Page 1

On-Load Tap-Changer

ECOTAP® VPD

®

Operating Instructions

6107891/02 EN

Page 2

© All rights reserved by Maschinenfabrik Reinhausen

Dissemination and reproduction of this document and use and disclosure of its content are strictly prohibited

unless expressly permitted.

Infringements will result in liability for compensation. All rights reserved in the event of the granting of patents,

utility models or designs.

The product may have been altered since this document was published.

We reserve the right to change the technical data, design and scope of supply.

Generally the information provided and agreements made when processing the individual quotations and orders

are binding.

The original operating instructions were written in German.

Page 3

Table of contents

Table of contents

1 Introduction......................................................................................................................... 6

1.1 Manufacturer....................................................................................................................................... 6

1.2 Completeness..................................................................................................................................... 6

1.3 Safekeeping........................................................................................................................................ 6

1.4 Notation conventions .......................................................................................................................... 6

1.4.1 Hazard communication system .............................................................................................................................7

1.4.2 Information system................................................................................................................................................8

1.4.3 Instruction system .................................................................................................................................................8

1.4.4 Typographic conventions ......................................................................................................................................9

2 Safety................................................................................................................................. 10

2.1 Appropriate use ................................................................................................................................ 10

2.2 Inappropriate use.............................................................................................................................. 11

2.3 Fundamental Safety Instructions ...................................................................................................... 11

2.4 Personnel qualification...................................................................................................................... 13

2.5 Personal protective equipment ......................................................................................................... 14

3 Product description.......................................................................................................... 16

3.1 Scope of delivery .............................................................................................................................. 16

3.2 Function description.......................................................................................................................... 16

3.3 Variants............................................................................................................................................. 17

3.4 Setup/models.................................................................................................................................... 17

3.4.1 ECOTAP® VPD® III without change-over selector.............................................................................................18

3.4.2 ECOTAP® VPD® III with change-over selector..................................................................................................20

3.4.3 ECOTAP® VPD® I without change-over selector...............................................................................................21

4 Packaging, transport and storage ..................................................................................24

4.1 Packaging ......................................................................................................................................... 24

4.1.1 Suitability.............................................................................................................................................................24

4.1.2 Markings..............................................................................................................................................................25

4.2 Transportation, receipt and handling of shipments........................................................................... 25

4.3 Storage of shipments........................................................................................................................ 26

4.4 Unpacking shipments and checking for transportation damages ..................................................... 27

Maschinenfabrik Reinhausen GmbH 2019 36107891/02 EN ECOTAP® VPD

®

Page 4

Table of contents

5 Mounting ...........................................................................................................................28

5.1 Fastening on-load tap-changer to transformer cover........................................................................ 28

5.1.1 Attaching the ECOTAP® VPD® III......................................................................................................................28

5.1.2 Attaching the ECOTAP® VPD® I........................................................................................................................32

5.2 Connecting tap winding and on-load tap-changer take-off lead ....................................................... 35

5.3 Mounting motor-drive unit and control unit ....................................................................................... 39

5.4 Taking measurements ...................................................................................................................... 44

5.5 Drying the on-load tap-changer ........................................................................................................ 46

5.6 Filling transformer with oil ................................................................................................................. 48

6 Commissioning................................................................................................................. 49

6.1 Commissioning the on-load tap-changer at the transformer manufacturer's site ............................. 49

6.1.1 Tests on the transformer .....................................................................................................................................50

6.1.2 Resetting automatic adjustment..........................................................................................................................52

6.2 Transporting transformer to the operating site.................................................................................. 53

6.3 Commissioning transformer at operating site ................................................................................... 54

6.3.1 Switching on the low-voltage busbar...................................................................................................................54

7 Operation........................................................................................................................... 56

7.1 Monitoring on-load tap-changer........................................................................................................ 56

7.2 Operating motor-drive unit and control unit ...................................................................................... 57

8 Fault elimination ...............................................................................................................58

9 Maintenance...................................................................................................................... 59

9.1 Inspection ......................................................................................................................................... 59

9.1.1 Visual check ........................................................................................................................................................59

9.1.2 Read out software version (F6)...........................................................................................................................60

9.1.3 Reading remaining life (F2).................................................................................................................................60

9.1.4 LED function test (F3) .........................................................................................................................................61

9.1.5 Checking the temperature blocking.....................................................................................................................62

9.1.6 Oil quality ............................................................................................................................................................62

9.2 Maintenance ..................................................................................................................................... 62

9.3 Care .................................................................................................................................................. 62

10 Disposal............................................................................................................................. 63

®

Maschinenfabrik Reinhausen GmbH 20194 6107891/02 ENECOTAP® VPD

Page 5

Table of contents

11 Technical data................................................................................................................... 64

11.1 On-load tap-changer type designation.............................................................................................. 64

11.1.1 ECOTAP®VPD on-load tap-changer designation.............................................................................................. 64

11.1.2 Number of positions and basic connection .........................................................................................................64

11.2 Technical data for the on-load tap-changer ...................................................................................... 65

11.3 Step capacity diagrams .................................................................................................................... 67

11.4 Permitted voltage stresses ............................................................................................................... 69

11.5 Tapped winding potential connection ............................................................................................... 74

11.6 Limit values for dielectric strength and water content of on-load tap-changer oil ............................. 75

12 Drawings ...........................................................................................................................76

12.1 Information on the drawings in the appendix .................................................................................... 76

12.2 Dimensional drawings....................................................................................................................... 76

12.2.1 SED_5872027.....................................................................................................................................................77

12.2.2 SED_5957148.....................................................................................................................................................80

12.2.3 SED_6330650.....................................................................................................................................................83

12.2.4 SED_6344630.....................................................................................................................................................86

12.3 High-voltage connection diagrams ................................................................................................... 89

12.3.1 SBI_5662910 ......................................................................................................................................................90

12.3.2 SBI_5798490 ......................................................................................................................................................91

12.3.3 SBI_5662912 ......................................................................................................................................................92

12.3.4 SBI_5662914 ......................................................................................................................................................93

12.3.5 SBI-6620632 .......................................................................................................................................................94

12.3.6 SBI_6620634 ......................................................................................................................................................95

Maschinenfabrik Reinhausen GmbH 2019 56107891/02 EN ECOTAP® VPD

®

Page 6

1 Introduction

1 Introduction

This technical file contains detailed descriptions on the safe and proper installation, connection, commissioning and monitoring of the product.

It also includes safety instructions and general information about the product.

This technical file is intended solely for specially trained and authorized personnel.

1.1 Manufacturer

The product is manufactured by:

Maschinenfabrik Reinhausen GmbH

Falkensteinstraße 8

93059 Regensburg, Germany

Tel.: (+49) 9 41/40 90-0

Fax: (+49) 9 41/40 90-7001

E-mail: sales@reinhausen.com

Further information on the product and copies of this technical file are available from this address if required.

1.2 Completeness

This technical file is incomplete without the supporting documents.

The following documents are considered supporting documents:

▪ Operating instructions for the associated ECOTAP® VPD® MD&C motor-

drive unit with control unit.

▪ Connection diagrams

▪ Routine test report

Also observe generally valid legislation, standards, and guidelines as well as

specifications on accident prevention and environmental protection in the respective country of use.

1.3 Safekeeping

Keep this technical file and all supporting documents ready at hand and accessible for future use at all times.

1.4 Notation conventions

This section contains an overview of the symbols and textual emphasis

used.

®

Maschinenfabrik Reinhausen GmbH 20196 6107891/02 ENECOTAP® VPD

Page 7

1 Introduction

1.4.1 Hazard communication system

Warnings in this technical file are displayed as follows.

1.4.1.1 Warning relating to section

Warnings relating to sections refer to entire chapters or sections, sub-sections or several paragraphs within this technical file. Warnings relating to

sections use the following format:

WARNING

Type of danger!

Source of the danger and outcome.

► Action

► Action

1.4.1.2 Embedded warning information

Embedded warnings refer to a particular part within a section. These warnings apply to smaller units of information than the warnings relating to sections. Embedded warnings use the following format:

DANGER! Instruction for avoiding a dangerous situation.

1.4.1.3 Signal words and pictograms

The following signal words are used:

Signal word Definition

DANGER Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE Indicates measures to be taken to prevent damage to property.

Table1: Signal words in warning notices

Maschinenfabrik Reinhausen GmbH 2019 76107891/02 EN ECOTAP® VPD

®

Page 8

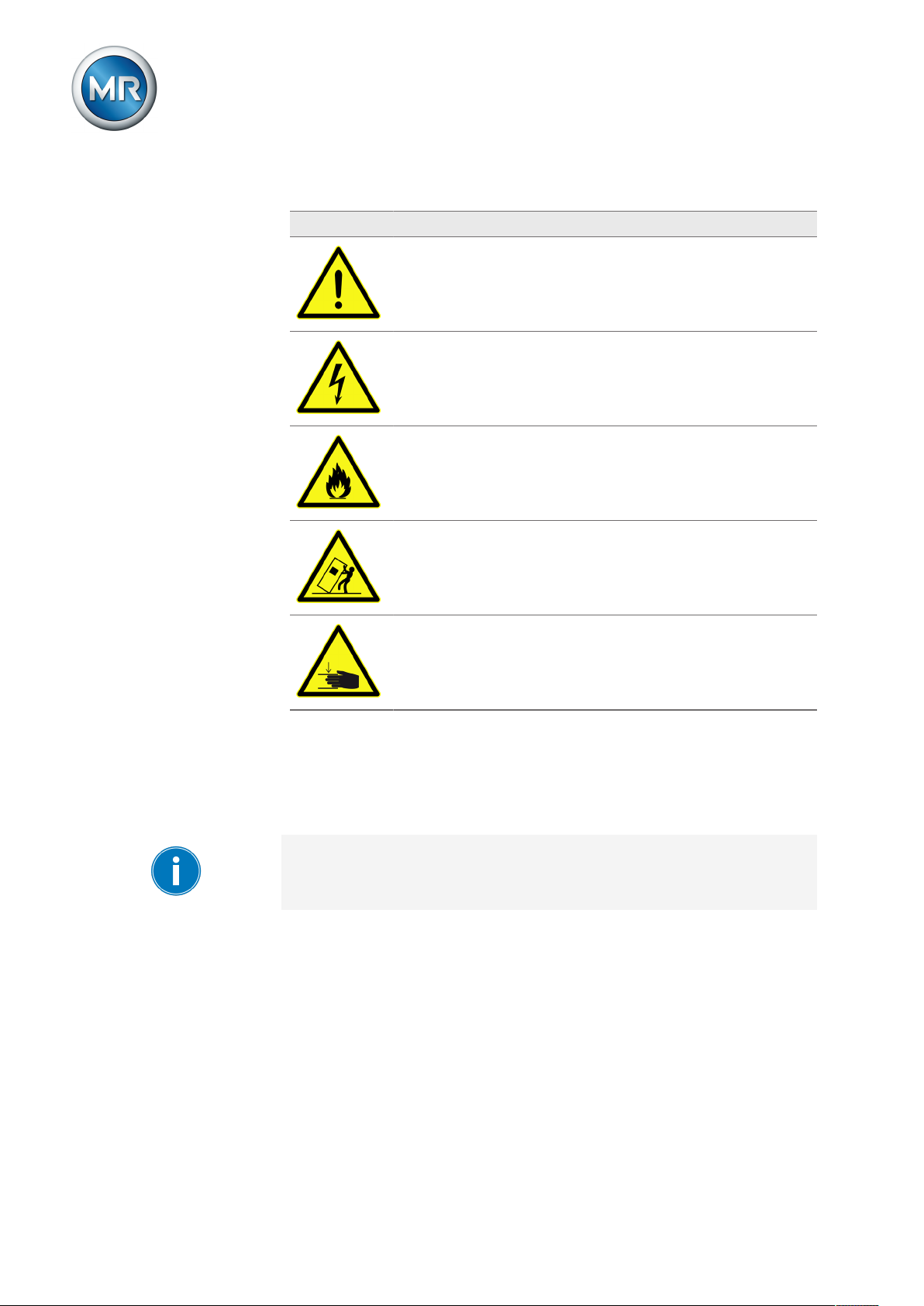

Pictograms warn of dangers:

Pictogram Definition

Warning of a danger point

Warning of dangerous electrical voltage

Warning of combustible substances

Warning of danger of tipping

1 Introduction

Warning of danger of crushing

Table2: Pictograms used in warning notices

1.4.2 Information system

Information is designed to simplify and improve understanding of particular

procedures. In this technical file it is laid out as follows:

Important information.

