MQ Whiteman B46H90 Specification

Pioneering concrete finishing

since 1939.

WALK-BEHIND TROWELS

MQ Whiteman power trowels have been at the center of

the concrete finishing world since 1939. Our commitment to

innovation and development enables us to offer the industry’s

premier line up of concrete finishing equipment.

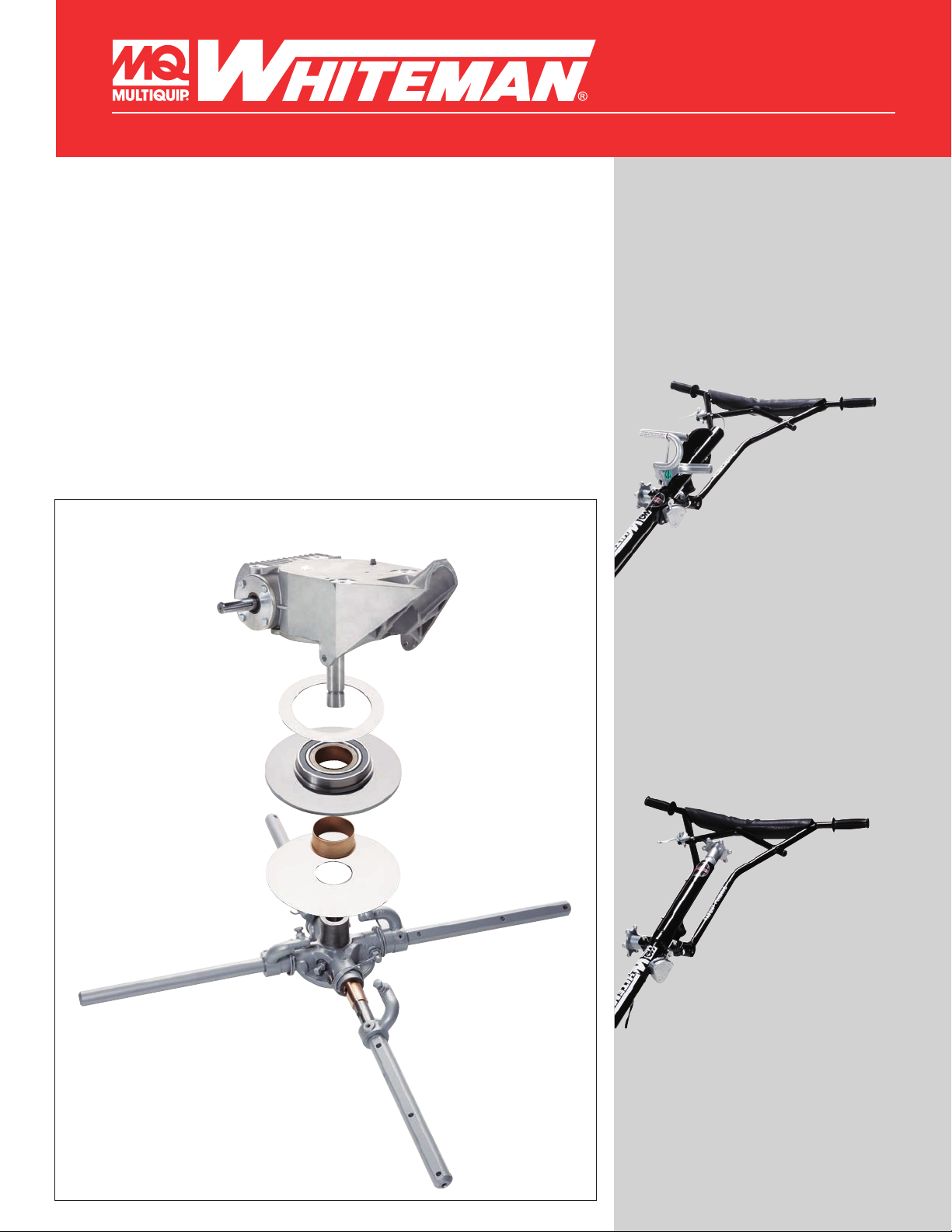

Top quality components. Concrete contractors demand reliable

equipment to get the job done right. The MQ Whiteman gearbox uses a heattreated worm gear and composite bronze gear to ensure that your machine

isn’t sidelined during a critical job.

Low cost of ownership. Our spider assembly uses high-strength wear

plates made of trowel steel to prevent wear on key components. Repairing

your trowel shouldn’t be costly so we make certain our replacement parts are

priced right.

The Industry’s Best Gearboxes —

heavy-duty design for years of troublefree service.

Upper Wear-Plate

Manufactured of trowel steel to

prevent bearing wear.

Handle Features:

• Ergonomic design provides

more comfort and helps

eliminate operator fatigue

• Built in height adjustment and

isolation mounts.

QXH-Series

TM

QuickPitch

A patented spring-loaded design

enables the operator to react

rapidly to changing concrete

conditions. Blade pitch is

increased or decreased in 1/8"

increments by moving the latching

lever back and forth.

handle

Thrust Collar Assembly

Sealed Thrust Bearing

for years of trouble-free service.

Lower Wear-Plate

Prevents wear on thrust collar surface

Spider Trowel Arm Bushings

Replacement of these high tolerance

bushings assure like new trowel arm

alignment.

Bronze Bushing

Eliminates wear on the thrust collar and

spider, providing tighter running tolerance.

SXH-Series Standard

handle

A favorite of contractors who prefer

to have infinite blade pitch control.

The large knob makes it easy to

increase or decrease blade pitch to

the desired angle.

B-SERIES - 46” DIAMETER

The MQ Whiteman walk-behind power trowel delivers high horsepower, excellent rotor speed

and built in durability. It has been the favorite of concrete contractors for generations.

1

Height adjustable handlebar includes vibration dampening for

superior ergonomics

2

Choose an optional QuickPitch™ or standard knob-style pitch control

3

Lifting bail

4

Centrifugal shut off switch to ensure safety on the job

5

Heavy-duty centrifugal clutch protected by fully enclosed

belt guard

6

Four blade spider assembly with original combination blades,

stabilizer ring and balanced for smooth finishing

7

Access panel for easy service and blade replacement

1

2

B46H90

Honda GX270

Centrifugal Clutch

60-130 RPM

3

(shown with QXH QuickPitchTM handle)

4

ALSO AVAILABLE:

ALSO AVAILABLE

B46H11H

Honda GX340

90-155 RPM

Centrifugal Clutch

5

7

Ideal for high speed burnishing.

(# LOW SPEEDKI TJB)

speed reducing kit also available

for panning

6

Loading...

Loading...