Page 1

OPERATION MANUAL

MODEL DCA6SPX4F

PORTABLE GENERATOR

(KUBOTA D1105-E4B-BGDE-1-S1 DIESEL ENGINE)

Revision #2 (03/12/21)

To find the latest revision of this publication or

associated parts manual, visit our website at:

www.mqpower.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

2

Page 2

PROPOSITION 65 WARNING

PAGE 2 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 3

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect that could cause a crash or could cause

injury or death, you should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Multiquip at 1-800-421-1244.

If NHTSA receives similar complaints, it may open an investigation, and if it finds

that a safety defect exists in a group of vehicles, it may order a recall and remedy

campaign. However, NHTSA cannot become involved in individual problems

between you, your dealer, or Multiquip.

To contact NHTSA, you may either call the Vehicle Safety Hotline toll-free at 1-888327-4236 (TTY: 1-800-424-9153), go to http://www.nhtsa.dot.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain information about motor vehicle safety from

http://www.safecar.gov.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 3

Page 4

DCA6SPX4F

60 Hz Generator

Proposition 65 Warning ........................................... 2

Reporting Safety Defects ......................................... 3

Table of Contents ..................................................... 4

Nameplate/Safety Information ................................. 5

Safety Information ............................................. 6–11

Specifications (Generator) ..................................... 12

Specifications (Engine) .......................................... 13

Dimensions ............................................................ 14

Installation ....................................................... 16–17

General Information ............................................... 18

Components (Generator) ....................................... 19

Components Control Panel ................................... 20

Components (Engine) ............................................ 21

Load Applications .................................................. 22

Inspection/Setup .............................................. 23–26

Operation ......................................................... 27–28

Operation/Shutdown .............................................. 29

Maintenance .................................................... 30–35

Troubleshooting (Generator) .................................. 36

Troubleshooting (Generator/Engine) ..................... 37

Troubleshooting (Engine) ................................. 38–39

Generator Wiring Diagram ..................................... 40

Engine Wiring Diagram .......................................... 41

TABLE OF CONTENTS

NOTICE

Specifications are subject to change without notice.

PAGE 4 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 5

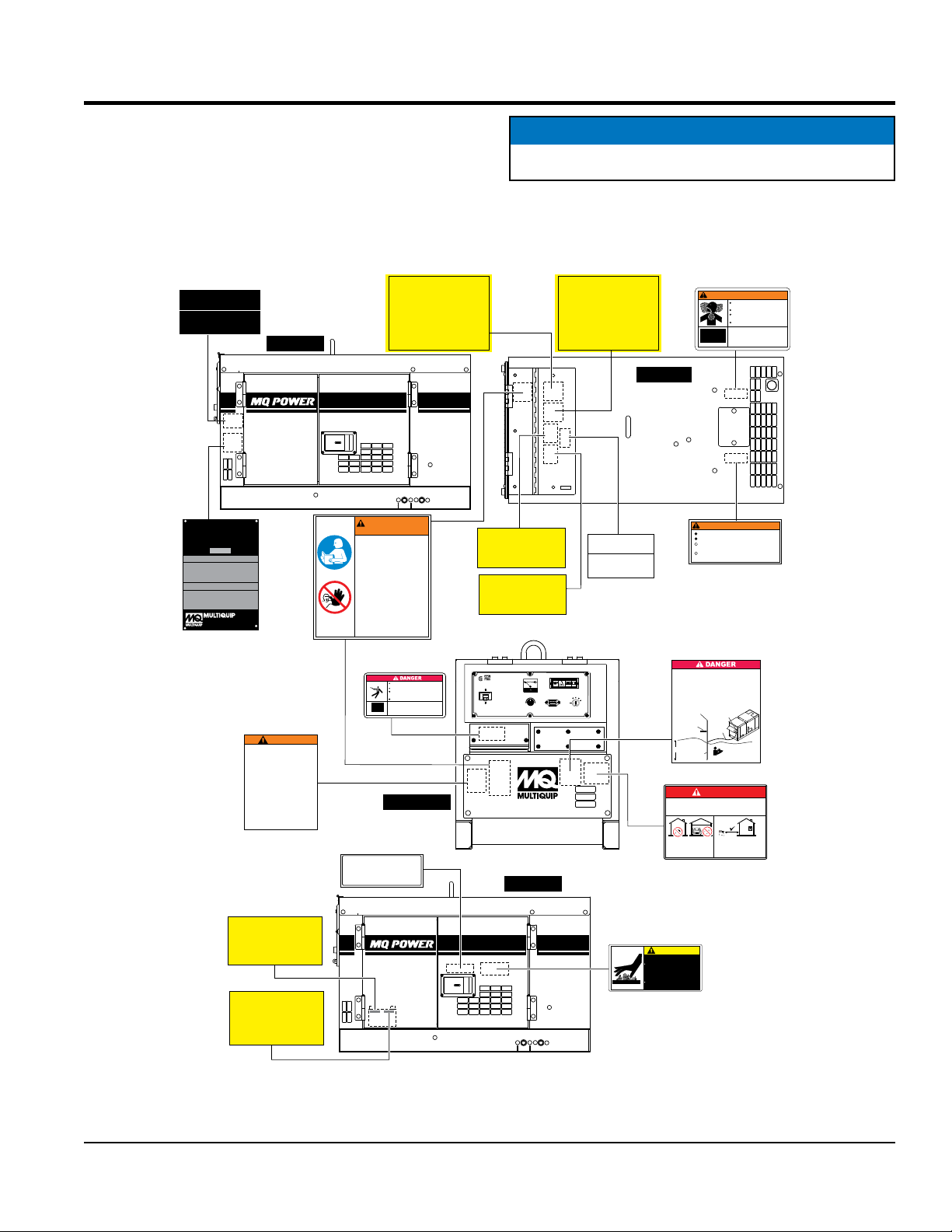

SAFETY DECALS

B90400040

WARNING

MOVING PARTS can cause

severe injury.

DO NOT operate with doors

open.

Stop engine before servicing.

Safety decals are attached to the generator as shown in

Figure 1. Keep these safety decals clean at all times. When

the safety decals become worn or damaged, contact your

nearest dealer or the Multiquip Parts Department.

CAUTION! ATTENTION!

READ OWNER’S SERVICE MANUAL BEFORE OPERATING OR

EMISSION CONTROL INFORMATION

SUPPLEMENTAL LABEL

KUBOTA Corporation

KUBOTA

XXXXX

XXXXXX

XXXX

XXXXX

XXXXXXX

XXXX

WHISPERWATT

DIESEL POWERED AC GENERATOR

MODEL: DAC-6SPX4F

SERIAL No.

AC GENERATOR/ GENERATRICE CA

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

DIESEL ENGINE/ MOTEUR DIESEL

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXXXX

XXXXX

XXXXXX

XXXX

XXXXX

XXXXXXX

XXXX

GENERTRICE CA DIESEL

XXXXXXX

XXXXX

XXXXXX

XXXX

XXXXX

XXXXXXX

XXXX

XXXXX

XXXXXX

XXXX

XXXXX

XXXXXXX

XXXX

XXXXX

XXXXXX

XXXX

XXXXX

XXXXXXX

XXXX

INC.

SIDE VIEW

A55100100

SERVICING THIS MACHINE.

ALWAYS KEEP UNAUTHORIZED INEXPERICENCED

UNTRAINED PEOPLE AWAY FROM THIS MACHINE.

MAKE SURE ALL SAFETY DEVICES ARE OPERATIONAL

BEFORE THIS MACHINE IS STARTED. MAKE SURE ENGINE

IS TURNED OFF AND SPARK PLUG WIRE DISCONNECTED

BEFORE SERVICING THE MACHINE OR COMING IN

CONTACT WITH ANY MOVING PART. IF EQUIPMENT IS

POWERED BY AN ELECTRIC MOTOR DISCONNECT

ELECTRICAL PLUG.

NEVER LEAVE MACHINE UNATTENDED WHEN OPERATING

ALWAYS STOP ENGINE AND ALLOW ENGINE TO COOL

BEFORE ADDING FUEL OR OIL.

6

WARNING /

AVERTISSEMENT

To avoid injury, you MUST

read and understand

operator’s manual before

using this machine.

This machine to be operated

by qualified personnel only.

Pour éviter toute blessure,

vous devez llre et comprendre

le manuel de l’ utilisateur

avant d’utiliser cette manuel.

Cette machine doit étre

opérer par un personnel

qualifié.

Demandez une formation si

nécessaire.

NOTICE

For safety decals part numbers, reference parts manual.

A55200070A

WARNING!

Before connecting this generator to any building’s

electrical system, a licensed electrician must install

an isolation (transfer) switch.

Serious injury or death may result without this

transfer switch.

ATTENTION!

Avant de brancher unité à un bâtiment, un

cette

interrupteur d’isolation doit être installé par

un technicien diplômé.

Utiliser cet appareil sans I’interrupteur d’isolation

peut entraîner des blessures graves voires mortelles.

II est impératif de lire le manuel d’utilisation

avant d’utiliser ou de réparer cet équipement.

II est impératif degarder tout personnel non

authorisé ou non qualifié à distance de cet equipement.

Assurez vous que tout equipement de sécurité est

fonctionnel avant d’engager l’equipement. Assurez vous

que le moteur est éteint et que le fil de la bougie

est d’econnecté avant de réparer la machine ou vant

tout contact avec toute pièce en mouvement.

Si l’equipement est alimenté par un moteur électrique

débranchez l’appareil.

Ne laissez jamis l’appareil sans supervision quand

il est en marche, II est impératif d’arrêter le

motour et de la laisser refroidir avant d’ajouter

de l’huile ou du carburant.

Do not use in rain or snow.

A35200030A

Ne pas utiliser en cas de

pluie ou neige.

A35200050

CAUTION!

ATTENTION!

A5520080

TOP VIEW

A3520000A

WARNING/ATTENTION

Only operate machine in well

ventilated areas.

Do not inhale exhaust gases.

N’utilizez l’equipment que dans

des endroits bien aérés.

Ne respirez paz les gas d’échappement.

Only qualified personnel should install, use,

Dangerous

or service this equipment.

Gas/Gas

Seul un personnel qualifié devrait avoir

dangereux

l’authorisation d’installer d’utilisier ou

de réparer cet équipement.

A63210090A

WARNING/ATTENTION

HOT COOLANT can cause severe burns.

Do not remove cap if radiator is hot.

Liquide réfrigérant chaud peut causer

des brûlures graves.