1.4.3 Instruction system

This technical file contains single-step and multi-step instructions.

Single-step instructions

Instructions which consist of only a single process step are structured as follows:

®

Maschinenfabrik Reinhausen GmbH 20198 6107891/02 ENECOTAP® VPD

Page 9

1 Introduction

Aim of action

ü Requirements (optional).

► Step 1 of 1.

ð Result of step (optional).

ð Result of action (optional).

Multi-step instructions

Instructions which consist of several process steps are structured as follows:

Aim of action

ü Requirements (optional).

1. Step 1.

ð Result of step (optional).

2. Step 2.

ð Result of step (optional).

ð Result of action (optional).

1.4.4 Typographic conventions

The following typographic conventions are used in this technical file:

Typographic convention

UPPERCASE Operating controls, keys AVR MANUAL

Bold Displays/menus P21

Italics System messages/LED dis-

[► Page number]. Cross reference [► 41].

Table3: Typographic conventions

Purpose Example

plays

ERROR LED

Maschinenfabrik Reinhausen GmbH 2019 96107891/02 EN ECOTAP® VPD

®

Page 10

2 Safety

This technical file contains detailed descriptions on the safe and proper installation, connection, commissioning and monitoring of the product.

▪ Read this technical file through carefully to familiarize yourself with the

product.

▪ This technical file is a part of the product.

▪ Read and observe the safety instructions provided in this chapter in partic-

ular.

▪ Observe the warnings in this technical file in order to avoid function-re-

lated dangers.

▪ The product is manufactured on the basis of state-of-the-art technology.

Nevertheless, risks to life and limb for the user or impairment of the product and other material assets may arise in the event of improper use.

2.1 Appropriate use

2 Safety

The product is an on-load tap-changer and adjusts the transmission ratio of

transformers without interrupting the load flow. The product is designed

solely for use in electrical energy systems and facilities. If used as intended

and in compliance with the requirements and conditions specified in this

technical file as well as the warning notices in this technical file and attached

to the product, then the product does not present any danger to people,

property or the environment. This applies throughout service life of the product, from delivery to installation and operation through to disassembly and

disposal.

The following is considered appropriate use:

▪ Only use the ECOTAP®VPD® on-load tap-changer in systems set up in

accordance with IEC61936-1.

▪ You will find the standard valid for the product and the year of issue on the

nameplate.

▪ Only operate the product in accordance with this technical file and the

agreed delivery conditions and technical data.

▪ Only operate standard design on-load tap-changers in entirely oil-filled

transformers. Use in transformers with a gas cushion below the transformer cover is only permitted with an appropriate special design. In such

cases, ensure that the minimum oil fill level stated on the dimensional

drawing supplied is observed.

▪ Operation with alternative insulating fluids is possible in accordance with

the specification in the Technical data [►Section 11, Page 64]. In such

cases, you must ensure compliance with the limited temperature ranges

by means of temperature blocking.

▪ Only operate the ECOTAP®VPD® on-load tap-changer and

ECOTAP®VPD®MD&C motor-drive unit in this combination. Operation

with another on-load tap-changer or motor-drive unit is not permitted.

®

Maschinenfabrik Reinhausen GmbH 201910 6107891/02 ENECOTAP® VPD

Page 11

2 Safety

▪ Ensure that all necessary work is performed by qualified personnel only.

▪ Use the equipment and special tools supplied solely for the intended pur-

pose and in accordance with the specifications of this technical file.

Permitted electrical operating conditions

In addition to the design data in accordance with the order confirmation, observe the following limits for the through-current and the step voltage:

In the standard version, the on-load tap-changer is designed for sinusoidal

50/60 Hz AC current with a curve form symmetrical to the zero axis and can

switch twice the rated through-current Ir at its rated step voltage Uir.

Exceeding the rated step voltage Uir for a short period by up to 10% is permitted if the rated through-current Ir is not exceeded.

2.2 Inappropriate use

Use is considered inappropriate if the product is used in a way other than as

described in the "Appropriate use" section. In addition, observe the following:

Prohibited electrical operating conditions

All operating conditions that do not comply with the design data in accordance with the order confirmation are prohibited.

Prohibited operating conditions may arise due to short circuits as well as due

to inrush current impulses when energizing transformers or other electrical

machines. This applies to the affected transformer itself just as it does to

transformers electrically connected in parallel or serially or other electrical

machines.

Higher voltages may occur due to transformer overexcitation following load

shedding, for example.

Operations outside of the permitted operating conditions can lead to injury to

persons and damage to the product.

▪ Prevent any such operations outside of the permitted operating conditions

by taking suitable measures.

2.3 Fundamental Safety Instructions

To prevent accidents, disruptions and damage as well as unacceptable adverse effects on the environment, those responsible for transport, installation, operation, maintenance and disposal of the product or parts of the product must ensure the following:

Maschinenfabrik Reinhausen GmbH 2019 116107891/02 EN ECOTAP® VPD

®

Page 12

2 Safety

Personal protective equipment

Loosely worn or unsuitable clothing increases the danger of becoming

trapped or caught up in rotating parts and the danger of getting caught on

protruding parts. This increases the danger to life and limb.

▪ All necessary devices and personal protective equipment required for the

specific task, such as a hard hat, safety footwear, etc. must be worn. Observe the section "Personal protective equipment" [►Section 2.5, Page

14].

▪ Never wear damaged personal protective equipment.

▪ Never wear rings, necklaces, or other jewelry.

▪ If you have long hair, wear a hairnet.

Work area

Untidy and poorly lit work areas can lead to accidents.

▪ Keep the work area clean and tidy.

▪ Make sure that the work area is well lit.

▪ Observe the applicable laws for accident prevention in the relevant coun-

try.

Working during operation

The product may only be operated in a sound, operational condition. Otherwise it poses a danger to life and limb.

▪ Regularly check the operational reliability of safety equipment.

▪ Comply with the inspection work, maintenance work and maintenance in-

tervals described in this technical file.

Working with current transformers

Dangerous high voltages may occur when a current transformer is operated

with an open secondary circuit. This can lead to injuries and property damage.

▪ Never operate a current transformer with an open secondary circuit; short-

circuit the current transformer to prevent this.

▪ Observe the information in the current transformer operating instructions.

Explosion protection

Highly flammable or explosive gases, vapors and dusts can cause serious

explosions and fire.

▪ Do not install or operate the product in areas where a risk of explosion is

present.

®

Maschinenfabrik Reinhausen GmbH 201912 6107891/02 ENECOTAP® VPD

Page 13

2 Safety

Safety markings

Warning signs and safety information plates are safety markings on the

product. They are an important aspect of the safety concept.

▪ Observe all safety markings on the product.

▪ Make sure all safety markings on the product remain intact and legible.

▪ Replace safety markings that are damaged or missing.

Ambient conditions

To ensure reliable and safe operation, the product must only be operated

under the ambient conditions specified in the technical data.

▪ Observe the specified operating conditions and requirements for the in-

stallation location.

Modifications and conversions

Unauthorized or inappropriate changes to the product may lead to personal

injury, material damage and operational faults.

▪ Only modify the product after consultation with the manufacturer.

Spare parts

Spare parts not approved by the manufacturer may lead to physical injury,

damage to the product and operational faults.

▪ Only use spare parts approved by the manufacturer.

▪ Contact the manufacturer.

2.4 Personnel qualification

The person responsible for assembly, commissioning, operation, maintenance and inspection must ensure that the personnel are sufficiently qualified.

Electrically skilled person

The electrically skilled person has a technical qualification and therefore has

the required knowledge and experience, and is also conversant with the applicable standards and regulations. The electrically skilled person is also proficient in the following:

▪ Can identify potential dangers independently and is able to avoid them.

▪ Is able to perform work on electrical systems.

▪ Is specially trained for the working environment in which (s)he works.

▪ Must satisfy the requirements of the applicable statutory regulations for

accident prevention.

Maschinenfabrik Reinhausen GmbH 2019 136107891/02 EN ECOTAP® VPD

®

Page 14

2 Safety

Electrically trained persons

An electrically trained person receives instruction and guidance from an

electrically skilled person in relation to the tasks undertaken and the potential dangers in the event of inappropriate handling as well as the protective

devices and safety measures. The electrically trained person works exclusively under the guidance and supervision of an electrically skilled person.

Operator

The operator uses and operates the product in line with this technical file.

The operating company provides the operator with instruction and training

on the specific tasks and the associated potential dangers arising from improper handling.

Technical Service

We strongly recommend having maintenance, repairs and retrofitting carried

out by our Technical Service department. This ensures that all work is performed correctly. If maintenance is not carried out by our Technical Service

department, please ensure that the personnel who carry out the maintenance are trained and authorized by Maschinenfabrik Reinhausen GmbH to

carry out the work.

Authorized personnel

Authorized personnel are trained by Maschinenfabrik Reinhausen GmbH to

carry out special maintenance.

2.5 Personal protective equipment

Personal protective equipment must be worn during work to minimize risks to

health.

▪ Always wear the personal protective equipment required for the job at

hand.

▪ Never wear damaged personal protective equipment.

▪ Observe information about personal protective equipment provided in the

work area.

®

Maschinenfabrik Reinhausen GmbH 201914 6107891/02 ENECOTAP® VPD

Page 15

2 Safety

Personal protective equipment to be worn at all times

Protective clothing

Close-fitting work clothing with a low tearing

strength, with tight sleeves and with no protruding parts. It mainly serves to protect the wearer

against being caught by moving machine parts.

Safety shoes

To protect against falling heavy objects and slipping on slippery surfaces.

Special personal protective equipment for particular environments

Safety glasses

To protect the eyes from flying parts and splashing liquids.

Visor

To protect the face from flying parts and splashing liquids or other dangerous substances.

Hard hat

To protect from falling and flying parts and materials.

Hearing protection

To protect from hearing damage.

Protective gloves

To protect from mechanical, thermal, and electrical hazards.

Maschinenfabrik Reinhausen GmbH 2019 156107891/02 EN ECOTAP® VPD

®

Page 16

3 Product description

3 Product description

This chapter contains an overview of the design and function of the product.

3.1 Scope of delivery

The product is packaged with protection against moisture and is delivered as

follows:

▪ On-load tap-changer

▪ Gasket

▪ Fixing screws with locking washers

▪ Nameplate (label)

▪ Technical files

Attach the on-load tap-changer nameplate to the corresponding motor-drive

unit. The position can be found in the section "Design/versions" [►Section

3.4, Page 17].

The crimp sleeves that may be needed for the connection are not included

in the scope of delivery.

Note the following information:

▪ Check the shipment for completeness on the basis of the shipping docu-

ments.

▪ Store the parts in a dry place until installation

▪ The product must remain in its airtight, protective wrapping and may only

be removed immediately before installation

You will find more information in the "Packaging, transport, and storage" [►Section 4, Page 24] chapter.

3.2 Function description

On-load tap-changers are used to adjust the desired tap of a tap winding under load.

The on-load tap-changer is based on the high-speed resistor-type tapchanger principle and uses vacuum cells to change the tap position under

load. In this process, the arc is extinguished while isolated in a vacuum cell,

preventing contaminants from entering the oil.

®

Maschinenfabrik Reinhausen GmbH 201916 6107891/02 ENECOTAP® VPD

Page 17

3 Product description

3.3 Variants

The ECOTAP®VPD® is available as a 3-phase or 1-phase version.

Type ECOTAP®VPD®III ECOTAP®VPD®I

Maximum rated through-current

I

rm

Highest voltage for equipment

U

m

Optional change-over selector Yes No

Table4: ECOTAP® VPD® versions

In the 1-phase version, the connection contacts are arranged on the left or

right side, depending on the order. Figures illustrating this can be found in

the section "ECOTAP® VPD® I without change-over selector" [►Section

3.4.3, Page 21].

For the correct connection, observe the order-specific connection diagram

supplied.

30A

100A

36kV

40.5kV

30A

100A

36kV

More important information can be found in the "Technical data" [►Section

11, Page 64] chapter.

3.4 Setup/models

The design and designation of the most important on-load tap-changer components are shown in the following illustrations. Further details can be found

in the dimensional drawings in the appendix.

