Page 1

VeriTape Cartridge Memory Analyzer

Tape Cartridge Memory Analyzer

User Manual

© 2009 MP Tapes - 1 -

Page 2

VeriTape Cartridge Memory Analyzer

Table of Contents:

1. Overview

2. Quick Start

3. Options

4. Exporting Data

5. Details

6. Summary of Menu Commands

7. Specifications

© 2009 MP Tapes - 2 -

Page 3

VeriTape Cartridge Memory Analyzer

Overview

All LTO Cartridges have an internal memory chip called Cartridge Memory (CM). This chip

contains vital information about the cartridge. VeriTape™ extracts the information from the CM

and displays it in a concise way. VeriTape also calculates the VeriScore,™ a single quality number based on all available information.

The CM data for all scanned cartridges is saved in a history database, as is information for all

drives mentioned in the CM. This allows VeriTape to analyze both cartridge and tape drive

quality.

© 2009 MP Tapes - 3 -

Page 4

VeriTape Cartridge Memory Analyzer

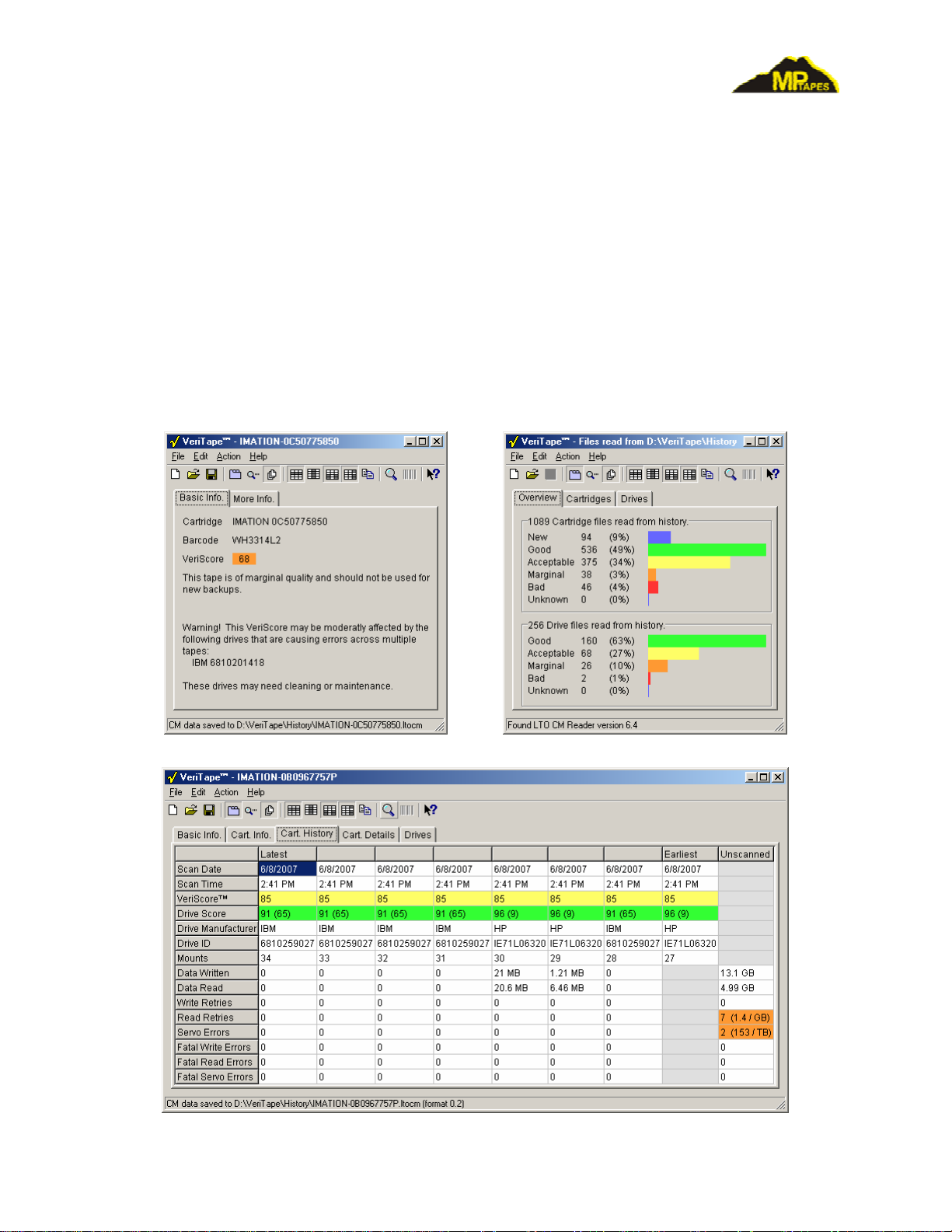

Typical VeriTape Displays

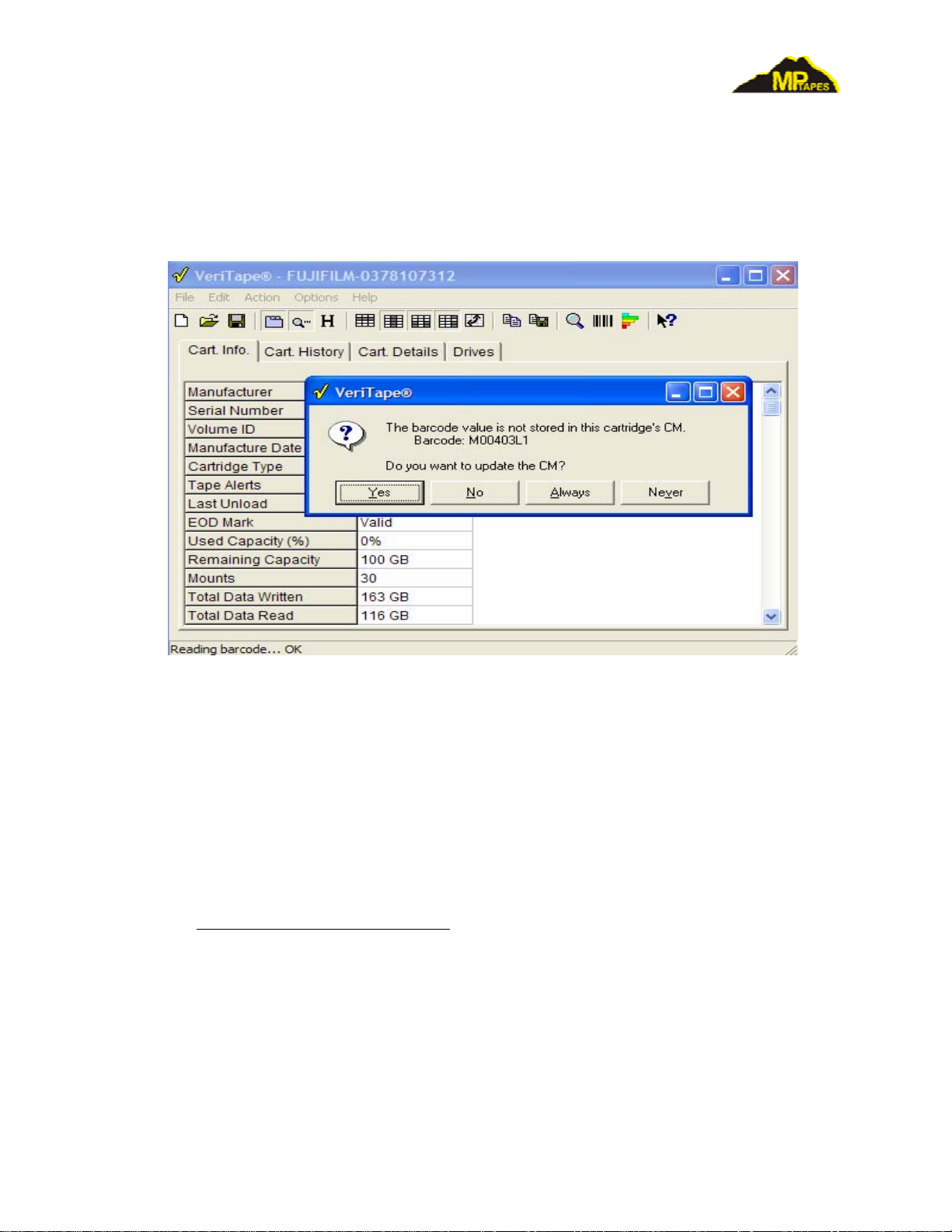

Barcode Reader option

The Tape CM Analyzer comes with an optional barcode reader.

VeriTape Display with barcode reader

Quick Start

Get the Latest Software and Documentation

The latest version of the VeriTape software and documentation is available on the MP Tapes

web site at

Connecting and Configuring the VeriTape Reader

The VeriTape Reader is connected to the PC using the USB/Serial converter included with the

product. The first time the USB/Serial converter is plugged into your PC Windows will identify

it as new device. Use the supplied CD-ROM to install the driver.