N’ôtez pas le capuchon si le radiateur

est chaud.

A55200180

WARNING

Operation of this equipment may create

sparks that can start fires around dry

vegetation.

A spark arrestor may be required.

The operator should contact local fire

agencies for laws or regulation relating

to fire prevention requirements.

Des étincelles pouvant enflammer la

végétation séche environnante peuvent être

produites pendant le fonctionnement de cet

équipement.

Un pare–étincelles peut être requis.

L’opérateur doit contacter les agences

anti–incendie locales pour s’ informer

des lois ou feglementations concernant les

exigences de prévention–incendie

DANGER

Cigarettes, ames or sparks could cause battery to explode.Always

shield eyes and face from battery

or adjust post connections without proper instruction and training.

KEEP VENT CAPSTIGHT AND LEVEL

POISON

Contains sulfuric acid.Avoid contact with skin, eyes or clothing. In

event of accident ush with water and call a physician immediately.

KEEP OUT OF REACH OF CHILDREN

DANGER

Cigarettes, flammes ou étincelles peuvent causer I’explosion de la

batterìe. Protégez toujours le visage et les yeux quand à proximité de la

batterìe. Ne chargez pas la batterìe, n’utilisez pas les cablesde démarrage

ou n’ajustez pas les poteaux de la batterìe sans instructions or pratique

Gardez le bouchon ventilateur au niveau et bien serré

POISON

Contient de l’acide sulfurique. Evitez tout contact avec la peau, les

yeux ou vêtements. En cas d’accident rincez avec de l’eau et appelez un

médecin immédiatement.

Gardez les enfants à distance

A90400020

EXPLOSIVE GASES

. Do not charge or use booster cables

CAUSES SEVERE BURNS

A63210110A

Gas explosifs

peut causer des brûlures sévères

A63210140

Do not touch output terminals or internal

wiring while unit is operating.

Turn off power before servicing.

Ne touchez ni les terminaux externes ou le

cablage electrique interne lorsque que

l’équipement est en operation.

Eteindre avant de réparer.

Only qualified personnel should install, use,

Electrical

or service this equipment.

shock hazard

Possibilité

Seul un personnel qualifié devrait avoir

de choc

electrique

l’authorisation d’installer d’utilisier ou

A63210100A

de réparer cet équipement.

FRONT VIEW

CAUTION/ ATTENTION

Do not operate with open doors.

N’ utilisez pas l’unité quand

les portes sont ouvertes.

Figure 1. Safety Decals

WHISPERWATT

6kW AC GENERATOR

211052

MAIN AC CIRCUIT BREAKER

DISJONCTEUR PRINCIPALE

DE COURANT CA

A55200120

240

120V120

V

AC VOLTMETER

VOLTOMETRE CA

DECREASE

INCREASE

DIMINUTION

AUGMENTATION

VOLTAGE REGULATOR

COMPTEUR D’ HEURE

REGULATEUR DE TENSION

SIDE VIEW

RUN

MARCHE

HEAT

STOP

PRECHAUFFAGE

ARRET

START

DEMARRAGE

HOURS

HOUR METER

STARTER SWITCH

COMMTATEUR

DE DEMARRAGE

6

THE POSSIBILITY EXISTS OF ELECTROCUTION IF

GENERATOR/WELDER IS NOT PROPERLY GROUNDED.

ALWAYS CONNECT EARTH GROUND (GROUND ROD) TO

GENERATOR G.F.C.I. GROUND TERMINAL.

IL Y AURAIT UN RISQUE D’ÉLECTROCUTION À MOINS

QUE LA GÉNÉRATRICE/SOUDEUSE NE SOIT PROPREMENT

MISE À LA TERRE. S’ASSURER DE RELIER À LA MASSE

(BARRE DE MASSE) LA BORNE DE MISE À LA TERRE

G.F.C.I. DE L’APPAREIL.

GROUND ROD FOR

EARTH GROUND

BARRE DE MASSE

CONNECT TO BUILDING

GROUND IF REQUIRED

ARELIER À LA MASSE

D’OUVRAGE EVENTUELLEMENT

8 FT. MINIMUM

8 PIEDS MINIMUM

REFERENCE NEC 250-52 (C)

RÉFERÉNCE NEC 250-52 (C)

DANGER

Using a generator indoors CAN KILL YOU IN MINUTES.

Utilser un générateur à l’ intérieur VOUS TUERA EN QUELQÙES MINUTES.

Exhaust contains carbon monoxide, a poison gas you cannot see or smell.

Les gaz d’ échappement contiennent du monoxyde de carbon, un gaz toxique

invisible et inodore.

NEUTRAL BONDED TO FRAME

120V

120

V

GAC-2.2H

NEUTRE MIS A LA MASSE A

15A

LA CARCASSE DU MOTEUR

POWERED by

Honda Engines

211052

AC CIRCUIT BREAKER

INTERRUPTEUR DE

OFF

GR PRISE DE

COURANT PRINCIPAL

TERRE

NEVER use in enclosed or partially

enclosed areas.

Utilisation INTERDITE dans un

espace clos ou partiellement clos.

CAUTION/ATTENTION

HOT PARTS can burn skin.

DO NOT touch until the machine

has sufficiently cooled.

Danger de brûlure, pièces chaudes.

Ne touchez pas avant que l’appareil

ne soit suffisamment refroidi.

A65200040A

GROUND TERMINAL

PRISE DE TERRE

GROUND CABLE

#8 MINIMUM

CÂBLE DE MASSE

#8 MINIMUM

FOR FURTHER GROUNDING

INSTRUCTIONS READ MANUAL

POUR PLUS DE DÉTAILS

CONCERNANT LA MISE Á LA

TERRE, LIRE LE MANUEL

NEUTRAL BONDED TO FRAME

120V

120

V

GAC-2.2H

NEUTRE MIS A LA MASSE A

15A

LA CARCASSE DU MOTEUR

POWERED by

Honda Engines

211052

AC CIRCUIT BREAKER

INTERRUPTEUR DE

OFF

GR PRISE DE

COURANT PRINCIPAL

TERRE

NEUTRAL BONDED TO FRAME

120V

120

V

GAC-2.2H

NEUTRE MIS A LA MASSE A

15A

LA CARCASSE DU MOTEUR

POWERED by

Honda Engines

211052

AC CIRCUIT BREAKER

INTERRUPTEUR DE

OFF

GR PRISE DE

COURANT PRINCIPAL

TERRE

ONLY use outdoors and away from

open windows, doors, and vents.

Utilisation UNIQUEMENT à l’ extér leur

portes et trous d’ aération

A91110030

A90400010

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 5

Page 6

SAFETY INFORMATION

Do not operate or service the generator before reading the

entire manual. Safety precautions should be followed at all

times when operating this generator. Failure to read and

understand the safety messages and operating instructions

could result in injury to yourself and others.

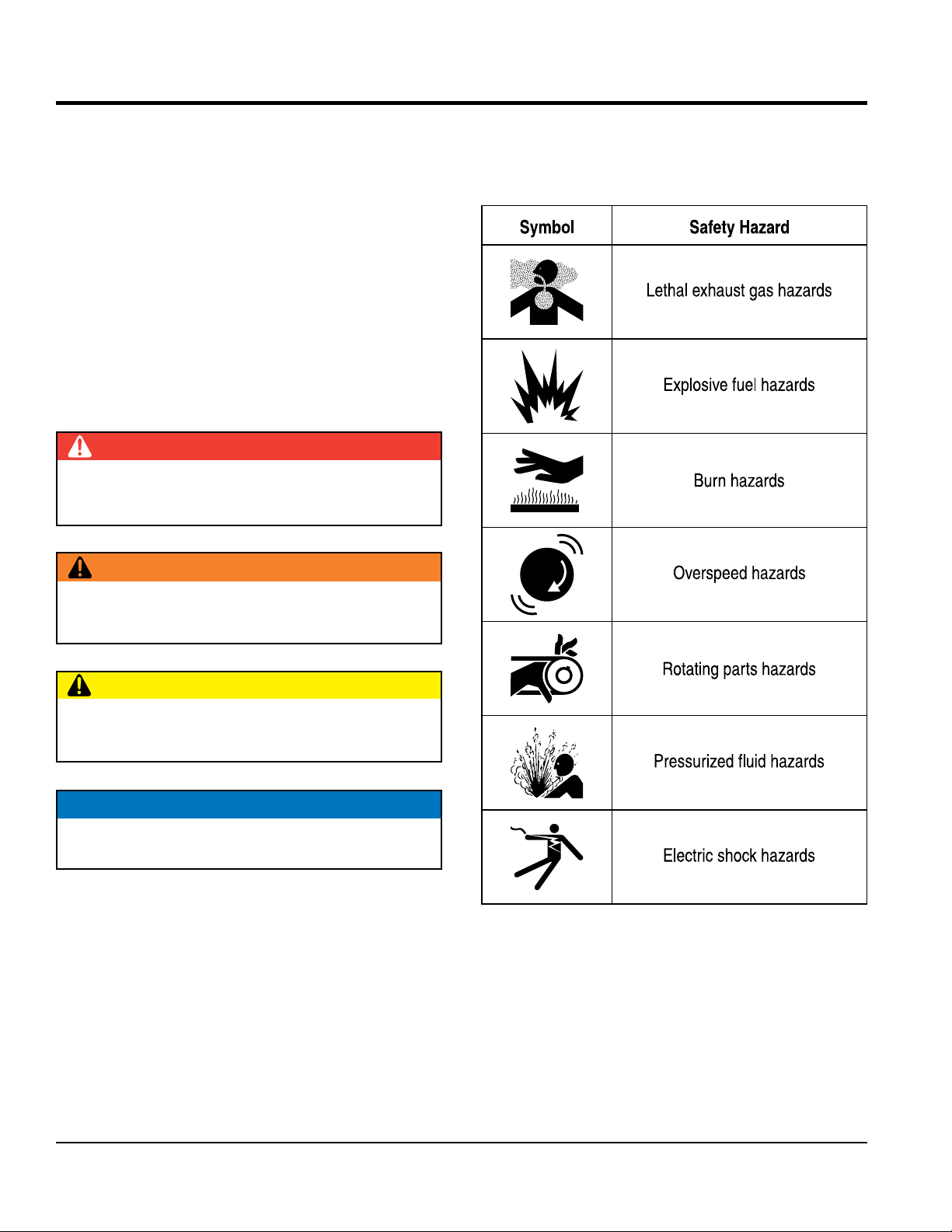

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION

SAFETY SYMBOLS

Potential hazards associated with the operation of this

generator will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

or NOTICE.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 7

GENERAL SAFETY

CAUTION

ALWAYS know the location of the nearest phone or keep

Also, know the phone numbers

fi re department.