Maschinenfabrik Reinhausen GmbH 2019 176107891/02 EN ECOTAP® VPD

®

Page 18

3 Product description

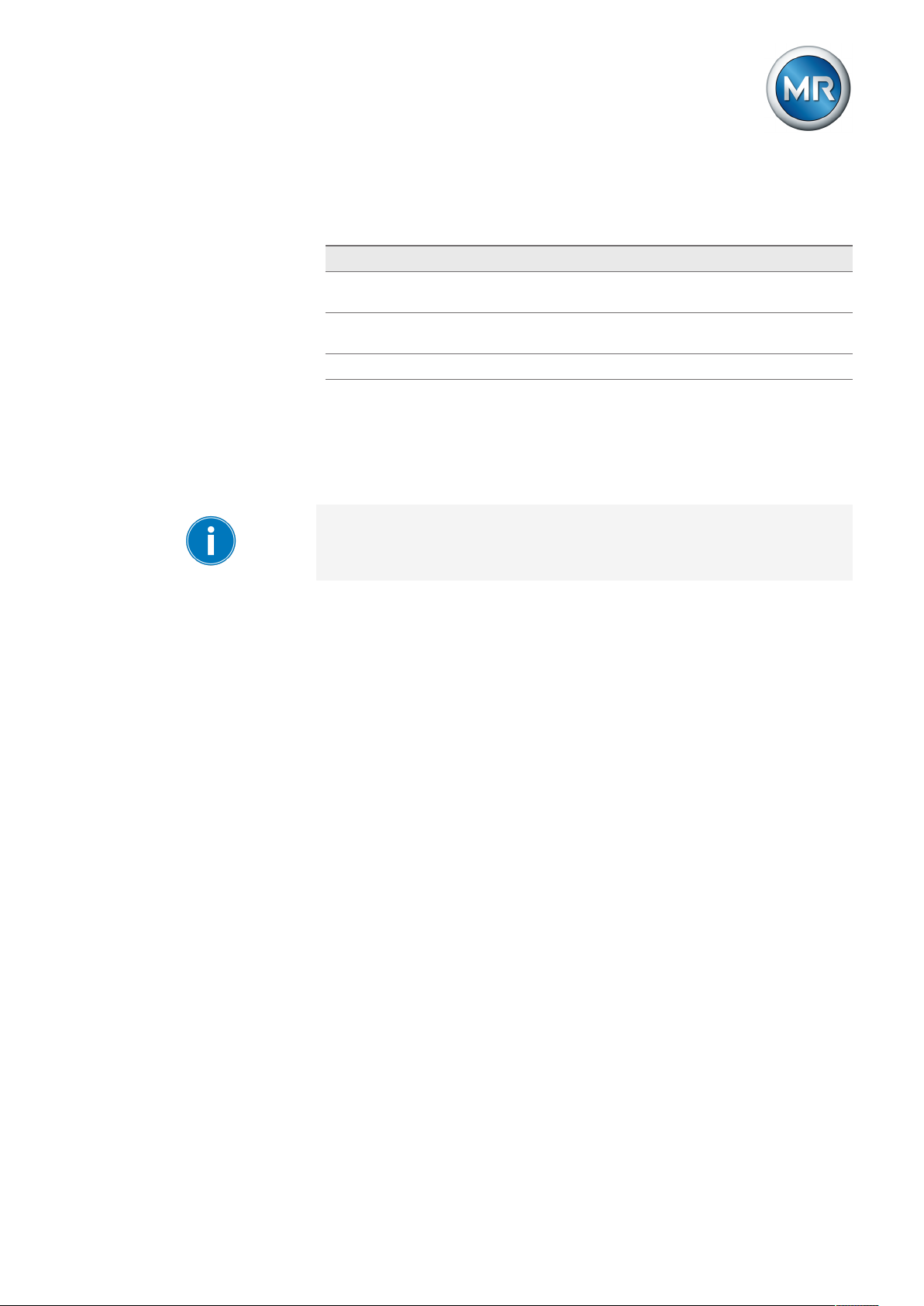

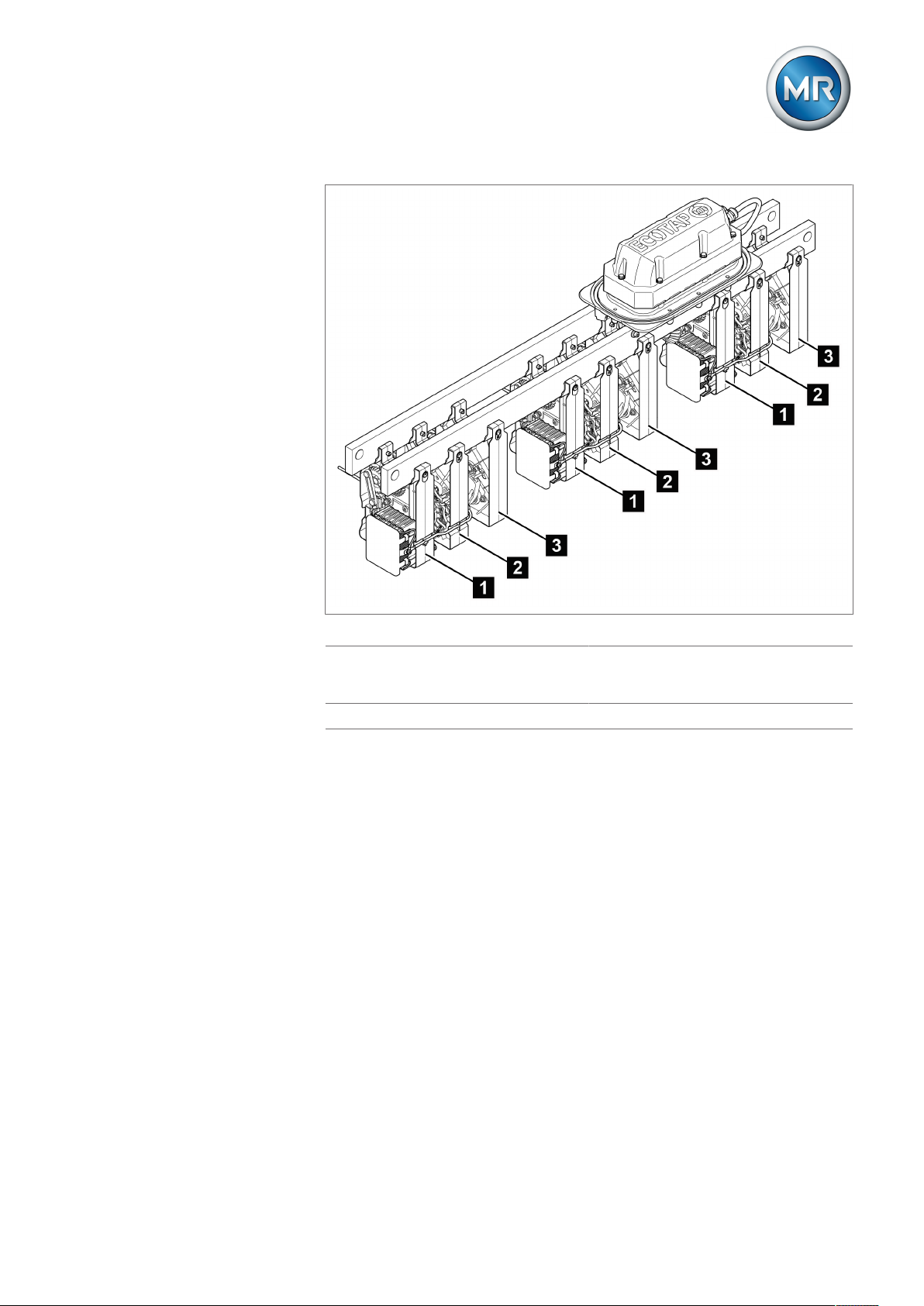

3.4.1 ECOTAP® VPD® III without change-over selector

The on-load tap-changer without change-over selector has 9 operating positions.