Run the VeriTape.exe program. The first time you run the program you may get an error message, “Error accessing serial port”. This is OK, it just means that the default configuration is trying to use a serial port that does not exist on your computer. Hit OK and the “Configure Serial

http://www.mptapes.com/veritape.

© 2009 MP Tapes - 4 -

Page 5

VeriTape Cartridge Memory Analyzer

Port” dialog will open. Select the serial port connected to the VeriTape Reader. If you don’t

know which serial port is connected to the VeriTape Reader, select the first one.

The VeriTape program will start looking for the VeriTape Reader. The status bar will show

“LTO CM Reader not found -- still looking…”. When the program successfully communicates

with the reader the status message will change to “Found LTO CM Reader version 5.0”. If the

“found” message never occurs, there is a cabling or configuration problem. Use the “File | Configure Serial Port” menu command and choose different serial ports until the VeriTape Reader is

found. (You must close the “Configure Serial Port” dialog each time you change the settings.)

Reading the CM

To read the CM from a cartridge, place the cartridge on the VeriTape Reader and press the

button or use the “Action | Read CM” menu command. The VeriTape program will read and display the cartridge data.

The serial number recorded in the CM does not in general match any markings on the cartridge

case. It is a good idea at this point to write the serial number on the cartridge for later identifica-

tion.

Basic information about a cartridge and its usage are displayed under the “Cartridge” tab. More