This information will be invaluable in the case of an

.

These devices are intended for operator safety.

severe injury,

. Disconnection of any of

lubricate components or attempt service on a

ensure the generator is on level ground

keep the generator in proper running condition.

Fix damage to the generator and replace any broken

store the generator properly when it is not

being used. The generator should be stored in a clean,

dry location out of the reach of children and unauthorized

NEVER operate this generator without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this generator when not

feeling well due to fatigue or illness, or when

on medication.

NEVER operate this generator under the infl uence of

drugs or alcohol.

SAFETY INFORMATION

a phone on the job site.

of the nearest ambulance, doctor, and

emergency.

GENERATOR SAFETY

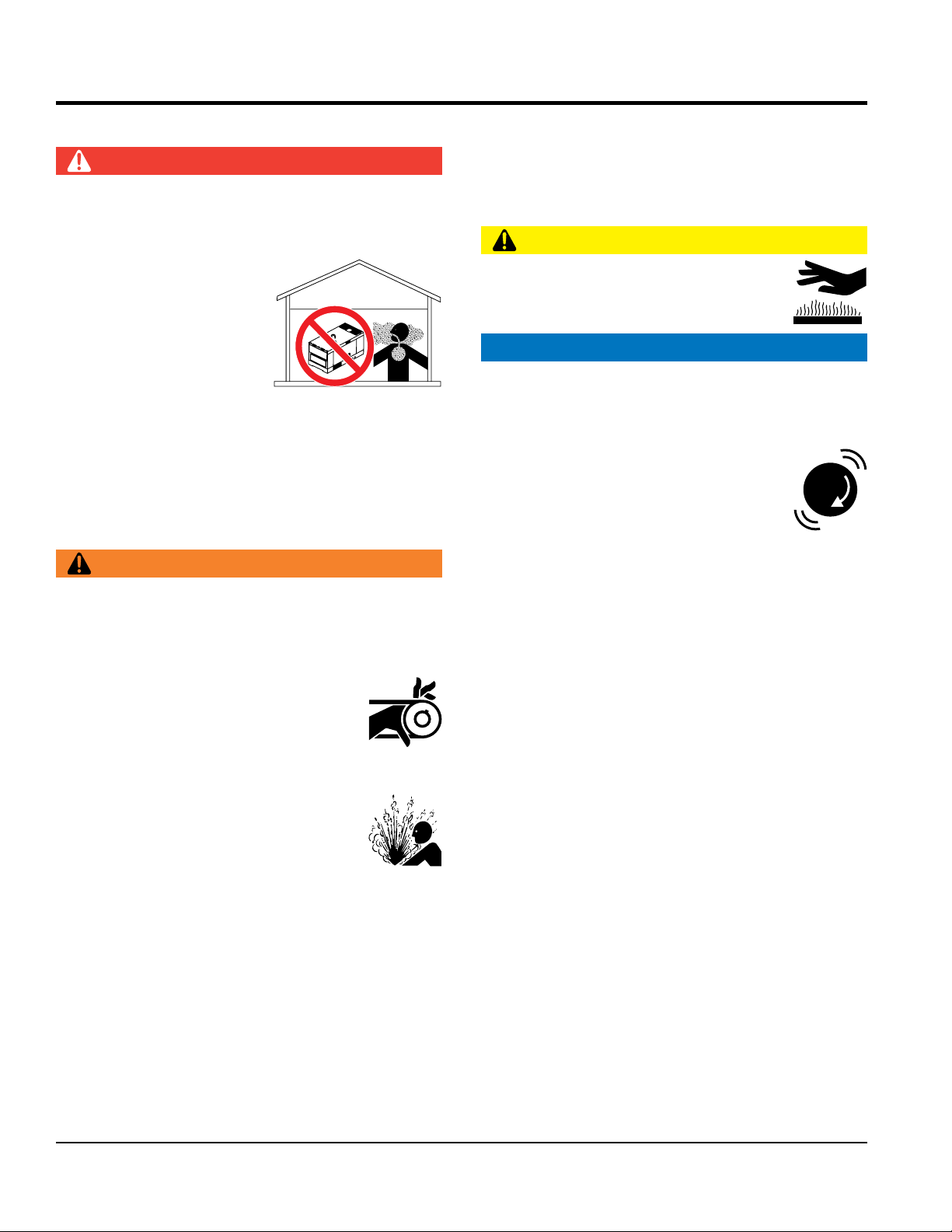

DANGER

NEVER operate the generator in an

explosive atmosphere or near combustible

materials. An explosion or fi re could result

causing severe bodily harm or even death.

WARNING

NEVER disconnect any emergency or safety devices

ALWAYS check the generator for loosened threads or

bolts before starting.

NEVER use the generator for any purpose other than

its intended purposes or applications.

NOTICE

This generator should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult to read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

modifi cation of the generator will void all warranties.

NEVER use accessories or attachments that are not

recommended by MQ Power for this generator. Damage

to the generator and/or injury to the user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

Disconnection of these devices can cause

bodily harm or even death

these devices will void all warranties.

CAUTION

NEVER

running generator.

NOTICE

ALWAYS

before use.

ALWAYS

parts immediately.

ALWAYS

personnel.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 7

Page 8

ENGINE SAFETY

DANGER

Operation of the generator may create sparks that

can start fi res around dry vegetation. A spark arrestor

may be required. The operator should contact local fi re

agencies for laws or regulations relating to fi re prevention

run the engine without an air fi lter or with a dirty

air fi lter. Severe engine damage may occur. Service the

Wet stacking is a common problem with diesel engines

which are operated for extended periods with light or

no load applied. When a diesel engine operates without

suffi cient load (less than 30-35% of the rated output),

it will not operate at its optimum temperature. This will

allow unburned fuel to accumulate in the exhaust system,

which can foul the fuel injectors, engine valves and

exhaust system, including turbochargers, and reduce

it must be able to provide fuel and air in the proper ratio

and at a high enough engine temperature for the engine

Wet stacking does not usually cause any permanent

damage and can be alleviated if additional load is

applied to relieve the condition. It can reduce the system

performance and increase maintenance. Applying an

increasing load over a period of time until the excess

fuel is burned off and the system capacity is reached

usually can repair the condition. This can take several

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this generator

requires an adequate, free

fl ow of cooling air. NEVER

operate this equipment in

any enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury to people and property and

serious damage to the equipment or engine.

When operating the generator outdoors, DO NOT place

the generator near doors, windows or vents that could

allow carbon monoxide to enter and build up in occupied

spaces.

WARNING

NEVER place hands or fingers inside the engine

compartment when the engine is running.

SAFETY INFORMATION

requirements.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing the generator.

NOTICE

NEVER

air fi lter frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or generator can result if

operating in speed ranges above the

maximum allowable.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands, hair and clothing away

from all moving parts to prevent injury.

NEVER operate the generator with the

doors open. Stop the engine before servicing.

DO NOT remove the radiator cap while the

engine is hot. High pressure boiling water

will gush out of the radiator and severely

scald any persons in the general area of

the generator.

DO NOT remove the coolant drain plug while the engine

is hot. Hot coolant will gush out of the coolant tank and

severely scald any persons in the general area of the

generator.

DO NOT drain the engine oil while the engine is hot. Hot

oil will gush out and severely scald any persons near

the generator.

the operating performance.

In order for a diesel engine to operate at peak effi ciency,

to completely burn all of the fuel.

hours to burn off the accumulated unburned fuel.

PAGE 8 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 9

SAFETY INFORMATION

State Health Safety Codes and Public Resources

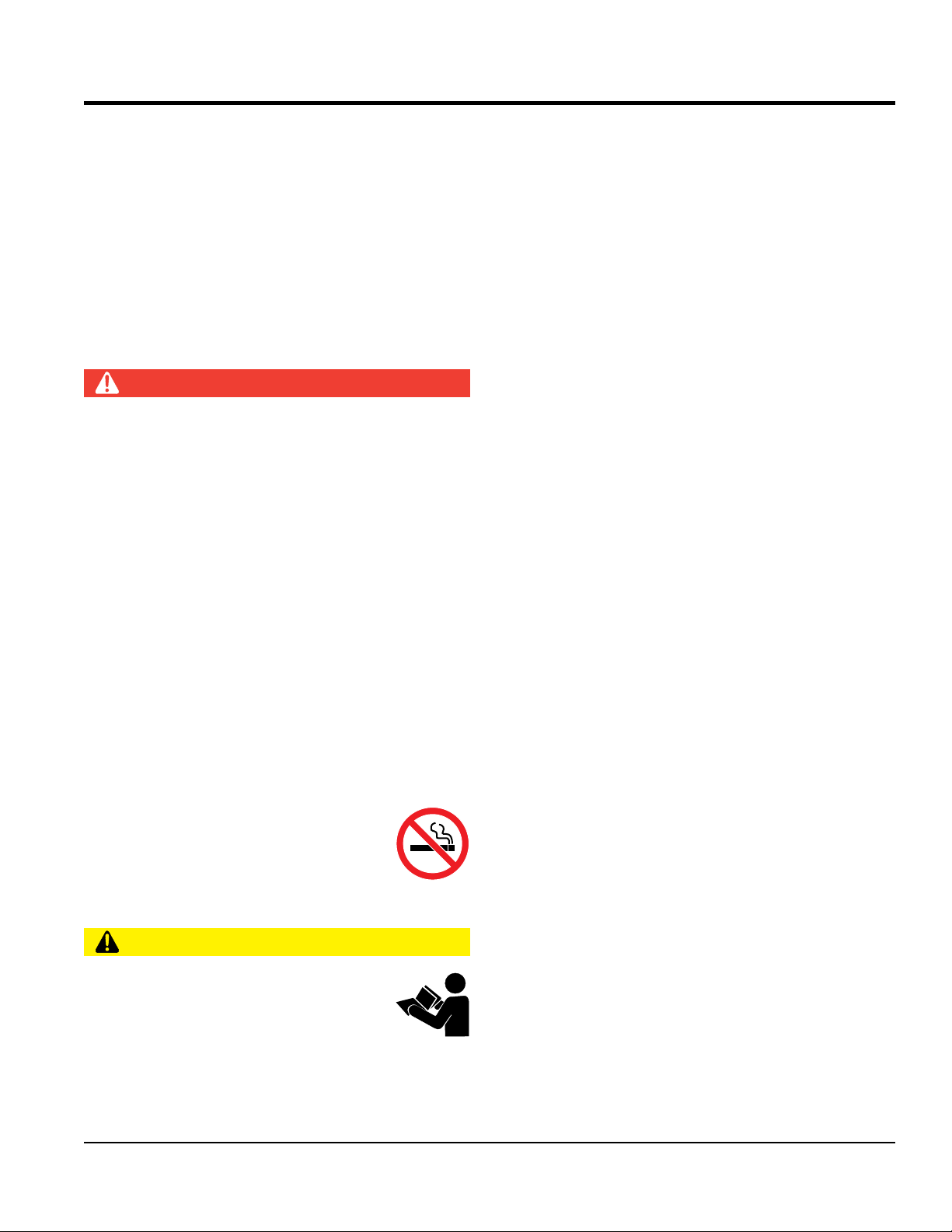

FUEL SAFETY

TOWING SAFETY

Refer to the MQ Power trailer manual for additional safety

In order to reduce the possibility of an accident

while transporting the generator on public roads,

make sure that the trailer that supports the

generator and the towing vehicle are both mechanically

Make sure the hitch and coupling of the towing

vehicle are rated equal to or greater than the trailer

inspect the hitch and coupling for wear.