Figure1: Front view of the ECOTAP® VPD® without change-over selector

1 Motor-drive unit 2 Nameplate

3 Sealing module 4 Connection contact

5 O-ring gasket

®

Maschinenfabrik Reinhausen GmbH 201918 6107891/02 ENECOTAP® VPD

Page 19

3 Product description

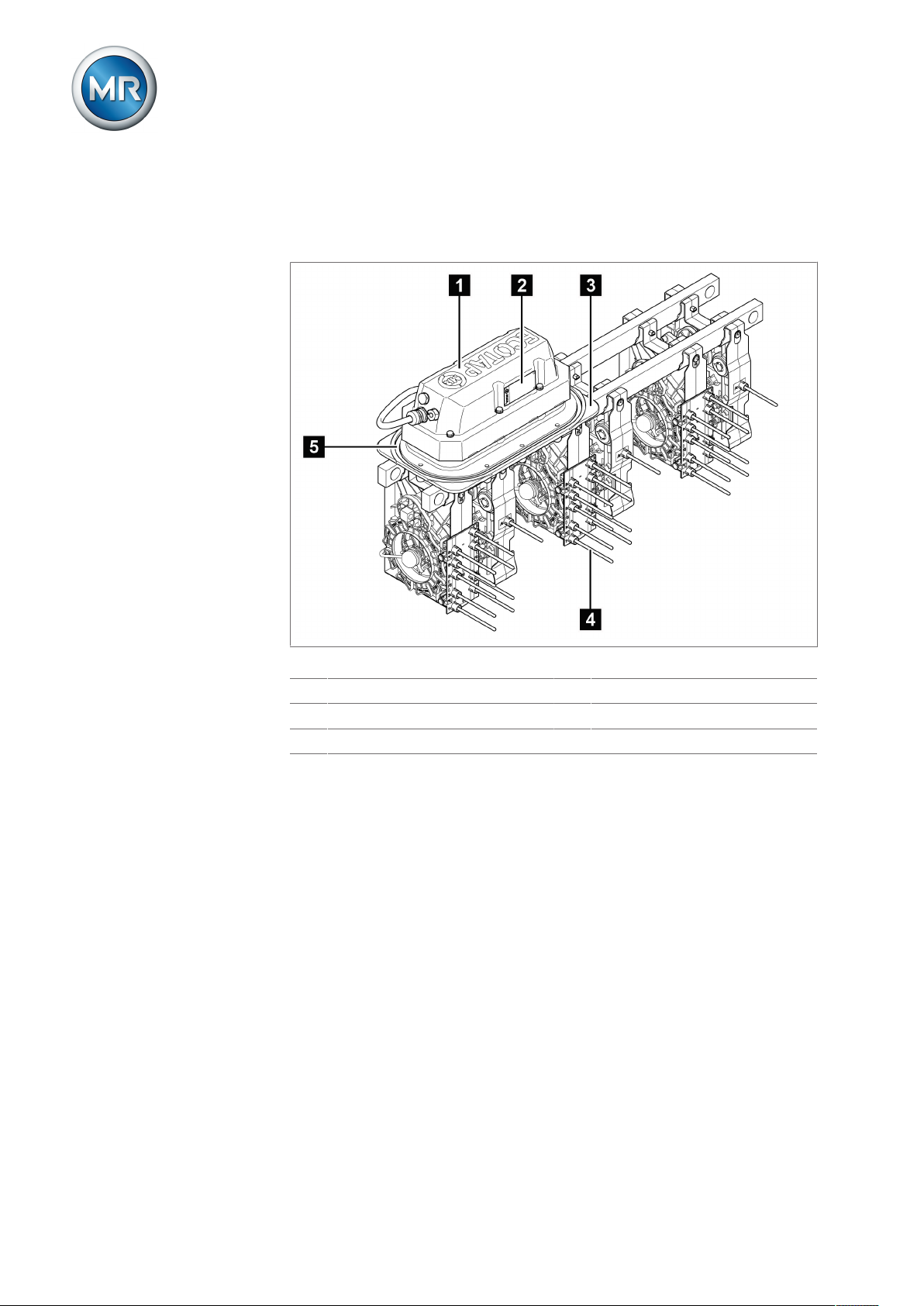

Figure2: Rear view of the ECOTAP® VPD® without change-over selector

1 Diverter switch assembly with tran-

2 Selector assembly

sition resistor and vacuum interrupter

Maschinenfabrik Reinhausen GmbH 2019 196107891/02 EN ECOTAP® VPD

®

Page 20

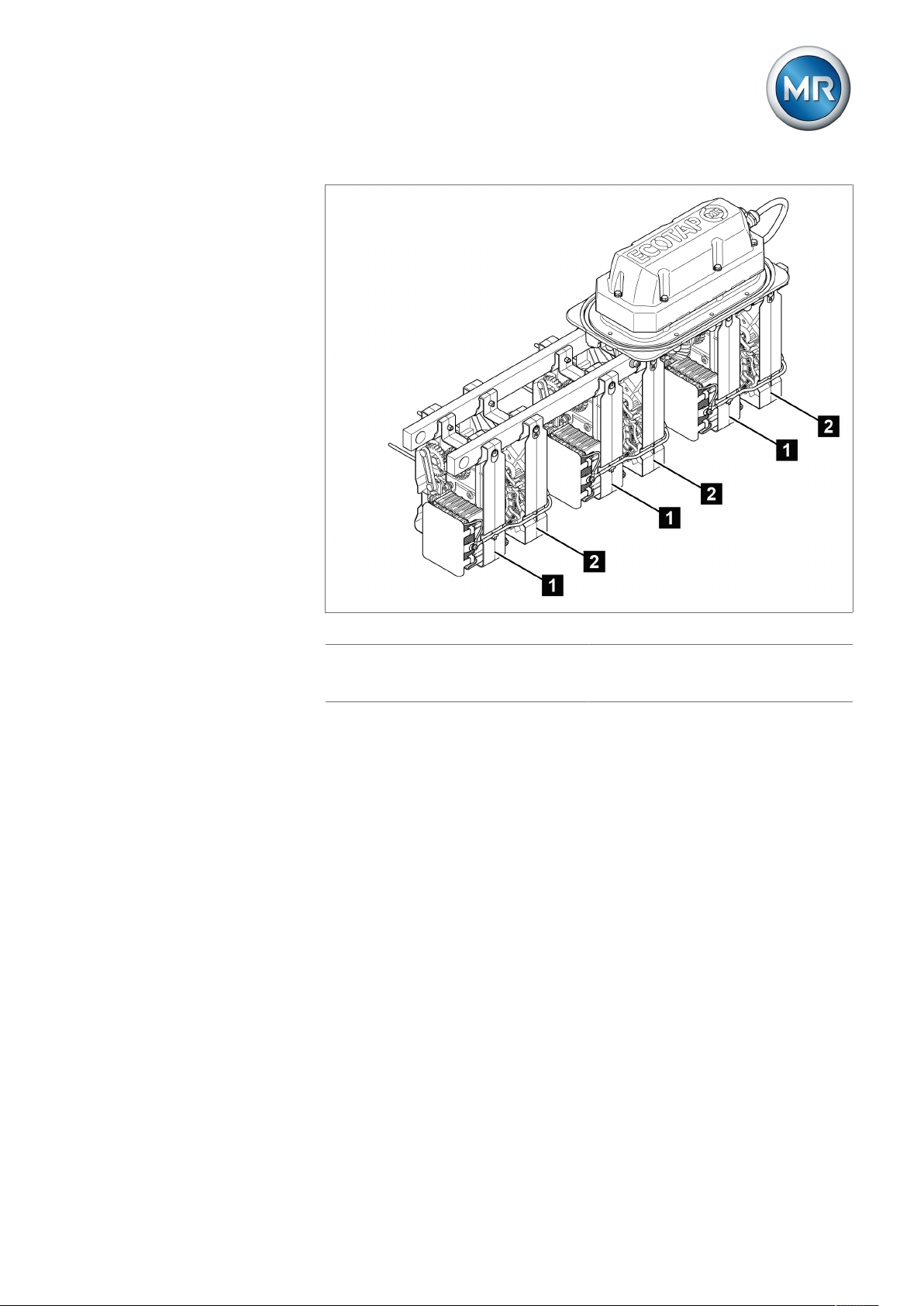

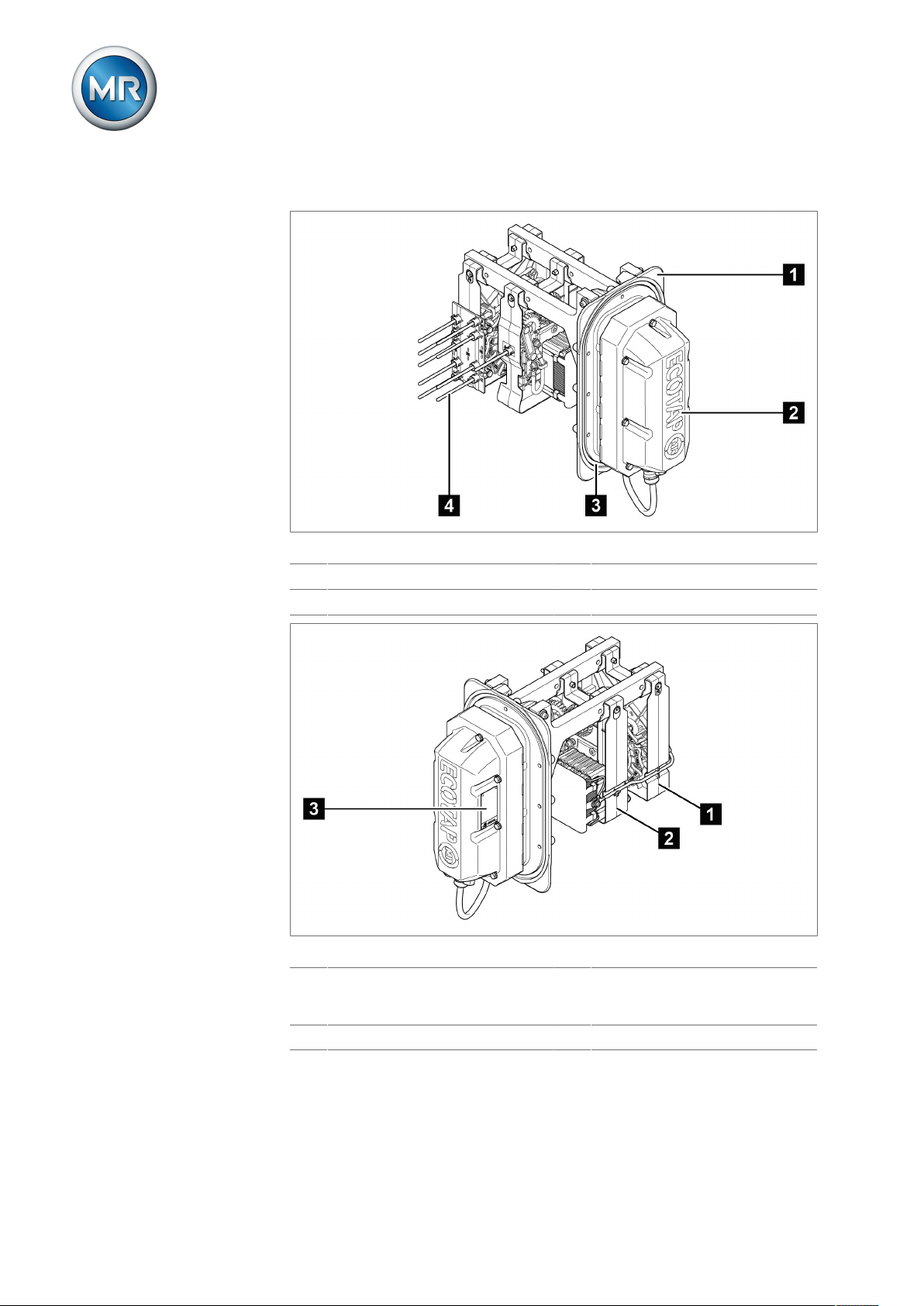

3.4.2 ECOTAP® VPD® III with change-over selector

The on-load tap-changer with change-over selector has 17 operating positions.