detailed information can be seen under the “Usage” and “Details” tabs.

Saving the CM to a File

The CM from a cartridge can be saved to a file for later analysis and comparison with other cartridges. Press the

button or use the “File | Save” menu command. The suggested file name is

the cartridge’s manufacturer and serial number. The “Save” command takes about 20 seconds

since it saves the entire CM memory1. (Only about 15% was read to get the information displayed by the “Read” command.)

Reading a Saved CM File

Press the

button or use the “File | Open” menu command and select a single CM file to dis-

play its contents.

Comparing Multiple Saved CM Files

Press the

button or use the “File | Open” menu command and select multiple CM files to simultaneously display their contents. The CM files’ basic information will be displayed in a table

under the “Summary” tab. Cartridges may not all have the same data fields present. Missing data

fields are indicated by an empty gray cell. A data field that is present but whose value is empty

will be an empty white cell.

Clicking on a row header will sort the columns by that rows’ values in ascending order. Clicking

again on the same row header will sort by descending values.

1

The VeriTape program saves the entire CM contents so that future versions of the program will be able to ex amine

other data in the CM that may be of use.

© 2009 MP Tapes - 5 -

Page 6

VeriTape Cartridge Memory Analyzer

Clicking on a column header will reread the file so that it’s “Cartridge,” “Usage” and “Details”

pages can be seen.

