Page 1

www.reinhausen.com

Voltage Regulator TAPCON® 230 VC (Substitution for VC 100)

Operating Instructions BA 251/02

251/02 en

1

Page 2

Contents

Contents

1 General .............................................................................................................................................................................................................. 4

1.1 Safety instructions ............................................................................................................................................................................ 4

1.2 Specified application ....................................................................................................................................................................... 4

1.3 Design and performance features of the TAPCON® 230 VC................................................................................................ 5

2 Technical Data................................................................................................................................................................................................ 6

3 Operation ......................................................................................................................................................................................................... 9

3.1 Input and output of data; functions .......................................................................................................................................... 9

3.2 Description of the front panel ...................................................................................................................................................... 9

3.2.1 Display..................................................................................................................................................................................... 10

3.2.2 Local/remote switch ........................................................................................................................................................... 11

4 Parametering .................................................................................................................................................................................................. 11

4.1 Normset setting ................................................................................................................................................................................. 11

4.2 Setting the desired voltage level 1 .............................................................................................................................................. 12

4.3 Setting the bandwidth .................................................................................................................................................................... 12

4.4 Setting the delay time T1 or T2 (DELAY 1/DELAY 2) and pulse duration (option) ........................................................ 12

4.5 Setting the overvoltage detection (U>) with automatic return control ......................................................................... 13

4.6 Setting the undervoltage blocking (U<) .................................................................................................................................... 13

4.7 Setting the overcurrent blocking (I>) ......................................................................................................................................... 13

4.8 Measuring transformers (VT, CT configuration) ....................................................................................................................... 15

4.9 Setting the desired voltage levels DVL2 and DVL3 ................................................................................................................. 15

4.10 Line compensation ............................................................................................................................................................................ 15

4.10.1 Line drop compensation (LDC) ........................................................................................................................................ 15

4.10.2 Z-Compensation .................................................................................................................................................................. 16

4.11 Analog remote position indication (option) ............................................................................................................................. 16

4.12 Voltage regulator identification ................................................................................................................................................... 17

4.13 Setting the unit to V or kV ............................................................................................................................................................. 17

4.14 Selection of the display in the 4th line of the display ........................................................................................................... 17

4.15 Language selection ........................................................................................................................................................................... 17

2

251/02 en

Page 3

Contents

5 Commissioning ............................................................................................................................................................................................... 18

5.1 Installation .......................................................................................................................................................................................... 18

5.2 Connection .......................................................................................................................................................................................... 18

5.3 Easy setting of operating modes with Normset ...................................................................................................................... 19

5.4 Function tests; operational settings............................................................................................................................................ 19

5.5 Tap position indication .................................................................................................................................................................... 20

6 Parallel operation.......................................................................................................................................................................................... 21

6.1 Parallel operation with "Minimum Circulating Reactive Current Method“ .................................................................... 22

6.1.1 System configuration, settings ....................................................................................................................................... 22

6.1.2 Setting the interference variable (CIRCUL. REAC. CURR. STABILITY) .................................................................. 22

6.1.3 Setting the bandwidth for circulating reactive current (blocking threshold) ................................................. 22

6.1.4 Function tests, commissioning ........................................................................................................................................ 23

6.1.4.1 Preliminary settings .......................................................................................................................................... 23

6.1.4.2 Setting the interference variable (CIRCUL. REAC. CURR. STABILITY) ................................................ 23

6.1.4.3 Setting the circulating reactive current monitoring

(CIRCUL. REAC. CURR. MON. BANDWIDTH) ............................................................................................... 23

6.2 Parallel operation according to synchronized tap-change operation Master/ Follower ............................................ 23

6.2.1 System configuration, settings, transfer of the on-load tap-changer setting................................................ 24

6.2.1.1 Setting the tapping position range ............................................................................................................. 24

6.2.1.2 Selecting the Master/Follower operation .................................................................................................. 25

6.2.2 Function tests, commissioning and preliminary settings ........................................................................................ 25

6.3 Parallel operation with existing parallel control unit SKB 30 based on

"minimum circulating reactive current" .................................................................................................................................... 25

6.4 Disturbances during parallel operation...................................................................................................................................... 25

7 Appendix ........................................................................................................................................................................................................... 27

NOTE

A "PARAM?" message appearing in the first line of the display indicates a negative result of the parameter verification that may

be caused by interference above the permissible electromagnetic compatibility limit (see information on standardisation and

verification in section 2). In this case, voltage regulation is blocked for safety reasons.

Check the settings in order to clear the blocking. Press and hold the "SELECT" key and press the "" or "" key for displaying

the current settings (see section 3.2.1). Voltage regulation is reinstated once invalid settings have been corrected while cycling

through the menu. The status LEDs and status relays are activated, and the display shows the current measurement readings.

NOTE

Data contained herein may differ in details from the equipment delivered. We reserve the right to make alterations without

notice.

251/02 en

3

Page 4

1 General

1 General

1.1 Safety instructions

All personnel involved in installation, commissioning,

maintenance or repair of this equipment must:

- be suitably qualified and

- strictly observe these operating instructions.

Improper operation or misuse can lead to

- serious or fatal injury,

- damage to the equipment and property of the user

and

- a reduction in the efficiency of the equipment.

Safety instructions in this manual are presented in three

different forms to emphasize important information.

WARNING

This information indicates particular danger to life and

health. Disregarding such a warning can lead to serious or

fatal injury.

CAUTION

This information indicates particular danger to the equipment or other property of the user. Serious or fatal injury

cannot be excluded.

NOTE

1.2 Specified application

The electronic voltage regulator TAPCON® 230 VC serves for

automatic control of transformers with a motor-driven onload tap-changer. The motor-drive mechanism receives the

corresponding control commands from the voltage regulator.

With these commands, the on-load tap-changer moves to

the next position and the transformer’s voltage value is

adapted to the preset desired voltage level.

To allow individual adaptation of the control system to the

various field service conditions encountered, influencing

variables such as time delay, bandwidth, and even linedependent and load-dependent parameters can be programmed for compensation of voltage-dependent and/or

current-dependent limits. As a special feature, the voltage

regulator is also capable of controlling parallel transformer

operation.

CAUTION

Installation, electrical connection and commissioning of

the electronic voltage regulator may only be carried out

by qualified, skilled personnel and only in accordance with

these operating instructions.

It is the responsibility of the user to make sure that the

electronic voltage regulator is used for the specific

application only. For safety reasons, any unauthorized and

improperly executed works, i.e. installation, modification,

alteration of the equipment, electrical connection, or

commissioning of the equipment, are forbidden without

first consulting MR!

The trouble-free operation of the drive, the on-load tapchanger, and the transformer may be put at risk.

These notes give important information on a certain

subject.

4

WARNING

All relevant fire protection regulations must be strictly

observed

251/02 en

Page 5

1 General

1.3 Design and performance features of the

TAPCON® 230 VC

The electronic voltage regulator TAPCON® 230 VC is mounted

in a protective housing with hinged cover and inspection

win-dow. The protective housing is suitable for both flush

and projected panel mounting.

The front panel contains several function keys for setting the

individual operating parameters.

Display of the operating status is achieved by a 4-line,

16-digit alphanumeric LC display and light emitting diodes.

The electronic voltage regulator is controlled by a microcontroller (see appendix, block/connection diagram).

Besides a voltage transformer and a current transformer it

contains optocoupler inputs with potential separation as well

as potential-free output relay contacts.

Apart from the usual well-known, versatile and individual setting options for the MR control system, the TAPCON® 230 VC

voltage regulator also offers the option of fast and easy

parametering by introducing the innovative "Normset"

function.

The term „Normset“ function stands for an automatism

which considerably simplifies the configuration of a voltage

regulator. If the desired voltage level is entered while the

„Normset“ function is active, the voltage regulator will

examine the given line/network conditions and proceed to

perform an automatic adaptation of all further inputs

(comprised in part of the pre-parametering and standard

reference values) which used to be required for customary

regulators (also refer to the standard configuration according to Sub-menu 2).

Parallel operation follows alternatively the principles of

either minimum circulating reactive current or the Master/

Follower principle for two transformers.

Using a supplementary device, up to six transformers can be

controlled in parallel operation using the principle of

minimum reactive current.

