twisted in pairs.

▪ The shield must be fully (360º) connected to the device or a nearby

ground rail.

Using "pigtails" may limit the effectiveness of the shielding. Connect closefitting shield to cover all areas.

Maschinenfabrik Reinhausen 201434 2374092/04 ENTAPCON® 260

Page 35

4 Mounting

Figure 25: Recommended connection of the shielding

4.3.3.3

1 Connection of the shielding

using a "pigtail"

2 Shielding connection covering

all areas

Wiring requirement in control cabinet

Note the following when wiring the control cabinet:

▪ The control cabinet where the device will be installed must be prepared

in accordance with EMC requirements:

– Functional division of control cabinet (physical separation)

– Constant potential equalization (all metal parts are joined)

– Line routing in accordance with EMC requirements (separation of

lines which cause interference and those susceptible to interfer-

ence)

– Optimum shielding (metal housing)

– Overvoltage protection (lightning protection)

– Collective grounding (main grounding rail)

– Cable bushings in accordance with EMC requirements

– Any contactor coils present must be interconnected

▪ The device's connection cables must be laid in close contact with the

grounded metal housing or in metallic cable ducts with a ground connection.

▪ Signal lines and power lines/switching lines must be laid in separate ca-

ble ducts.

▪ The device must be grounded at the screw provided, the protective

grounding connection, using a ground strap (cross-section min. 8 mm²).

Maschinenfabrik Reinhausen 2014 352374092/04 EN TAPCON® 260

Page 36

4 Mounting

Figure 26: Ground strap connection

4.3.3.4

NOTICE

Information about shielding the CAN bus

In order for the CAN bus to operate faultlessly, you have to connect the

shielding using one of the following variants. If you are not able to use any of

the variants detailed below, we recommend using fiber optic cables. Fiber

optic cables decouple the voltage regulators and are not sensitive to electromagnetic interferences (surge and burst).

Damage to the device

If you connect the CAN bus cable to devices with different potential, current

may flow over the shielding. This current may damage the device.

► Connect the devices to a potential compensation rail to compensate for

potential.

► If both devices have different potentials, only connect the CAN bus ca-

ble's shielding to one device.

Variant 1: The connected devices share the same potential

If the devices to be connected share the same potential, proceed as follows:

1. Connect all devices to a potential compensation rail to compensate for

the potential.

2. Connect CAN bus cable's shielding to all connected devices.

Maschinenfabrik Reinhausen 201436 2374092/04 ENTAPCON® 260

Page 37

4 Mounting

Variant 2: The connected devices have different potential

Note that the shielding is less effective with this variant.

If the devices to be connected have different potential, proceed as follows:

► Connect CAN bus cable's shielding to just one device.

Connecting shielding

Connect the CAN bus cable's shielding to the intended point on the CPU

card using the cable clips provided:

Figure 27: Securing the shielding

1 Securing the CAN bus cable's shielding

4.3.4

4.3.5

Connecting cables to the system periphery

To obtain a better overview when connecting cables, only use as many

leads as necessary.

To connect cables to the system periphery, proceed as follows:

ü Use only the specified cables for wiring. Note the cable recommendation

[► 31].

► Connect the lines to be wired to the device to the system periphery as

shown in the connection diagrams supplied.

Wiring device

To obtain a better overview when connecting cables, only use as many

leads as necessary.

Maschinenfabrik Reinhausen 2014 372374092/04 EN TAPCON® 260

Page 38

4 Mounting

4.3.6

NOTICE

To wire the device, proceed as follows:

ü Note the connection diagram.

ü Use only the specified cables for wiring. Note the cable recommendation

[► 31].

ü Wire the lines to the system periphery [► 37].

1. Strip insulation from lines and leads.

2. Crimp stranded wires with wire end sleeves.

3. Guide leads into corresponding connector terminals.

4. Fasten screws for the corresponding terminals using a screwdriver.

5. Plug connectors into the correct slots.

Checking functional reliability

To ensure that the device is wired correctly, check its functional reliability.

Damage to device and system periphery

An incorrectly connected device can lead to damages in the device and system periphery.

► Check the entire configuration before commissioning.

► Prior to commissioning, be sure to check the actual voltage and operat-

ing voltage.