VeriTape Summary Display

Click on a row header to sort the columns by that row’s values.

Click on a column header to display the “Cartridge,” “Usage” and “Details” tabs for the selected

cartridge.

Options

Automatic Cartridge Detection

button or “File | Options > Autodetect Cartridge” menu item:

Setting the Autodetect option will cause the VeriTape program to continuously poll the VeriTape

Reader to detect the presence of a cartridge.

When a new cartridge is detected it is automatically read and displayed.

Automatic Cartridge Detection is temporarily disabled when a CM file is read. Use the

or the “File | New” menu command to re-enable automatic detection.

button

Automatic File Save

button or “File | Options > Autosave” menu item:

© 2009 MP Tapes - 6 -

Page 7

VeriTape Cartridge Memory Analyzer

Setting the Autosave option will cause the VeriTape program to automatically save the CM data

after it is read. When this option is turned on you need to select a directory into which the files

will be saved. Autosave does not overwrite files; if a file exists with the same name the File Save

as dialog is displayed.

QuickSave

button or “File | Options > QuickSave” menu item:

Setting the QuickSave option will cause the VeriTape program to only save that portion of the

CM data that was needed to be read to decode the information that is currently displayed. This

makes save nearly instantaneous at the cost of future compatibility; future versions of VeriTape

may be limited in what additional information they can display.

Exporting data

VeriTape can export data to the Windows Clipboard so that it may be pasted into a word processor or spreadsheet program. The data can then be formatted as desired and printed.

Table Tabs

Select the cells in the table that you want to export. If no cells are selected the entire table will be

exported.

To automatically extend selection to include entire rows or columns, select Edit | Select by Rows

or Edit | Select by Columns. The program default is to select by columns.

Normally the row and column headers are copied as well as the selected cells. This can be controlled by checking/unchecking the Edit | Include Row Headers and Edit | Include Column Head-

ers menu items.

Click the

button or the Edit | Copy menu item to copy the selected portion of the table to the

Clipboard.

Paste the Clipboard into your word processor or spreadsheet program.

Some word processors have trouble with wide tables; you may want to limit the number of columns you select when copying data to them. You can also use your word processor’s Paste Spe-

cial command and select Unformatted Text to paste the data as tab-separated text.

Most spreadsheet programs do not automatically set column widths based on pasted data. You

will need to do this after pasting the data. For Excel,

2

the pasted data remains selected so you can

immediately use the Format | Column > AutoFit Selection command.

2

Excel is a trademark of Microsoft, Inc.

© 2009 MP Tapes - 7 -

Page 8

VeriTape Cartridge Memory Analyzer

Sample Data Pasted into Excel™

Text Tabs

Select the text that you want to export.

Click the

Clipboard.

If no text is selected the Copy command will be disabled.

Paste the Clipboard into your word processor.

button or the Edit | Copy menu item to copy the selected portion of the table to the

© 2009 MP Tapes - 8 -

Page 9

VeriTape Cartridge Memory Analyzer

Details

Cartridge Tab

Manufacturer

Cartridge manufacturer as recorded in

CM. This may be different than the label

on the cartridge because some vendors

OEM their cartridges.

Serial Number

Cartridge serial number as recorded in

CM. Some vendors print a different serial

number on the cartridge, usually if they

OEM their cartridges.

VeriScore

Composite score computed from informa-

tion stored in CM. The score ranges from

0 to 100 and is interpreted and colored as:

90-100 Good Green

70-89 Fair Yellow

50-69 Poor Orange

0-49 Bad Red

Media Manufacturer

Some cartridge manufacturers OEM their tape. If the Cartridge Manufacturer and Media

Manufacturer do not match, the Media Manufacturer is also displayed.

Manufacture Date

The date the cartridge was manufactured. Older cartridges are given slightly lower

VeriScores.

Cartridge Type

LTO 1, LTO 2, LTO 3 and LTO 4. Cleaning cartridges are also identified here. Cleaning

cartridges are not scored but you can see any usage information that may be stored on

them.