NOTE

When voltage regulation is effected by tap transformers

and voltage regulators, it is assumed that a change of the

tap position results in a significant voltage change. When

generators feed the voltage level to be regulated, however,

quite different conditions may result so that a correct

regulation of the voltage cannot be guaranteed. In such

cases MR should be consulted as early as the planning

stage.

The parameters of the regulator can be set by means of a PC

via the incorporated serial interface (RS232) integrated in

the regulator; the appropriate PC software will be furnished

by MR.

A load-dependent line-voltage drop, e.g. of a spur line leading from the transformer to the load, can be compensated

either by line simulation (Line Drop Compensation) or by

load-current dependent increase of the voltage level

(Z compensation).

Trouble-free operation is ensured by the regulator’s inherent

undervoltage blocking, overcurrent blocking and overvoltage

monitoring.

The functions of the TAPCON® 230 VC voltage regulator are

just about compatible with those of the earlier voltage

regulators VC 100-BU.

251/02 en

5

Page 6

2 Technical Data

2 Technical Data

Setting ranges

Standard Standard

setting range step width

Desired voltage level 1 85 – 140 V 0.1 V steps

Desired voltage level 2 85 – 140 V 0.1 V steps

Desired voltage level 3 85 – 140 V 0.1 V steps

Bandwidth ± 0.5 ... ± 9 % 0.1 %

Delay time T1 0 ... 180 s 1 s

Delay time T2 1 … 10 s 1 s

Switching pulse duration 0.5 ... 10 s 0.5 s

LDC Ur = 0 ... ± 25 V 0.1 V

Ux = 0 ... ± 25 V 0.1 V

With optional

Z compensation selection Voltage rise 0.1 %

0...15 %

Limitation 0...15 % 0.1 %

Undervoltage blocking 70 ... 99 % 1 %

Overvoltage detection 101 ... 130 % 1 %

with high speed return control pulse signal 1.5 / 1.5 s

Overcurrent blocking 50 ... 210 % 5 %

Voltage transformer 0.1 ... 999,9 kV/100 V

Current transformer 100 ... 5000 A/5/1/0.2 A

Measuring circuit Phase angle adjustable

between current and

voltage circuit:

-30° 3-phase

0° 3-phae

+30° 3-phase

+90° 3-phase

0° 1-phase

6

251/02 en

Page 7

2 Technical Data

Display 4-line, 16-digit LC display

1 LED lamp (green) for signalling status

1 LED lamp (red) each for signalling U<, U>, I>

1 LED lamp (green) for signalling“parallel operation active“ status

1 LED lamp (green) for signalling "Normset active“ status

Inputs and outputs Input relays Output relays

1x parallel Rating of relay contacts:

1x high-speed circuit breaker of voltage AC: 250 V 5 A

limit monitoring indicator DC: 30 V 5 A; 110 V 0.4 A;

1 x analogue input of tapping position 4- 20 mA 220 V 0.3 A

1 x desired voltage level 2 1 x raise

1 x desired voltage level 3 1 x lower

1 x automatic control mode

1 x status

1x group interrupt U<, U>, I>

1x monitoring (function monitoring)

Voltage transformer 85 ... 140 V, measuring range 60 ... 185 V,

r.m.s. value 40 ... 60 Hz, intrinsic consumption < 1 VA

Current transformer 0.2 / 1 / 5 A, 40 ... 60 Hz, r.m.s. value

intrinsic consumption < 1 VA,

overload capacity 2x In continuously, 100x In/1 s

Measuring errors Voltage measuring: < 0.3 % ± 40 ppm/°C

Current measuring: < 0.5 % ± 40 ppm/°C

Serial interfaces 1 x RS232 (COM1) for

parametering via PC

1 x RS 232 for parallel operation of two transformers with a second regulator or for parallel

operation with digital MR parallel control unit SKB

IEC EN 60688

Power supply 115 V (+25 % - 35 %) 40 - 60 Hz, can be changed over either from

the measuring voltage or by separate change-over in the factory to

a supply voltage of 230 V

Power consumption approx. 5.5 VA (at 115V, idle state)

251/02 en

7

Page 8

2 Technical Data

Protective housing Steel-plate housing with inspection window for flush or projected panel mounting

W x H x D: 216 x 326 x 137mm

Degree of protection provided by enclosure: IP 44 according to IEC 60529

Weight: approx. 5.4 kgs

Temperature limits Admissible ambient temperature for operation: -10 °C ... + 70 °C

Admissible ambient temperature for storage and transport: -25 °C ... +80 °C

Tests

IEC 255-5 Dielectric tests performed at 2.5 kV/1 min operating frequency and 5 kV, 1.2|50 μs impulse voltage

IEC 61000-4-2 Interference immunity tests (EMC): electrostatic discharge 4 kV / 8 kV

IEC 61000-4-3 Interference immunity tests (EMC): electromagnetic fields 10 V/m

80-1000 MHz

IEC 61000-4-4 Interference immunity tests (EMC): burst 1MHz, 4 kV

IEC 61000-4-5 Interference immunity, surge 2 kV

IEC 61000-4-6 HF interference immunity of leads: 10V, 150 kHz – 80 MHz

EN 61000-6-2 Immunity for industrial environments

EN 61000-6-4 Emission standards for industrial environments

VDE 0435 Short-time current and continuous rating of the current transformer inputs,

100 x In/1s and 2 x In/continuously

VDE 0100 Provisions governing the erection of electrical power installations featuring rated system voltages

up to 1,000 V

Grounding conductors, protective conductors, equipotential bonding conductors,

arrangement of operating elements

IEC 61010 / VDE 0411 Safety requirements for electrical equipment for measurement, control, regulation and

laboratory use

VDE 0110 Provisions governing the rating of clearance in air and creepage distances in electrical equipment

IEC 60529 Determination of the degree of protection provided by enclosures: „Shock-hazard protection,

protection against ingress of solid foreign bodies and protection against the ingress of water for

electrical equipment“ Level IP00

IEC 60068 Basic environmental test procedures

IEC 60068-2-1 Cold test for heat-dissipating specimens, with slow temperature change rate -10°C / 20 hours

IEC 60068-2-2 Dry-heat test for heat-dissipating specimens, with slow temperature change rate

+70 °C / 16 hous

IEC 60068-2-3 Humid heat, constant

+40 °C / 93 % / 56 days

IEC 60068-2-30 Humid heat, cyclical (12 + 12 hours)

+ 55 °C / 93 % and + 25 °C / 95 % / 6 cycles

IEC 60068-2-31 Drops and topple, unpacked, 100 mm height

IEC 60068-2-32 Free fall, unpacked, 250 mm height

IEC 61000-4-8 Power frequency magnetic field immunity test

IEC 61000-4-11 Voltage dips, short interruptions and voltage variations immunity tests

8

251/02 en

Page 9

3 Operation

3 Operation

3.1 Input and output of data; functions

The following instructions tell you how to call up the basic

functions of the TAPCON® 230 VC voltage regulator and how

to reset parameters.