Check the following:

▪ Once you have connected the device to the grid, the screen displays the

MR logo and then the operating screen.

▪ The green Operating display LED top left on the device's front panel

lights up.

The device is fully mounted and can be configured. The actions required for

this are described in the following chapter.

Maschinenfabrik Reinhausen 201438 2374092/04 ENTAPCON® 260

Page 39

5 Commissioning

Commissioning

5

You need to set several parameters and perform function tests before commissioning the device. These are described in the following sections.

NOTICE

Damage to device and system periphery

An incorrectly connected device can lead to damages in the device and system periphery.

► Check the entire configuration before commissioning.

► Prior to commissioning, be sure to check the actual voltage and operat-

ing voltage.

We recommend using a device for industrial instrumentation to record the

actual transformer voltage value in order to evaluate how the device is functioning.

Setting the display contrast

5.1

You can adjust the contrast in the display with the help of an adjustment

screw on the front of the device. To adjust the contrast, proceed as follows:

► Use a screwdriver to turn the adjustment screw on the front until the

contrast is adjusted to the desired setting.

Figure 28: Setting the display contrast

Setting parameters

5.2

To commission the device, you must set the following parameters. For more

detailed information about the parameters, refer to the respective sections.

Maschinenfabrik Reinhausen 2014 392374092/04 EN TAPCON® 260

Page 40

5 Commissioning

5.2.1

5.2.2

Setting the language

You can use this parameter to set the display language for the device. The

following languages are available:

English Italian

German Portuguese

French Russian

Spanish

To set the language, proceed as follows:

1. > Configuration > General.

ð Language

2. Press or to select the required language.

3. Press .

ð The language is set.

Setting date and time

You must set the system date and system time on the device. You must set

the date and time in the following formats:

Date Time

DD.MM.YY HH:MM:SS

Table 9: Formats

The time does not switch from daylight saving time to standard time and

back automatically. You have to change the time manually.

Time

To set the time, proceed as follows:

1. > Configuration > Continue > Memory > Press

until the desired display appears.

ð Time

2. Press to highlight a digit.

ð The desired position is highlighted and the value can be changed.

3. Press to increase the value or to reduce it.

4. Press .

ð The time is set.

Maschinenfabrik Reinhausen 201440 2374092/04 ENTAPCON® 260

Page 41

5 Commissioning

Date

To set the date, proceed as follows:

1. > Configuration > Continue > Memory > Press

until the desired display appears.

ð Date

2. Press to highlight a digit.

ð The desired position is highlighted and the value can be changed.

3. Press to increase the value or to reduce it.

4. Press .

ð The date is set.

5.2.3

Setting further parameters

Set further parameters to commission the device. More detailed information

about each of the parameters can be found in the Functions and settings

[► 52] chapter.

Setting transformer data

Set the transformer data and phase difference of the current transformer and

voltage transformer:

1. Set primary transformer voltage [► 85].

2. Set secondary transformer voltage [► 85].

3. Set primary transformer current [► 86].

4. Select current-transformer connection [► 87].

5. Select transformer circuit [► 87].

Setting NORMset

If you want to commission voltage regulation quickly, you can activate

NORMset mode. If you want to set the parameters yourself, continue with

the sections below.

► Activate NORMset and set the relevant parameters [► 61].

Setting control parameters

Set the following control parameters:

1. Set desired value 1 [► 65].

2. Set the bandwidth [► 66].

3. Set delay time T1 [► 66].

4. Switch all motor-drive units into the same tap position [► 52].

Maschinenfabrik Reinhausen 2014 412374092/04 EN TAPCON® 260

Page 42

5 Commissioning

Setting line drop compensation (optional)

If you need line drop compensation, you must set all important parameters

for this:

1. Select the LDC compensation method [► 75].

2. Set the line data for the ohmic voltage drop Ur [► 77].

3. Set the line data for the inductive voltage drop Ux [► 77].

Setting parallel operation on several banks of transformers (optional)

If you need parallel operation, you must set all important parameters for this:

1. Set the parallel operation method to the circulating reactive current

method [► 92].

2. Assign the CAN bus address [► 91].

3. Set circulating reactive current sensitivity [► 93].

4. Set circulating reactive current blocking [► 93].

Setting control system protocol (optional)

If you need a control system protocol, you must set all important parameters

for this. More detailed information about this can be found in the control system protocol description.