tow a trailer with defective hitches, couplings,

Check the tire air pressure on both the towing vehicle and

Infl ate trailer tires as indicated on side wall

Also check the tire tread wear on both vehicles.

make sure the trailer is equipped with

attach the trailer’s safety chains to

make sure the vehicle and trailer directional,

backup, brake, and trailer lights are connected and

• Secure portable power cables in cable tray with

55 MPH

unless posted otherwise. Recommended off-road towing

or less depending on the type

Avoid sudden stops and starts. These can cause skidding

or jackknifi ng. Smooth, gradual starts and stops will

The trailer should be adjusted to a level position at all

Codes specify that in certain locations, spark arresters

must be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed

to prevent accidental discharge of sparks or fl ames

from the engine exhaust. Spark arresters are qualifi ed

and rated by the United States Forest Service for this

purpose. In order to comply with local laws regarding

spark arresters, consult the engine distributor or the

local Health and Safety Administrator.

DANGER

NEVER start the engine near spilled fuel or combustible

fl uids. Diesel fuel is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

NEVER fill the fuel tank while the engine is

running or hot.

NEVER overfi ll the fuel tank. Spilled fuel can ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

NEVER smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

information.

ALWAYS

sound and in good operating condition.

ALWAYS shut down the engine before transporting.

gross vehicle weight rating.

ALWAYS

NEVER

chains, etc.

the trailer.

of tire.

ALWAYS

safety chains.

ALWAYS properly

the towing vehicle.

ALWAYS

working properly.

DOT requirements include the following:

• Connect and test electric brake operation.

tie wraps.

The maximum speed for highway towing is

is not to exceed 15 MPH

of terrain.

CAUTION

Check with your local county or state safety

towing regulations, in addition to meeting

Department of Transportation (DOT)

Safety Towing Regulations, before towing

your generator.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 9

improve towing.

Avoid sharp turns to prevent rolling.

times when towing.

Page 10

Raise and lock the trailer wheel stand in the upright

position when towing.

ELECTRICAL SAFETY

Power Cord/Cable Safety

NEVER use damaged or worn cables or cords when

connecting equipment to the generator. Inspect the

connected to the generator’s output receptacles.

Incorrect connections may cause electrical shock and

make certain that the proper power or

extension cord has been selected for the job. See the

make sure that electrical circuits are properly

grounded to a suitable earth ground (ground rod) per

the National Electrical Code (NEC) and local codes

Severe injury or

can result from operating an

drop the battery. There is a possibility that the

Place chock blocks underneath the wheels to prevent

rolling while parked.

Place support blocks underneath the trailer’s bumper

to prevent tipping while parked.

Use the trailer’s swivel jack to adjust the trailer height to

a level position while parked.

DANGER

NEVER touch the output terminals

during operation. Contact with the

output terminals during operation can

cause electrocution, electrical shock,

or burn.

The electrical voltage required to

operate the generator can cause severe injury or even

death through physical contact with live circuits. Turn the

generator and all circuit breakers OFF before performing

maintenance on the generator or making contact with

the output terminals.

NEVER insert any objects into the output

receptacles during operation. This is

extremely dangerous. The possibility exists

of electrical shock, electrocution or death.

Backfeed to a utility system can cause

electrocution and/or property damage.

NEVER connect the generator to a

building’s electrical system without

a transfer switch or other approved

device. All installations should be

performed by a licensed electrician in accordance

with all applicable laws and electrical codes. Failure to

do so could result in electrical shock or burn, causing

serious injury or even death.

SAFETY INFORMATION

insulation for cuts.

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

Make sure power cables are securely

damage to the generator.

NOTICE

ALWAYS

Cable Selection Chart in this manual.

Grounding Safety

DANGER

ALWAYS

before operating the generator.

death by electrocution

ungrounded generator.

NEVER use gas piping as an electrical ground.

BATTERY SAFETY

DANGER

DO NOT

battery will explode.

NEVER expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

DANGER

NEVER let power cords or cables lay in water.

NEVER stand in water while AC power from the

generator is being transferred to a load.

PAGE 10 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

WARNING

ALWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up the battery.

Page 11

ALWAYS keep the battery charged. If the battery is not

charged, combustible gas will build up.

ENVIRONMENTAL SAFETY/DECOMMISSIONING

Decommissioning is a controlled process used to safely

retire a piece of equipment that is no longer serviceable.

If the equipment poses an unacceptable and unrepairable

safety risk due to wear or damage or is no longer cost

effective to maintain (beyond life-cycle reliability) and is to

be decommissioned (demolition and dismantlement), be

sure to follow the rules below:

Metal recycling involves the collection of metal from

discarded products and its transformation into raw

Recyclers and manufacturers alike promote the process

of recycling metal. Using a metal recycling center

The diesel engine used in this equipment has been

designed to reduce harmful levels of carbon monoxide

(CO), hydrocarbons (HC), and nitrogen oxides (NOx)

This engine has been certifi ed to meet US EPA evaporative

Attempting to modify or make adjustments to the engine

emission system by unauthorized personnel without proper

training could damage the equipment or create an unsafe

Additionally, modifying the fuel system may adversely affect

evaporative emissions, resulting in fi nes or other penalties.

The emission control label is an integral part of the emission

If a replacement emission label is needed, please contact

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

of combustible gases.

If the battery liquid (dilute sulfuric acid) comes into

contact with clothing or skin, rinse skin or clothing

immediately with plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the generator.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

SAFETY INFORMATION

materials to use in manufacturing a new product.

promotes energy cost savings.

EMISSIONS INFORMATION

NOTICE

contained in diesel exhaust emissions.

emissions requirements in the installed confi guration.

condition.

NOTICE

NEVER pour waste or oil directly onto the ground, down

a drain, or into any water source.

Contact your country’s Department of Public

Works or recycling agency in your area and

arrange for proper disposal of any electrical

components, waste or oil associated with

this equipment.

When the life cycle of this equipment is over, remove

the battery and bring it to an appropriate facility for lead

reclamation. Use safety precautions when handling

batteries that contain sulfuric acid.

Emission Control Label

system and is strictly controlled by regulations.

The label must remain with the engine for its entire life.

your authorized engine distributor.

When the life cycle of this equipment is over, it is

recommended that the frame and all other metal parts

be sent to a recycling center.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 11

Page 12

AC Generator

60 Hz AC Power Source

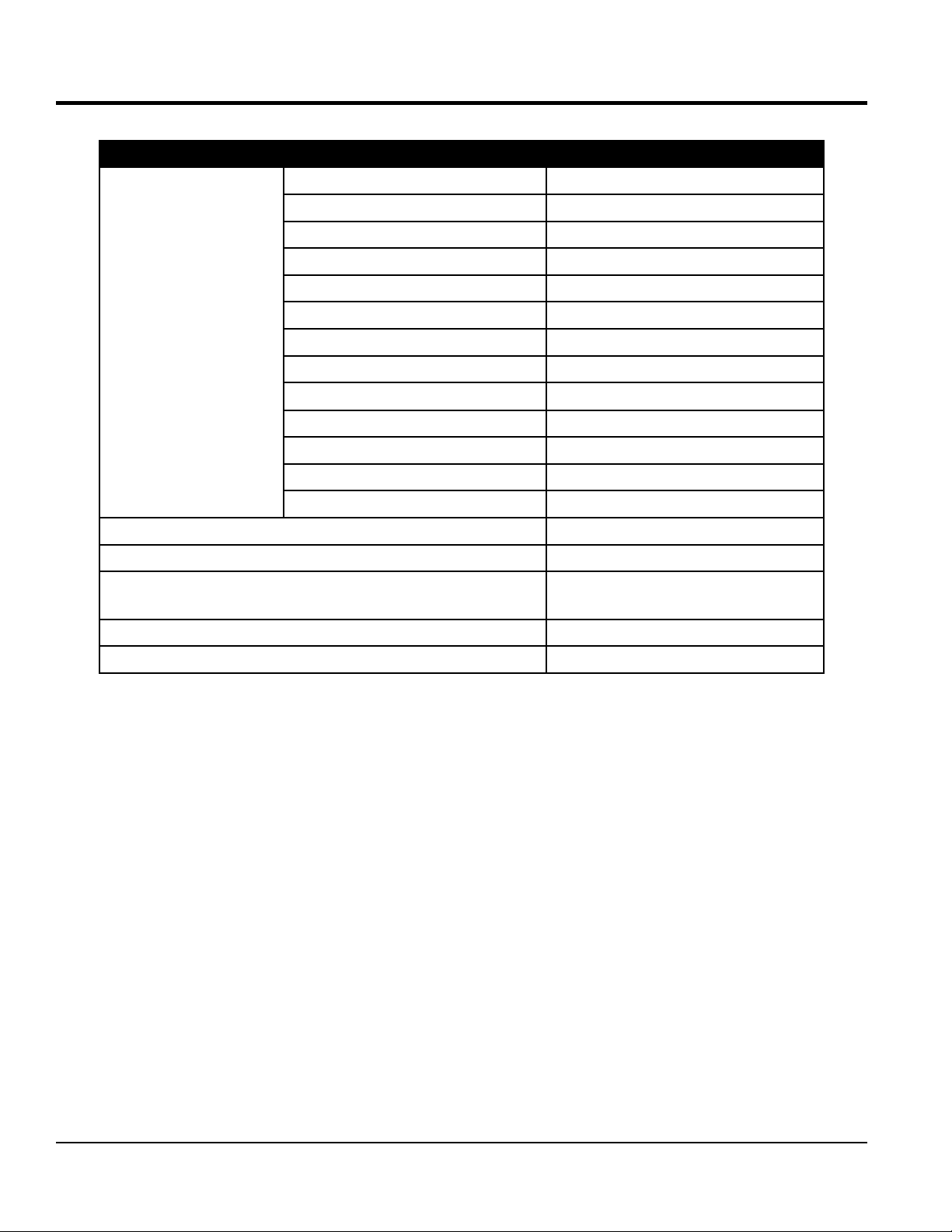

SPECIFICATIONS (GENERATOR)

Table 1. Specifications (Generator)

Model DCA6SPX4F

Type 4-pole, brushless, revolving-field type

Excitation Solid-state, statically excited system

Speed 1,800 rpm

Cooling System Self-ventilation

Maximum Power Output 7 kW

Continuous Power Output 6 kW

Rated Voltage 120/240V

Current Max./Continuous (120V) 58.3/50 amps

Current Max./Continuous (240V) 29.2/25 amps

Phase Single phase (4 wire)

Frequency 60 Hz

Power Factor 1

Battery

Generator Enclosure Color

Dimensions

(L × W × H)

Dry Net Weight

Wet Weight

12-36Ah × 1

White

25.6 × 48.4 × 33.3 in.