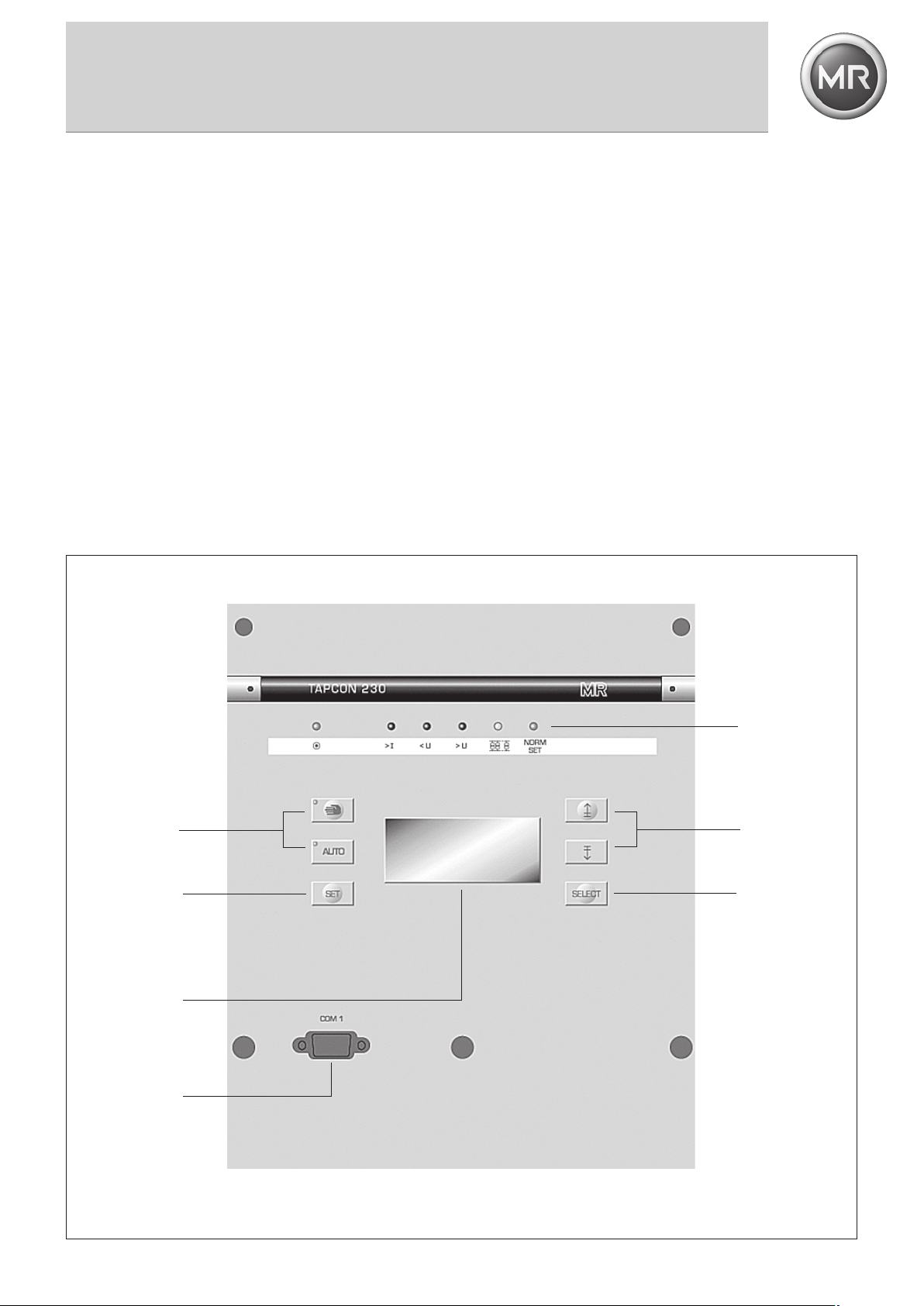

3.2 Description of the front panel (fig. 1)

Generally, the keys located at the front panel fall into two

different basic groups.

• Operating keys

• Function keys for menu guidance

The LED’s located in the front panel’s upper area serve for

signalling the following system statuses:

• Operating status display

• Overcurrent blocking

• Undervoltage blocking

• Overvoltage monitoring

• Parallel operation

• NORMSET

Change-over

between manual

mode/automatic mode

Reset

setting values via

the Higher/Lower keys

LCD-Display

Parametering

interface

Light-

emitting

diodes

Reset setting

values

via „SET“

Change the

windows via

the Higher/

Lower keys

1

251/02 en

9

Page 10

3 Operation

3.2.1 Display

<

<

The TAPCON® 230 VC contains a 4-line, 16-digit LC display.

A distinction is made between the two following types of

displays: Basic display and parametering display.

a) Basic display

In addition to the actual voltage level, the desired voltage

level and the deviations the basic display indicates an

additional measuring value in the 4th line during normal

operation. Selection of this measuring value in the display

window „SELECT 4th LINE“.

The following values are available:

- Current I - Power factor cos PHI

- Apparent power S - Frequency f

- Reactive power Q - Status line

- Active power P - Position, optional

- Phase angle PHI

ACTUAL VOLT.LEVEL 64.90 kV

DESIRED VOLT.LEVEL 66.00 kV

dU% 1.67 %

CURRENT I 253 A

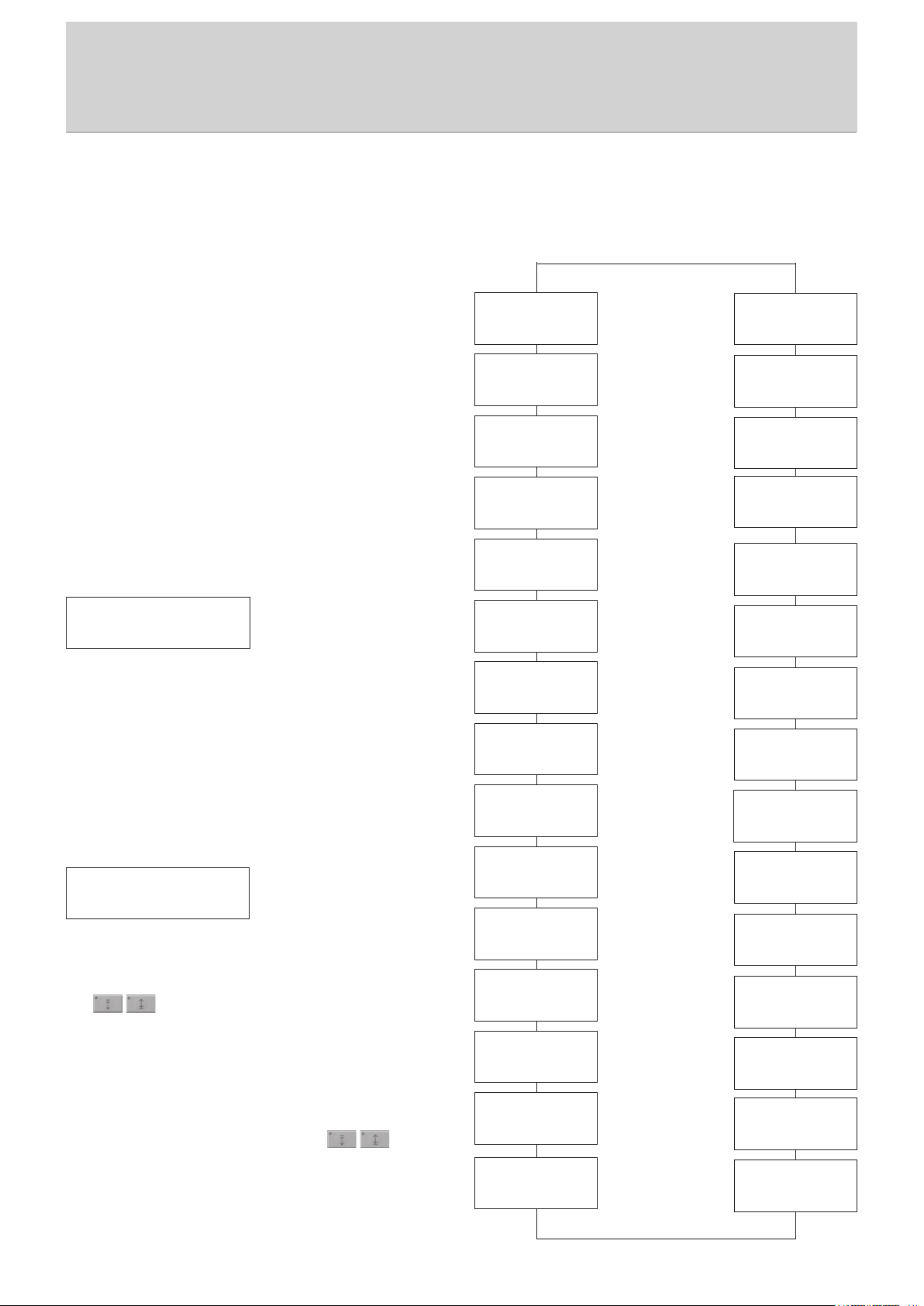

b) Parametering display windows

The TAPCON® 230 VC contains parametering display

windows which serve to display set parameters and allow the

user to modify any previously set parameters to suit his

specifica-tions.

Generally, these windows are set up as follows:

- 1st line: Title/designation of the parameter

- 2nd line: Set value

- 3rd line: Possible setting values and/or setting limits

- 4th line: Serial number of the display

DESIRED VOLT.LEVEL SW1

110V

(85V- 140V)

02/30

The displays are situated behind one another in a ringshaped arrangement, as shown in the illustration to the right,

and can be selected by operating the function keys SELECT

and . The display will remain visible for as long as

the SELECT key is being pressed, plus an additional 10

seconds after the SELECT key was released. It is possible to

move in both directions within the menu. As a result, display

no. 30 of the basic display can be reached just as quickly as

display no. 1.