3 Product description

Figure3: Front view of the ECOTAP® VPD® with change-over selector

1 Motor-drive unit 2 Nameplate

3 Sealing module 4 Connection contact

5 O-ring gasket

®

Maschinenfabrik Reinhausen GmbH 201920 6107891/02 ENECOTAP® VPD

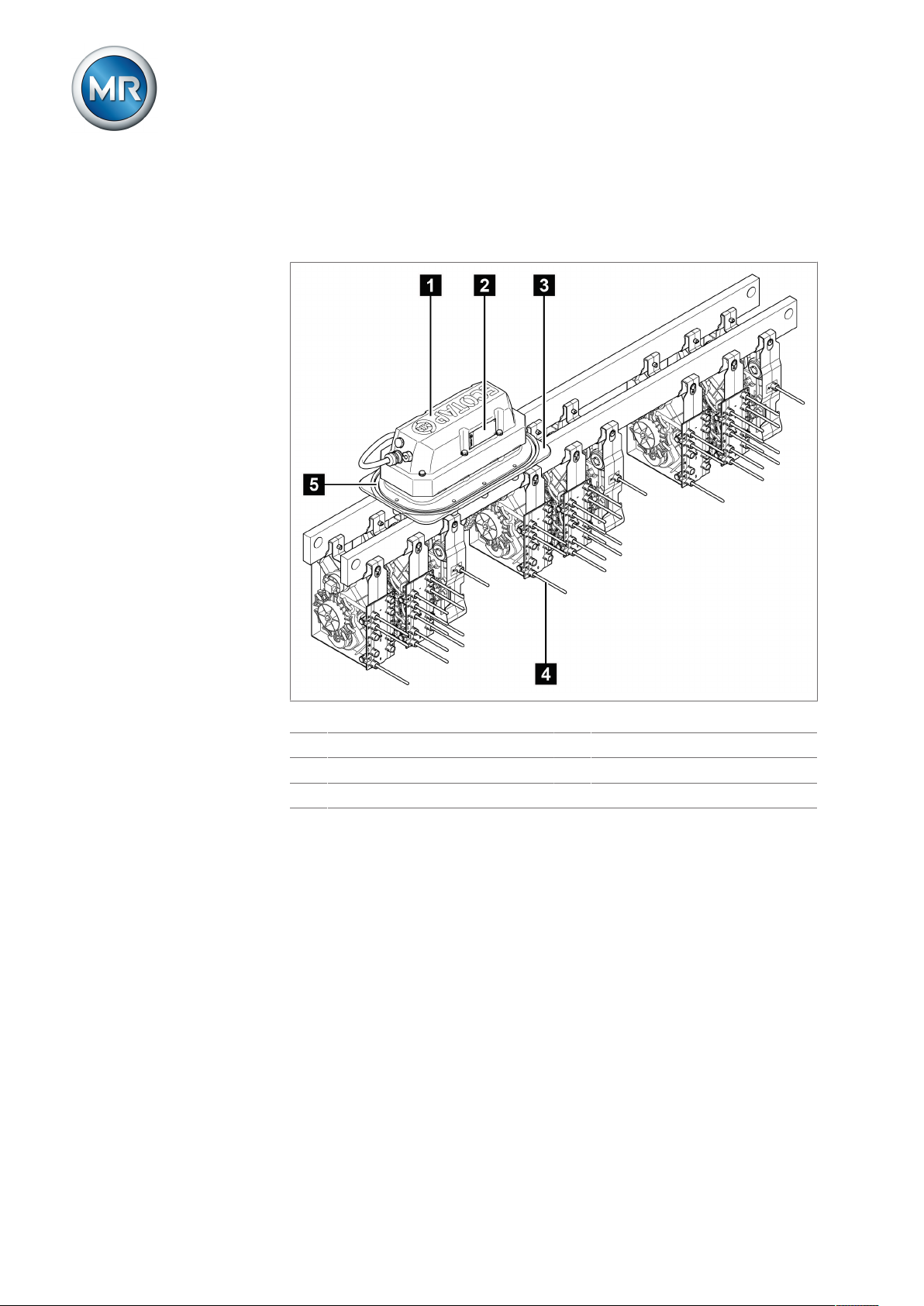

Page 21

3 Product description

Figure4: Rear view of the ECOTAP® VPD® with change-over selector

1 Diverter switch assembly with tran-

2 Selector assembly

sition resistor and vacuum interrupter

3 Change-over selector assembly

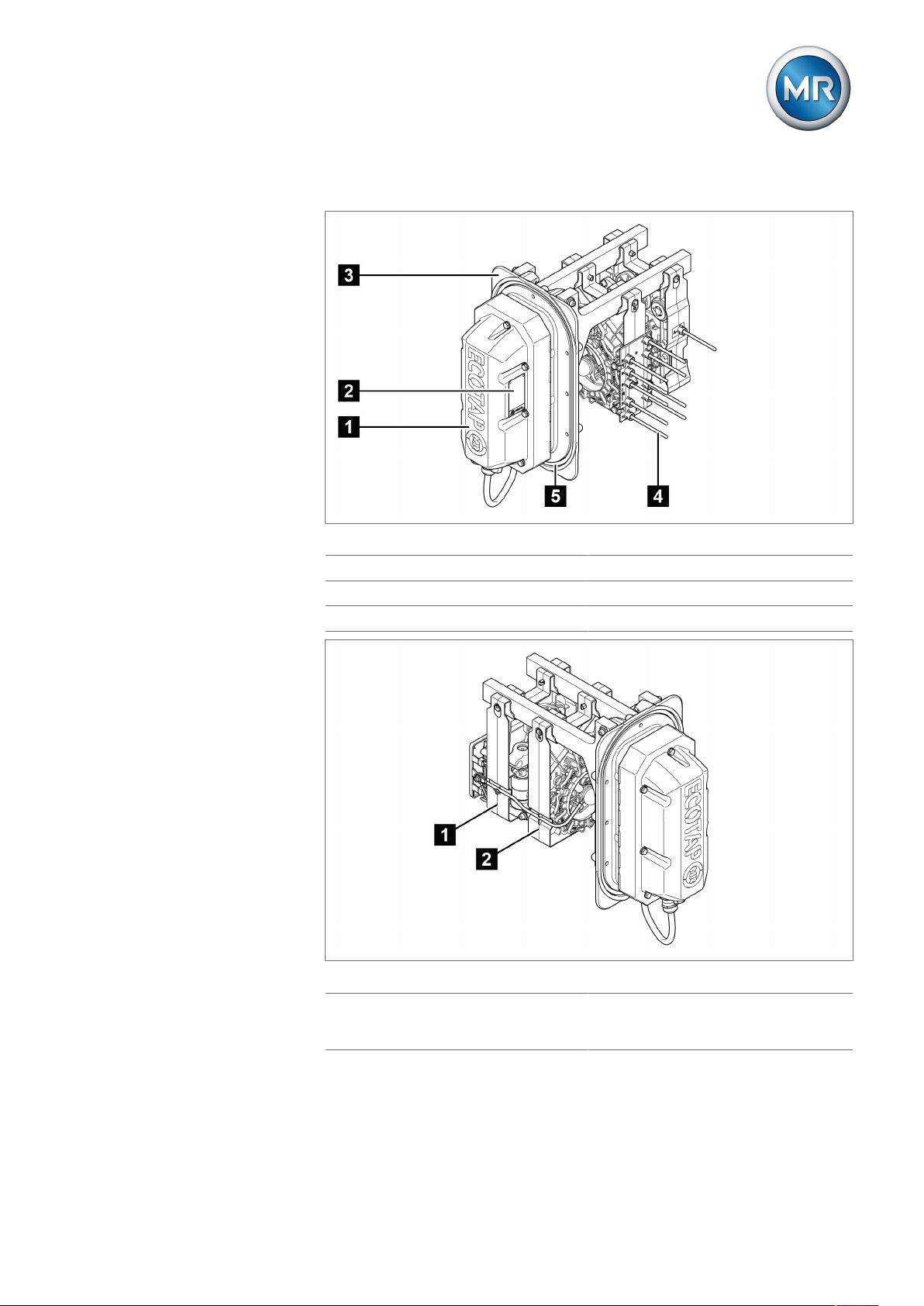

3.4.3 ECOTAP® VPD® I without change-over selector

The 1-phase on-load tap-changer is only available without a change-over selector and has 9 operating positions.

Maschinenfabrik Reinhausen GmbH 2019 216107891/02 EN ECOTAP® VPD

®

Page 22

3 Product description

1-phase on-load tap-changer with connection contacts on the left

Figure5: Front view, ECOTAP® VPD® I, connection contacts on left

1 Sealing module 2 Motor-drive unit

3 O-ring gasket 4 Connection contact

Figure6: Rear view, ECOTAP® VPD® I, connection contacts on left

1 Selector assembly 2 Diverter switch assembly with tran-

sition resistor and vacuum interrupter

3 Nameplate

®

Maschinenfabrik Reinhausen GmbH 201922 6107891/02 ENECOTAP® VPD

Page 23

3 Product description

1-phase on-load tap-changer with connection contacts on the right

Figure7: Front view, ECOTAP® VPD® I, connection contacts on right

1 Motor-drive unit 2 Nameplate

3 Sealing module 4 Connection contact

5 O-ring gasket

Figure8: Rear view, ECOTAP® VPD® I, connection contacts on right

1 Diverter switch assembly with tran-

2 Selector assembly

sition resistor and vacuum interrupter

Maschinenfabrik Reinhausen GmbH 2019 236107891/02 EN ECOTAP® VPD

®

Page 24

4 Packaging, transport and storage

4 Packaging, transport and storage

4.1 Packaging

The products are sometimes supplied with sealed packaging and sometimes

in a dry state, depending on requirements.

Sealed packaging surrounds the packaged goods with plastic foil on all

sides.

Products that have also been dried are identified by a yellow label on the

sealed packaging. In the dry state, delivery is also possible in a transport

container.

The information in the following sections should be applied as appropriate.

4.1.1 Suitability

NOTICE

Property damage due to incorrectly stacked crates!

Stacking the crates incorrectly can lead to damage to the packaged goods.

► The outer marking on the packaging states if, for example, the on-load

tap-changer or selector has been packed upright. Never stack these

crates.

► General rule: Do not stack crates above a height of 1.5 m.

► For other crates: Only stack up to 2 equally sized crates on top of one an-

other.

The packaging is suitable to ensure undamaged and fully functional means

of transportation in compliance with local transportation laws and regulations.

The packaged goods are packed in a sturdy crate. This crate ensures that,

when in the intended transportation position, the packaged goods are stabilized to prevent impermissible changes in position, and that none of the parts

touch the loading surface of the means of transport or touch the ground after

unloading.

Sealed packaging surrounds the packaged goods with plastic foil on all

sides. The packaged goods are protected from humidity using a desiccant.

The plastic foil was bonded after the desiccant is added.

®

Maschinenfabrik Reinhausen GmbH 201924 6107891/02 ENECOTAP® VPD

Page 25

4 Packaging, transport and storage

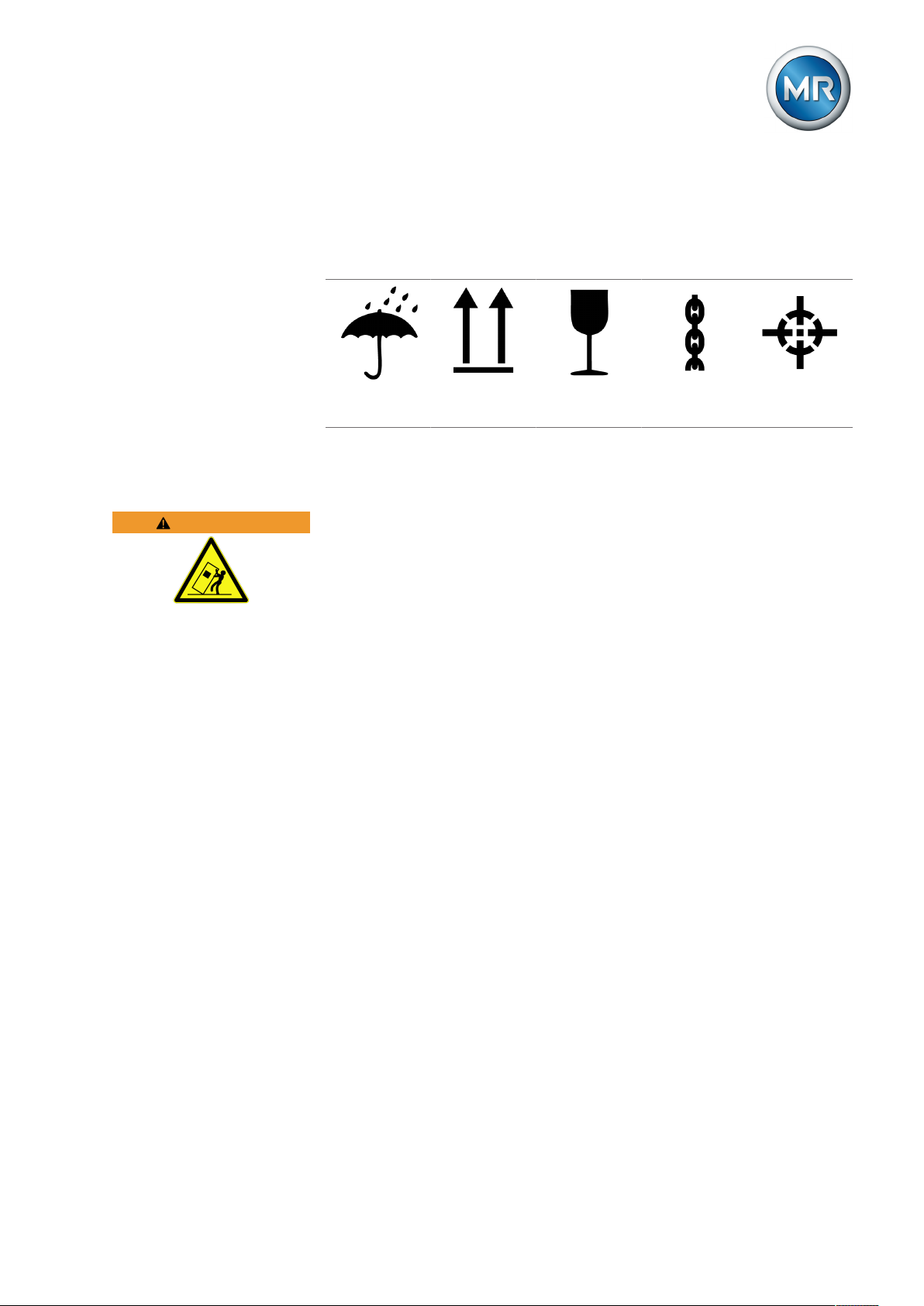

4.1.2 Markings

The packaging bears a signature with instructions for safe transport and correct storage. The following symbols apply to the shipment of non-hazardous

goods. Adherence to these symbols is mandatory.

WARNING

Protect against

moisture

Table5: Shipping pictograms

Top Fragile Attach lifting

gear here

Center of mass

4.2 Transportation, receipt and handling of shipments

Danger of death and damage to property!

Danger of death and damage to property due to tipping or falling load.

► Only transport the crate when closed.

► Do not remove the securing material used in the crate during transport.

► If the product is delivered on a pallet, secure it sufficiently.

► Only trained and authorized persons may select the sling gear and se-

cure the load.

► Do not walk under the hanging load.

► Use means of transport and lifting gear with a sufficient carrying capacity

in accordance with the weight stated on the delivery slip.

In addition to oscillation stress, jolts must also be expected during transportation. In order to prevent possible damage, avoid dropping, tipping,

knocking over and colliding with the product.

If a crate tips over, falls from a certain height (e.g. when slings tear) or is

subject to an unbroken fall, damage must be expected regardless of the

weight.

Every delivered shipment must be checked for the following by the recipient

before acceptance (acknowledgment of receipt):

▪ Completeness based on the delivery slip

▪ External damage of any type

The checks must take place after unloading when the crate or transport container can be accessed from all sides.

Maschinenfabrik Reinhausen GmbH 2019 256107891/02 EN ECOTAP® VPD

®

Page 26

4 Packaging, transport and storage

Visible damage If external transport damage is found upon receipt of the shipment, proceed

as follows:

▪ Immediately record the identified transport damage in the shipping docu-

ments and have this countersigned by the carrier.

▪ In the event of severe damage, total loss or high damage costs, immedi-

ately notify the manufacturer and the relevant insurance company.

▪ After identifying damage, do not modify the condition of the shipment fur-

ther and retain the packaging material until an inspection decision has

been made by the transport company or the insurance company.

▪ Record the details of the damage immediately on site together with the

carrier involved. This is essential for any claim for damages.

▪ Photograph damage to packaging and packaged goods. This also applies

to signs of corrosion on the packaged goods due to moisture inside the

packaging (rain, snow, condensation).

▪ NOTICE! If the product is delivered in sealed packaging, inspect this im-

mediately. If the sealed packaging is damaged, do not under any circumstances install or commission the packaged goods. Either re-dry the dried

packaged goods as per the operating instructions, or contact the manufacturer to agree on how to proceed. Failure to do so may result in damage to the packaged goods.

▪ Identify the damaged parts.

Hidden damage When damages are not determined until unpacking after receipt of the ship-

ment (hidden damage), proceed as follows:

▪ Make the party responsible for the damage liable as soon as possible by

telephone and in writing, and prepare a damage report.

▪ Observe the time periods applicable to such actions in the respective

country. Inquire about these in good time.

With hidden damage, it is very hard to make the transportation company (or

other responsible party) liable. Any insurance claims for such damages can

only be successful if relevant provisions are expressly included in the insurance terms and conditions.