(650 × 1,230 × 845 mm)

831 lb. (377 kg)

860 lb. (390 kg)

PAGE 12 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 13

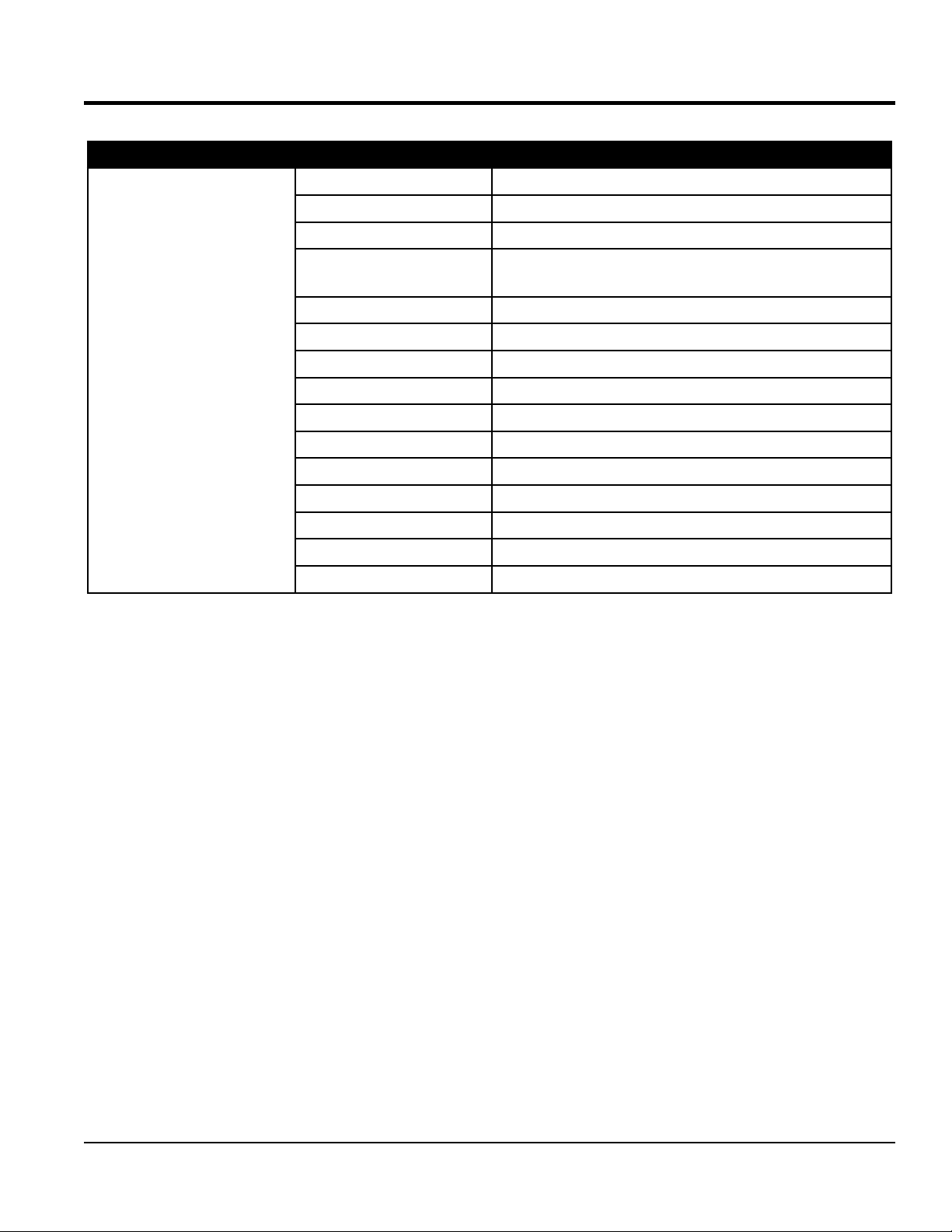

SPECIFICATIONS (ENGINE)

Table 2. Specifications (Engine)

Kubota Engine Model D1105-E4B-BGDE-1-S1

Tier 4

Type Vertical, water-cooled, 4-cycle diesel engine

Engine

Bore × Stroke

Displacement 68.53 cu. in. (1,123 cm³)

Number of Cylinders 3

Rated Output 14.1 hp / 1,800 rpm

Fuel #2 diesel fuel

Fuel Capacity No internal fuel tank

Fuel Consumption 0.70 gal. (2.65 liters)/hr.

Coolant Capacity 4.23 quarts (4.0 liters)

Lube Oil Capacity 5.39 quarts (5.1 liters)

Oil Alert System Ye s

Starting Method Electric start

Battery 12 volts @ 36 Ah

3.07 in. × 3.09 in.

(78 mm × 78.4 mm)

Effects of Altitude and Heat

The maximum output of the engines listed above are applicable to supplying electrical power for continuous service at

ambient conditions in accordance with SAE test cord J607. The above ambient conditions are at standard sea level, with

a barometric reading of 29.92 inches and a temperature of 60°F (15.5°C).

Generally, the engine’s output power will decrease 3-1/2% for each 1,000 feet (305 meters) of altitude above sea level,

and 1% for each 10°F (–12.2°C) above the standard temperature of 60°F (15.5°C).

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 13

Page 14

DIMENSIONS

E

F

Figure 2. Dimensions

G

D

6

B C

A

I H

Table 3. Dimensions

A B C D

48.4 in.

(1,230 mm)

E F G H

L

Housing

J

37.2 in.

(945 mm)

I J K L

15.4 in.

(390 mm)

44.5 in.

(1,130 mm)

33.3 in.

(845 mm)

24.0 in.

(610 mm)

2.0 in.

(50 mm)

29.9 in.

(760 mm)

25.6 in.

(650 mm)

K

PAGE 14 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

7.3 in.

(185 mm)

17.9 in.

(455 mm)

13.8 in.

(350 mm)

Page 15

NOTES

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 15

Page 16

INSTALLATION

CONNECTING THE GROUND

Consult with local electrical and safety codes for proper

connection based on condition of use.

EXAMPLE of how to ground the unit if the condition

of use requires such a device:

The ground terminal on the generator should always be

used to connect the generator to a suitable ground when

required.

Either copper or aluminum wire can be used as the ground

cable. Cable size is determined by the maximum amperage

of the generator. Reference Conductor Grounding Table,

Article 250 of the NEC handbook.

Connect one end of the ground cable terminal to the

generator ground point (Figure 3). Connect the other end

of the ground cable to a suitable earth ground (ground rod).

Figure 3. Generator Grounding

NOTICE

Trailer mounted generators are the sole responsibility

of MQ Power.

PAGE 16 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 17

INSTALLATION

OUTDOOR INSTALLATION

Install the generator in an area that is free of debris,

bystanders, and overhead obstructions. Make sure the

generator is on secure, level ground so that it cannot slide

or shift around. Also, install the generator in a manner so

that the exhaust will not be discharged in the direction of

nearby homes.

The installation site must be relatively free from moisture

and dust. All electrical equipment should be protected

from excessive moisture. Failure to do so will result in

deterioration of the insulation, short circuits, and grounding.

Foreign materials such as dust, sand, lint, and abrasive

materials have a tendency to cause excessive wear to

engine and alternator parts.

CAUTION

Pay close attention to ventilation when operating the

generator inside tunnels and caves. The engine exhaust

contains noxious elements. Engine exhaust must be

routed to a ventilated area.

INDOOR INSTALLATION

Exhaust gases from diesel engines are extremely

poisonous. Whenever an engine is installed indoors the

exhaust fumes must be vented to the outside. The engine

should be installed at least two feet from any outside wall.

Using an exhaust pipe which is too long or too small can

cause excessive back pressure which will cause the engine

to heat excessively and possibly burn the valves.

MOUNTING

The generator must be mounted on a solid foundation

(such as concrete) and set firmly on the foundation to

isolate vibration of the generator when it is running. The

generator must be mounted at least 6 inches above the floor

or grade level as referenced in the National Fire Protection

Association handbook (NFPA 110, Chapter 7, section 7.4).

GENERATOR GROUNDING

NOTICE

The Occupational Safety and Health Administration

(OSHA) and the National Electrical Code (NEC)

recommend that if the generator is providing electrical

power to a structure (home, office shop, trailer, or

similar) it must be connected to a grounding electrode

system, such a driven ground rod (Figure 3).

If applicable, to guard against electrical shock and possible

damage to the equipment, it is important to provide a good

EARTH ground (Figure 3).

NOTICE

ALWAYS check with state, province, district and

municipalities for electrical grounding requirements

before using generator.

Article 250 (Grounding) of the NEC handbook provides

guidelines for proper grounding and specifies that the cable

ground shall be connected to the grounding system of the

building as close to the point of cable entry as practical.

1. Use one of the following wire types to connect the

generator to earth ground.

a. Copper

b. Aluminum

NOTICE

Reference Conductor Grounding Table, Article 250

of the NEC handbook for proper conductor wire size.