The preset value can be altered within the setting values and/

or setting limits by operating the SET and function keys. Once the SET key is released, the new value will be

set to ‚active’.

For parametering purposes, please use the displays listed

below, the functions of which are explained in detail in the

following.

10

NORMSET

ON

ON/ OFF

DES.VOLTAGE LEVEL DVL1

100V

(85V- 140V

BANDWIDTH

9.0%

(0.5% - 9%)

DELAY T1

10s

(0s- 180s)

T1 LINEAR INTEGRAL

LINEAR

(LINEAR/INTEGRAL)

DELAY T2

10s

(PERM,1-10s,OFF)

OVERVOLTAGE U>

105%

(101%-130%)

UNDERVOLTAGE U<

70%

(70%- 99%)

OVERCURRENT I>

110%

(50% - 210%)

NOM.TRANSF.VOLTAGE

10.0V

(0.1kV- 999.9kV)

CURRENT

100A

(100A- 5000A)

TRANSFORMER PHASE

90 3 PH

(30,0,30,90,1PH)

DES.VOLT.LEVEL DVL2

100V

(85V- 140.0V)

DES.VOLT.LEVEL DV3

100.0V

(85.0V- 140.0V)

LDC UR

0.0V

(-25.0V - 25.0V)

01/30

)

02/30

03/30

04/30

05/30

06/30

07/30

08/30

09/30

10/30

11/30

12/30

13/30

14/30

15/30

LANGUAGE

GERMAN

GER/GB/F/E

SELECTION 4th LINE

CURRENT I

(I,S,Q,P,PHI,..)

DISPLAY V/kV

kV

(V/ kV)

H/T PULSE DURATION

0,5 s

(0.0 s - 10.0 s)

VOLT.REG.IDENTIFIER

1111

(0- 9999)

PARAL. OPERATION

TWIN PARALLEL

SKB/TWIN PARALL

CIRCUL.REAC.CURR.

BANDWIDTH

20%

(0.5% - 20.0%)24/30

CIRCUL.REAC.CURR.

STABILITY

0.0

(0.0- 100.0) 23/30

TAPPING DIRECTION

NEGATIVE

POSITIVE / NEGATIVE

POS MAX

35

(-35 – 35)

POS MIN

1

(-35 – 35)

SELECT PARALLEL

CIRCUL.REAC.CURR.

CRC/MAST/FOLLOW

Z-COMP LIMIT

0.0%

(0%- 15.0%)

Z-COMP VOLTRISE

0.0%

(0.0% - 15.0%)

LDC UX

0.0V

(-25.0V - 25.0V)

<

<

30/30

29/30

28/30

27/30

26/30

25/30

22/30

21/30

20/30

19/30

18/30

17/30

16/30

251/02 en

Page 11

3 Operation

4 Parametering

4 Parametering

3.2.2 Local/remote switch

The local/remote switch next to the terminal strip of the VC

extension module has no function during normal operation

of the TAPCON® 230 VC voltage regulator since its original

functions have now been completely taken over by the software of the voltage regulator. However, this switch can be

assigned a function for special tasks for special applications.

4.1 Normset setting

NORMSET

ON

ON/ OFF

The term „Normset“ function stands for an automatism

which considerably simplifies the configuration of a voltage

regulator. The only thing left to do for the operator when

commissioning during the Normset mode is to enter the

desired voltage level and subsequently take the device into

operation.

All other parameters required for simple voltage regulation

will be preassigned at the factory (e.g. bandwidth of ± 1 %).

Should the actual value exit the set bandwidth, an appropriate switching operation will be initiated at the on-load

tap-changer. The voltage change ensuing from the switching

operation corresponds to the transformer’s tap voltage and is

checked for plausibility by the regulator, using the preset

bandwidth. The bandwidth value is then optimised in accordance with the results gleaned from this check.

If the next system deviation occurs, the new bandwidth will

be used as basis, which will be rechecked and readjusted, if

necessary.

01/30

The time parameters are handled in the same way by the

regulator, which ensures optimum self-adjustment of the

regulator after only a few regulating sequences.

Should the marginal conditions change, the regulator will

again optimise itself automatically.

It goes without saying that mains-specific and/or customerspecific settings such as LDC, parallel operation or position

indication can still be done in the standard mode and will be

taken into consideration during determination of the

optimum parameters.

NONO

TETE

NO

TE

NONO

TETE

The parameters for undervoltage/overvoltage and overcurrent are not set by the Normset function. These parameters have to be entered manually during commissioning/

initiation.

251/02 en

11

Page 12

4 Parametering

4.2 Setting the desired voltage level 1

DES.VOLTAGE LEVEL DVL1

100V

(85V- 140V

)

02/30

The setting of the desired voltage level refers either to the

secondary or to the primary voltage side of the voltage

transformer connected to the TAPCON® 230 VC.

‘V’ stands for the secondary voltage which is indicated in

Volt. ‘kV’ stands for the primary voltage which is indicated in

Kilovolt. Press the SET and function keys to set

the desired voltage level.

4.3 Setting the bandwidth

BANDWIDTH

9.0%

(0.5% - 9%)

03/30

Set the bandwidth from ± 0.5 % to ± 9% in steps of 0.1 %

by pressing the SET and function keys. The transformer’s step voltage must be known to ensure proper

setting of this value.

B (%) =

Control range (%)

No. of steps No. of positions -1

Control range (%)

=

For increased regulating sensitivity it is also possible to set

lower values, although it is highly unadvisable to go beneath

60 % of the computed value. Higher values will cause a

decrease in regulating sensitivity.

If the measuring-circuit voltage is altered far enough during

operation to exceed the set bandwidth, the presignal will

respond. An output pulse will be generated according to the

set delay time.

If no compensation occurs for more than 15 min, the

„function monitoring“ relay will respond (see connection

diagram). The relay will not be reset until a shortfall of the

bandwidth threshold has occurred.

Standard setting range: ± 0.5 – ±9 %

Standard step width: 0.1 %

4.4 Setting the delay time T1 or T2 (DELAY 1/

DELAY 2) and pulse duration (option)

The delay time starts as soon as the deviation exceeds the set

bandwidth limits above or below. At the same time the corresponding presignal arrow appears. If the deviation is still

present after the delay time has elapsed, an output pulse is

emitted. If the deviation returns to within bandwidth limits,

then the current delay time is cancelled immediately.

Delay time T1

DELAY T1

10s

(0s- 180s)

04/30

The delay time can be set from 0....180 s by pressing the SET

and function keys.

T1 Linear/integral

T1 LINEAR INTEGRAL

LINEAR

(LINEAR/INTEGRAL)

05/30

The delay time T1 can be set with linear or integral response.

If a delay time with integral response „Int“ is set, the delay

time is automatically shortened according to the relation of

actual system deviation to set bandwidth, down to a

minimum of 1 s (fig. 2).

The desired time behavior can be set by pressing the SET and

function keys.

DU [%]

B [± %]

T1

<

12

Delay of the delay time

DU/B – voltage change DU in % of the desired value, in

relation to the set bandwidth of B in ± % of the desired

value.

2

251/02 en

Page 13

4 Parametering

Delay time T2

DELAY T2

10s

(PERM,1-10s,OFF)

06/30

The delay time T2 will become effective only if more than one

tap change is required for reduction of the control deviation

below the bandwidth limit. The set delay time T2 is then valid

for all consecutive output pulses.

Set the delay time T2 for a range of 1.0 … 10 s by pressing

the SET and function keys.

If the voltage regulator is set to PERM, it will emit a

continuous signal. If it is set to OFF, the delay time T2 will be

deactivated.

H/T Pulse duration (option)

H/T PULSE DURATION

0.5 s

(0.0 s - 10.0 s)

27/30

The value designated as "H/L pulse duration“ is the time

interval occurring between two pulses during high-speed

return control. The adjusting range is between 0 and 10 s at

an increment of 0.1 s each.

The value parameterised in "H/T pulse duration“ is used both

for the 'on’ time and the 'off’ time of a switching operation,

i. e. for an adjusting value of "2 s“, the relay will be switched

on for 2 seconds, and then remains switched off for another

2 seconds. That way a new switching operation cannot be

initiated until after 4 seconds.