4.3 Storage of shipments

Packaged goods dried by Maschinenfabrik Reinhausen

Upon receipt of the shipment, immediately remove the packaged goods

dried by Maschinenfabrik Reinhausen from the sealed packaging and store

air-tight in dry insulating oil until used if the packaged goods were not supplied in oil.

Non-dried packaged goods

Non-dried packaged goods but with a functional sealed packaging can be

stored outdoors when the following conditions are complied with.

®

Maschinenfabrik Reinhausen GmbH 201926 6107891/02 ENECOTAP® VPD

Page 27

4 Packaging, transport and storage

When selecting and setting up the storage location, ensure the following:

▪ Protect stored goods against moisture (flooding, water from melting snow

and ice), dirt, pests such as rats, mice, termites and so on, and against

unauthorized access.

▪ Store the crates on timber beams and planks as a protection against ris-

ing damp and for better ventilation.

▪ Ensure sufficient carrying capacity of the ground.

▪ Keep entrance paths free.

▪ Check stored goods at regular intervals. Also take appropriate action after

storms, heavy rain or snow and so on.

Protect the packaging foil from direct sunlight so that it does not disintegrate

under the influence of UV rays, which would cause the packaging to lose its

sealing function.

If the product is installed more than 6 months after delivery, suitable measures must be taken without delay. The following measures can be used:

▪ Correctly regenerate the drying agent and restore the sealed packaging.

▪ Unpack the packed goods and store in a suitable storage space (well ven-

tilated, as dust-free as possible, humidity < 50% where possible).

4.4 Unpacking shipments and checking for transportation

damages

▪ NOTICE! Transport the packaged crate to the place where installation will

take place. Do not open the sealed packaging until just before installation.

If this is not done, damage to the packaged goods may occur due to ineffectively sealed packaging.

▪ WARNING! When unpacking, check the condition of the packaged

goods.Secure packaged goods in an upright crate from tipping out. If this

is not done, the packaged goods may be damaged and serious injuries

may result.

▪ Check completeness of supplementary parts on the basis of the delivery

slip.

Maschinenfabrik Reinhausen GmbH 2019 276107891/02 EN ECOTAP® VPD

®

Page 28

5 Mounting

5 Mounting

5.1 Fastening on-load tap-changer to transformer cover

NOTICE

Damage to the on-load tap-changer and transformer!

Damage to on-load tap-changer and transformer due to electrical flashover

caused by insufficient distance from the motor-drive unit!

► When positioning the opening in the transformer, ensure a sufficient dis-

tance from adjacent energized parts.

Mount the on-load tap-changer horizontally with the sealing module on the

transformer cover.

Do not paint the surface on the underside of the transformer cover, which

later makes contact with the sealing module's o-ring. Only one coating of

primer is permitted.

1. Make opening for sealing module and holes for fixing screws in the transformer cover. The measurements and position can be found in the dimensional drawing in the appendix.

2. Clean sealing surfaces on sealing module and underside of transformer

cover. Insert O-ring supplied in sealing module.

3. CAUTION! Gradually tighten screws crosswise as described below

without warping or deforming. Improper screw connection will result in

damage to the on-load tap-changer.

4. Guide on-load tap-changer from below through the opening in the transformer cover.

5. Evenly tighten screws crosswise by hand. Tighten screws crosswise with

a pre-tightening torque of 9 Nm.

6. Check seat of flange and seal for regularity.

7. Tighten screws crosswise with the full tightening torque of 16 Nm.

8. Tighten screws again with full tightening torque, working clockwise and

tightening one screw after another as far as each screw will go.

NOTICE

5.1.1 Attaching the ECOTAP® VPD® III

Damage to the on-load tap-changer and transformer!

The on-load tap-changer may only be operated in transformers that are

completely filled with insulating fluid. Non-compliance may result in voltage

flashovers that cause serious damage to the on-load tap-changer and transformer.

► Use in hermetic transformers with a gas cushion below the transformer

cover is only permitted with an appropriate special design.

®

Maschinenfabrik Reinhausen GmbH 201928 6107891/02 ENECOTAP® VPD

Page 29

5 Mounting

Mount the on-load tap-changer horizontally with the sealing module on the

transformer cover.

Do not paint the surface on the underside of the transformer cover, which

later makes contact with the sealing module's o-ring. Only one coating of

primer is permitted.

1. Make opening for sealing module and holes for fixing screws in the transformer cover. The measurements and position can be found in the dimensional drawing in the appendix.

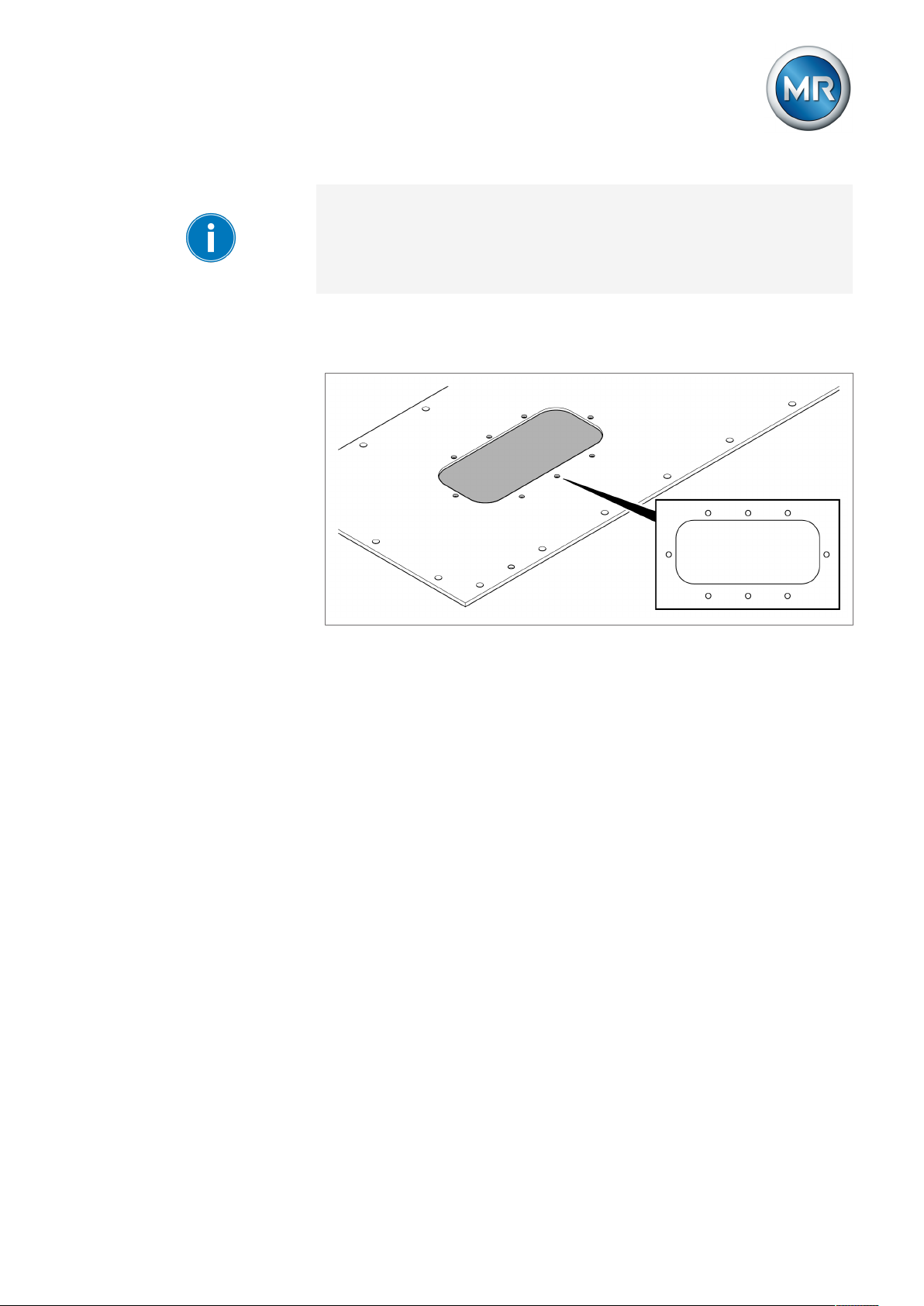

Figure9: Top view of transformer cover with opening for sealing module

Maschinenfabrik Reinhausen GmbH 2019 296107891/02 EN ECOTAP® VPD

®

Page 30

5 Mounting

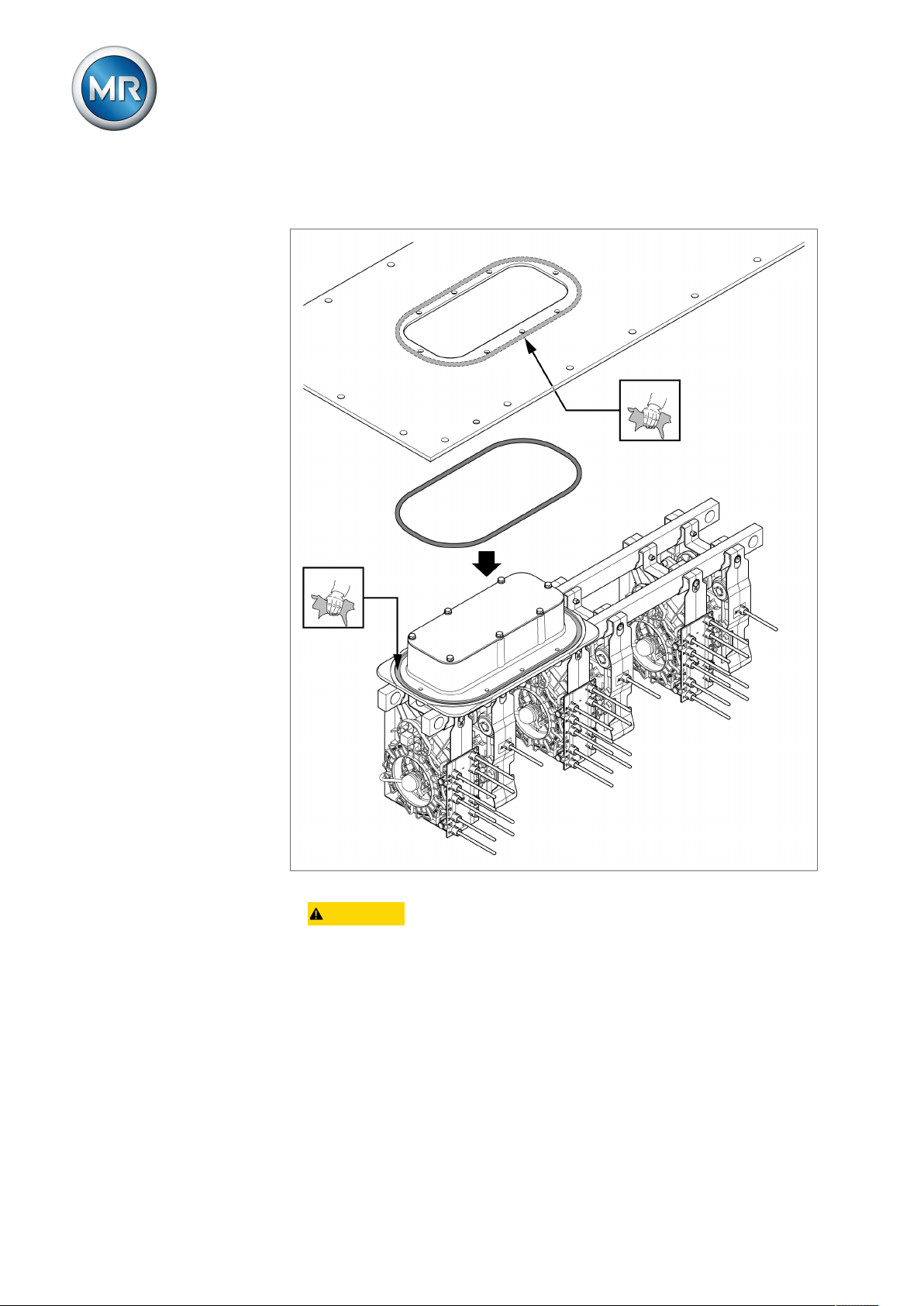

2. Clean sealing surfaces on sealing module and underside of transformer

cover. Insert O-ring supplied in sealing module.

Figure10: O-ring gasket

3. CAUTION! Gradually tighten screws crosswise as described below

without warping or deforming. Improper screw connection will result in

damage to the on-load tap-changer.

4. Guide on-load tap-changer from below through the opening in the transformer cover.

5. Evenly tighten screws crosswise by hand. Tighten screws crosswise with

a pre-tightening torque of 9 Nm.