Last Unload

This indicates how the cartridge was last removed from the tape drive. The possible val-

ues are:

Normal The cartridge was unloaded normally.

Abnormal - not writing The cartridge was not unloaded normally, but the drive was

not writing at the time. This usually indicates a power failure while the cartridge was loaded in the drive.

© 2009 MP Tapes - 9 -

Page 10

VeriTape Cartridge Memory Analyzer

Abnormal - during write The cartridge was not unloaded normally and the drive was

writing at the time. This usually indicates a power failure

while the cartridge was loaded in the drive.

Abnormal – unknown An out-of-spec value in this field of the CM; assume the

worst…

Thread Count

This is the number of times the cartridge has been loaded into a tape drive.

CM Corrected Count (LTO 3 only)

This is the number of times a tape drive has found the CM to contain invalid data and has

attempted to correct the bad data.

For all of the following, two values are displayed: Total and Recent. The Total value is exactly

that, the total number of the named event that has ever occurred on the cartridge. The Recent

value is number of such events that have occurred in the last 3 times the cartridge has been

loaded.

Data Written

This is the amount of data that has been written to the tape.

Data Read

This is the amount of data that has been read from the tape.

Write Retries

This is the number of recovered write errors. Write retries occur when a tape drive detects

that a dataset

3

it just wrote failed read-while-write verification. The dataset will be rewritten further along the tape. A small number of write retries are expected due to media

dropouts and dust on the media. The number in parentheses is the error rate in errors per

dataset. The rate, not the gross number, is used in computing the VeriScore.

Read Retries

This is the number of recovered read errors. Read retries occur when a tape drive reads a

dataset that fails read verification. The tape must be repositioned and the data reread. A

small number of read retries are expected due to dust on the media. The number in parentheses is the error rate in errors per dataset. The rate, not the gross number, is used in

computing the VeriScore.

Servo Errors

This is the number of servo tracking errors. Servo errors occur when a tape drive loses

lock on the tape’s servo tracks. This can be caused by media dropouts, but is less likely to

be caused by dust on the tape since there are multiple servo tracks that are read simultaneously. The number in parentheses is the error rate in errors per dataset. The rate, not the

gross number, is used in computing the VeriScore.

3

A dataset is the smallest unit of data that can be written to the tape. You can think of it as the physical record size.

The dataset size is 403,884 bytes for LTO 1 and LTO 2, and 1,616,940 bytes for LTO 3.

© 2009 MP Tapes - 10 -

Page 11

VeriTape Cartridge Memory Analyzer

Fatal Write Errors

This is the number of fatal write errors. Fatal write errors cause a backup operation to

fail. They occur when a tape drive cannot successfully rewrite a dataset after multiple

read-while-write verification failures. Fatal write errors can be caused by damaged media, excessive dropouts, and rarely by dust on the media. The number in parentheses is

the error rate in errors per dataset. The gross number of fatal errors is used in computing

the VeriScore.

Fatal Read Errors

This is the number of fatal read errors. Fatal read errors cause a restore operation to fail.

They occur when a tape drive cannot successfully reread a dataset after multiple attempts.

Fatal read errors can be caused by damaged media, excessive dropouts, and rarely by dust

on the media . The number in parentheses is the error rate in errors per dataset. The gross

number of fatal errors is used in computing the VeriScore.

Fatal Servo Errors

This is the number of fatal servo errors. Fatal servo errors cause a backup operation to

fail. They occur when a tape drive loses lock on the tape’s servo tracks and cannot reacquire lock. Fatal servo errors can be caused by damaged media or excessive dropouts.

The number in parentheses is the error rate in errors per dataset. The gross number of fatal errors is used in computing the VeriScore.

© 2009 MP Tapes - 11 -

Page 12

VeriTape Cartridge Memory Analyzer

Last Usage Tab

The Last Usage Tab shows the usage information for the last three times the cartridge was

loaded. For LTO 3 cartridges it also shows the usage information for the last fatal read and write

errors.