Here, the make time is identified as "n –> 1" or "1 –> n", and

the break time is identified as "MOTOR RUNNING“ in the

third display line.

4.5 Setting the overvoltage detection (U>)

with automatic return control

OVERVOLTAGE U>

105%

(101%-130%)

07/30

The response threshold can be set from 101 % to 130 % of

the desired voltage level in steps of 1 % by pressing the SET

and function keys.

In the event of an overvoltage detection response, the onload tap-changer is operated by periodic pulses to the

motor-drive until the overvoltage falls below the response

threshold. The motor-drive is controlled by periodic pulses of

1.5 s through the "Lower“ output relay while the set delay

time re-mains inactive during this operation. At the same

time the alarm signalling LED lamp "U>" responds and a

signalling relay is energized (contacts 24/25/55) as long as

overvoltage is present. If the voltage regulator regulates

towards a higher voltage than the set limit U> due to an

unfavourable parametering (e.g. too high LDC settings), it is

prevented from exceeding the limit. This condition is

signalled by the signalling relay for ‘function monitoring’,

after 15 minutes.

4.6 Setting the undervoltage blocking (U<)

UNDERVOLTAGE U<

70%

(70%- 99%)

08/30

The response threshold for undervoltage blocking can be set

from 70 % to 99 % of the desired voltage level in steps of

1 % by pressing the function keys Set and .

Undervoltage blocking prevents tap change operations in the

event of a network breakdown. The voltage regulator output

pulses are blocked and the alarm signalling LED lamp "U<"

and a signalling relay (contacts 22/23/56) respond when the

measuring voltage falls below the set blocking value. After a

delay time of approx. 10 s, the associated signalling relay is

energized and remains that way. The signalling relay does

not respond in case of a failure of the measuring-circuit

voltage or supply voltage (< 30 V).

251/02 en

13

Page 14

4 Parametering

4.7 Setting the overcurrent blocking (I>)

OVERCURRENT I>

110%

(50% - 210%)

09/30

The overcurrent blocking response threshold can be set from

50 % to 210 % (of the rated current of the current transformer) in steps of 1 % by pressing the Set and

function keys. Overcurrent blocking prevents tap change

operations in the presence of overload.

The voltage regulator output pulses are blocked and the

alarm signalling LED lamp responds when the measured

current exceeds the set blocking value. At the same time the

corresponding signalling relay is energized and remains

energized (contacts 26/27/28).

4.8 Measuring transformers

(VT, CT CONFIGURATION)

The transformation ratios and measuring set-ups of the

voltage and current transformers used can be set in the

corresponding display windows by pressing the SET and

function keys.

Setting values for customary measuring circuits:

0° (for single-phase systems)

0° (for three-phase systems)

90° (for three-phase systems)

30° (for three-phase systems)

-30° (for three-phase systems)

Configuration a Phase angle setting

Configuration a Phase angle setting

Rated transformer voltage

NOM.TRANSF.VOLTAGE

10.0V

(0.1kV- 999.9kV)

10/30

Primary voltage of the voltage transformer in kV, in relation

to 100 V secondary voltage.

Rated transformer current

CURRENT

100A

(100A- 5000A)

11/30

Primary voltage of the voltage transformer in A

Transformer phase, measuring circuit

TRANSFORMER PHASE

90 3 PH

(30,0,30,90,1PH)

12/30

Phase angle of the current/voltage transformer, see fig. 3 for

explanations.

Configuration b Phase angle setting

Configuration c Phase angle setting

Configuration d Phase angle setting

Configuration e Phase angle setting

14

3

intc230m

251/02 en

Page 15

4 Parametering

4.9 Setting the desired voltage levels DVL2 and DVL3 4.10.1 Line Drop Compensation (LDC)

DES.VOLT.LEVEL DVL2

100V

(85V- 140.0V)

13/30

NOTE

DES.VOLT.LEVEL DV3

100.0V

(85.0V- 140.0V)

14/30

The voltage regulator TAPCON® 230 VC permits the

preselection of three different desired voltage levels, each of

which will be activated specifically in relation to the

actuation of inputs 33/34.

No signal present at terminals 33 and 34 => Desired voltage

level 1 is active

Presence of a signal at terminal 34 => Desired voltage

level 2 is active

Presence of a signal at terminal 33 => Desired voltage

level 3 is active

Setting the desired voltage levels 2 and 3 is identical to the

setting procedure for the desired voltage level 1, i.e. by

operating the function keys SET and .

4.10 Line compensation

The line compensation, i.e. the inclusion of the voltage drop

of a line connected to the transformer in the regulating

process, can be accomplished in two different ways.

Comparison between LDC and Z Compensation

Application of the vectorial compensation (LDC):

- requires knowledge of the exact line data

- permits a more accurate determination of the line voltage

drops

Application of the Z compensation:

- can be used in the case of minor shifts of the phase

angle j

- can be also used in meshed network applications.

For the correct setting of the LDC it is necessary to calculate the resistive and inductive line voltage drop in relation

to the secondary side of the voltage transformer in V and

the correct setting of the existing measuring transformer

configuration according to paragraph 4.8

Setting the resistive voltage drop Ur

LDC UR

0.0V

(-25.0V - 25.0V)

15/30

The calculated resistive voltage drop is set in the LDC UR

display by pressing the function keys SET and .

The effect of the compensation can be reversed by 180°

(minus sign preceding the setting). If no compensation is

desired, then the value „0“ is to be set (condition at the time

of delivery).

Setting the inductive voltage drop Ux

LDC UX

0.0V

(-25.0V - 25.0V)

16/30

The calculated inductive voltage drop is set in the LDC Ux

display by pressing the function keys SET and .

The effect of the compensation can be reversed by 180°

(minus sign preceding the setting). If no compensation is

desired, then the value „0“ is to be set (condition at the time

of delivery).

251/02 en

4

intVC13a

15

Page 16

4 Parametering

Calculation of the required setting values:

Ur = I

N

Ux = IN

.

R

RCT

.

R

VT

VT

.

r . L (V)

.

x . L (V)

R

CT

Where

Ur = LDC setting for resistive line voltage drop in V

Ux = LDC setting for inductive line voltage drop in V

I

= Rated current in A of the selected current trans-

N

former connection to the voltage regulator,

i.e. 0.2 A or 1 A or 5 A

RCT= Current transformer ratio, e. g. 200 A/ 5 A

RVT= Voltage transformer ratio, e. g.

30000 V /Ö 3

100 V

r = Ohmic resistance of line in Ω/ km per phase

x = Inductive reactance of line in Ω / km per phase

L = Length of line in km

Setting the voltage rise (VOLTRISE)

The calculated percentage of the voltage rise, referred to the

desired voltage level, is set by pressing the function keys SET

and . If no compensation is desired, the value „0“ is

to be set (link with ®LIMIT).

Z-COMP VOLTRISE

0.0%

(0.0% - 15.0%)

17/30

Setting the limitation for DUmax (LIMIT)

Z-COMP LIMIT

0.0%

(0%- 15.0%)

18/30

The value is set by pressing the function keys SET and

. If compensation is set to a certain value while

avoidance of excessive transformer voltage rises (e.g. in case

of an unusually high load) is desired, the limit values can be

set to the desired voltage level.

If no compensation is desired, the value „0“ is to be set.

If the active voltage drops Ur and reactive voltage drops Ux

are set correctly, then the line end voltage will remain

constant regardless of load.

4.10.2 Z-Compensation

For correct setting of the parameters the voltage rise (ΔU)

has to be calculated in consideration of the current.

Calculation of the required setting values:

UTr - U

= =

ΔU (%)

= 100

• •

= =

U

Load

Load

IN . R

I

CT

ΔU = Setting of Z-Compensation in %

UTr= Transformer voltage at current I

ULa= Line end voltage at current I and with the same

service position of the tap-changer

I = Load current in A

I

= Rated current in A of the selected current trans-

N

former connection to the voltage regulator,

i.e. 0.2 A or 1 A or 5 A

RCT= Current transformer ratio, e. g. 200 A / 5 A

4.11 Analog remote position indication (option)

Optionally, the voltage regulator TAPCON® 230 VC is

available with an analog control/activation of the remote

position indication. This option requires an analog module.