Wire size is determined by the maximum amperage of

the generator.

2. When grounding of the generator (Figure 3) is required,

connect one end of the ground cable to the ground lug

on the generator. Connect the other end of the ground

cable to the ground rod (earth ground).

DO NOT remove the metal skids on the bottom of the

generator. They are to resist damage to the bottom of the

generator and to maintain alignment.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 17

3. NEC Article 250 specifies that the earth ground rod

should be buried a minimum of 8 feet into the ground.

NOTICE

When connecting the generator to any building’s

electrical system, ALWAYS consult with a licensed

electrician.

Page 18

GENERAL INFORMATION

Generator

The Multiquip DCA6SPX4F is a 6.0 kW (continuous output),

7.0 kW (max. output) AC generator designed as a portable,

dual-purpose power source for 60 Hz (single phase),

120/240V for lighting facilities, power tools, submersible

pumps and other industrial and construction machinery.

Control Panel

The control panel is provided with the following:

Single Phase 3-Wire Output Terminal

AC Voltmeter

Circuit Breaker @25 Amps

Starter Switch

Warning Lamp Unit

Hour Meter

Ground Terminal

Voltage Regulator

Engine Protection System

Engine protection fail-safe features are provided in the event

of low oil pressure, high coolant temperature, or failure of

the battery to charge. If any of the above conditions occur

while operating the generator it will cause a complete unit

shutdown.

Excitation System

The DCA6SPX4F generator uses a brushless exciter to

create rated-output electricity. This system will use the

mechanical energy generated by the 1,800 rpm engine

to spin the rotor (or armature) inside the generator (or

alternator end).

Excitation current is sourced from the battery to the

excitation winding in the stator. Current applied to this coil

creates a magnetic field. The rotating armature within the

stator is then induced with AC current.

Engine

The DCA6SPX4F generator is powered by a water-cooled,

4-cycle, Kubota D1105 diesel engine. This engine is

designed to meet every performance requirement of the

generator. Reference Table 2, engine specifications.

In keeping with Multiquip’s policy of constantly improving

its products, the specifications quoted herein are subject

to change without prior notice.

Power Tools (Grounding)

When using power tools or electrical equipment requiring

AC power from the generator, make sure power tool cord

has a ground pin or is double insulated as shown in Figure 4.

Battery Charge Alarm

This unit is equipped with a protective shutdown device

that signals the emergency relay and automatically stops

the engine when loss of charge from the engine alternator

occurs. An indicator lamp will be displayed on the control

panel.

Water Temperature Alarm

This unit is equipped with a temperature switch that signals

the emergency relay and automatically stops the engine

when the temperature of the engine coolant becomes

abnormally high.The coolant temperature switch will not

function properly if the machine is operated with less than

the proper amount of coolant.

Oil Pressure Warning Alarm

This unit is equipped with an oil pressure switch that detects

low oil pressure. If the lubricating oil pressure of this unit

should become abnormally low, the oil pressure switch

signals the emergency relay to shut down the engine. If

this condition should occur, please refer to the engine

troubleshooting table in this manual.

Figure 4. Ground Pin

NOTICE

Double-insulated power tools and small appliances

have specially insulated housings that eliminate the

need for a ground. These types of double-insulated

power cords are designed so that no part of the device

will be electrically live even if the internal insulation fails.

PAGE 18 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 19

COMPONENTS (GENERATOR)

2

13

15

1

3

4

11

14

10

9

12

Figure 5. Generator Components

5

6

7

8

1. Lifting Hook — Use this hook to lift the generator.

Maximum weight is 827 lb. (375 kg).

2. Air Outlet Exhaust — Allows engine exhaust to exit

the generator into the open air. NEVER block this

opening.

3. Radiator Cap Access Cover— Remove this cover to

gain access to radiator cap.

4. Air Filter — Prevents dirt and other debris from

entering the air intake system.

5. Radiator — Provides coolant to engine block.

6. Engine Oil Filler Port — Remove this cap to add

engine oil. Use only the recommended oil type. See

Table 6.

7. Expansion Bottle — Supplies coolant to the radiator

when radiator coolant level is low. Fill to indicated level

as shown on expansion bottle.

8. Coolant Drain Plug — Remove this plug to drain

coolant from the radiator.

10. Oil Filter — Provides filtering for the engine oil. Change

oil filter as recommended in the maintenance section

of this manual.

11. Dipstick — Remove to check amount and condition

of oil in crankcase.

12. Fuel Filter — Provides filtering for the engine fuel.

Change fuel filter as recommended in the maintenance

section of this manual.

13. Battery Terminals — Connect cables to the terminals

on the battery. Always pay close attention to the polarity

of the terminals when connecting to the battery, RED

(positive), and BLACK (negative).

14. Battery — Provides +12 VDC power for the generator.

When replacing battery (12V, 35 Ah) use only

recommended type battery.

15. Air Inlet Vent — Allows outside air to enter the

generator. NEVER block this opening.

9. Oil Drain Plug — Remove this plug to drain oil from

the engine.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 19

Page 20

211052

COMPONENTS CONTROL PANEL

WHISPERWATT

6kW AC GENERATOR

2

240

3

120V120

V

1

MAIN AC CIRCUIT BREAKER

DISJONCTEUR PRINCIPALE

DE COURANT CA

Figure 6. Control Panel

U O V

7 8

1. Main Breaker — 2-pole, 25-amp circuit breaker

protects the generator from short circuiting or

overloading. When starting the generator, always place

this circuit breaker in the OFF position.

2. AC Voltmeter — This voltmeter indicates (with a

mark) the rated 60 Hz (single-phase) output voltage.

The voltmeter can also be used as a diagnostic tool.

If the voltmeter indicator (needle) is below the rated

voltage, engine problems may exist (low/high RPM).

To prevent damage to the generator or power tools,

turn the generator OFF and consult your authorized

Multiquip service dealer.

3. Engine Warning Lamps — There are four engine

warning lamps, they are defined as follows:

a. Low Oil Pressure Alarm Lamp — During normal

operation of the generator this lamp

will remain OFF. When the ignition

switch is placed in the RUN position

to start the engine, the lamp will be

ON. When the oil pressure rises

after start-up the lamp will go OFF.

If this lamp is ever lit (ON) during normal operation

of the generator, the emergency shutdown system

will stop the engine automatically.

b. Water Temperature Alarm Lamp — This lamp

goes ON when the cooling water

temperature rises abnormally. If

the lamp goes ON during normal

operation of the generator, the

emergency shutdown system will

stop the engine automatically.

AC VOLTMETER

VOLTOMETRE CA

4

DECREASE

DIMINUTION

VOLTAGE REGULATOR

REGULATEUR DE TENSION

INCREASE

AUGMENTATION

5

HOURS

HOUR METER

COMPTEUR D’ HEURE

STOP

ARRET

6

STARTER SWITCH

DE DEMARRAGE

RUN

MARCHE

COMMTATEUR

HEAT

PRECHAUFFAGE

START

DEMARRAGE

c. Battery Charge Alarm Lamp — This lamp is ON

when the output voltage of the

alternator drops below a set value.

If this lamp is ON during normal

operation, the emergency

shutdown system will immediately

stop the engine.

d. Pre-Heat Lamp — The pre-heat lamp will be

ON during the pre-heating cycle

(cold weather conditions). When

the pre-heat cycle is completed the

lamp will turn OFF and the engine

can be started.

4. Voltage Regulator Knob — Allows ± 5% manual

adjustment of the generator output voltage.

5. Hour Meter — Indicates number of hours machine has

been in use or hours engine was run.

6. Starter Switch — With key inserted, turn clockwise

to start engine.

7. 120/240V, 1-Phase, 3-Wire Output Terminal —

Provides 240V, 60 Hz output at 25 amps or 120V,

60 Hz at 25 amps × 2.

8. Ground Terminal — This ground connection terminal

must be used at all times. Connect a ground cable

between this terminal and a ground rod. Reference

grounding section (Figure 3) in this manual for more

detailed information.

PAGE 20 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 21

COMPONENTS (ENGINE)

1

2

8

A

4

3

7

6

Figure 7. Kubota D1105 Diesel Engine

INITIAL SERVICING

The engine (Figure 7) must be checked for proper

lubrication and filled with fuel prior to operation. Refer to the

manufacturer’s engine manual for instructions and details

of operation and servicing.

1. Muffler — Reduces noise and emissions. NEVER

touch muffler when the generator is in use. Always

allow time for engine to cool before servicing.

9

A

10

5

14

13

11

12

7. V-Belt — ALWAYS make sure V-belt is properly

tensioned. A loose or defective V-belt can adversely

affect the performance of the generator.

8. Alternator — Provides power to the +12 VDC

electrical system. Replace only with manufacturer’s

recommended type alternator.

9. Injector Pump — Provides fuel under pressure to the

injector nozzles.

2. Cooling Fan Blades — Make sure cooling fan blades

are not bent or broken. A damaged fan blade can cause

the engine to run hot and overheat.

3. Oil Filler Cap — Remove this cap to add oil. Fill with

recommended type oil as listed in Table 6.

4. Air Filter — Prevents dirt and other debris from

entering the air intake system. Loosen clips on side

of air filter canister to gain access to filter element.

Replace with manufacturer’s recommended type air

cleaner only.

5. Starter Solenoid — Starts engine when ignition key

is rotated clockwise to the ON position.

6. Oil Pressure Switch — Monitors engine oil pressure.

In the event of low oil pressure engine will shut down.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 21

10. Fuel Feed Pump — Pumps fuel to the injection system.

11. Speed Control Lever — Controls engine speed. This

lever is factory set at 1,800 rpm to maintain proper

voltage and frequency. DO NOT adjust this lever out

of factory range.

12. Oil Filter — Spin-on type, filters oil contaminants.

Replace filter as recommended in the maintenance

section of this manual.

13. Oil Dipstick/Gauge — Remove to check amount and

condition of oil in crankcase. Refill or replace with

recommended type oil as listed in Table 6.

14. Oil Drain Plug — Remove to drain crankcase oil.

Fill with recommended type oil as listed in Table 6.

Crankcase holds a maximum of 2.64 quarts (2.5 liters)

of motor oil.

Page 22

LOAD APPLICATIONS

SINGLE-PHASE LOAD — 60 HZ

Always be sure to check the nameplate on the generator

and equipment to ensure the wattage, amperage and

frequency requirements are satisfactorily supplied by the

generator for operating the equipment.