6. Check seat of flange and seal for regularity.

®

Maschinenfabrik Reinhausen GmbH 201930 6107891/02 ENECOTAP® VPD

Page 31

5 Mounting

7. Tighten screws crosswise with the full tightening torque of 16 Nm.

Figure11: Fastening the on-load tap-changer

Pre-tightening torque 9 Nm

Full tightening torque 16 Nm

8. Tighten screws again with full tightening torque, working clockwise and

tightening one screw after another as far as each screw will go.

Maschinenfabrik Reinhausen GmbH 2019 316107891/02 EN ECOTAP® VPD

®

Page 32

5.1.2 Attaching the ECOTAP® VPD® I

5 Mounting

NOTICE

Damage to the on-load tap-changer and transformer!

The on-load tap-changer must be fully immersed in insulating fluid. Energized parts of the on-load tap-changer coming into contact with air may result in voltage flashovers that cause serious damage to the on-load tapchanger and transformer.

► Use in hermetic transformers with a gas cushion is only permitted if there

is sufficient distance between the gas cushion and the on-load tapchanger and connection contacts.

► The distance to the gas cushion must ensure that the on-load tap-

changer is fully immersed in insulating fluid in every operating situation.

Mount the on-load tap-changer vertically with the sealing module on the

transformer side wall.

Do not paint the inner surface of the transformer side wall which will later

make contact with the sealing module o-ring. Only one coating of primer is

permitted.

1. Make an opening for the sealing module and holes for the fixing screws

on the transformer side wall. The measurements and position can be

found in the dimensional drawing in the appendix.

Figure12: View of the transformer side wall with opening for sealing module

®

Maschinenfabrik Reinhausen GmbH 201932 6107891/02 ENECOTAP® VPD

Page 33

5 Mounting

2. Clean the sealing surfaces on the sealing module and the transformer

side wall. Insert O-ring supplied in sealing module.

Figure13: O-ring gasket

3. CAUTION! Gradually tighten screws crosswise as described below

without warping or deforming. Improper screw connection will result in

damage to the on-load tap-changer.

4. Lead the on-load tap-changer sideways from the inside through the opening in the transformer side wall.

5. Evenly tighten screws crosswise by hand. Tighten screws crosswise with

a pre-tightening torque of 9 Nm.

6. Check seat of flange and seal for regularity.

Maschinenfabrik Reinhausen GmbH 2019 336107891/02 EN ECOTAP® VPD

®

Page 34

5 Mounting

7. Tighten screws crosswise with the full tightening torque of 16 Nm.

Figure14: Fastening the on-load tap-changer

Pre-tightening torque 9 Nm

Full tightening torque 16 Nm

8. Tighten screws again with full tightening torque, working clockwise and

tightening one screw after another as far as each screw will go.

®

Maschinenfabrik Reinhausen GmbH 201934 6107891/02 ENECOTAP® VPD

Page 35

5 Mounting

5.2 Connecting tap winding and on-load tap-changer take-off

lead

NOTICE

Damage to the on-load tap-changer caused by improper mounting!

Mounting mistakes will damage the on-load tap-changer and jeopardize

safe operation.

► Connect connecting leads without warping or deforming them and ensure

that no forces are transferred from the connecting leads to the on-load

tap-changer.

► Place at least 3mm of paper insulation on the connecting leads – includ-

ing connection points – that face the transformer cover or the transformer

side wall to ensure the dielectric strength.

► Bending the connection contacts may limit the dielectric strength in accor-

dance with the specification in the "Technical data" [►Section 11.4, Page

69] chapter and reduce the rated withstand voltages! Ensure that the dielectric strength needed for the application is still ensured after assembly.

► The diagram below shows the areas particularly critical for insulation

spacing. Avoid bending the connection contacts into these critical areas.

ECOTAP® VPD® III on-load tap-changer without change-over selector

Figure15: Insulation spacing for ECOTAP®VPD® III without change-over selector

1 Transformer cover

2 Critical area: Spacing to grounded parts

3 Critical area: Spacing between the phases

Maschinenfabrik Reinhausen GmbH 2019 356107891/02 EN ECOTAP® VPD

®

Page 36

5 Mounting

ECOTAP® VPD® III on-load tap-changer with change-over selector

Figure16: Insulation spacing for ECOTAP®VPD® III with change-over selector

1 Transformer cover

2 Critical area: Spacing to grounded parts

3 Critical area: Spacing between the phases

®

Maschinenfabrik Reinhausen GmbH 201936 6107891/02 ENECOTAP® VPD

Page 37

5 Mounting

ECOTAP® VPD® I on-load tap-changer without change-over selector

NOTICE

Figure17: Insulation spacing for ECOTAP®VPD® I without change-over selector

1 Transformer side wall

2 Supporting bar

3 Critical area: Spacing to grounded parts

Damage to on-load tap-changer due to improperly carried out

crimp connections!

Improperly carried out crimp connections jeopardize safe operation.

► Carry out crimp connections in accordance with DIN EN 61238-1.

► The connection contacts on crimp connections may be shortened by no

more than 6 cm.

Maschinenfabrik Reinhausen GmbH 2019 376107891/02 EN ECOTAP® VPD

®

Page 38

5 Mounting

NOTICE

Damage to on-load tap-changer due to improperly carried out

solder connections!

Improperly carried out solder connections jeopardize safe operation.

► The connection contacts may not be shortened.

► The solder connection may only be produced on the end of the connec-

tion contacts (approx. 30 mm).

► Depending on the materials used, ensure the correct application of heat

to prevent both cold solder spots and thermal damage to the on-load tapchanger.

► Ensure that sharp edges or points are not produced at the connection

points. These may cause a local concentration of the field strength and

therefore result in partial discharge.

► Remove flux material residue.

Taking these safety notices into consideration, you can establish the connections in accordance with the supplied order-specified connection diagram. This connection diagram also contains the exact assignment of the individual connecting pieces of the on-load tap-changer.

1. To do so, connect the leads for the tap winding and on-load tap-changer

take-off leads to the on-load tap-changer's connection contacts by means

of crimping or soldering, without twisting.

Figure18: Tap winding connection (example for ECOTAP® VPD® III)

®

Maschinenfabrik Reinhausen GmbH 201938 6107891/02 ENECOTAP® VPD

Page 39

5 Mounting

Figure19: Tap winding connection (example for ECOTAP® VPD® I)

2. If the connection contacts have to be bent, observe the aforementioned

safety notices and use additional pliers to hold in place during bending so

that none of the forces are transferred to the on-load tap-changer. For

reasons of accessibility, we recommend starting with the bottom connections.

If you have any questions about producing the connections, please contact

Maschinenfabrik Reinhausen GmbH's Technical Service department.

5.3 Mounting motor-drive unit and control unit

As preparation, you must ensure that the on-load tap-changer is in a defined

operating position.

1. DANGER! Check the operating position before the transformer is

commissioned or ensure that the transformer is disconnected from all voltage sources and secured against reconnection. Failure to do so can lead

to death or serious injuries.

Maschinenfabrik Reinhausen GmbH 2019 396107891/02 EN ECOTAP® VPD

®

Page 40

5 Mounting

2. Remove transport locking plate and store safely. To avoid contamination

and mechanical damage, do not leave the sealing module open for long

periods of time.

Figure20: Removing the transport locking plate

3. When mounting for the first time: remove label with warning.

Figure21: Removing the label

®

Maschinenfabrik Reinhausen GmbH 201940 6107891/02 ENECOTAP® VPD

Page 41

5 Mounting

4. Check the position of the on-load tap-changer: The current operating position is displayed by the control wheel.

Figure22: Checking operating position (exemplary illustration)

5. Check additionally the position of the shaft of the on-load tap-changer: If

the previous on-load tap-change operation has been finished correctly,

the arrow on the cam disk is pointing to the arrow in the cover .

Figure23: Position of the shaft of the on-load tap-changer

ð If the shaft of the on-load tap-changer is in this position, the on-load

tap-changer is in a defined operating position. If this is not the case,

correct the position as described below.

6. NOTICE! Only use the emergency drive shaft installed in the sealing

module. Failure to do so can result in damage to the on-load tap-changer.

Maschinenfabrik Reinhausen GmbH 2019 416107891/02 EN ECOTAP® VPD

®

Page 42

5 Mounting

7. Pull the emergency drive shaft out of the bracket in the sealing module.

Figure24: Removing emergency drive shaft

8. Plug the emergency drive shaft with feather key into the shaft of the onload tap-changer.

Figure25: Attaching emergency drive shaft

9. Rotate emergency drive shaft in direction of desired operating position using an appropriate tool.

Figure26: Emergency drive shaft actuation

®

Maschinenfabrik Reinhausen GmbH 201942 6107891/02 ENECOTAP® VPD

Page 43

5 Mounting

10. NOTICE! Using the emergency drive shaft, turn for every tap-change

operation in one direction until one revolution has been completed and

the arrow on the cam disk (1) is again pointing to the arrow in the cover

(2). Otherwise the tap-change operation is not completed correctly,

which may result in damage to the on-load tap-changer and transformer.

Figure27: Position of the shaft of the on-load tap-changer

ð The current operating position is displayed by the control wheel.

Figure28: Checking operating position (exemplary illustration)

11. Pull the emergency drive shaft out of the shaft of the on-load tapchanger and plug it back into the bracket.

Figure29: Plugging the emergency drive shaft back in

12. Close the sealing module with the transport locking plate if the motordrive unit is not to be mounted immediately.

Maschinenfabrik Reinhausen GmbH 2019 436107891/02 EN ECOTAP® VPD

®

Page 44

5 Mounting

You have to mount and remove the motor-drive unit and control unit several

times:

1. After installing the on-load tap-changer, mount the motor-drive unit and

control unit and start them up, including automatic adjustment and trial

tap-change operations.

This first partial commissioning process is needed for you to be able to

check the wiring between the on-load tap-changer and transformer in accordance with the following description in the "Taking measurements" [►Section 5.4, Page 44] section.

2. Before "Drying the on-load tap-changer" [►Section 5.5, Page 46], remove the motor-drive unit and control unit again to avoid damage.

3. Drying and filling with oil [►Section 5.6, Page 48] is followed by the step

"Commissioning the on-load tap-changer at the transformer manufacturer's site" [►Section 6.1, Page 49]. This involves mounting the motordrive unit and control unit for a second time.

4. Before performing the "dielectric tests on the transformer wiring [►Section

6.1.1.2, Page 51]", disconnect the connection cable to the motor-drive

unit on the control unit to avoid damage.

5. Before "Commissioning the transformer at the operating site" [►Section

6.3, Page 54], reconnect and commission the control unit.

WARNING

NOTICE

You will find the description of how to mount, commission, and test the motor-drive unit and control unit in the operating instructions for the

ECOTAP®VPD®MD&C motor-drive unit.

5.4 Taking measurements

Electric shock from incorrect operation!

Danger of death or severe injury from electric shock!

► Only take measurements when the transformer is de-energized.

► Only perform tap-change operation with the control unit.

► Tap-change operations initiated by actuation with the emergency drive

shaft are not permitted during this test.

Damage to on-load tap-changer and motor-drive unit!

Damage to on-load tap-changer and transformer due to improper transformer ratio test!

► Do not perform more than 100 tap-change operations without a full oil fill.

► Only switch on-load tap-changer with the help of the control unit.

► Only use emergency drive shaft to rectify faults [►Section 8, Page 58]

and never operate with a drill.

Before drying the transformer, undertake the transformer ratio test and DC

resistance measurement as described below.

®

Maschinenfabrik Reinhausen GmbH 201944 6107891/02 ENECOTAP® VPD

Page 45

5 Mounting

This requires the motor-drive unit and control unit to be correctly mounted

and commissioned in accordance with the operating instructions for the

ECOTAP®VPD®MD&C motor-drive unit. These instructions also contain

further details of the trial tap-change operations required, automatic adjustment, and how to operate the control unit.

Carrying out transformer ratio test

1. Press on the control unit to activate manual mode.

ð LED above the key lights up.

Figure30: Activating manual mode

2. Press or until the desired operating position is reached.

ð The new operating position is displayed on the control unit.

3. Carry out the transformer ratio test in all operating positions.

ð Once the results have been checked, the transformer ratio test is com-

plete.

Maschinenfabrik Reinhausen GmbH 2019 456107891/02 EN ECOTAP® VPD

®

Page 46

5 Mounting

Check the transformer configuration in accordance with the supplied connection diagrams if the tap-change operation is not in the desired direction.