The following analog values can be processed:

• 4 – 20 mA

• Potentiometer range with a minimum total resistance of

50 Ω , up to a maximum total resistance of 2 kΩ .

Press the SET and function keys to set the

respective minimum and maximum positions.

For POS MIN, please enter the position corresponding to e.g.

4mA; for POS MAX, please enter the position corresponding

to e.g. 20mA.

The analog position indication will be included automatically

if the TAPCON® 230 VC is equipped with the parallel

operation option.

POS MIN

1

(-35 – 35)

POS MAX

35

(-35 – 35)

20/30

21/30

16

251/02 en

Page 17

4 Parametering

4.12 Voltage regulator identification

VOLT.REG.IDENTIFIER

1111

(0- 9999)

26/30

The voltage regulator contains a parametering interface to

allow parametering via laptop. The required visualization

software is included in the standard scope of delivery.

The purpose of voltage regulator identifier is to assign a

specific ‘address’ to the individual voltage regulator to

permit specified operation via visualization software.

A number ranging between 0 and 9999 can be entered to

serve as a „name“ by operating the SET and

function keys.

4.13 Setting the unit to V or kV

DISPLAY V/kV

kV

(V/ kV)

28/30

The voltage regulator TAPCON® 230 VC allows the user to

both display and enter the unit of the actual voltage level

and the desired voltage level in the basic display as well as

the parametering displays for the "desired voltage level 1, 2

and 3" in the primary voltage transformer unit kV.

To that end it is indispensable that the rated voltage of the

voltage transformer be entered as indicated under paragraph

4.8. Set the desired unit by operating the SET and

function keys.

4.14 Selection of the display in the 4th line of

the display

SELECTION 4th LINE

CURRENT I

(I,S,Q,P,PHI,..)

29/30

The basic display of the voltage regulator TAPCON® 230 VC

shows an additional measuring value in the 4th line. This

measuring value can be set individually by operating the SET and

function keys.

The following measuring values are available:

- Current I

- Apparent power S

- Reactive power Q

- Active power P

- Phase angle PHI

- Power factor cos PHI

- Frequency f

- Status line

- Position, optional

4.15 Language selection

LANGUAGE

GERMAN

GER/GB/F/E

30/30

The screen texts are available in four languages. Select the

desired language by operating the SET and

function key.

251/02 en

17

Page 18

5 Commissioning

5 Commissioning

5.1 Installation

The voltage regulator is suitable for both flush and projected

panel mounting (see dimension diagram). Be sure to install

the device in an easily accessible place in the control room or

in a switching cabinet attached to the transformer.

5.2 Connection

The voltage regulator is to be connected in accordance with

the wiring diagram (see Appendix).

When connecting the equipment, please pay attention to:

– the correct phase angle of the secondary terminals of

current transformer and potential transformer

– correct connection of the output relays to the motor

drive unit

– correct connection to earth of the housing.

WARNING

NOTE

The TAPCON® 230 VC was developed in accordance with

the relevant EMC standards. The following instructions

must be observed to ensure preservation of the EMC

properties:

– Ensure correct connection to ground by means of the

ground screw attached to the housing, wire section not

less than 4mm².

– Be sure to lead the individual power circuits (motor-

drive control, inputs, outputs) in separate cables.

– Be sure to use only shielded cables for the parallel

operation data links for the remote tap position

indication of the motor-drive unit. The screenings at

both line ends must be connected to ground via the

grounding angle cable clamps at the housing included

in the delivery (see fig. 6)

Take care to properly connect the voltage regulator and

the housing to ground. Danger to life.

The voltage regulator is normally fed by the voltage transformer.

NOTES

When using an auxiliary voltage AC 115V, 50...60Hz, be

sure to remove the links between terminals 1/3 and 2/4:

Connect the voltage transformer to terminals 1 and 2, and

the auxiliary voltage to terminals 3 and 4 (see fig. 5).

The TAPCON® 230 VC is optionally available with a supply

input of AC 230 V preset at the factory.

TAPCON® 230 VC

Required connection for use of the auxiliary voltage

5

intVC18

18

GROUND INTERFACE CABLE SHIELDINGS HERE

6

ERD-ANL

251/02 en

Page 19

5 Commissioning

5.3 Easy setting of operating modes with Normset

Prior to commissioning, be sure to check the entire circuity

and the measuring and operating voltage. To assess the

working mode of the voltage regulator, the use of a registering device to record the regulator voltage (actual voltage

level) is highly recommended.

The related transformer should be subject to normal load.

a) Select the MANUAL operating mode at TAPCON® 230 VC

b) Select the NORMSET function as indicated under 4.1

c) Set the Desired Voltage Level 1 as indicated under 4.2.

If you do not require a voltage display of the primary voltage

in kV you may now proceed to initiate the regulator by

operating the AUTO function key.

If you do require a voltage display in kV, however, please

proceed as follows:

d) Set the rated transformer voltage and the rated

transformer current as indicated under 4.8.

If you wish to configure the TAPCON® 230 VC voltage regulator to suit your specific requirements, please proceed as

indicated under 5.4.

f) Set the VOLTAGE LEVEL to this value.

g) Set the bandwidth "ΔU max“ to 1.0 %. In most cases the

voltage regulator is now in a balanced state (no presignal

LED lamp lights up). Otherwise change the desired voltage

level in steps of 0.5 V until a balanced state is reached.

h) Set the bandwidth „ΔU max“ dependently of the step

voltage (see paragraph 4.3).

i) Set the delay time T1 to 20 s lin. as per paragraph 4.4;

by manual control, move the on-load tap-changer

towards "Raise" (arrow in the display right "–>") by one

step, the presignal LED lamp for "Lower“ (arrow in the

display left "–>") must come on. Set the mode of opera-

tion to "AUTO"; 20 s after the presignal lamp lights up,

the voltage regulator must control the on-load tapchanger back to its previous service position. The presignal LED lamp goes out. Set the mode of operation to

"MANUAL". Repeat the control procedure towards

"Lower".

Set the operating delay time T2 to 10 s. Set the mode of

operation to "MANUAL". By manual control, move the

on-load tap-changer towards "Raise" by two steps, the

pre-signal LED lamp for "Lower" must come on.

5.4 Function tests; operational settings

Prior to commissioning, be sure to check the entire circuity

and the measuring and operating voltage. To assess the

working mode of the voltage regulator, the use of a

registering device to record the regulator voltage (actual

voltage level) is highly recommended. The related transformer should be subject to normal load.

a) Select the MANUAL operating mode at TAPCON® 230 VC

b) Set the transformation ratios of the transformers as

specified under paragraph 4.8, as well as the measuring

circuit.

c) Let the measured actual voltage (= voltage from the

voltage transformer) be indicated on the display of the

voltage regulator.

d) Let the current, power, and phase angle values be

indicated on the display and compare these values with

those from possibly existing service measuring

instruments. If wrong signs are indicated, reverse the

polarity of the current or voltage transformer.

e) Set the desired voltage level. By manual control of the

motor-drive, bring the on-load tap-changer to the service

position so that the desired voltage level is obtained

(see paragraph 5.5).

Set the mode of operation to "AUTO", then 20 s after the

presignal lamp has come on, the voltage regulator must

automatically control the on-load tap-changer back to

its previous service position by one step and after further

10 s by another step.

Set the delay times T1 and T2 to the desired value. If T2 is

not utilized, the "OFF" setting will be required.

When putting the transformer into service, it is recommended to set the delay time T1 provisionally to 100 s.

Depending on the existing operating conditions, you may

want to determine the definitive setting only after some

time of observation. For this purpose it is recommended

to register the variation of the actual voltage and the

number of tap change operations on a day-to-day basis.

If an inverse response of the voltage regulator is desired,

set an integral time response for the delay time 1. In this

case the delay time is automatically shortened inversely

proportional to the deviation.j) a

251/02 en

19

Page 20

5 Commissioning

k) Set the response threshold for undervoltage blocking

U < to 85 %. Set the mode of operation to "MANUAL“

and set the existing voltage level, e.g. 110 V, to 110 V /

0.85 ≈ 130 V, so that the actual voltage now corresponds

to the set percentage of the response threshold for the

blocking value. The presignal LED lamp for "Raise“ must

light up. Set the mode of operation switch to "AUTO“.