Drive Manufacturer

The manufacturer of the tape drive in which the cartridge was loaded.

Drive ID

The ID string of the tape drive in which the cartridge was loaded. This may or may not be

the drive’s serial number.

For other items, see descriptions in the Cartridge Tab section. The values displayed are the numbers of that item that occurred during the indicated threading. The values for fatal errors may be

lower than the values for the threading if further activity occurred after the fatal error.

© 2009 MP Tapes - 12 -

Page 13

VeriTape Cartridge Memory Analyzer

Details Tab

The Details Tab shows all the information that is available in the portion of CM that was read to

get the information displayed in the Cartridge and Last Usage Tabs. This may be useful for debugging cartridge interchange problems. The CM is documented in ECMA-319 Standard, Annex D.

Errors Tab

If there are any communications errors between The VeriTape program and the VeriTape Reader

The Errors Tab that lists the errors will be displayed.

© 2009 MP Tapes - 13 -

Page 14

VeriTape Cartridge Memory Analyzer

Summary of Menu Commands

File | New

Clears the currently displayed data. If Automatic Cartridge Detection is enabled, starts looking

for a cartridge on the VeriTape Reader.

File | Open

Open a saved CM File and display its contents.

File | Save

Save the currently displayed cartridge to a CM File.

File | Save As

Save the currently displayed cartridge to a CM File with a different name.

File | Options > Autodetect Cartridge

When checked, the VeriTape program periodically polls the VeriTape Reader to see if the cartridge has been changed. If it has, the new cartridge’s data is automatically read and displayed.

File | Options > Autosave

When checked, the VeriTape program automatically saves the cartridge’s data to a CM File after

reading it. When Autosave is first checked, a directory must be selected into which the CM Files

will be saved.

File | Options > QuickSave

When checked, the VeriTape program will only save that portion of the CM data that was needed

to be read to decode the information that is currently displayed. This makes save nearly instantaneous at the cost of future compatibility; future versions of VeriTape may be limited in what additional information they can display.

File | Configure Serial Port

Opens the “Configure Serial Port” dialog which is used to select the serial port connected to the

VeriTape Reader. The “change settings” checkbox is a debugging relic; do not use it. The set-

tings must be 4800 / none / 8 / 1 / none.

File | Show Serial Data

Opens a window that displays the serial data sent between the VeriTape Reader and the

VeriTape program. This is only useful for debugging connection problems. It slows things down

a bit when it is displayed.

File | Exit

Closes the VeriTape program.

© 2009 MP Tapes - 14 -

Page 15

VeriTape Cartridge Memory Analyzer

Edit | Copy

Copies the currently displayed table to the clipboard so that it can be pasted into another application. If only a portion of the table’s cells are selected, only those cells and their row and column

headers will be copied.

Edit | Select by Rows

When checked, table cell selection will automatically be extended to include the entire row if any

cells in that row are selected.

Edit | Select by Columns

When checked, table cell selection will automatically be extended to include the entire column if

any cells in that column are selected.

Edit | Include Row Headers

When checked, row header cells are included in tables copied to the clipboard.

Edit | Include Column Headers

When checked, column header cells are included in tables copied to the clipboard.

Action | Read CM

Reads the information from the cartridge currently on the VeriTape Reader. If there is no cartridge present, displays an error message.

Action | Hex Dump

Technical information used for diagnostic purposes.

© 2009 MP Tapes - 15 -

Page 16

VeriTape Cartridge Memory Analyzer

Specifications

Operating Conditions

Temperature: 0 - 120 degrees F

Relative Humidity: 0-95%,Non-condensing

Storage Conditions

Temperature: -40 - 140 degrees F

Relative Humidity: 0-95%, Non-condensing

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio comm unicat i ons. O p eration of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

© 2009 MP Tapes - 16 -

Loading...

Loading...