The behavior of the control unit (lowest voltage at smallest or largest position) can be adjusted accordingly via parameterization. To do so, follow the

description in the ECOTAP®VPD®MD&C motor-drive unit operating instructions, section "Inverting travel commands".

Carrying out DC resistance measurement

The measured DC current is normally restricted to 10% of the rated current

of the measured transformer winding in order to prevent the winding from

overheating.

Observe the maximum permitted measured currents for the on-load tapchanger during the DC resistance measurement on the transformer.

Maximum permissible measured current

Transformer tank empty Maximum 10 A DC

Transformer tank filled with insulating oil Maximum 10 A DC

Table6: Maximum permissible measured currents

NOTICE

Carry out the DC resistance measurement as follows:

1. Press on the control unit to activate manual mode.

ð LED above the key lights up.

2. Press or until the desired operating position is reached.

ð The new operating position is displayed on the control unit.

3. Carry out the DC resistance measurement in all operating positions.

ð Once the results have been checked, the DC resistance measurement is

complete.

5.5 Drying the on-load tap-changer

Damage to the on-load tap-changer, motor-drive unit, and control unit from drying!

Incorrectly performed drying will damage components sensitive to temperature.

► Remove motor-drive unit and control unit and do not dry.

► Before drying, fit transport locking plate to protect the on-load tap-

changer in accordance with the description below.

► Ensure that the temperature of the on-load tap-changer does not exceed

135 °C.

®

Maschinenfabrik Reinhausen GmbH 201946 6107891/02 ENECOTAP® VPD

Page 47

5 Mounting

To prepare for drying, proceed as follows:

ü Remove motor-drive unit and control unit as described in the section "Dis-

assembly before transformer drying" in the operating instructions for the

ECOTAP®VPD®MD&C motor-drive unit.

1. Clean sealing surfaces on sealing module and transport locking plate and

check that o-ring is in the correct position.

2. Attach and fasten transport locking plate before drying.

Figure31: Fastening transport locking plate

Potential drying methods:

You can dry the on-load tap-changer using one of the following methods.

▪ Vacuum-drying in an autoclave

▪ Vacuum-drying in the transformer tank

▪ Vapor-phase drying in an autoclave

▪ Vapor-phase drying in the transformer tank

▪ Low-frequency drying in an autoclave

▪ Low-frequency drying in a transformer tank

The drying time depends on the transformer.

Maschinenfabrik Reinhausen GmbH 2019 476107891/02 EN ECOTAP® VPD

®

Page 48

5.6 Filling transformer with oil

For the oil filling of the transformer, use new mineral insulating oil for transformers as per IEC60296 (Specification of unused mineral insulating oils for

transformers and switchgear).

If approved by the transformer manufacturer, synthetic ester liquids as per

IEC61099 (Specification for unused synthetic organic esters for electrical

purposes) or natural ester liquids as per IEC62770 (Specification for unused

natural esters for transformers and similar electrical equipment) can be used

as alternatives.

Contact Maschinenfabrik Reinhausen GmbH if you want to use an alternative insulating fluid.

Observe the permitted temperature range of the transformer oil in the "Technical data" [►Section 11.2, Page 65] chapter.

5 Mounting

NOTICE

Damage to the on-load tap-changer!

If a transformer is not completely filled with oil, the on-load tap-changer may

be damaged!

► Before commissioning the on-load tap-changer, completely fill trans-

former with oil.

► If using the special design of the 3-phase on-load tap-changer for her-

metic transformers with gas cushion, be sure to observe the oil fill details

on the supplied dimensional drawing.

1. Completely fill transformer with oil.

2. Take oil sample from transformer.

3. Record temperature of oil sample just after sample is taken.

4. Determine dielectric strength and water content at an oil temperature of

20°C ± 5°C. The dielectric strength and water content must comply with

the limit values stated below:

U

d

When commissioning the

transformer for the first

time

Table7: Limit values for mineral insulating oil (dielectric strength Ud measured in accordance

with IEC60156)

> 60 kV/2.5 mm < 12ppm

H2O

®

Maschinenfabrik Reinhausen GmbH 201948 6107891/02 ENECOTAP® VPD

Page 49

6 Commissioning

6 Commissioning

This chapter describes how to commission the device. Commissioning is

broken down into the following sections:

▪ Commissioning at the transformer manufacturer's site

▪ Transporting transformer to the operating site

▪ Commissioning at the operating site

6.1 Commissioning the on-load tap-changer at the transformer

manufacturer's site

WARNING

NOTICE

Flying parts and spraying of hot oil resulting from on-load tapchanger overload!

The on-load tap-changer can switch currents of up to twice the rated

through-current. Higher currents occur when activating transformers (inrush

current impulse) or in the event of short-circuits, for example. Higher voltages may occur due to transformer overexcitation following load shedding,

for example.

Danger of death or severe injury due to flying parts and spraying of hot oil!

► Ensure that the on-load tap-changer is not overloaded.

► Prevent on-load tap-change operations if higher currents arise.

► Ensure that the rated step voltage is not exceeded. The rated step volt-

age may be briefly exceeded by up to 10% as long as the rated throughcurrent is not exceeded.

► Ensure that the temperature limit values stated in the technical data are

not exceeded.

Damage to on-load tap-changer resulting from switching without oil!

Performing too many operations without a complete transformer oil fill will

damage the on-load tap-changer!

► Do not perform more than 100 tap-change operations without a full oil fill.

► Only use emergency drive shaft to rectify faults [►Section 8, Page 58]

and never operate with a drill.

Before starting to test the transformer, take the following steps, which are

described in detail in the operating instructions for the ECOTAP® VPD® motor-drive unit:

1. Mount and connect motor-drive unit and control unit.

2. Commission motor-drive unit and control unit.

3. Carry out automatic adjustment and trial tap-change operations.

ð You can then start the transformer tests. Observe the description below.

Maschinenfabrik Reinhausen GmbH 2019 496107891/02 EN ECOTAP® VPD

®

Page 50

6.1.1 Tests on the transformer

Please contact Maschinenfabrik Reinhausen GmbH (MR) if any aspect of

the tests is not clear.

6.1.1.1 Electrical high-voltage tests on the transformer

6 Commissioning

WARNING

Danger of death or severe injury from explosive gases when

testing the transformer!

Danger of death from flying debris and spraying of hot oil if incorrect action

is taken when explosive gases accumulate under the transformer cover, in

the piping, in the oil conservator, and at the dehydrating breather opening!

► Ensure that there are no naked flames, hot surfaces or sparks (for exam-

ple caused by static charging) in the immediate surroundings and that

none occur.

► Ensure that the on-load tap-changer is fully submerged in oil.

► Only use conductive and grounded hoses, pipes, and pump equipment

that are approved for flammable liquids.

► Ensure that all safety equipment is ready for use.

► Use suitable personal protective equipment/clothing.

► Keep away from the danger area during the transformer test.

► Observe applicable fire protection regulations.

► Make sure that only trained technicians perform work on the transformer.

Every on-load tap-changer has been specially designed by the manufacturer

for the transformer in the respective purchase order and is subjected to strict

tests and quality controls at the manufacturer’s factory.

However, joint operation of transformer and on-load tap-changer cannot be

simulated by the manufacturer and cannot be tested on the on-load tapchanger alone.

For this reason, irregularities or malfunctions cannot be completely ruled out

during the transformer test (i.e. testing the first joint operation of transformer

and on-load tap-changer).

It is essential that you ensure only trained, instructed expert personnel who

are familiar with and comply with the pertinent safety and technical regulations, who are aware of the potential risks, and who consistently use the occupational safety equipment provided to prevent injury and property damage

are assigned to perform such a transformer test.

Remove all leads used for testing before the high voltage test as these function as antennas. Ensure that the clearance needed between bushings and

motor-drive unit, including the connection cable, is observed at all times.

®

Maschinenfabrik Reinhausen GmbH 201950 6107891/02 ENECOTAP® VPD

Page 51

6 Commissioning

If you have any questions about possible sources of danger, consult the

manufacturer before starting to test the transformer.

Only undertake the electrical tests required for transformer acceptance once

the aforementioned work is complete.

6.1.1.2 Dielectric tests on transformer wiring

The motor-drive unit and control unit are subjected to dielectric tests before

delivery. Another dielectric test is not necessary. If you would like to perform

a dielectric test on the transformer wiring, observe the following information.

NOTICE

Damage to the control unit.

Damage to the control unit due to impermissibly high voltages during the dielectric test on the transformer wiring.

► Disconnect the connection cable to the motor-drive unit on the control

unit prior to performing a dielectric test on the transformer wiring.

To disconnect the control unit, proceed as follows:

1. DANGER! Ensure that all cables in the working area are de-energized

and that the shutdown equipment is locked so it cannot be switched on

again. Otherwise, there is a risk of fatal injury due to electrical voltage during the following work.

The LED can remain lit for up to 30 minutes after disconnection of the

voltage supply. This indicates that the energy accumulator is still charged.

This does not represent a hazard during mounting or removing the control

unit.

2. Remove plug connector from terminal X1 on the control unit.

3. Remove plug connector from terminal X2 on the control unit.

Maschinenfabrik Reinhausen GmbH 2019 516107891/02 EN ECOTAP® VPD

®

Page 52

6 Commissioning

4. Remove plug connector from terminal X4 on the control unit.

Figure32: Connection cable

5. Wind up connection cable and fix on motor-drive unit.

You can then perform the dielectric test.

6.1.2 Resetting automatic adjustment

Reset the automatic adjustment prior to transporting the transformer to the

installation site. This ensures that automatic adjustment is carried out again

during commissioning at the installation site.

To reset the automatic adjustment, proceed as follows:

ü The AVR MANUAL operating mode is active.

1. Press .

2. Press + for longer than 5 seconds.

ð

3. Press until code 3 is displayed.

ð

®

Maschinenfabrik Reinhausen GmbH 201952 6107891/02 ENECOTAP® VPD

Page 53

6 Commissioning

4. Press to confirm the selection.

ð The LED lights up and the error code E4.1 is displayed.

6.2 Transporting transformer to the operating site

DANGER

NOTICE

Risk of life-threatening injury due to electric shock!

If the device and system peripherals are not disconnected from the mains,

electric shock may occur!

► De-energize the device and system peripherals and lock them to prevent

them from being switched back on.

Damage to the on-load tap-changer!

Damage to the on-load tap-changer due to incorrect positioning!

► Do not disconnect the motor-drive unit from the on-load tap-changer after

the on-load tap-changer's automatic adjustment.

1. To transport the transformer, disconnect connection cable from control

unit. You will find a description of this process in the "Dielectric tests on

the transformer wiring" [►Section 6.1.1.2, Page 51] section.

2. Wind up connection cable, fix on motor-drive unit, and use plastic film and

adhesive tape to protect from moisture.

3. NOTICE! If you do not package the connection cable correctly, moisture

may get in and cause damage to the motor-drive unit.

4. Transport control unit in MR packaging used for delivery.

5. NOTICE! The control unit is not intended for operation, transport or stor-

age outdoors.

Maschinenfabrik Reinhausen GmbH 2019 536107891/02 EN ECOTAP® VPD

®

Page 54

6.3 Commissioning transformer at operating site

6 Commissioning

WARNING

Flying parts and spraying of hot oil resulting from on-load tapchanger overload!

The on-load tap-changer can switch currents of up to twice the rated

through-current. Higher currents occur when activating transformers (inrush

current impulse) or in the event of short-circuits, for example. Higher voltages may occur due to transformer overexcitation following load shedding,

for example.

Danger of death or severe injury due to flying parts and spraying of hot oil!

► Ensure that the on-load tap-changer is not overloaded.

► Prevent on-load tap-change operations if higher currents arise.

► Ensure that the rated step voltage is not exceeded. The rated step volt-

age may be briefly exceeded by up to 10% as long as the rated throughcurrent is not exceeded.

► Ensure that the temperature limit values stated in the technical data are

not exceeded.

Before energizing the transformer, take the following steps, which are described in detail in the operating instructions for the ECOTAP® VPD® MD&C

motor-drive unit:

1. Mount and connect motor-drive unit and control unit.

2. Commission motor-drive unit and control unit.

3. Carry out automatic adjustment and trial tap-change operations.

4. Check control parameters and automatic voltage regulation.

5. When operating with alternative insulating fluids, activate temperature

blocking

NOTICE

6.3.1 Switching on the low-voltage busbar

Damage to the on-load tap-changer and transformer!

An inrush current impulse which has not fully subsided can damage the onload tap-changer and transformer in the event of an on-load tap changing

operation!

► Once the transformer has been switched on, ensure that the inrush cur-