After approx.10 s the signalling relay "U <" must be

energized, the signalling contact (Contacts 22/23/56) will

open; the output relay "Raise" must not issue a control

command. LED U < will now respond. Upon completion of

this func-tion test you may now set the desired response

threshold for undervoltage blocking.

l) Set the response threshold for overvoltage detection U>

to 115 %. Set the mode of operation to "MANUAL", e. g.

110 V to 110 V / 1.15 ≈ 95 V so that the actual voltage

now corresponds to the set percentage of the response

threshold for overvoltage detection. The presignal LED

lamp for "Lower" must light up. Set the mode of operation to "AUTO".

The output relay "Lower" must issue periodic control commands at 1.5 s intervals. The signalling contact 24/25/55

will close/open. LED U > will now respond.

Now set the desired response threshold for overvoltage

detection to the initially desired voltage level.

m) Set the response threshold for overcurrent blocking I >.

A function check is not necessary.

o) Setting of Z Compensation (as per paragraph 4.10.2) as an

alternative to LDC.

Set the mode of operation to MANUAL.

Set the voltage rise to 0, the voltage regulator is in a

balanced state, no presignal LED lamp must light up.

Set the voltage rise to 15 %, the presignal LED lamp for

"Raise" must light up (during this functional check a load

current of 10 % of the rated current of the current

transformer must flow).

The desired values for Z Compensation can be set upon

completion of the above settings.

Set the mode of operation to AUTO. Check if the setting

is correct by observing the voltage at a specific point in

the line and with different loads. When the setting is

correct the voltage at the line end will remain constant.

p) Set the DESIRED VOLTAGE LEVEL 2 to the desired value

(see paragraph 4.9). Set the mode of operation to

MANUAL and connect terminals 31/34. According to

the set value for Desired Voltage Level 2, the presignal

"Lower" or "Raise" must respond.

Please proceed in the same manner for DESIRED VOLTAGE

LEVEL 3 by connecting terminals 31/33 signalling relay for

DESIRED VOLTAGE LEVEL 3. Set the mode of operation to

AUTO.

5.5 Tap position indication

n) Setting the load drop LDC (as per paragraph 4.10.1). Set

the mode of operation to "MANUAL".

Settings for Ux = Ur = 0, no presignal LED lamp for Raise/

Lower must light up.

Setting of Ur = 20 V, Ux = 0 V, the presignal LED lamp for

"Raise" must light up.

Setting of Ur = -20 V, Ux = 0 V, the presignal LED lamp

for "Lower" must light up (during this function check a

minimum load current of 5 % of the rated current of the

current transformer must flow.)

If the presignals appear in opposite direction, change the

polarity of the current transformer.

The actually desired LDC can be set upon completion of

the above settings.

Set the mode of operation to AUTO.

Check if the setting is correct by observing the voltage at

the line end during service and with different loads. When

the setting is correct the voltage at the line end will

remain constant.

20

The position signal can be fed as a 4 - 20 mA signal to the

regulator on terminals 94/95 (see connection diagram).

The position range must be set as described in section 6.2.1.1.

251/02 en

Page 21

6 Parallel operation

6 Parallel operation

The voltage regulator can be run with the SKB 30 parallel

control unit (parallel operation of 2 to 6 transformers).

Another possibility is to use parallel operation of two transformers which are each equipped with a voltage regulator

but without an additional parallel control unit (twin parallel

operation).

The selection is made with the following menu item:

PARAL. OPERATION

TWIN PARALLEL

SKB/TWIN PARALL

The menu item is selected by pressing the SELECT key and the

keys and then using the SET and keys to

choose between parallel operation with supplementary

device SKB 30 and the twin parallel operation.

Parallel operation (twin parallel operation)

This setting permits parallel control of two transformers on

one busbar.

Parallel operation management is handled via an RS 232

connection.

Activation of parallel operation is performed via the status

inputs terminals 90, 91.

Parallel control can be performed in two ways.

Parallel operation using the principle of "minimum circulat-

ing reactive current"

or

Parallel operation using the principle of "synchronism control

of tap-changer master-follower"

A menu item is used to select the principle of parallel

operation.

SELECT PARALLEL

CIRCUL.REAC.CURR.

CRC/MAST/FOLLOW

Select the menu item by pressing the SELECT key and the

keys and then setting the desired method of paral-

lel operation with jumper A (terminal 90/92), (see fig. 8/9).

Connect both parallel-operating voltage regulators via the

interface (see fig. 7).

The voltage regulators in parallel operation report the status

on terminals 80/81/82 and with LED .

25/30

19/30

TAPCON® 230 VC

TAPCON ® 230 VC / VC 100-BU-02

shielded cable, max. 25 m

7

7

6.1 Parallel operation with "Minimum Circulating

Reactive Current Method“

The circulating reactive current is computed from the transformer currents and their respective phase angles. For correction of the measuring circuit voltage, a voltage proportional

to the circulating reactive current is applied to self-sufficiently operating regulators. This correction voltage can be

either decreased or increased through adjustment of the

"stability" (see paragraph 6.1.3).

If an inadmissibly high circulating reactive current is detected, all on-load tap-changers involved will be reset after only

10 s, regardless of the delay time preset at the regulator.

This method is suitable for transformers of comparable output and uk, whether with uniform or with non-uniform step

voltage. No information on tap position is required.

to the second

251/02 en

21

Page 22

6 Parallel operation

6.1.1 System configuration, settings

Feed the additional connections/terminals to the regulators

(see fig. 8).

to the second

shielded cable, max. 25 m

TAPCON ® 230 VC / VC 100-BU-02

6.1.2 Setting the interference variable

(CIRCUL. REAC. CURR. STABILITY)

CIRCUL.REAC.CURR.

STABILITY

0.0

(0.0- 100.0) 23/30

Operate the SELECT key and the keys to select the

menu point and press the SET and function keys to

set a stability value between 0 and 100. The stability value is

a measure used for determining the effect of the circulating

reactive current on the voltage regulator. If it is set to "0",

no effects will occur. For a circulating reactive current equal

to the rated current of the voltage transformer, a setting

value of 10 would result in a voltage correction of 10 % in

the voltage regulators.

6.1.3 Setting the bandwidth for circulating

reactive current (blocking threshold)

CIRCUL.REAC.CURR.

BANDWIDTH

20%

(0.5% - 20.0%)24/30

TACPCON® 230 VC

Operate the SELECT key and the keys to select the

menu point and press the SET and function keys to

set the bandwidth from 0.5 to 20 % (in relation to the rated

current of the voltage transformer). If the circulating reactive current exceeds the preset threshold value during parallel operation, the message "circulating reactive current" will

be displayed in the status line and after a period of 30 s the

signalling relay contact (terminal 83/84/85) will respond.

All voltage regulators engaged in parallel operation will be

blocked.

Single/parallel

22

8

251/02 en

Page 23

6 Parallel operation

6.1.4 Function tests, commissioning

6.1.4.1 Preliminary settings

NOTE

The prerequisite for the proper functioning of parallel

operation is the commissioning of the voltage regulators

for individual operation.

The current transformer inputs must be connected and the

transformer configuration must be parameterised correctly.

The voltage regulators must be set to identical operating

parameters for the desired voltage, bandwidth, time delay 1,

and line compensation, if applicable (LDC or Z Compensation,

respectively).

In all cases, set STABILITY to "0“ and Blocking to "20“.

During parallel operation, time delay 2 must never be set

below 8 s!

All settings must be performed in the "Manual“ operating

mode.

6.1.4.2 Setting the interference variable

(CIRCUL. REAC. CURR. STABILITY)

Individually set both transformers to identical voltage with

the on-load tap-changers so that both voltage regulators are

in a balanced state (no presignal LED are lighting up, the

indication of "dU %" must be as low as possible, i. e. lower

than the preset bandwidth "dU max").

Now switch the transformers to parallel operation and enable

parallel control (connect terminal 90/91).

The voltage regulators must continue to remain in a balanced

state, the LED lamp "parallel operation" on the front panel is

lighting up.

Raise one of the two transformers by one voltage step and

lower the other of the two transformers by one voltage step.

Both regulators must continue to remain in a balanced state.

Raise the setting value "CIRC.REAC.CURR.STABILITY" of both

regulators in small steps starting with "0" until the corresponding presignals appear (the regulator of the transformer

with the higher voltage step must show the tendency "lower"

while the other transformer must show the tendency "raise“).

Now add the setting values thus established and set the

added-up value for both regulators.