Generally, the wattage listed on the nameplate of the

equipment is its rated output. Equipment may require

130–150% more wattage than the rating on the nameplate,

as the wattage is influenced by the efficiency, power factor

and starting system of the equipment.

NOTICE

If wattage is not given on the equipment’s nameplate,

approximate wattage may be determined by multiplying

nameplate voltage by the nameplate amperage.

WATTS = VOLTAGE × AMPERAGE

The power factor of this generator is 1.0. See Table 4 below

when connecting loads.

Table 4. Power Factor by Load

Type of Load Power Factor

Single-phase induction motors 0.4–0.75

Electric heaters,

incandescent lamps

Fluorescent lamps,

mercury lamps

Electronic devices,

communication equipment

Common power tools 0.8

Table 5. Cable Selection (60 Hz, Single-Phase Operation)

Current

in

Amperes

2.5 300 600 1,000 ft. 600 ft. 375 ft. 250 ft.

5 600 1,200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1,800 350 ft. 200 ft. 125 ft. 100 ft.

10 1,200 2,400 250 ft. 150 ft. 100 ft.

15 1,800 3,600 150 ft. 100 ft. 65 ft.

20 2,400 4,800 125 ft. 75 ft. 50 ft.

Load in Watts Maximum Allowable Cable Length

At 100

Volts

CAUTION: Equipment damage can result from low voltage.

At 200

Volts

#10 Wire #12 Wire #14 Wire #16 Wire

1.0

0.4–0.9

1.0

NOTICE

When connecting power tools or equipment, pay close

attention to the required starting current capacity.

To determine the running wattage for your load, multiply

the running wattage as indicated by steps 1, 2 and 3 below:

1. INCANDESCENT LOADS

Lights, heaters and similar appliances.

Total the running wattage and multiply by 1.

Example:

29 light bulbs @ 100W each = 2.9 kW

Use a 3 kW generator.

2. SMALL MOTORS

Drills and other small power tools.

Total the running wattage and multiply by 2.

Example:

A 1-inch drill runs at 1 kW.

Use a 2 kW generator.

3. LARGE MOTORS

Submersible pumps, table saws etc.

Total the running wattage and multiply by 3.

Example:

A conveyor belt runs at 8 kW.

Use a 24 kW generator.

NOTICE

Motors and motor-driven equipment draw much greater

current for starting than during operation. Always use

an adequately sized extension cable which can carry

the required load.

DANGER

Before connecting this generator to any building’s

electrical system, a licensed electrician must install

an isolation (transfer) switch. Serious damage to

the building’s electrical system may occur without this

transfer switch.

EXTENSION CABLES

When electric power is to be provided to various tools or

loads at some distance from the generator, extension cords

are normally used. Cables should be sized to allow for

distance in length and amperage so that the voltage drop

between the generator and point of use (load) is held

to a minimum. Use the cable selection chart (Table 5) as a

guide for selecting proper cable size.

PAGE 22 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 23

BEFORE STARTING

1. Read safety instructions at the beginning of manual.

2. Clean the generator, removing dirt and dust, particularly

the engine cooling air inlet. Caution must be taken to

ensure generator is 100% dry before use.

3. Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one as required.

4. Check fastening nuts and bolts for tightness.

ENGINE OIL CHECK

NOTICE

This Kubota engine is equipped with a low oil shutdown

capability. A built-in sensor will automatically turn off the

engine should the oil level fall below a safe operating

condition. Make sure the generator is placed on level

ground. Placing the generator on level ground will

ensure that the low oil sensor will function properly.

INSPECTION/SETUP

Figure 9. Engine Oil Dipstick

4. Verify that the engine oil level is maintained between

the H and L markings on the dipstick as referenced in

Figure 9A.

5. If the engine oil level is low (Figure 9C), remove the oil

filler cap (Figure 10) and fill to a safe operating level

(max.) as indicated by the dipstick (Figure 9A).

NOTICE

When adding engine oil, DO NOT overfill (Figure 9B).

1. To check the engine oil level, place the generator on

secure, level ground with the engine stopped.

2. Remove the dipstick from its holder (Figure 8) and wipe

clean.

DIPSTICK

6. Fill with recommended type oil as listed in Table 6.

Maximum oil capacity is 5.39 quarts (5.1 liters).

Figure 8. Engine Oil Dipstick Removal

3. Reinsert dipstick, then remove dipstick from its holder.

Check the oil level shown on the dipstick (Figure 9).

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 23

Figure 10. Engine Oil Filler Port

Page 24

INSPECTION/SETUP

Table 6. Oil Type

Temperature Oil Type

Above 77°F (25°C)

32°–77°F

(0°–25°C)

Below 32°F (0°C)

SAE 30 or SAE 10W-30

SAE 15W-40

SAE 20 or SAE 10W-30

SAE 15W-40

SAE 10 or SAE 10W-30

SAE 15W-40

FUEL TANK CONNECTION

NOTICE

This generator does not have an internal fuel tank. An

external fuel tank needs to be connected.

Make sure the external fuel tank is positioned higher

than the engine, or pump the fuel to the engine using

a fuel pump.

1. Set the fuel cock to the OFF position.

2. Connect the suction hose to the fuel filter. Use a suction

hose with an inner diameter of 7 mm and attach a hose

clamp so that there is no leak in the connection.

3. Connect the return hose to the engine. Use a return

hose with an inner diameter of 4 mm and attach it with

a hose clamp so there is no leak in the connection.

4. Set the fuel cock to the ON position and make sure

there is no fuel leaking at the joints.

COOLANT (ANTIFREEZE)

Kubota recommends antifreeze/summer coolant for use in

their engines, which can be purchased in concentrate (and

mixed with 50% demineralized water) or pre-diluted. See

the Kubota Engine Owner’s Manual for further details.

WARNING

When adding coolant/antifreeze mix to the

radiator, DO NOT remove the radiator cap

until the unit has completely cooled. The

possibility of hot coolant exists which can

cause severe burns.

Day-to-day addition of coolant is done from the recovery

tank (Figure 11). When adding coolant to the radiator,

DO NOT remove the radiator cap until the unit has

completely cooled. See Table 7 for engine, radiator, and

recovery tank coolant capacities.

NOTICE

Normally, only the coolant level in the recovery tank

needs to be checked. However, the radiator cap should

be opened once a week to verify that coolant is visible

(full) in the radiator.

1. Verify that the coolant level in the coolant recovery tank

is between the FULL and LOW markings as shown in

Figure 11.

5. Loosen the bolt at the inlet of the injection pump and

remove the air inside the piping.

6. Tighten the bolt when all of the air has come out and

the fuel starts to overflow.

DANGER

Motor fuels are highly flammable and can

be dangerous if mishandled. DO NOT

smoke while refueling. DO NOT attempt

to refuel if the engine is hot!, running or

in the dark.

PAGE 24 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Figure 11. Coolant Recovery Tank

Table 7. Coolant Capacity

Engine and Radiator 4.23 quarts (4.0 liters)

Reserve Tank (Full) 0.95 quarts (0.9 liters)

Page 25

INSPECTION/SETUP

Operation in Freezing Weather

When operating in freezing weather, be certain the proper

amount of antifreeze (Table 8) has been added.

Table 8. Antifreeze Operating

Temperatures

Vol. %

Antifreeze

Freezing Point

°C °F

50 –37 –34

NOTICE

When the antifreeze is mixed with water, the antifreeze

mixing ratio must be less than 50%.

CLEANING THE RADIATOR

The engine may overheat if the radiator fins become

overloaded with dust or debris. Periodically clean the

radiator fins with compressed air. Cleaning inside the

machine is dangerous, so clean only with the engine turned

off and the negative battery terminal disconnected.

The fan belt tension is proper if the fan belt bends

10 to 15 mm when depressed with the thumb as shown

in Figure 12.

Figure 12. Fan Belt Tension

CAUTION

NEVER place hands near the belts or fan

while the generator set is running.

AIR CLEANER

Periodic cleaning/replacement is necessary. Inspect it in

accordance with the Kubota Engine Owner’s Manual.

FAN BELT TENSION

A slack fan belt may contribute to overheating, or to

insufficient charging of the battery. Inspect the fan belt for

damage and wear and adjust it in accordance with the

Kubota Engine Owner’s Manual.

BATTERY

This unit is of negative ground. DO NOT connect in reverse.

Always maintain battery fluid level between the specified

marks. Battery life will be shortened if the fluid level is

not properly maintained. Add only distilled water when

replenishment is necessary.

DO NOT overfill. Check to see whether the battery

cables are loose. Poor contact may result in poor starting

or malfunctions. ALWAYS keep the terminals firmly

tightened. Coat the terminals with an approved battery

terminal treatment compound. Replace battery with only

recommended type battery.

The battery is sufficiently charged if the specific gravity

of the battery fluid is 1.28 (at 68°F). If the specific gravity

should fall to 1.245 or lower, it indicates that the battery is

dead and needs to be recharged or replaced.

Before charging the battery with an external electric source,

be sure to disconnect the battery cables.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 25

Page 26

INSPECTION/SETUP

BATTERY CABLE INSTALLATION

ALWAYS be sure the battery cables (Figure 13) are

properly connected to the battery terminals as shown below.

The red cable is connected to the positive terminal of the

battery, and the black cable is connected to the negative

terminal of the battery.

CAUTION

ALWAYS disconnect the negative terminal FIRST and

reconnect negative terminal LAST.

NEGATIVE

POSITIVE

ALTERNATOR

The polarity of the alternator is negative grounding type.

When an inverted circuit connection takes place, the circuit

will be in short circuit instantaneously resulting in alternator

failure.

DO NOT put water directly on the alternator. Entry of water

into the alternator can cause corrosion and damage the

alternator.

WIRING

Inspect the entire generator for bad or worn electrical wiring

or connections. If any wiring or connections are exposed

(insulation missing), replace wiring immediately.

PIPING AND HOSE CONNECTION

Inspect all piping, oil hose, and fuel hose connections for

wear and tightness. Tighten all hose clamps and check

hoses for leaks.

If any hose (fuel or oil) lines are defective replace them

immediately.

Figure 13. Battery Connections

When connecting battery do the following:

1. NEVER connect the battery cables to the battery

terminals when the Ignition Switch is in the START

position. ALWAYS make sure that the Ignition Switch

is in the OFF position when connecting the battery.

2. Place a small amount of battery terminal treatment

compound around both battery terminals. This will

ensure a good connection and will help prevent

corrosion around the battery terminals.

NOTICE

If the battery cable is connected incorrectly, electrical

damage to the generator will occur. Pay close attention

to the polarity of the battery when connecting the battery.