Setting tap position capture via analog input (optional)

If you want to capture the tap position via the analog input, you must set the

parameters required for this:

► Capture tap positions via analog input (input 1 or input 2) [► 96].

All parameters relevant to commissioning are entered. Continue with the

function tests.

Function tests

5.3

Before switching from manual mode to auto mode, Maschinenfabrik Reinhausen recommends carrying out function tests. These function tests are described in the following sections. Note the following points for all function

tests:

▪ You must ensure that the REMOTE mode is disabled before you can

control the on-load tap-changer manually in manual mode.

▪ You can only activate the on-load tap-changer manually in manual

mode using the and keys.

▪ During the function test, you must set the most important parameters.

Details on the parameters listed can be found in the Functions and settings [► 52] chapter.

Maschinenfabrik Reinhausen 201442 2374092/04 ENTAPCON® 260

Page 43

5 Commissioning

5.3.1

Checking control functions

This section describes how you can check the device's control functions:

ü Supply voltage must be present.

ü All motor-drive units must be in the same tap position.

1. Press to select manual mode.

2. Set transmission ratio for voltage transformer, current transformer and

measuring set-up.

3. Measure actual voltage and compare with the measured value displayed on the device's main screen.

4. Press key several times to display the operating values for current,

power and phase angle and compare them with values of service instruments.

5. Control all on-load tap-changers manually with the or keys and

the "ED all" selection until the measured voltage (U

sired voltage (U

) set in the next stage.

desired

6. Set desired value 1 to the value you want [► 65].

7. Set bandwidth depending on step voltage [► 66].

8. Set delay time T1 to 20 seconds [► 66].

9. Set control response T1 to linear [► 67].

) reaches the de-

actual

10. Press and select the "ED all" option to raise the on-load tap-changer 1 step.

11. Press to select auto mode.

ð After 20 seconds, the device returns the on-load tap-changer to the

original operating position.

12. Press to select manual mode.

13. Press and select the "ED all" option to lower the on-load tap-changer 1 step.

14. Press to select auto mode.

ð After 20 seconds, the device returns the on-load tap-changer to the

original operating position.

15. Press to select manual mode.

16. Set delay time T2 to 10 seconds [► 68].

17. Activate delay time T2.

18. Press twice and select the "ED all" option to raise the on-load tapchanger 2 steps.

Maschinenfabrik Reinhausen 2014 432374092/04 EN TAPCON® 260

Page 44

5 Commissioning

19. Press to select auto mode.

ð After 20 seconds, the device lowers the on-load tap-changer one

step and after another 10 seconds another step.

20. Press to select manual mode.

21. Set delay time T1 [► 66] and delay time T2 [► 68] to the desired

value.

We recommend a temporary setting of 100 seconds for delay time T1 when

commissioning the transformer. Depending on the operating conditions, you

can also specify the delay time following a longer observation period. In this

regard, it is useful to register how the actual voltage progresses and the

number of tap-change operations per day.

5.3.2

Checking additional functions

This section describes how you can check the following additional functions:

▪ Undervoltage blocking

▪ Overvoltage blocking

▪ Activation of desired values 2 and 3

▪ Line drop compensation

▪ Z compensation

Proceed as follows:

Checking undervoltage blocking U<

1. Press to select manual mode.

2. Set undervoltage U < [%] to 85 % [► 70].

3. Set the absolute limit values parameter to Off [► 69].

4. Set the U< blocking parameter to On [► 71].

5. Set desired value 1 such that the measured voltage is below the undervoltage U< [%] limit value [► 65].

Measured voltage = 100 V

Desired value 1 = Set to 120 V (greater than 100 V/0.85 = 117 V).

ð The Undervoltage U< LED will light up.

ð After around 10 seconds the Undervoltage message appears in the

display and the relevant signaling relay is activated.

6. Press to select auto mode.

ð The device blocks and does not issue any control commands.

7. Press to select manual mode.

Maschinenfabrik Reinhausen 201444 2374092/04 ENTAPCON® 260

Page 45

5 Commissioning

8. Reset the operating values for desired value 1 and undervoltage U<

[%] to the desired operating values.