Select the "Auto" operating mode for both voltage regulators. Both voltage regulators must control the on-load tapchangers back into their previous service positions.

The presignals will go out.

If the previous service position cannot be achieved that way,

the "CIRC.REAC.CURR. STABILITY“ setting needs to be increased. If the on-load tap-changers are regulating out of

sync ("pumping“), this setting needs to be reduced.

6.1.4.3 Setting the circulating reactive current

monitoring (CIRCUL. REAC. CURR. MON.

BANDWIDTH)

Switch over one of the two voltage regulators to the

"Manual“ operating mode. Using the manual control, the

associated motor drive must now be reset to "Raise“ by the

maximum admissible difference of the service positions

between the parallel operating transformers (e. g. by 1 … 2

steps).

Starting with the preset value of "20 %", reset the blocking

towards a lower value in small steps until the message

"Circulating reactive current" appears in the status line of the

display (please wait 2 – 3 s between the individual steps).

The bandwidth threshold of the circulating reactive current

monitoring is reached as soon as this message appears.

The voltage regulators will block all further regulating actions

and the signalling relay will respond (terminal 83/84/85).

Now reset the blocking again towards a higher value until

the message „circulating reactive current“ disappears from

the status line of the display.

Again switch the voltage regulator back to the "Auto"

operating mode. The motor-drive will be automatically

controlled back to the original service position.

Use the value established for the "Blocking" threshold to set

it for all of the other regulators.

6.2 Parallel operation according to synchronized

tap-change operation Master/ Follower

This method is suitable for transformers featuring an identical rated current, identical step voltage, and an identical

number of service positions. The motor-drive must signal the

tap-change position by means of a current of 4 … 20 mA

(with 4 mA corresponding to the lowest position and 20 mA

corresponding to the highest position).

During parallel operation, actual voltage regulation is performed by one of the voltage regulators (Master function).

The second voltage regulator (Follower) receives the tapchange position of the motor-drive from the first regulator,

for comparison with the tap-change position of its own

motor drive. If a difference is noted, the motor-drive in

question will receive a suitable control pulse.

251/02 en

23

Page 24

6 Parallel operation

6.2.1 System configuration, settings, transfer of

the on-load tap-changer setting

Lead the additional connections/terminals (see fig. 9) to the

regulators.

zto the second

ashielded cable, max. 25 m

TAPCON ® 230 VC / VC 100-BU-02

TACPCON® 230 VC

6.2.1.1 Setting the tapping position range

POS MIN

0

(-35 – 35)

POS MAX

35

(-35 – 35)

20/30

21/30

Operate the SELECT key and the keys to select the

menu point and set the respective lowest/highest tap positions between –35 and +35 by pressing the SET and

keys. To perform a function check, set the deactivated

transformer for all positions of the entire tap position range

while checking the position indicator.

TAPPING DIRECTION

NEGATIVE

POSITIVE / NEGATIVE

22/30

Since a comparison of the tap positions of the transformers

jointly engaged in parallel operation is performed during

parallel operation in accordance with the principle of tap-

change synchronicity (Master-Follower), it is imperative to

maintain identical position designations for all of these

transformers, and to ensure that the „higher“ and „lower“

signals will effect identical voltage changes in all the

transformers.

If this is not the case, e.g. if the "Higher" command (higher

voltage) is not equal to a higher position, it is also possible to

"turn the tap direction" within the voltage regulator.

This function can be switched on or off by inserting or

removing jumper B.

Single/parallel

With jumper A: Synchronism "master-follower"

4 ... 20 mA Þ tap position n min ...nmax

Insert jumper B when negative switching direction desired

9

Fig. 9

Feed the position signal in the form of a 4 ... 20 mA signal to

the regulator at terminals 44-45 (see connection diagram).

24

6.2.1.2 Selecting the Master/Follower operation

SELECT PARALLEL

CIRCUL.REAC.CURR.

CRC/MAST/FOLLOW

19/30

Operate the SELECT key and the keys to select the

menu point and assign the respective regulator as a Master

or a Follower by pressing the SET and keys.

If both regulators were assigned as „Follower“ or „Master“

during parallel operation, the regulators will be blocked (see

section 6.3 – Disturbances during parallel operation).

251/02 en

Page 25

6 Parallel operation

6.2.2 Function tests, commissioning and

preliminary settings

NOTE

The prerequisite for the proper functioning of parallel

operation is the commissioning of the voltage regulators

for individual operation.

The voltage regulators must be set to identical operating

parameters for the desired voltage, bandwidth, time delay 1,

and line compensation, if applicable.

The tap position indication at the regulators must function

correctly.

Select the "MANUAL“ operating mode at the voltage

regulators.

Individually set all on-load tap-changers involved in parallel

operation to identical voltage so that the voltage regulators

are in a balanced state (no presignal appearing on the dis-

play).

Now switch the transformers to parallel operation connect

terminals 90/91. The voltage regulators must continue to

remain in a balanced state and the LED lamps "Parallel“ at

the regulators must respond. Switch the Follower voltage

regulator to the "AUTO“ operating mode.

Use the manual control to raise the MASTER regulating unit

engaged in the "MANUAL“ operating mode by one step; the

follower regulator now has to automatically drag along the

associated transformer to do the same.

6.3 Parallel operation with existing parallel control

unit SKB 30 based on "minimum circulating

reactive current"

The following menu item is used for the selection:

PARALLEL OPERATION

TWIN PARALLEL

SKB/TWIN PARALLEL

25/30

The menu item can be selected by pressing the SELECT key

and the keys and then using the SET and

keys to select parallel operation with supplementary device

SKB 30.

To expand existing plants, the TAPCON® 230 VC voltage

regulator is equipped with a communication interface to an

existing SKB 30 parallel control unit.

The connection of the regulator with the parallel control

unit and the setting for parallel control are made as

described in operating instructions BA 117 (parallel control

unit SKB 30).

Terminals 90, 91, 92, 93, 94, and 95 on the TAPCON® 230 VC

have no function. The parallel operation signal, LED and

signal relay (terminals 80, 81, 82) remain functional, however.

6.4 Disturbances during parallel operation

In parallel operation the following messages appear in the

status line (only for twin parallel operation, not for chap.

6.3).

During the short period while a tap position difference is

present, the message "TAP DIFFERENCE“ will appear in the

status line of the display. If a follower regulator fails to drag

along its associated transformer, regulating action will be

blocked and a signalling relay will respond (terminals 83/84/

85).

251/02 en

Message Cause

CIRCULATING Circulat. reactive current

REACTIVE CURRENT was exceeded

TAP DIFFERENCE Synchronism disturbance

(tap difference £ 2 steps)

>1 MASTER More than one Master

was selected

NO MASTER No Master was selected

NO POSITION Failure of position

indication

DIFF. METHOD Different methods of

parallel operation were

selected

If any of the above disturbances occur, the regulators will be

blocked.

25

Page 26

7 Appendix

7 Appendix

7 Appendix

Front view.................................................................................................................................................................................................... TC230_1

Control panel set-up and mounting ................................................................................................................................................... 899564

Block/connection diagram,115 V.......................................................................................................................................................... BA251_1.PIC

Block/connection diagram, 230 V ........................................................................................................................................................ BA251_2.PIC

26

251/02 en

Page 27

TC230_1

TAPCON® 230

TAPCON® 230

Front view

Front view

251/02 en

27

Page 28

8995640E

TAPCON® 230

Control panel set-up and mounting

Remove crimp cableentries for flush

mounting

Clamp for

flush mounting

Bracketing fishplate

for panel mounting

Panel cutout for

flush mounting

28

251/02 en

Page 29

BA 251_1.PIC

TAPCON® 230 VC

Block/connection diagram, 115 V

251/02 en

29

Page 30

BA 251_2.PIC

TAPCON® 230 VC

Block/connection diagram, 230 V

30

251/01/01/0

Page 31

Page 32

www.reinhausen.com

©Maschinenfabrik Reinhausen GmbH Phone +49 941 40 90-0

Falkensteinstrasse 8 Fax +49 941 40 90-7001

93059 Regensburg, Germany E-mail sales@reinhausen.com

Please note: The data in our publications may differ from the data of devices delivered.

We reserve the right to make changes without notice.

BA 251/02 en • 0909 • F0125701 • Printed in Germany

Loading...

Loading...