CAUTION

Inadequate battery connections may cause poor

starting of the generator, and create other malfunctions.

PAGE 26 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 27

OPERATION

BEFORE STARTING THE ENGINE

CAUTION

The engine’s exhaust contains harmful emissions.

ALWAYS have adequate ventilation when operating.

Direct exhaust away from nearby personnel.

1. Place the external fuel valve lever in the ON position.

2. NEVER operate the generator with the doors open

(Figure 14). Operation with the doors open may cause

insufficient cooling of the unit, and engine damage may

result. Close the doors for normal operation.

STARTING THE ENGINE

1. Insert the key into the starter switch (Figure 16) and

turn it to the RUN position.

Figure 16. Starter Switch (RUN)

2. Verify that the oil pressure, temperature, charge and

glow plug lamps on the “Engine Warning Lamp Unit

Display” are lit. If either lamp is not lit, check the system

and wiring (refer to the Engine Operation Manual).

Figure 14. Generator Doors

3. NEVER start the engine with the main circuit breaker

in the ON position. Always place circuit breaker

(Figure 15) in the OFF position before starting.

Figure 15. Main Circuit Breaker (OFF)

Figure 17. Engine Warning Lamp Unit (ON)

3. Turn the ignition key to the HEAT position (Figure 18).

When the preheat light goes off, turn the key to the

START position to start the engine. As soon as the

engine starts, release the key. The key will automatically

return to the RUN position.

Figure 18. Starter Switch (HEAT/RUN)

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 27

Page 28

OPERATION

INCREASE

DECREASE

NOTICE

In cold weather conditions, it may be required to

extend the duration of the HEAT position for proper

starting.

4. If the engine does not start within 10 seconds after

the key is turned to the START position, wait for about

30 seconds and repeat the procedure as described in

steps 1–3.

5. When the engine starts, the oil pressure light and

charge light should go out. If these lights stay on,

immediately stop the engine and check the system and

wiring (refer to the Engine Operation Manual).

UNV OUTPUT TERMINAL VOLTAGES

The single-phase, 3-wire output terminal has dual voltage

(120/240V) capability. Using an external voltmeter as shown

in Figure 21, verify that 120 VAC is present at the output

terminals.

1Ø-120 Output Terminal Voltage

The voltage regulator (VR), allows the user to increase or

decrease the selected voltage. Turn the voltage regulator

knob clockwise to increase the voltage output, turn

counterclockwise to decrease the voltage output. Use the

voltage regulator adjustment knob whenever fine tuning of

the output voltage is required.

2. Measure the voltage at the output terminals. The

reading across terminals U and N (Figure 21A) should

be 120 VAC and the voltage across terminals U and V

(Figure 21B) should also read 120 VAC.

BLACK

U

N

GREEN

V

RED

WHITE

A

GROUND CONNECTION

120 VAC

OFF

V~

V

240

120

V

300 mV

A~

A

V

COM

WHITE

BLACK

U

N

MUST BE USED

AT ALL TIMES

RED

GREEN

V

B

GROUND CONNECTION

120 VAC

OFF

V~

V

240

120

V

300 mV

A~

A

V

COM

Figure 21. Output Terminal VoltageVerification

(120 VAC)

1Ø-240 VAC Output Voltage Verification

MUST BE USED

AT ALL TIMES

1Ø-120 VAC Output Voltage Verification

1. Place main circuit breaker (Figure 20) in the ON

Figure 19. Voltage Regulator Knob

position.

Figure 20. Main Circuit Breaker (ON)

PAGE 28 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

1. Measure the voltage at the output terminals. The

reading across terminals U and V (Figure 22) should

be 240 VAC.

RED

WHITE

BLACK

N

U

240 VAC

OFF

V~

V

240

120

V

300 mV

A~

A

V

COM

Figure 22. Output Terminal Voltage Verification

(240 VAC)

GREEN

V

GROUND CONNECTION

MUST BE USED

AT ALL TIMES

Page 29

OPERATION/SHUTDOWN

2. Once the correct voltage (240 VAC) has been verfied,

place the main circuit breaker (Figure 23) on the OFF

position.

Figure 23. Main Circuit Breaker (OFF)

3. Loads (power tools, lighting, etc.) can now be

connected to the generator output terminals.

Stopping the Engine (Normal Shutdown)

1. Place main circuit breaker (Figure 24) in the OFF

position.

Emergency Shutdown

1. Place starter switch key (Figure 25) in STOP position.

Remove key.

2. Place the external fuel valve lever in the OFF position.

Generator Storage

For storage of the generator for more than 30 days, the

following is required:

Run the engine until all the fuel is completely consumed.

Completely drain the oil from the crankcase and refill

with fresh oil.

Disconnect the negative battery cable from the battery.

Clean all external parts of the generator with a cloth.

If generator is mounted on a trailer, jack trailer up and

place on blocks so tires do not touch the ground or block

and completely remove the tires.

Cover the generator and store in a clean, dry place.

Figure 24. Main Circuit Breaker (OFF)

2. Let engine run at idle with no load for 3–5 minutes.

3. Place the starter switch key (Figure 25) in the STOP

position and remove the key.

Figure 25. Starter Switch (Stop Position)

4. Place the external fuel valve in the OFF position.

5. Remove all load connections from the generator.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 29

Page 30

MAINTENANCE

Use Table 9 as a general maintenance guideline

when servicing your engine. For more detailed engine

maintenance information, refer to the engine owner’s

manual supplied with your engine.

Table 9. Engine Maintenance Schedule

First

Every 3

Description (3) Operation Daily

Month

or

50 Hours

Engine Oil

Oil Filter

Cartridge

Air Cleaner

Element

All Nuts & Bolts

Cooling Fins Check X

Fuel Tank Clean X

Fuel Filter Clean X X X

Fuel Filter

Element

Fuel Lines Change Every 2 years, replace if necessary (2)

Battery Change X

Radiator Hoses/

Clamps

Radiator

Coolant

Idle Speed Check-Adjust X (2)

Valve Clearance Check-Adjust X (2)

Fan Belt Check tightness

Water Separator Drain

(1) Service more frequently when used in DUSTY areas.

(2) These items should be serviced by your service dealer, unless you have the proper tools and are mechanically proficient.

Refer to the Kubota Shop Manual for service procedures.

(3) For commercial use, log hours of operation to determine proper maintenance intervals.

(4) When using engine oil of CF, CG-4, CH-4, CI-4 in API classification.

(5) When this machine is used as the power supply exclusively for the ground heater using the engine oil of CK-4

according to API classification.

Check X

Change X X(4) X(5)

Change X X(4) X(5)

Check X X

Change X (1) X

Retighten if

necessary

Change X X

Change Every 2 years, replace if necessary (2)

Change X

X

Months

25 Hours

or

Every 6

Months

50 Hours

or

Every

Year or

100

Hours

X

X

Every 2

Years or

200

Hours

Every 8

Years or

800

Hours

Every

Year or

750

Hours

NOTICE

Thoroughly remove dirt and oil from the engine and

control area. Clean or replace the air cleaner elements

as necessary. Check and retighten all fasteners as

necessary.

PAGE 30 — DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21)

Page 31

MAINTENANCE

AIR CLEANER

This is a dry type filter. NEVER apply oil to it. If

generator is used in severe dusty areas service air

cleaner element more frequently.

NOTICE

If the engine is operating in very dusty or dry grass

conditions, a clogged air cleaner will result. This can

lead to a loss of power, excessive carbon buildup in

the combustion chamber and high fuel consumption.

Change air cleaner more frequently if these conditions

exist.

Every 50 hours: Remove air filter element (Figure 26) and

clean the heavy-duty paper element with light spray of

compressed air. Replace the air cleaner as needed.

This Kubota diesel engine is equipped with a replaceable,

high-density paper air filter element.

Primary Air Cleaner Elements

CAUTION

Wear protective equipment such as

approved safety glasses or face shields

and dust masks or respirators when

cleaning air filters with compressed air.

1. Release the latches (Figure 26) that secure the cover

to the air filter body.

2. Remove the air filter cover and set aside.

3. Remove the air filter element.

4. Check the air filter daily or before starting the engine.

6. To clean the air filter element (paper air filter) as

referenced in Figure 26, tap the filter element

several times on a hard surface to remove dirt, or

blow compressed air, not to exceed 30 psi (207 kPa,

2.1 kgf/cm2), through the filter element from the inside

out.

BODY

AIR FILTER

ELEMENT

LATCH

BLOW COMPRESSED

AIR FROM THE

INSIDE OUT

EVACUATOR

VALV E

Figure 26. Air Filter

7. Replace air filter element if it is damaged or excessively

dirty.

8. Clean the inside of the air filter body.

9. Reinstall the air filter element back into air filter body.

10. Reinstall the air filter cover, and secure with latches.

NOTICE

DO NOT run the engine with the air filter removed or

without an element.

5. Check for and correct heavy buildup of dirt and debris

along with loose or damaged components.

NOTICE

Operating the engine with loose or damaged air filter

components could allow unfiltered air into the engine

causing premature wear and failure.

DCA6SPX4F GENERATOR • OPERATION MANUAL — REV. #2 (03/12/21) — PAGE 31

Page 32

ENGINE OIL

Every 100 hours: Change engine oil after the first 50 hours

of operation and every 100/750 hours thereafter. Always

check the crankcase oil level prior to each use, or when the

fuel tank is filled. Insufficient oil may cause severe engine

damage. Make sure generator is level when checking oil

level. The oil level must be between the two notches on the

dipstick as shown in Figure 9.

1. Remove engine oil drain plug located at the bottom

of the generator enclosure (Figure 27) and drain oil

from crankcase.For best results drain oil while engine

is warm. Reinstall oil drain plug, and add engine oil

as specified in Table 6. Crankcase oil capacity is 5.39

quarts (5.1 liters).

OIL FILTER

WRENCH

MAINTENANCE

RUBBER

SEAL

ENGINE

OIL FILTER

CARTRIDGE

Figure 28. Oil Filter Cartridge

LAYER OF OIL

OIL

COAT SEAL

WITH THIN

OIL DRAIN BOLT

AND O-RING

Figure 27. Engine Oil Drain Plug

Oil Filter Cartridge

Every 200/750 hours: Replace the engine oil filter cartridge

after every 200/750 hours of operation.

1. Clean the area around the lubricating oil filter head.

2. Coat oil filter seal (Figure 28) with clean engine oil.

3. Install new oil filter first by hand until it makes contact